torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1025 of 2870

CO(H4SO)-42

COOLING

Coolant Filler Tank

11.Coolant Filler Tank

A: REMOVAL

WARNING:

The radiator is pressurized. Wait until the en-

gine cools down before working on the radia-

tor.

1) Drain the coolant about 3.02 (3.2 US qt, 2.6 Imp

qt).

ant.>

2) Remove the air cleaner upper cover and air in-

take boot.

3) Remove the air cleaner element.

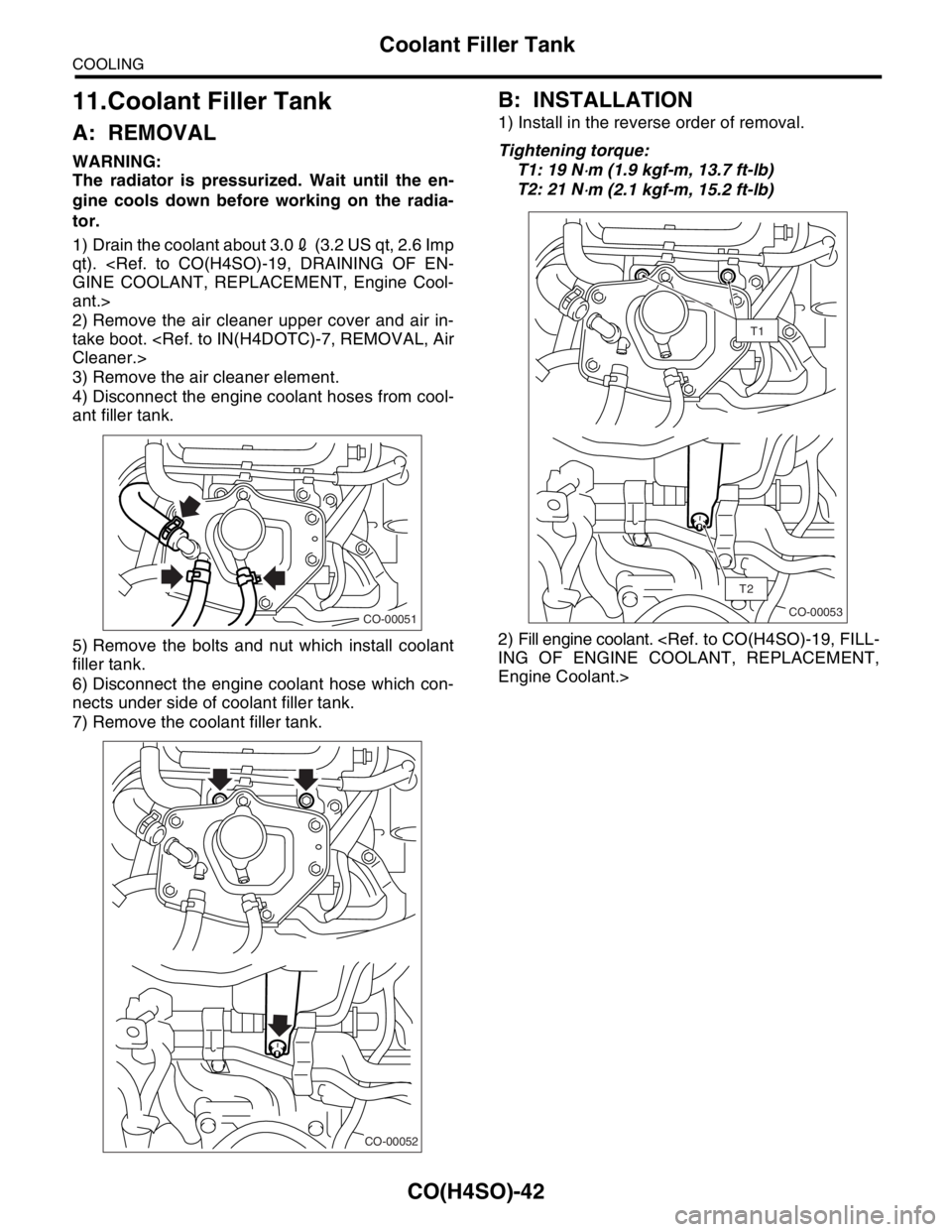

4) Disconnect the engine coolant hoses from cool-

ant filler tank.

5) Remove the bolts and nut which install coolant

filler tank.

6) Disconnect the engine coolant hose which con-

nects under side of coolant filler tank.

7) Remove the coolant filler tank.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

T1: 19 N

⋅m (1.9 kgf-m, 13.7 ft-lb)

T2: 21 N

⋅m (2.1 kgf-m, 15.2 ft-lb)

2) Fill engine coolant.

Engine Coolant.>

CO-00051

CO-00052

T2

T1

CO-00053

Page 1031 of 2870

LU(H4SO)-3

LUBRICATION

General Description

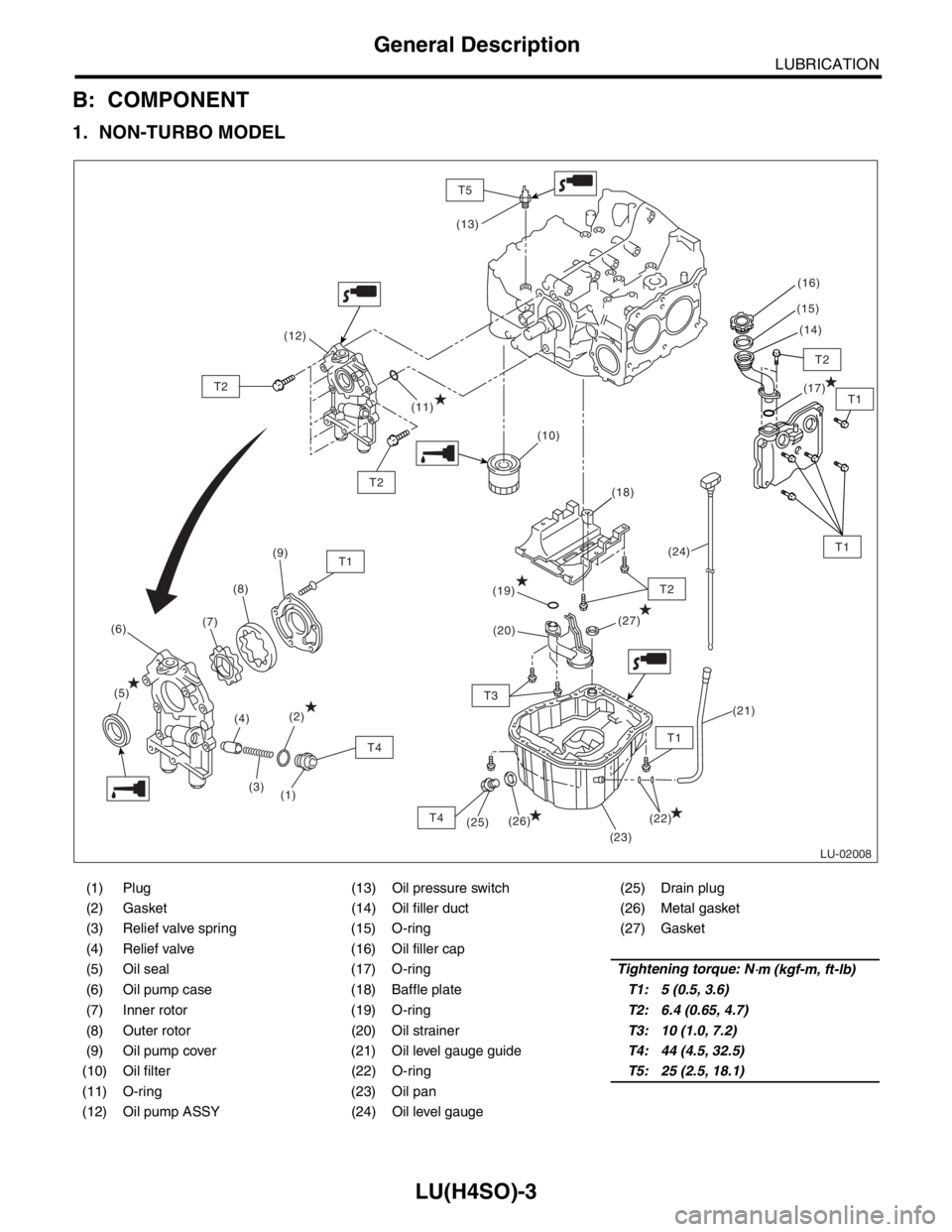

B: COMPONENT

1. NON-TURBO MODEL

(1) Plug (13) Oil pressure switch (25) Drain plug

(2) Gasket (14) Oil filler duct (26) Metal gasket

(3) Relief valve spring (15) O-ring (27) Gasket

(4) Relief valve (16) Oil filler cap

(5) Oil seal (17) O-ringTightening torque: N

⋅m (kgf-m, ft-lb)

(6) Oil pump case (18) Baffle plateT1: 5 (0.5, 3.6)

(7) Inner rotor (19) O-ringT2: 6.4 (0.65, 4.7)

(8) Outer rotor (20) Oil strainerT3: 10 (1.0, 7.2)

(9) Oil pump cover (21) Oil level gauge guideT4: 44 (4.5, 32.5)

(10) Oil filter (22) O-ringT5: 25 (2.5, 18.1)

(11) O-ring (23) Oil pan

(12) Oil pump ASSY (24) Oil level gauge

LU-02008

(12)

(11)

T5

T2

T1

T2

T2

T1

T1

T1

T3

T4

T2

(13)

(9)

(8)

(7)

(6)

(20) (19)

(27) (18)(17) (15)

(14) (16)

(24)

(23) (10)

(25)(26)

(5)

(4)

(3)(2)

(1)

(22)

(21)

T4

Page 1033 of 2870

LU(H4SO)-5

LUBRICATION

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn yourself, because each

part in the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

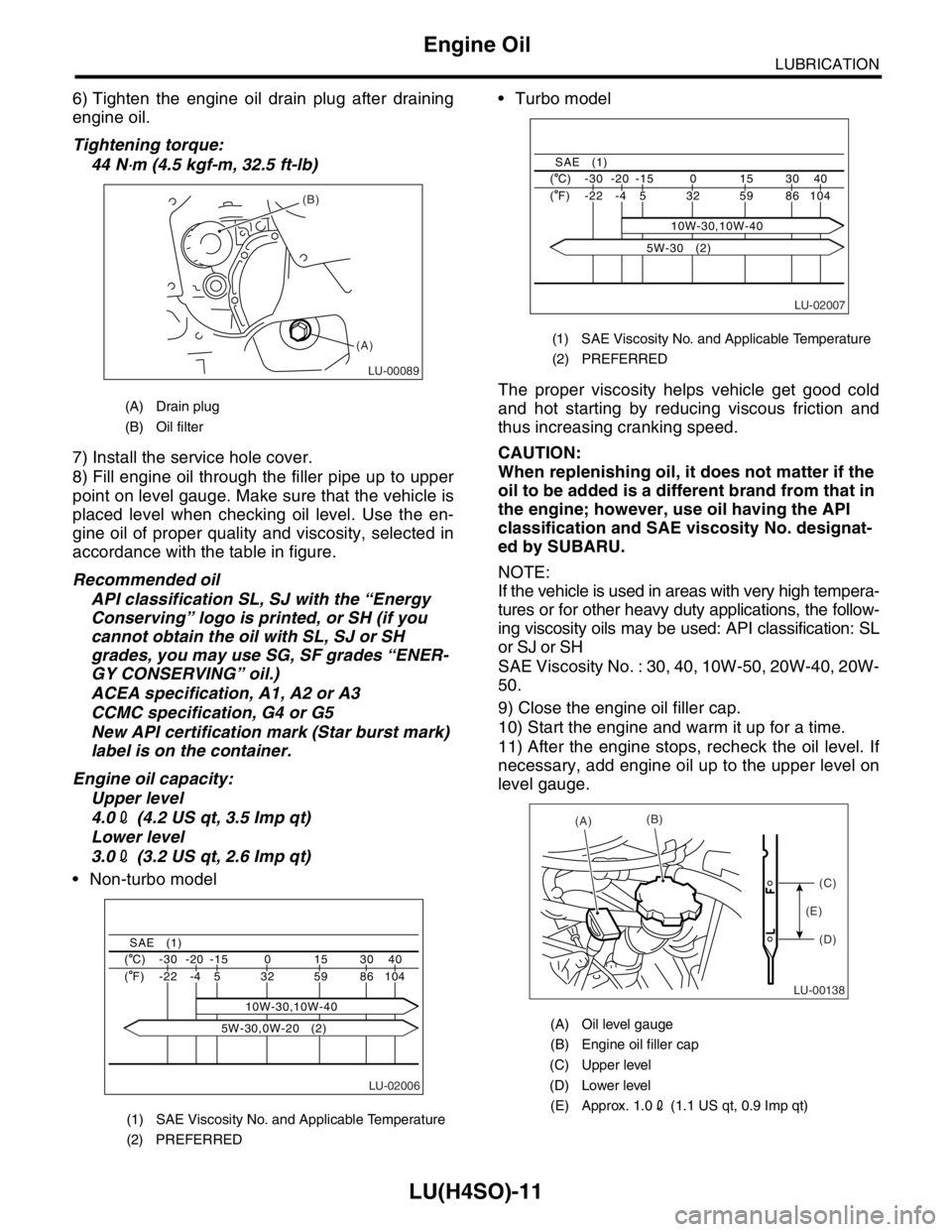

(1) Plug (16) Oil pressure switch (33) O-ring

(2) Gasket (17) Oil filler cap (34) Oil filter connector (model without

oil cooler)

(3) Relief valve spring (18) O-ring

(4) Relief valve (19) Oil filler duct (35) Plug (model without oil cooler)

(5) Oil seal (20) O-ring (36) O-ring

(6) Oil pump case (21) Rocker cover

(7) Inner rotor (22) Oil strainerTightening torque: N

⋅m (kgf-m, ft-lb)

(8) Outer rotor (23) GasketT1: 5 (0.5, 3.6)

(9) Oil pump cover (24) Oil level gauge guideT2: 6.4 (0.65, 4.7)

(10) Oil filter (25) Oil panT3: 10 (1.0, 7.0)

(11) Oil cooler connector (model with

oil cooler)(26) Oil level gaugeT4: 44 (4.5, 32.5)

(27) Metal gasketT5: 69 (7.0, 50.9)

(12) Water by-pass pipe (model with oil

cooler)(28) Drain plugT6: 6.4 (0.65, 4.7)

(29) O-ringT7: 25 (2.5, 18.1)

(13) Oil cooler (model with oil cooler) (30) Adapter (1)T8: 44 (4.5, 32.5)

(14) O-ring (31) Adapter (2)T9: 54 (5.5, 40)

(15) Oil pump ASSY (32) Baffle plate

Page 1039 of 2870

LU(H4SO)-11

LUBRICATION

Engine Oil

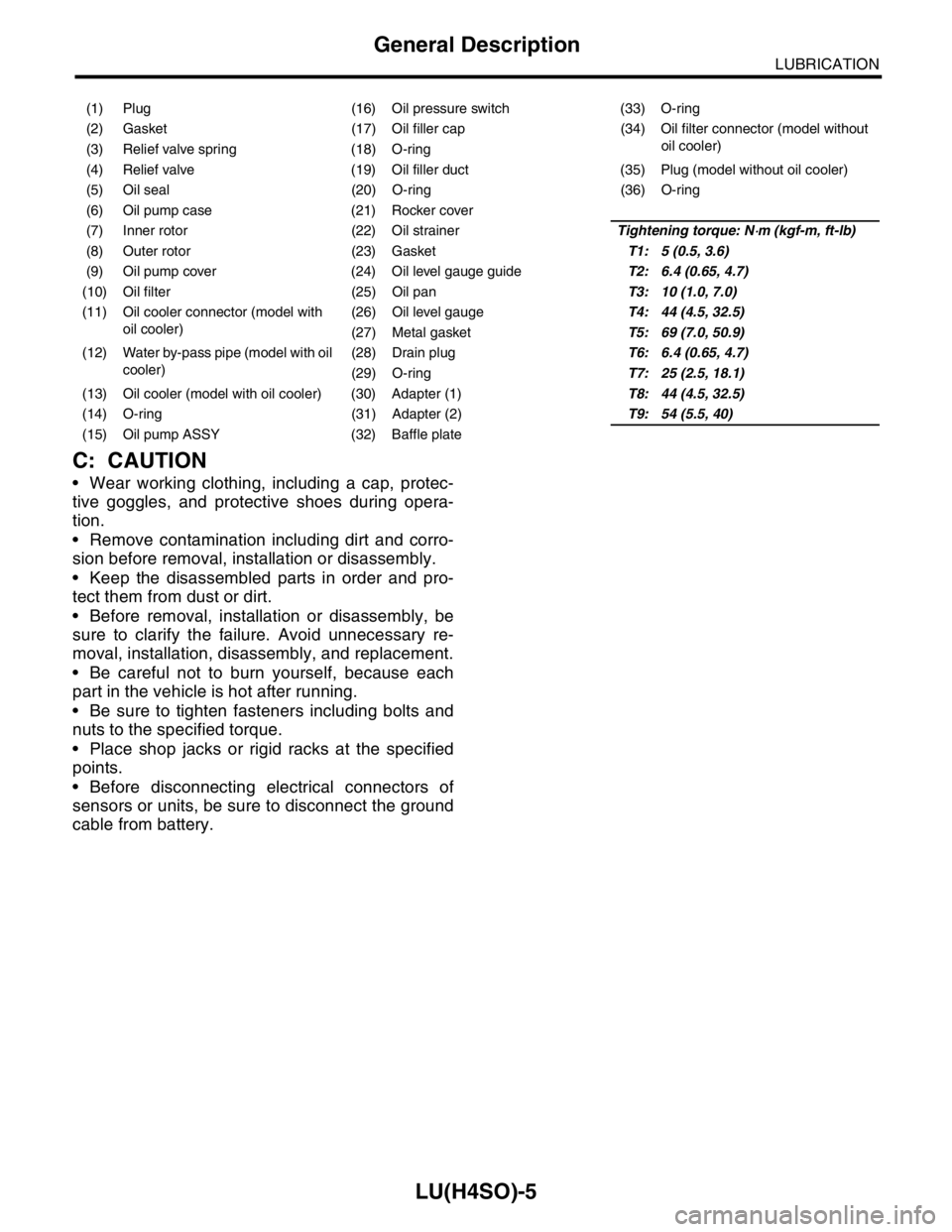

6) Tighten the engine oil drain plug after draining

engine oil.

Tightening torque:

44 N

⋅m (4.5 kgf-m, 32.5 ft-lb)

7) Install the service hole cover.

8) Fill engine oil through the filler pipe up to upper

point on level gauge. Make sure that the vehicle is

placed level when checking oil level. Use the en-

gine oil of proper quality and viscosity, selected in

accordance with the table in figure.

Recommended oil

API classification SL, SJ with the “Energy

Conserving” logo is printed, or SH (if you

cannot obtain the oil with SL, SJ or SH

grades, you may use SG, SF grades “ENER-

GY CONSERVING” oil.)

ACEA specification, A1, A2 or A3

CCMC specification, G4 or G5

New API certification mark (Star burst mark)

label is on the container.

Engine oil capacity:

Upper level

4.02 (4.2 US qt, 3.5 Imp qt)

Lower level

3.02 (3.2 US qt, 2.6 Imp qt)

Non-turbo model Turbo model

The proper viscosity helps vehicle get good cold

and hot starting by reducing viscous friction and

thus increasing cranking speed.

CAUTION:

When replenishing oil, it does not matter if the

oil to be added is a different brand from that in

the engine; however, use oil having the API

classification and SAE viscosity No. designat-

ed by SUBARU.

NOTE:

If the vehicle is used in areas with very high tempera-

tures or for other heavy duty applications, the follow-

ing viscosity oils may be used: API classification: SL

or SJ or SH

SAE Viscosity No. : 30, 40, 10W-50, 20W-40, 20W-

50.

9) Close the engine oil filler cap.

10) Start the engine and warm it up for a time.

11) After the engine stops, recheck the oil level. If

necessary, add engine oil up to the upper level on

level gauge.

(A) Drain plug

(B) Oil filter

(1) SAE Viscosity No. and Applicable Temperature

(2) PREFERRED

LU-00089

(B)

(A)

LU-02006

40 30 15 0 -15 -20 -30 ( C)

104 86 59 32

10W-30,10W-40 5 -4 -22 ( F)

SAE (1)

5W-30,0W-20 (2)

(1) SAE Viscosity No. and Applicable Temperature

(2) PREFERRED

(A) Oil level gauge

(B) Engine oil filler cap

(C) Upper level

(D) Lower level

(E) Approx. 1.02 (1.1 US qt, 0.9 Imp qt)

LU-02007

40 30 15 0 -15 -20 -30 ( C)

104 86 59 32 5 -4 -22 ( F)

SAE (1)

10W-30,10W-40

5W-30 (2)

LU-00138

(A)(B)

(C)

(D) (E)

Page 1041 of 2870

LU(H4SO)-13

LUBRICATION

Oil Pump

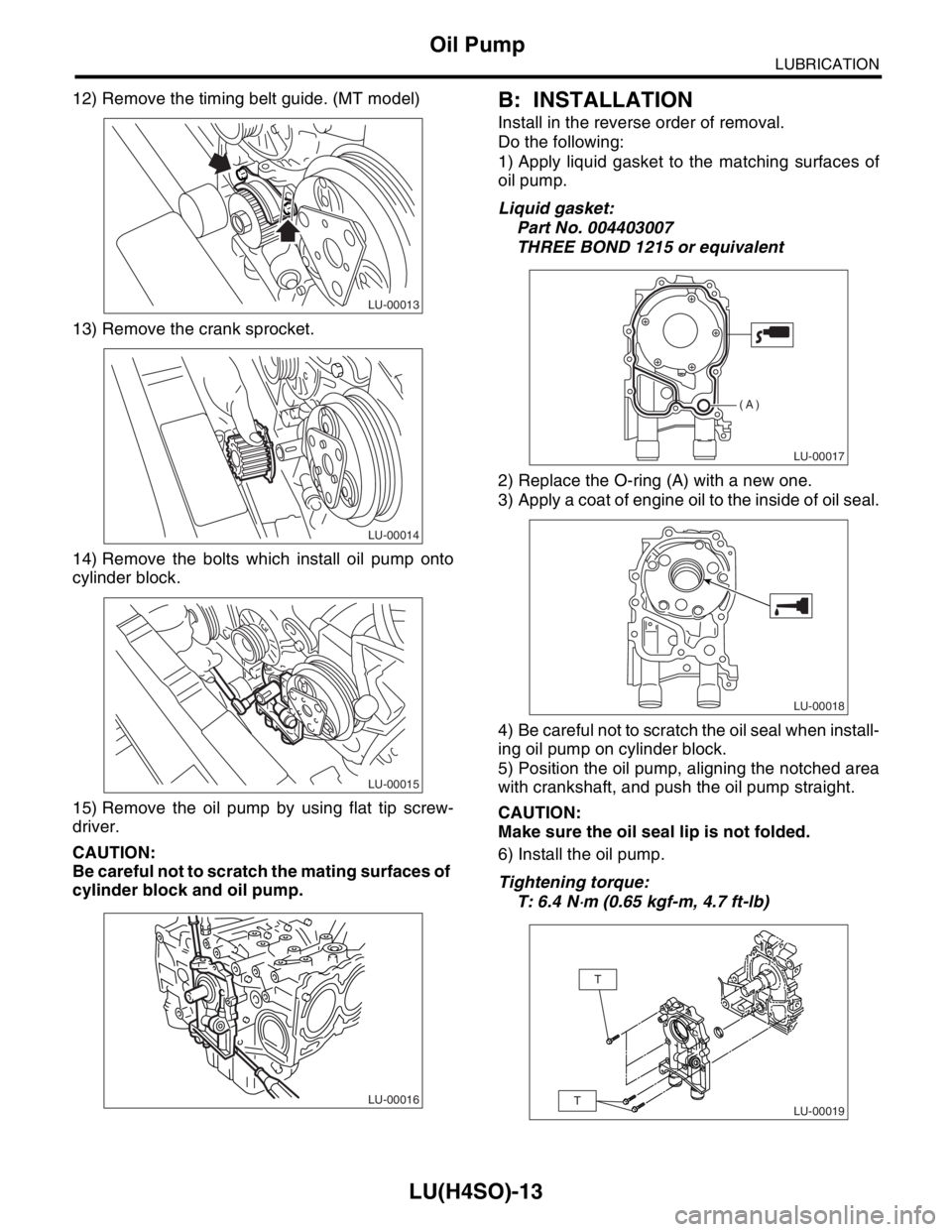

12) Remove the timing belt guide. (MT model)

13) Remove the crank sprocket.

14) Remove the bolts which install oil pump onto

cylinder block.

15) Remove the oil pump by using flat tip screw-

driver.

CAUTION:

Be careful not to scratch the mating surfaces of

cylinder block and oil pump.B: INSTALLATION

Install in the reverse order of removal.

Do the following:

1) Apply liquid gasket to the matching surfaces of

oil pump.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

2) Replace the O-ring (A) with a new one.

3) Apply a coat of engine oil to the inside of oil seal.

4) Be careful not to scratch the oil seal when install-

ing oil pump on cylinder block.

5) Position the oil pump, aligning the notched area

with crankshaft, and push the oil pump straight.

CAUTION:

Make sure the oil seal lip is not folded.

6) Install the oil pump.

Tightening torque:

T: 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

LU-00013

LU-00014

LU-00015

LU-00016

LU-00017

(A)

LU-00018

LU-00019

T

T

Page 1042 of 2870

LU(H4SO)-14

LUBRICATION

Oil Pump

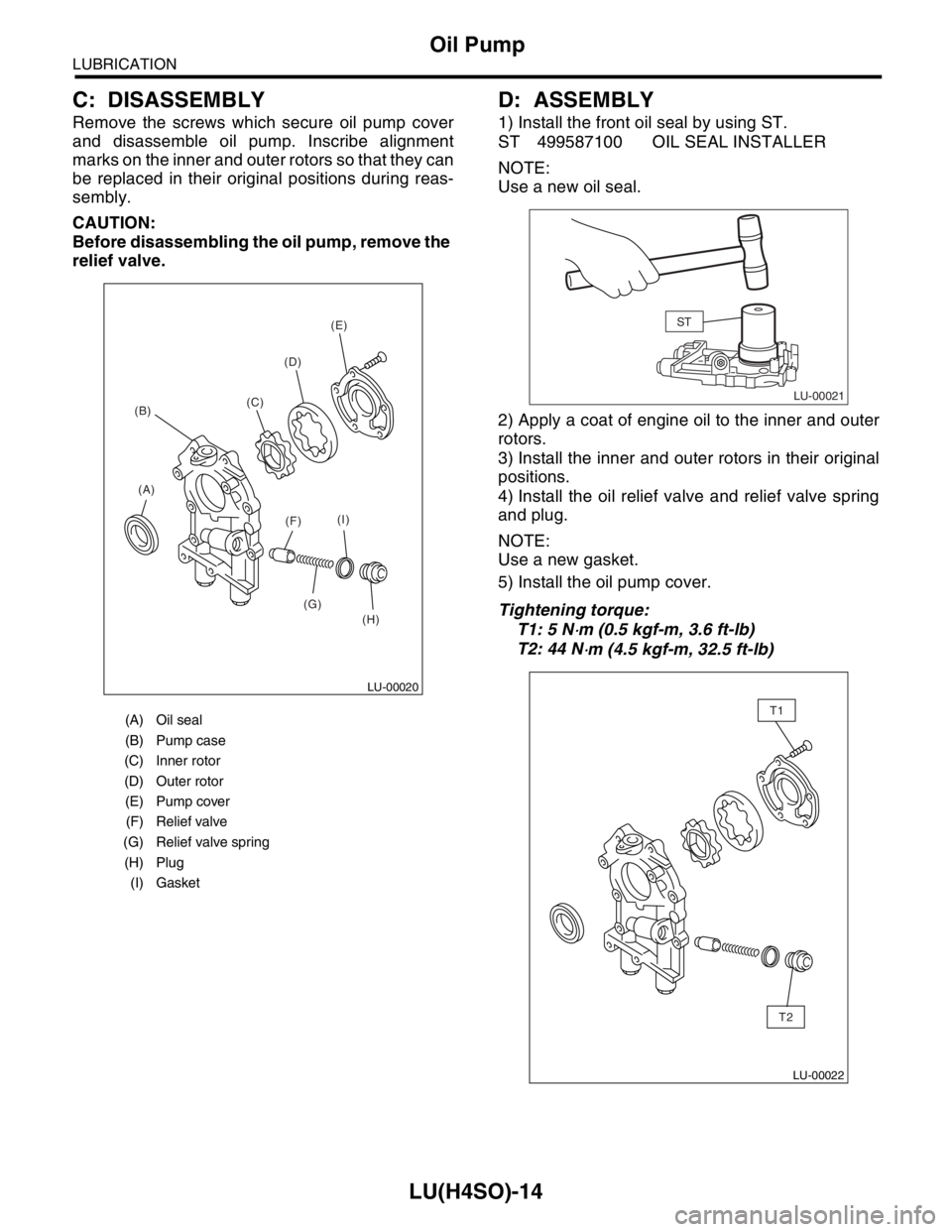

C: DISASSEMBLY

Remove the screws which secure oil pump cover

and disassemble oil pump. Inscribe alignment

marks on the inner and outer rotors so that they can

be replaced in their original positions during reas-

sembly.

CAUTION:

Before disassembling the oil pump, remove the

relief valve.

D: ASSEMBLY

1) Install the front oil seal by using ST.

ST 499587100 OIL SEAL INSTALLER

NOTE:

Use a new oil seal.

2) Apply a coat of engine oil to the inner and outer

rotors.

3) Install the inner and outer rotors in their original

positions.

4) Install the oil relief valve and relief valve spring

and plug.

NOTE:

Use a new gasket.

5) Install the oil pump cover.

Tightening torque:

T1: 5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

T2: 44 N

⋅m (4.5 kgf-m, 32.5 ft-lb)

(A) Oil seal

(B) Pump case

(C) Inner rotor

(D) Outer rotor

(E) Pump cover

(F) Relief valve

(G) Relief valve spring

(H) Plug

(I) Gasket

LU-00020

(E)

(D)

(C)

(B)

(A)

(F)

(G)(I)

(H)

LU-00021

ST

LU-00022

T1

T2

Page 1046 of 2870

LU(H4SO)-18

LUBRICATION

Oil Pan and Strainer

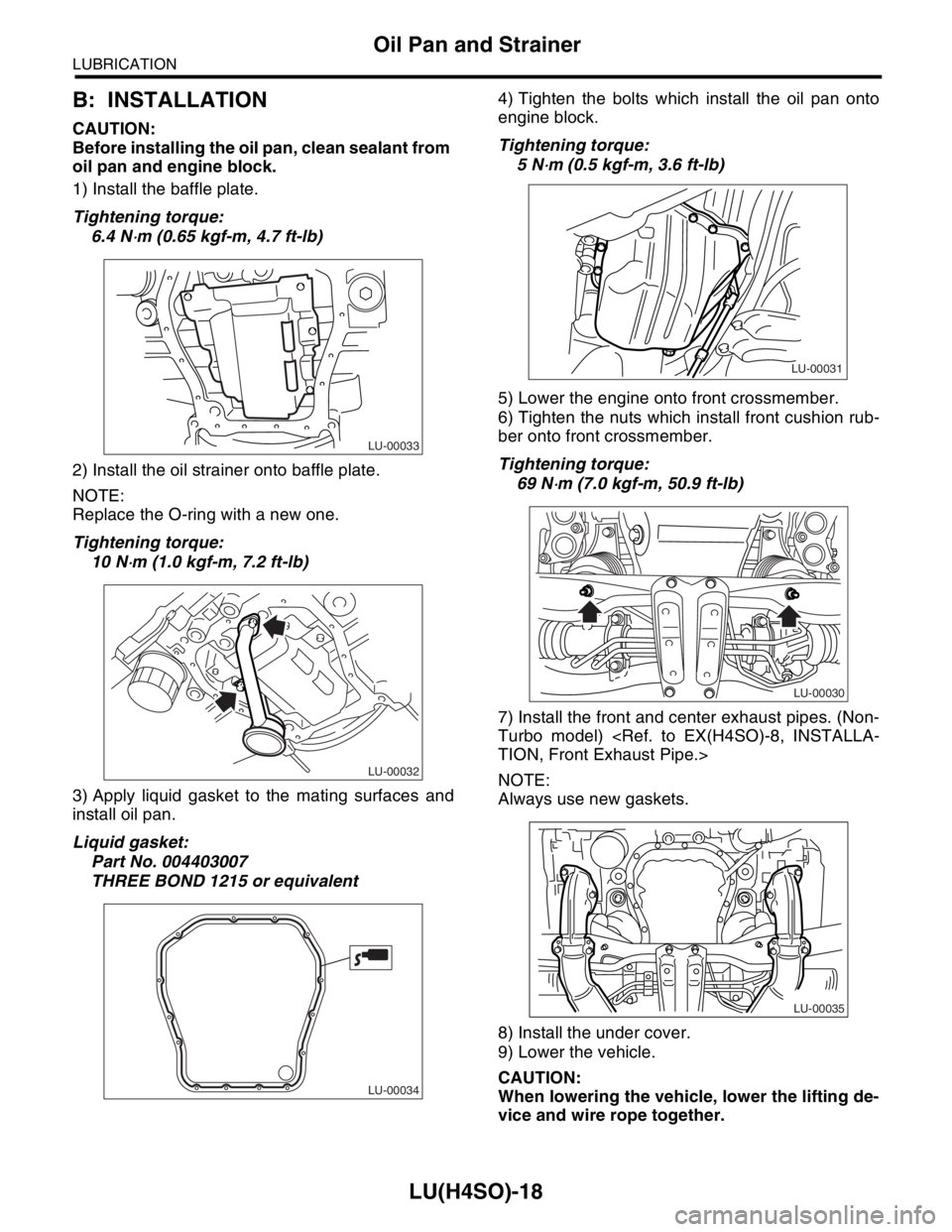

B: INSTALLATION

CAUTION:

Before installing the oil pan, clean sealant from

oil pan and engine block.

1) Install the baffle plate.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

2) Install the oil strainer onto baffle plate.

NOTE:

Replace the O-ring with a new one.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

3) Apply liquid gasket to the mating surfaces and

install oil pan.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent4) Tighten the bolts which install the oil pan onto

engine block.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

5) Lower the engine onto front crossmember.

6) Tighten the nuts which install front cushion rub-

ber onto front crossmember.

Tightening torque:

69 N

⋅m (7.0 kgf-m, 50.9 ft-lb)

7) Install the front and center exhaust pipes. (Non-

Turbo model)

NOTE:

Always use new gaskets.

8) Install the under cover.

9) Lower the vehicle.

CAUTION:

When lowering the vehicle, lower the lifting de-

vice and wire rope together.

LU-00033

LU-00032

LU-00034

LU-00031

LU-00030

LU-00035

Page 1047 of 2870

LU(H4SO)-19

LUBRICATION

Oil Pan and Strainer

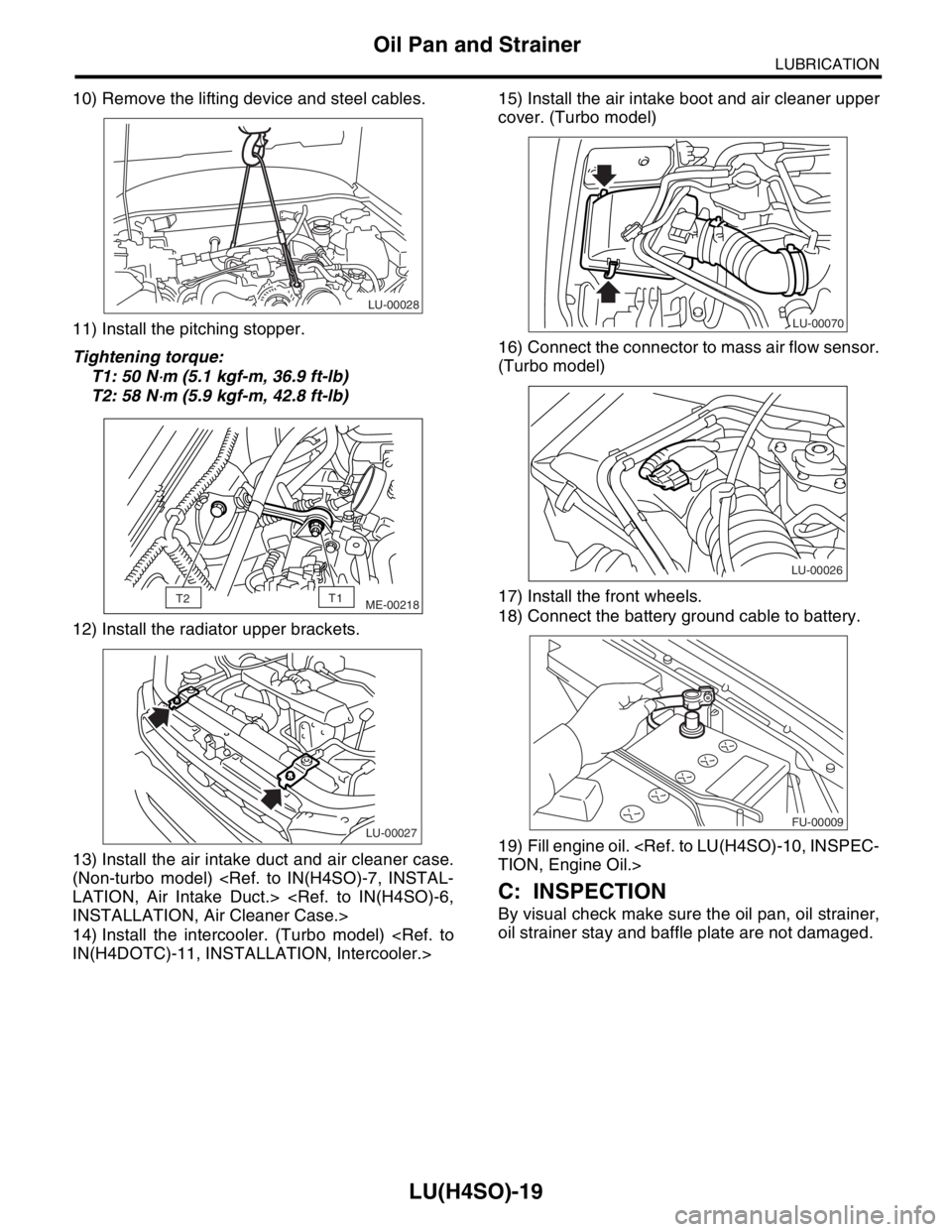

10) Remove the lifting device and steel cables.

11) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅m (5.1 kgf-m, 36.9 ft-lb)

T2: 58 N

⋅m (5.9 kgf-m, 42.8 ft-lb)

12) Install the radiator upper brackets.

13) Install the air intake duct and air cleaner case.

(Non-turbo model)

14) Install the intercooler. (Turbo model)

cover. (Turbo model)

16) Connect the connector to mass air flow sensor.

(Turbo model)

17) Install the front wheels.

18) Connect the battery ground cable to battery.

19) Fill engine oil.

C: INSPECTION

By visual check make sure the oil pan, oil strainer,

oil strainer stay and baffle plate are not damaged.

LU-00028

ME-00218T2T1

LU-00027

LU-00070

LU-00026

FU-00009

Page 1048 of 2870

LU(H4SO)-20

LUBRICATION

Oil Pressure Switch

6. Oil Pressure Switch

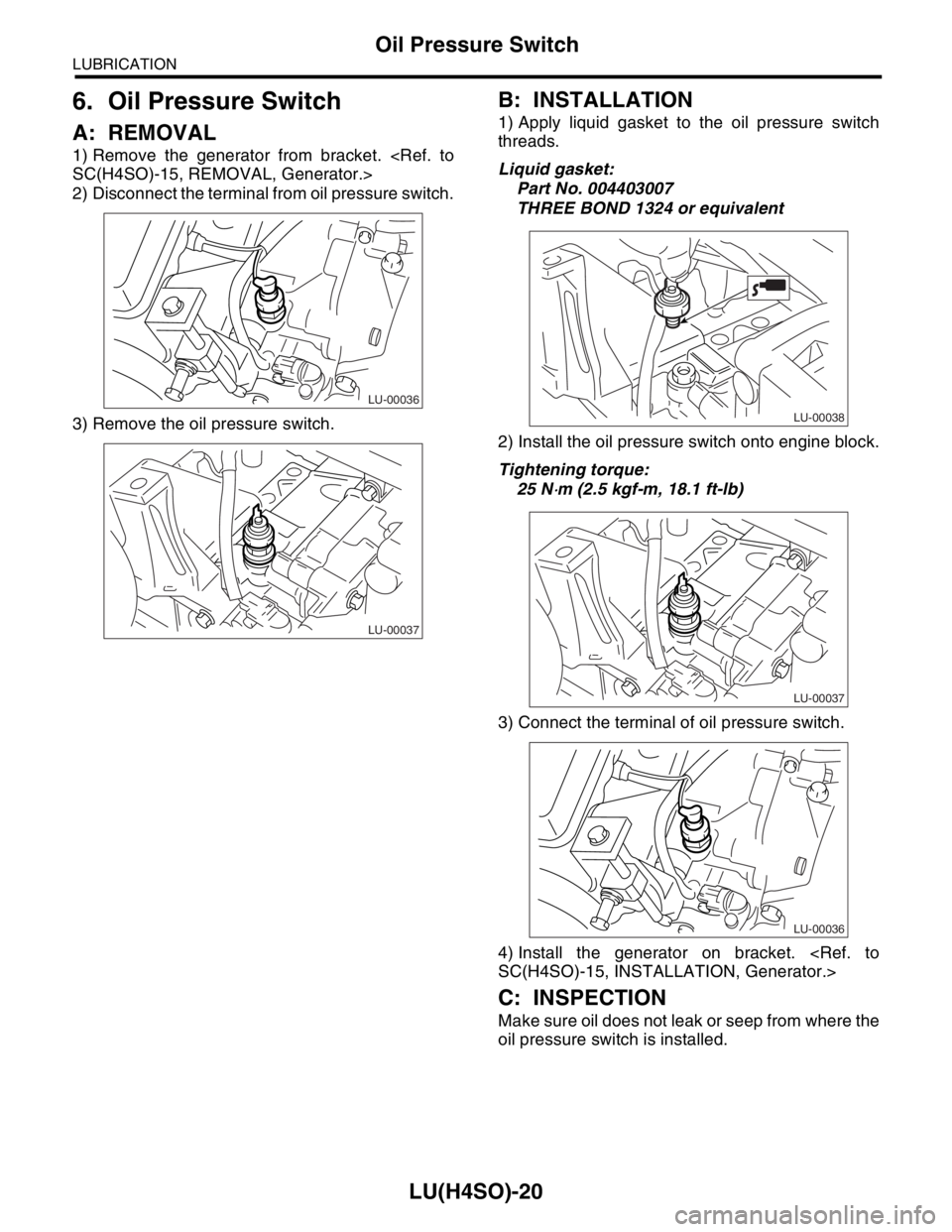

A: REMOVAL

1) Remove the generator from bracket.

2) Disconnect the terminal from oil pressure switch.

3) Remove the oil pressure switch.

B: INSTALLATION

1) Apply liquid gasket to the oil pressure switch

threads.

Liquid gasket:

Part No. 004403007

THREE BOND 1324 or equivalent

2) Install the oil pressure switch onto engine block.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

3) Connect the terminal of oil pressure switch.

4) Install the generator on bracket.

C: INSPECTION

Make sure oil does not leak or seep from where the

oil pressure switch is installed.

LU-00036

LU-00037

LU-00038

LU-00037

LU-00036

Page 1050 of 2870

LU(H4SO)-22

LUBRICATION

Engine Oil Cooler

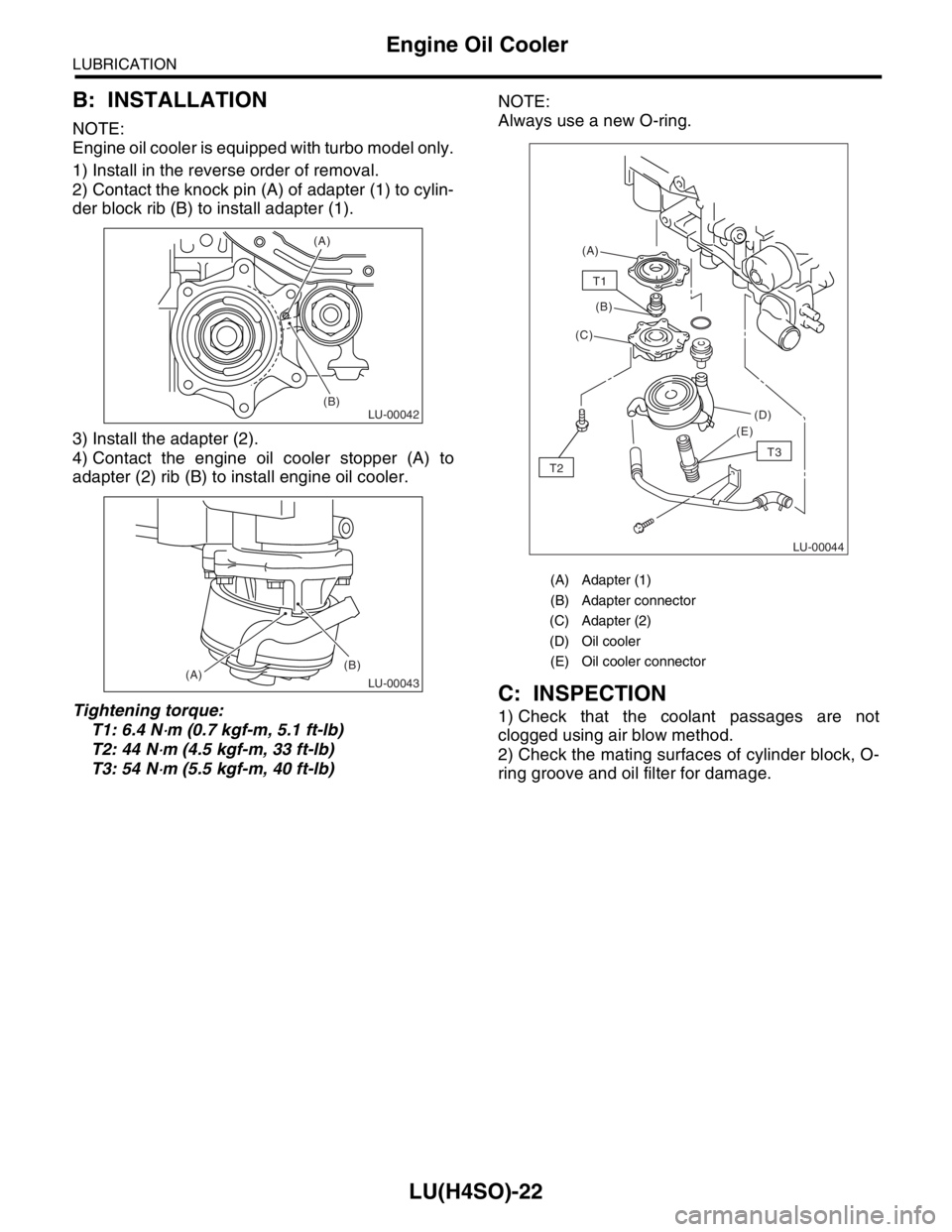

B: INSTALLATION

NOTE:

Engine oil cooler is equipped with turbo model only.

1) Install in the reverse order of removal.

2) Contact the knock pin (A) of adapter (1) to cylin-

der block rib (B) to install adapter (1).

3) Install the adapter (2).

4) Contact the engine oil cooler stopper (A) to

adapter (2) rib (B) to install engine oil cooler.

Tightening torque:

T1: 6.4 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

T2: 44 N

⋅m (4.5 kgf-m, 33 ft-lb)

T3: 54 N

⋅m (5.5 kgf-m, 40 ft-lb)NOTE:

Always use a new O-ring.

C: INSPECTION

1) Check that the coolant passages are not

clogged using air blow method.

2) Check the mating surfaces of cylinder block, O-

ring groove and oil filter for damage.

LU-00042

(A)

(B)

LU-00043

(B)(A)

(A) Adapter (1)

(B) Adapter connector

(C) Adapter (2)

(D) Oil cooler

(E) Oil cooler connector

LU-00044

(A)

(B)

(C)

(D)

(E)

T1

T2

T3