lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1577 of 2870

ME(H4DOTC)-117

MECHANICAL

Crankshaft

24.Crankshaft

A: REMOVAL AND INSTALLATION

For operations related to crankshaft, refer to “20.

Cylinder Block.”

Page 1652 of 2870

EN(H4DOTC)-22

ENGINE (DIAGNOSTIC)

Electrical Component Location

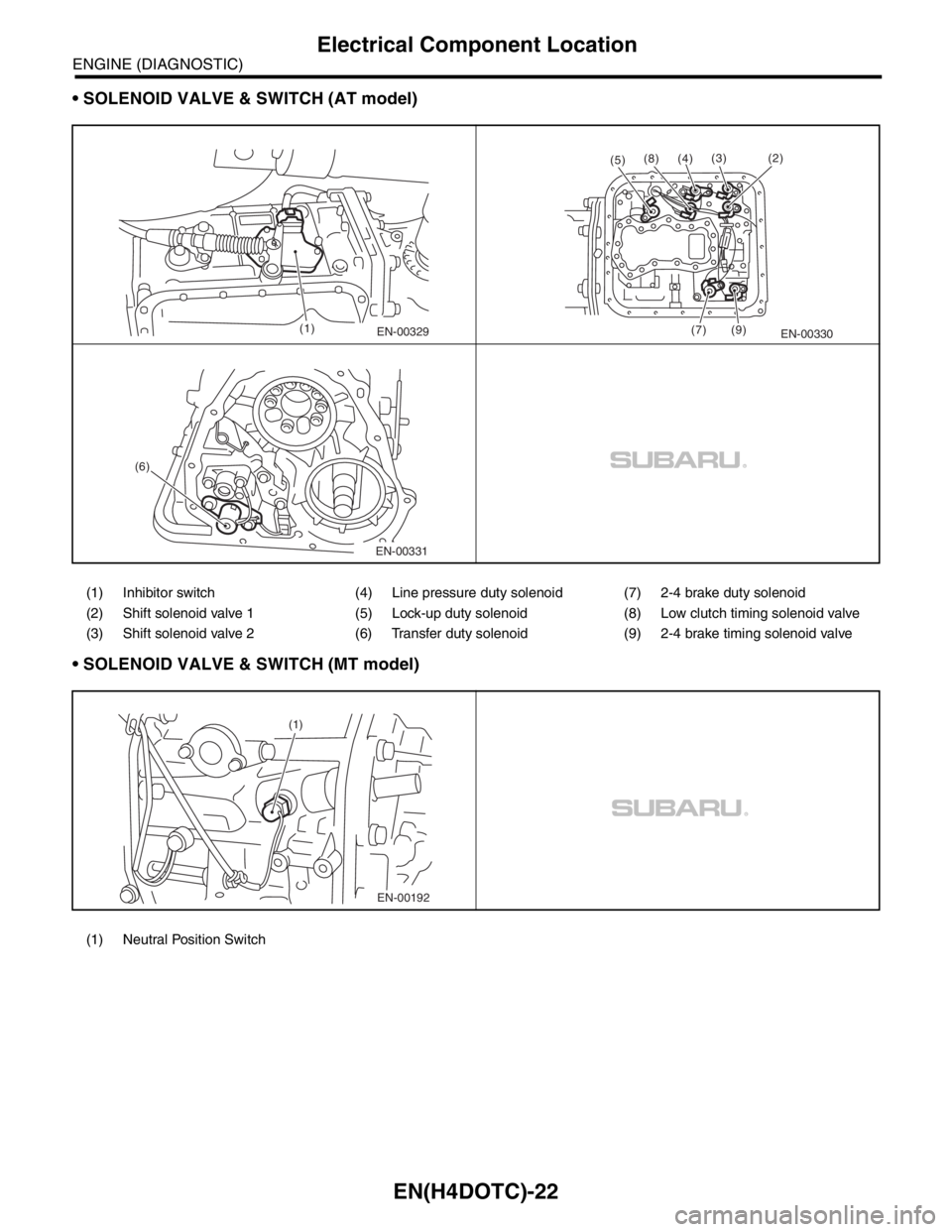

SOLENOID VALVE & SWITCH (AT model)

SOLENOID VALVE & SWITCH (MT model)

(1) Inhibitor switch (4) Line pressure duty solenoid (7) 2-4 brake duty solenoid

(2) Shift solenoid valve 1 (5) Lock-up duty solenoid (8) Low clutch timing solenoid valve

(3) Shift solenoid valve 2 (6) Transfer duty solenoid (9) 2-4 brake timing solenoid valve

(1) Neutral Position Switch

EN-00329(1)

(2)(3)

EN-00330 (4)

(8)

(5)

(7) (9)

EN-00331 (6)

EN-00192 (1)

Page 1668 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4DOTC)-38

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System S SUBARU FORESTER 2004 Service Repair Manual EN(H4DOTC)-38

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System S](/img/17/57426/w960_57426-1667.png)

EN(H4DOTC)-38

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

8. READ CURRENT DATA FOR AT

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Transmission} and press the [YES] key.

3) Press the [YES] key after displayed the information of transmission type.

4) On the «Transmission Diagnosis» screen, select the {Current Data Display/Save}, and then press the

[YES] key.

5) On the «Data Display Menu» screen, select the {Data Display} and press the [YES] key.

6) Using the scroll key, move the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

NOTE:

For detailed operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MANUAL”.

Description Display Unit of measure

Battery voltage Battery Voltage V

Rear vehicle speed sensor signal Rear Wheel Speed km/h or MPH

Front vehicle speed sensor signal Front Wheel Speed km/h or MPH

Engine speed signal Engine Speed rpm

ATF temperature signal ATF Temp.°C or °F

Mass air flow sensor signal Air Flow Sensor Voltage V

Throttle position signal Throttle Sensor Voltage V

Gear Position Gear position —

Line pressure control duty ratio Line Pressure Duty Ratio %

Lock up clutch control duty ratio Lock Up Duty Ratio %

Transfer clutch control duty ratio Transfer Duty Ratio %

Throttle position sensor power supply Throttle Sensor Power V

Turbine revolution signal Turbine Revolution Speed rpm

2-4 Brake timing pressure control duty ratio Brake Clutch Duty Ratio %

Stop light switch signal Stop Light Switch ON or OFF

Anti lock brake system signal ABS Signal ON or OFF

Cruise control system signal Cruise Control Signal ON or OFF

Neutral/Parking range signal N/P Range Signal ON or OFF

Reverse range signal R Range Signal ON or OFF

Drive range signal D Range Signal ON or OFF

3rd range signal 3rd Range Signal ON or OFF

2nd range signal 2nd Range Signal ON or OFF

1st range signal 1st Range Signal ON or OFF

Shift control solenoid A Shift Solenoid #1 ON or OFF

Shift control solenoid B Shift Solenoid #2 ON or OFF

Torque control output signal #1 Torque Control Signal #1 ON or OFF

Torque control output signal #2 Torque Control Signal #2 ON or OFF

Torque control cut signal Torque Control Cut Sig. ON or OFF

2-4 brake timing control solenoid valve 2-4 Brake Timing Sol. ON or OFF

Low clutch timing control solenoid valve Low Clutch Timing Sol. ON or OFF

Automatic transmission diagnosis indicator lamp Diagnosis Lamp ON or OFF

Page 1672 of 2870

EN(H4DOTC)-42

ENGINE (DIAGNOSTIC)

Inspection Mode

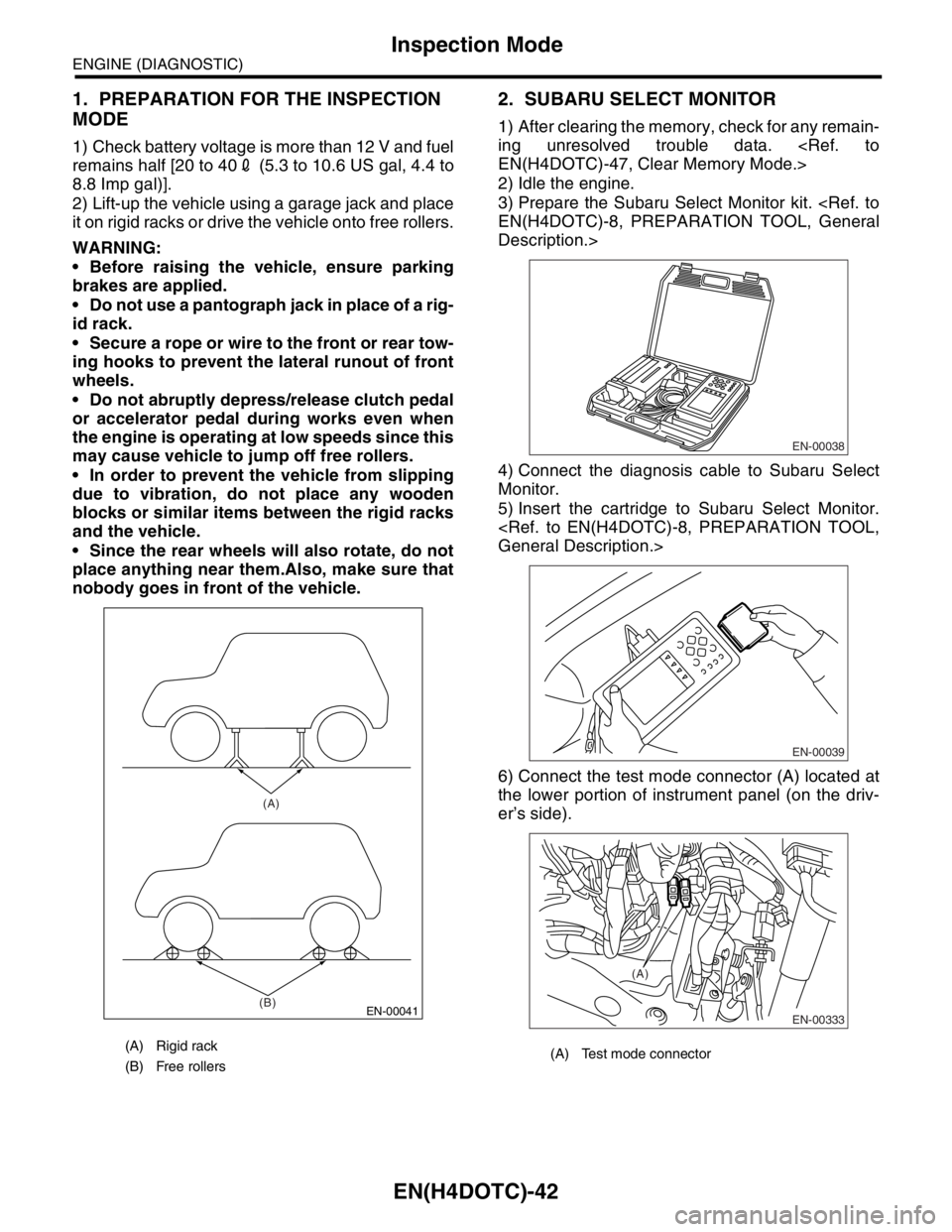

1. PREPARATION FOR THE INSPECTION

MODE

1) Check battery voltage is more than 12 V and fuel

remains half [20 to 402 (5.3 to 10.6 US gal, 4.4 to

8.8 Imp gal)].

2) Lift-up the vehicle using a garage jack and place

it on rigid racks or drive the vehicle onto free rollers.

WARNING:

Before raising the vehicle, ensure parking

brakes are applied.

Do not use a pantograph jack in place of a rig-

id rack.

Secure a rope or wire to the front or rear tow-

ing hooks to prevent the lateral runout of front

wheels.

Do not abruptly depress/release clutch pedal

or accelerator pedal during works even when

the engine is operating at low speeds since this

may cause vehicle to jump off free rollers.

In order to prevent the vehicle from slipping

due to vibration, do not place any wooden

blocks or similar items between the rigid racks

and the vehicle.

Since the rear wheels will also rotate, do not

place anything near them.Also, make sure that

nobody goes in front of the vehicle.

2. SUBARU SELECT MONITOR

1) After clearing the memory, check for any remain-

ing unresolved trouble data.

2) Idle the engine.

3) Prepare the Subaru Select Monitor kit.

Description.>

4) Connect the diagnosis cable to Subaru Select

Monitor.

5) Insert the cartridge to Subaru Select Monitor.

6) Connect the test mode connector (A) located at

the lower portion of instrument panel (on the driv-

er’s side).

(A) Rigid rack

(B) Free rollers

EN-00041

(A)

(B)

(A) Test mode connector

EN-00038

EN-00039

EN-00333

(A)

Page 1800 of 2870

EN(H4DOTC)-167

ENGINE (DIAGNOSTIC)

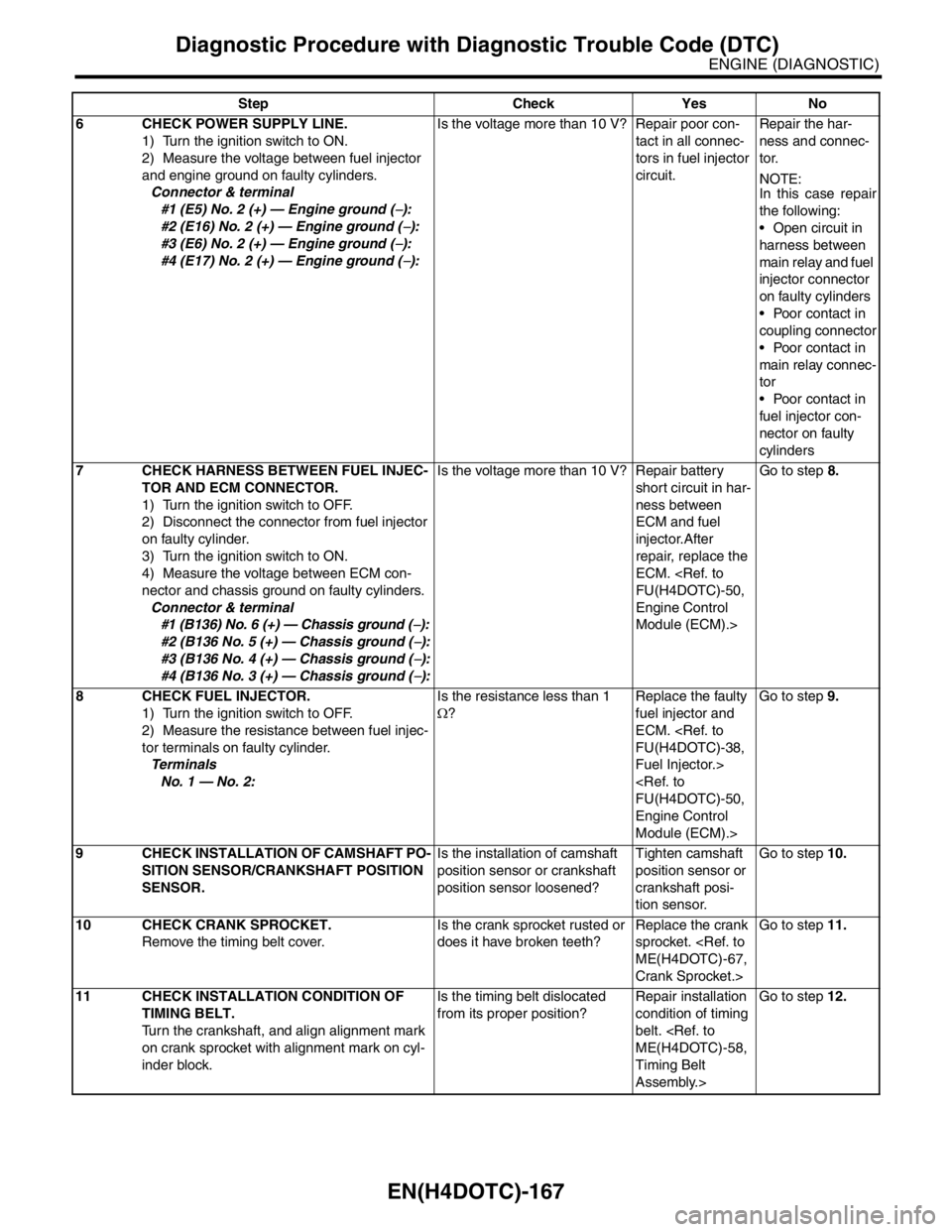

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

6 CHECK POWER SUPPLY LINE.

1) Turn the ignition switch to ON.

2) Measure the voltage between fuel injector

and engine ground on faulty cylinders.

Connector & terminal

#1 (E5) No. 2 (+) — Engine ground (

−):

#2 (E16) No. 2 (+) — Engine ground (

−):

#3 (E6) No. 2 (+) — Engine ground (

−):

#4 (E17) No. 2 (+) — Engine ground (

−):Is the voltage more than 10 V? Repair poor con-

tact in all connec-

tors in fuel injector

circuit.Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

main relay and fuel

injector connector

on faulty cylinders

Poor contact in

coupling connector

Poor contact in

main relay connec-

tor

Poor contact in

fuel injector con-

nector on faulty

cylinders

7 CHECK HARNESS BETWEEN FUEL INJEC-

TOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel injector

on faulty cylinder.

3) Turn the ignition switch to ON.

4) Measure the voltage between ECM con-

nector and chassis ground on faulty cylinders.

Connector & terminal

#1 (B136) No. 6 (+) — Chassis ground (

−):

#2 (B136 No. 5 (+) — Chassis ground (

−):

#3 (B136 No. 4 (+) — Chassis ground (

−):

#4 (B136 No. 3 (+) — Chassis ground (

−):Is the voltage more than 10 V? Repair battery

short circuit in har-

ness between

ECM and fuel

injector.After

repair, replace the

ECM.

Engine Control

Module (ECM).>Go to step 8.

8 CHECK FUEL INJECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between fuel injec-

tor terminals on faulty cylinder.

Te r m i n a l s

No. 1 — No. 2:Is the resistance less than 1

Ω?Replace the faulty

fuel injector and

ECM.

Fuel Injector.>

Engine Control

Module (ECM).>Go to step 9.

9 CHECK INSTALLATION OF CAMSHAFT PO-

SITION SENSOR/CRANKSHAFT POSITION

SENSOR.Is the installation of camshaft

position sensor or crankshaft

position sensor loosened?Tighten camshaft

position sensor or

crankshaft posi-

tion sensor.Go to step 10.

10 CHECK CRANK SPROCKET.

Remove the timing belt cover.Is the crank sprocket rusted or

does it have broken teeth?Replace the crank

sprocket.

Crank Sprocket.>Go to step 11.

11 CHECK INSTALLATION CONDITION OF

TIMING BELT.

Turn the crankshaft, and align alignment mark

on crank sprocket with alignment mark on cyl-

inder block.Is the timing belt dislocated

from its proper position?Repair installation

condition of timing

belt.

Timing Belt

Assembly.>Go to step 12. Step Check Yes No

Page 1809 of 2870

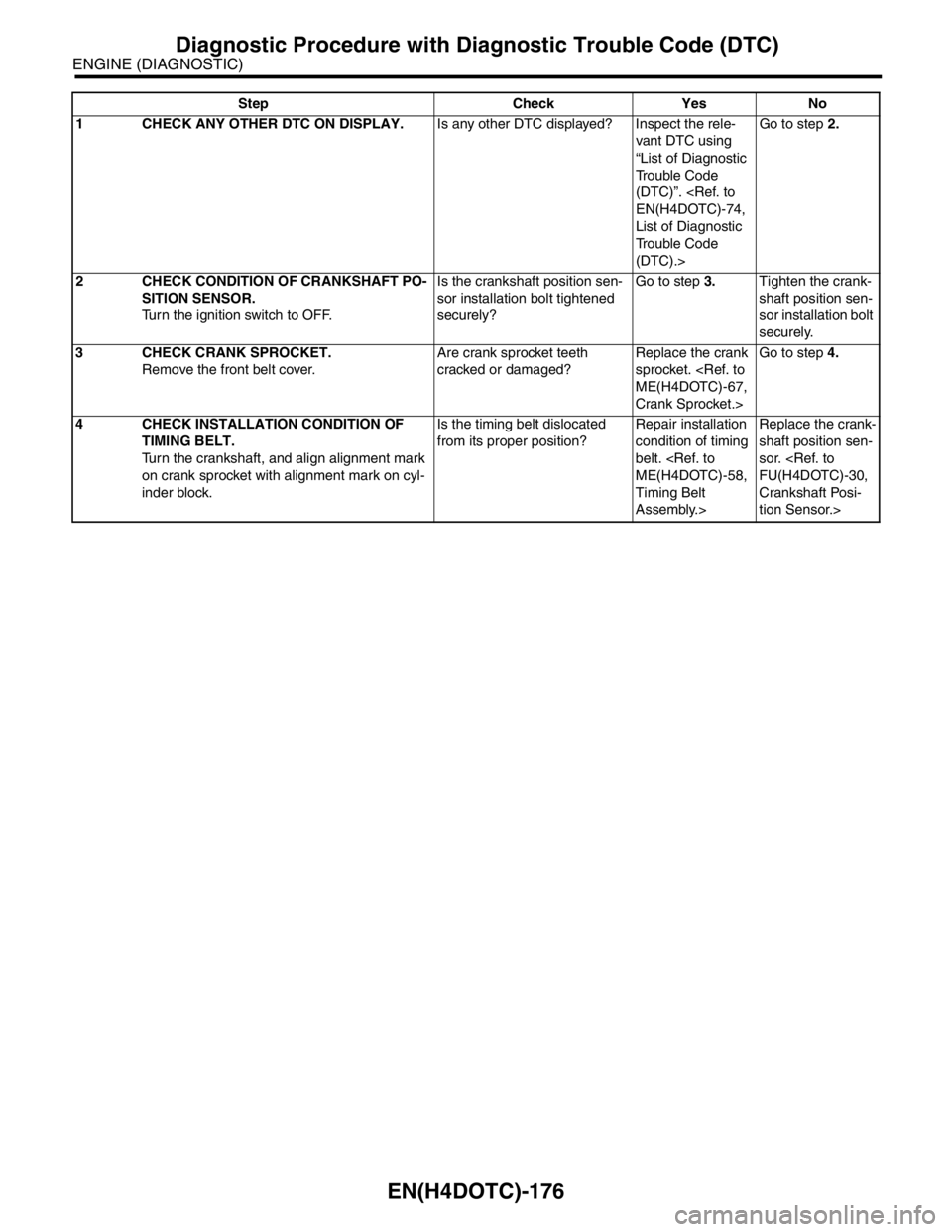

EN(H4DOTC)-176

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the rele-

vant DTC using

“List of Diagnostic

Trouble Code

(DTC)”.

List of Diagnostic

Trouble Code

(DTC).>Go to step 2.

2 CHECK CONDITION OF CRANKSHAFT PO-

SITION SENSOR.

Turn the ignition switch to OFF.Is the crankshaft position sen-

sor installation bolt tightened

securely?Go to step 3.Tighten the crank-

shaft position sen-

sor installation bolt

securely.

3 CHECK CRANK SPROCKET.

Remove the front belt cover.Are crank sprocket teeth

cracked or damaged?Replace the crank

sprocket.

Crank Sprocket.>Go to step 4.

4 CHECK INSTALLATION CONDITION OF

TIMING BELT.

Turn the crankshaft, and align alignment mark

on crank sprocket with alignment mark on cyl-

inder block.Is the timing belt dislocated

from its proper position?Repair installation

condition of timing

belt.

Timing Belt

Assembly.>Replace the crank-

shaft position sen-

sor.

Crankshaft Posi-

tion Sensor.>

Page 1838 of 2870

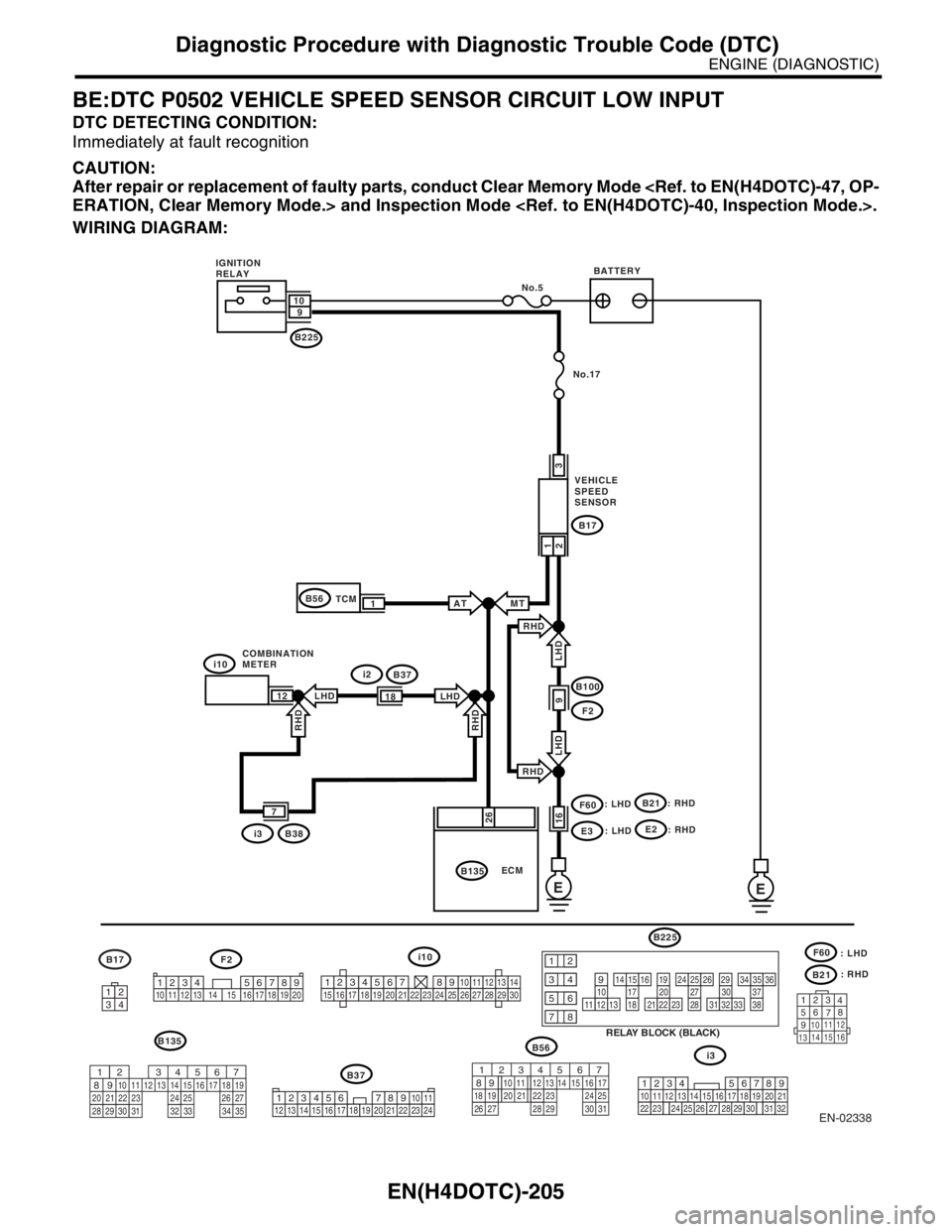

EN(H4DOTC)-205

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

BE:DTC P0502 VEHICLE SPEED SENSOR CIRCUIT LOW INPUT

DTC DETECTING CONDITION:

Immediately at fault recognition

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02338

E

i10

B135

B2259 10

No.5

: RHD

B21

F60

: LHD

: RHD

123

4

56

78

9

1011 12

1314 15 16

F2B17

i10i2B37

12

i3B38

7

E

F2

B100

B17

B21

E3

F60

9 LHD LHD

B135

26

No.17

: LHD

RHD

RHD

23

161

1B56ATMT

RHD

RHD

LHD LHD18

B37

i3

1234567891011121314151617181920212223242526272829301234 5678910 11 12 13 14 15 16 17 18 19 203412

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

B56

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 3134

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7219

32

1234

5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

: RHDE2

: LHD

RELAY BLOCK (BLACK)

10111213

1415161718

1920212223

2425262728

2930313233

3435363738

12

934

56

78

B225 BATTERY IGNITION

RELAY

COMBINATION

METERVEHICLE

SPEED

SENSOR

ECM TCM

Page 1840 of 2870

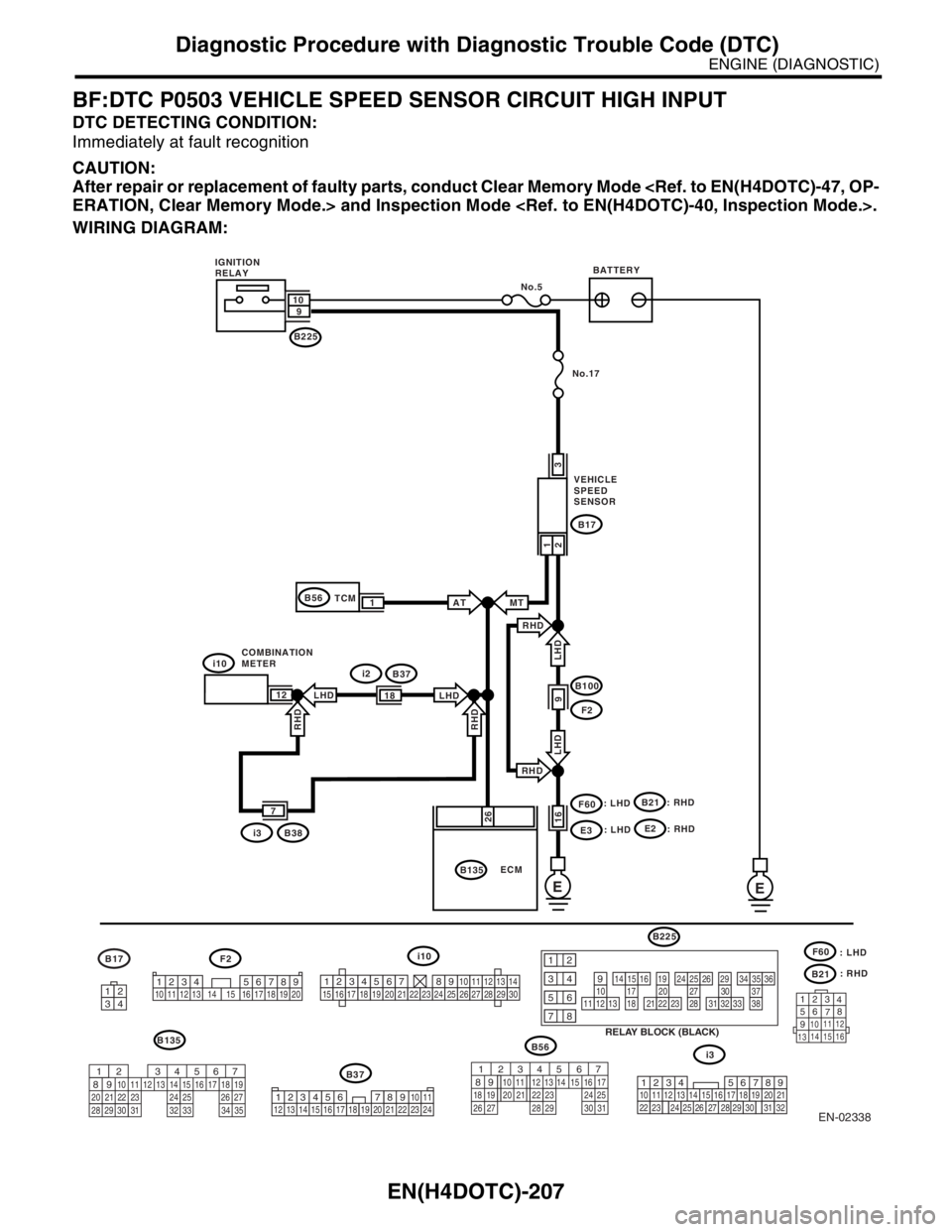

EN(H4DOTC)-207

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

BF:DTC P0503 VEHICLE SPEED SENSOR CIRCUIT HIGH INPUT

DTC DETECTING CONDITION:

Immediately at fault recognition

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02338

E

i10

B135

B2259 10

No.5

: RHD

B21

F60

: LHD

: RHD

123

4

56

78

9

1011 12

1314 15 16

F2B17

i10i2B37

12

i3B38

7

E

F2

B100

B17

B21

E3

F60

9 LHD LHD

B135

26

No.17

: LHD

RHD

RHD

23

161

1B56ATMT

RHD

RHD

LHD LHD18

B37

i3

1234567891011121314151617181920212223242526272829301234 5678910 11 12 13 14 15 16 17 18 19 203412

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

B56

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 3134

12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7219

32

1234

5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

: RHDE2

: LHD

RELAY BLOCK (BLACK)

10111213

1415161718

1920212223

2425262728

2930313233

3435363738

12

934

56

78

B225 BATTERY IGNITION

RELAY

COMBINATION

METERVEHICLE

SPEED

SENSOR

ECM TCM

Page 1957 of 2870

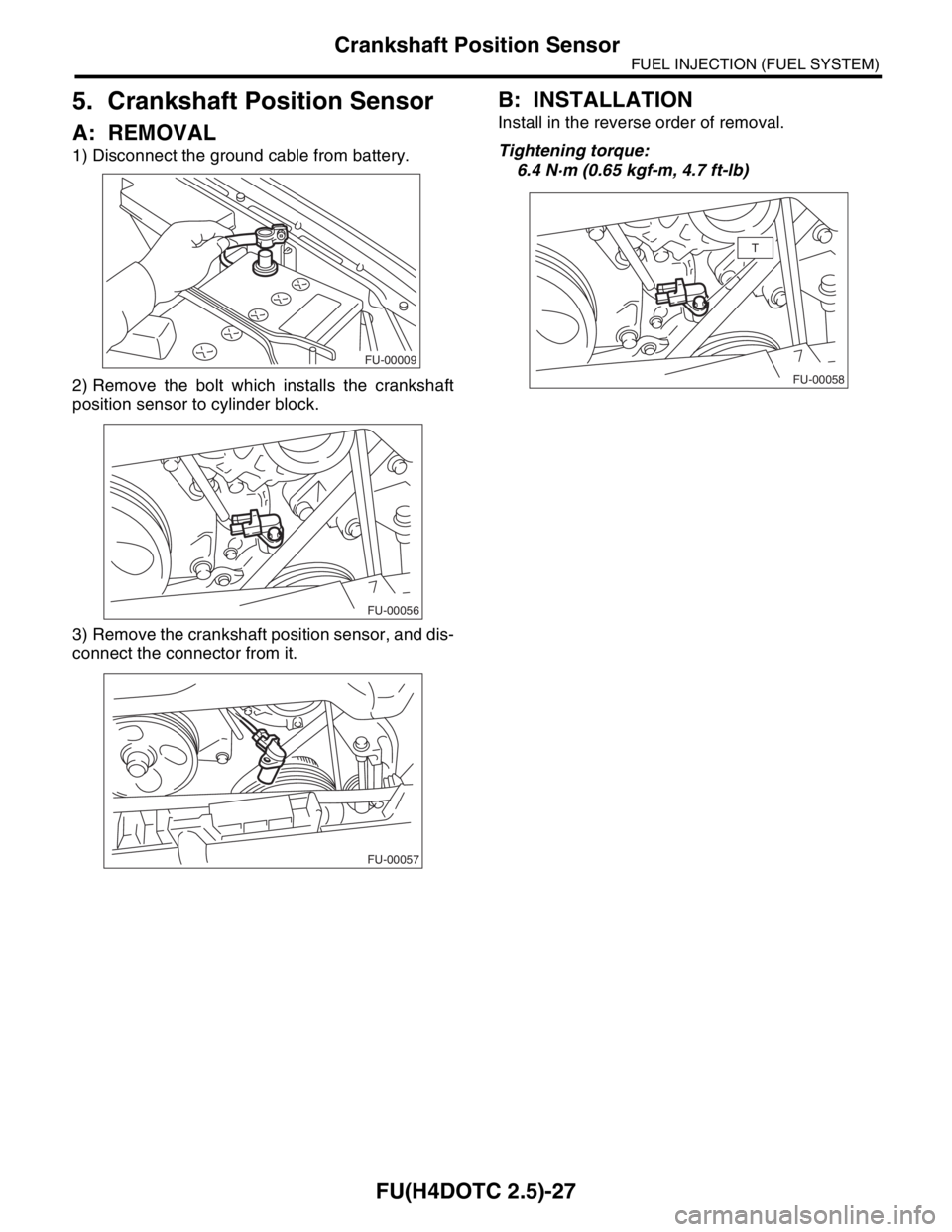

FU(H4DOTC 2.5)-27

FUEL INJECTION (FUEL SYSTEM)

Crankshaft Position Sensor

5. Crankshaft Position Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the bolt which installs the crankshaft

position sensor to cylinder block.

3) Remove the crankshaft position sensor, and dis-

connect the connector from it.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

FU-00009

FU-00056

FU-00057

FU-00058

T

Page 1959 of 2870

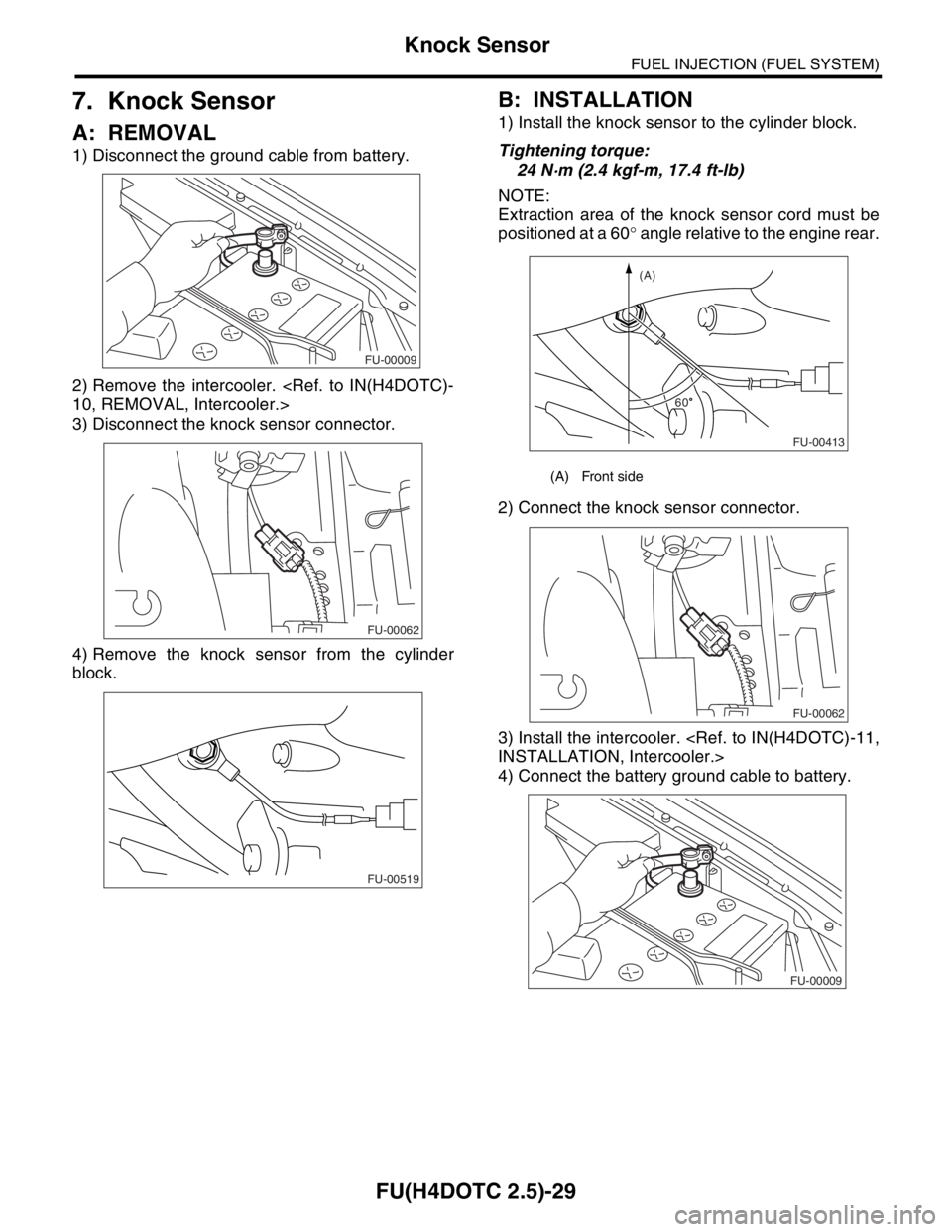

FU(H4DOTC 2.5)-29

FUEL INJECTION (FUEL SYSTEM)

Knock Sensor

7. Knock Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the intercooler.

3) Disconnect the knock sensor connector.

4) Remove the knock sensor from the cylinder

block.

B: INSTALLATION

1) Install the knock sensor to the cylinder block.

Tightening torque:

24 N·m (2.4 kgf-m, 17.4 ft-lb)

NOTE:

Extraction area of the knock sensor cord must be

positioned at a 60° angle relative to the engine rear.

2) Connect the knock sensor connector.

3) Install the intercooler.

4) Connect the battery ground cable to battery.

FU-00009

FU-00062

FU-00519

(A) Front side

FU-00413

(A)

60

FU-00062

FU-00009