SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2811 of 2870

5MT-98

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

2. SIDE RETAINER

NOTE:

Replace the oil seal and O-ring after adjustment of

drive pinion gear backlash and tooth contact.

1) Remove the O-ring.

2) Remove the oil seal.

NOTE:

Remove the oil seal using a flat tip screwdriver

Do not reuse the oil seal. Prepare a new oil seal.

D: ASSEMBLY

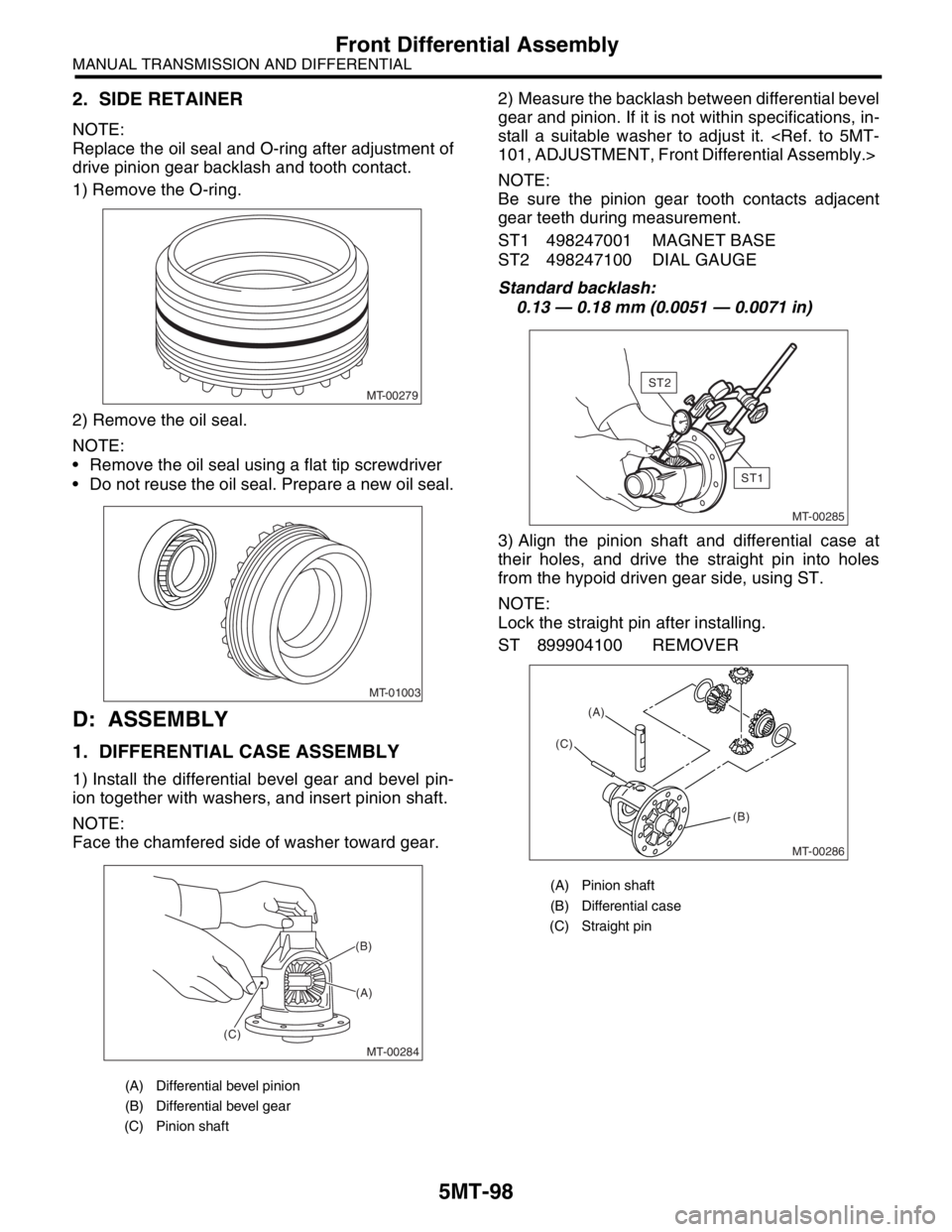

1. DIFFERENTIAL CASE ASSEMBLY

1) Install the differential bevel gear and bevel pin-

ion together with washers, and insert pinion shaft.

NOTE:

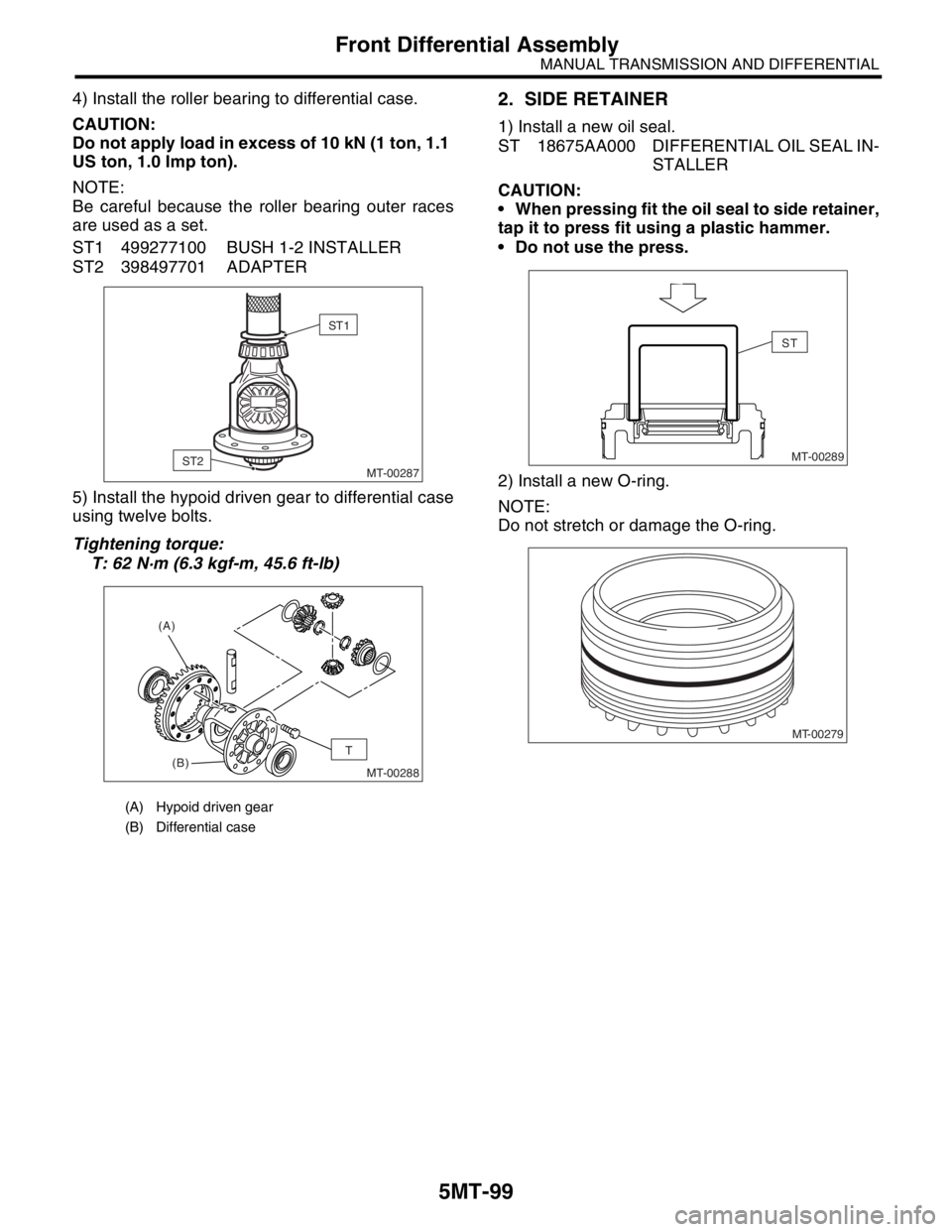

Face the chamfered side of washer toward gear.2) Measure the backlash between differential bevel

gear and pinion. If it is not within specifications, in-

stall a suitable washer to adjust it.

NOTE:

Be sure the pinion gear tooth contacts adjacent

gear teeth during measurement.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

3) Align the pinion shaft and differential case at

their holes, and drive the straight pin into holes

from the hypoid driven gear side, using ST.

NOTE:

Lock the straight pin after installing.

ST 899904100 REMOVER

(A) Differential bevel pinion

(B) Differential bevel gear

(C) Pinion shaft

MT-00279

MT-01003

MT-00284

(A) (B)

(C)

(A) Pinion shaft

(B) Differential case

(C) Straight pin

MT-00285

ST1

ST2

MT-00286

(A)

(C)

(B)

Page 2812 of 2870

5MT-99

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

4) Install the roller bearing to differential case.

CAUTION:

Do not apply load in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton).

NOTE:

Be careful because the roller bearing outer races

are used as a set.

ST1 499277100 BUSH 1-2 INSTALLER

ST2 398497701 ADAPTER

5) Install the hypoid driven gear to differential case

using twelve bolts.

Tightening torque:

T: 62 N·m (6.3 kgf-m, 45.6 ft-lb)2. SIDE RETAINER

1) Install a new oil seal.

ST 18675AA000 DIFFERENTIAL OIL SEAL IN-

STALLER

CAUTION:

When pressing fit the oil seal to side retainer,

tap it to press fit using a plastic hammer.

Do not use the press.

2) Install a new O-ring.

NOTE:

Do not stretch or damage the O-ring.

(A) Hypoid driven gear

(B) Differential case

MT-00287

ST1

ST2

MT-00288

(B) (A)T

MT-00289

ST

MT-00279

Page 2813 of 2870

5MT-100

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

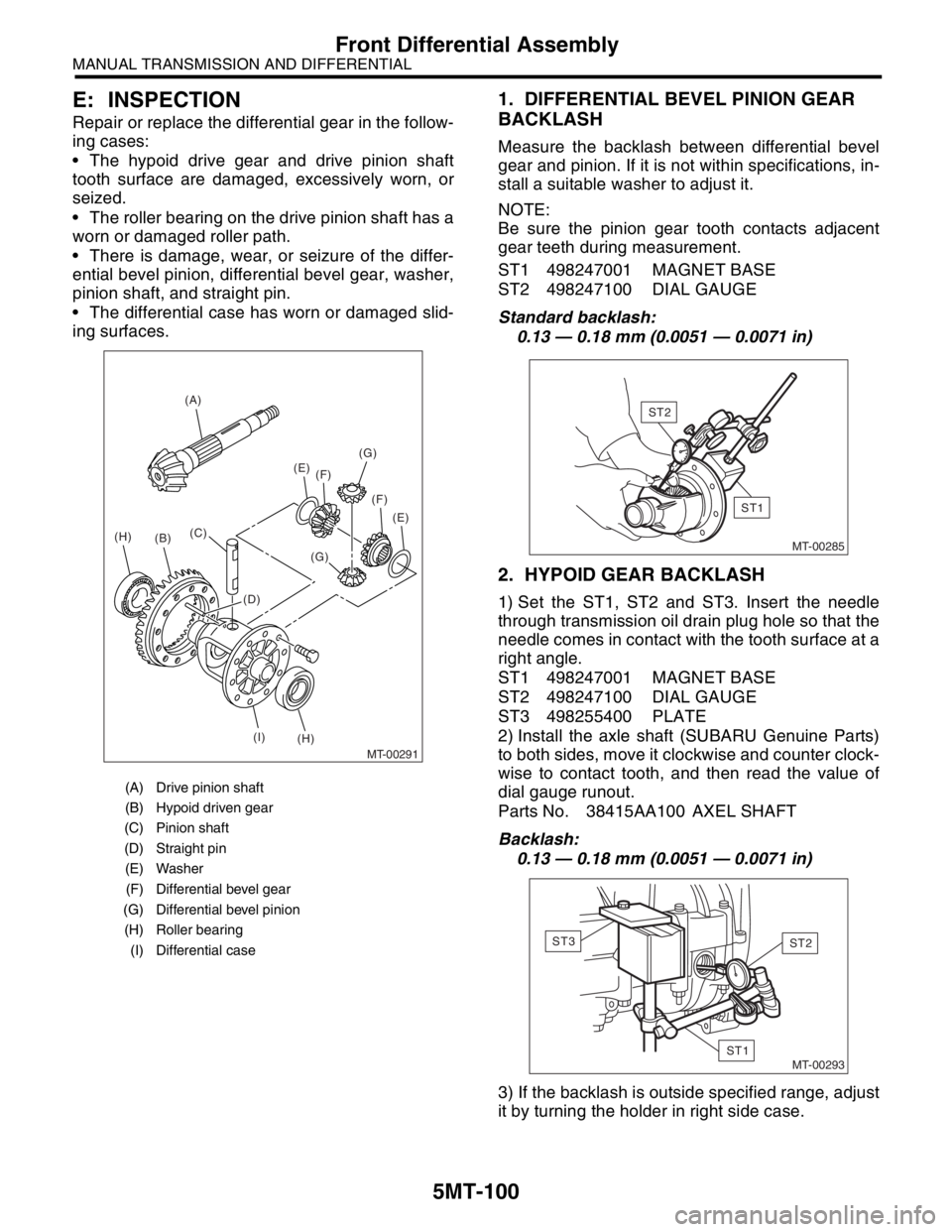

E: INSPECTION

Repair or replace the differential gear in the follow-

ing cases:

The hypoid drive gear and drive pinion shaft

tooth surface are damaged, excessively worn, or

seized.

The roller bearing on the drive pinion shaft has a

worn or damaged roller path.

There is damage, wear, or seizure of the differ-

ential bevel pinion, differential bevel gear, washer,

pinion shaft, and straight pin.

The differential case has worn or damaged slid-

ing surfaces.

1. DIFFERENTIAL BEVEL PINION GEAR

BACKLASH

Measure the backlash between differential bevel

gear and pinion. If it is not within specifications, in-

stall a suitable washer to adjust it.

NOTE:

Be sure the pinion gear tooth contacts adjacent

gear teeth during measurement.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

2. HYPOID GEAR BACKLASH

1) Set the ST1, ST2 and ST3. Insert the needle

through transmission oil drain plug hole so that the

needle comes in contact with the tooth surface at a

right angle.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

ST3 498255400 PLATE

2) Install the axle shaft (SUBARU Genuine Parts)

to both sides, move it clockwise and counter clock-

wise to contact tooth, and then read the value of

dial gauge runout.

Parts No. 38415AA100 AXEL SHAFT

Backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

3) If the backlash is outside specified range, adjust

it by turning the holder in right side case.

(A) Drive pinion shaft

(B) Hypoid driven gear

(C) Pinion shaft

(D) Straight pin

(E) Washer

(F) Differential bevel gear

(G) Differential bevel pinion

(H) Roller bearing

(I) Differential case

MT-00291

(A)

(B)(C)

(E)

(E)

(F)

(F)

(G)

(G)

(D)

(H) (I)

(H)MT-00285

ST1

ST2

MT-00293ST1

ST2ST3

Page 2814 of 2870

5MT-101

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

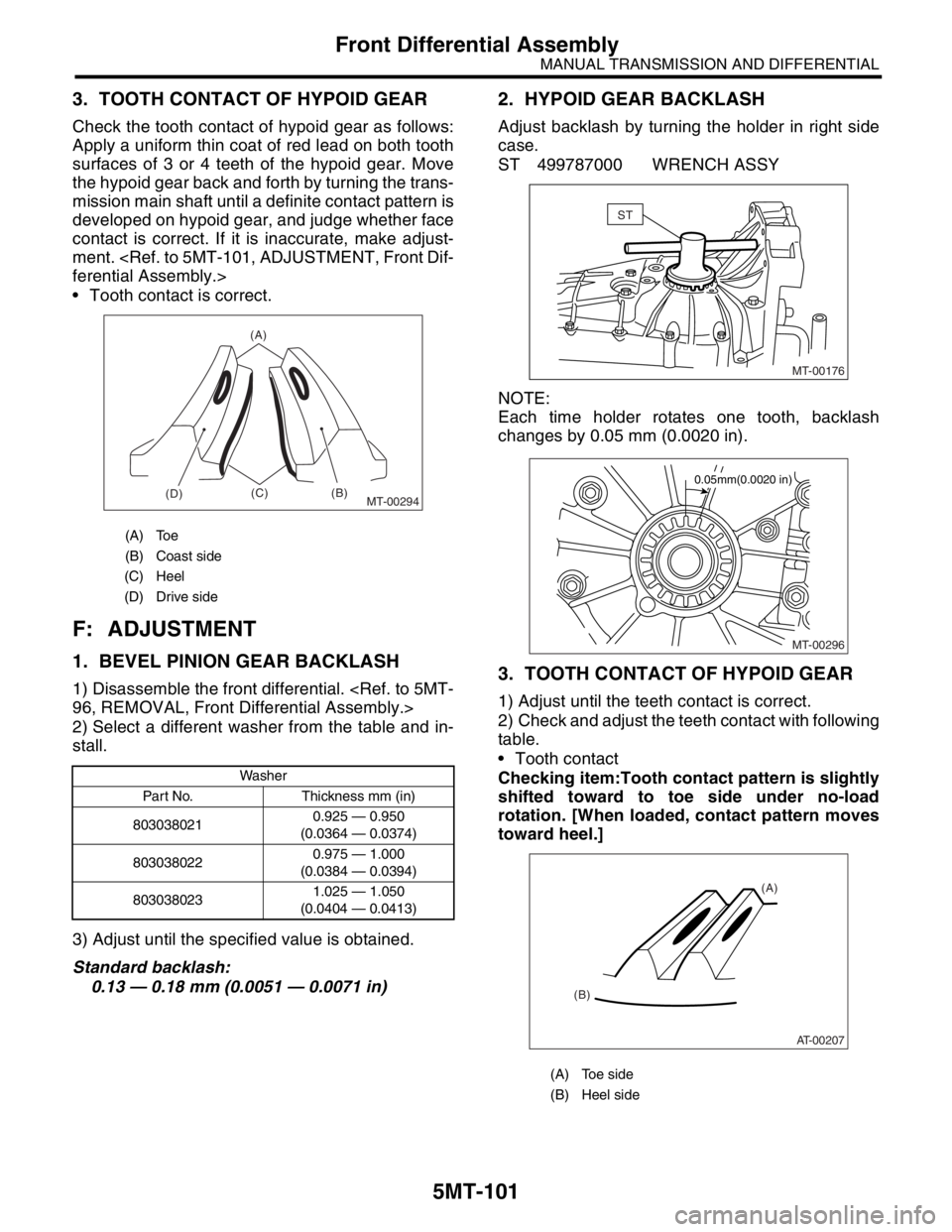

3. TOOTH CONTACT OF HYPOID GEAR

Check the tooth contact of hypoid gear as follows:

Apply a uniform thin coat of red lead on both tooth

surfaces of 3 or 4 teeth of the hypoid gear. Move

the hypoid gear back and forth by turning the trans-

mission main shaft until a definite contact pattern is

developed on hypoid gear, and judge whether face

contact is correct. If it is inaccurate, make adjust-

ment.

Tooth contact is correct.

F: ADJUSTMENT

1. BEVEL PINION GEAR BACKLASH

1) Disassemble the front differential.

2) Select a different washer from the table and in-

stall.

3) Adjust until the specified value is obtained.

Standard backlash:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

2. HYPOID GEAR BACKLASH

Adjust backlash by turning the holder in right side

case.

ST 499787000 WRENCH ASSY

NOTE:

Each time holder rotates one tooth, backlash

changes by 0.05 mm (0.0020 in).

3. TOOTH CONTACT OF HYPOID GEAR

1) Adjust until the teeth contact is correct.

2) Check and adjust the teeth contact with following

table.

Tooth contact

Checking item:Tooth contact pattern is slightly

shifted toward to toe side under no-load

rotation. [When loaded, contact pattern moves

toward heel.]

(A) Toe

(B) Coast side

(C) Heel

(D) Drive side

Washer

Part No. Thickness mm (in)

8030380210.925 — 0.950

(0.0364 — 0.0374)

8030380220.975 — 1.000

(0.0384 — 0.0394)

803038023 1.025 — 1.050

(0.0404 — 0.0413)

MT-00294

(A)

(B) (C)

(D)

(A) Toe side

(B) Heel side

MT-00176

ST

MT-00296

0.05mm(0.0020 in)

AT-00207

(A)

(B)

Page 2815 of 2870

5MT-102

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

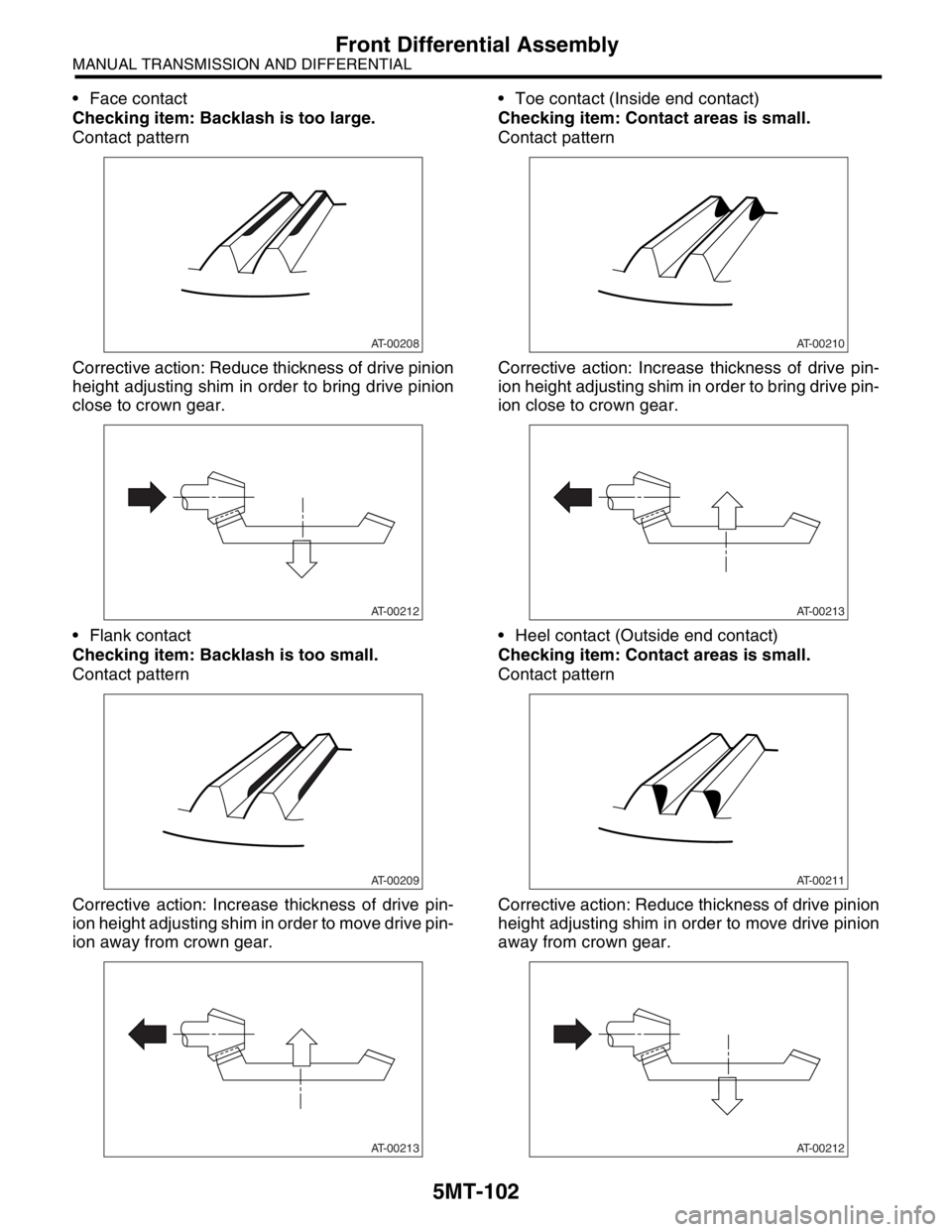

Face contact

Checking item: Backlash is too large.

Contact pattern

Corrective action: Reduce thickness of drive pinion

height adjusting shim in order to bring drive pinion

close to crown gear.

Flank contact

Checking item: Backlash is too small.

Contact pattern

Corrective action: Increase thickness of drive pin-

ion height adjusting shim in order to move drive pin-

ion away from crown gear. Toe contact (Inside end contact)

Checking item: Contact areas is small.

Contact pattern

Corrective action: Increase thickness of drive pin-

ion height adjusting shim in order to bring drive pin-

ion close to crown gear.

Heel contact (Outside end contact)

Checking item: Contact areas is small.

Contact pattern

Corrective action: Reduce thickness of drive pinion

height adjusting shim in order to move drive pinion

away from crown gear.

AT-00208

AT-00212

AT-00209

AT-00213

AT-00210

AT-00213

AT-00211

AT-00212

Page 2816 of 2870

5MT-103

MANUAL TRANSMISSION AND DIFFERENTIAL

Speedometer Gear

22.Speedometer Gear

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the back-up light switch and neutral po-

sition switch.

3) Remove the transfer case with extension case

assembly.

4) Remove the transmission case.

5) Remove the vehicle speed sensor.

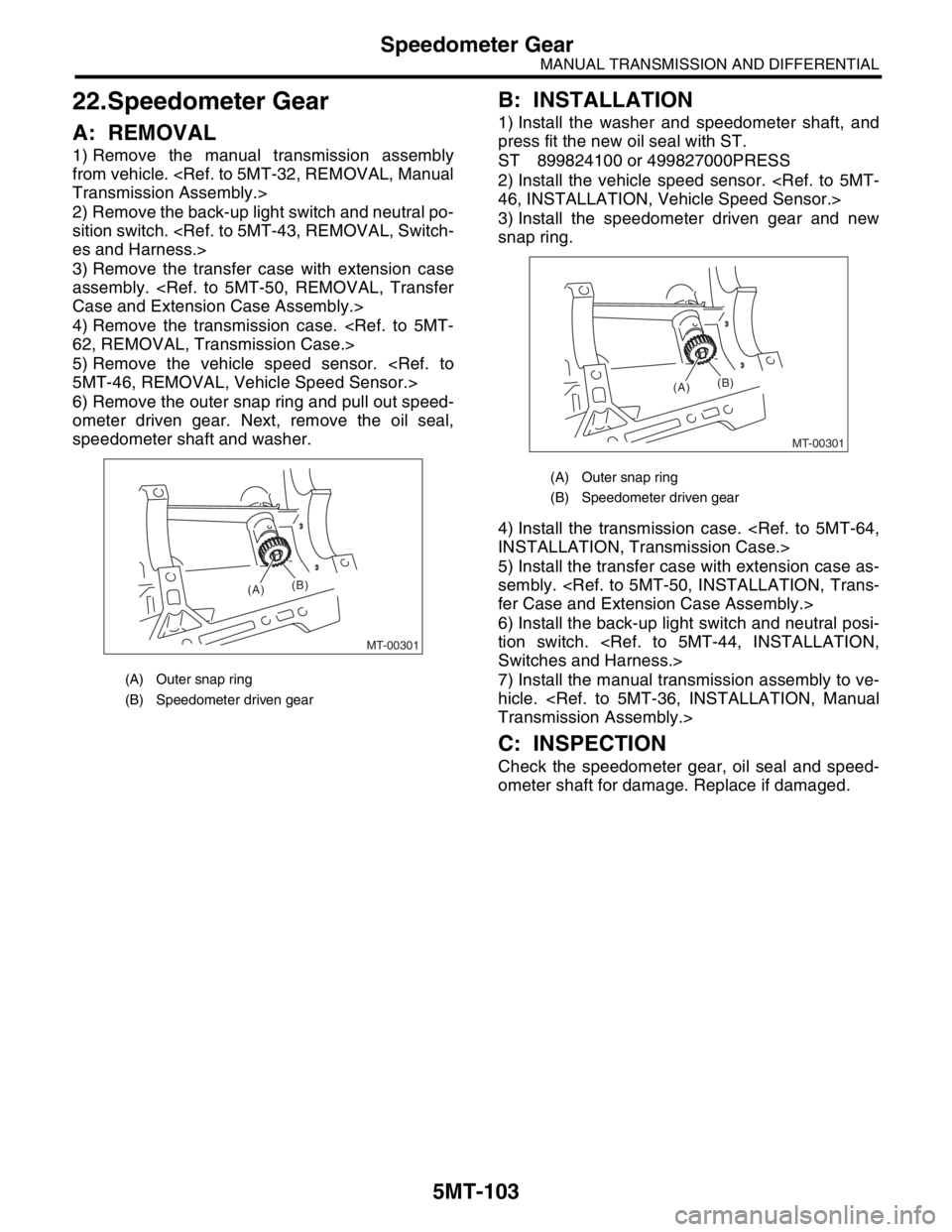

6) Remove the outer snap ring and pull out speed-

ometer driven gear. Next, remove the oil seal,

speedometer shaft and washer.

B: INSTALLATION

1) Install the washer and speedometer shaft, and

press fit the new oil seal with ST.

ST 899824100 or 499827000PRESS

2) Install the vehicle speed sensor.

3) Install the speedometer driven gear and new

snap ring.

4) Install the transmission case.

5) Install the transfer case with extension case as-

sembly.

6) Install the back-up light switch and neutral posi-

tion switch.

7) Install the manual transmission assembly to ve-

hicle.

C: INSPECTION

Check the speedometer gear, oil seal and speed-

ometer shaft for damage. Replace if damaged.

(A) Outer snap ring

(B) Speedometer driven gear

MT-00301

(A)(B)

(A) Outer snap ring

(B) Speedometer driven gear

MT-00301

(A)(B)

Page 2817 of 2870

5MT-104

MANUAL TRANSMISSION AND DIFFERENTIAL

Reverse Idler Gear

23.Reverse Idler Gear

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the back-up light switch and neutral po-

sition switch.

3) Remove the transfer case with extension case

assembly.

4) Remove the transmission case.

5) Remove the drive pinion shaft assembly.

bly.>

6) Remove the main shaft assembly.

Single-Range model

Dual-Range model

7) Remove the differential assembly.

8) Remove the shifter forks and rods.

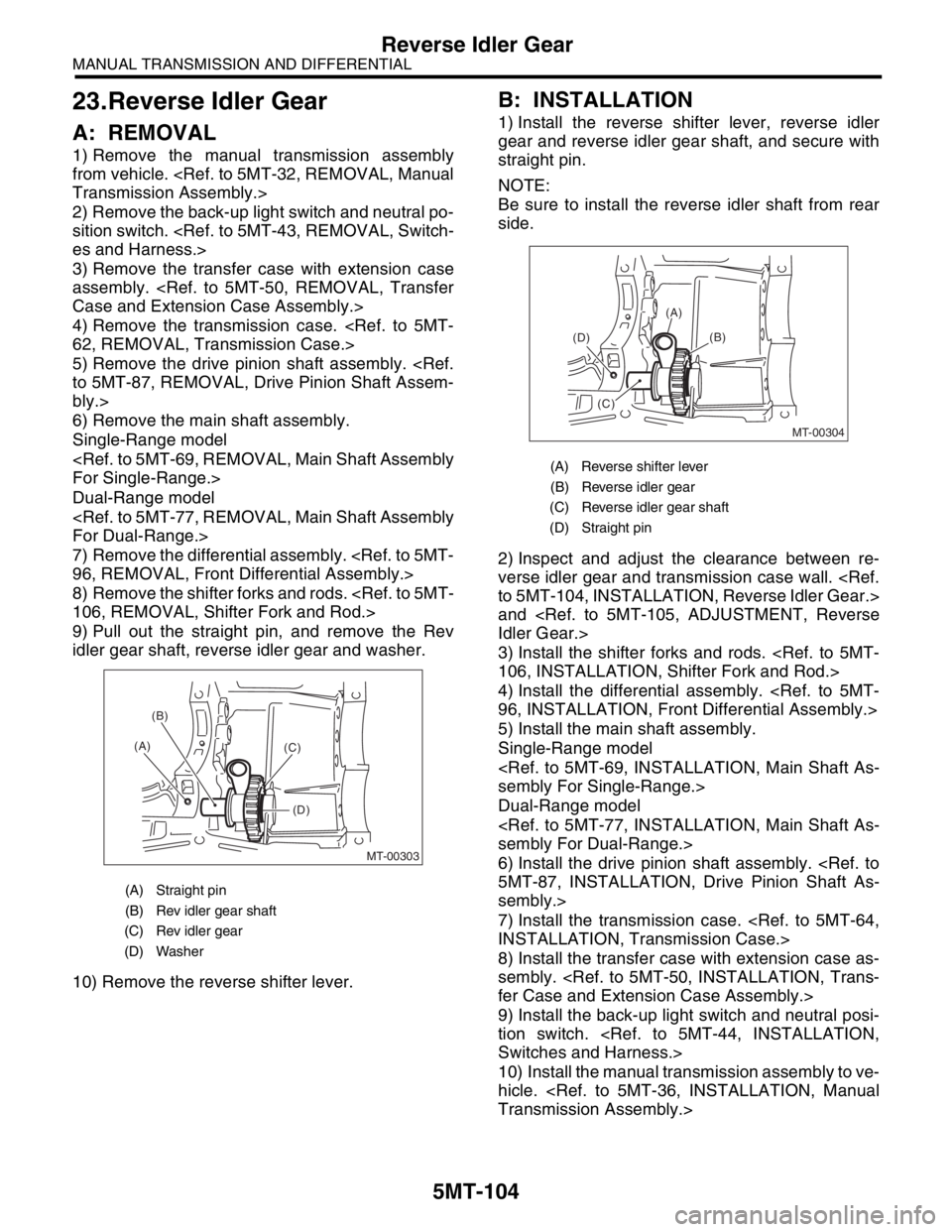

9) Pull out the straight pin, and remove the Rev

idler gear shaft, reverse idler gear and washer.

10) Remove the reverse shifter lever.

B: INSTALLATION

1) Install the reverse shifter lever, reverse idler

gear and reverse idler gear shaft, and secure with

straight pin.

NOTE:

Be sure to install the reverse idler shaft from rear

side.

2) Inspect and adjust the clearance between re-

verse idler gear and transmission case wall.

and

3) Install the shifter forks and rods.

4) Install the differential assembly.

5) Install the main shaft assembly.

Single-Range model

Dual-Range model

6) Install the drive pinion shaft assembly.

sembly.>

7) Install the transmission case.

8) Install the transfer case with extension case as-

sembly.

9) Install the back-up light switch and neutral posi-

tion switch.

10) Install the manual transmission assembly to ve-

hicle.

(A) Straight pin

(B) Rev idler gear shaft

(C) Rev idler gear

(D) Washer

MT-00303

(A)(B)

(C)

(D)

(A) Reverse shifter lever

(B) Reverse idler gear

(C) Reverse idler gear shaft

(D) Straight pin

MT-00304

(A)

(B)

(D)

(C)

Page 2818 of 2870

5MT-105

MANUAL TRANSMISSION AND DIFFERENTIAL

Reverse Idler Gear

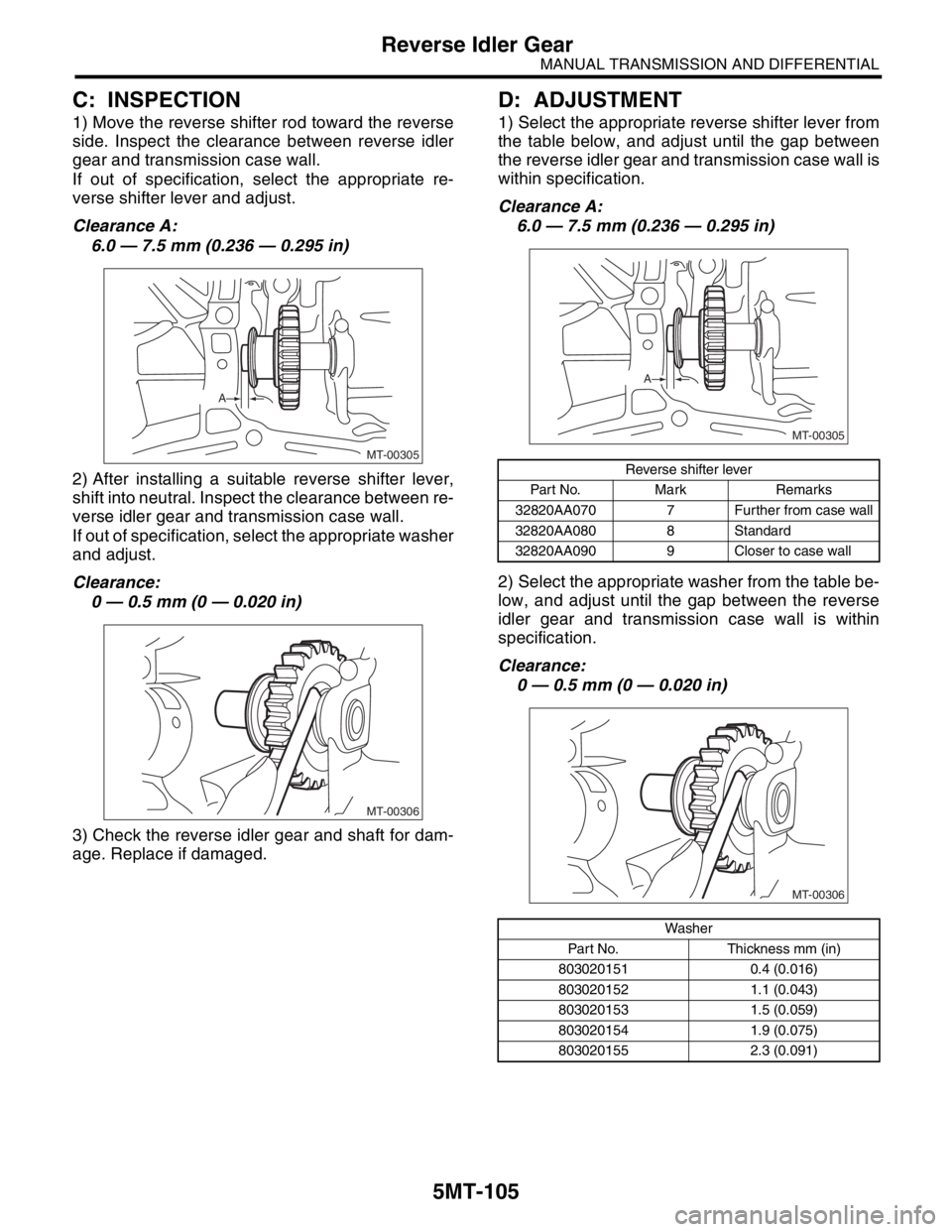

C: INSPECTION

1) Move the reverse shifter rod toward the reverse

side. Inspect the clearance between reverse idler

gear and transmission case wall.

If out of specification, select the appropriate re-

verse shifter lever and adjust.

Clearance A:

6.0 — 7.5 mm (0.236 — 0.295 in)

2) After installing a suitable reverse shifter lever,

shift into neutral. Inspect the clearance between re-

verse idler gear and transmission case wall.

If out of specification, select the appropriate washer

and adjust.

Clearance:

0 — 0.5 mm (0 — 0.020 in)

3) Check the reverse idler gear and shaft for dam-

age. Replace if damaged.

D: ADJUSTMENT

1) Select the appropriate reverse shifter lever from

the table below, and adjust until the gap between

the reverse idler gear and transmission case wall is

within specification.

Clearance A:

6.0 — 7.5 mm (0.236 — 0.295 in)

2) Select the appropriate washer from the table be-

low, and adjust until the gap between the reverse

idler gear and transmission case wall is within

specification.

Clearance:

0 — 0.5 mm (0 — 0.020 in)

MT-00305

A

MT-00306

Reverse shifter lever

Part No. Mark Remarks

32820AA070 7 Further from case wall

32820AA080 8 Standard

32820AA090 9 Closer to case wall

Washer

Part No. Thickness mm (in)

803020151 0.4 (0.016)

803020152 1.1 (0.043)

803020153 1.5 (0.059)

803020154 1.9 (0.075)

803020155 2.3 (0.091)

MT-00305

A

MT-00306

Page 2819 of 2870

5MT-106

MANUAL TRANSMISSION AND DIFFERENTIAL

Shifter Fork and Rod

24.Shifter Fork and Rod

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the back-up light switch and neutral po-

sition switch.

3) Remove the transfer case with extension case

assembly.

4) Remove the transmission case.

5) Remove the drive pinion shaft assembly.

bly.>

6) Remove the main shaft assembly.

Single-Range model

Dual-Range model

7) Remove the differential assembly.

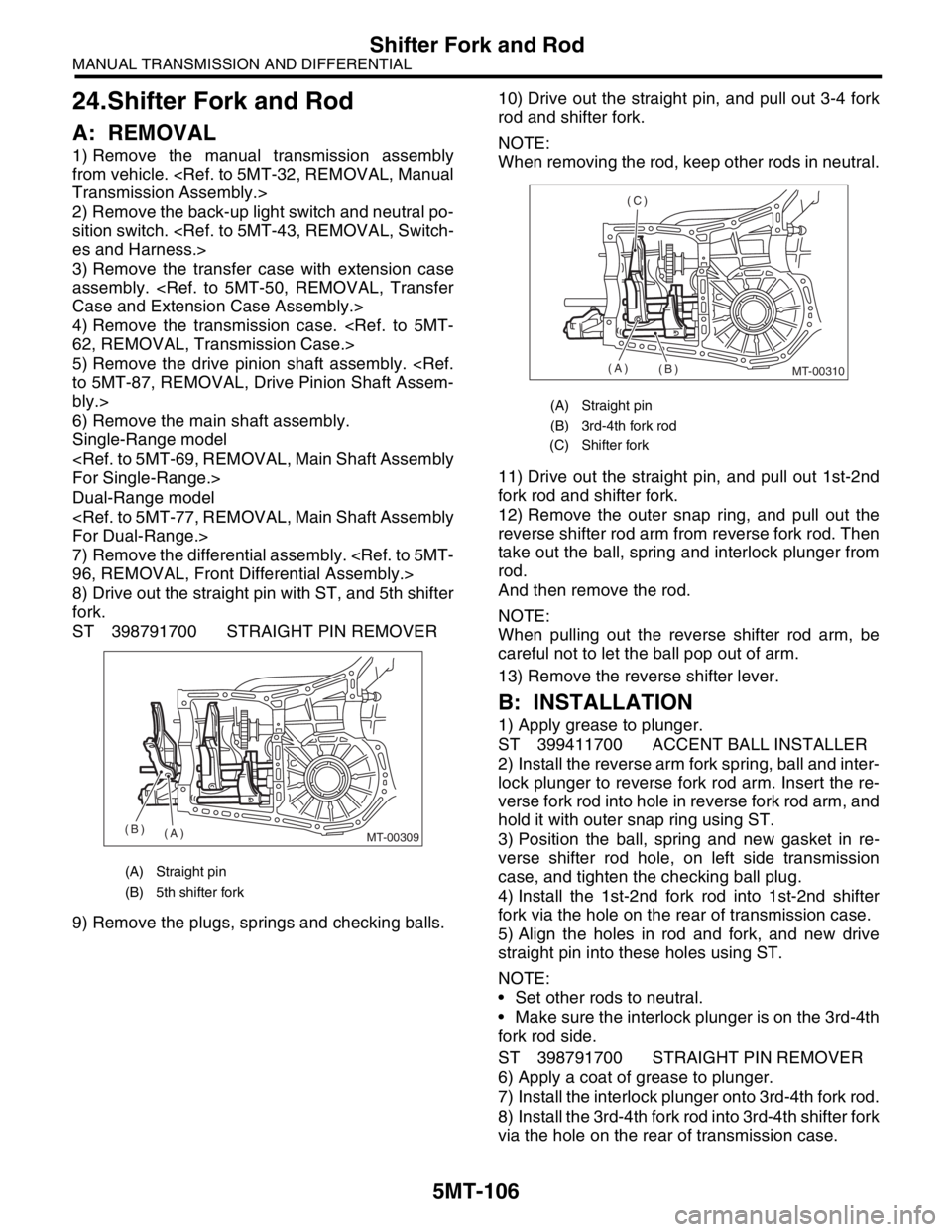

8) Drive out the straight pin with ST, and 5th shifter

fork.

ST 398791700 STRAIGHT PIN REMOVER

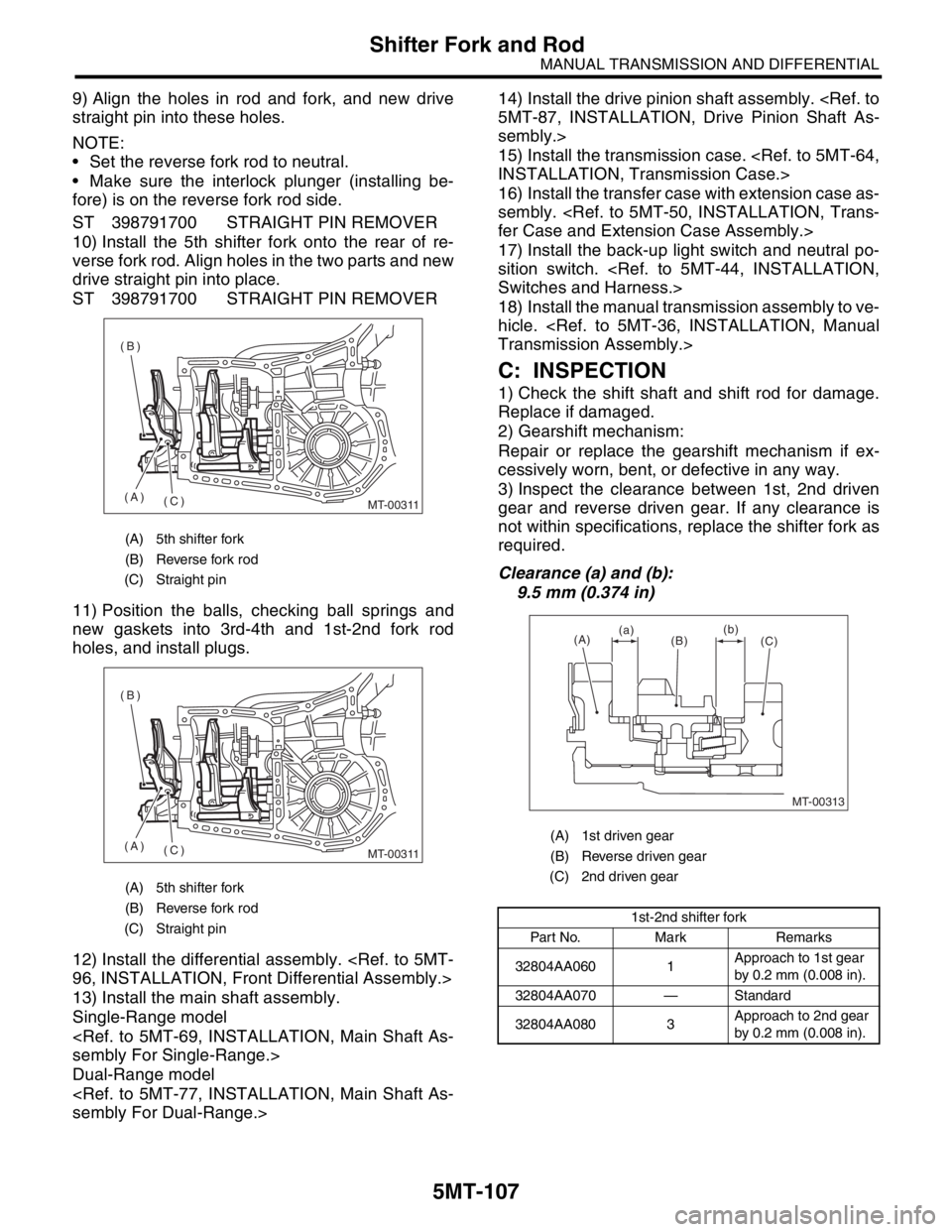

9) Remove the plugs, springs and checking balls.10) Drive out the straight pin, and pull out 3-4 fork

rod and shifter fork.

NOTE:

When removing the rod, keep other rods in neutral.

11) Drive out the straight pin, and pull out 1st-2nd

fork rod and shifter fork.

12) Remove the outer snap ring, and pull out the

reverse shifter rod arm from reverse fork rod. Then

take out the ball, spring and interlock plunger from

rod.

And then remove the rod.

NOTE:

When pulling out the reverse shifter rod arm, be

careful not to let the ball pop out of arm.

13) Remove the reverse shifter lever.

B: INSTALLATION

1) Apply grease to plunger.

ST 399411700 ACCENT BALL INSTALLER

2) Install the reverse arm fork spring, ball and inter-

lock plunger to reverse fork rod arm. Insert the re-

verse fork rod into hole in reverse fork rod arm, and

hold it with outer snap ring using ST.

3) Position the ball, spring and new gasket in re-

verse shifter rod hole, on left side transmission

case, and tighten the checking ball plug.

4) Install the 1st-2nd fork rod into 1st-2nd shifter

fork via the hole on the rear of transmission case.

5) Align the holes in rod and fork, and new drive

straight pin into these holes using ST.

NOTE:

Set other rods to neutral.

Make sure the interlock plunger is on the 3rd-4th

fork rod side.

ST 398791700 STRAIGHT PIN REMOVER

6) Apply a coat of grease to plunger.

7) Install the interlock plunger onto 3rd-4th fork rod.

8) Install the 3rd-4th fork rod into 3rd-4th shifter fork

via the hole on the rear of transmission case.

(A) Straight pin

(B) 5th shifter fork

MT-00309(A) (B)

(A) Straight pin

(B) 3rd-4th fork rod

(C) Shifter fork

MT-00310(A)

(B) (C)

Page 2820 of 2870

5MT-107

MANUAL TRANSMISSION AND DIFFERENTIAL

Shifter Fork and Rod

9) Align the holes in rod and fork, and new drive

straight pin into these holes.

NOTE:

Set the reverse fork rod to neutral.

Make sure the interlock plunger (installing be-

fore) is on the reverse fork rod side.

ST 398791700 STRAIGHT PIN REMOVER

10) Install the 5th shifter fork onto the rear of re-

verse fork rod. Align holes in the two parts and new

drive straight pin into place.

ST 398791700 STRAIGHT PIN REMOVER

11) Position the balls, checking ball springs and

new gaskets into 3rd-4th and 1st-2nd fork rod

holes, and install plugs.

12) Install the differential assembly.

13) Install the main shaft assembly.

Single-Range model

Dual-Range model

sembly.>

15) Install the transmission case.

16) Install the transfer case with extension case as-

sembly.

17) Install the back-up light switch and neutral po-

sition switch.

18) Install the manual transmission assembly to ve-

hicle.

C: INSPECTION

1) Check the shift shaft and shift rod for damage.

Replace if damaged.

2) Gearshift mechanism:

Repair or replace the gearshift mechanism if ex-

cessively worn, bent, or defective in any way.

3) Inspect the clearance between 1st, 2nd driven

gear and reverse driven gear. If any clearance is

not within specifications, replace the shifter fork as

required.

Clearance (a) and (b):

9.5 mm (0.374 in)

(A) 5th shifter fork

(B) Reverse fork rod

(C) Straight pin

(A) 5th shifter fork

(B) Reverse fork rod

(C) Straight pin

MT-00311(C) (A) (B)

MT-00311(C) (A) (B)(A) 1st driven gear

(B) Reverse driven gear

(C) 2nd driven gear

1st-2nd shifter fork

Part No. Mark Remarks

32804AA060 1Approach to 1st gear

by 0.2 mm (0.008 in).

32804AA070 — Standard

32804AA080 3Approach to 2nd gear

by 0.2 mm (0.008 in).

MT-00313

(A)

(B)

(C) (a)(b)