lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1556 of 2870

ME(H4DOTC)-96

MECHANICAL

Cylinder Block

1) Remove oil in the mating surface of bearing and

cylinder block before installation. Apply a coat of

engine oil to crankshaft pins.

2) Install crankshaft bearings on the cylinder block,

apply a coat of engine oil to crankshaft bearings,

and position the crankshaft on #2 and #4 cylinder

block.

3) Apply liquid gasket to the mating surface of #1

and #3 cylinder block, and position it on #2 and #4

cylinder block.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

NOTE:

Do not allow liquid gasket to jut into O-ring grooves,

oil passages, bearing grooves, etc.

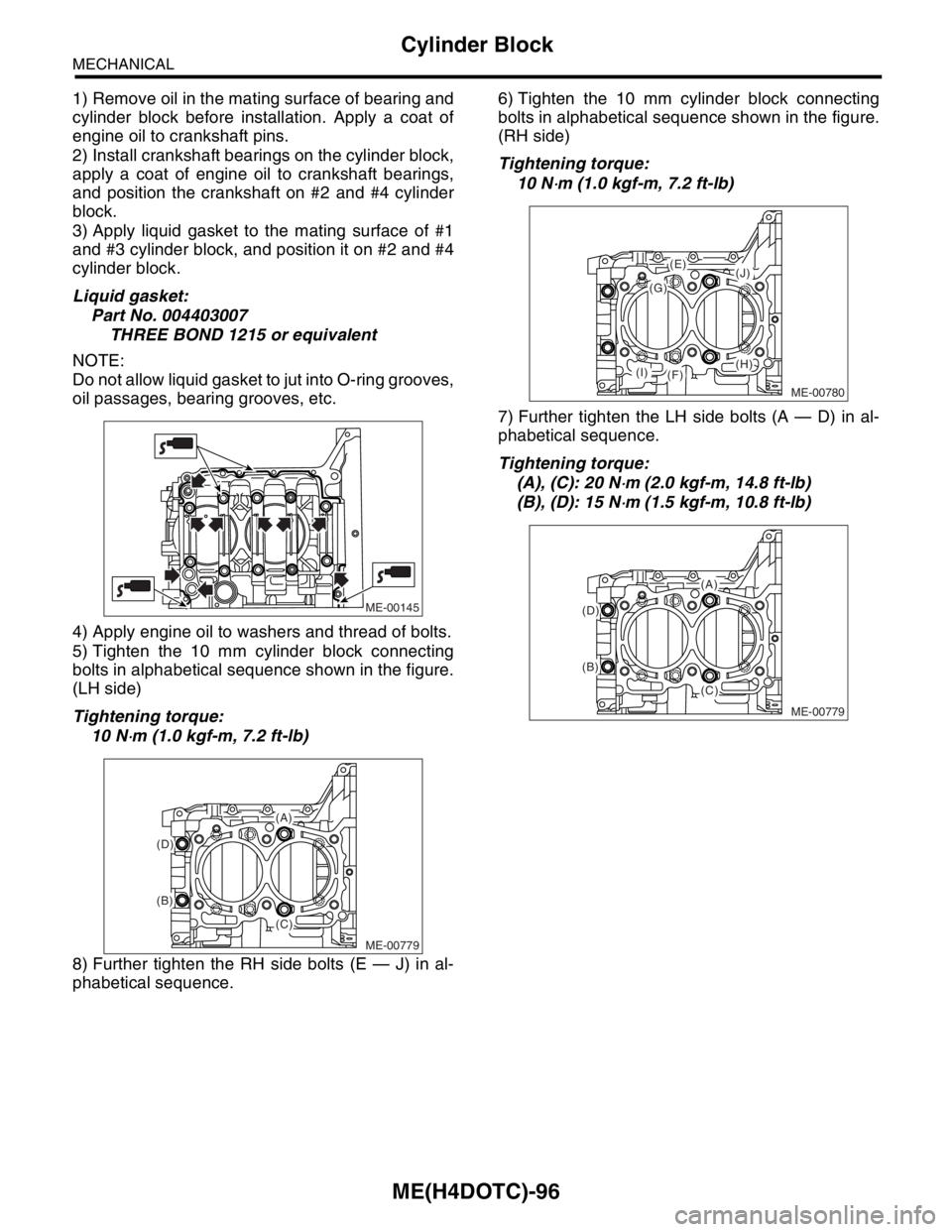

4) Apply engine oil to washers and thread of bolts.

5) Tighten the 10 mm cylinder block connecting

bolts in alphabetical sequence shown in the figure.

(LH side)

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)6) Tighten the 10 mm cylinder block connecting

bolts in alphabetical sequence shown in the figure.

(RH side)

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

7) Further tighten the LH side bolts (A — D) in al-

phabetical sequence.

Tightening torque:

(A), (C): 20 N

⋅m (2.0 kgf-m, 14.8 ft-lb)

(B), (D): 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

8) Further tighten the RH side bolts (E — J) in al-

phabetical sequence.

ME-00145

ME-00779

(A)

(B)

(D)

(C)

ME-00780

(J)

(H)

(G)

(E)

(F)(I)

ME-00779

(A)

(B)

(D)

(C)

Page 1557 of 2870

ME(H4DOTC)-97

MECHANICAL

Cylinder Block

Tightening torque:

(E), (F), (G), (I): 20 N

⋅m (2.0 kgf-m, 14.8 ft-lb)

(H), (J): 18 N

⋅m (1.8 kgf-m, 13.3 ft-lb)

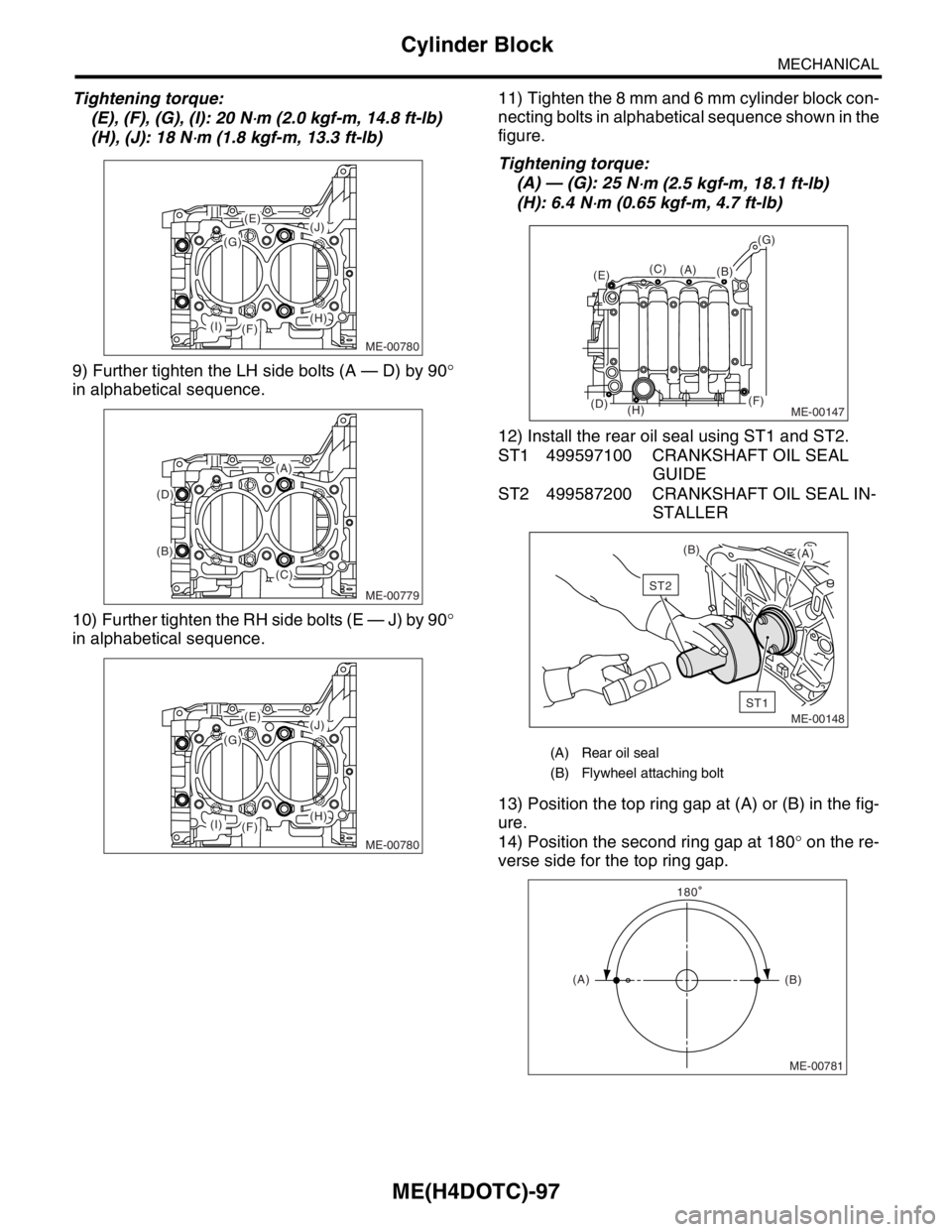

9) Further tighten the LH side bolts (A — D) by 90°

in alphabetical sequence.

10) Further tighten the RH side bolts (E — J) by 90°

in alphabetical sequence.11) Tighten the 8 mm and 6 mm cylinder block con-

necting bolts in alphabetical sequence shown in the

figure.

Tightening torque:

(A) — (G): 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(H): 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

12) Install the rear oil seal using ST1 and ST2.

ST1 499597100 CRANKSHAFT OIL SEAL

GUIDE

ST2 499587200 CRANKSHAFT OIL SEAL IN-

STALLER

13) Position the top ring gap at (A) or (B) in the fig-

ure.

14) Position the second ring gap at 180° on the re-

verse side for the top ring gap.

ME-00780

(J)

(H)

(G)

(E)

(F)(I)

ME-00779

(A)

(B)

(D)

(C)

ME-00780

(J)

(H)

(G)

(E)

(F)(I)

(A) Rear oil seal

(B) Flywheel attaching bolt

ME-00147

(B)(C)

(D)

(E)

(F)

(G)

(H)

(A)

ME-00148

ST1

ST2

(B)

(A)

ME-00781

(A)(B) 180

Page 1558 of 2870

ME(H4DOTC)-98

MECHANICAL

Cylinder Block

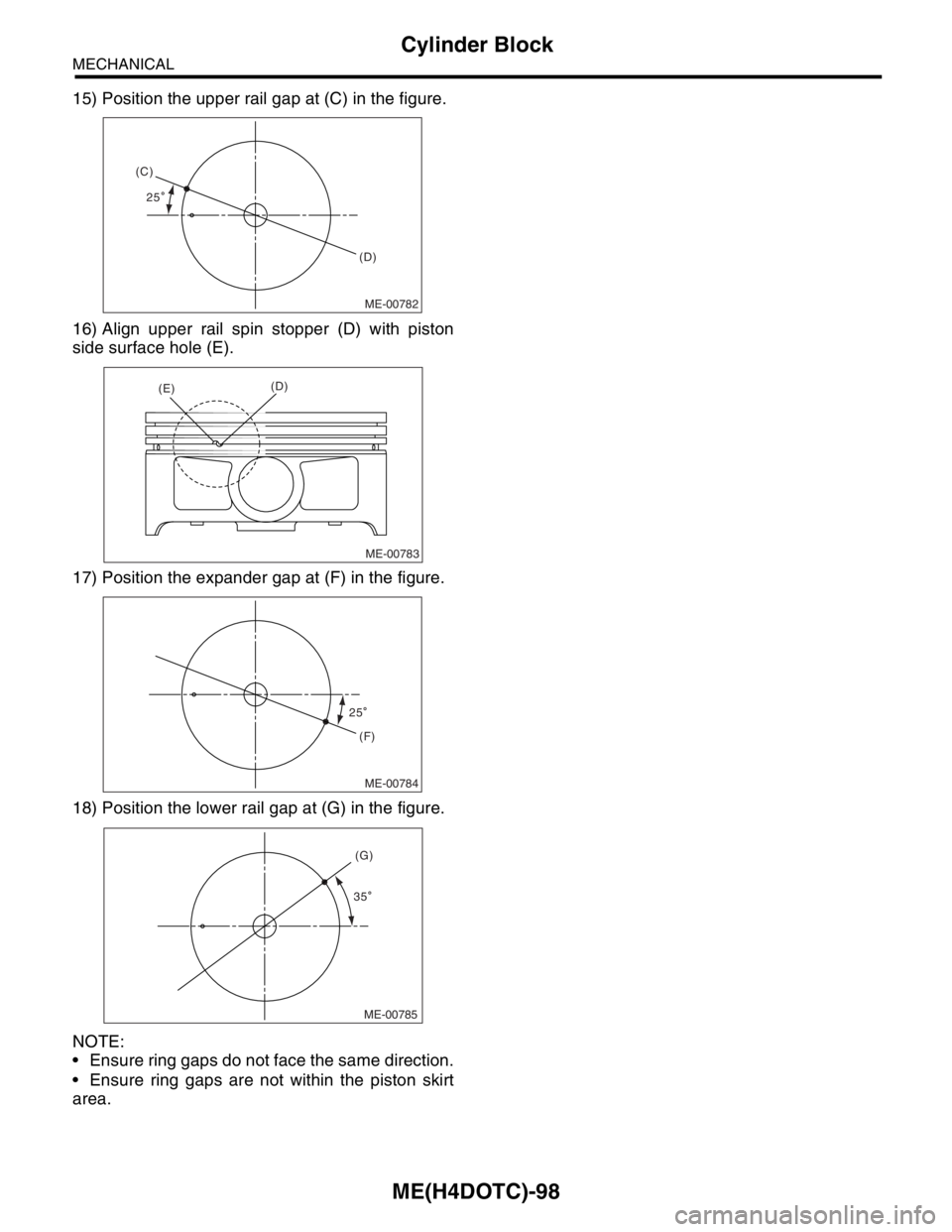

15) Position the upper rail gap at (C) in the figure.

16) Align upper rail spin stopper (D) with piston

side surface hole (E).

17) Position the expander gap at (F) in the figure.

18) Position the lower rail gap at (G) in the figure.

NOTE:

Ensure ring gaps do not face the same direction.

Ensure ring gaps are not within the piston skirt

area.

ME-00782

(D)

(C)

25

ME-00783

(E)(D)

ME-00784

(F)

25

ME-00785

35(G)

Page 1559 of 2870

ME(H4DOTC)-99

MECHANICAL

Cylinder Block

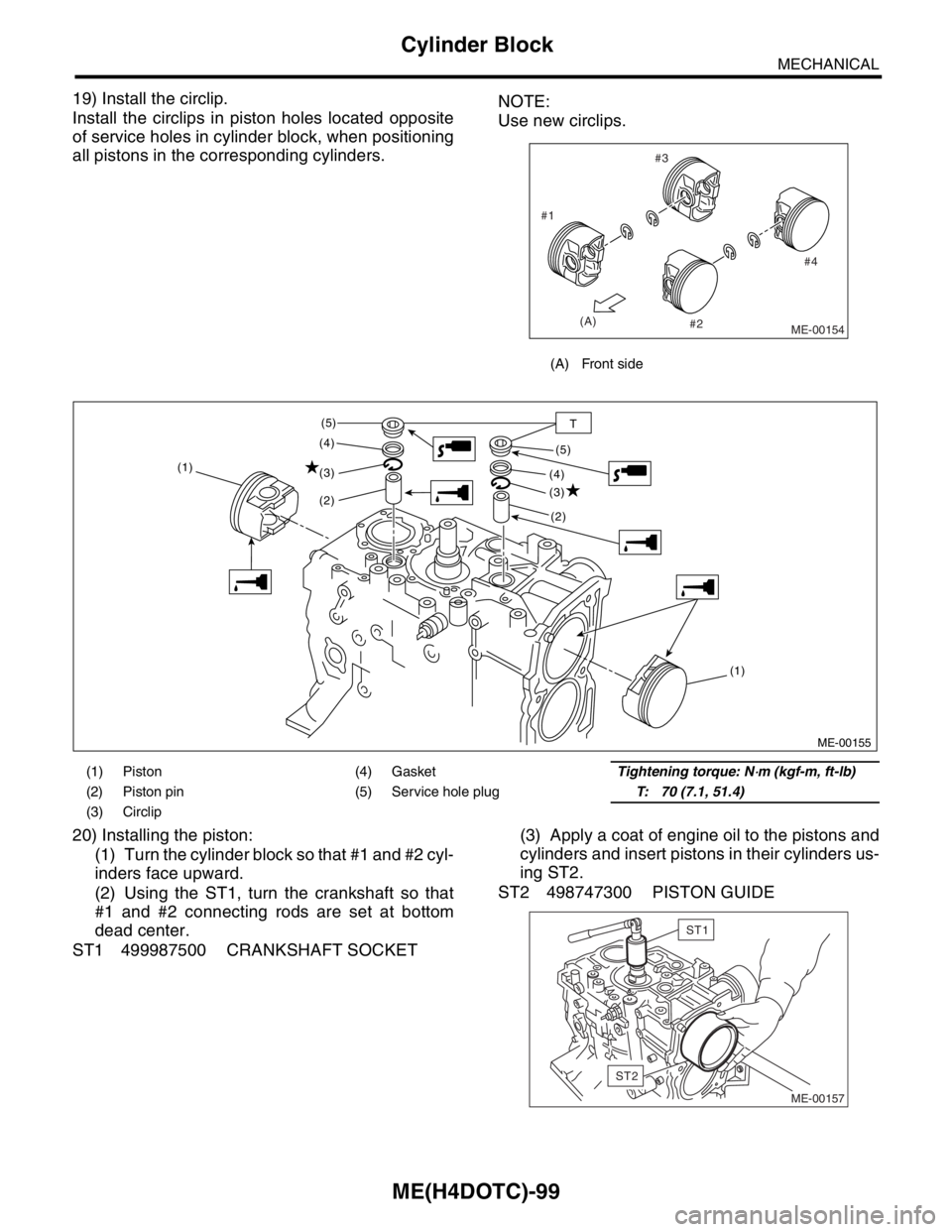

19) Install the circlip.

Install the circlips in piston holes located opposite

of service holes in cylinder block, when positioning

all pistons in the corresponding cylinders.NOTE:

Use new circlips.

20) Installing the piston:

(1) Turn the cylinder block so that #1 and #2 cyl-

inders face upward.

(2) Using the ST1, turn the crankshaft so that

#1 and #2 connecting rods are set at bottom

dead center.

ST1 499987500 CRANKSHAFT SOCKET(3) Apply a coat of engine oil to the pistons and

cylinders and insert pistons in their cylinders us-

ing ST2.

ST2 498747300 PISTON GUIDE

(A) Front side

ME-00154

#4 #3

#2 #1

(A)

(1) Piston (4) GasketTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (5) Service hole plugT: 70 (7.1, 51.4)

(3) Circlip

ME-00155

(1) (1)

(2)

(2) (3)

(3) (4)

(4) (5)

(5)

T

ME-00157

ST2

ST1

Page 1560 of 2870

ME(H4DOTC)-100

MECHANICAL

Cylinder Block

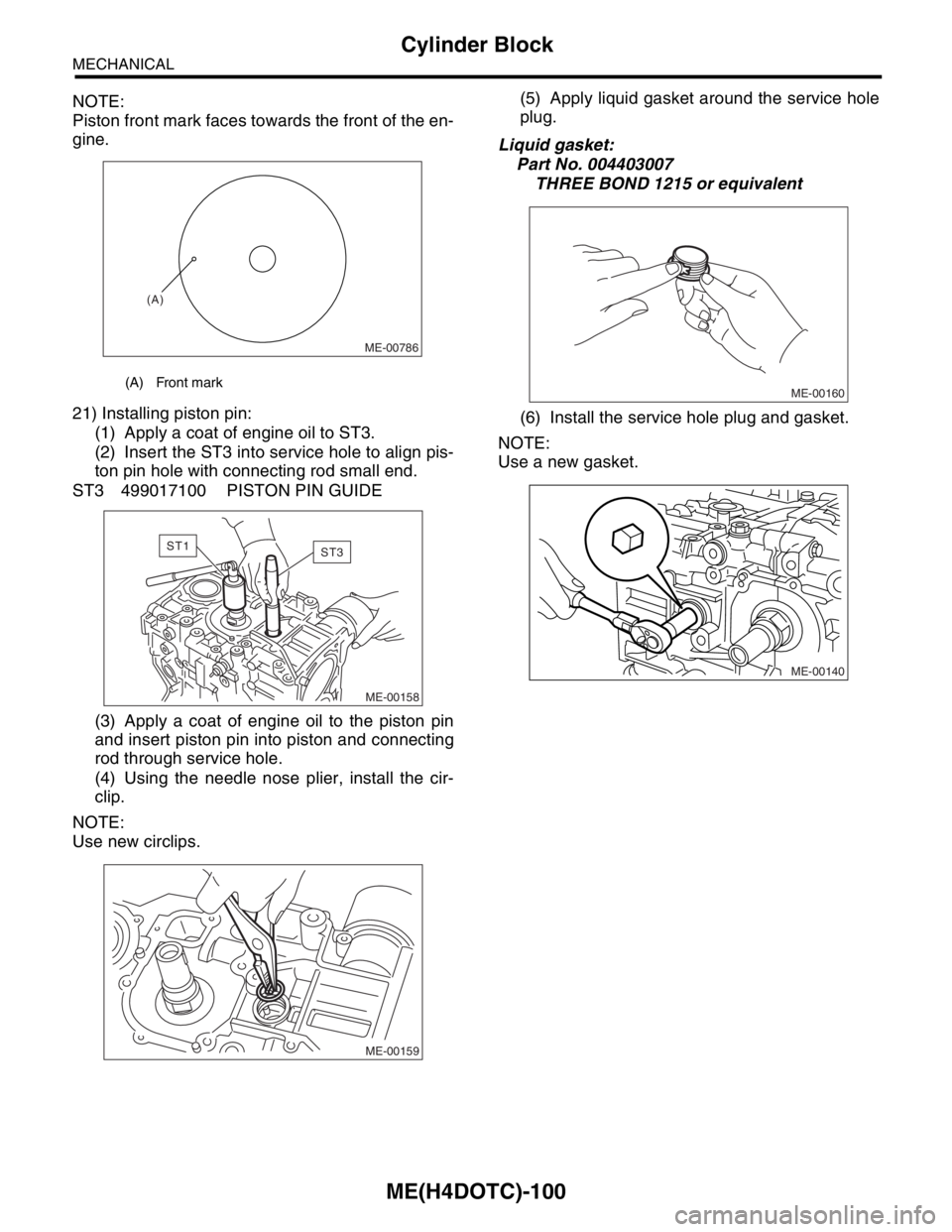

NOTE:

Piston front mark faces towards the front of the en-

gine.

21) Installing piston pin:

(1) Apply a coat of engine oil to ST3.

(2) Insert the ST3 into service hole to align pis-

ton pin hole with connecting rod small end.

ST3 499017100 PISTON PIN GUIDE

(3) Apply a coat of engine oil to the piston pin

and insert piston pin into piston and connecting

rod through service hole.

(4) Using the needle nose plier, install the cir-

clip.

NOTE:

Use new circlips.(5) Apply liquid gasket around the service hole

plug.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

(6) Install the service hole plug and gasket.

NOTE:

Use a new gasket.

(A) Front mark

ME-00786

(A)

ME-00158

ST1ST3

ME-00159

ME-00160

ME-00140

Page 1561 of 2870

ME(H4DOTC)-101

MECHANICAL

Cylinder Block

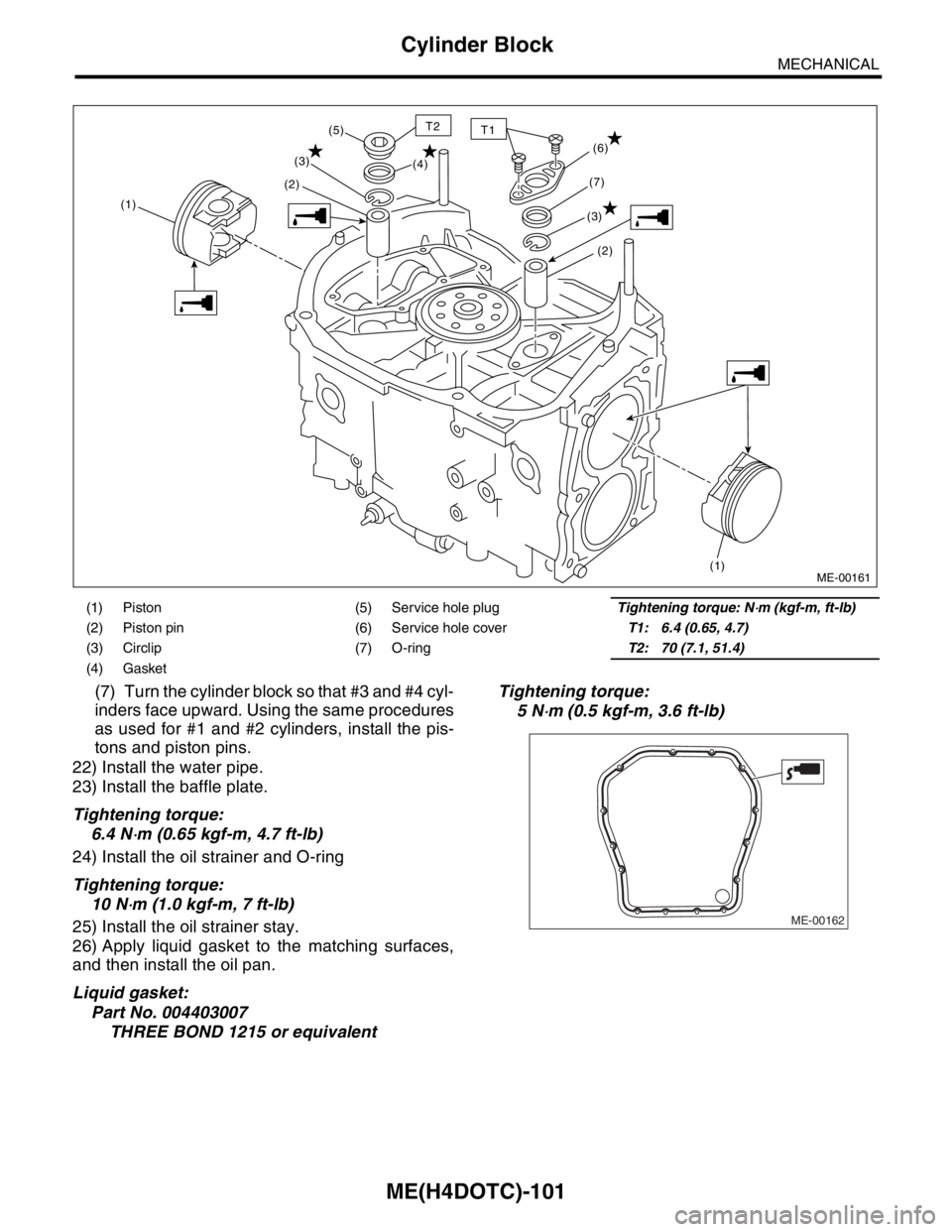

(7) Turn the cylinder block so that #3 and #4 cyl-

inders face upward. Using the same procedures

as used for #1 and #2 cylinders, install the pis-

tons and piston pins.

22) Install the water pipe.

23) Install the baffle plate.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

24) Install the oil strainer and O-ring

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7 ft-lb)

25) Install the oil strainer stay.

26) Apply liquid gasket to the matching surfaces,

and then install the oil pan.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalentTightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

(1) Piston (5) Service hole plugTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (6) Service hole coverT1: 6.4 (0.65, 4.7)

(3) Circlip (7) O-ringT2: 70 (7.1, 51.4)

(4) Gasket

(1)(2)(3)

(1)

(2) (6)

(3)(7) (4) (5)

ME-00161

T2T1

ME-00162

Page 1562 of 2870

ME(H4DOTC)-102

MECHANICAL

Cylinder Block

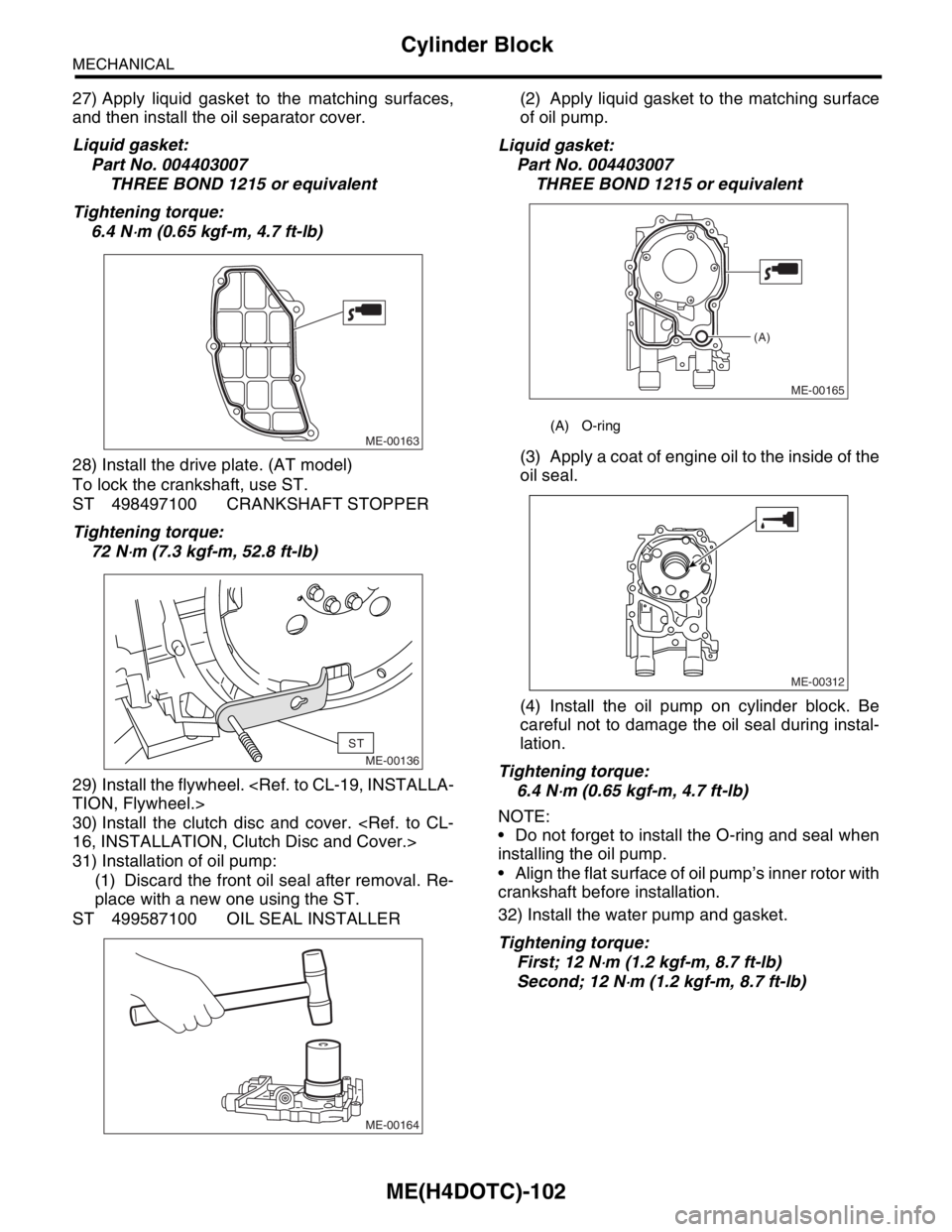

27) Apply liquid gasket to the matching surfaces,

and then install the oil separator cover.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

28) Install the drive plate. (AT model)

To lock the crankshaft, use ST.

ST 498497100 CRANKSHAFT STOPPER

Tightening torque:

72 N

⋅m (7.3 kgf-m, 52.8 ft-lb)

29) Install the flywheel.

30) Install the clutch disc and cover.

31) Installation of oil pump:

(1) Discard the front oil seal after removal. Re-

place with a new one using the ST.

ST 499587100 OIL SEAL INSTALLER(2) Apply liquid gasket to the matching surface

of oil pump.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

(3) Apply a coat of engine oil to the inside of the

oil seal.

(4) Install the oil pump on cylinder block. Be

careful not to damage the oil seal during instal-

lation.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

NOTE:

Do not forget to install the O-ring and seal when

installing the oil pump.

Align the flat surface of oil pump’s inner rotor with

crankshaft before installation.

32) Install the water pump and gasket.

Tightening torque:

First; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Second; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

ME-00163

ME-00136

ST

ME-00164

(A) O-ring

ME-00165

(A)

ME-00312

Page 1563 of 2870

ME(H4DOTC)-103

MECHANICAL

Cylinder Block

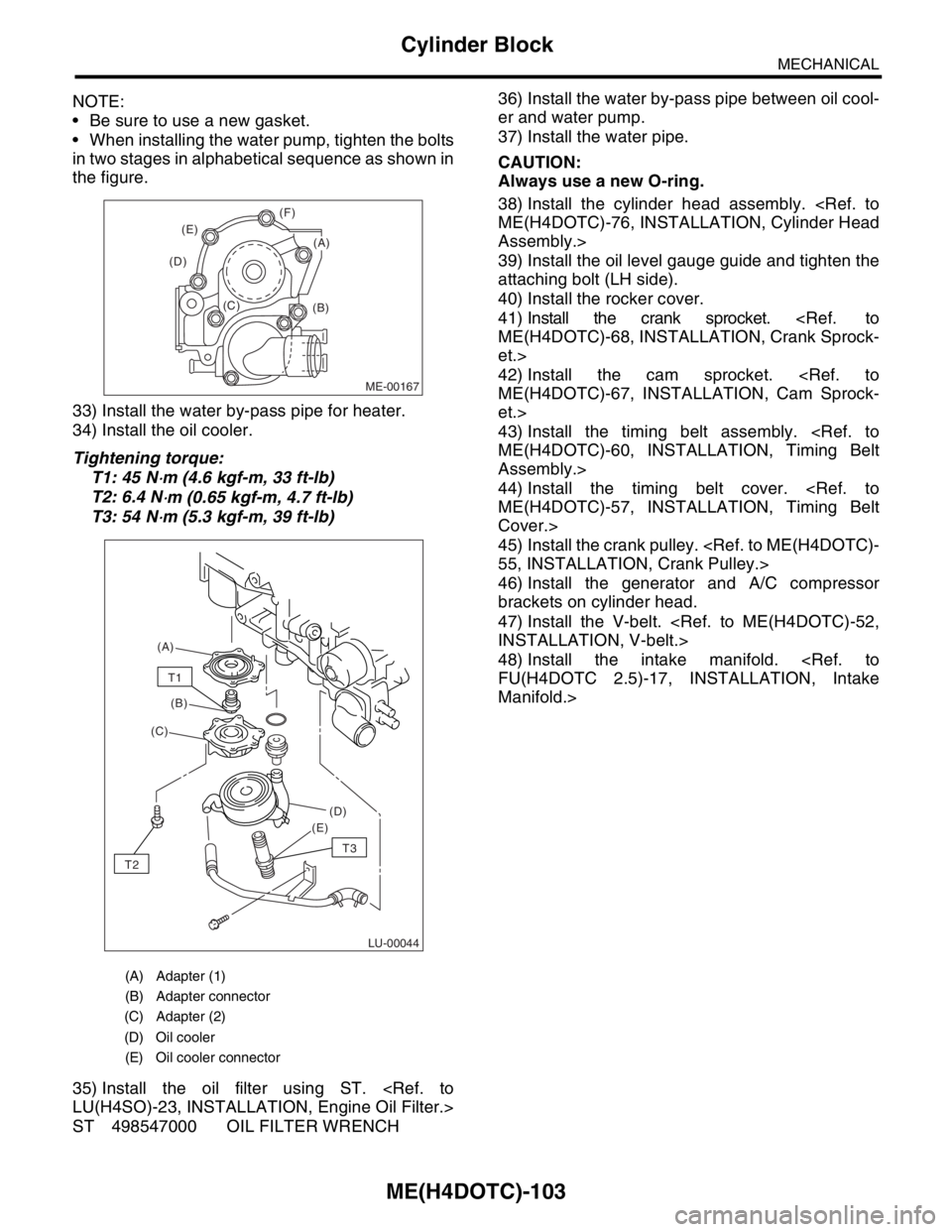

NOTE:

Be sure to use a new gasket.

When installing the water pump, tighten the bolts

in two stages in alphabetical sequence as shown in

the figure.

33) Install the water by-pass pipe for heater.

34) Install the oil cooler.

Tightening torque:

T1: 45 N

⋅m (4.6 kgf-m, 33 ft-lb)

T2: 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

T3: 54 N

⋅m (5.3 kgf-m, 39 ft-lb)

35) Install the oil filter using ST.

ST 498547000 OIL FILTER WRENCH36) Install the water by-pass pipe between oil cool-

er and water pump.

37) Install the water pipe.

CAUTION:

Always use a new O-ring.

38) Install the cylinder head assembly.

Assembly.>

39) Install the oil level gauge guide and tighten the

attaching bolt (LH side).

40) Install the rocker cover.

41) Install the crank sprocket.

et.>

42) Install the cam sprocket.

et.>

43) Install the timing belt assembly.

Assembly.>

44) Install the timing belt cover.

Cover.>

45) Install the crank pulley.

46) Install the generator and A/C compressor

brackets on cylinder head.

47) Install the V-belt.

48) Install the intake manifold.

Manifold.>

(A) Adapter (1)

(B) Adapter connector

(C) Adapter (2)

(D) Oil cooler

(E) Oil cooler connector

ME-00167

(B) (C) (D)(E)(F)

(A)

LU-00044

(A)

(B)

(C)

(D)

(E)

T1

T2

T3

Page 1564 of 2870

ME(H4DOTC)-104

MECHANICAL

Cylinder Block

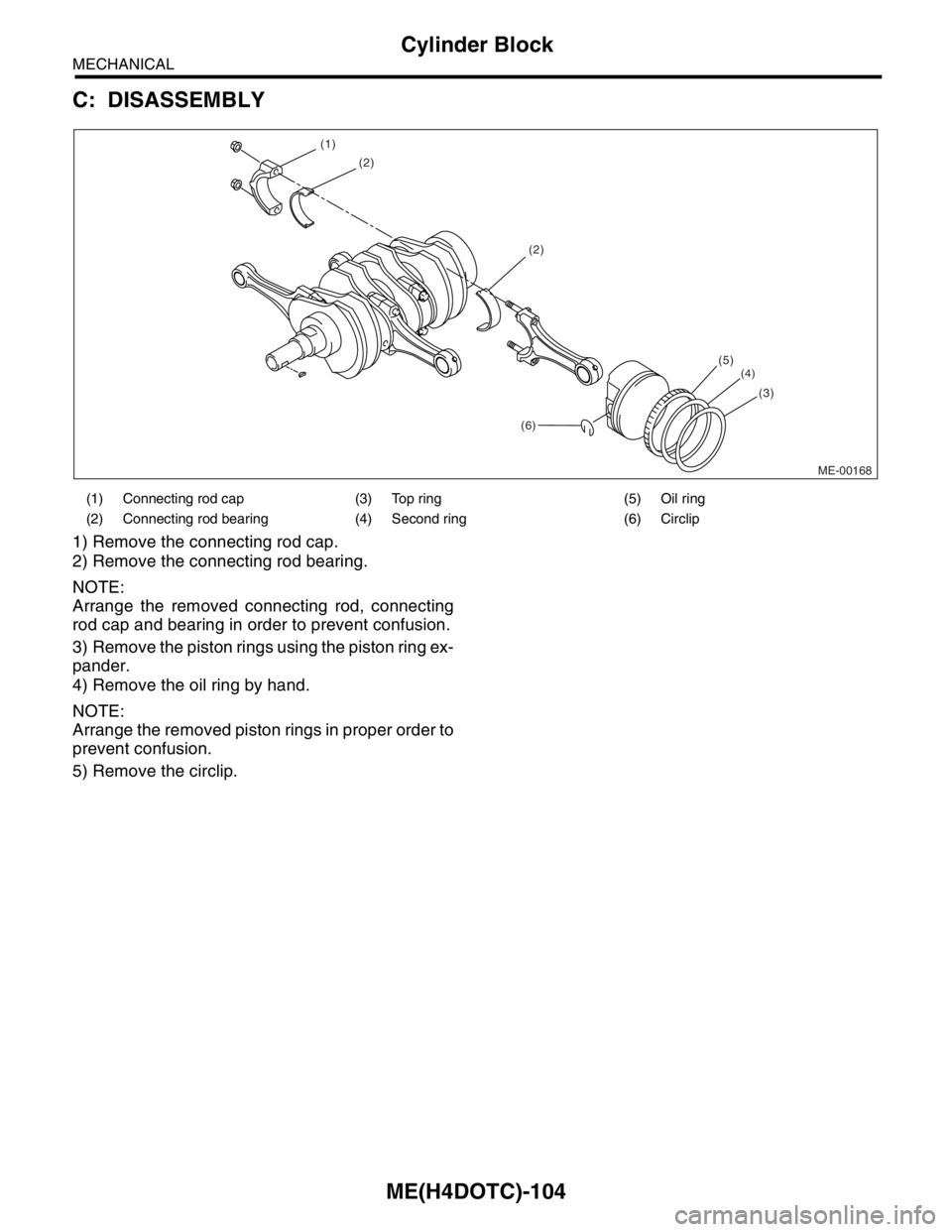

C: DISASSEMBLY

1) Remove the connecting rod cap.

2) Remove the connecting rod bearing.

NOTE:

Arrange the removed connecting rod, connecting

rod cap and bearing in order to prevent confusion.

3) Remove the piston rings using the piston ring ex-

pander.

4) Remove the oil ring by hand.

NOTE:

Arrange the removed piston rings in proper order to

prevent confusion.

5) Remove the circlip.

(1) Connecting rod cap (3) Top ring (5) Oil ring

(2) Connecting rod bearing (4) Second ring (6) Circlip

ME-00168

(2)

(2)

(6)(5)

(4)

(3) (1)

Page 1565 of 2870

ME(H4DOTC)-105

MECHANICAL

Cylinder Block

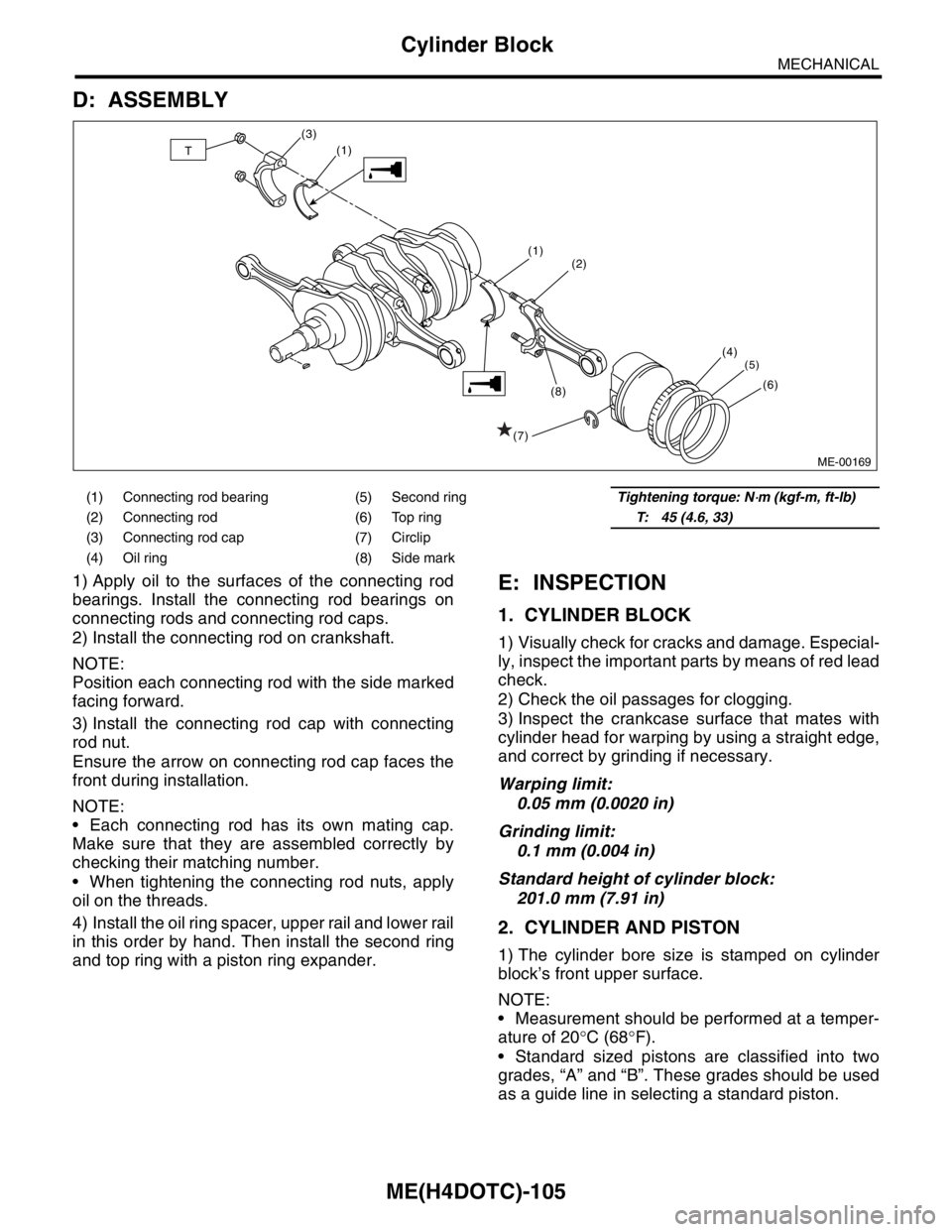

D: ASSEMBLY

1) Apply oil to the surfaces of the connecting rod

bearings. Install the connecting rod bearings on

connecting rods and connecting rod caps.

2) Install the connecting rod on crankshaft.

NOTE:

Position each connecting rod with the side marked

facing forward.

3) Install the connecting rod cap with connecting

rod nut.

Ensure the arrow on connecting rod cap faces the

front during installation.

NOTE:

Each connecting rod has its own mating cap.

Make sure that they are assembled correctly by

checking their matching number.

When tightening the connecting rod nuts, apply

oil on the threads.

4) Install the oil ring spacer, upper rail and lower rail

in this order by hand. Then install the second ring

and top ring with a piston ring expander.E: INSPECTION

1. CYLINDER BLOCK

1) Visually check for cracks and damage. Especial-

ly, inspect the important parts by means of red lead

check.

2) Check the oil passages for clogging.

3) Inspect the crankcase surface that mates with

cylinder head for warping by using a straight edge,

and correct by grinding if necessary.

Warping limit:

0.05 mm (0.0020 in)

Grinding limit:

0.1 mm (0.004 in)

Standard height of cylinder block:

201.0 mm (7.91 in)

2. CYLINDER AND PISTON

1) The cylinder bore size is stamped on cylinder

block’s front upper surface.

NOTE:

Measurement should be performed at a temper-

ature of 20°C (68°F).

Standard sized pistons are classified into two

grades, “A” and “B”. These grades should be used

as a guide line in selecting a standard piston.

(1) Connecting rod bearing (5) Second ringTightening torque: N⋅m (kgf-m, ft-lb)

(2) Connecting rod (6) Top ringT: 45 (4.6, 33)

(3) Connecting rod cap (7) Circlip

(4) Oil ring (8) Side mark

ME-00169

(2)

(4)

(5)

(6)

(1)

(1)

(7)(8) (3)T