SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2841 of 2870

CL-15

CLUTCH SYSTEM

General Description

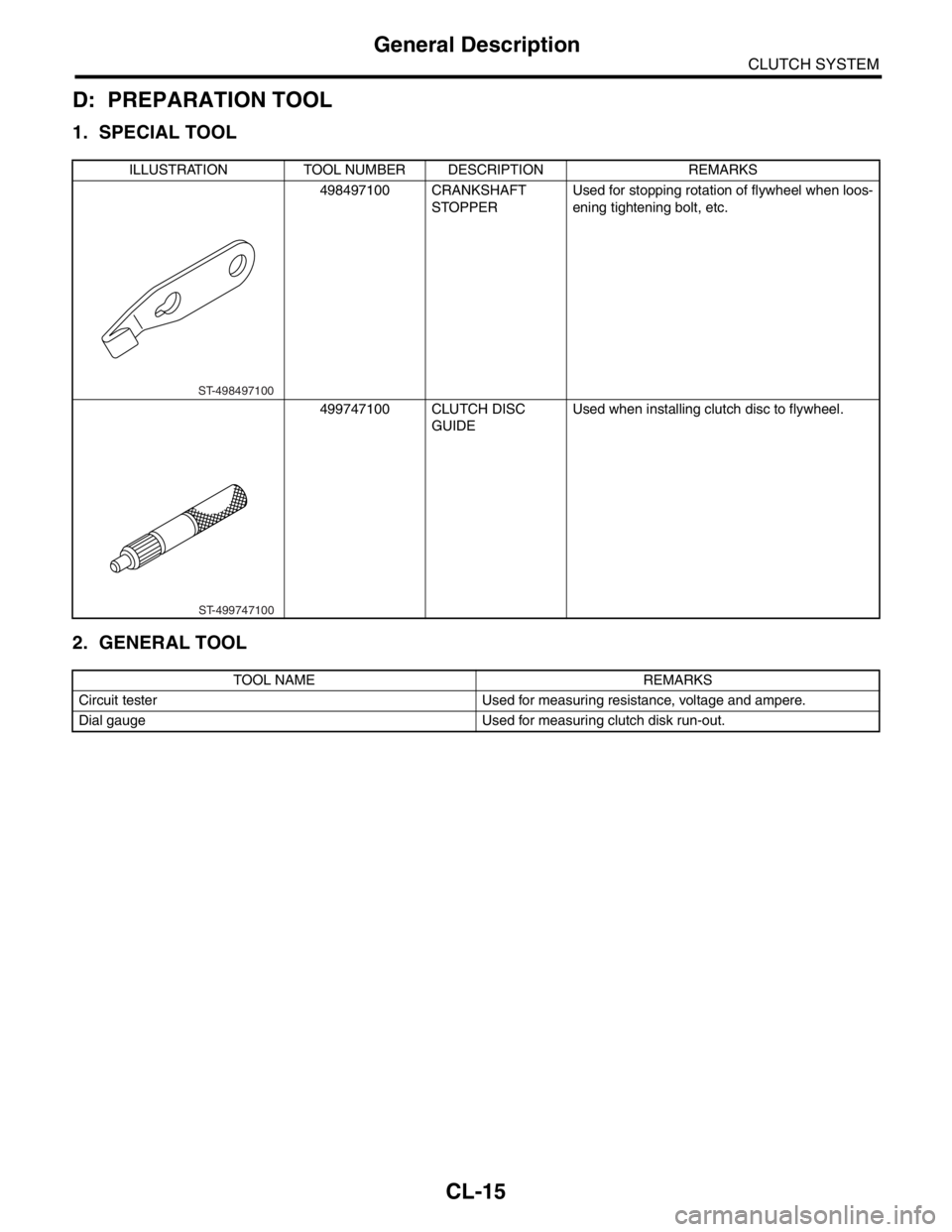

D: PREPARATION TOOL

1. SPECIAL TOOL

2. GENERAL TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

498497100 CRANKSHAFT

STOPPER Used for stopping rotation of flywheel when loos-

ening tightening bolt, etc.

499747100 CLUTCH DISC

GUIDEUsed when installing clutch disc to flywheel.

TOOL NAME REMARKS

Circuit tester Used for measuring resistance, voltage and ampere.

Dial gauge Used for measuring clutch disk run-out.

ST-498497100

ST-499747100

Page 2842 of 2870

CL-16

CLUTCH SYSTEM

Clutch Disc and Cover

2. Clutch Disc and Cover

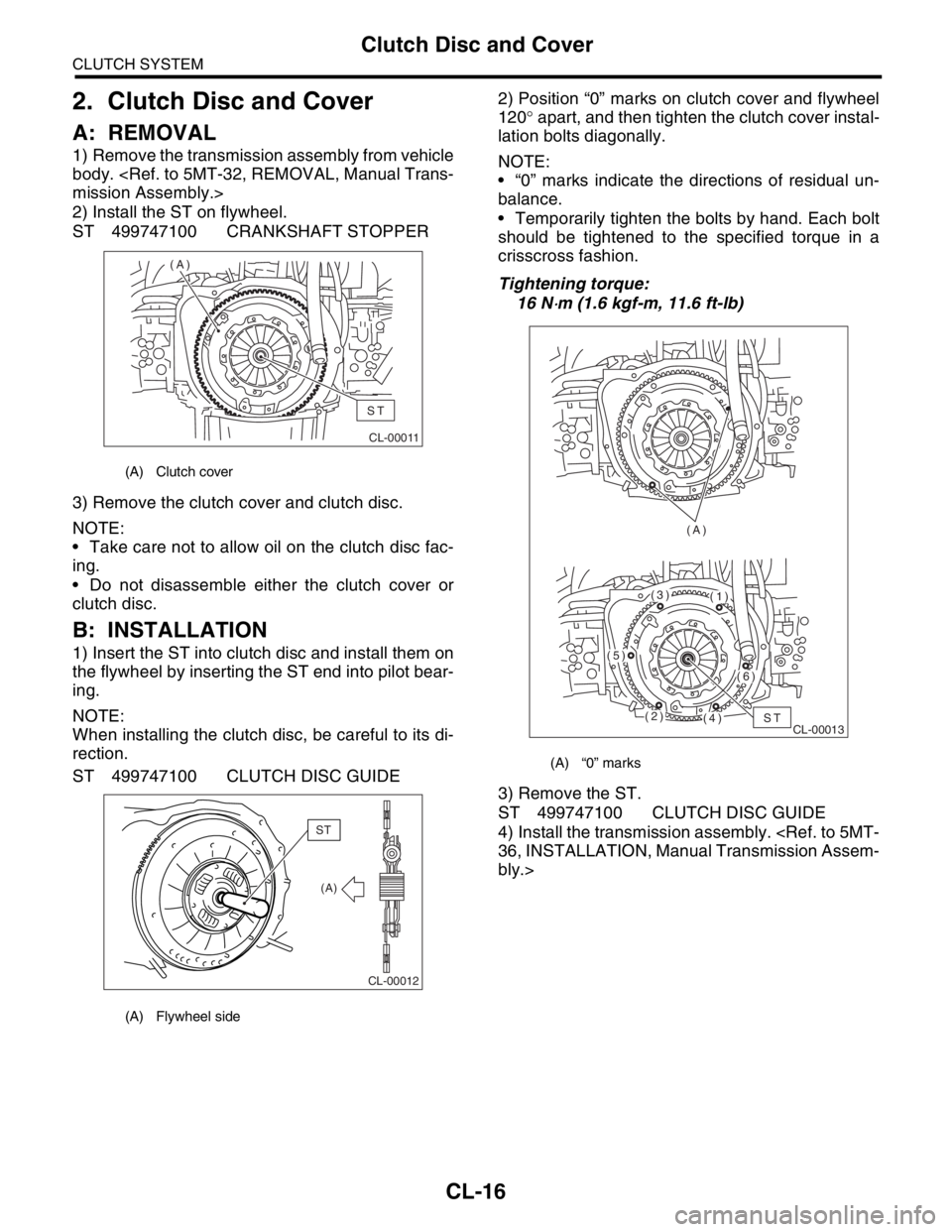

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Install the ST on flywheel.

ST 499747100 CRANKSHAFT STOPPER

3) Remove the clutch cover and clutch disc.

NOTE:

Take care not to allow oil on the clutch disc fac-

ing.

Do not disassemble either the clutch cover or

clutch disc.

B: INSTALLATION

1) Insert the ST into clutch disc and install them on

the flywheel by inserting the ST end into pilot bear-

ing.

NOTE:

When installing the clutch disc, be careful to its di-

rection.

ST 499747100 CLUTCH DISC GUIDE2) Position “0” marks on clutch cover and flywheel

120° apart, and then tighten the clutch cover instal-

lation bolts diagonally.

NOTE:

“0” marks indicate the directions of residual un-

balance.

Temporarily tighten the bolts by hand. Each bolt

should be tightened to the specified torque in a

crisscross fashion.

Tightening torque:

16 N

⋅m (1.6 kgf-m, 11.6 ft-lb)

3) Remove the ST.

ST 499747100 CLUTCH DISC GUIDE

4) Install the transmission assembly.

bly.>

(A) Clutch cover

(A) Flywheel side

CL-00011

(A)

ST

CL-00012

(A)

ST

(A) “0” marks

CL-00013 (A)ST(2)

(5)

(3)(1)

(6)

(4)

Page 2843 of 2870

CL-17

CLUTCH SYSTEM

Clutch Disc and Cover

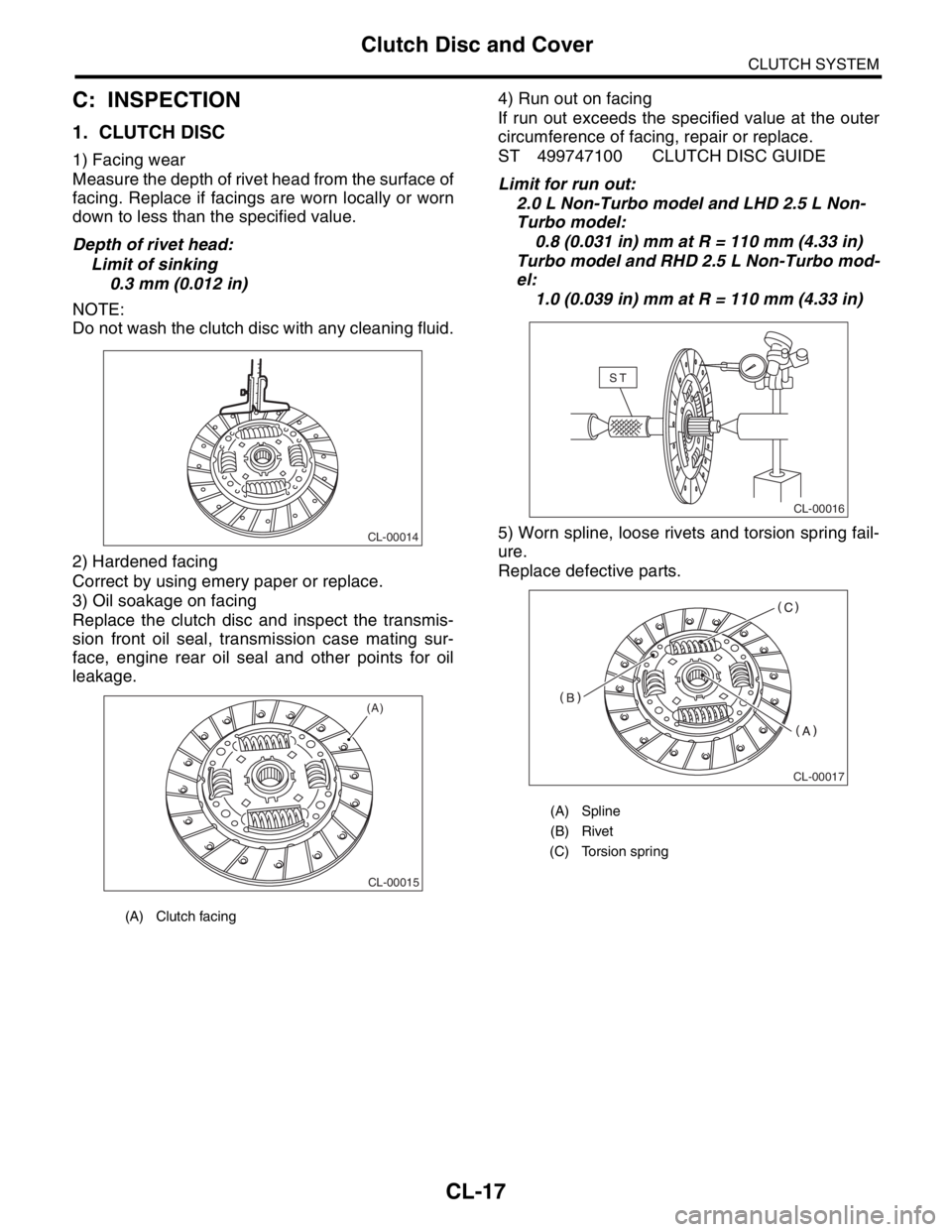

C: INSPECTION

1. CLUTCH DISC

1) Facing wear

Measure the depth of rivet head from the surface of

facing. Replace if facings are worn locally or worn

down to less than the specified value.

Depth of rivet head:

Limit of sinking

0.3 mm (0.012 in)

NOTE:

Do not wash the clutch disc with any cleaning fluid.

2) Hardened facing

Correct by using emery paper or replace.

3) Oil soakage on facing

Replace the clutch disc and inspect the transmis-

sion front oil seal, transmission case mating sur-

face, engine rear oil seal and other points for oil

leakage.4) Run out on facing

If run out exceeds the specified value at the outer

circumference of facing, repair or replace.

ST 499747100 CLUTCH DISC GUIDE

Limit for run out:

2.0 L Non-Turbo model and LHD 2.5 L Non-

Turbo model:

0.8 (0.031 in) mm at R = 110 mm (4.33 in)

Turbo model and RHD 2.5 L Non-Turbo mod-

el:

1.0 (0.039 in) mm at R = 110 mm (4.33 in)

5) Worn spline, loose rivets and torsion spring fail-

ure.

Replace defective parts.

(A) Clutch facing

CL-00014

CL-00015

(A)

(A) Spline

(B) Rivet

(C) Torsion spring

CL-00016

ST

CL-00017

Page 2844 of 2870

CL-18

CLUTCH SYSTEM

Clutch Disc and Cover

2. CLUTCH COVER

NOTE:

Visually check for the following items without disas-

sembling, and replace or repair if defective.

1) Loose thrust rivet.

2) Damaged or worn bearing contact area at center

of diaphragm spring.

(A) Thrust rivet

(B) Diaphragm spring

CL-00018

(A)

(B)

Page 2845 of 2870

CL-19

CLUTCH SYSTEM

Flywheel

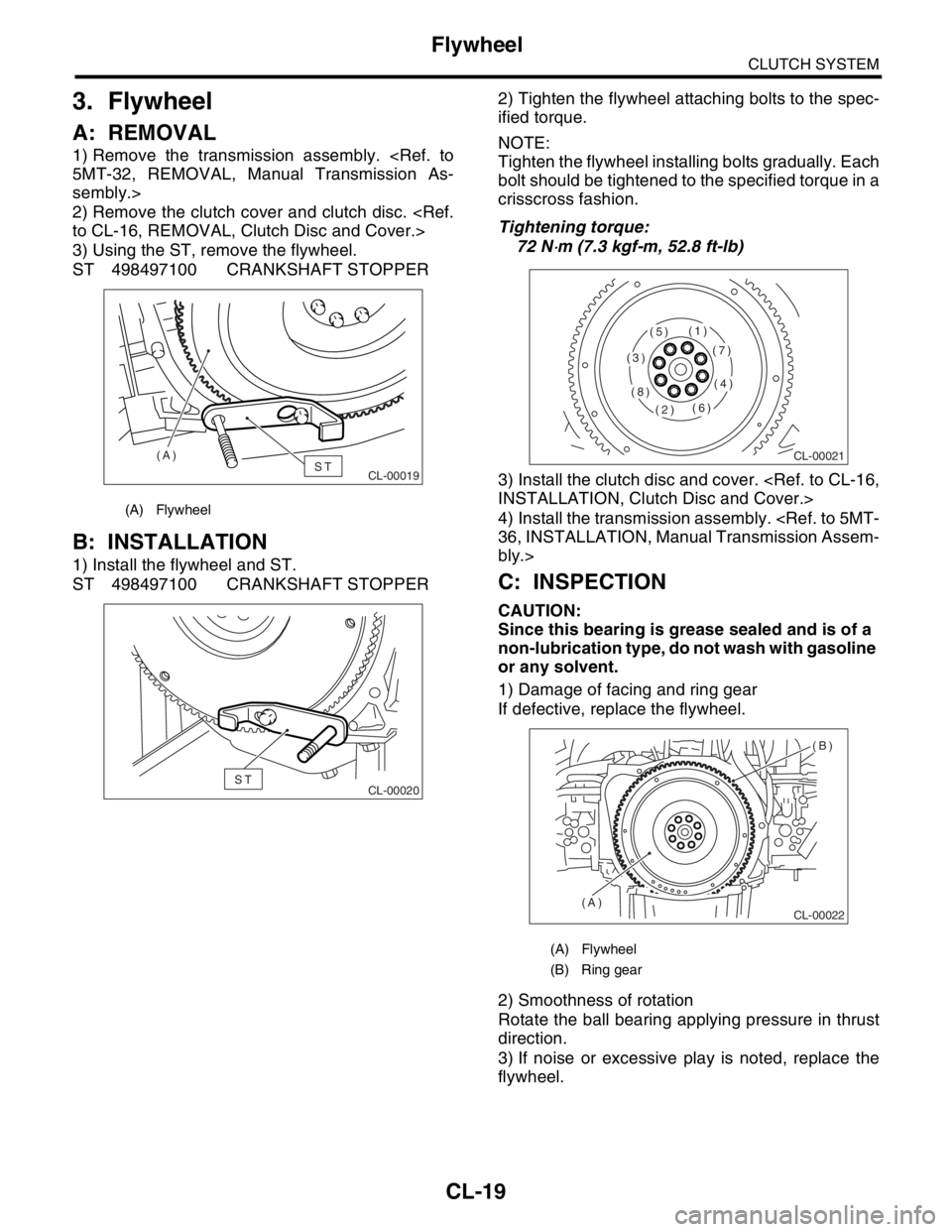

3. Flywheel

A: REMOVAL

1) Remove the transmission assembly.

sembly.>

2) Remove the clutch cover and clutch disc.

3) Using the ST, remove the flywheel.

ST 498497100 CRANKSHAFT STOPPER

B: INSTALLATION

1) Install the flywheel and ST.

ST 498497100 CRANKSHAFT STOPPER2) Tighten the flywheel attaching bolts to the spec-

ified torque.

NOTE:

Tighten the flywheel installing bolts gradually. Each

bolt should be tightened to the specified torque in a

crisscross fashion.

Tightening torque:

72 N

⋅m (7.3 kgf-m, 52.8 ft-lb)

3) Install the clutch disc and cover.

4) Install the transmission assembly.

bly.>

C: INSPECTION

CAUTION:

Since this bearing is grease sealed and is of a

non-lubrication type, do not wash with gasoline

or any solvent.

1) Damage of facing and ring gear

If defective, replace the flywheel.

2) Smoothness of rotation

Rotate the ball bearing applying pressure in thrust

direction.

3) If noise or excessive play is noted, replace the

flywheel.

(A) Flywheel

CL-00019ST (A)

CL-00020ST

(A) Flywheel

(B) Ring gear

CL-00021

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

CL-00022

(B)

(A)

Page 2846 of 2870

CL-20

CLUTCH SYSTEM

Release Bearing and Lever

4. Release Bearing and Lever

A: REMOVAL

1. NON-TURBO MODEL

1) Remove the transmission assembly from vehicle

body.

2) Remove the two clips from clutch release lever

and remove the release bearing.

CAUTION:

Be careful not to deform clips.

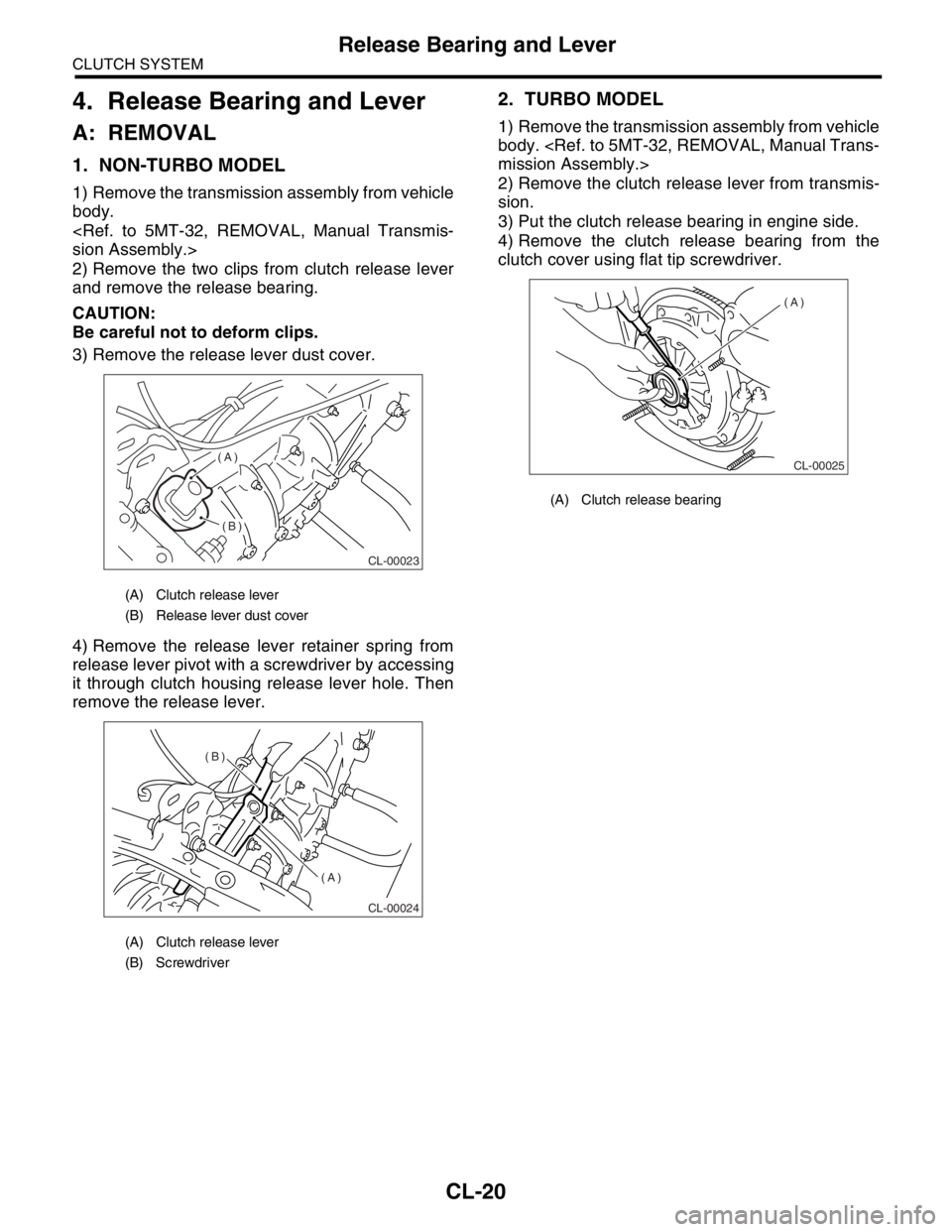

3) Remove the release lever dust cover.

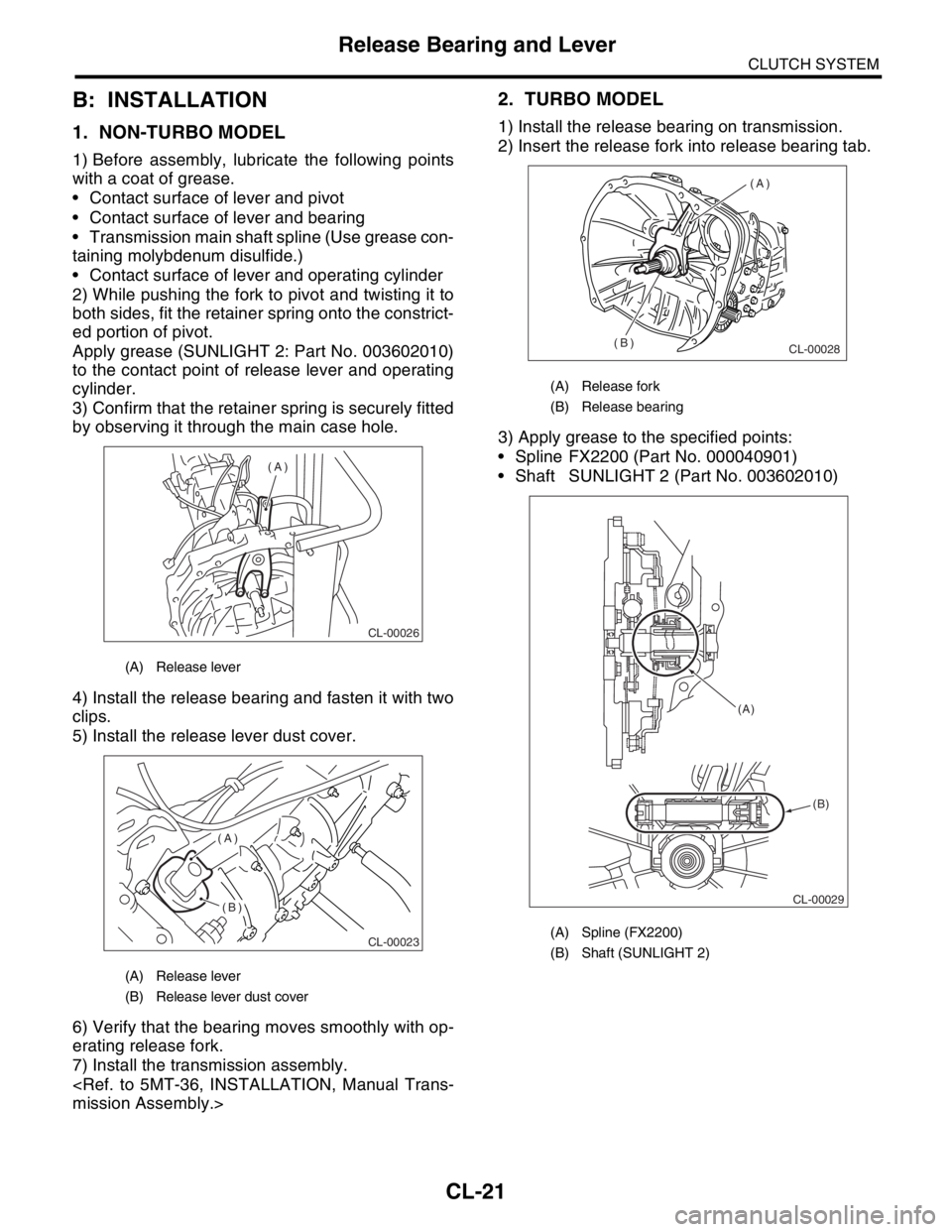

4) Remove the release lever retainer spring from

release lever pivot with a screwdriver by accessing

it through clutch housing release lever hole. Then

remove the release lever.

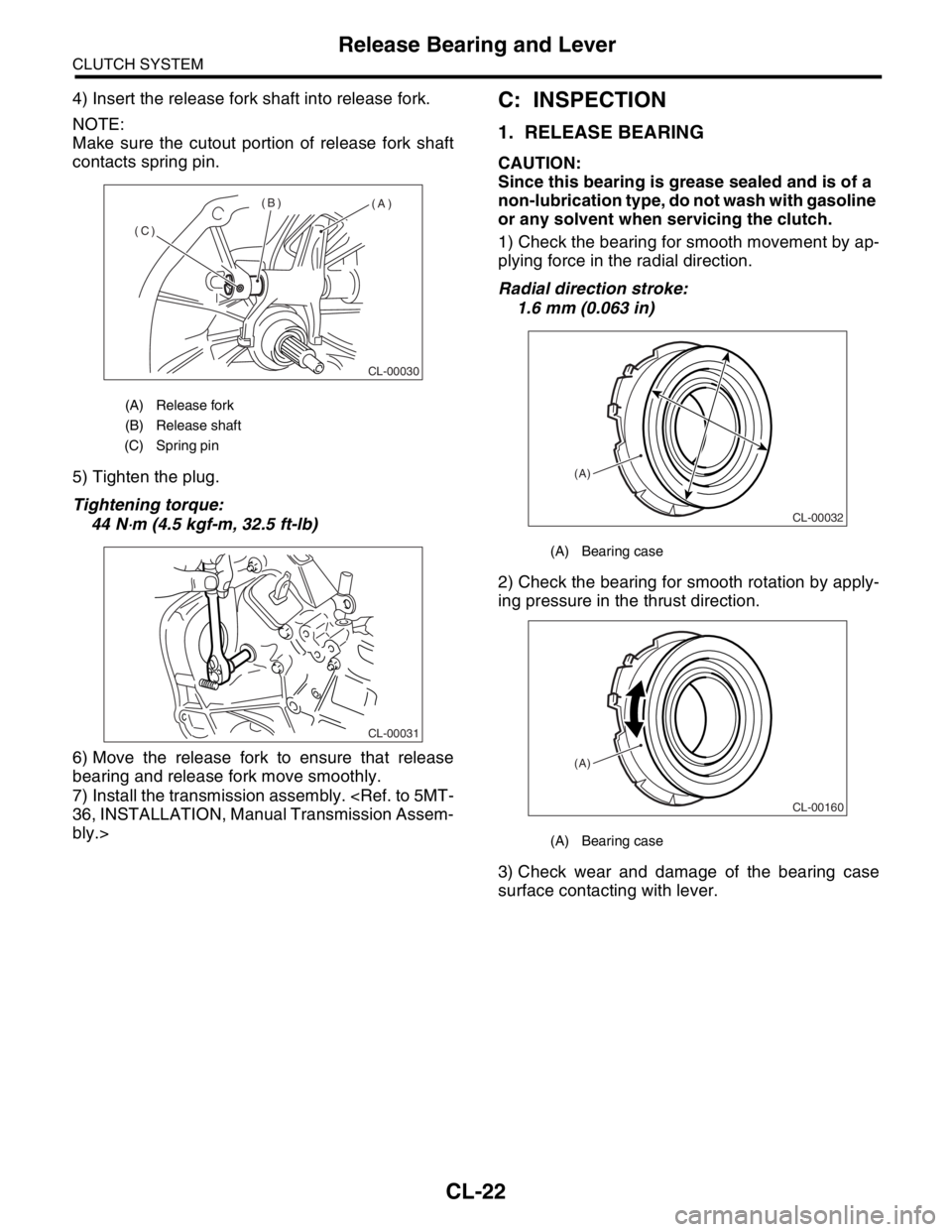

2. TURBO MODEL

1) Remove the transmission assembly from vehicle

body.

2) Remove the clutch release lever from transmis-

sion.

3) Put the clutch release bearing in engine side.

4) Remove the clutch release bearing from the

clutch cover using flat tip screwdriver.

(A) Clutch release lever

(B) Release lever dust cover

(A) Clutch release lever

(B) Screwdriver

CL-00023

(A)

(B)

CL-00024

(B)

(A)

(A) Clutch release bearing

CL-00025

(A)

Page 2847 of 2870

CL-21

CLUTCH SYSTEM

Release Bearing and Lever

B: INSTALLATION

1. NON-TURBO MODEL

1) Before assembly, lubricate the following points

with a coat of grease.

Contact surface of lever and pivot

Contact surface of lever and bearing

Transmission main shaft spline (Use grease con-

taining molybdenum disulfide.)

Contact surface of lever and operating cylinder

2) While pushing the fork to pivot and twisting it to

both sides, fit the retainer spring onto the constrict-

ed portion of pivot.

Apply grease (SUNLIGHT 2: Part No. 003602010)

to the contact point of release lever and operating

cylinder.

3) Confirm that the retainer spring is securely fitted

by observing it through the main case hole.

4) Install the release bearing and fasten it with two

clips.

5) Install the release lever dust cover.

6) Verify that the bearing moves smoothly with op-

erating release fork.

7) Install the transmission assembly.

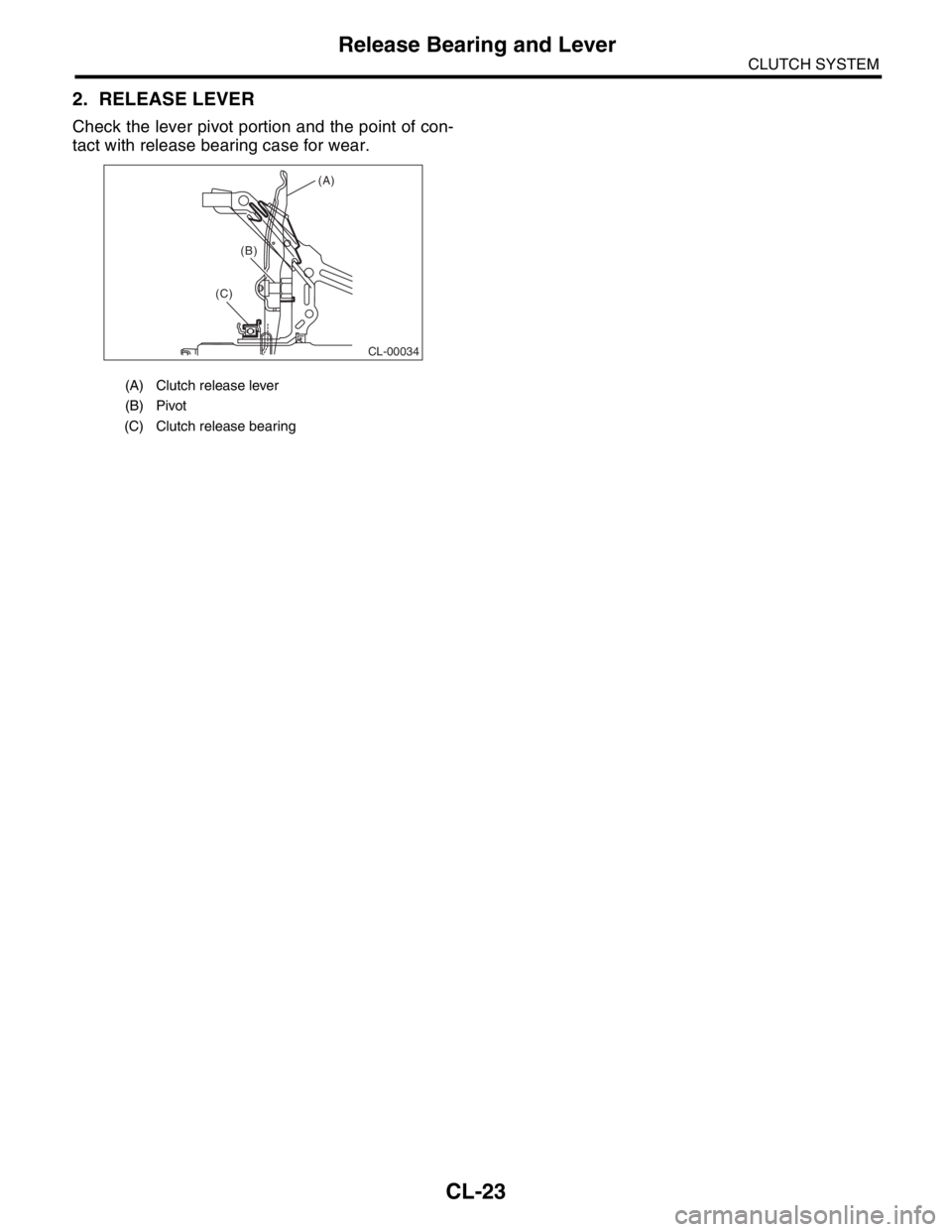

2. TURBO MODEL

1) Install the release bearing on transmission.

2) Insert the release fork into release bearing tab.

3) Apply grease to the specified points:

Spline FX2200 (Part No. 000040901)

Shaft SUNLIGHT 2 (Part No. 003602010)

(A) Release lever

(A) Release lever

(B) Release lever dust cover

CL-00026

(A)

CL-00023

(A)

(B)

(A) Release fork

(B) Release bearing

(A) Spline (FX2200)

(B) Shaft (SUNLIGHT 2)

CL-00028

(A)

(B)

CL-00029 (A)

(B)

Page 2848 of 2870

CL-22

CLUTCH SYSTEM

Release Bearing and Lever

4) Insert the release fork shaft into release fork.

NOTE:

Make sure the cutout portion of release fork shaft

contacts spring pin.

5) Tighten the plug.

Tightening torque:

44 N

⋅m (4.5 kgf-m, 32.5 ft-lb)

6) Move the release fork to ensure that release

bearing and release fork move smoothly.

7) Install the transmission assembly.

bly.>

C: INSPECTION

1. RELEASE BEARING

CAUTION:

Since this bearing is grease sealed and is of a

non-lubrication type, do not wash with gasoline

or any solvent when servicing the clutch.

1) Check the bearing for smooth movement by ap-

plying force in the radial direction.

Radial direction stroke:

1.6 mm (0.063 in)

2) Check the bearing for smooth rotation by apply-

ing pressure in the thrust direction.

3) Check wear and damage of the bearing case

surface contacting with lever.

(A) Release fork

(B) Release shaft

(C) Spring pin

CL-00030

(A) (B)

(C)

CL-00031

(A) Bearing case

(A) Bearing case

CL-00032

(A)

CL-00160

(A)

Page 2849 of 2870

CL-23

CLUTCH SYSTEM

Release Bearing and Lever

2. RELEASE LEVER

Check the lever pivot portion and the point of con-

tact with release bearing case for wear.

(A) Clutch release lever

(B) Pivot

(C) Clutch release bearing

CL-00034

(A)

(B)

(C)

Page 2850 of 2870

CL-24

CLUTCH SYSTEM

Operating Cylinder

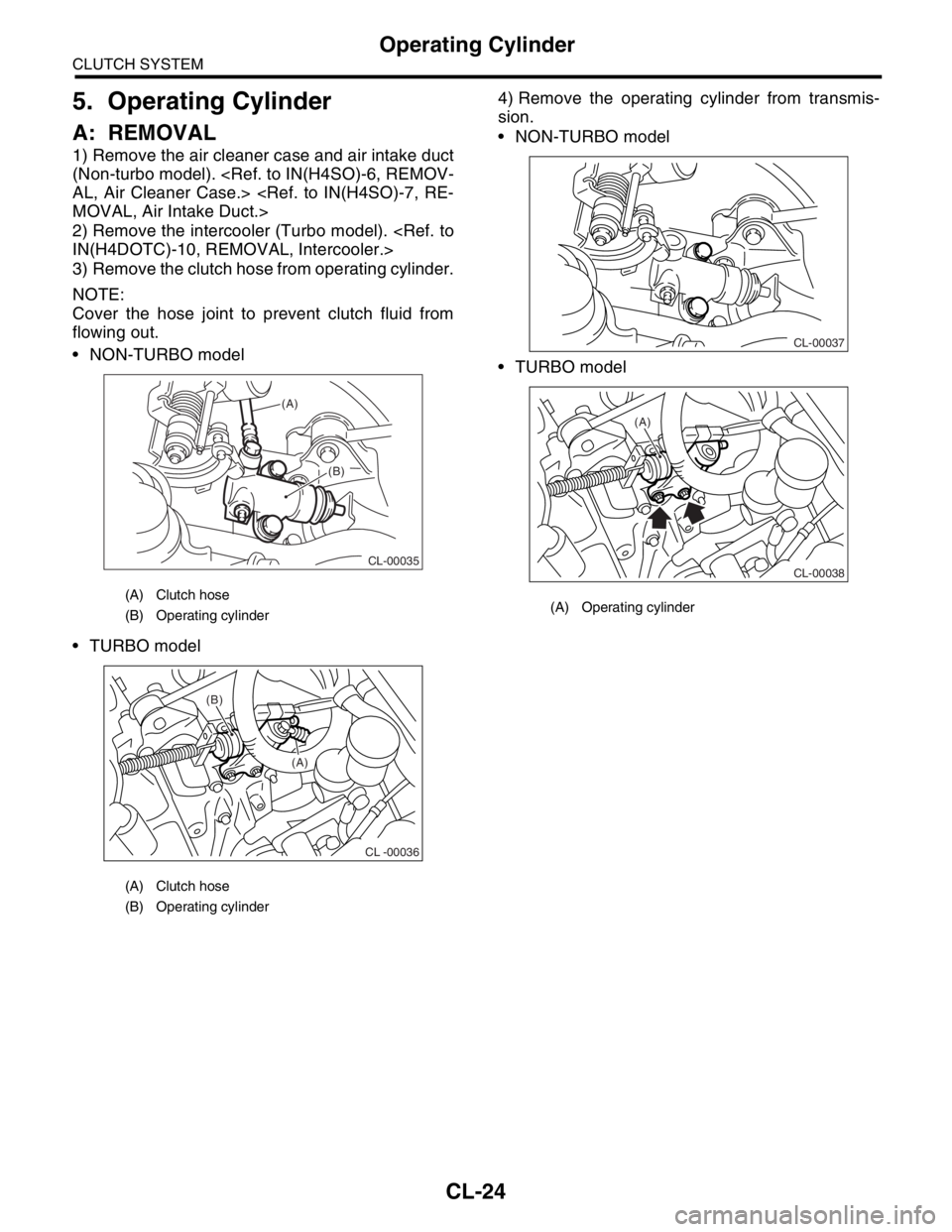

5. Operating Cylinder

A: REMOVAL

1) Remove the air cleaner case and air intake duct

(Non-turbo model).

2) Remove the intercooler (Turbo model).

3) Remove the clutch hose from operating cylinder.

NOTE:

Cover the hose joint to prevent clutch fluid from

flowing out.

NON-TURBO model

TURBO model4) Remove the operating cylinder from transmis-

sion.

NON-TURBO model

TURBO model

(A) Clutch hose

(B) Operating cylinder

(A) Clutch hose

(B) Operating cylinder

CL-00035

(A)

(B)

CL -00036

(B)

(A)

(A) Operating cylinder

CL-00037

CL-00038

(A)