lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2398 of 2870

4AT-85

AUTOMATIC TRANSMISSION

ATF Cooler (With Warmer Function)

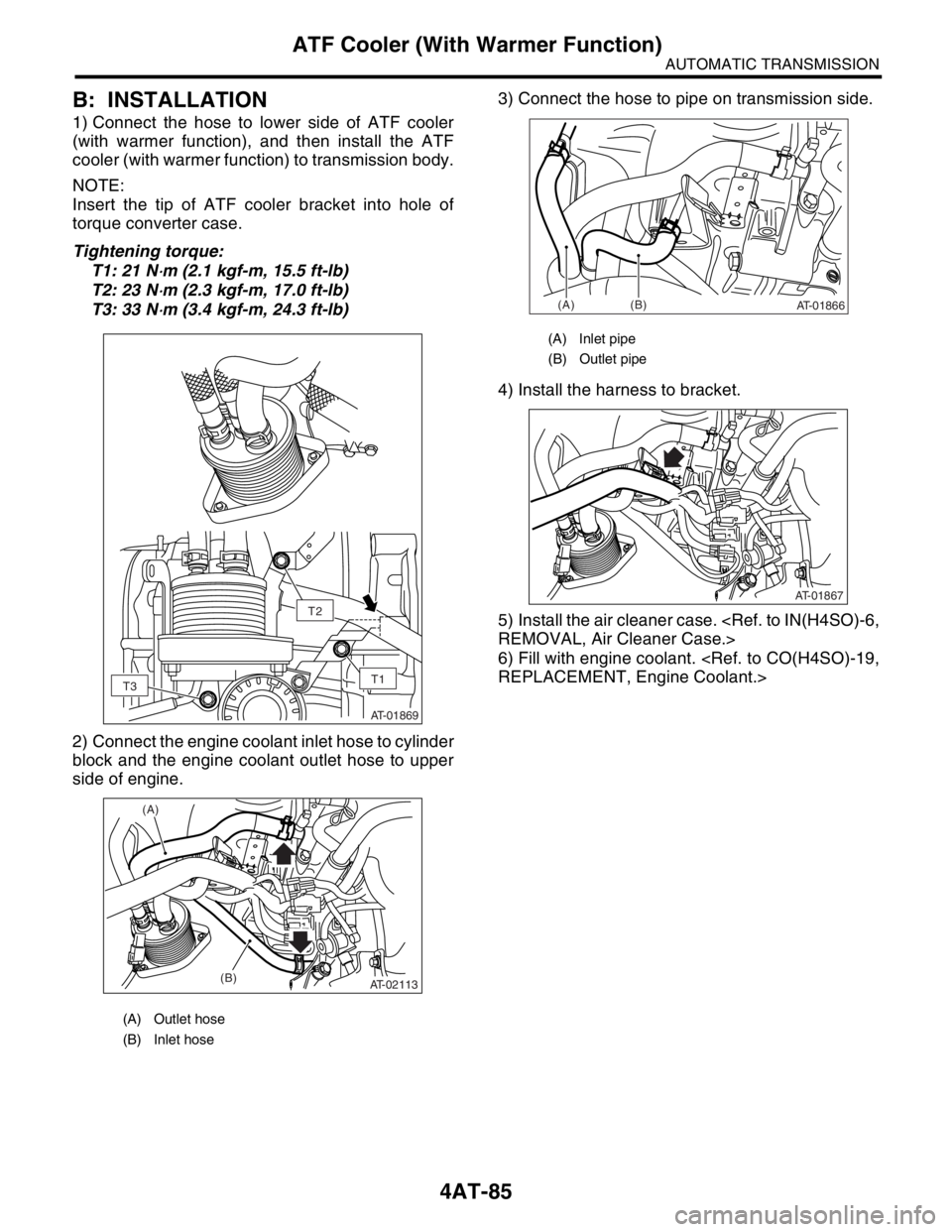

B: INSTALLATION

1) Connect the hose to lower side of ATF cooler

(with warmer function), and then install the ATF

cooler (with warmer function) to transmission body.

NOTE:

Insert the tip of ATF cooler bracket into hole of

torque converter case.

Tightening torque:

T1: 21 N

⋅m (2.1 kgf-m, 15.5 ft-lb)

T2: 23 N

⋅m (2.3 kgf-m, 17.0 ft-lb)

T3: 33 N

⋅m (3.4 kgf-m, 24.3 ft-lb)

2) Connect the engine coolant inlet hose to cylinder

block and the engine coolant outlet hose to upper

side of engine.3) Connect the hose to pipe on transmission side.

4) Install the harness to bracket.

5) Install the air cleaner case.

6) Fill with engine coolant.

(A) Outlet hose

(B) Inlet hose

AT-01869

T2

T1T3

AT-02113

(A)

(B)

(A) Inlet pipe

(B) Outlet pipe

AT-01866(A)(B)

AT-01867

Page 2408 of 2870

4AT-95

AUTOMATIC TRANSMISSION

Transfer Clutch

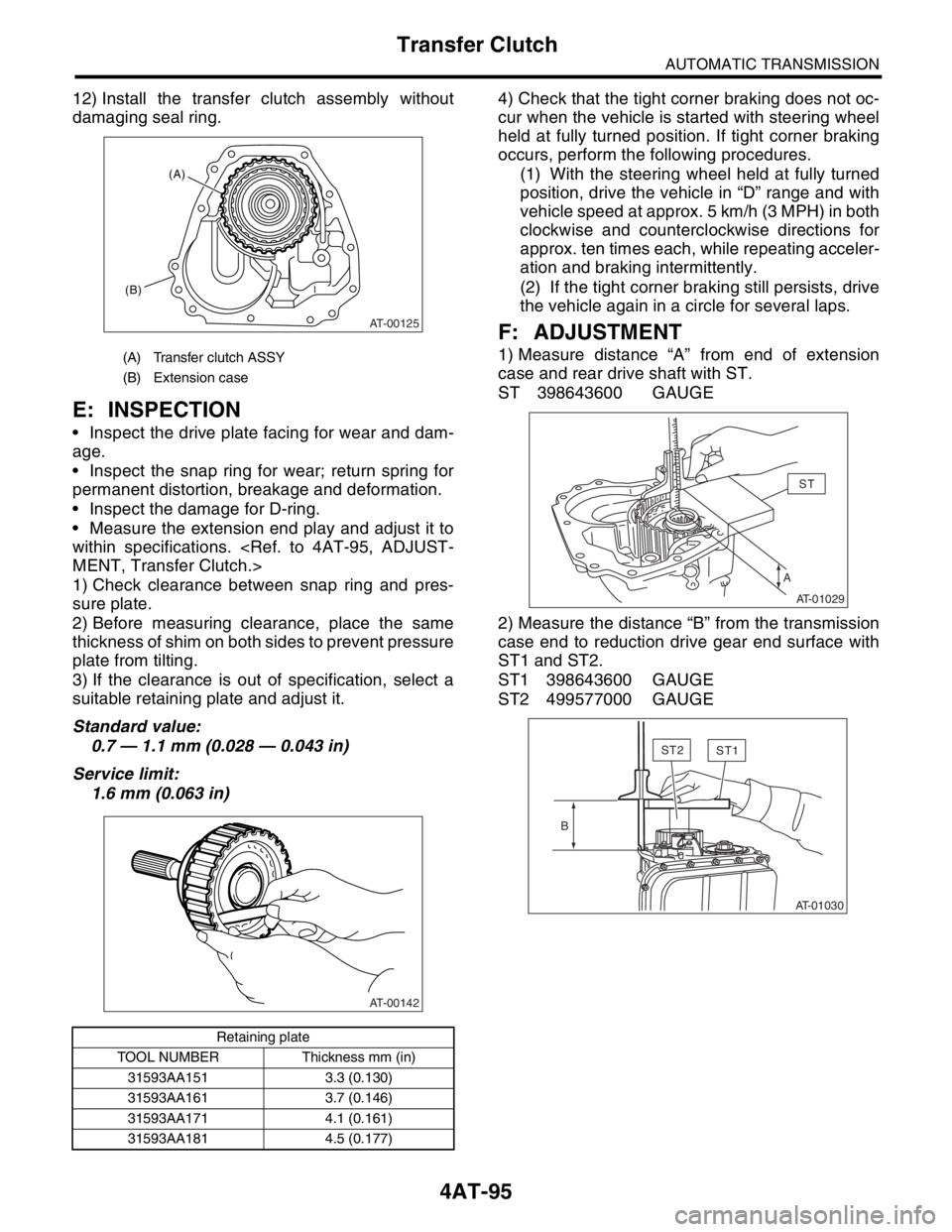

12) Install the transfer clutch assembly without

damaging seal ring.

E: INSPECTION

Inspect the drive plate facing for wear and dam-

age.

Inspect the snap ring for wear; return spring for

permanent distortion, breakage and deformation.

Inspect the damage for D-ring.

Measure the extension end play and adjust it to

within specifications.

1) Check clearance between snap ring and pres-

sure plate.

2) Before measuring clearance, place the same

thickness of shim on both sides to prevent pressure

plate from tilting.

3) If the clearance is out of specification, select a

suitable retaining plate and adjust it.

Standard value:

0.7 — 1.1 mm (0.028 — 0.043 in)

Service limit:

1.6 mm (0.063 in)4) Check that the tight corner braking does not oc-

cur when the vehicle is started with steering wheel

held at fully turned position. If tight corner braking

occurs, perform the following procedures.

(1) With the steering wheel held at fully turned

position, drive the vehicle in “D” range and with

vehicle speed at approx. 5 km/h (3 MPH) in both

clockwise and counterclockwise directions for

approx. ten times each, while repeating acceler-

ation and braking intermittently.

(2) If the tight corner braking still persists, drive

the vehicle again in a circle for several laps.

F: ADJUSTMENT

1) Measure distance “A” from end of extension

case and rear drive shaft with ST.

ST 398643600 GAUGE

2) Measure the distance “B” from the transmission

case end to reduction drive gear end surface with

ST1 and ST2.

ST1 398643600 GAUGE

ST2 499577000 GAUGE(A) Transfer clutch ASSY

(B) Extension case

Retaining plate

TOOL NUMBER Thickness mm (in)

31593AA151 3.3 (0.130)

31593AA161 3.7 (0.146)

31593AA171 4.1 (0.161)

31593AA181 4.5 (0.177)

AT-00125

(A)

(B)

AT-00142

AST

AT-01029

ST2ST1

B

AT-01030

Page 2411 of 2870

4AT-97

AUTOMATIC TRANSMISSION

Reduction Driven Gear

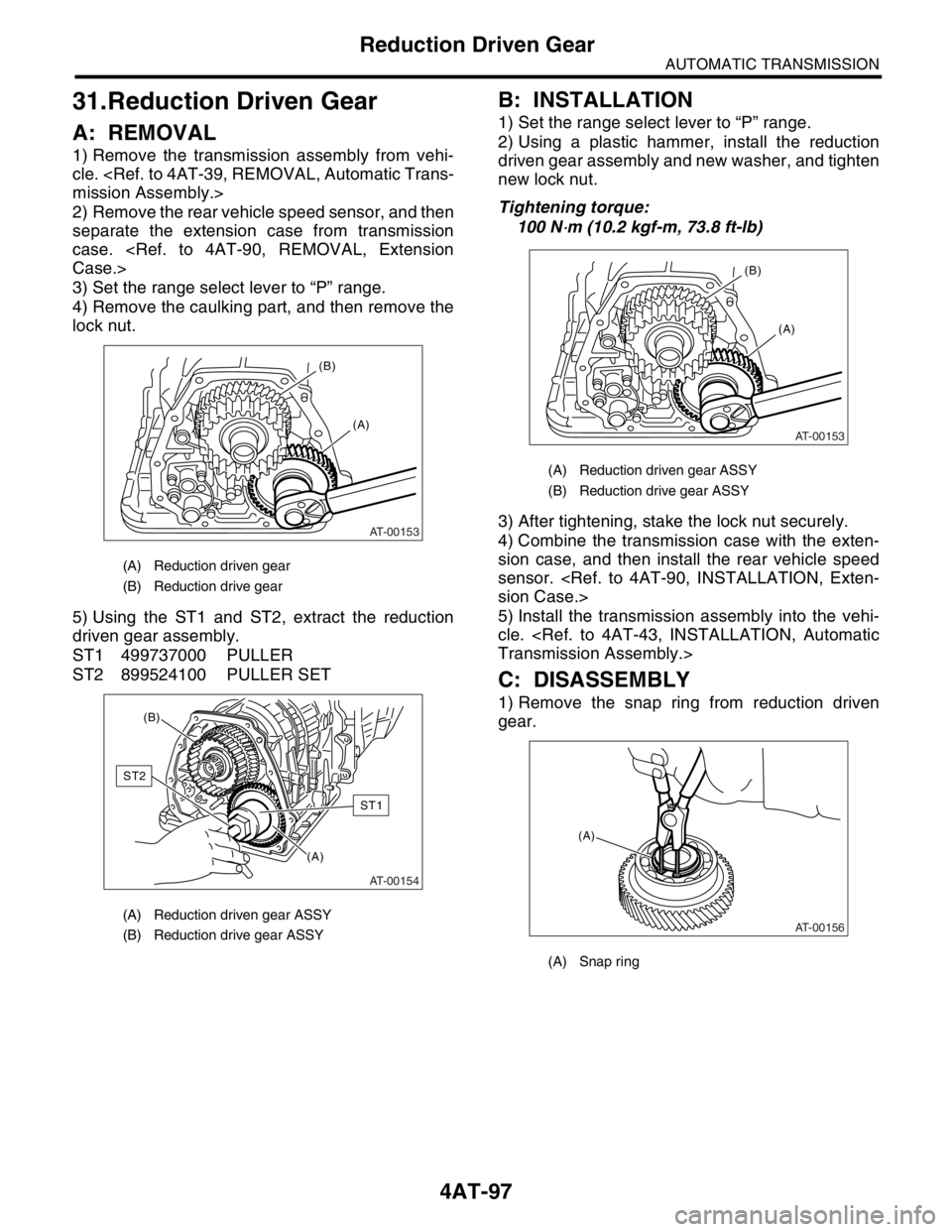

31.Reduction Driven Gear

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle.

2) Remove the rear vehicle speed sensor, and then

separate the extension case from transmission

case.

3) Set the range select lever to “P” range.

4) Remove the caulking part, and then remove the

lock nut.

5) Using the ST1 and ST2, extract the reduction

driven gear assembly.

ST1 499737000 PULLER

ST2 899524100 PULLER SET

B: INSTALLATION

1) Set the range select lever to “P” range.

2) Using a plastic hammer, install the reduction

driven gear assembly and new washer, and tighten

new lock nut.

Tightening torque:

100 N

⋅m (10.2 kgf-m, 73.8 ft-lb)

3) After tightening, stake the lock nut securely.

4) Combine the transmission case with the exten-

sion case, and then install the rear vehicle speed

sensor.

5) Install the transmission assembly into the vehi-

cle.

C: DISASSEMBLY

1) Remove the snap ring from reduction driven

gear.

(A) Reduction driven gear

(B) Reduction drive gear

(A) Reduction driven gear ASSY

(B) Reduction drive gear ASSY

AT-00153

(A) (B)

AT-00154

(A) (B)

ST1

ST2

(A) Reduction driven gear ASSY

(B) Reduction drive gear ASSY

(A) Snap ring

AT-00153

(A) (B)

AT-00156

(A)

Page 2419 of 2870

4AT-105

AUTOMATIC TRANSMISSION

Oil Pump Housing

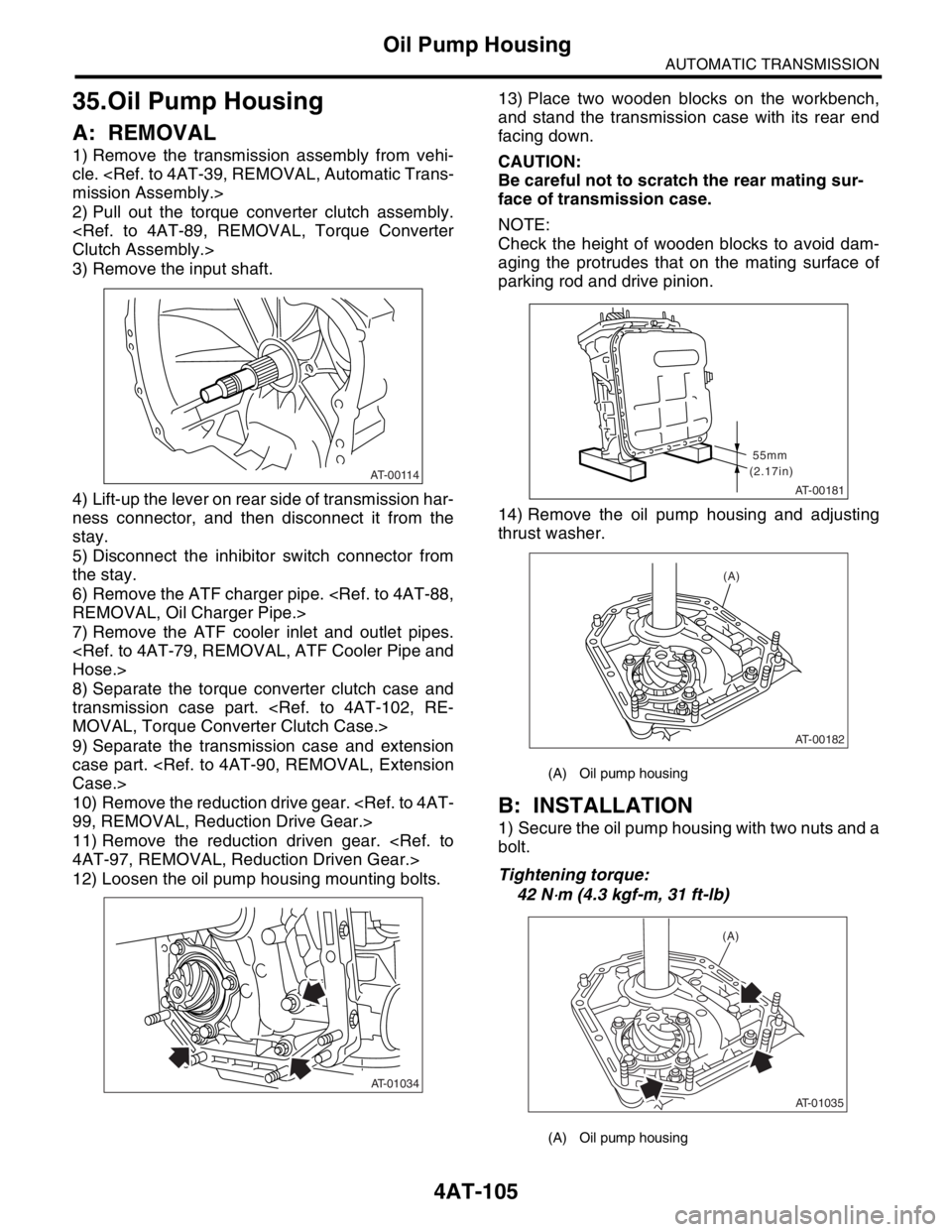

35.Oil Pump Housing

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle.

2) Pull out the torque converter clutch assembly.

3) Remove the input shaft.

4) Lift-up the lever on rear side of transmission har-

ness connector, and then disconnect it from the

stay.

5) Disconnect the inhibitor switch connector from

the stay.

6) Remove the ATF charger pipe.

7) Remove the ATF cooler inlet and outlet pipes.

8) Separate the torque converter clutch case and

transmission case part.

9) Separate the transmission case and extension

case part.

10) Remove the reduction drive gear.

11) Remove the reduction driven gear.

12) Loosen the oil pump housing mounting bolts.13) Place two wooden blocks on the workbench,

and stand the transmission case with its rear end

facing down.

CAUTION:

Be careful not to scratch the rear mating sur-

face of transmission case.

NOTE:

Check the height of wooden blocks to avoid dam-

aging the protrudes that on the mating surface of

parking rod and drive pinion.

14) Remove the oil pump housing and adjusting

thrust washer.

B: INSTALLATION

1) Secure the oil pump housing with two nuts and a

bolt.

Tightening torque:

42 N

⋅m (4.3 kgf-m, 31 ft-lb)

AT-00114

AT-01034

(A) Oil pump housing

(A) Oil pump housing

AT-00181

(2.17in)55mm

AT-00182

(A)

AT-01035

(A)

Page 2426 of 2870

4AT-112

AUTOMATIC TRANSMISSION

Drive Pinion Shaft Assembly

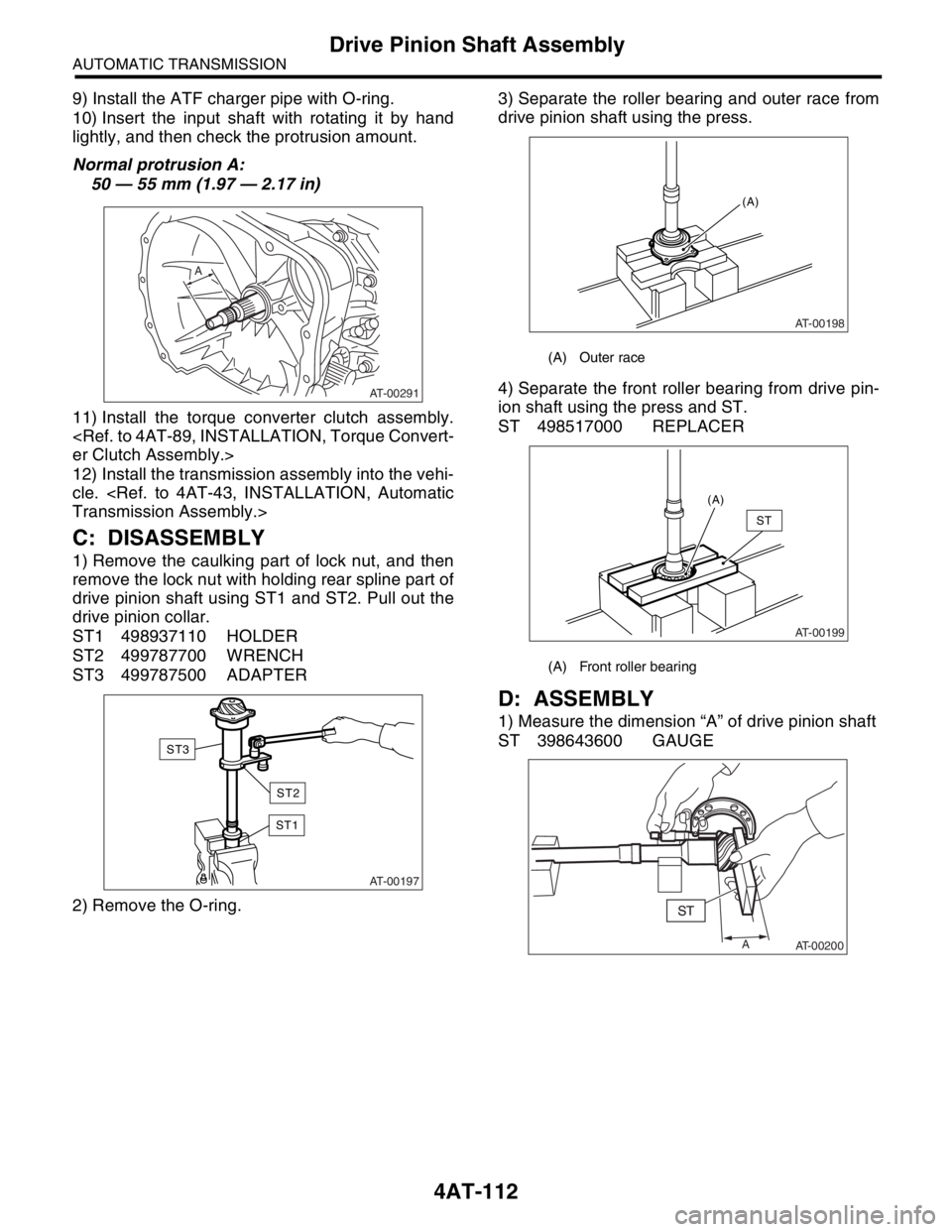

9) Install the ATF charger pipe with O-ring.

10) Insert the input shaft with rotating it by hand

lightly, and then check the protrusion amount.

Normal protrusion A:

50 — 55 mm (1.97 — 2.17 in)

11) Install the torque converter clutch assembly.

12) Install the transmission assembly into the vehi-

cle.

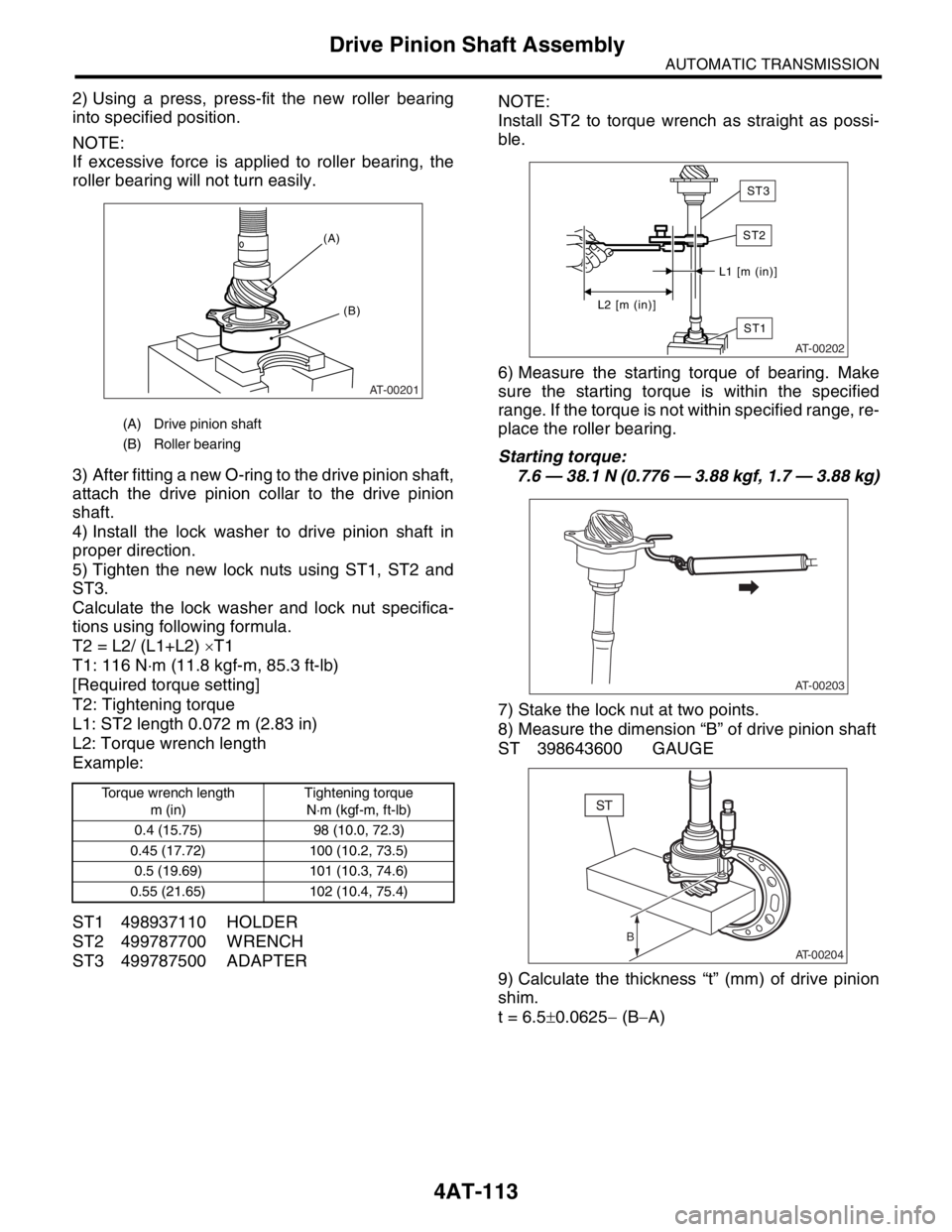

C: DISASSEMBLY

1) Remove the caulking part of lock nut, and then

remove the lock nut with holding rear spline part of

drive pinion shaft using ST1 and ST2. Pull out the

drive pinion collar.

ST1 498937110 HOLDER

ST2 499787700 WRENCH

ST3 499787500 ADAPTER

2) Remove the O-ring.3) Separate the roller bearing and outer race from

drive pinion shaft using the press.

4) Separate the front roller bearing from drive pin-

ion shaft using the press and ST.

ST 498517000 REPLACER

D: ASSEMBLY

1) Measure the dimension “A” of drive pinion shaft

ST 398643600 GAUGE

AT-00291

A

AT-00197

ST1

ST3

ST2

(A) Outer race

(A) Front roller bearing

AT-00198

(A)

AT-00199

(A)

ST

A

AT-00200

Page 2427 of 2870

4AT-113

AUTOMATIC TRANSMISSION

Drive Pinion Shaft Assembly

2) Using a press, press-fit the new roller bearing

into specified position.

NOTE:

If excessive force is applied to roller bearing, the

roller bearing will not turn easily.

3) After fitting a new O-ring to the drive pinion shaft,

attach the drive pinion collar to the drive pinion

shaft.

4) Install the lock washer to drive pinion shaft in

proper direction.

5) Tighten the new lock nuts using ST1, ST2 and

ST3.

Calculate the lock washer and lock nut specifica-

tions using following formula.

T2 = L2/ (L1+L2) ×T1

T1: 116 N⋅m (11.8 kgf-m, 85.3 ft-lb)

[Required torque setting]

T2: Tightening torque

L1: ST2 length 0.072 m (2.83 in)

L2: Torque wrench length

Example:

ST1 498937110 HOLDER

ST2 499787700 WRENCH

ST3 499787500 ADAPTERNOTE:

Install ST2 to torque wrench as straight as possi-

ble.

6) Measure the starting torque of bearing. Make

sure the starting torque is within the specified

range. If the torque is not within specified range, re-

place the roller bearing.

Starting torque:

7.6 — 38.1 N (0.776 — 3.88 kgf, 1.7 — 3.88 kg)

7) Stake the lock nut at two points.

8) Measure the dimension “B” of drive pinion shaft

ST 398643600 GAUGE

9) Calculate the thickness “t” (mm) of drive pinion

shim.

t = 6.5±0.0625− (B−A)

(A) Drive pinion shaft

(B) Roller bearing

Torque wrench length

m (in)Tightening torque

N⋅m (kgf-m, ft-lb)

0.4 (15.75) 98 (10.0, 72.3)

0.45 (17.72) 100 (10.2, 73.5)

0.5 (19.69) 101 (10.3, 74.6)

0.55 (21.65) 102 (10.4, 75.4)

AT-00201

(B)

(A)

ST1

AT-00202

L1 [m (in)]

L2 [m (in)]

ST2

ST3

AT-00203

B

AT-00204

Page 2430 of 2870

4AT-116

AUTOMATIC TRANSMISSION

Drive Pinion Shaft Assembly

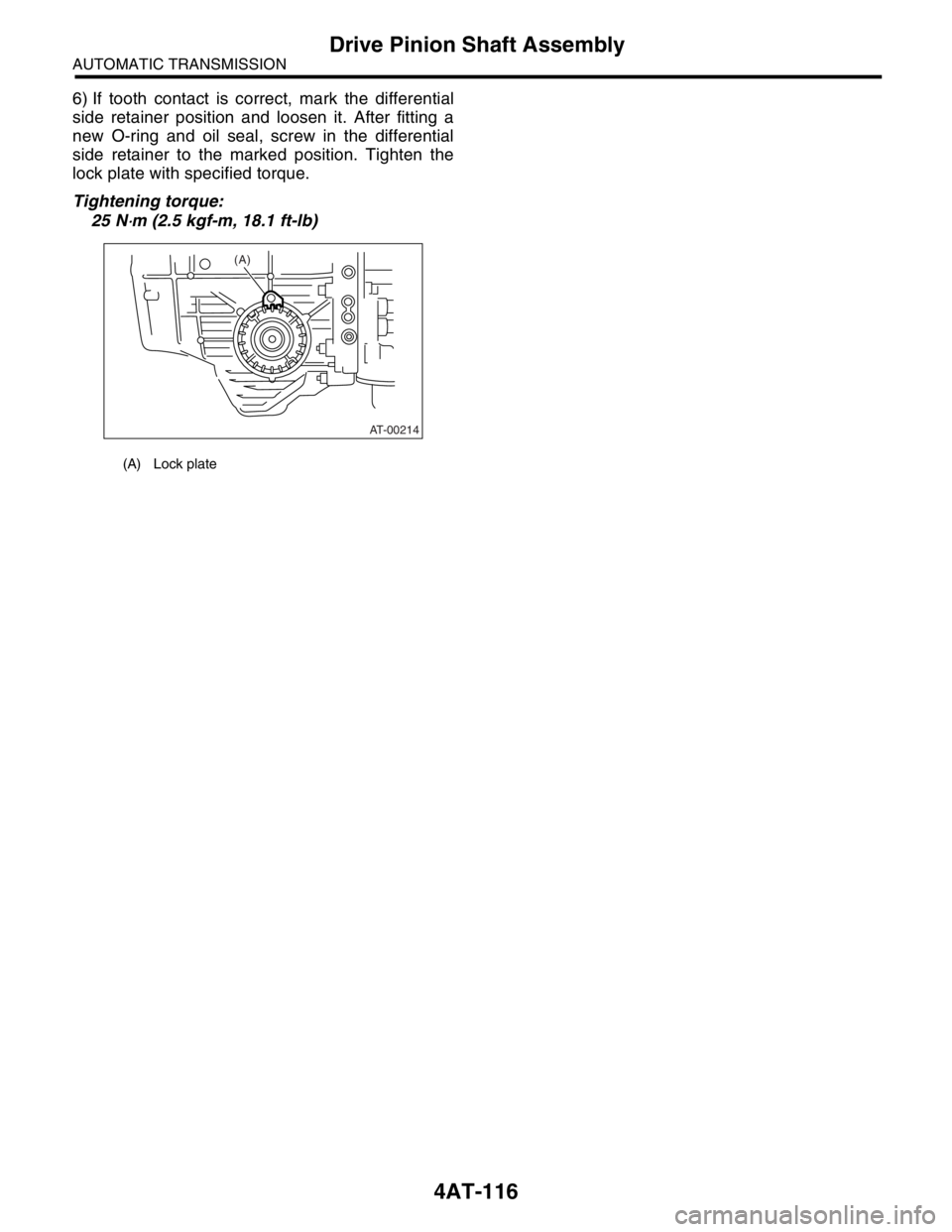

6) If tooth contact is correct, mark the differential

side retainer position and loosen it. After fitting a

new O-ring and oil seal, screw in the differential

side retainer to the marked position. Tighten the

lock plate with specified torque.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(A) Lock plate

AT-00214

(A)

Page 2431 of 2870

4AT-117

AUTOMATIC TRANSMISSION

Front Differential

37.Front Differential

A: REMOVAL

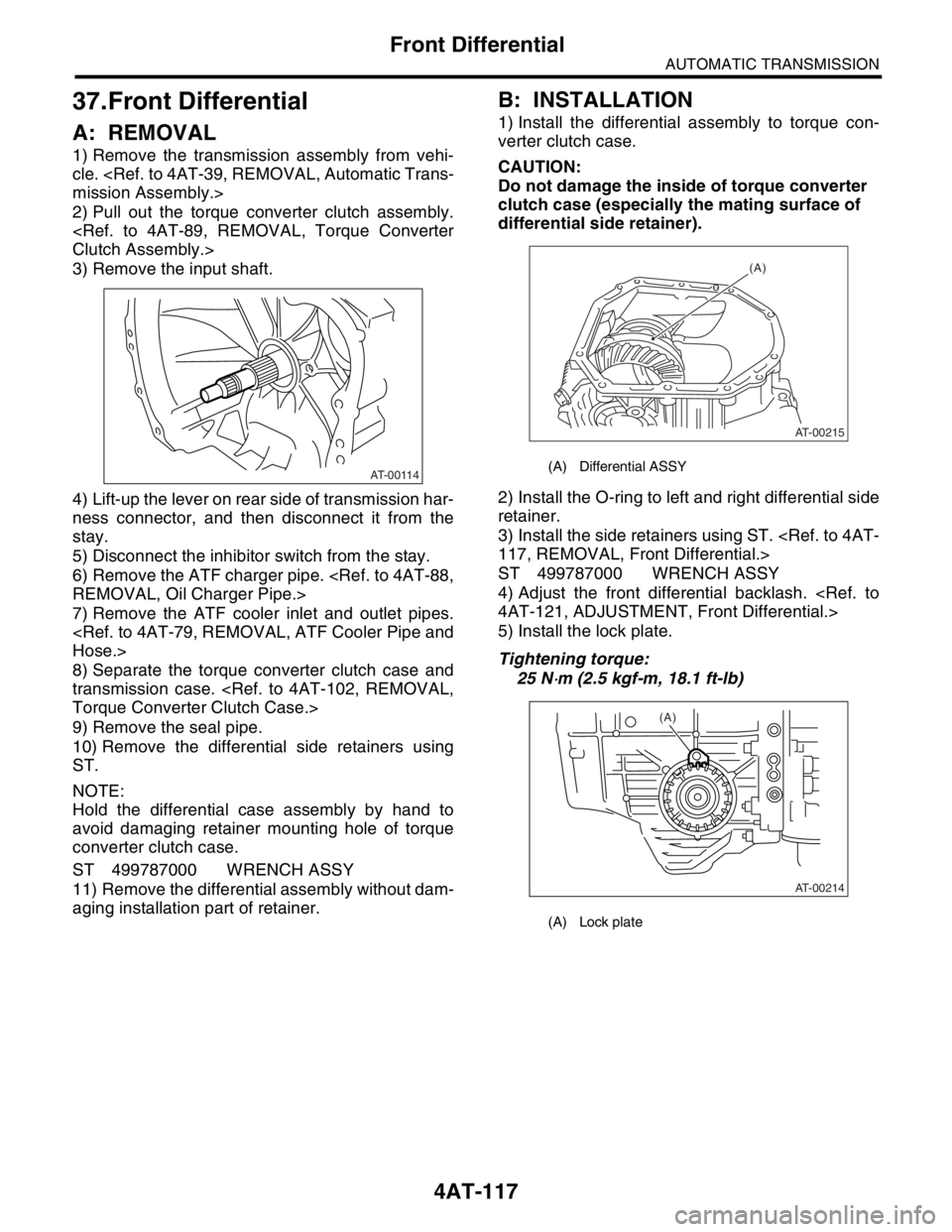

1) Remove the transmission assembly from vehi-

cle.

2) Pull out the torque converter clutch assembly.

3) Remove the input shaft.

4) Lift-up the lever on rear side of transmission har-

ness connector, and then disconnect it from the

stay.

5) Disconnect the inhibitor switch from the stay.

6) Remove the ATF charger pipe.

7) Remove the ATF cooler inlet and outlet pipes.

8) Separate the torque converter clutch case and

transmission case.

9) Remove the seal pipe.

10) Remove the differential side retainers using

ST.

NOTE:

Hold the differential case assembly by hand to

avoid damaging retainer mounting hole of torque

converter clutch case.

ST 499787000 WRENCH ASSY

11) Remove the differential assembly without dam-

aging installation part of retainer.

B: INSTALLATION

1) Install the differential assembly to torque con-

verter clutch case.

CAUTION:

Do not damage the inside of torque converter

clutch case (especially the mating surface of

differential side retainer).

2) Install the O-ring to left and right differential side

retainer.

3) Install the side retainers using ST.

ST 499787000 WRENCH ASSY

4) Adjust the front differential backlash.

5) Install the lock plate.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

AT-00114(A) Differential ASSY

(A) Lock plate

AT-00215

(A)

AT-00214

(A)

Page 2436 of 2870

4AT-122

AUTOMATIC TRANSMISSION

Front Differential

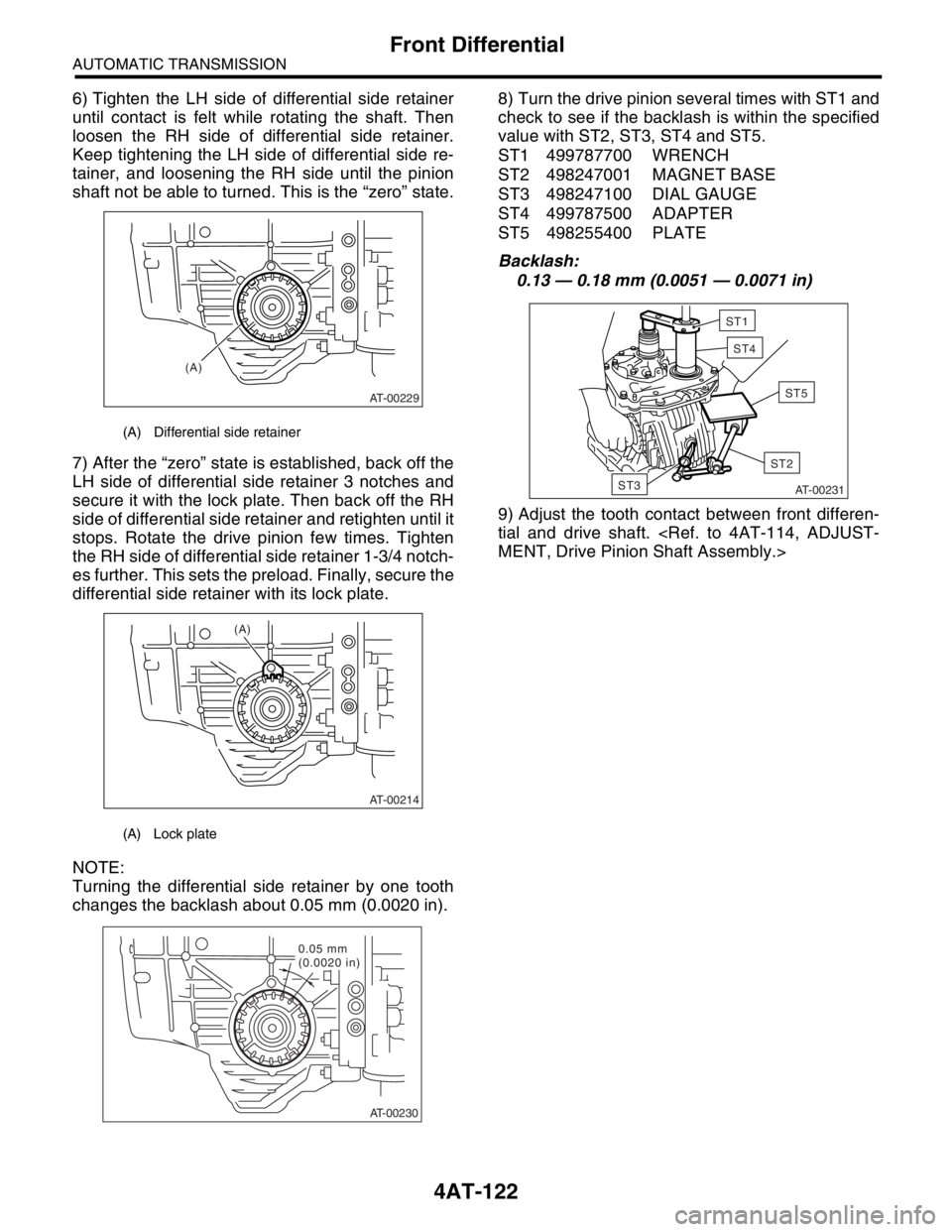

6) Tighten the LH side of differential side retainer

until contact is felt while rotating the shaft. Then

loosen the RH side of differential side retainer.

Keep tightening the LH side of differential side re-

tainer, and loosening the RH side until the pinion

shaft not be able to turned. This is the “zero” state.

7) After the “zero” state is established, back off the

LH side of differential side retainer 3 notches and

secure it with the lock plate. Then back off the RH

side of differential side retainer and retighten until it

stops. Rotate the drive pinion few times. Tighten

the RH side of differential side retainer 1-3/4 notch-

es further. This sets the preload. Finally, secure the

differential side retainer with its lock plate.

NOTE:

Turning the differential side retainer by one tooth

changes the backlash about 0.05 mm (0.0020 in).8) Turn the drive pinion several times with ST1 and

check to see if the backlash is within the specified

value with ST2, ST3, ST4 and ST5.

ST1 499787700 WRENCH

ST2 498247001 MAGNET BASE

ST3 498247100 DIAL GAUGE

ST4 499787500 ADAPTER

ST5 498255400 PLATE

Backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

9) Adjust the tooth contact between front differen-

tial and drive shaft.

(A) Differential side retainer

(A) Lock plate

AT-00229

(A)

AT-00214

(A)

0.05 mm

(0.0020 in)

AT-00230

AT-00231

ST5

ST3

ST2

ST1

ST4

Page 2454 of 2870

4AT-140

AUTOMATIC TRANSMISSION

AT Main Case

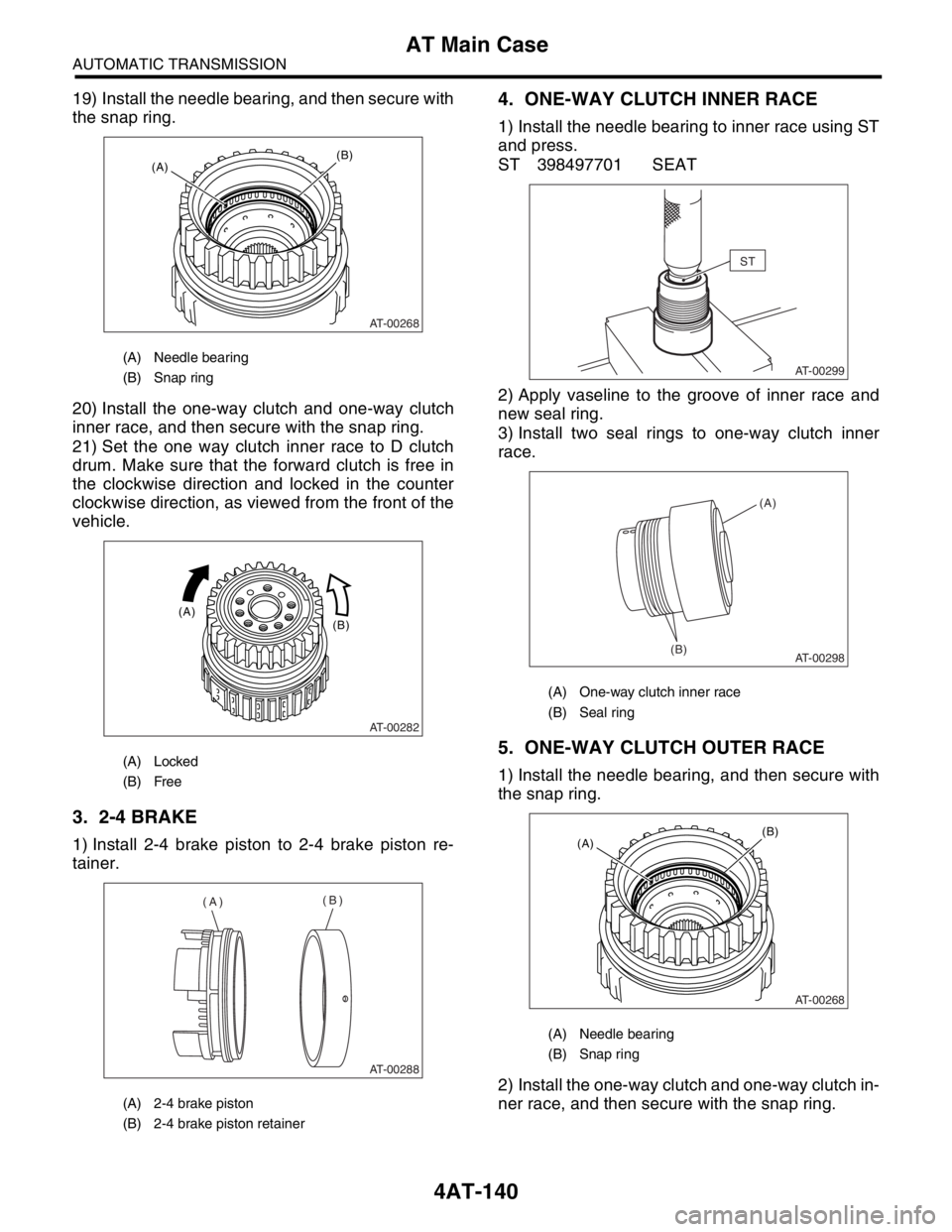

19) Install the needle bearing, and then secure with

the snap ring.

20) Install the one-way clutch and one-way clutch

inner race, and then secure with the snap ring.

21) Set the one way clutch inner race to D clutch

drum. Make sure that the forward clutch is free in

the clockwise direction and locked in the counter

clockwise direction, as viewed from the front of the

vehicle.

3. 2-4 BRAKE

1) Install 2-4 brake piston to 2-4 brake piston re-

tainer.

4. ONE-WAY CLUTCH INNER RACE

1) Install the needle bearing to inner race using ST

and press.

ST 398497701 SEAT

2) Apply vaseline to the groove of inner race and

new seal ring.

3) Install two seal rings to one-way clutch inner

race.

5. ONE-WAY CLUTCH OUTER RACE

1) Install the needle bearing, and then secure with

the snap ring.

2) Install the one-way clutch and one-way clutch in-

ner race, and then secure with the snap ring.

(A) Needle bearing

(B) Snap ring

(A) Locked

(B) Free

(A) 2-4 brake piston

(B) 2-4 brake piston retainer

AT-00268

(B)(A)

AT-00282

(B) (A)

AT-00288

(A)(B)

(A) One-way clutch inner race

(B) Seal ring

(A) Needle bearing

(B) Snap ring

ST

AT-00299

AT-00298(B)(A)

AT-00268

(B)(A)