lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1518 of 2870

ME(H4DOTC)-60

MECHANICAL

Timing Belt Assembly

Do not release the press pressure until stopper

pin is completely inserted.

(1) Attach the automatic belt tension adjuster

assembly to the vertical pressing tool.

(2) Slowly move the adjuster rod down with a

pressure of 294 N (30 kgf, 66 lb) until the adjust-

er rod is aligned with the stopper pin hole in the

cylinder.

(3) With a 2 mm (0.08 in) dia. stopper pin or a 2

mm (0.08 in) (nominal) dia. hex bar wrench in-

serted into the stopper pin hole in the cylinder,

secure the adjuster rod.

2) Install the automatic belt tension adjuster as-

sembly.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)3) Install the belt idler No. 2.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

4) Install the belt idler.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

2. TIMING BELT

1) Preparation for installation of automatic belt ten-

sion adjuster assembly.

SEMBLY AND BELT IDLER, INSTALLATION,

Timing Belt Assembly.>

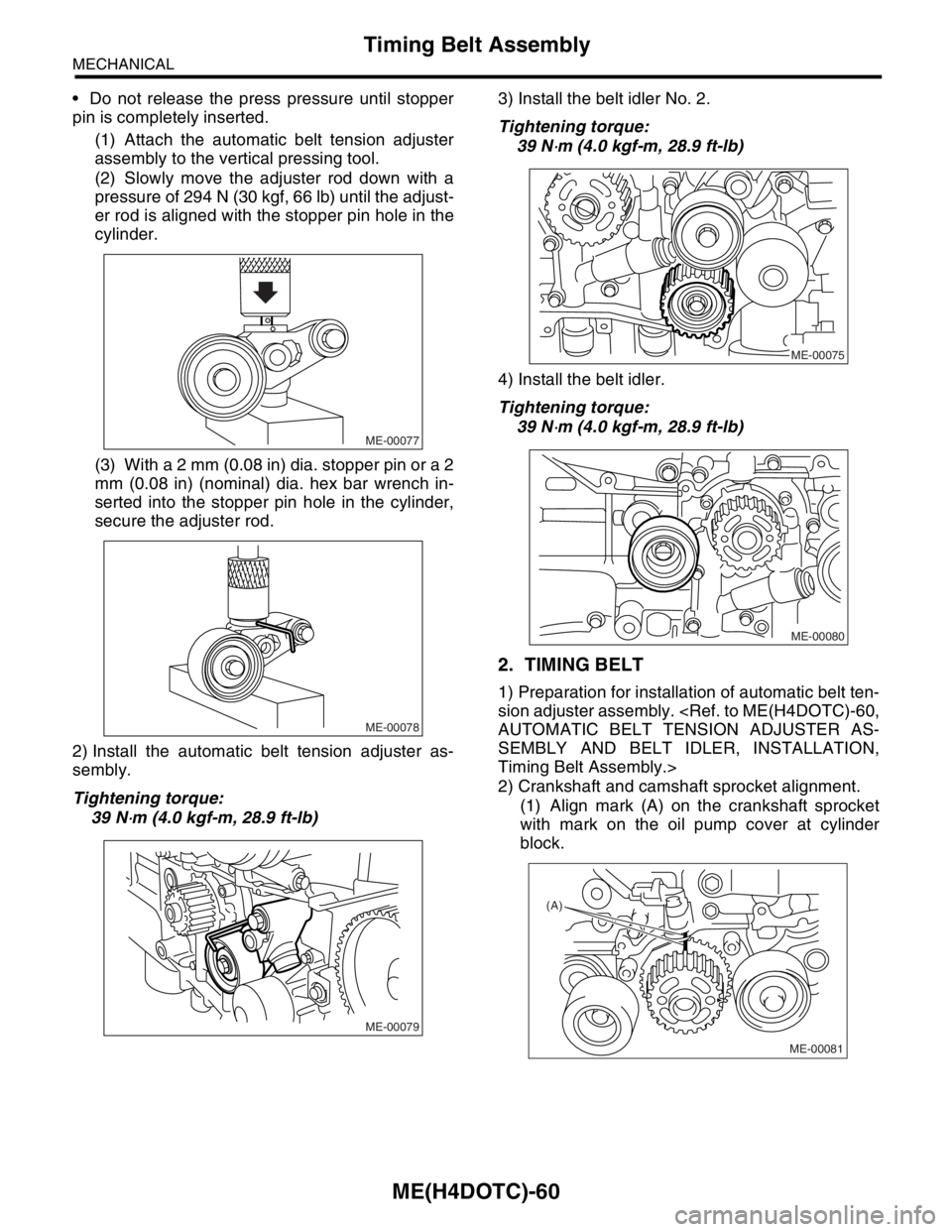

2) Crankshaft and camshaft sprocket alignment.

(1) Align mark (A) on the crankshaft sprocket

with mark on the oil pump cover at cylinder

block.

ME-00077

ME-00078

ME-00079

ME-00075

ME-00080

(A)

ME-00081

Page 1519 of 2870

ME(H4DOTC)-61

MECHANICAL

Timing Belt Assembly

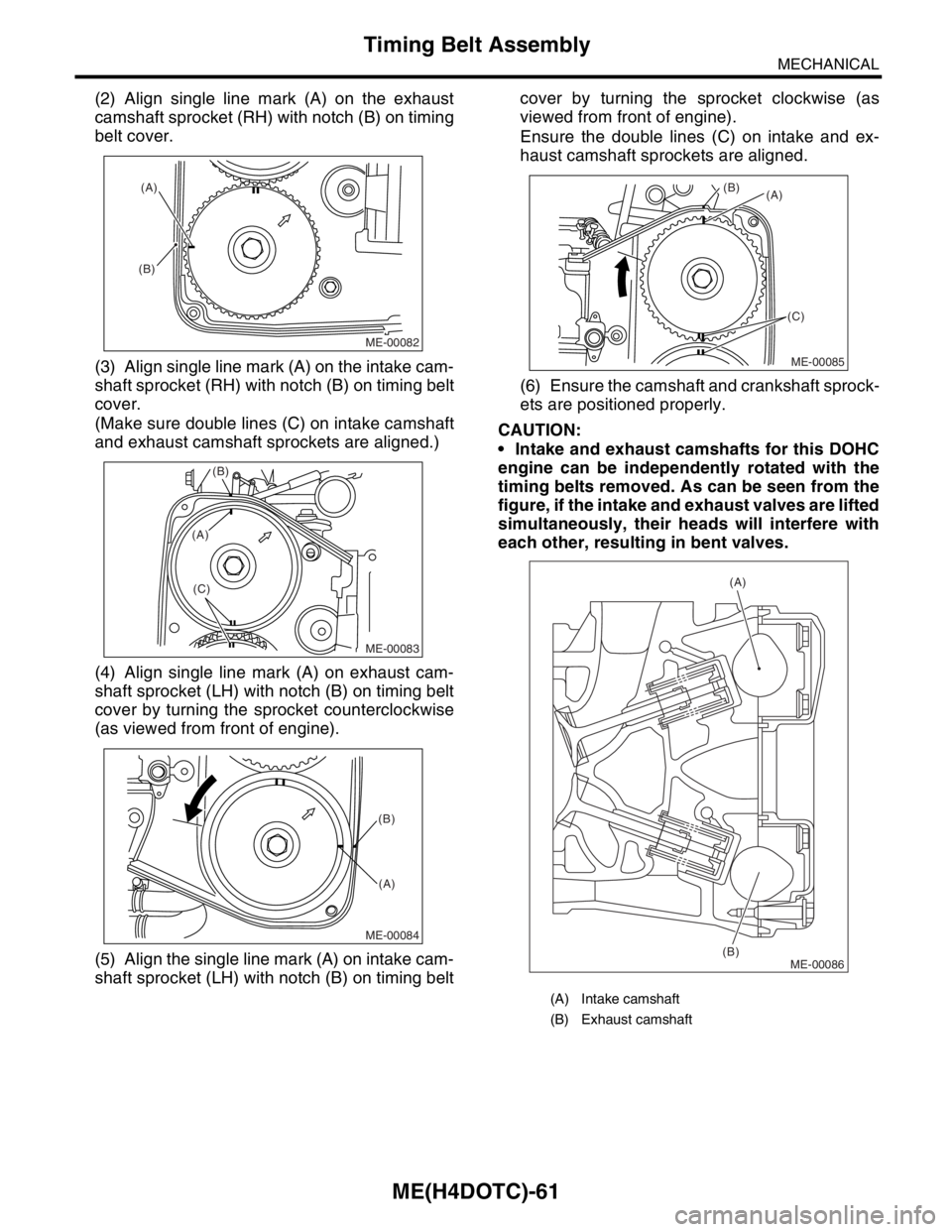

(2) Align single line mark (A) on the exhaust

camshaft sprocket (RH) with notch (B) on timing

belt cover.

(3) Align single line mark (A) on the intake cam-

shaft sprocket (RH) with notch (B) on timing belt

cover.

(Make sure double lines (C) on intake camshaft

and exhaust camshaft sprockets are aligned.)

(4) Align single line mark (A) on exhaust cam-

shaft sprocket (LH) with notch (B) on timing belt

cover by turning the sprocket counterclockwise

(as viewed from front of engine).

(5) Align the single line mark (A) on intake cam-

shaft sprocket (LH) with notch (B) on timing beltcover by turning the sprocket clockwise (as

viewed from front of engine).

Ensure the double lines (C) on intake and ex-

haust camshaft sprockets are aligned.

(6) Ensure the camshaft and crankshaft sprock-

ets are positioned properly.

CAUTION:

Intake and exhaust camshafts for this DOHC

engine can be independently rotated with the

timing belts removed. As can be seen from the

figure, if the intake and exhaust valves are lifted

simultaneously, their heads will interfere with

each other, resulting in bent valves.

ME-00082

(A)

(B)

ME-00083

(B)

(C)

(A)

ME-00084

(B)

(A)

(A) Intake camshaft

(B) Exhaust camshaft

ME-00085

(A) (B)

(C)

ME-00086

(A)

(B)

Page 1524 of 2870

ME(H4DOTC)-66

MECHANICAL

Cam Sprocket

16.Cam Sprocket

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt assembly.

bly.>

5) Remove the camshaft position sensor. (2.0 L

model)

6) Remove the cam sprockets. To lock the cam-

shaft, use ST.

ST 499207400 CAM SPROCKET WRENCH

ST 499977500 CAM SPROCKET WRENCH

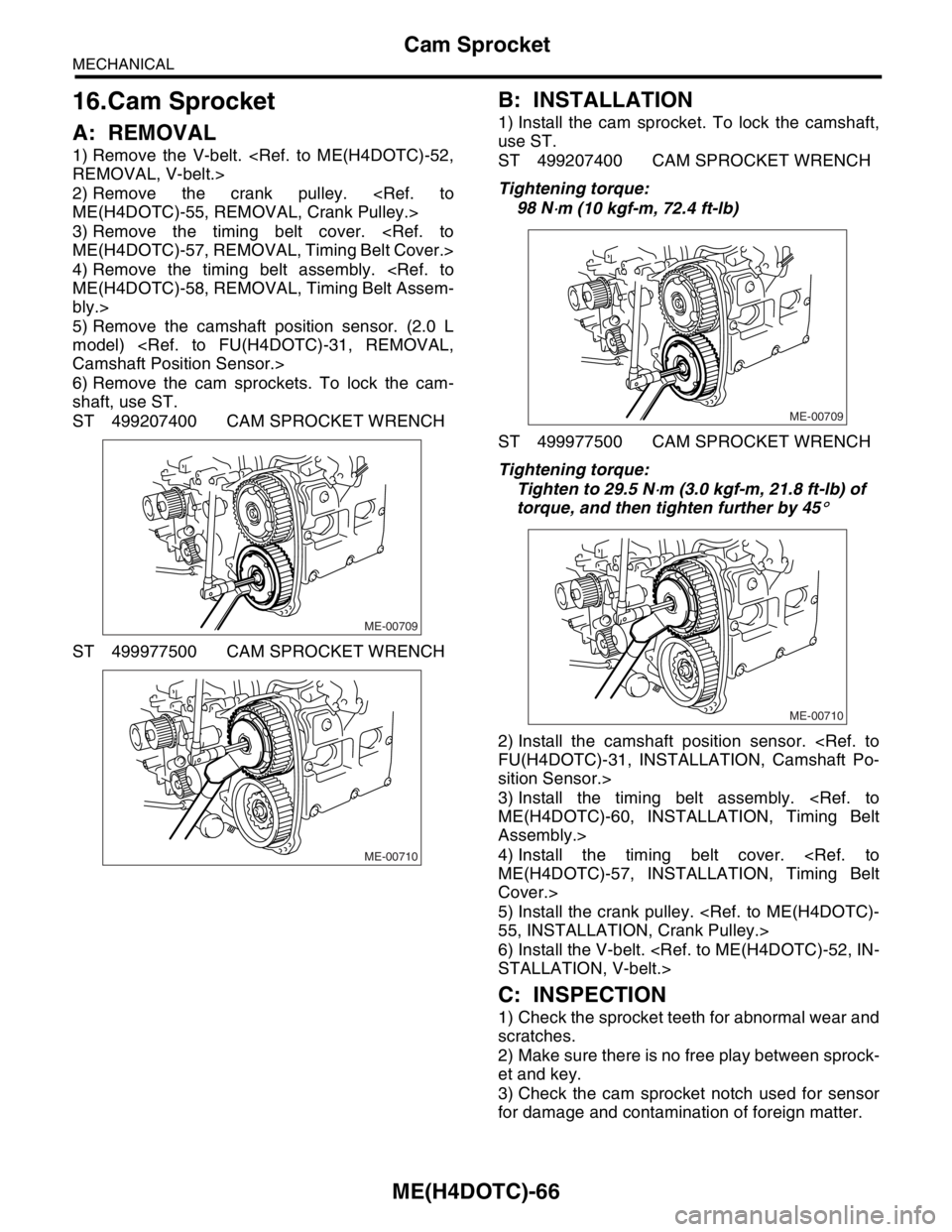

B: INSTALLATION

1) Install the cam sprocket. To lock the camshaft,

use ST.

ST 499207400 CAM SPROCKET WRENCH

Tightening torque:

98 N

⋅m (10 kgf-m, 72.4 ft-lb)

ST 499977500 CAM SPROCKET WRENCH

Tightening torque:

Tighten to 29.5 N

⋅m (3.0 kgf-m, 21.8 ft-lb) of

torque, and then tighten further by 45

°

2) Install the camshaft position sensor.

sition Sensor.>

3) Install the timing belt assembly.

Assembly.>

4) Install the timing belt cover.

Cover.>

5) Install the crank pulley.

6) Install the V-belt.

C: INSPECTION

1) Check the sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between sprock-

et and key.

3) Check the cam sprocket notch used for sensor

for damage and contamination of foreign matter.

ME-00709

ME-00710

ME-00709

ME-00710

Page 1527 of 2870

ME(H4DOTC)-69

MECHANICAL

Camshaft

16) Remove the oil flow control solenoid valve as-

sembly, intake camshaft cap, and camshaft.

17) Loosen the exhaust camshaft cap bolts equal-

ly, a little at a time in alphabetical sequence shown

in the figure.

2.0 L MODEL

2.5 L MODEL

18) Remove the exhaust camshaft cap and cam-

shaft.

NOTE:

Arrange the camshaft caps in order so that they

can be installed in their original positions.

19) Similarly, remove the camshafts (RH) and re-

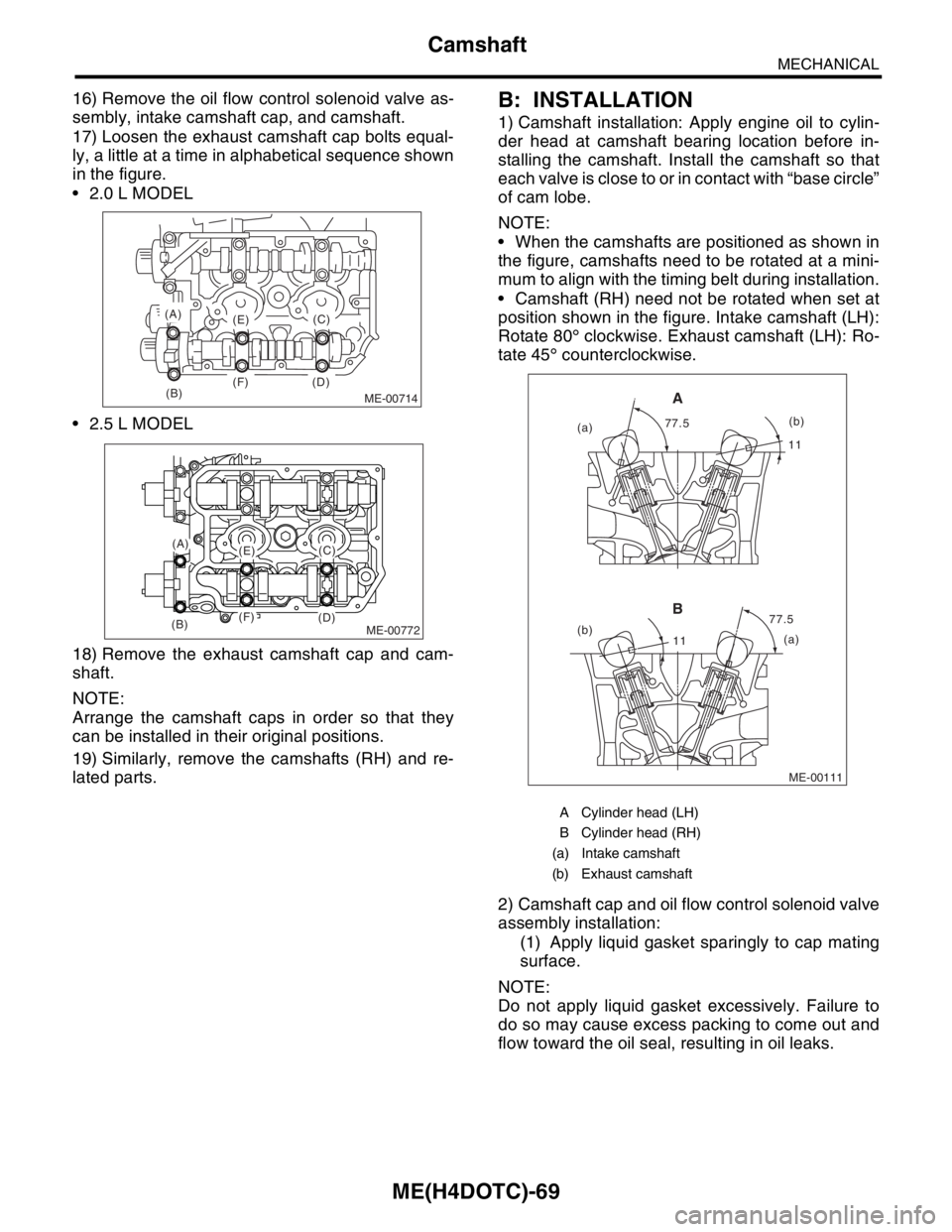

lated parts.B: INSTALLATION

1) Camshaft installation: Apply engine oil to cylin-

der head at camshaft bearing location before in-

stalling the camshaft. Install the camshaft so that

each valve is close to or in contact with “base circle”

of cam lobe.

NOTE:

When the camshafts are positioned as shown in

the figure, camshafts need to be rotated at a mini-

mum to align with the timing belt during installation.

Camshaft (RH) need not be rotated when set at

position shown in the figure. Intake camshaft (LH):

Rotate 80° clockwise. Exhaust camshaft (LH): Ro-

tate 45° counterclockwise.

2) Camshaft cap and oil flow control solenoid valve

assembly installation:

(1) Apply liquid gasket sparingly to cap mating

surface.

NOTE:

Do not apply liquid gasket excessively. Failure to

do so may cause excess packing to come out and

flow toward the oil seal, resulting in oil leaks.

ME-00714(B)

(A)

(E)

(F) (D)(C)

ME-00772

(A)(E)

(F)(B)(D)

(C)

A Cylinder head (LH)

B Cylinder head (RH)

(a) Intake camshaft

(b) Exhaust camshaft

ME-00111

1111

77.5 77.5

(a)

(b)

(a)(b)

A

B

Page 1533 of 2870

ME(H4DOTC)-75

MECHANICAL

Cylinder Head Assembly

19.Cylinder Head Assembly

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt assembly.

bly.>

5) Remove the cam sprocket.

6) Remove the intake manifold.

7) Remove the bolt which installs the A/C compres-

sor bracket on cylinder head.

8) Remove the camshaft.

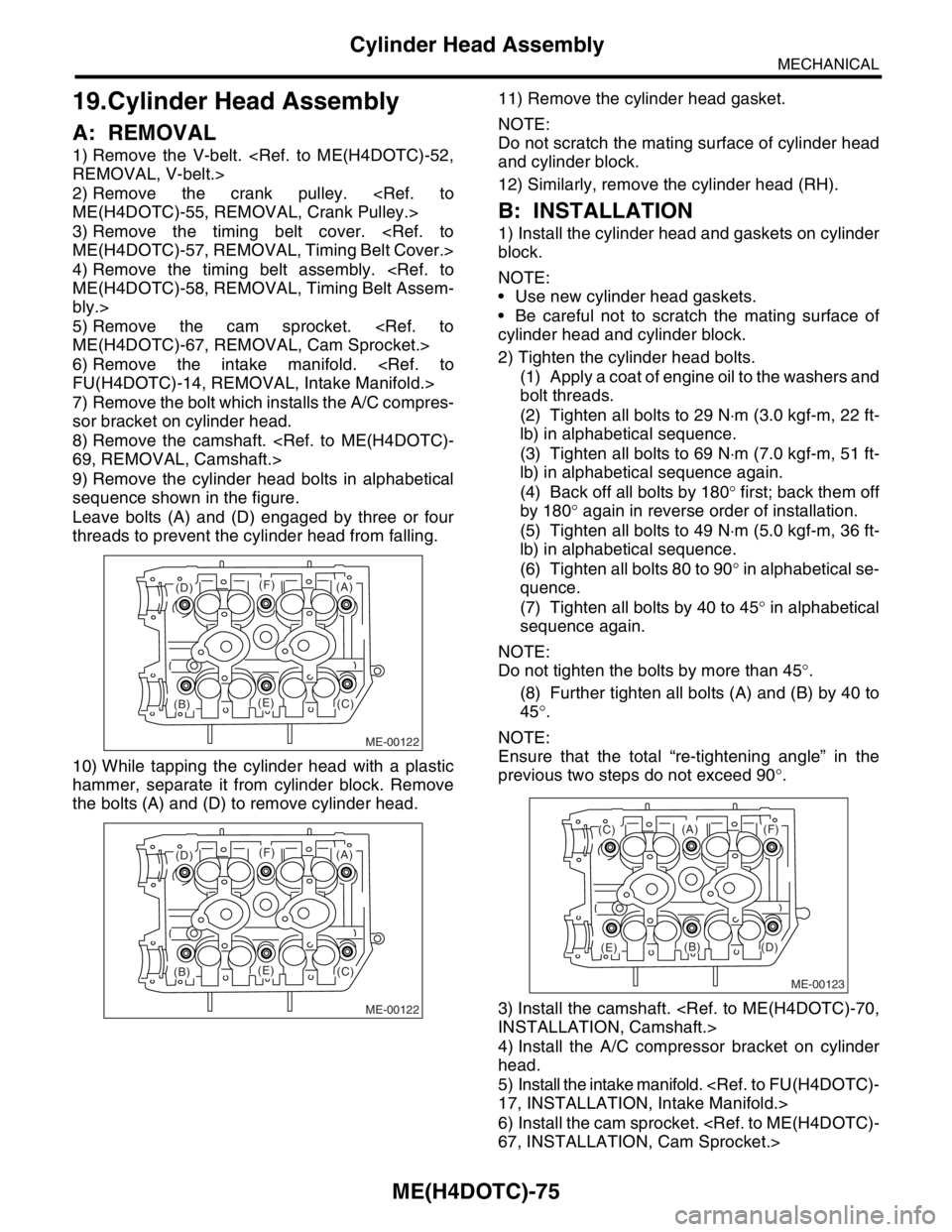

9) Remove the cylinder head bolts in alphabetical

sequence shown in the figure.

Leave bolts (A) and (D) engaged by three or four

threads to prevent the cylinder head from falling.

10) While tapping the cylinder head with a plastic

hammer, separate it from cylinder block. Remove

the bolts (A) and (D) to remove cylinder head.11) Remove the cylinder head gasket.

NOTE:

Do not scratch the mating surface of cylinder head

and cylinder block.

12) Similarly, remove the cylinder head (RH).

B: INSTALLATION

1) Install the cylinder head and gaskets on cylinder

block.

NOTE:

Use new cylinder head gaskets.

Be careful not to scratch the mating surface of

cylinder head and cylinder block.

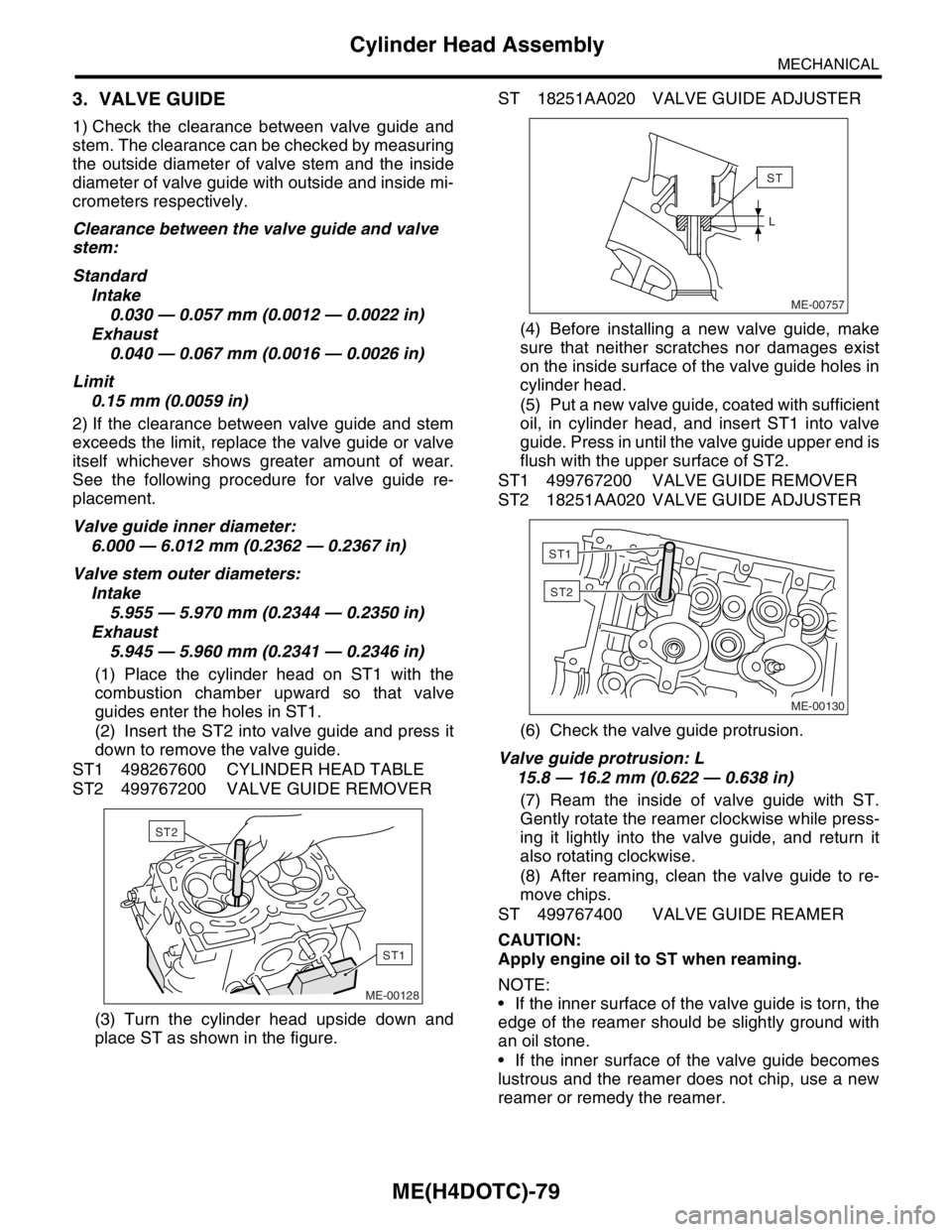

2) Tighten the cylinder head bolts.

(1) Apply a coat of engine oil to the washers and

bolt threads.

(2) Tighten all bolts to 29 N⋅m (3.0 kgf-m, 22 ft-

lb) in alphabetical sequence.

(3) Tighten all bolts to 69 N⋅m (7.0 kgf-m, 51 ft-

lb) in alphabetical sequence again.

(4) Back off all bolts by 180° first; back them off

by 180° again in reverse order of installation.

(5) Tighten all bolts to 49 N⋅m (5.0 kgf-m, 36 ft-

lb) in alphabetical sequence.

(6) Tighten all bolts 80 to 90° in alphabetical se-

quence.

(7) Tighten all bolts by 40 to 45° in alphabetical

sequence again.

NOTE:

Do not tighten the bolts by more than 45°.

(8) Further tighten all bolts (A) and (B) by 40 to

45°.

NOTE:

Ensure that the total “re-tightening angle” in the

previous two steps do not exceed 90°.

3) Install the camshaft.

4) Install the A/C compressor bracket on cylinder

head.

5) Install the intake manifold.

6) Install the cam sprocket.

ME-00122

(B)(C)

(D)

(E)

(F)(A)

ME-00122

(B)(C)

(D)

(E)

(F)(A)

ME-00123

(B)

(C)

(D)(E)

(F)(A)

Page 1537 of 2870

ME(H4DOTC)-79

MECHANICAL

Cylinder Head Assembly

3. VALVE GUIDE

1) Check the clearance between valve guide and

stem. The clearance can be checked by measuring

the outside diameter of valve stem and the inside

diameter of valve guide with outside and inside mi-

crometers respectively.

Clearance between the valve guide and valve

stem:

Standard

Intake

0.030 — 0.057 mm (0.0012 — 0.0022 in)

Exhaust

0.040 — 0.067 mm (0.0016 — 0.0026 in)

Limit

0.15 mm (0.0059 in)

2) If the clearance between valve guide and stem

exceeds the limit, replace the valve guide or valve

itself whichever shows greater amount of wear.

See the following procedure for valve guide re-

placement.

Valve guide inner diameter:

6.000 — 6.012 mm (0.2362 — 0.2367 in)

Valve stem outer diameters:

Intake

5.955 — 5.970 mm (0.2344 — 0.2350 in)

Exhaust

5.945 — 5.960 mm (0.2341 — 0.2346 in)

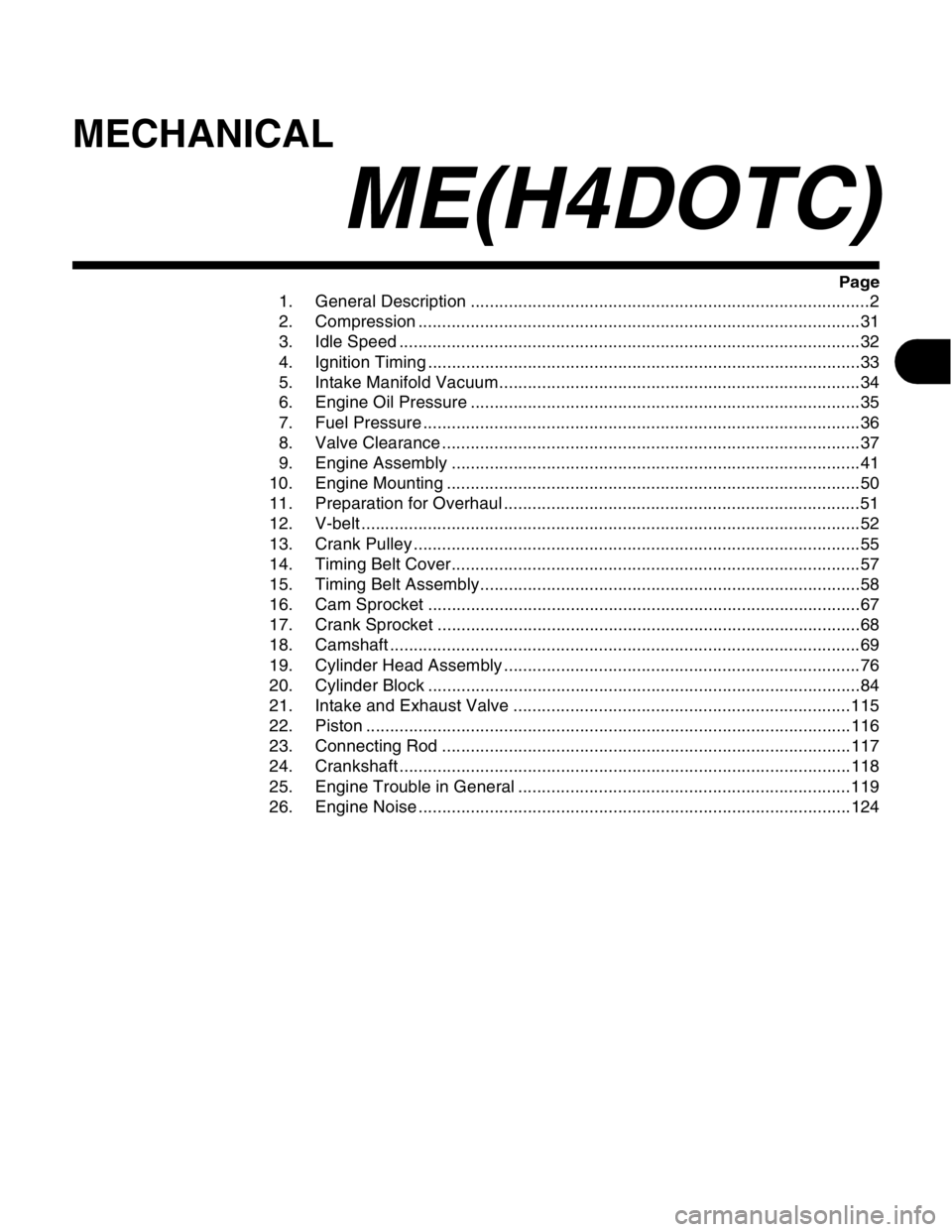

(1) Place the cylinder head on ST1 with the

combustion chamber upward so that valve

guides enter the holes in ST1.

(2) Insert the ST2 into valve guide and press it

down to remove the valve guide.

ST1 498267600 CYLINDER HEAD TABLE

ST2 499767200 VALVE GUIDE REMOVER

(3) Turn the cylinder head upside down and

place ST as shown in the figure.ST 18251AA020 VALVE GUIDE ADJUSTER

(4) Before installing a new valve guide, make

sure that neither scratches nor damages exist

on the inside surface of the valve guide holes in

cylinder head.

(5) Put a new valve guide, coated with sufficient

oil, in cylinder head, and insert ST1 into valve

guide. Press in until the valve guide upper end is

flush with the upper surface of ST2.

ST1 499767200 VALVE GUIDE REMOVER

ST2 18251AA020 VALVE GUIDE ADJUSTER

(6) Check the valve guide protrusion.

Valve guide protrusion: L

15.8 — 16.2 mm (0.622 — 0.638 in)

(7) Ream the inside of valve guide with ST.

Gently rotate the reamer clockwise while press-

ing it lightly into the valve guide, and return it

also rotating clockwise.

(8) After reaming, clean the valve guide to re-

move chips.

ST 499767400 VALVE GUIDE REAMER

CAUTION:

Apply engine oil to ST when reaming.

NOTE:

If the inner surface of the valve guide is torn, the

edge of the reamer should be slightly ground with

an oil stone.

If the inner surface of the valve guide becomes

lustrous and the reamer does not chip, use a new

reamer or remedy the reamer.

ME-00128

ST1

ST2ME-00757

ST

L

ME-00130

ST1

ST2

Page 1542 of 2870

MECHANICAL

ME(H4DOTC)

Page

1. General Description ....................................................................................2

2. Compression .............................................................................................31

3. Idle Speed .................................................................................................32

4. Ignition Timing ...........................................................................................33

5. Intake Manifold Vacuum............................................................................34

6. Engine Oil Pressure ..................................................................................35

7. Fuel Pressure ............................................................................................36

8. Valve Clearance ........................................................................................37

9. Engine Assembly ......................................................................................41

10. Engine Mounting .......................................................................................50

11. Preparation for Overhaul ...........................................................................51

12. V-belt .........................................................................................................52

13. Crank Pulley ..............................................................................................55

14. Timing Belt Cover......................................................................................57

15. Timing Belt Assembly................................................................................58

16. Cam Sprocket ...........................................................................................67

17. Crank Sprocket .........................................................................................68

18. Camshaft ...................................................................................................69

19. Cylinder Head Assembly ...........................................................................76

20. Cylinder Block ...........................................................................................84

21. Intake and Exhaust Valve .......................................................................115

22. Piston ......................................................................................................116

23. Connecting Rod ......................................................................................117

24. Crankshaft ...............................................................................................118

25. Engine Trouble in General ......................................................................119

26. Engine Noise ...........................................................................................124

Page 1543 of 2870

ME(H4DOTC)-83

MECHANICAL

Cylinder Block

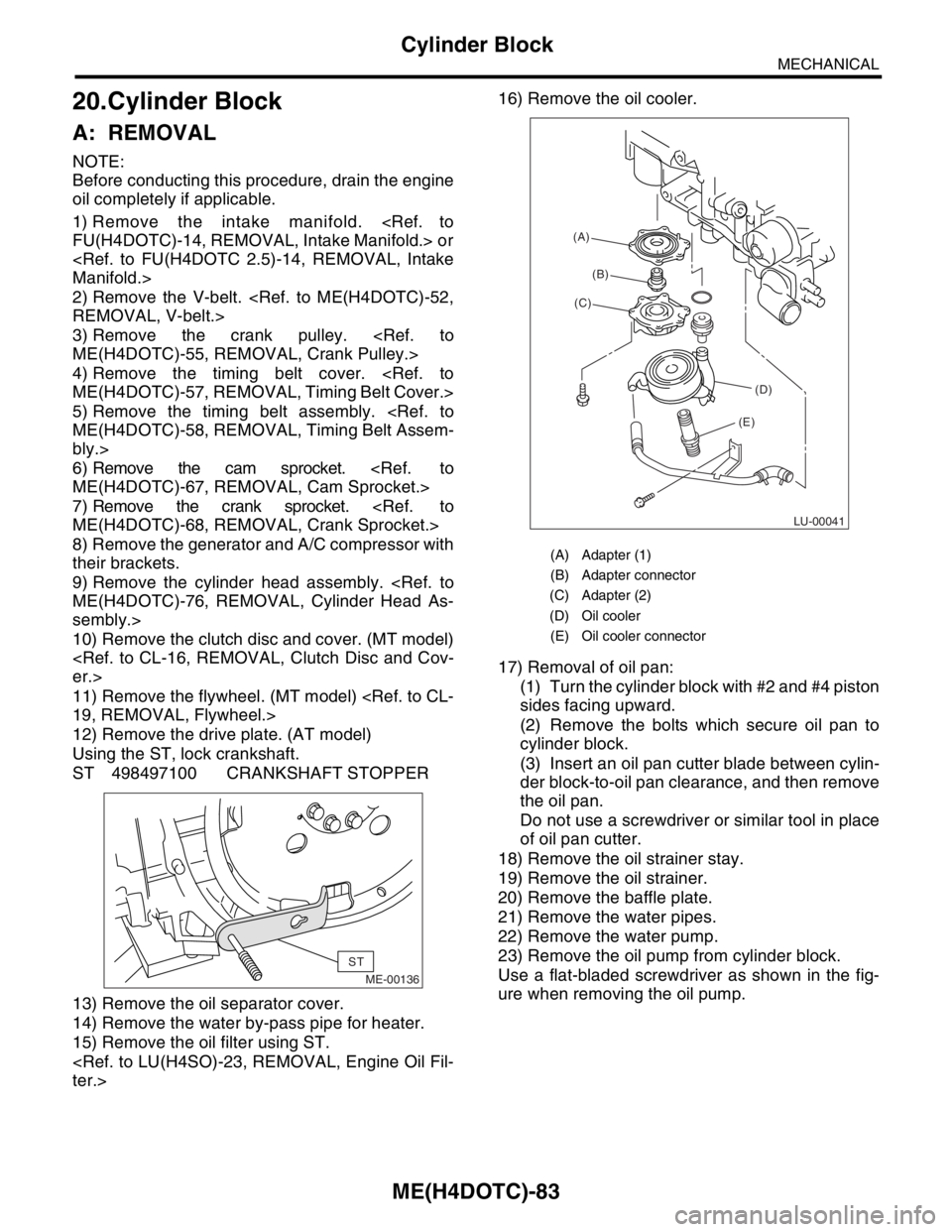

20.Cylinder Block

A: REMOVAL

NOTE:

Before conducting this procedure, drain the engine

oil completely if applicable.

1) Remove the intake manifold.

2) Remove the V-belt.

3) Remove the crank pulley.

4) Remove the timing belt cover.

5) Remove the timing belt assembly.

bly.>

6) Remove the cam sprocket.

7) Remove the crank sprocket.

8) Remove the generator and A/C compressor with

their brackets.

9) Remove the cylinder head assembly.

sembly.>

10) Remove the clutch disc and cover. (MT model)

11) Remove the flywheel. (MT model)

12) Remove the drive plate. (AT model)

Using the ST, lock crankshaft.

ST 498497100 CRANKSHAFT STOPPER

13) Remove the oil separator cover.

14) Remove the water by-pass pipe for heater.

15) Remove the oil filter using ST.

17) Removal of oil pan:

(1) Turn the cylinder block with #2 and #4 piston

sides facing upward.

(2) Remove the bolts which secure oil pan to

cylinder block.

(3) Insert an oil pan cutter blade between cylin-

der block-to-oil pan clearance, and then remove

the oil pan.

Do not use a screwdriver or similar tool in place

of oil pan cutter.

18) Remove the oil strainer stay.

19) Remove the oil strainer.

20) Remove the baffle plate.

21) Remove the water pipes.

22) Remove the water pump.

23) Remove the oil pump from cylinder block.

Use a flat-bladed screwdriver as shown in the fig-

ure when removing the oil pump.

ME-00136

ST

(A) Adapter (1)

(B) Adapter connector

(C) Adapter (2)

(D) Oil cooler

(E) Oil cooler connector

LU-00041

(A)

(B)

(C)

(D)

(E)

Page 1544 of 2870

ME(H4DOTC)-84

MECHANICAL

Cylinder Block

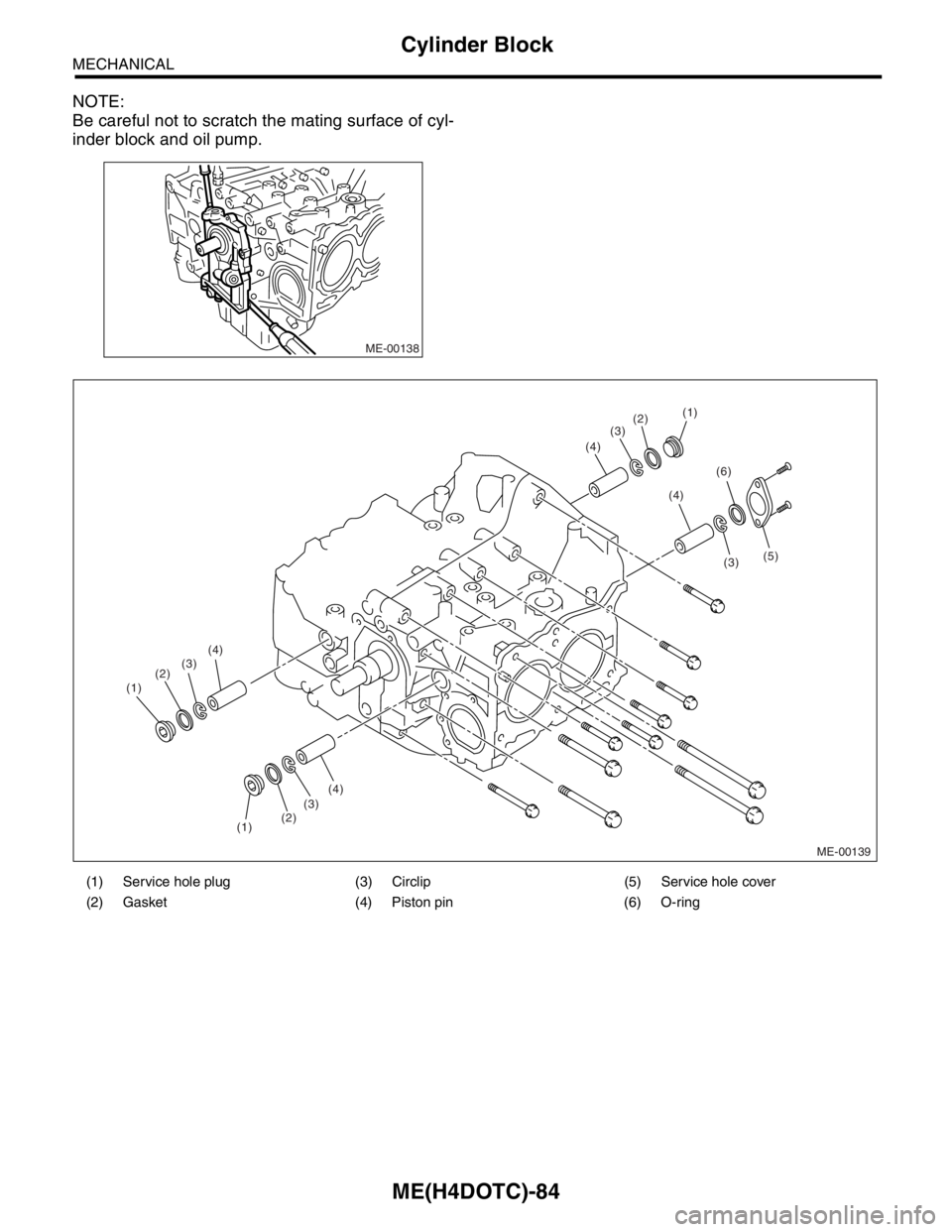

NOTE:

Be careful not to scratch the mating surface of cyl-

inder block and oil pump.

ME-00138

(1) Service hole plug (3) Circlip (5) Service hole cover

(2) Gasket (4) Piston pin (6) O-ring

ME-00139

(3)

(4) (2)(1)

(3)

(4)

(5)

(6)

(2)(3)

(2)

(1)(3)(4)

(4)

(1)

Page 1545 of 2870

![SUBARU FORESTER 2004 Service Repair Manual ME(H4DOTC)-85

MECHANICAL

Cylinder Block

24) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].

25) Rotate the crankshaft to bring #1 and #2 pis-

tons to botto SUBARU FORESTER 2004 Service Repair Manual ME(H4DOTC)-85

MECHANICAL

Cylinder Block

24) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].

25) Rotate the crankshaft to bring #1 and #2 pis-

tons to botto](/img/17/57426/w960_57426-1544.png)

ME(H4DOTC)-85

MECHANICAL

Cylinder Block

24) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].

25) Rotate the crankshaft to bring #1 and #2 pis-

tons to bottom dead center position, and then re-

move the piston circlip through service hole of #1

and #2 cylinders.

26) Draw out the piston pin from #1 and #2 pistons

using ST.

ST 499097600 PISTON PIN REMOVER (2.0

L model)

ST 499097700 PISTON PIN REMOVER (2.5

L model)

NOTE:

Be careful not to confuse the original combination

of piston, piston pin and cylinder.

27) Similarly remove the piston pins from #3 and #4

pistons.

28) Remove the bolts which connect the cylinder

block on the side of #2 and #4 cylinders.29) Back off the bolts which connect the cylinder

block on the side of #1 and #3 cylinders two or

three turns.

30) Set up the cylinder block so that #1 and #3 cyl-

inders are on the upper side, then remove the cyl-

inder block connecting bolts.

31) Separate the cylinder blocks (LH) and (RH).

ME-00140

ME-00141

ME-00142

ST