SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2821 of 2870

5MT-108

MANUAL TRANSMISSION AND DIFFERENTIAL

Shifter Fork and Rod

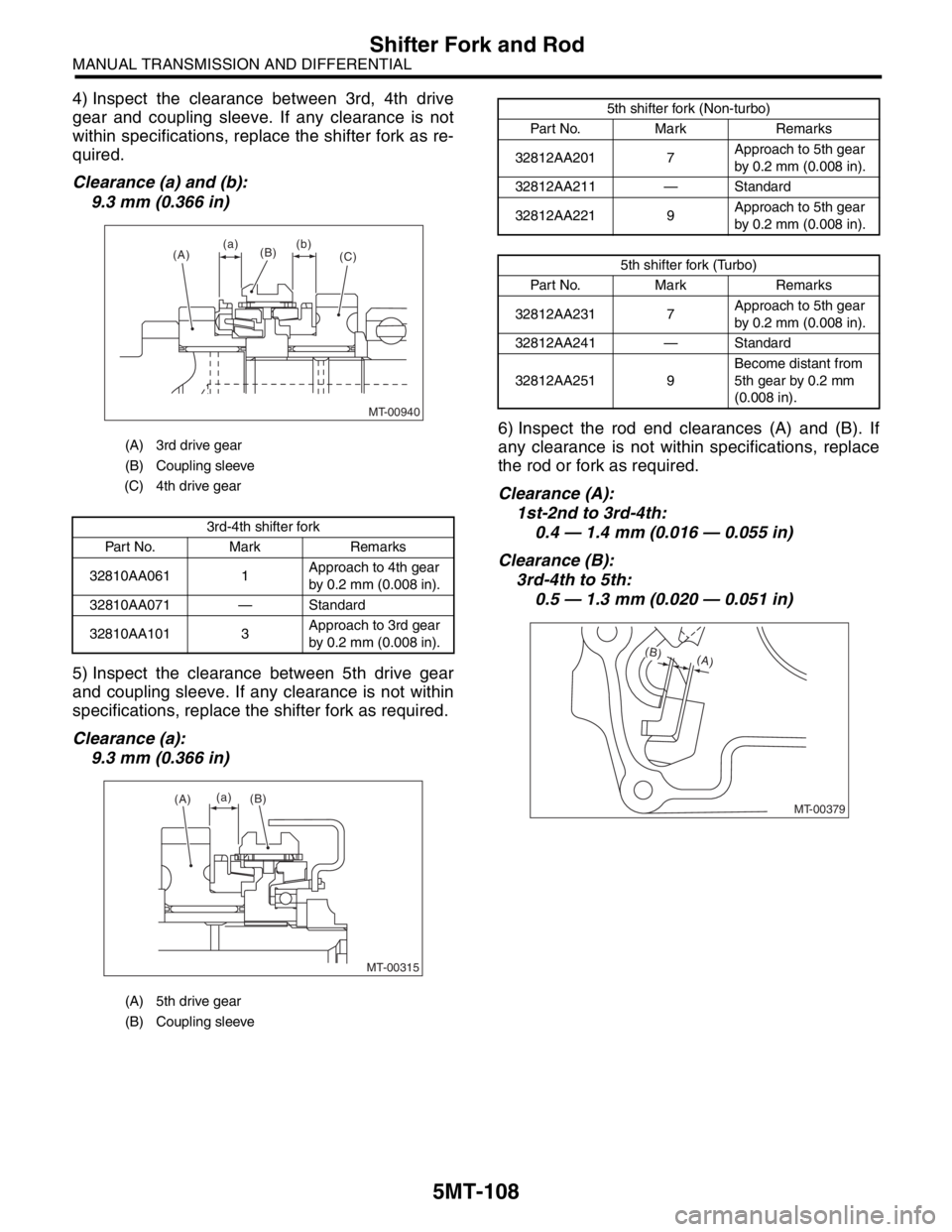

4) Inspect the clearance between 3rd, 4th drive

gear and coupling sleeve. If any clearance is not

within specifications, replace the shifter fork as re-

quired.

Clearance (a) and (b):

9.3 mm (0.366 in)

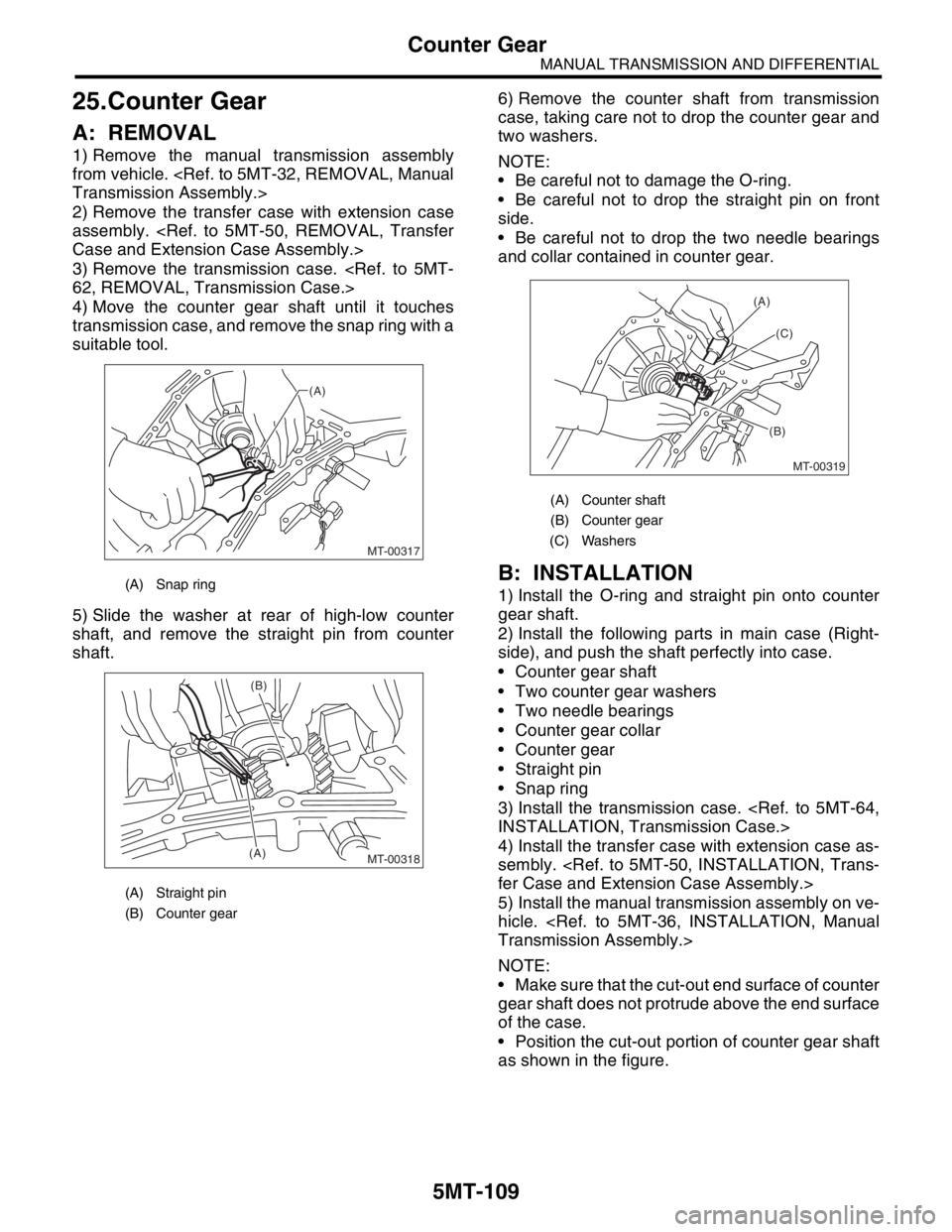

5) Inspect the clearance between 5th drive gear

and coupling sleeve. If any clearance is not within

specifications, replace the shifter fork as required.

Clearance (a):

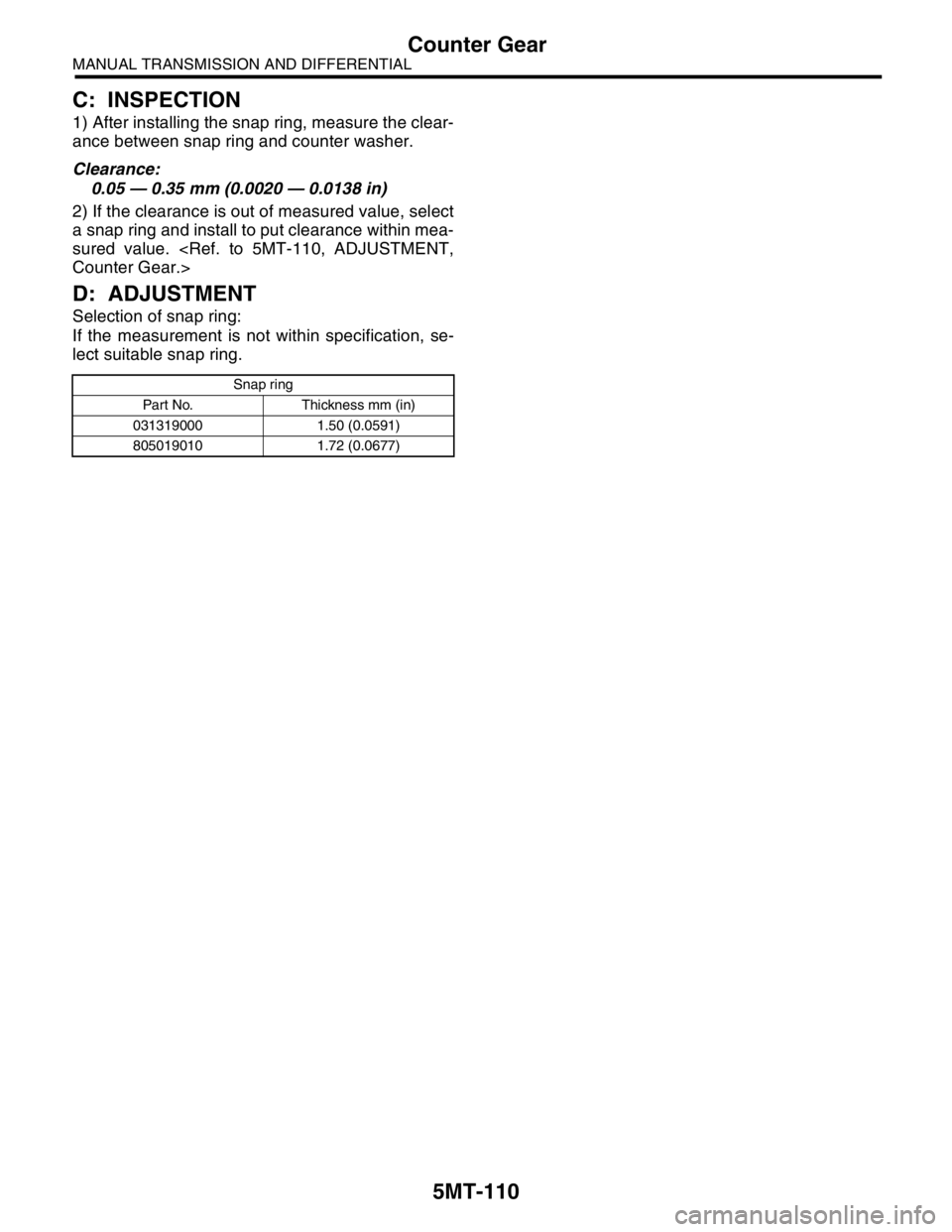

9.3 mm (0.366 in) 6) Inspect the rod end clearances (A) and (B). If

any clearance is not within specifications, replace

the rod or fork as required.

Clearance (A):

1st-2nd to 3rd-4th:

0.4 — 1.4 mm (0.016 — 0.055 in)

Clearance (B):

3rd-4th to 5th:

0.5 — 1.3 mm (0.020 — 0.051 in)

(A) 3rd drive gear

(B) Coupling sleeve

(C) 4th drive gear

3rd-4th shifter fork

Part No. Mark Remarks

32810AA061 1Approach to 4th gear

by 0.2 mm (0.008 in).

32810AA071 — Standard

32810AA101 3Approach to 3rd gear

by 0.2 mm (0.008 in).

(A) 5th drive gear

(B) Coupling sleeve

MT-00940

(A)(B)

(C) (a) (b)

MT-00315

(A)(B) (a)

5th shifter fork (Non-turbo)

Part No. Mark Remarks

32812AA201 7Approach to 5th gear

by 0.2 mm (0.008 in).

32812AA211 — Standard

32812AA221 9Approach to 5th gear

by 0.2 mm (0.008 in).

5th shifter fork (Turbo)

Part No. Mark Remarks

32812AA231 7Approach to 5th gear

by 0.2 mm (0.008 in).

32812AA241 — Standard

32812AA251 9Become distant from

5th gear by 0.2 mm

(0.008 in).

MT-00379

(B)(A)

Page 2822 of 2870

5MT-109

MANUAL TRANSMISSION AND DIFFERENTIAL

Counter Gear

25.Counter Gear

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the transfer case with extension case

assembly.

3) Remove the transmission case.

4) Move the counter gear shaft until it touches

transmission case, and remove the snap ring with a

suitable tool.

5) Slide the washer at rear of high-low counter

shaft, and remove the straight pin from counter

shaft.6) Remove the counter shaft from transmission

case, taking care not to drop the counter gear and

two washers.

NOTE:

Be careful not to damage the O-ring.

Be careful not to drop the straight pin on front

side.

Be careful not to drop the two needle bearings

and collar contained in counter gear.

B: INSTALLATION

1) Install the O-ring and straight pin onto counter

gear shaft.

2) Install the following parts in main case (Right-

side), and push the shaft perfectly into case.

Counter gear shaft

Two counter gear washers

Two needle bearings

Counter gear collar

Counter gear

Straight pin

Snap ring

3) Install the transmission case.

4) Install the transfer case with extension case as-

sembly.

5) Install the manual transmission assembly on ve-

hicle.

NOTE:

Make sure that the cut-out end surface of counter

gear shaft does not protrude above the end surface

of the case.

Position the cut-out portion of counter gear shaft

as shown in the figure.(A) Snap ring

(A) Straight pin

(B) Counter gear

MT-00317

(A)

MT-00318(A)

(B)

(A) Counter shaft

(B) Counter gear

(C) Washers

MT-00319

(A)

(B)(C)

Page 2823 of 2870

5MT-110

MANUAL TRANSMISSION AND DIFFERENTIAL

Counter Gear

C: INSPECTION

1) After installing the snap ring, measure the clear-

ance between snap ring and counter washer.

Clearance:

0.05 — 0.35 mm (0.0020 — 0.0138 in)

2) If the clearance is out of measured value, select

a snap ring and install to put clearance within mea-

sured value.

D: ADJUSTMENT

Selection of snap ring:

If the measurement is not within specification, se-

lect suitable snap ring.

Snap ring

Part No. Thickness mm (in)

031319000 1.50 (0.0591)

805019010 1.72 (0.0677)

Page 2824 of 2870

5MT-111

MANUAL TRANSMISSION AND DIFFERENTIAL

General Diagnostic

26.General Diagnostic

A: INSPECTION

1. MANUAL TRANSMISSION

Symptom Possible cause Remedy

1. Gears are difficult to intermesh.

N

OTE:

The cause for difficulty in shifting gears

can be classified into two kinds: one is

malfunction of the gear shift system and

the other is malfunction of the transmis-

sion. However, if the operation is heavy

and engagement of the gears is difficult,

defective clutch disengagement may also

be responsible. Check whether the clutch

is correctly functioning, before checking

the gear shift system and transmission.(a) Worn, damaged or burred chamfer of

internal spline of sleeve and reverse

driven gearReplace.

(b) Worn, damaged or burred chamfer of

spline of gearsReplace.

(c) Worn or scratched bushings Replace.

(d) Incorrect contact between synchro-

nizer ring and gear cone or wear Correct or replace.

2. Gear slips out.

Gear slips out when coasting on rough

road.

Gear slips out during acceleration.(a) Defective pitching stopper adjustment Adjust.

(b) Loose engine mounting bolts Tighten or replace.

(c) Worn fork shifter, broken shifter fork

rail springReplace.

(d) Worn or damaged ball bearing Replace.

(e) Excessive clearance between splines

of synchronizer hub and synchronizer

sleeveReplace.

(f) Worn tooth step of synchronizer hub Replace.

(g) Worn 1st driven gear and driven shaft Replace.

(h) Worn 2nd driven gear and 2nd bush Replace.

(i) Worn reverse idler gear and bushing Replace.

3. Unusual noise comes from transmis-

sion.

N

OTE:

If an unusual noise is heard when the ve-

hicle is parked with its engine idling and if

the noise ceases when the clutch is disen-

gaged, it may be considered that the

noise comes from the transmission.(a) Insufficient or improper lubrication Lubricate or replace with specified oil.

(b) Worn or damaged gears and bearings

NOTE:

If the trouble is only wear of the tooth sur-

faces, merely a high roaring noise will oc-

cur at high speeds, but if any part is

broken, rhythmical knocking sound will be

heard even at low speeds.Replace.

Page 2825 of 2870

5MT-112

MANUAL TRANSMISSION AND DIFFERENTIAL

General Diagnostic

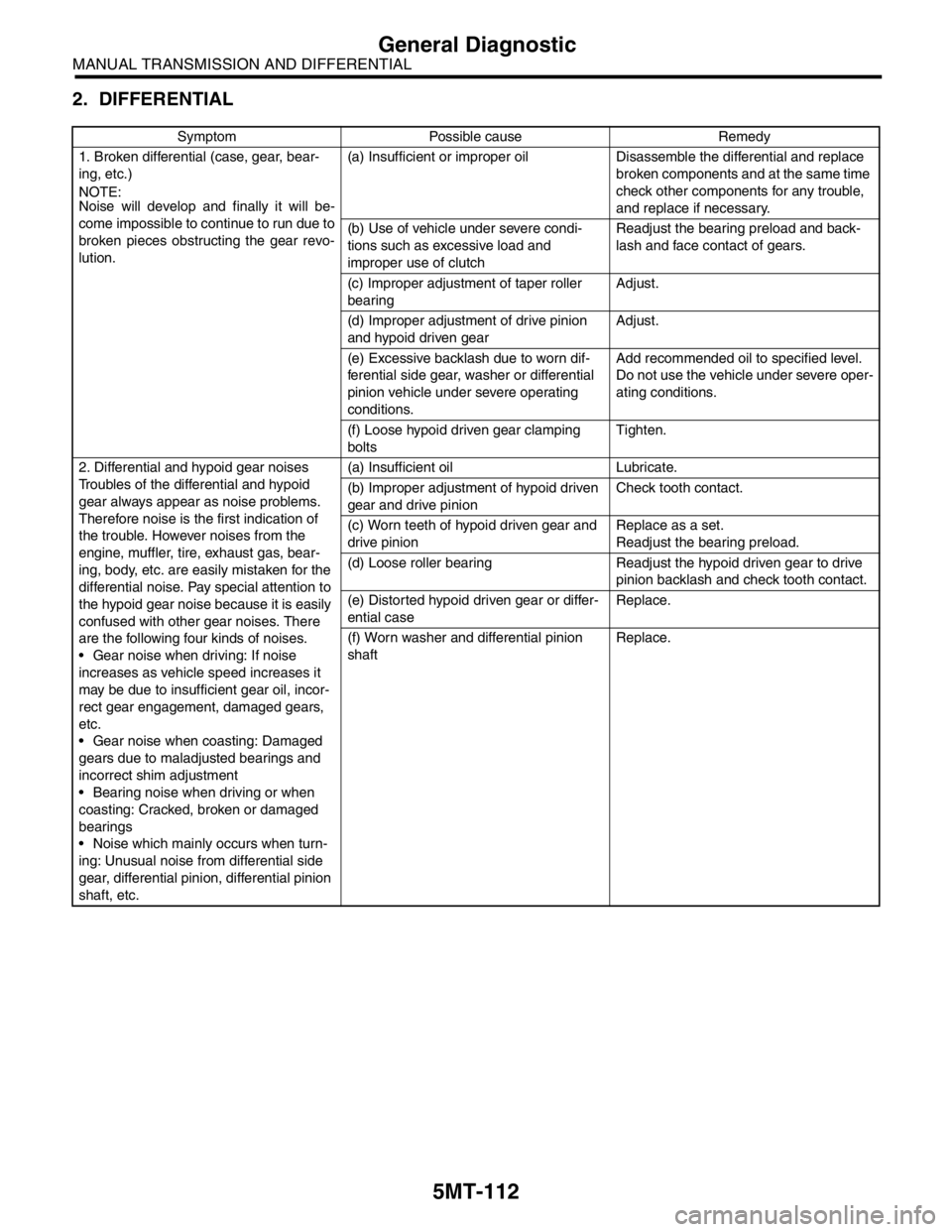

2. DIFFERENTIAL

Symptom Possible cause Remedy

1. Broken differential (case, gear, bear-

ing, etc.)

N

OTE:

Noise will develop and finally it will be-

come impossible to continue to run due to

broken pieces obstructing the gear revo-

lution. (a) Insufficient or improper oil Disassemble the differential and replace

broken components and at the same time

check other components for any trouble,

and replace if necessary.

(b) Use of vehicle under severe condi-

tions such as excessive load and

improper use of clutch Readjust the bearing preload and back-

lash and face contact of gears.

(c) Improper adjustment of taper roller

bearingAdjust.

(d) Improper adjustment of drive pinion

and hypoid driven gear Adjust.

(e) Excessive backlash due to worn dif-

ferential side gear, washer or differential

pinion vehicle under severe operating

conditions. Add recommended oil to specified level.

Do not use the vehicle under severe oper-

ating conditions.

(f) Loose hypoid driven gear clamping

boltsTighten.

2. Differential and hypoid gear noises

Troubles of the differential and hypoid

gear always appear as noise problems.

Therefore noise is the first indication of

the trouble. However noises from the

engine, muffler, tire, exhaust gas, bear-

ing, body, etc. are easily mistaken for the

differential noise. Pay special attention to

the hypoid gear noise because it is easily

confused with other gear noises. There

are the following four kinds of noises.

Gear noise when driving: If noise

increases as vehicle speed increases it

may be due to insufficient gear oil, incor-

rect gear engagement, damaged gears,

etc.

Gear noise when coasting: Damaged

gears due to maladjusted bearings and

incorrect shim adjustment

Bearing noise when driving or when

coasting: Cracked, broken or damaged

bearings

Noise which mainly occurs when turn-

ing: Unusual noise from differential side

gear, differential pinion, differential pinion

shaft, etc. (a) Insufficient oil Lubricate.

(b) Improper adjustment of hypoid driven

gear and drive pinionCheck tooth contact.

(c) Worn teeth of hypoid driven gear and

drive pinionReplace as a set.

Readjust the bearing preload.

(d) Loose roller bearing Readjust the hypoid driven gear to drive

pinion backlash and check tooth contact.

(e) Distorted hypoid driven gear or differ-

ential caseReplace.

(f) Worn washer and differential pinion

shaftReplace.

Page 2826 of 2870

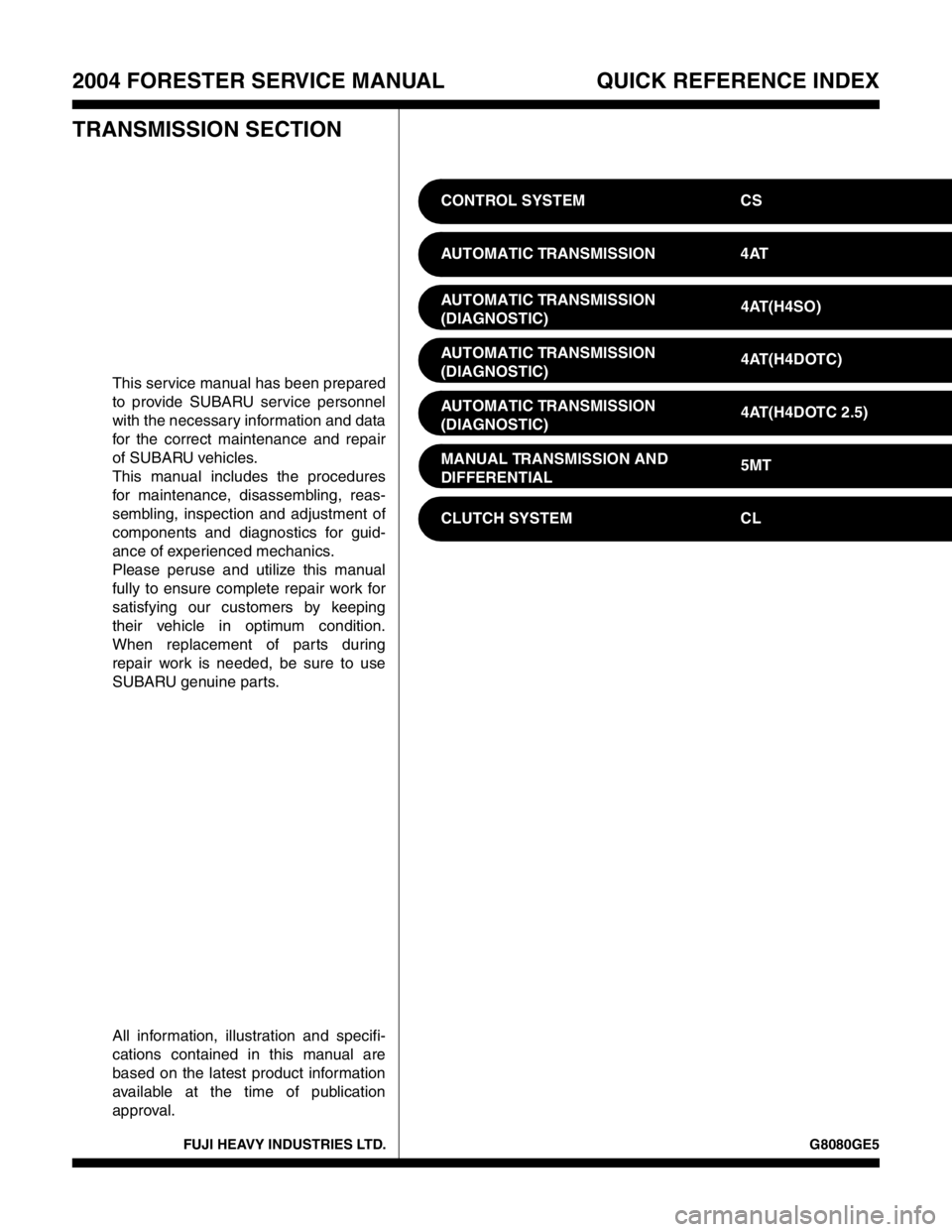

FUJI HEAVY INDUSTRIES LTD. G8080GE5

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

TRANSMISSION SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.CONTROL SYSTEM CS

AUTOMATIC TRANSMISSION 4AT

AUTOMATIC TRANSMISSION

(DIAGNOSTIC)4AT(H4SO)

AUTOMATIC TRANSMISSION

(DIAGNOSTIC)4AT(H4DOTC)

AUTOMATIC TRANSMISSION

(DIAGNOSTIC)4AT(H4DOTC 2.5)

MANUAL TRANSMISSION AND

DIFFERENTIAL5MT

CLUTCH SYSTEM CL

Page 2827 of 2870

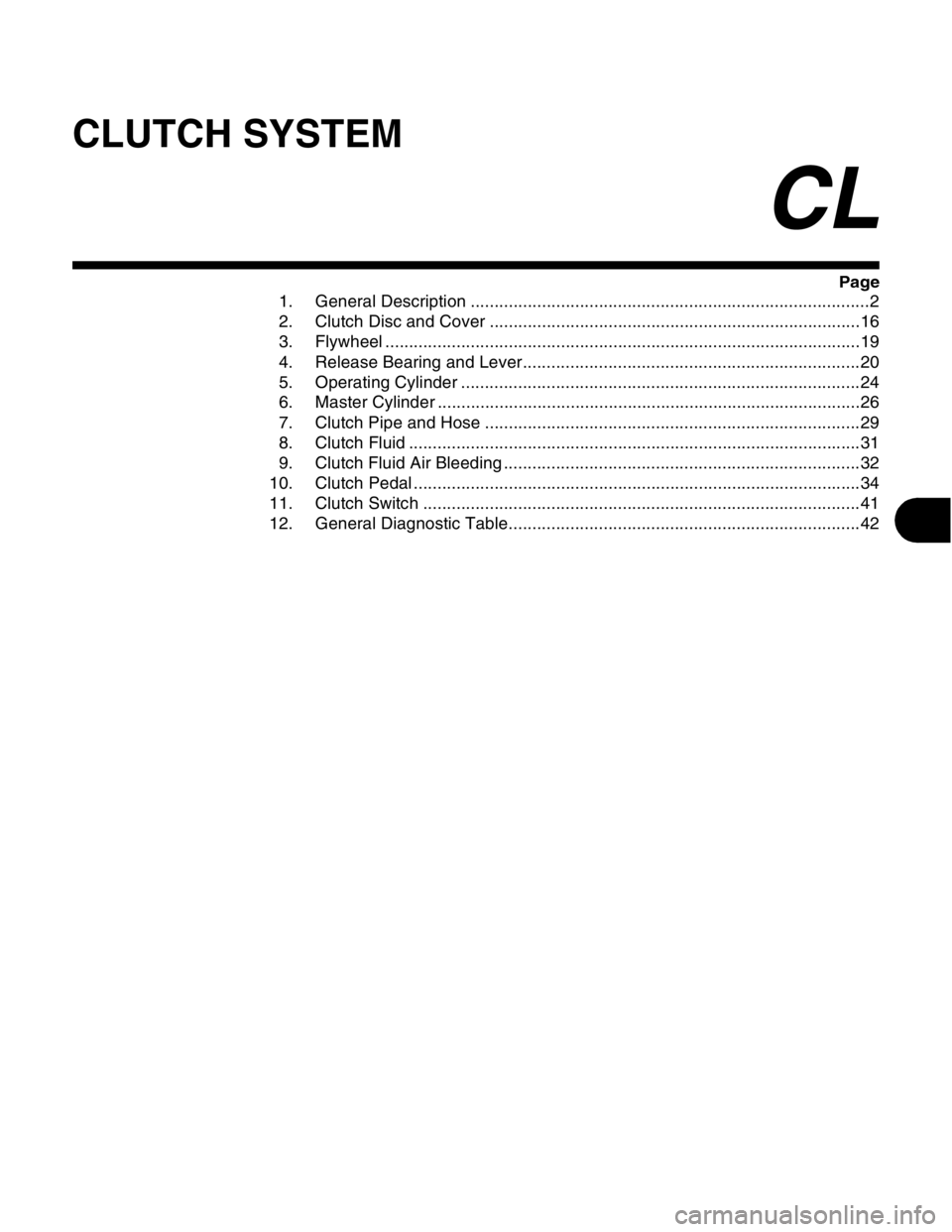

CLUTCH SYSTEM

CL

Page

1. General Description ....................................................................................2

2. Clutch Disc and Cover ..............................................................................16

3. Flywheel ....................................................................................................19

4. Release Bearing and Lever.......................................................................20

5. Operating Cylinder ....................................................................................24

6. Master Cylinder .........................................................................................26

7. Clutch Pipe and Hose ...............................................................................29

8. Clutch Fluid ...............................................................................................31

9. Clutch Fluid Air Bleeding ...........................................................................32

10. Clutch Pedal ..............................................................................................34

11. Clutch Switch ............................................................................................41

12. General Diagnostic Table..........................................................................42

Page 2828 of 2870

CL-2

CLUTCH SYSTEM

General Description

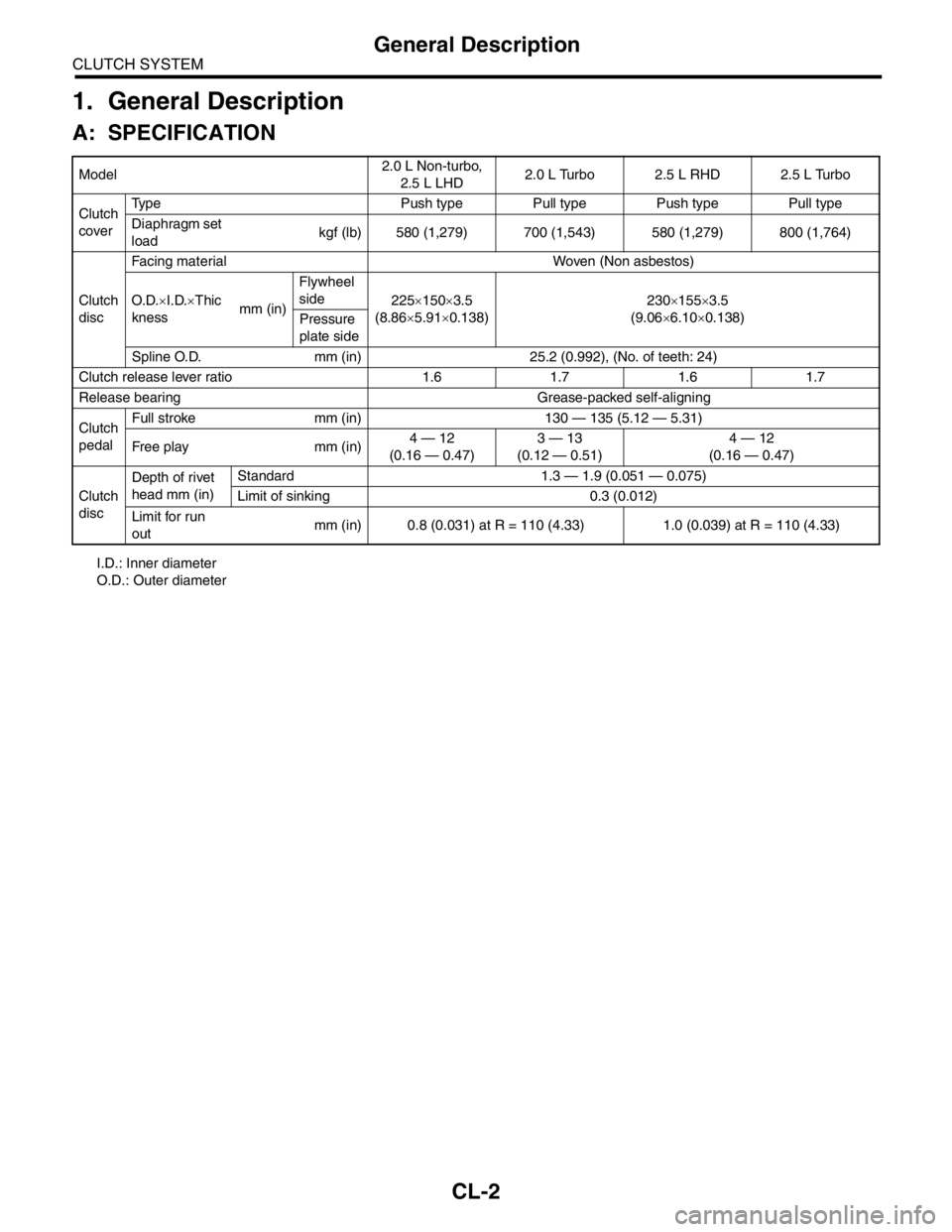

1. General Description

A: SPECIFICATION

I.D.: Inner diameter

O.D.: Outer diameter Model2.0 L Non-turbo,

2.5 L LHD2.0 L Turbo 2.5 L RHD 2.5 L Turbo

Clutch

coverType Push type Pull type Push type Pull type

Diaphragm set

loadkgf (lb) 580 (1,279) 700 (1,543) 580 (1,279) 800 (1,764)

Clutch

discFacing material Woven (Non asbestos)

O.D.×I.D.×Thic

knessmm (in)Flywheel

side

225×150×3.5

(8.86×5.91×0.138)230×155×3.5

(9.06×6.10×0.138)

Pressure

plate side

Spline O.D. mm (in) 25.2 (0.992), (No. of teeth: 24)

Clutch release lever ratio 1.6 1.7 1.6 1.7

Release bearing Grease-packed self-aligning

Clutch

pedalFull stroke mm (in) 130 — 135 (5.12 — 5.31)

Free play mm (in)4 — 12

(0.16 — 0.47)3 — 13

(0.12 — 0.51)4 — 12

(0.16 — 0.47)

Clutch

discDepth of rivet

head mm (in)Standard 1.3 — 1.9 (0.051 — 0.075)

Limit of sinking 0.3 (0.012)

Limit for run

outmm (in) 0.8 (0.031) at R = 110 (4.33) 1.0 (0.039) at R = 110 (4.33)

Page 2829 of 2870

CL-3

CLUTCH SYSTEM

General Description

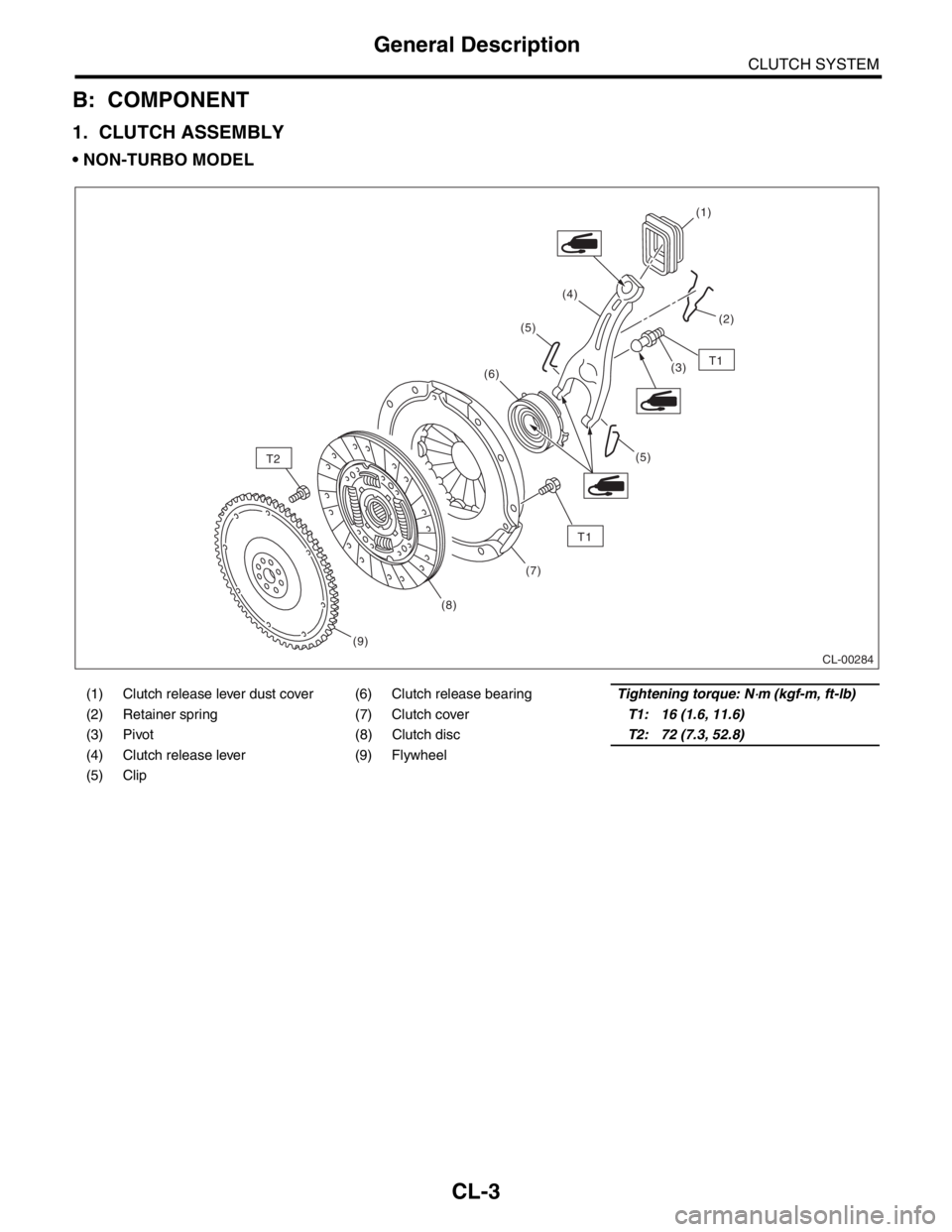

B: COMPONENT

1. CLUTCH ASSEMBLY

NON-TURBO MODEL

(1) Clutch release lever dust cover (6) Clutch release bearingTightening torque: N⋅m (kgf-m, ft-lb)

(2) Retainer spring (7) Clutch coverT1: 16 (1.6, 11.6)

(3) Pivot (8) Clutch discT2: 72 (7.3, 52.8)

(4) Clutch release lever (9) Flywheel

(5) Clip

CL-00284

(4)

(2) (1)

(9)(5)

(6)

(7)

(8)(3)

(5)

T2

T1

T1

Page 2830 of 2870

CL-4

CLUTCH SYSTEM

General Description

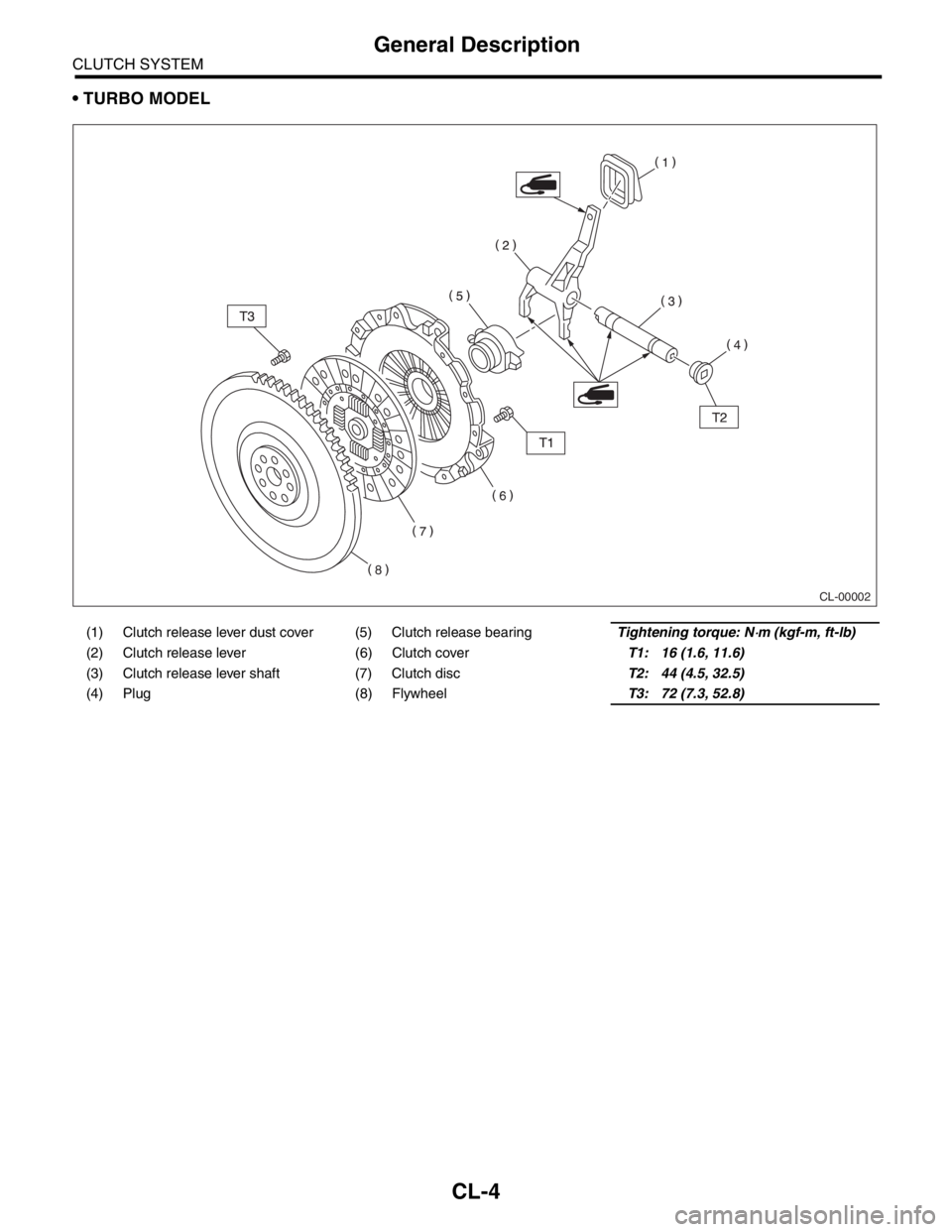

TURBO MODEL

(1) Clutch release lever dust cover (5) Clutch release bearingTightening torque: N⋅m (kgf-m, ft-lb)

(2) Clutch release lever (6) Clutch coverT1: 16 (1.6, 11.6)

(3) Clutch release lever shaft (7) Clutch discT2: 44 (4.5, 32.5)

(4) Plug (8) FlywheelT3: 72 (7.3, 52.8)

CL-00002