SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2851 of 2870

CL-25

CLUTCH SYSTEM

Operating Cylinder

B: INSTALLATION

1) Apply grease (SUNLIGHT 2: Part No.

003602010) to the contact point of the release lever

and operating cylinder.

2) Install in the reverse order of removal.

Before installing the operating cylinder, apply

grease (SUNLIGHT 2: Part No. 003602010) to con-

tact point of the release lever and operating cylin-

der.

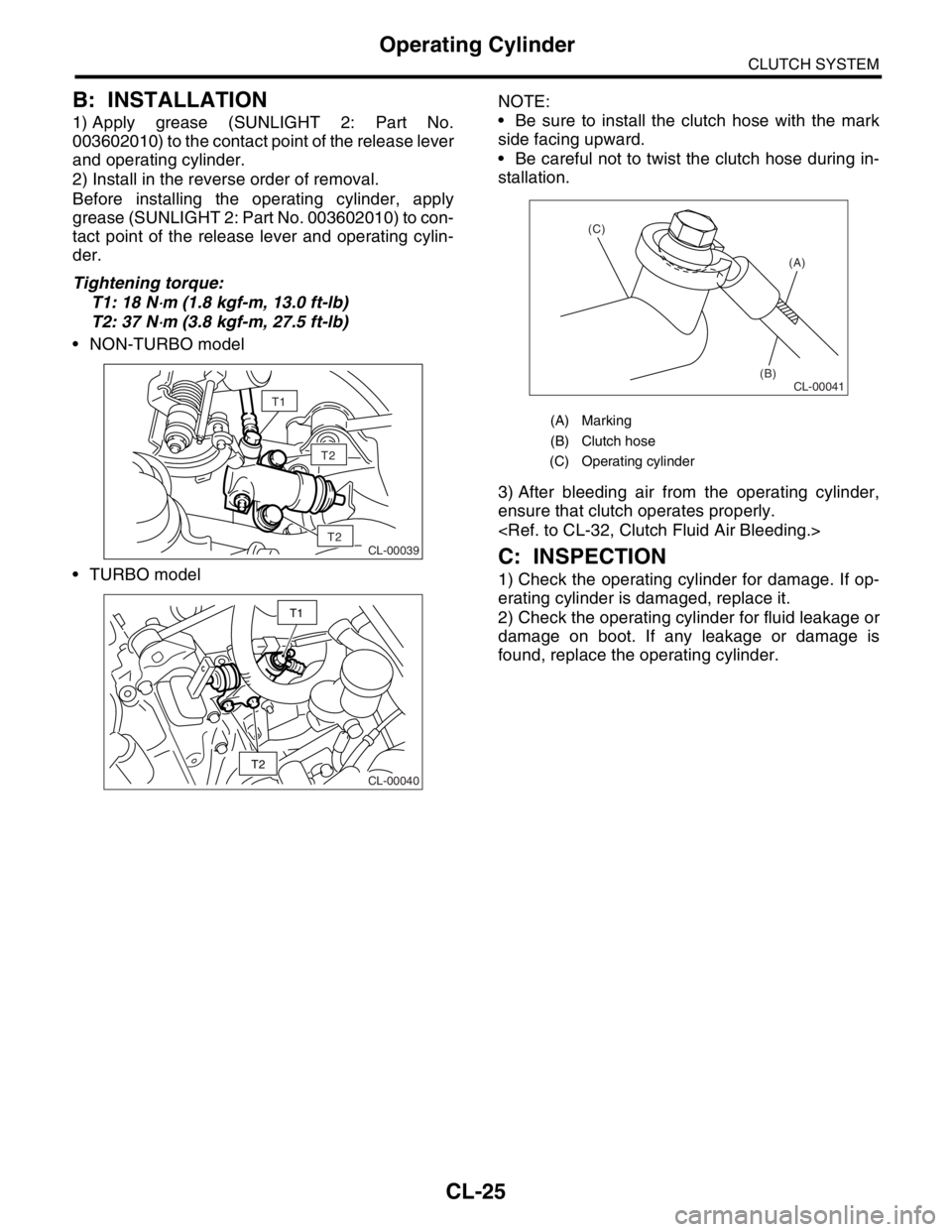

Tightening torque:

T1: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

T2: 37 N

⋅m (3.8 kgf-m, 27.5 ft-lb)

NON-TURBO model

TURBO modelNOTE:

Be sure to install the clutch hose with the mark

side facing upward.

Be careful not to twist the clutch hose during in-

stallation.

3) After bleeding air from the operating cylinder,

ensure that clutch operates properly.

C: INSPECTION

1) Check the operating cylinder for damage. If op-

erating cylinder is damaged, replace it.

2) Check the operating cylinder for fluid leakage or

damage on boot. If any leakage or damage is

found, replace the operating cylinder.

T2

CL-00039T2

T1

CL-00040

T2

T1

(A) Marking

(B) Clutch hose

(C) Operating cylinder

CL-00041

(A)

(B) (C)

Page 2852 of 2870

CL-26

CLUTCH SYSTEM

Master Cylinder

6. Master Cylinder

A: REMOVAL

1) Thoroughly drain the brake fluid from reservoir

tank.

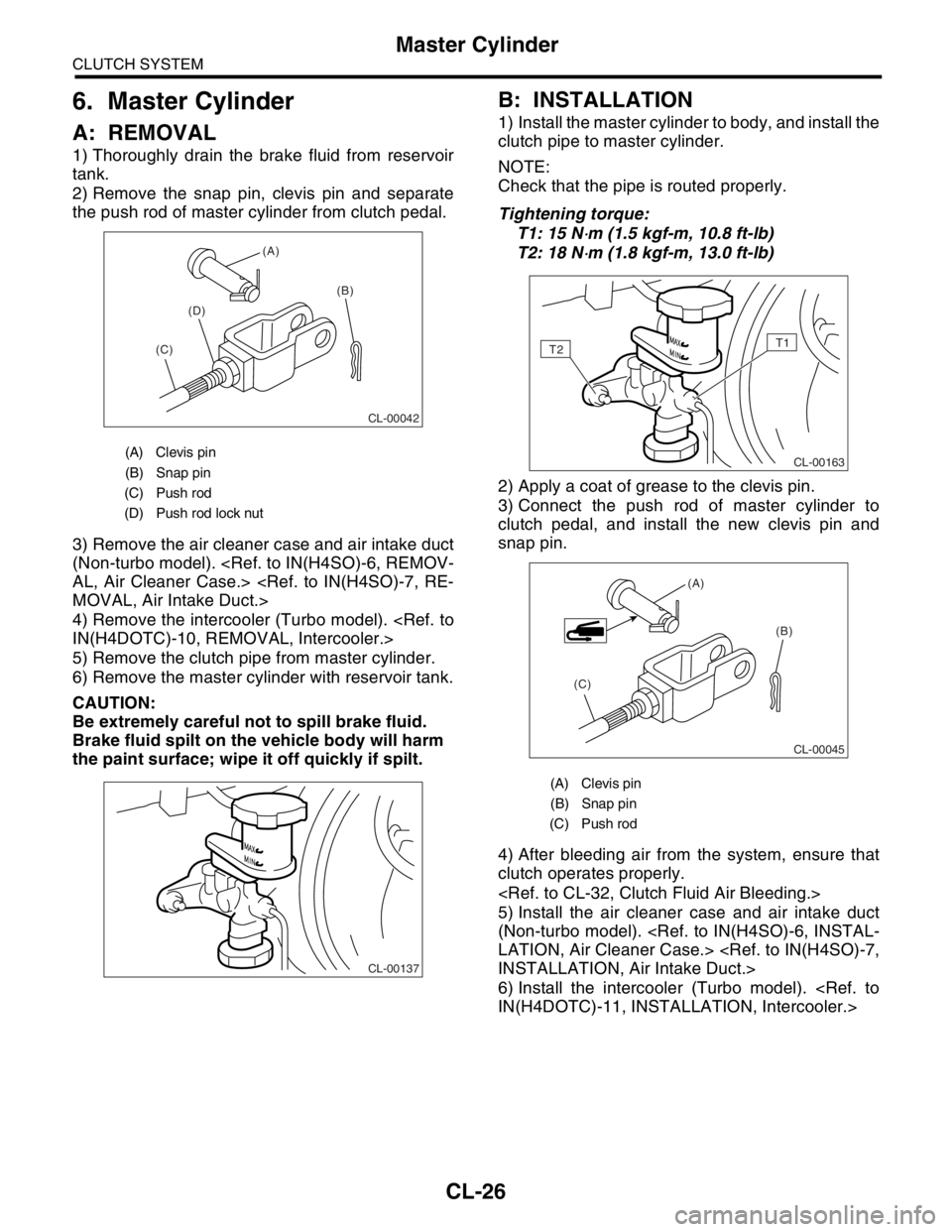

2) Remove the snap pin, clevis pin and separate

the push rod of master cylinder from clutch pedal.

3) Remove the air cleaner case and air intake duct

(Non-turbo model).

4) Remove the intercooler (Turbo model).

5) Remove the clutch pipe from master cylinder.

6) Remove the master cylinder with reservoir tank.

CAUTION:

Be extremely careful not to spill brake fluid.

Brake fluid spilt on the vehicle body will harm

the paint surface; wipe it off quickly if spilt.

B: INSTALLATION

1) Install the master cylinder to body, and install the

clutch pipe to master cylinder.

NOTE:

Check that the pipe is routed properly.

Tightening torque:

T1: 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

T2: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

2) Apply a coat of grease to the clevis pin.

3) Connect the push rod of master cylinder to

clutch pedal, and install the new clevis pin and

snap pin.

4) After bleeding air from the system, ensure that

clutch operates properly.

5) Install the air cleaner case and air intake duct

(Non-turbo model).

6) Install the intercooler (Turbo model).

(A) Clevis pin

(B) Snap pin

(C) Push rod

(D) Push rod lock nut

CL-00042

(A)

(B)

(C)(D)

CL-00137

(A) Clevis pin

(B) Snap pin

(C) Push rod

CL-00163

T2T1

CL-00045

(A)

(B)

(C)

Page 2853 of 2870

CL-27

CLUTCH SYSTEM

Master Cylinder

C: DISASSEMBLY

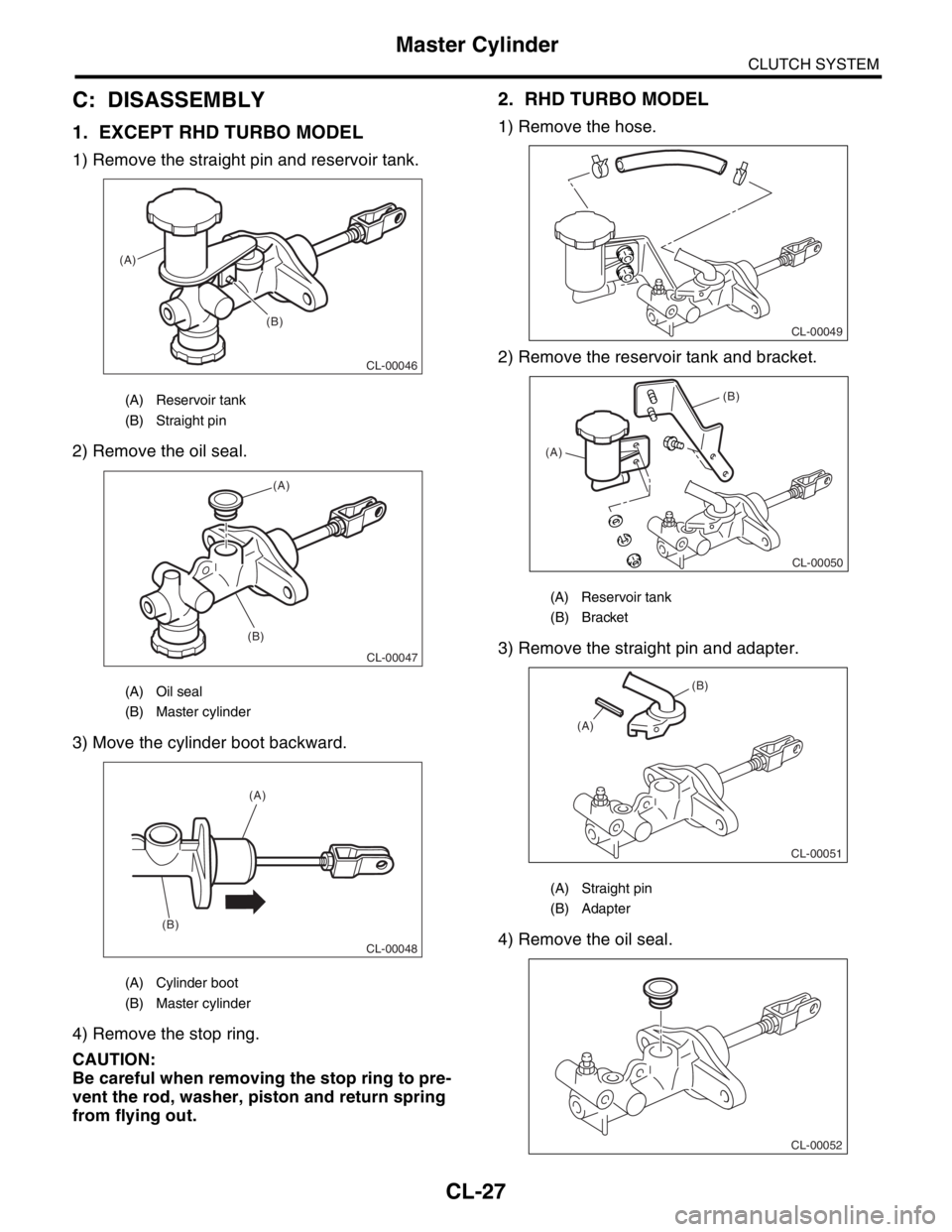

1. EXCEPT RHD TURBO MODEL

1) Remove the straight pin and reservoir tank.

2) Remove the oil seal.

3) Move the cylinder boot backward.

4) Remove the stop ring.

CAUTION:

Be careful when removing the stop ring to pre-

vent the rod, washer, piston and return spring

from flying out.

2. RHD TURBO MODEL

1) Remove the hose.

2) Remove the reservoir tank and bracket.

3) Remove the straight pin and adapter.

4) Remove the oil seal.

(A) Reservoir tank

(B) Straight pin

(A) Oil seal

(B) Master cylinder

(A) Cylinder boot

(B) Master cylinder

CL-00046

(A)

(B)

CL-00047

(A)

(B)

CL-00048

(A)

(B)

(A) Reservoir tank

(B) Bracket

(A) Straight pin

(B) Adapter

CL-00049

CL-00050

(A)(B)

CL-00051 (A)(B)

CL-00052

Page 2854 of 2870

CL-28

CLUTCH SYSTEM

Master Cylinder

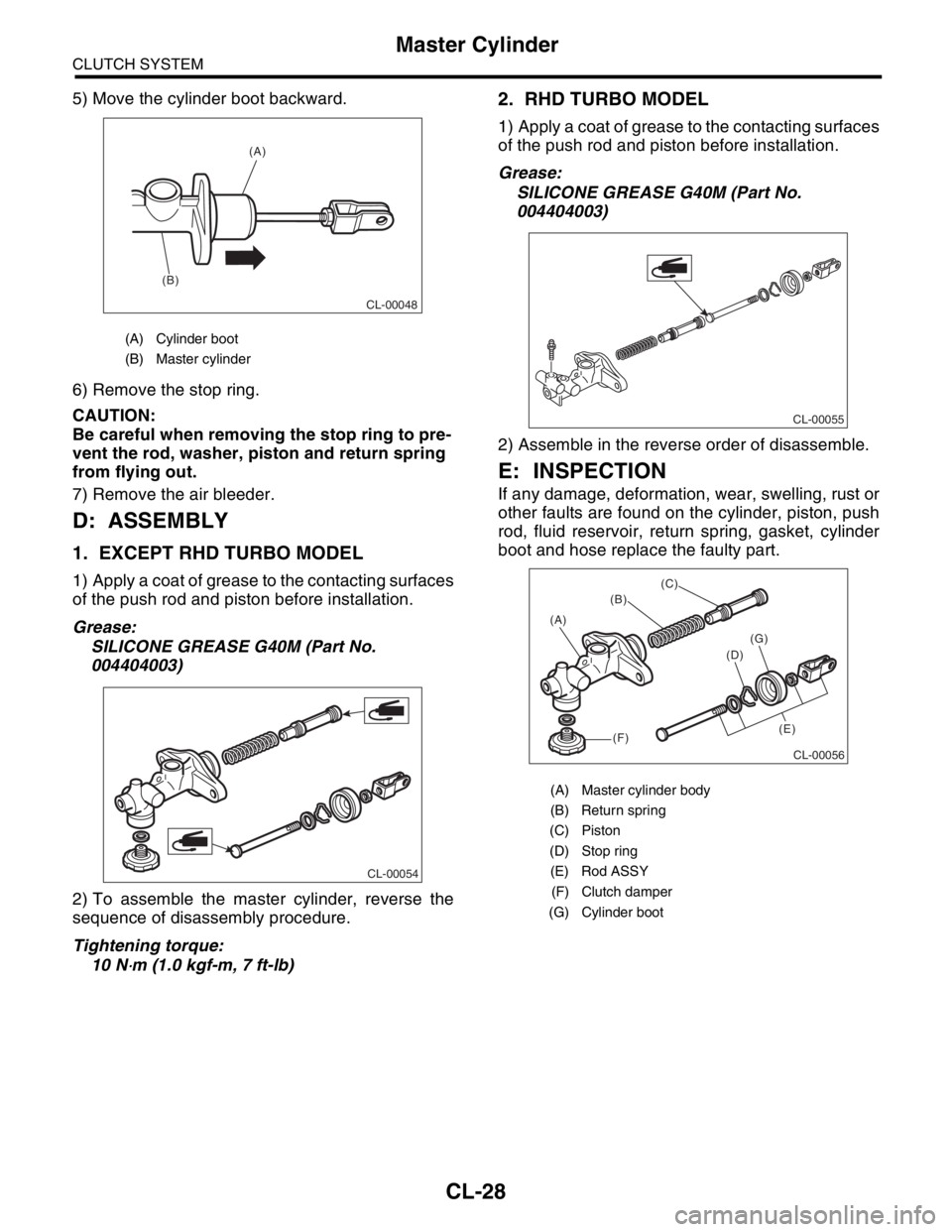

5) Move the cylinder boot backward.

6) Remove the stop ring.

CAUTION:

Be careful when removing the stop ring to pre-

vent the rod, washer, piston and return spring

from flying out.

7) Remove the air bleeder.

D: ASSEMBLY

1. EXCEPT RHD TURBO MODEL

1) Apply a coat of grease to the contacting surfaces

of the push rod and piston before installation.

Grease:

SILICONE GREASE G40M (Part No.

004404003)

2) To assemble the master cylinder, reverse the

sequence of disassembly procedure.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7 ft-lb)

2. RHD TURBO MODEL

1) Apply a coat of grease to the contacting surfaces

of the push rod and piston before installation.

Grease:

SILICONE GREASE G40M (Part No.

004404003)

2) Assemble in the reverse order of disassemble.

E: INSPECTION

If any damage, deformation, wear, swelling, rust or

other faults are found on the cylinder, piston, push

rod, fluid reservoir, return spring, gasket, cylinder

boot and hose replace the faulty part.

(A) Cylinder boot

(B) Master cylinder

CL-00048

(A)

(B)

CL-00054

(A) Master cylinder body

(B) Return spring

(C) Piston

(D) Stop ring

(E) Rod ASSY

(F) Clutch damper

(G) Cylinder boot

CL-00055

CL-00056

(B)

(C)

(D)

(E) (A)

(F)

(G)

Page 2855 of 2870

CL-29

CLUTCH SYSTEM

Clutch Pipe and Hose

7. Clutch Pipe and Hose

A: REMOVAL

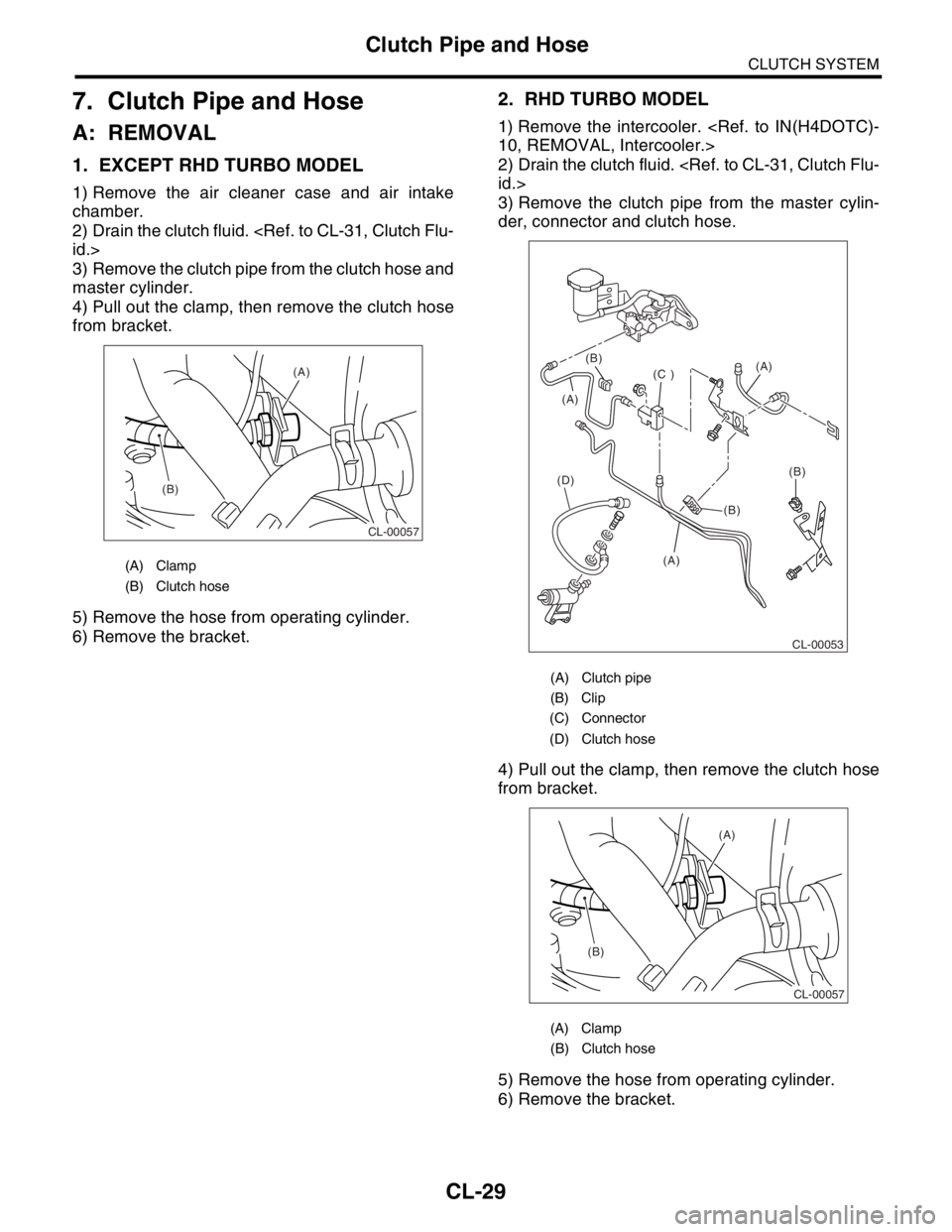

1. EXCEPT RHD TURBO MODEL

1) Remove the air cleaner case and air intake

chamber.

2) Drain the clutch fluid.

3) Remove the clutch pipe from the clutch hose and

master cylinder.

4) Pull out the clamp, then remove the clutch hose

from bracket.

5) Remove the hose from operating cylinder.

6) Remove the bracket.

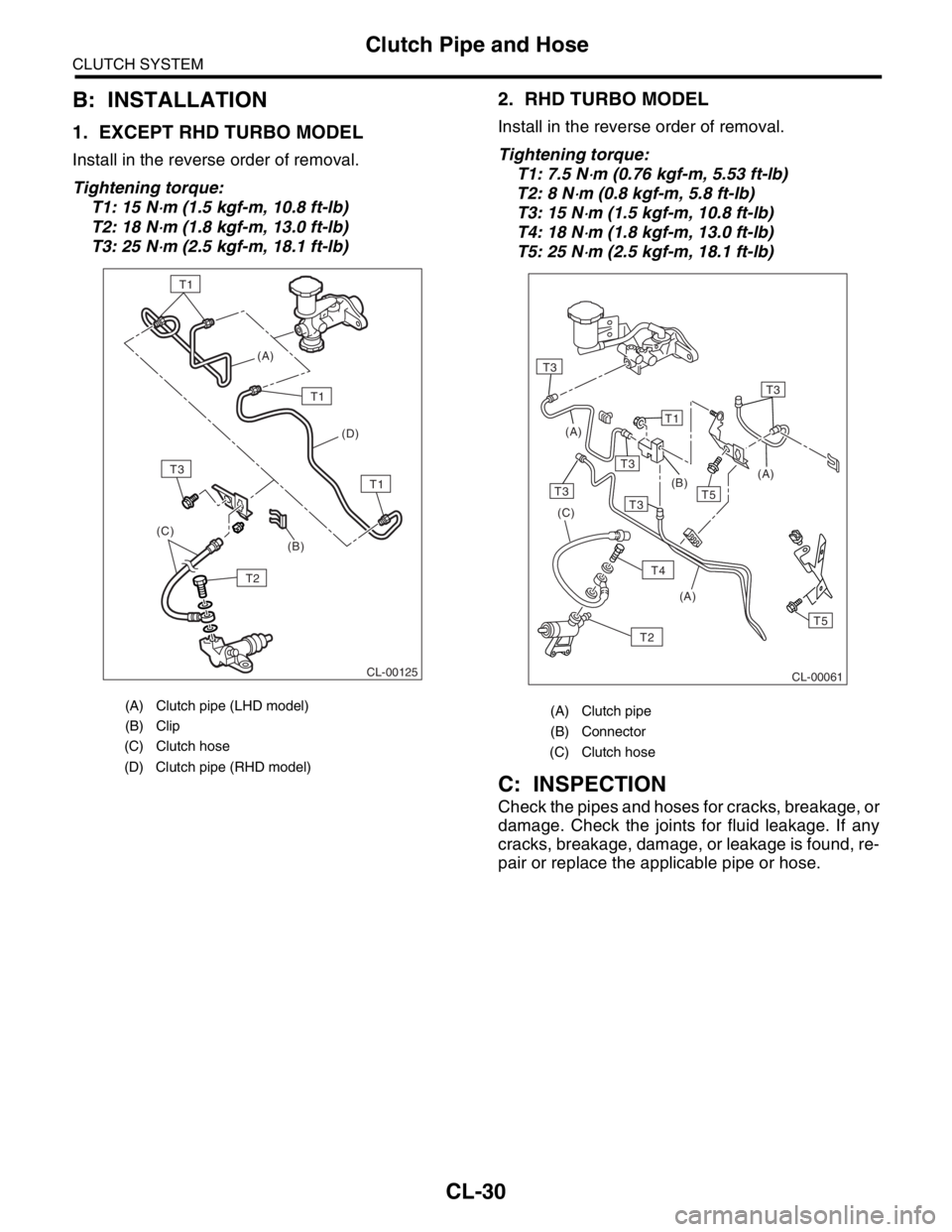

2. RHD TURBO MODEL

1) Remove the intercooler.

2) Drain the clutch fluid.

3) Remove the clutch pipe from the master cylin-

der, connector and clutch hose.

4) Pull out the clamp, then remove the clutch hose

from bracket.

5) Remove the hose from operating cylinder.

6) Remove the bracket.

(A) Clamp

(B) Clutch hose

CL-00057

(A)

(B)

(A) Clutch pipe

(B) Clip

(C) Connector

(D) Clutch hose

(A) Clamp

(B) Clutch hose

CL-00053

(A)

(B)(B) (B)

(A)

(D)

(A)

(C )

CL-00057

(A)

(B)

Page 2856 of 2870

CL-30

CLUTCH SYSTEM

Clutch Pipe and Hose

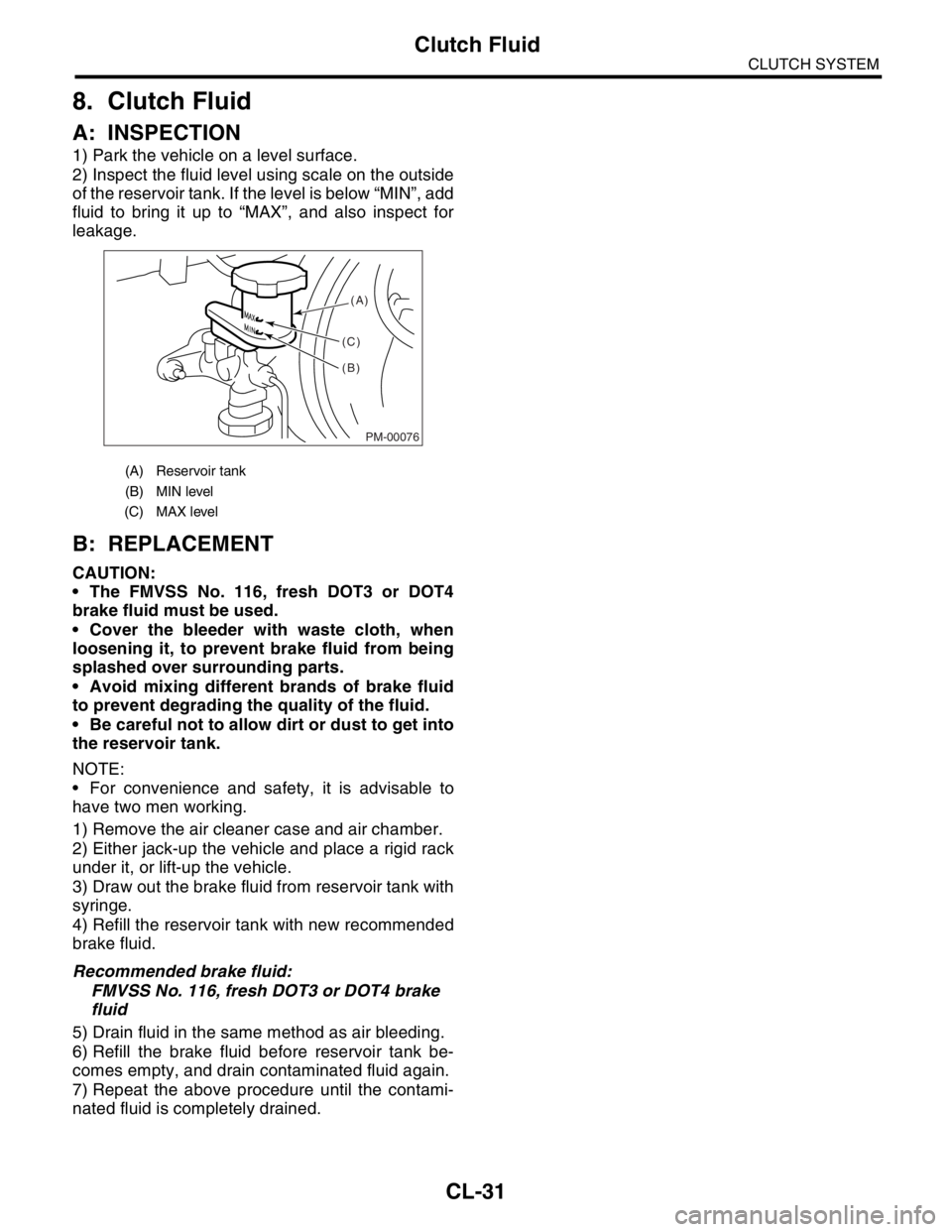

B: INSTALLATION

1. EXCEPT RHD TURBO MODEL

Install in the reverse order of removal.

Tightening torque:

T1: 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

T2: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

T3: 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

2. RHD TURBO MODEL

Install in the reverse order of removal.

Tightening torque:

T1: 7.5 N

⋅m (0.76 kgf-m, 5.53 ft-lb)

T2: 8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

T3: 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

T4: 18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

T5: 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

C: INSPECTION

Check the pipes and hoses for cracks, breakage, or

damage. Check the joints for fluid leakage. If any

cracks, breakage, damage, or leakage is found, re-

pair or replace the applicable pipe or hose.

(A) Clutch pipe (LHD model)

(B) Clip

(C) Clutch hose

(D) Clutch pipe (RHD model)

(D)

(B) (C)(A)

T1

T1

T2

T1

T3

CL-00125

(A) Clutch pipe

(B) Connector

(C) Clutch hose

(A)

(A) (A)

T3

T3T3

T3

T1

T3

T5

T5

(C)

T2

T4

(B)

CL-00061

Page 2857 of 2870

CL-31

CLUTCH SYSTEM

Clutch Fluid

8. Clutch Fluid

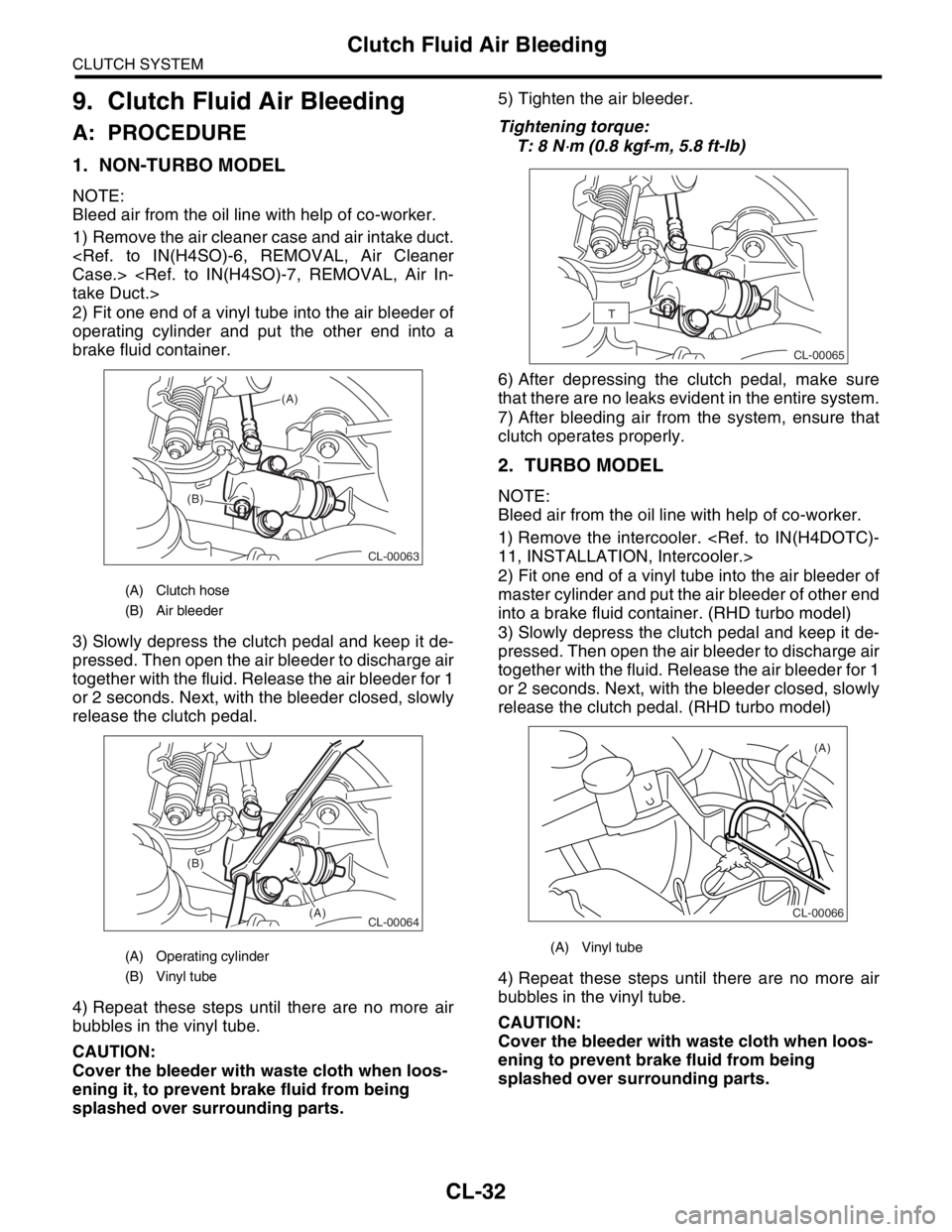

A: INSPECTION

1) Park the vehicle on a level surface.

2) Inspect the fluid level using scale on the outside

of the reservoir tank. If the level is below “MIN”, add

fluid to bring it up to “MAX”, and also inspect for

leakage.

B: REPLACEMENT

CAUTION:

The FMVSS No. 116, fresh DOT3 or DOT4

brake fluid must be used.

Cover the bleeder with waste cloth, when

loosening it, to prevent brake fluid from being

splashed over surrounding parts.

Avoid mixing different brands of brake fluid

to prevent degrading the quality of the fluid.

Be careful not to allow dirt or dust to get into

the reservoir tank.

NOTE:

For convenience and safety, it is advisable to

have two men working.

1) Remove the air cleaner case and air chamber.

2) Either jack-up the vehicle and place a rigid rack

under it, or lift-up the vehicle.

3) Draw out the brake fluid from reservoir tank with

syringe.

4) Refill the reservoir tank with new recommended

brake fluid.

Recommended brake fluid:

FMVSS No. 116, fresh DOT3 or DOT4 brake

fluid

5) Drain fluid in the same method as air bleeding.

6) Refill the brake fluid before reservoir tank be-

comes empty, and drain contaminated fluid again.

7) Repeat the above procedure until the contami-

nated fluid is completely drained.

(A) Reservoir tank

(B) MIN level

(C) MAX level

PM-00076

(A)

(B) (C)

Page 2858 of 2870

CL-32

CLUTCH SYSTEM

Clutch Fluid Air Bleeding

9. Clutch Fluid Air Bleeding

A: PROCEDURE

1. NON-TURBO MODEL

NOTE:

Bleed air from the oil line with help of co-worker.

1) Remove the air cleaner case and air intake duct.

2) Fit one end of a vinyl tube into the air bleeder of

operating cylinder and put the other end into a

brake fluid container.

3) Slowly depress the clutch pedal and keep it de-

pressed. Then open the air bleeder to discharge air

together with the fluid. Release the air bleeder for 1

or 2 seconds. Next, with the bleeder closed, slowly

release the clutch pedal.

4) Repeat these steps until there are no more air

bubbles in the vinyl tube.

CAUTION:

Cover the bleeder with waste cloth when loos-

ening it, to prevent brake fluid from being

splashed over surrounding parts.5) Tighten the air bleeder.

Tightening torque:

T: 8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

6) After depressing the clutch pedal, make sure

that there are no leaks evident in the entire system.

7) After bleeding air from the system, ensure that

clutch operates properly.

2. TURBO MODEL

NOTE:

Bleed air from the oil line with help of co-worker.

1) Remove the intercooler.

2) Fit one end of a vinyl tube into the air bleeder of

master cylinder and put the air bleeder of other end

into a brake fluid container. (RHD turbo model)

3) Slowly depress the clutch pedal and keep it de-

pressed. Then open the air bleeder to discharge air

together with the fluid. Release the air bleeder for 1

or 2 seconds. Next, with the bleeder closed, slowly

release the clutch pedal. (RHD turbo model)

4) Repeat these steps until there are no more air

bubbles in the vinyl tube.

CAUTION:

Cover the bleeder with waste cloth when loos-

ening to prevent brake fluid from being

splashed over surrounding parts.

(A) Clutch hose

(B) Air bleeder

(A) Operating cylinder

(B) Vinyl tube

CL-00063

(B)(A)

CL-00064

(B)

(A)

(A) Vinyl tube

CL-00065

T

(A)

CL-00066

Page 2859 of 2870

CL-33

CLUTCH SYSTEM

Clutch Fluid Air Bleeding

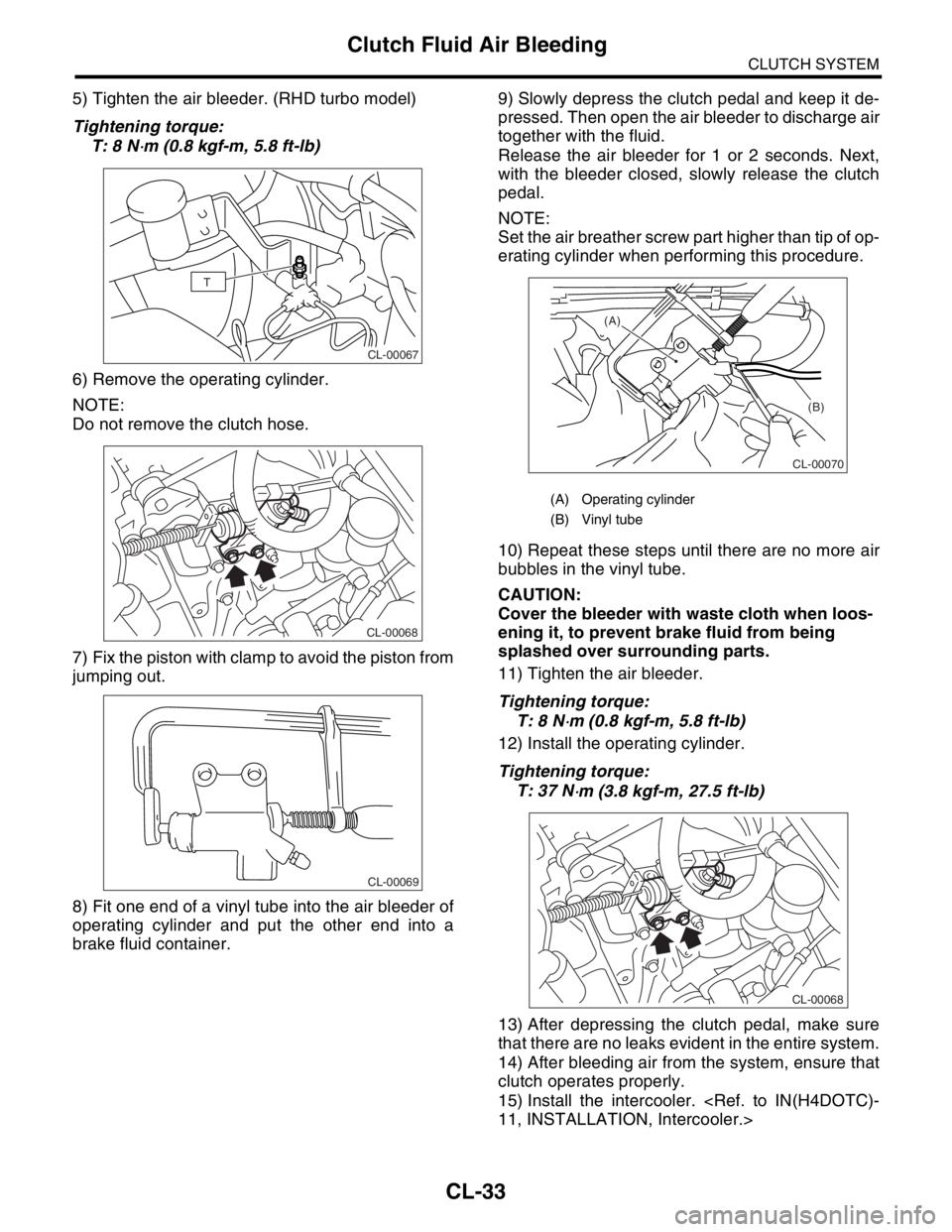

5) Tighten the air bleeder. (RHD turbo model)

Tightening torque:

T: 8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

6) Remove the operating cylinder.

NOTE:

Do not remove the clutch hose.

7) Fix the piston with clamp to avoid the piston from

jumping out.

8) Fit one end of a vinyl tube into the air bleeder of

operating cylinder and put the other end into a

brake fluid container.9) Slowly depress the clutch pedal and keep it de-

pressed. Then open the air bleeder to discharge air

together with the fluid.

Release the air bleeder for 1 or 2 seconds. Next,

with the bleeder closed, slowly release the clutch

pedal.

NOTE:

Set the air breather screw part higher than tip of op-

erating cylinder when performing this procedure.

10) Repeat these steps until there are no more air

bubbles in the vinyl tube.

CAUTION:

Cover the bleeder with waste cloth when loos-

ening it, to prevent brake fluid from being

splashed over surrounding parts.

11) Tighten the air bleeder.

Tightening torque:

T: 8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

12) Install the operating cylinder.

Tightening torque:

T: 37 N

⋅m (3.8 kgf-m, 27.5 ft-lb)

13) After depressing the clutch pedal, make sure

that there are no leaks evident in the entire system.

14) After bleeding air from the system, ensure that

clutch operates properly.

15) Install the intercooler.

CL-00067

T

CL-00068

CL-00069

(A) Operating cylinder

(B) Vinyl tube

CL-00070

(B) (A)

CL-00068

Page 2860 of 2870

CL-34

CLUTCH SYSTEM

Clutch Pedal

10.Clutch Pedal

A: REMOVAL

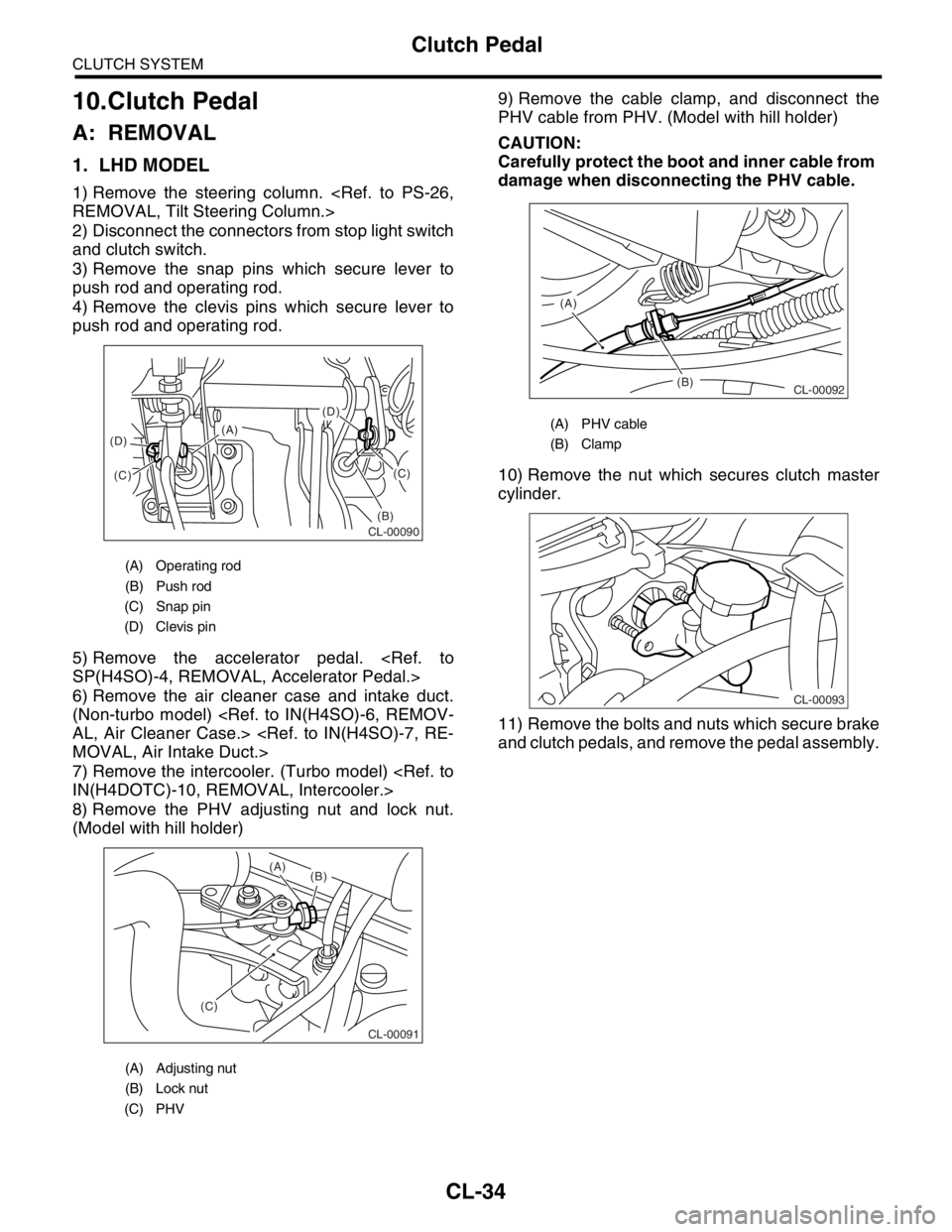

1. LHD MODEL

1) Remove the steering column.

2) Disconnect the connectors from stop light switch

and clutch switch.

3) Remove the snap pins which secure lever to

push rod and operating rod.

4) Remove the clevis pins which secure lever to

push rod and operating rod.

5) Remove the accelerator pedal.

6) Remove the air cleaner case and intake duct.

(Non-turbo model)

7) Remove the intercooler. (Turbo model)

8) Remove the PHV adjusting nut and lock nut.

(Model with hill holder)9) Remove the cable clamp, and disconnect the

PHV cable from PHV. (Model with hill holder)

CAUTION:

Carefully protect the boot and inner cable from

damage when disconnecting the PHV cable.

10) Remove the nut which secures clutch master

cylinder.

11) Remove the bolts and nuts which secure brake

and clutch pedals, and remove the pedal assembly.

(A) Operating rod

(B) Push rod

(C) Snap pin

(D) Clevis pin

(A) Adjusting nut

(B) Lock nut

(C) PHV

(D)

(B)(C)

(C) (D)(A)

CL-00090

CL-00091

(C)(B) (A)

(A) PHV cable

(B) Clamp

(B) (A)

CL-00092

CL-00093