SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2551 of 2870

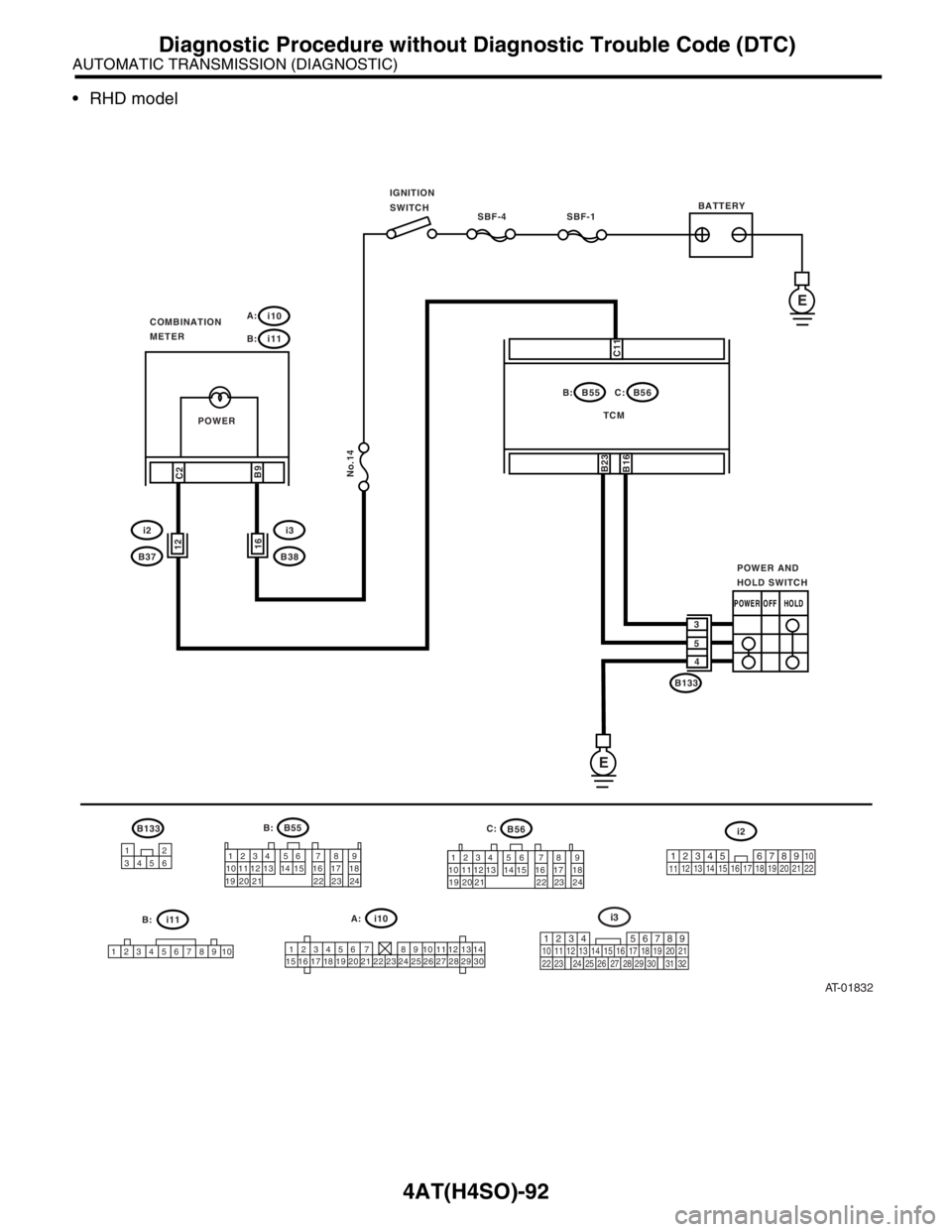

4AT(H4SO)-92

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

RHD model

AT-01832

SBF-4 SBF-1

No.14

IGNITION

SWITCH

i10BATTERY

A:

B55

TCM B:B56

B133 C: B:

i11

C2

B9

C11

B23

COMBINATION

METER

E

E

B55

B56

1234 56 7 8 9

10 11 12 13 14 15 16 17 18

19 20 21 22 23 241234 5 6 7 8 9

10 11 12 13 14 15 16 17 18

19 20 21 22 23 24

123456 7 891011121314

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

i10

12345678910

i11

B16

POWER AND

HOLD SWITCH

3

5

4 POWER

POWER OFF

i2

34 12 8910

1112 13 14 15 16 17 18 19 20 21 22567

B133

12

3456

i3

B3816i2

B3712

219

32

i3

1234

5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

HOLD

C:

A: B:

B:

Page 2552 of 2870

4AT(H4SO)-93

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

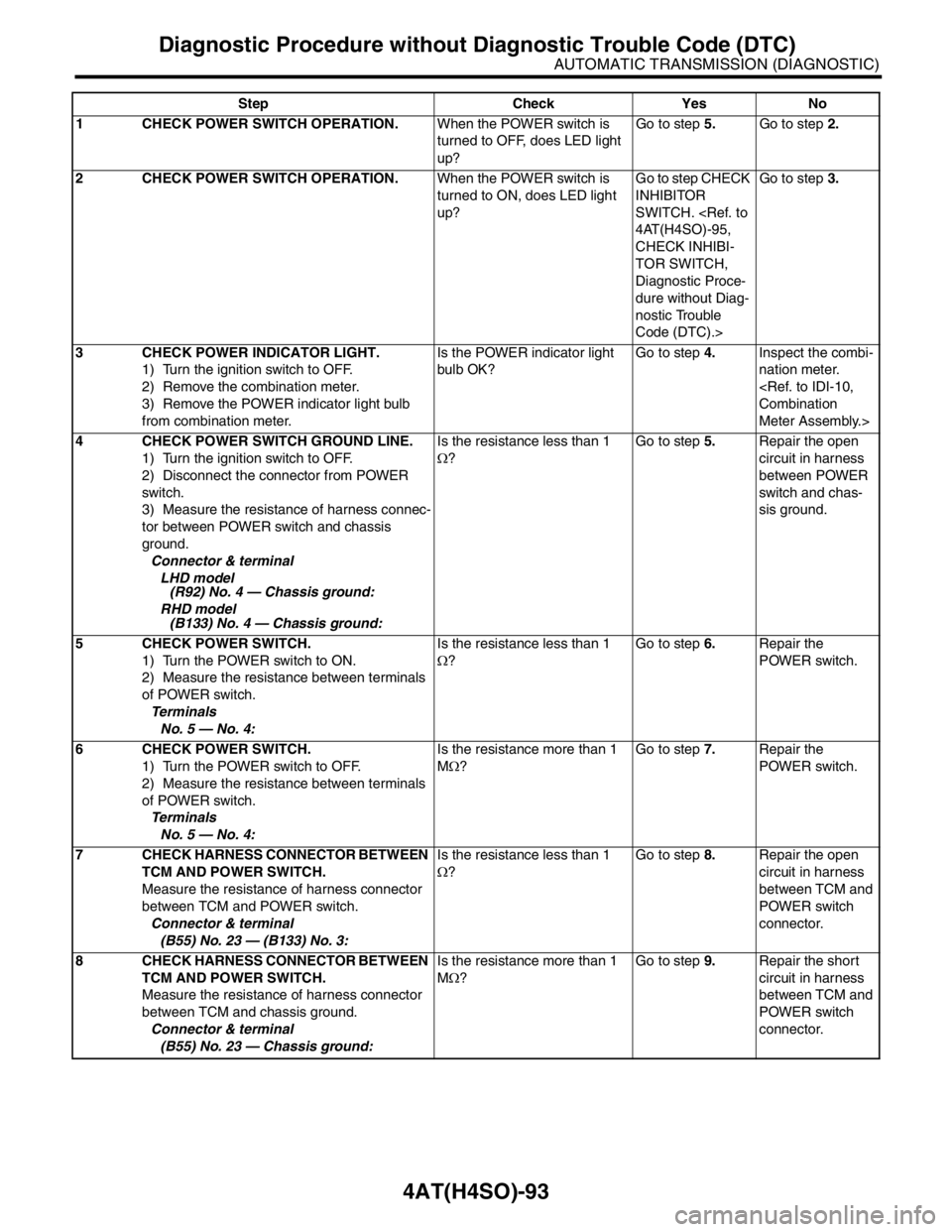

Step Check Yes No

1 CHECK POWER SWITCH OPERATION.When the POWER switch is

turned to OFF, does LED light

up?Go to step 5.Go to step 2.

2 CHECK POWER SWITCH OPERATION.When the POWER switch is

turned to ON, does LED light

up?Go to step CHECK

INHIBITOR

SWITCH.

CHECK INHIBI-

TOR SWITCH,

Diagnostic Proce-

dure without Diag-

nostic Trouble

Code (DTC).>Go to step 3.

3 CHECK POWER INDICATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Remove the POWER indicator light bulb

from combination meter.Is the POWER indicator light

bulb OK?Go to step 4.Inspect the combi-

nation meter.

Meter Assembly.>

4 CHECK POWER SWITCH GROUND LINE.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from POWER

switch.

3) Measure the resistance of harness connec-

tor between POWER switch and chassis

ground.

Connector & terminal

LHD model

(R92) No. 4 — Chassis ground:

RHD model

(B133) No. 4 — Chassis ground:Is the resistance less than 1

Ω?Go to step 5.Repair the open

circuit in harness

between POWER

switch and chas-

sis ground.

5 CHECK POWER SWITCH.

1) Turn the POWER switch to ON.

2) Measure the resistance between terminals

of POWER switch.

Te r m i n a l s

No. 5 — No. 4:Is the resistance less than 1

Ω?Go to step 6.Repair the

POWER switch.

6 CHECK POWER SWITCH.

1) Turn the POWER switch to OFF.

2) Measure the resistance between terminals

of POWER switch.

Te r m i n a l s

No. 5 — No. 4:Is the resistance more than 1

MΩ?Go to step 7.Repair the

POWER switch.

7 CHECK HARNESS CONNECTOR BETWEEN

TCM AND POWER SWITCH.

Measure the resistance of harness connector

between TCM and POWER switch.

Connector & terminal

(B55) No. 23 — (B133) No. 3:Is the resistance less than 1

Ω?Go to step 8.Repair the open

circuit in harness

between TCM and

POWER switch

connector.

8 CHECK HARNESS CONNECTOR BETWEEN

TCM AND POWER SWITCH.

Measure the resistance of harness connector

between TCM and chassis ground.

Connector & terminal

(B55) No. 23 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 9.Repair the short

circuit in harness

between TCM and

POWER switch

connector.

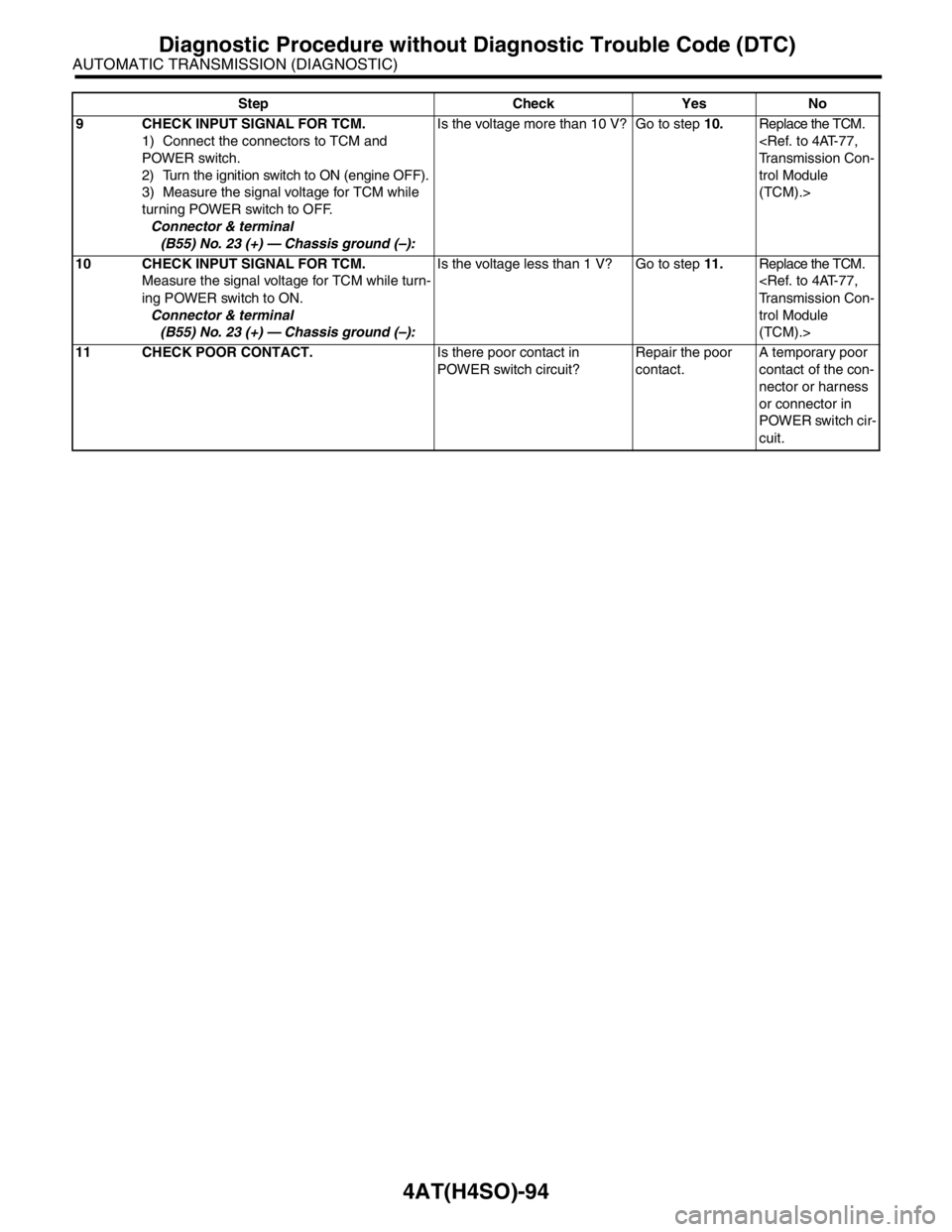

Page 2553 of 2870

4AT(H4SO)-94

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

9 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connectors to TCM and

POWER switch.

2) Turn the ignition switch to ON (engine OFF).

3) Measure the signal voltage for TCM while

turning POWER switch to OFF.

Connector & terminal

(B55) No. 23 (+) — Chassis ground (–):Is the voltage more than 10 V? Go to step 10.Replace the TCM.

trol Module

(TCM).>

10 CHECK INPUT SIGNAL FOR TCM.

Measure the signal voltage for TCM while turn-

ing POWER switch to ON.

Connector & terminal

(B55) No. 23 (+) — Chassis ground (–):Is the voltage less than 1 V? Go to step 11.Replace the TCM.

trol Module

(TCM).>

11 CHECK POOR CONTACT.Is there poor contact in

POWER switch circuit?Repair the poor

contact.A temporary poor

contact of the con-

nector or harness

or connector in

POWER switch cir-

cuit. Step Check Yes No

Page 2554 of 2870

4AT(H4SO)-95

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

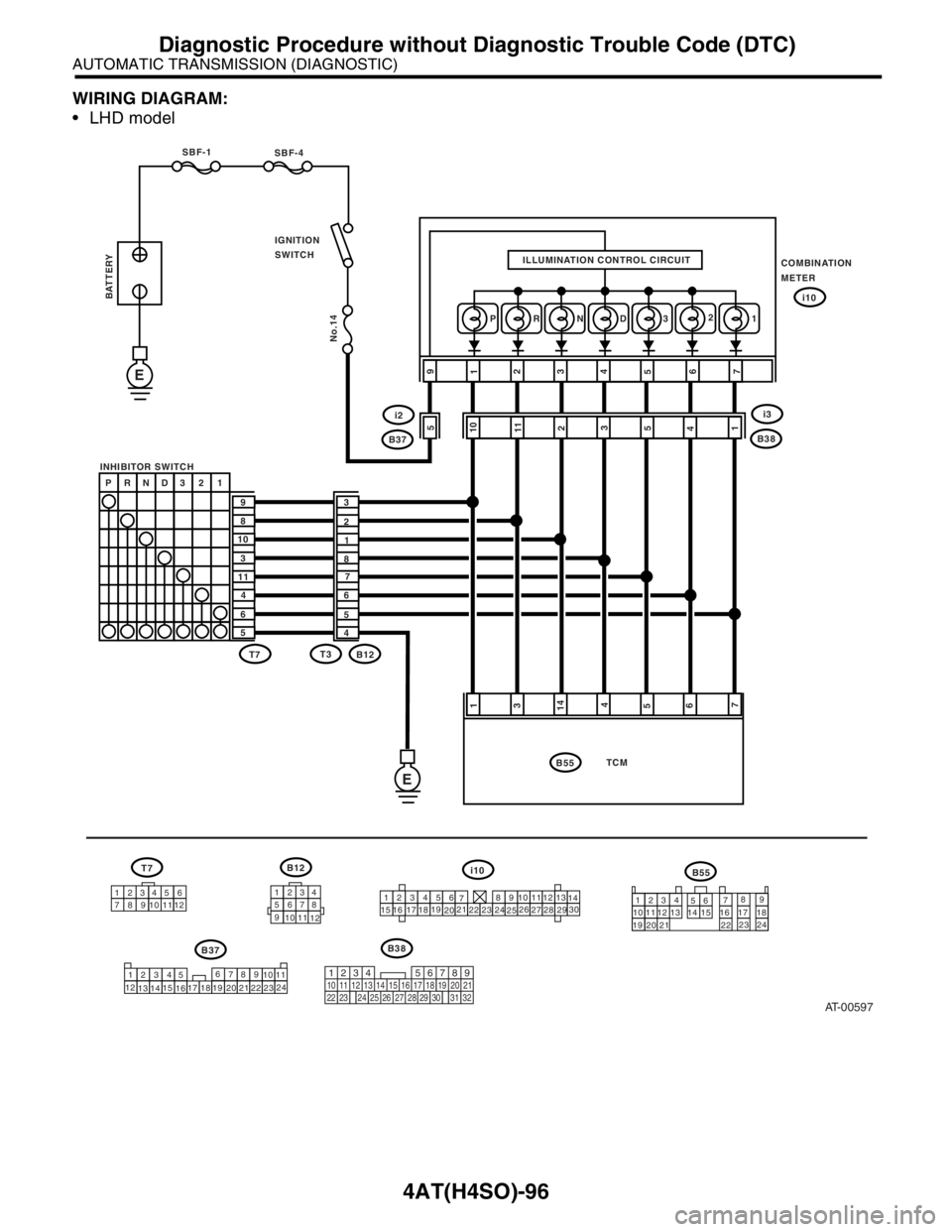

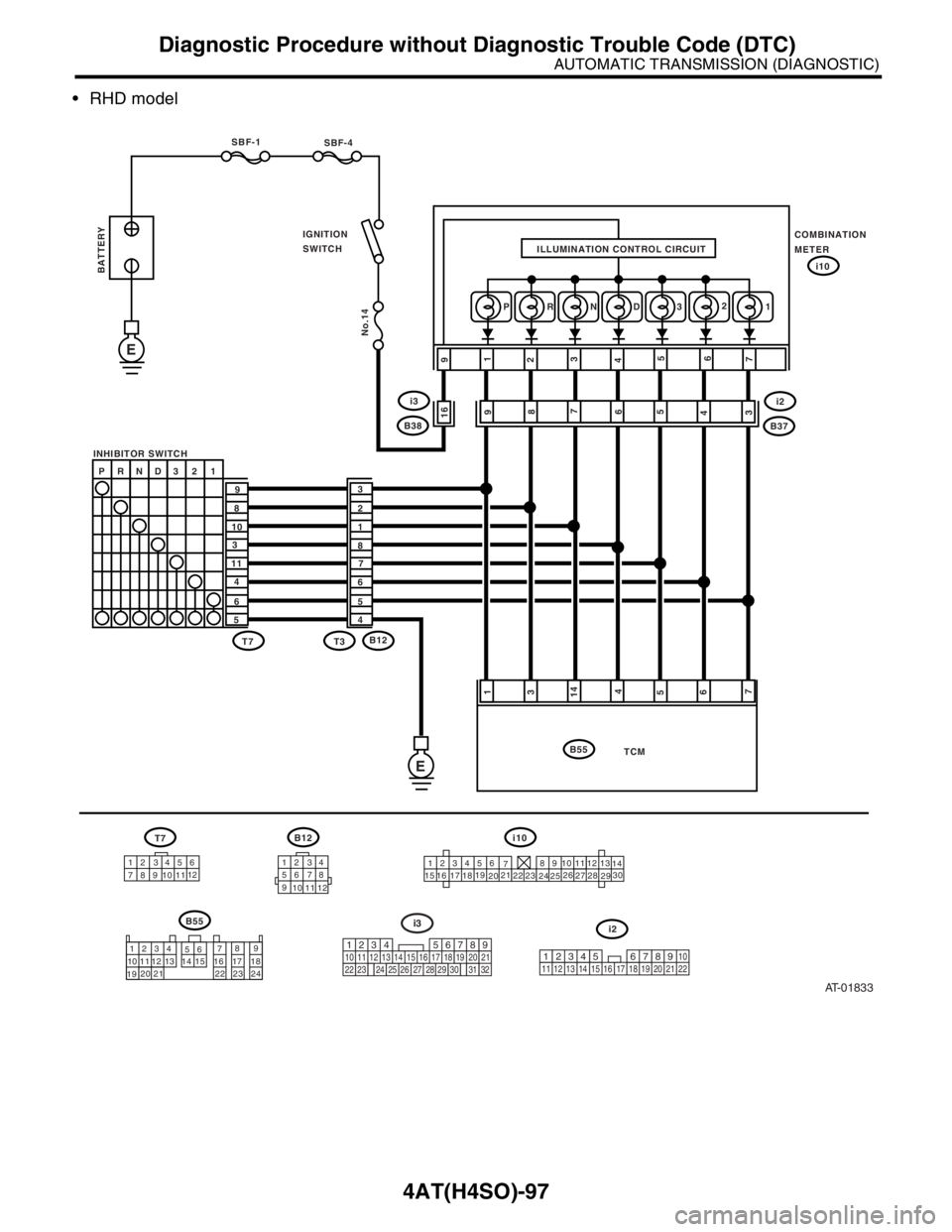

G: CHECK INHIBITOR SWITCH

DETECTING CONDITION:

The input signal circuit of inhibitor switch is open or shorted.

TROUBLE SYMPTOM:

Shift characteristics are erroneous.

Engine brake is not effected when selector lever is in “3” range.

Engine brake is not effected when selector lever is in “2” range.

Engine brake is not effected when selector lever is in “1” range.

Page 2555 of 2870

4AT(H4SO)-96

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

WIRING DIAGRAM:

LHD model

AT-00597

BATTERY

SBF-4

COMBINATION

METER IGNITION

SWITCH SBF-1

INHIBITOR SWITCH

E

E

1

3

14

4

5

6

7

10

11

2

3

5

4

1

PRND321

9

8

10

3

11

4

6

53

2

1

8

7

6

5

4

T7

T7B12

B55

B55

B37T3

B12

1234

1234 56

56

12345 7897

78

89

9 10 1112

10 11

10

1112

13

12

1314 15

141516

1617 18

17 18192021

19 20212223 24

22 2324

1 2

i3

B38

TCM

i10

i10

1234

5678

9

10

11

12

No.14

19

2

3

4

5

6

7

ILLUMINATION CONTROL CIRCUIT

3 D N R P

5i2

B37

123456

78 9 10 1112

13

14

15 16 17

1819

2021

2223

24

2526

2728

2930

219

32

1234 5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

B38

6

Page 2556 of 2870

4AT(H4SO)-97

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

RHD model

AT-01833

BATTERY

SBF-4

COMBINATION

METER IGNITION

SWITCH SBF-1

INHIBITOR SWITCH

E

E

1

3

14

4

5

6

7

98

7

6

5

4

3

P RND3 2 1

9

8

10

3

11

4

6

53

2

1

8

7

6

5

4

T7

T7B12

B55

B55T3B12

12 34

123456

56 789

789 10 1112

10 1112

13 14 15 16 17 18

192021

2223 24

1 2

TCM

i10

12 34

56 78

9

10

11

12

No.14

ILLUMINATION CONTROL CIRCUIT

3 D N R P

9

3

4

5

6

7 21

123456

78 9 10 1112

13

14

15 16 17

1819

2021

2223

24

2526

2728

2930

i10

219

32

i3

1234

5610 11 12 13 14 15716

23 3019 20

22 26 27 28 29817

24 3118

25

16i3

B38i2

B37

i2

12345 678910

11

1219 20 21

13 14 15 1617

18 22

Page 2557 of 2870

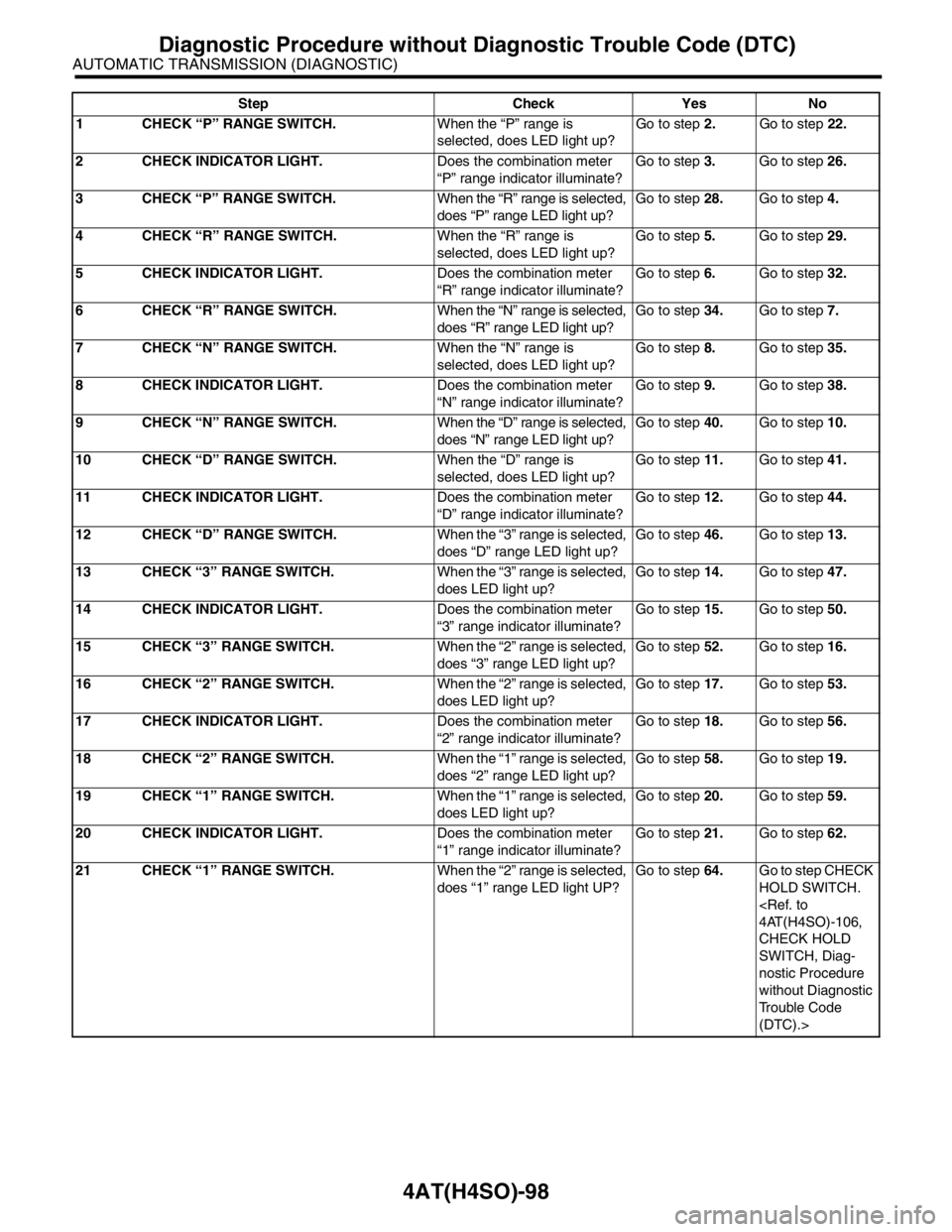

4AT(H4SO)-98

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

Step Check Yes No

1 CHECK “P” RANGE SWITCH.When the “P” range is

selected, does LED light up?Go to step 2.Go to step 22.

2 CHECK INDICATOR LIGHT.Does the combination meter

“P” range indicator illuminate?Go to step 3.Go to step 26.

3 CHECK “P” RANGE SWITCH.When the “R” range is selected,

does “P” range LED light up?Go to step 28.Go to step 4.

4 CHECK “R” RANGE SWITCH.When the “R” range is

selected, does LED light up?Go to step 5.Go to step 29.

5 CHECK INDICATOR LIGHT.Does the combination meter

“R” range indicator illuminate?Go to step 6.Go to step 32.

6 CHECK “R” RANGE SWITCH.When the “N” range is selected,

does “R” range LED light up?Go to step 34.Go to step 7.

7 CHECK “N” RANGE SWITCH.When the “N” range is

selected, does LED light up?Go to step 8.Go to step 35.

8 CHECK INDICATOR LIGHT.Does the combination meter

“N” range indicator illuminate?Go to step 9.Go to step 38.

9 CHECK “N” RANGE SWITCH.When the “D” range is selected,

does “N” range LED light up?Go to step 40.Go to step 10.

10 CHECK “D” RANGE SWITCH.When the “D” range is

selected, does LED light up?Go to step 11.Go to step 41.

11 CHECK INDICATOR LIGHT.Does the combination meter

“D” range indicator illuminate?Go to step 12.Go to step 44.

12 CHECK “D” RANGE SWITCH.When the “3” range is selected,

does “D” range LED light up?Go to step 46.Go to step 13.

13 CHECK “3” RANGE SWITCH.When the “3” range is selected,

does LED light up?Go to step 14.Go to step 47.

14 CHECK INDICATOR LIGHT.Does the combination meter

“3” range indicator illuminate?Go to step 15.Go to step 50.

15 CHECK “3” RANGE SWITCH.When the “2” range is selected,

does “3” range LED light up?Go to step 52.Go to step 16.

16 CHECK “2” RANGE SWITCH.When the “2” range is selected,

does LED light up?Go to step 17.Go to step 53.

17 CHECK INDICATOR LIGHT.Does the combination meter

“2” range indicator illuminate?Go to step 18.Go to step 56.

18 CHECK “2” RANGE SWITCH.When the “1” range is selected,

does “2” range LED light up?Go to step 58.Go to step 19.

19 CHECK “1” RANGE SWITCH.When the “1” range is selected,

does LED light up?Go to step 20.Go to step 59.

20 CHECK INDICATOR LIGHT.Does the combination meter

“1” range indicator illuminate?Go to step 21.Go to step 62.

21 CHECK “1” RANGE SWITCH.When the “2” range is selected,

does “1” range LED light UP?Go to step 64.Go to step CHECK

HOLD SWITCH.

CHECK HOLD

SWITCH, Diag-

nostic Procedure

without Diagnostic

Trouble Code

(DTC).>

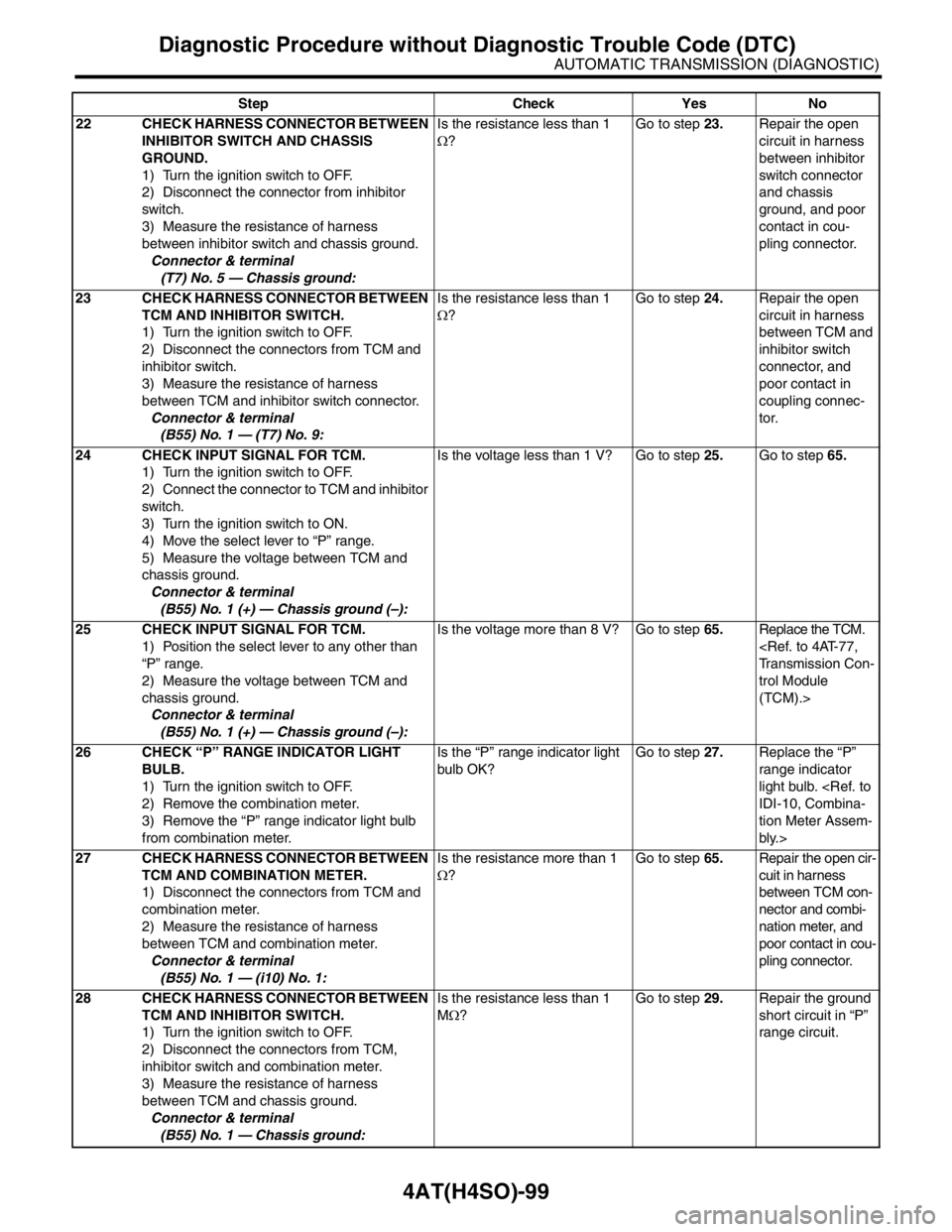

Page 2558 of 2870

4AT(H4SO)-99

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

22 CHECK HARNESS CONNECTOR BETWEEN

INHIBITOR SWITCH AND CHASSIS

GROUND.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from inhibitor

switch.

3) Measure the resistance of harness

between inhibitor switch and chassis ground.

Connector & terminal

(T7) No. 5 — Chassis ground:Is the resistance less than 1

Ω?Go to step 23.Repair the open

circuit in harness

between inhibitor

switch connector

and chassis

ground, and poor

contact in cou-

pling connector.

23 CHECK HARNESS CONNECTOR BETWEEN

TCM AND INHIBITOR SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

inhibitor switch.

3) Measure the resistance of harness

between TCM and inhibitor switch connector.

Connector & terminal

(B55) No. 1 — (T7) No. 9:Is the resistance less than 1

Ω?Go to step 24.Repair the open

circuit in harness

between TCM and

inhibitor switch

connector, and

poor contact in

coupling connec-

tor.

24 CHECK INPUT SIGNAL FOR TCM.

1) Turn the ignition switch to OFF.

2) Connect the connector to TCM and inhibitor

switch.

3) Turn the ignition switch to ON.

4) Move the select lever to “P” range.

5) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 1 (+) — Chassis ground (–):Is the voltage less than 1 V? Go to step 25.Go to step 65.

25 CHECK INPUT SIGNAL FOR TCM.

1) Position the select lever to any other than

“P” range.

2) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 1 (+) — Chassis ground (–):Is the voltage more than 8 V? Go to step 65.Replace the TCM.

trol Module

(TCM).>

26 CHECK “P” RANGE INDICATOR LIGHT

BULB.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Remove the “P” range indicator light bulb

from combination meter.Is the “P” range indicator light

bulb OK?Go to step 27.Replace the “P”

range indicator

light bulb.

tion Meter Assem-

bly.>

27 CHECK HARNESS CONNECTOR BETWEEN

TCM AND COMBINATION METER.

1) Disconnect the connectors from TCM and

combination meter.

2) Measure the resistance of harness

between TCM and combination meter.

Connector & terminal

(B55) No. 1 — (i10) No. 1:Is the resistance more than 1

Ω?Go to step 65.Repair the open cir-

cuit in harness

between TCM con-

nector and combi-

nation meter, and

poor contact in cou-

pling connector.

28 CHECK HARNESS CONNECTOR BETWEEN

TCM AND INHIBITOR SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM,

inhibitor switch and combination meter.

3) Measure the resistance of harness

between TCM and chassis ground.

Connector & terminal

(B55) No. 1 — Chassis ground:Is the resistance less than 1

MΩ?Go to step 29.Repair the ground

short circuit in “P”

range circuit. Step Check Yes No

Page 2559 of 2870

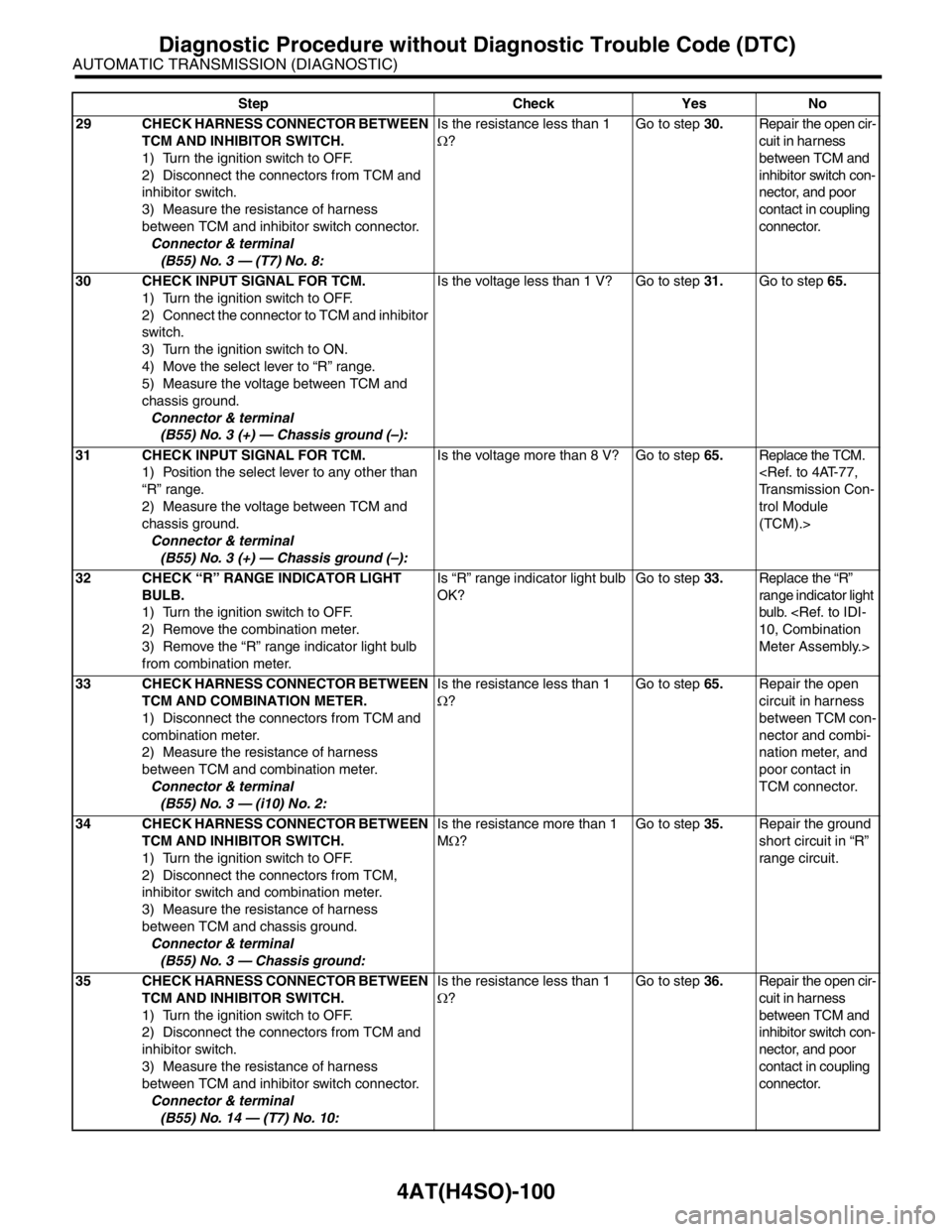

4AT(H4SO)-100

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

29 CHECK HARNESS CONNECTOR BETWEEN

TCM AND INHIBITOR SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

inhibitor switch.

3) Measure the resistance of harness

between TCM and inhibitor switch connector.

Connector & terminal

(B55) No. 3 — (T7) No. 8:Is the resistance less than 1

Ω?Go to step 30.Repair the open cir-

cuit in harness

between TCM and

inhibitor switch con-

nector, and poor

contact in coupling

connector.

30 CHECK INPUT SIGNAL FOR TCM.

1) Turn the ignition switch to OFF.

2) Connect the connector to TCM and inhibitor

switch.

3) Turn the ignition switch to ON.

4) Move the select lever to “R” range.

5) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 3 (+) — Chassis ground (–):Is the voltage less than 1 V? Go to step 31.Go to step 65.

31 CHECK INPUT SIGNAL FOR TCM.

1) Position the select lever to any other than

“R” range.

2) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 3 (+) — Chassis ground (–):Is the voltage more than 8 V? Go to step 65.Replace the TCM.

trol Module

(TCM).>

32 CHECK “R” RANGE INDICATOR LIGHT

BULB.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Remove the “R” range indicator light bulb

from combination meter.Is “R” range indicator light bulb

OK?Go to step 33.Replace the “R”

range indicator light

bulb.

Meter Assembly.>

33 CHECK HARNESS CONNECTOR BETWEEN

TCM AND COMBINATION METER.

1) Disconnect the connectors from TCM and

combination meter.

2) Measure the resistance of harness

between TCM and combination meter.

Connector & terminal

(B55) No. 3 — (i10) No. 2:Is the resistance less than 1

Ω?Go to step 65.Repair the open

circuit in harness

between TCM con-

nector and combi-

nation meter, and

poor contact in

TCM connector.

34 CHECK HARNESS CONNECTOR BETWEEN

TCM AND INHIBITOR SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM,

inhibitor switch and combination meter.

3) Measure the resistance of harness

between TCM and chassis ground.

Connector & terminal

(B55) No. 3 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 35.Repair the ground

short circuit in “R”

range circuit.

35 CHECK HARNESS CONNECTOR BETWEEN

TCM AND INHIBITOR SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

inhibitor switch.

3) Measure the resistance of harness

between TCM and inhibitor switch connector.

Connector & terminal

(B55) No. 14 — (T7) No. 10:Is the resistance less than 1

Ω?Go to step 36.Repair the open cir-

cuit in harness

between TCM and

inhibitor switch con-

nector, and poor

contact in coupling

connector. Step Check Yes No

Page 2560 of 2870

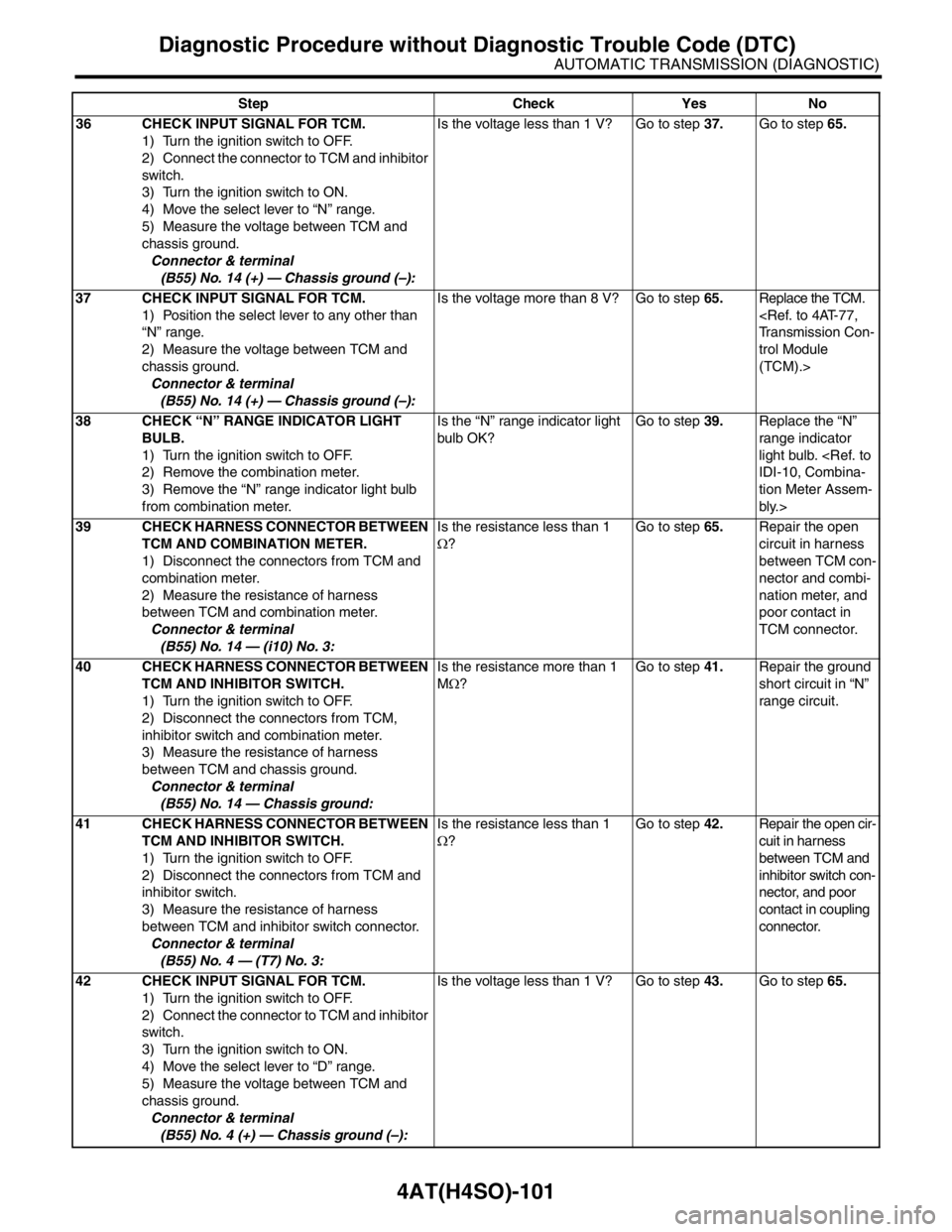

4AT(H4SO)-101

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

36 CHECK INPUT SIGNAL FOR TCM.

1) Turn the ignition switch to OFF.

2) Connect the connector to TCM and inhibitor

switch.

3) Turn the ignition switch to ON.

4) Move the select lever to “N” range.

5) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 14 (+) — Chassis ground (–):Is the voltage less than 1 V? Go to step 37.Go to step 65.

37 CHECK INPUT SIGNAL FOR TCM.

1) Position the select lever to any other than

“N” range.

2) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 14 (+) — Chassis ground (–):Is the voltage more than 8 V? Go to step 65.Replace the TCM.

trol Module

(TCM).>

38 CHECK “N” RANGE INDICATOR LIGHT

BULB.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Remove the “N” range indicator light bulb

from combination meter.Is the “N” range indicator light

bulb OK?Go to step 39.Replace the “N”

range indicator

light bulb.

tion Meter Assem-

bly.>

39 CHECK HARNESS CONNECTOR BETWEEN

TCM AND COMBINATION METER.

1) Disconnect the connectors from TCM and

combination meter.

2) Measure the resistance of harness

between TCM and combination meter.

Connector & terminal

(B55) No. 14 — (i10) No. 3:Is the resistance less than 1

Ω?Go to step 65.Repair the open

circuit in harness

between TCM con-

nector and combi-

nation meter, and

poor contact in

TCM connector.

40 CHECK HARNESS CONNECTOR BETWEEN

TCM AND INHIBITOR SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM,

inhibitor switch and combination meter.

3) Measure the resistance of harness

between TCM and chassis ground.

Connector & terminal

(B55) No. 14 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 41.Repair the ground

short circuit in “N”

range circuit.

41 CHECK HARNESS CONNECTOR BETWEEN

TCM AND INHIBITOR SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

inhibitor switch.

3) Measure the resistance of harness

between TCM and inhibitor switch connector.

Connector & terminal

(B55) No. 4 — (T7) No. 3:Is the resistance less than 1

Ω?Go to step 42.Repair the open cir-

cuit in harness

between TCM and

inhibitor switch con-

nector, and poor

contact in coupling

connector.

42 CHECK INPUT SIGNAL FOR TCM.

1) Turn the ignition switch to OFF.

2) Connect the connector to TCM and inhibitor

switch.

3) Turn the ignition switch to ON.

4) Move the select lever to “D” range.

5) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 4 (+) — Chassis ground (–):Is the voltage less than 1 V? Go to step 43.Go to step 65. Step Check Yes No