lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2061 of 2870

EN(H4DOTC 2.5)-37

ENGINE (DIAGNOSTIC)

Inspection Mode

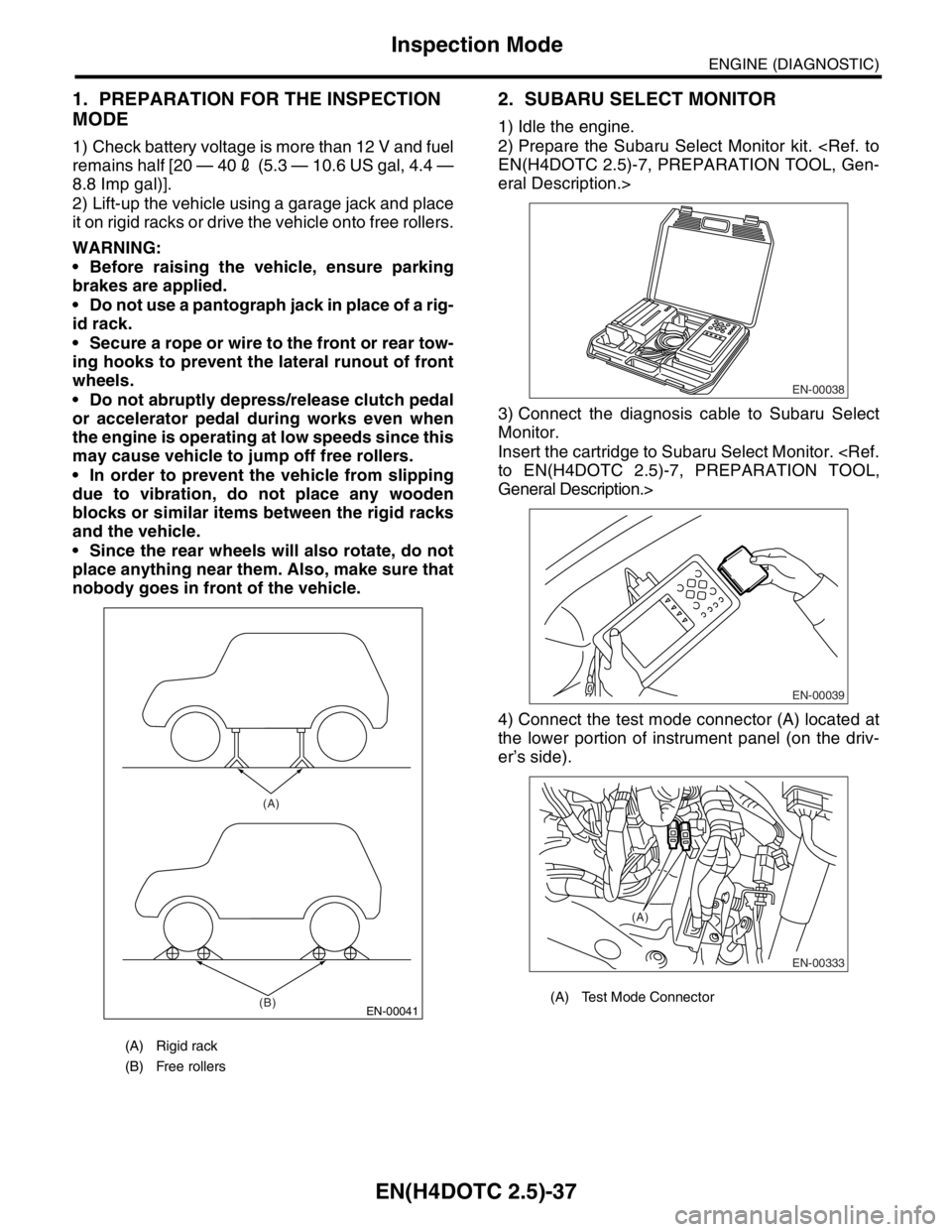

1. PREPARATION FOR THE INSPECTION

MODE

1) Check battery voltage is more than 12 V and fuel

remains half [20 — 402 (5.3 — 10.6 US gal, 4.4 —

8.8 Imp gal)].

2) Lift-up the vehicle using a garage jack and place

it on rigid racks or drive the vehicle onto free rollers.

WARNING:

Before raising the vehicle, ensure parking

brakes are applied.

Do not use a pantograph jack in place of a rig-

id rack.

Secure a rope or wire to the front or rear tow-

ing hooks to prevent the lateral runout of front

wheels.

Do not abruptly depress/release clutch pedal

or accelerator pedal during works even when

the engine is operating at low speeds since this

may cause vehicle to jump off free rollers.

In order to prevent the vehicle from slipping

due to vibration, do not place any wooden

blocks or similar items between the rigid racks

and the vehicle.

Since the rear wheels will also rotate, do not

place anything near them. Also, make sure that

nobody goes in front of the vehicle.

2. SUBARU SELECT MONITOR

1) Idle the engine.

2) Prepare the Subaru Select Monitor kit.

eral Description.>

3) Connect the diagnosis cable to Subaru Select

Monitor.

Insert the cartridge to Subaru Select Monitor.

General Description.>

4) Connect the test mode connector (A) located at

the lower portion of instrument panel (on the driv-

er’s side).

(A) Rigid rack

(B) Free rollers

EN-00041

(A)

(B)

(A) Test Mode Connector

EN-00038

EN-00039

EN-00333

(A)

Page 2175 of 2870

EN(H4DOTC 2.5)-151

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

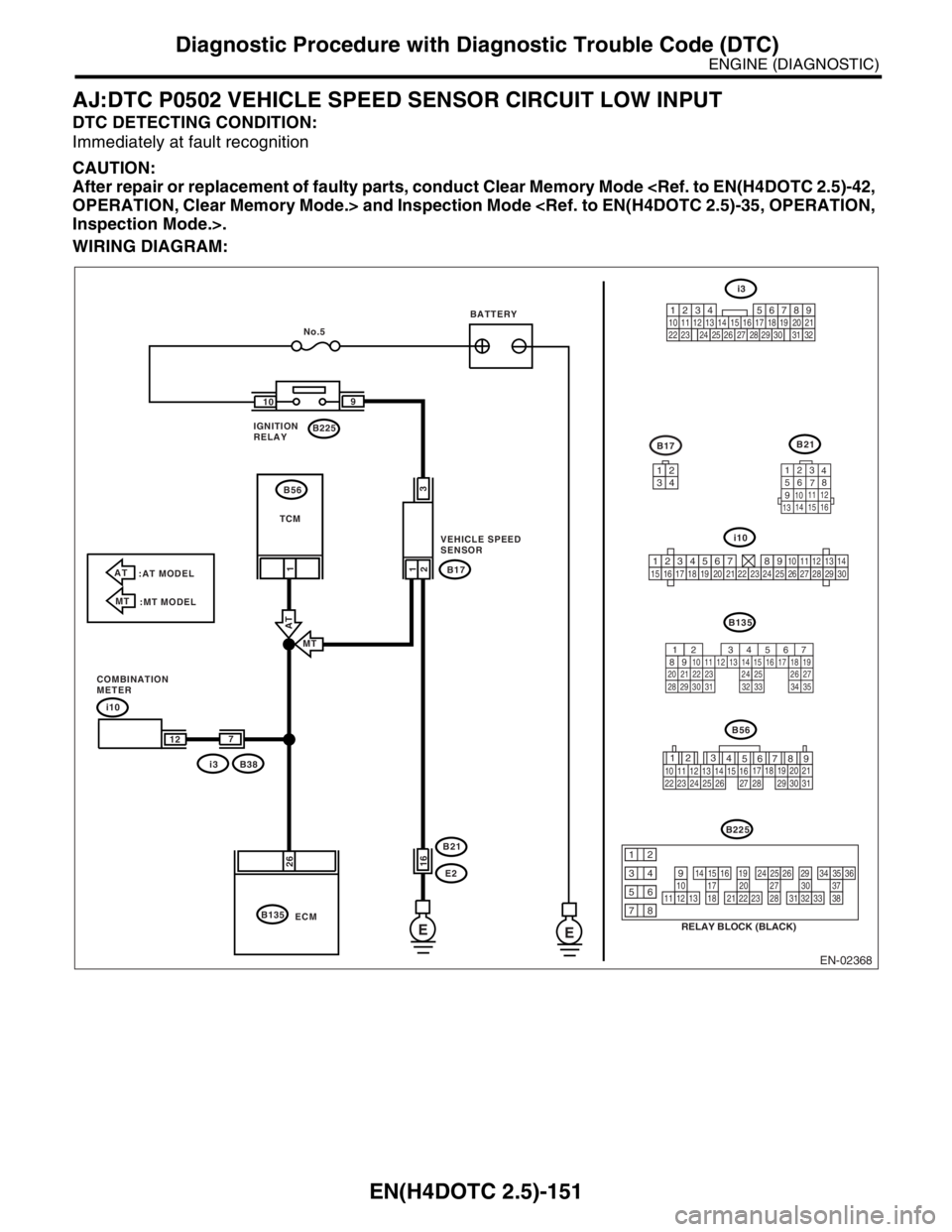

AJ:DTC P0502 VEHICLE SPEED SENSOR CIRCUIT LOW INPUT

DTC DETECTING CONDITION:

Immediately at fault recognition

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02368

i10

B135B21

123

4

56

78

9

1011 12

1314 15 16

B17

i3

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

E E

i10

B38

i3B17

E2 B21

B135B225 109

26

2

21

1

No.5

ECM

3

16

7

12

AT

:AT MODEL

MT

:MT MODEL

MT

AT

IGNITION

RELAYBATTERY

TCM

VEHICLE SPEED

SENSOR

COMBINATION

METERB56

3412

123456789101112131415161718192021222324252627282930

12

789 56 3

410 11 1219 20 21

29 30 31 13 14 15 1617

27 2818

22 23 24 25 26

B56

B225

RELAY BLOCK (BLACK)

10111213

1415161718

1920212223

2425262728

2930313233

3435363738

12

934

56

78

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

Page 2177 of 2870

EN(H4DOTC 2.5)-153

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

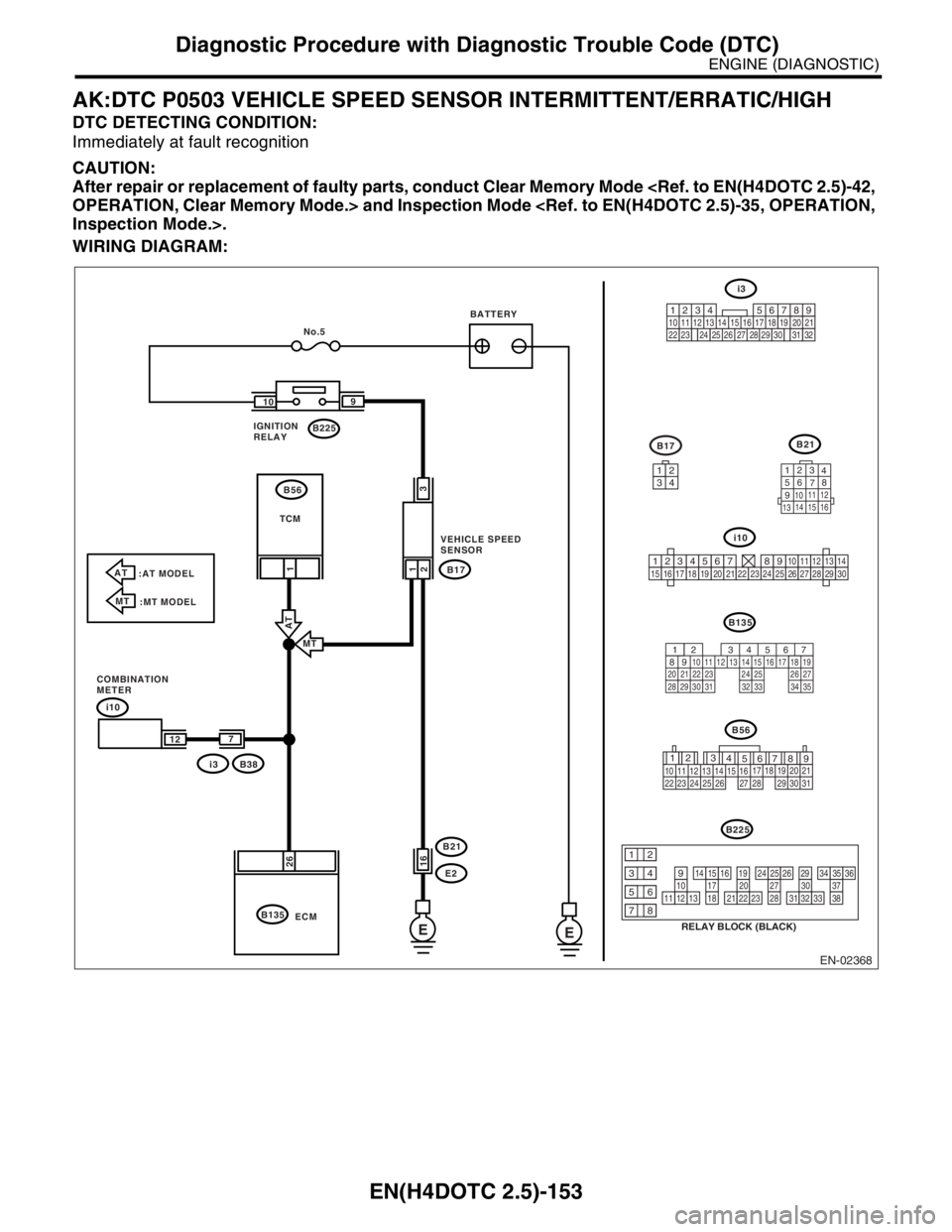

AK:DTC P0503 VEHICLE SPEED SENSOR INTERMITTENT/ERRATIC/HIGH

DTC DETECTING CONDITION:

Immediately at fault recognition

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02368

i10

B135B21

123

4

56

78

9

1011 12

1314 15 16

B17

i3

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

E E

i10

B38

i3B17

E2 B21

B135B225 109

26

2

21

1

No.5

ECM

3

16

7

12

AT

:AT MODEL

MT

:MT MODEL

MT

AT

IGNITION

RELAYBATTERY

TCM

VEHICLE SPEED

SENSOR

COMBINATION

METERB56

3412

123456789101112131415161718192021222324252627282930

12

789 56 3

410 11 1219 20 21

29 30 31 13 14 15 1617

27 2818

22 23 24 25 26

B56

B225

RELAY BLOCK (BLACK)

10111213

1415161718

1920212223

2425262728

2930313233

3435363738

12

934

56

78

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

Page 2286 of 2870

CONTROL SYSTEM

CS

Page

1. General Description ....................................................................................2

2. Select Lever ................................................................................................8

3. Select Cable ..............................................................................................13

4. N-R Lock Solenoid ....................................................................................16

5. MT Gear Shift Lever ..................................................................................17

6. MT Drive Select Lever...............................................................................23

7. Drive Select Cable ....................................................................................25

8. General Diagnostic Table..........................................................................26

Page 2289 of 2870

CS-4

CONTROL SYSTEM

General Description

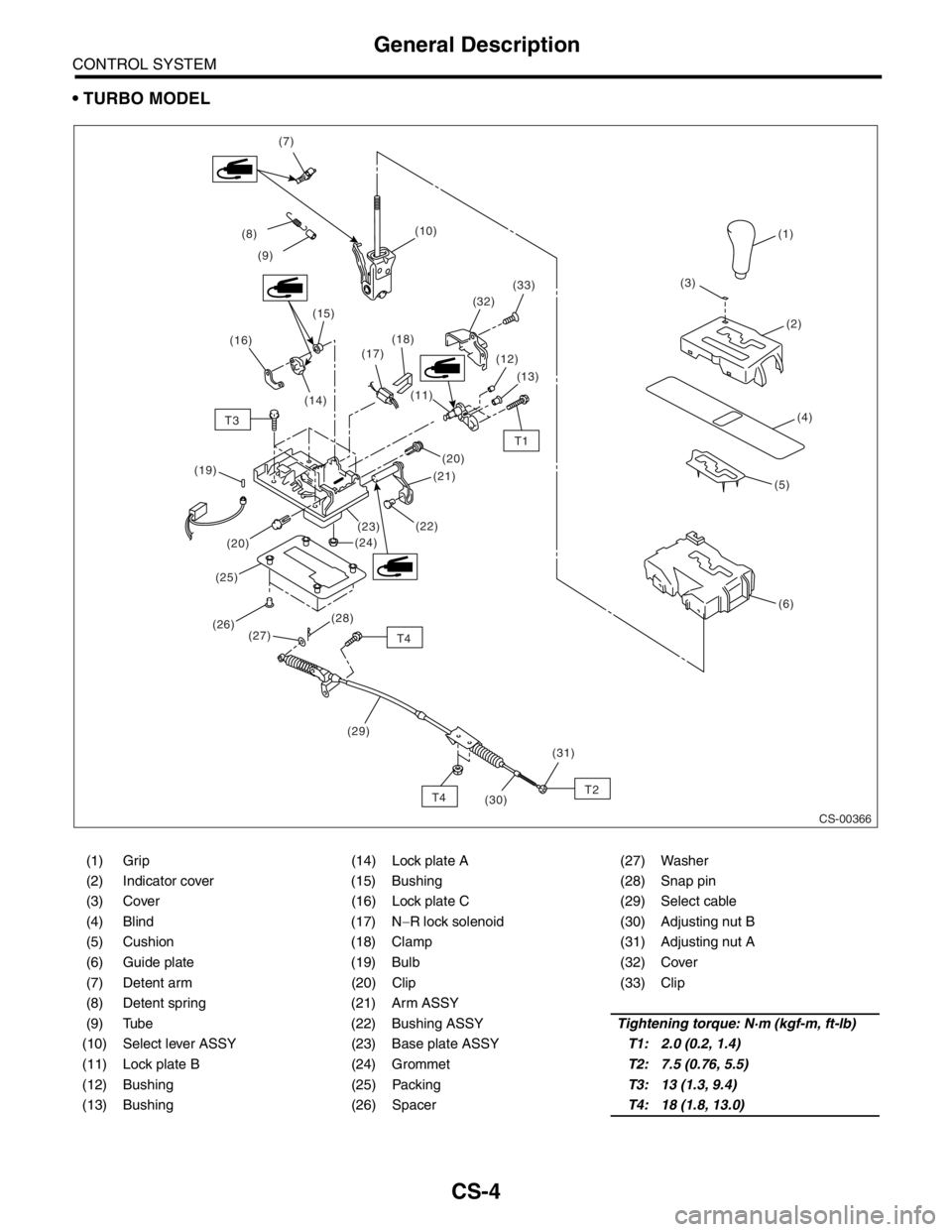

TURBO MODEL

CS-00366

T2

T4 T4T1 T3

(31) (29) (27)(28) (20)

(25)(22) (19)

(23)

(24)(21)

(30) (20)(12)

(11)(13) (18)(3)

(17)(10)

(8)

(9)(7)

(15)

(26)(1)

(2)

(4)

(5)

(6) (33)

(32)

(14)

(16)

(1) Grip (14) Lock plate A (27) Washer

(2) Indicator cover (15) Bushing (28) Snap pin

(3) Cover (16) Lock plate C (29) Select cable

(4) Blind (17) N−R lock solenoid (30) Adjusting nut B

(5) Cushion (18) Clamp (31) Adjusting nut A

(6) Guide plate (19) Bulb (32) Cover

(7) Detent arm (20) Clip (33) Clip

(8) Detent spring (21) Arm ASSY

(9) Tube (22) Bushing ASSYTightening torque: N·m (kgf-m, ft-lb)

(10) Select lever ASSY (23) Base plate ASSYT1: 2.0 (0.2, 1.4)

(11) Lock plate B (24) GrommetT2: 7.5 (0.76, 5.5)

(12) Bushing (25) PackingT3: 13 (1.3, 9.4)

(13) Bushing (26) SpacerT4: 18 (1.8, 13.0)

Page 2290 of 2870

CS-5

CONTROL SYSTEM

General Description

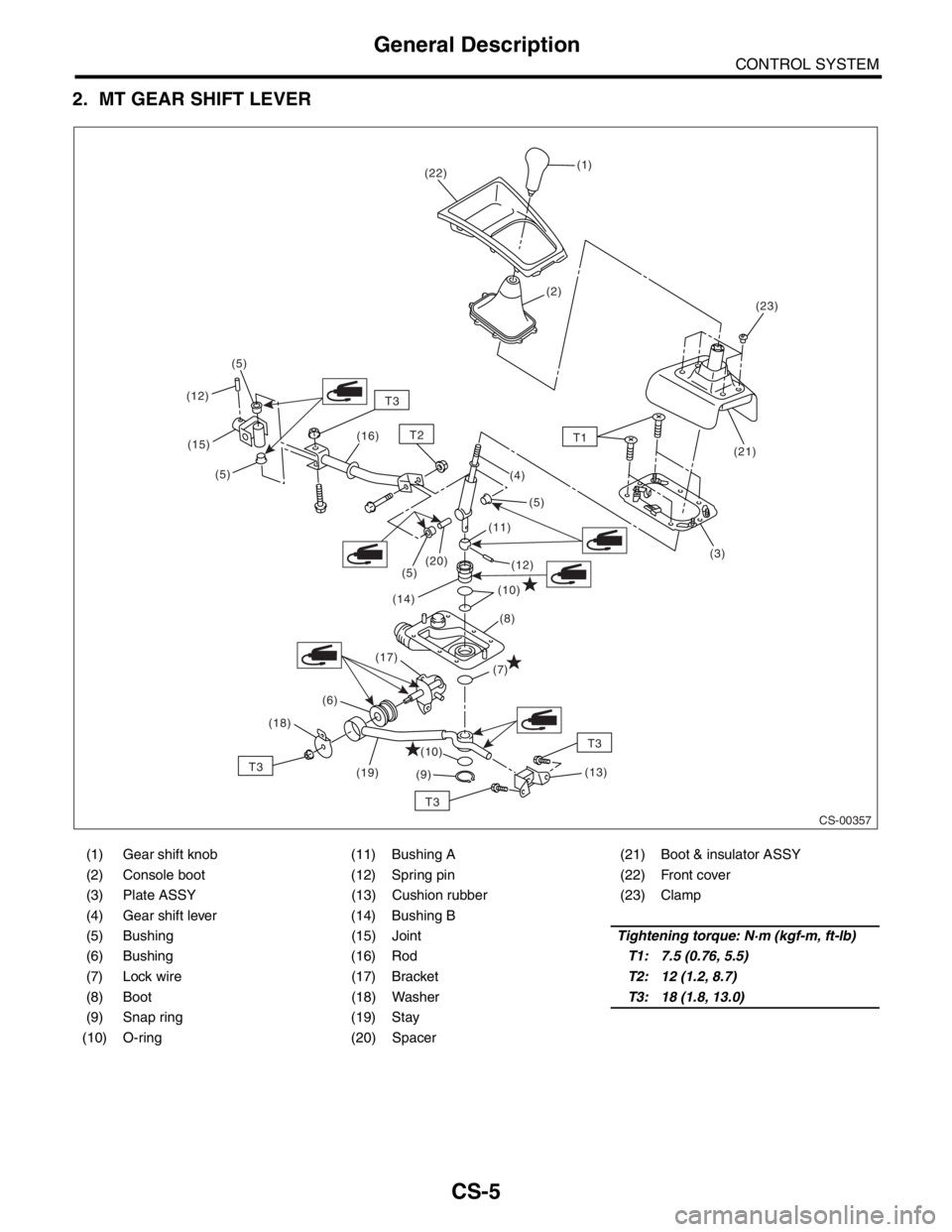

2. MT GEAR SHIFT LEVER

(1) Gear shift knob (11) Bushing A (21) Boot & insulator ASSY

(2) Console boot (12) Spring pin (22) Front cover

(3) Plate ASSY (13) Cushion rubber (23) Clamp

(4) Gear shift lever (14) Bushing B

(5) Bushing (15) JointTightening torque: N·m (kgf-m, ft-lb)

(6) Bushing (16) RodT1: 7.5 (0.76, 5.5)

(7) Lock wire (17) BracketT2: 12 (1.2, 8.7)

(8) Boot (18) WasherT3: 18 (1.8, 13.0)

(9) Snap ring (19) Stay

(10) O-ring (20) Spacer

CS-00357

T2

(5) (5)

(5) (5)

(4)

(6)(3) (2)(1)

(18)(21)(23) (22)

(20)

(19)(17)T1

(14)

(13) (16)

(15)

(12) (12)

(11)

(10)

(10)

(9)(8)

(7)

T3

T3

T3

T3

Page 2292 of 2870

CS-7

CONTROL SYSTEM

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly and replacement.

Use SUBARU genuine fluid, grease etc. or the

equivalent. Do not mix grease etc. with that of an-

other grade or from other manufacturers.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Apply grease onto sliding or revolution surfaces

before installation.

Before installing O-rings or snap rings, apply suf-

ficient amount of grease to avoid damage and de-

formation.

Before securing a part on a vise, place cushion-

ing material such as wood blocks, aluminum plate,

or cloth between the part and vise.

Before disconnecting electrical connectors, be

sure to disconnect the ground cable from battery.

Page 2295 of 2870

CS-10

CONTROL SYSTEM

Select Lever

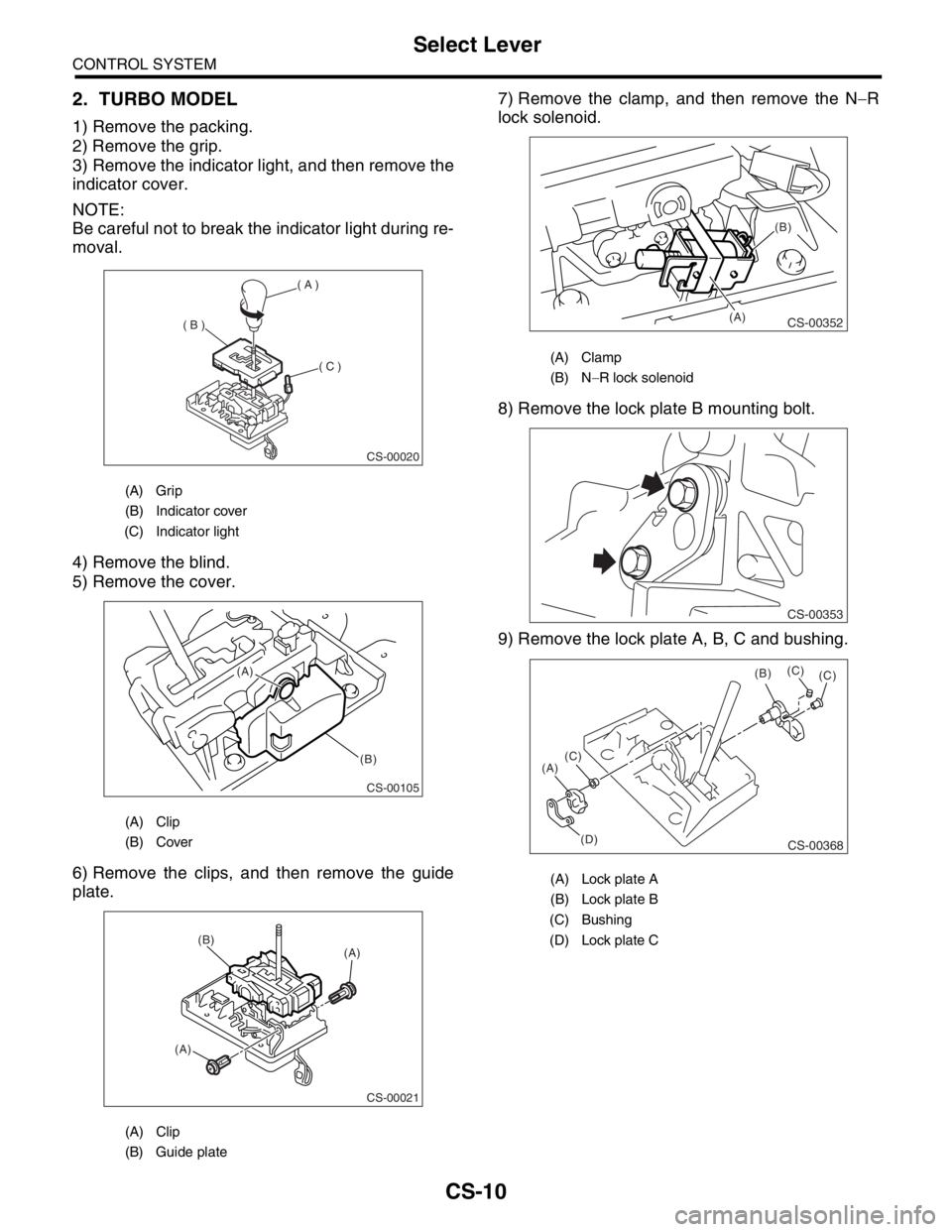

2. TURBO MODEL

1) Remove the packing.

2) Remove the grip.

3) Remove the indicator light, and then remove the

indicator cover.

NOTE:

Be careful not to break the indicator light during re-

moval.

4) Remove the blind.

5) Remove the cover.

6) Remove the clips, and then remove the guide

plate.7) Remove the clamp, and then remove the N−R

lock solenoid.

8) Remove the lock plate B mounting bolt.

9) Remove the lock plate A, B, C and bushing.

(A) Grip

(B) Indicator cover

(C) Indicator light

(A) Clip

(B) Cover

(A) Clip

(B) Guide plate

CS-00020

( A )

( B )

( C )

CS-00105

(A)

(B)

CS-00021

(A)(A) (B)

(A) Clamp

(B) N−R lock solenoid

(A) Lock plate A

(B) Lock plate B

(C) Bushing

(D) Lock plate C

CS-00352

(B)

(A)

CS-00353

CS-00368

(A)(C)

(D)(C)

(B)

(C)

Page 2297 of 2870

![SUBARU FORESTER 2004 Service Repair Manual CS-12

CONTROL SYSTEM

Select Lever

D: ASSEMBLY

1) Clean all parts before assembly.

2) Apply grease [SUNLIGHT 2 (Part No.

003602010) or equivalent] to each part. <Ref. to

CS-3, AT SELECT LEVER, COMPONEN SUBARU FORESTER 2004 Service Repair Manual CS-12

CONTROL SYSTEM

Select Lever

D: ASSEMBLY

1) Clean all parts before assembly.

2) Apply grease [SUNLIGHT 2 (Part No.

003602010) or equivalent] to each part. <Ref. to

CS-3, AT SELECT LEVER, COMPONEN](/img/17/57426/w960_57426-2296.png)

CS-12

CONTROL SYSTEM

Select Lever

D: ASSEMBLY

1) Clean all parts before assembly.

2) Apply grease [SUNLIGHT 2 (Part No.

003602010) or equivalent] to each part.

al Description.>

CAUTION:

Apply grease [SUNCALL] around the axle of lock

plate (Turbo model). Apply grease to only indi-

cated portion.

3) Assemble is in the reverse order of disassembly.

NOTE:

Refer to “COMPOTNENT” for tightening torque.

Tighten the lock plate bolt uniformly. After installa-

tion, put the base plate upside down, and then push

the lock plate up. Make sure the lock plate falls by its

weight when releasing it. If not, retighten the bolt.

4) After completion of fitting, transfer the select le-

ver to range “P” — “1”, then check the indicator and

select lever are matched, the pointer and position

mark are matched and the operating force.

E: INSPECTION

1) Inspect the removed parts by comparing with

new ones for deformation, damage and wear. Cor-

rect or replace if defective.

2) Confirm the following parts for operating condi-

tion before assembly. Moving condition of the se-

lect lever assembly, it should move smoothly.

CS-00355

CS-00356

Page 2301 of 2870

CS-16

CONTROL SYSTEM

N-R Lock Solenoid

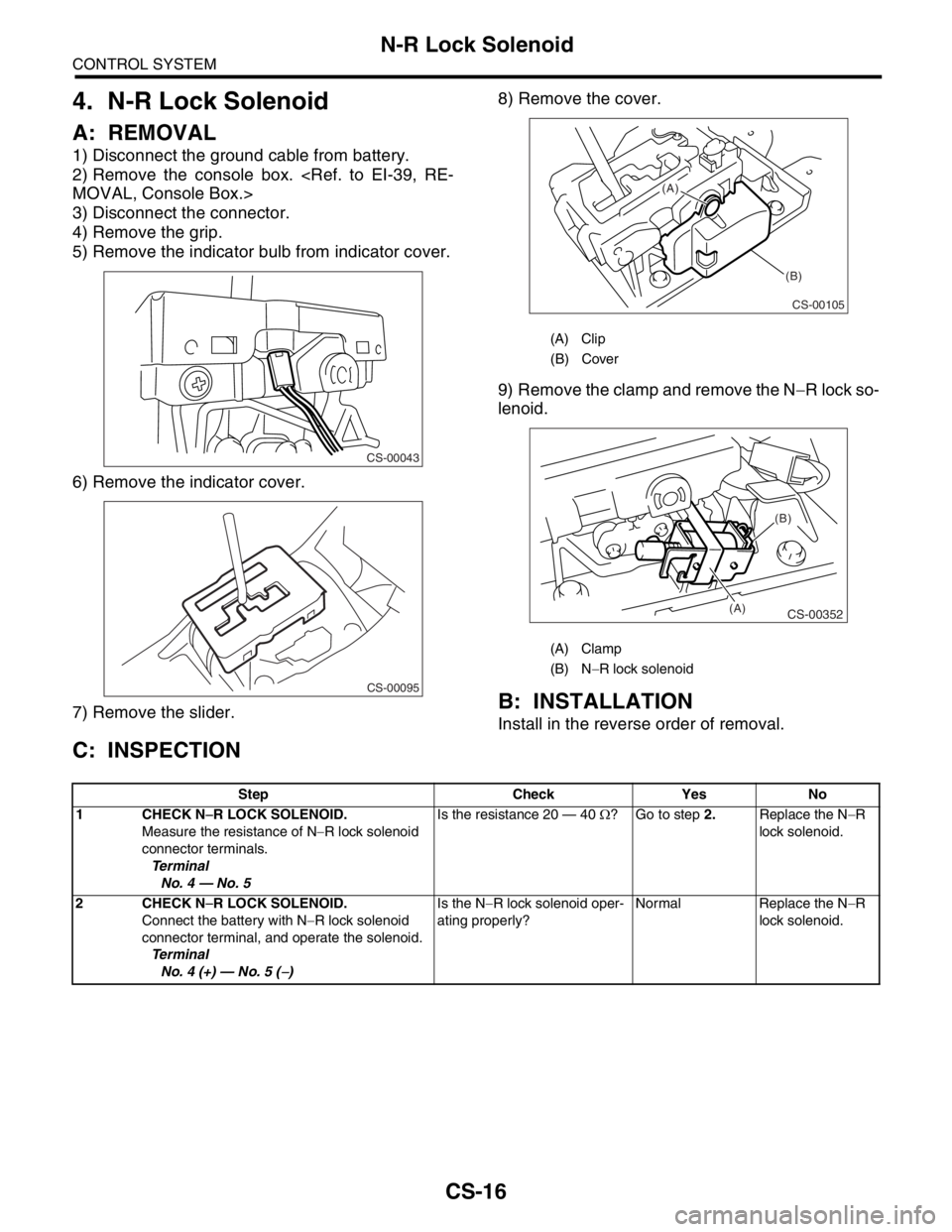

4. N-R Lock Solenoid

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the console box.

3) Disconnect the connector.

4) Remove the grip.

5) Remove the indicator bulb from indicator cover.

6) Remove the indicator cover.

7) Remove the slider.8) Remove the cover.

9) Remove the clamp and remove the N−R lock so-

lenoid.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

CS-00043

CS-00095

(A) Clip

(B) Cover

(A) Clamp

(B) N−R lock solenoid

CS-00105

(A)

(B)

CS-00352

(B)

(A)

Step Check Yes No

1 CHECK N−R LOCK SOLENOID.

Measure the resistance of N−R lock solenoid

connector terminals.

Te r m i n a l

No. 4 — No. 5Is the resistance 20 — 40 Ω? Go to step 2.Replace the N−R

lock solenoid.

2 CHECK N−R LOCK SOLENOID.

Connect the battery with N−R lock solenoid

connector terminal, and operate the solenoid.

Te r m i n a l

No. 4 (+) — No. 5 (

−)Is the N−R lock solenoid oper-

ating properly?Normal Replace the N−R

lock solenoid.