torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2306 of 2870

CS-21

CONTROL SYSTEM

MT Gear Shift Lever

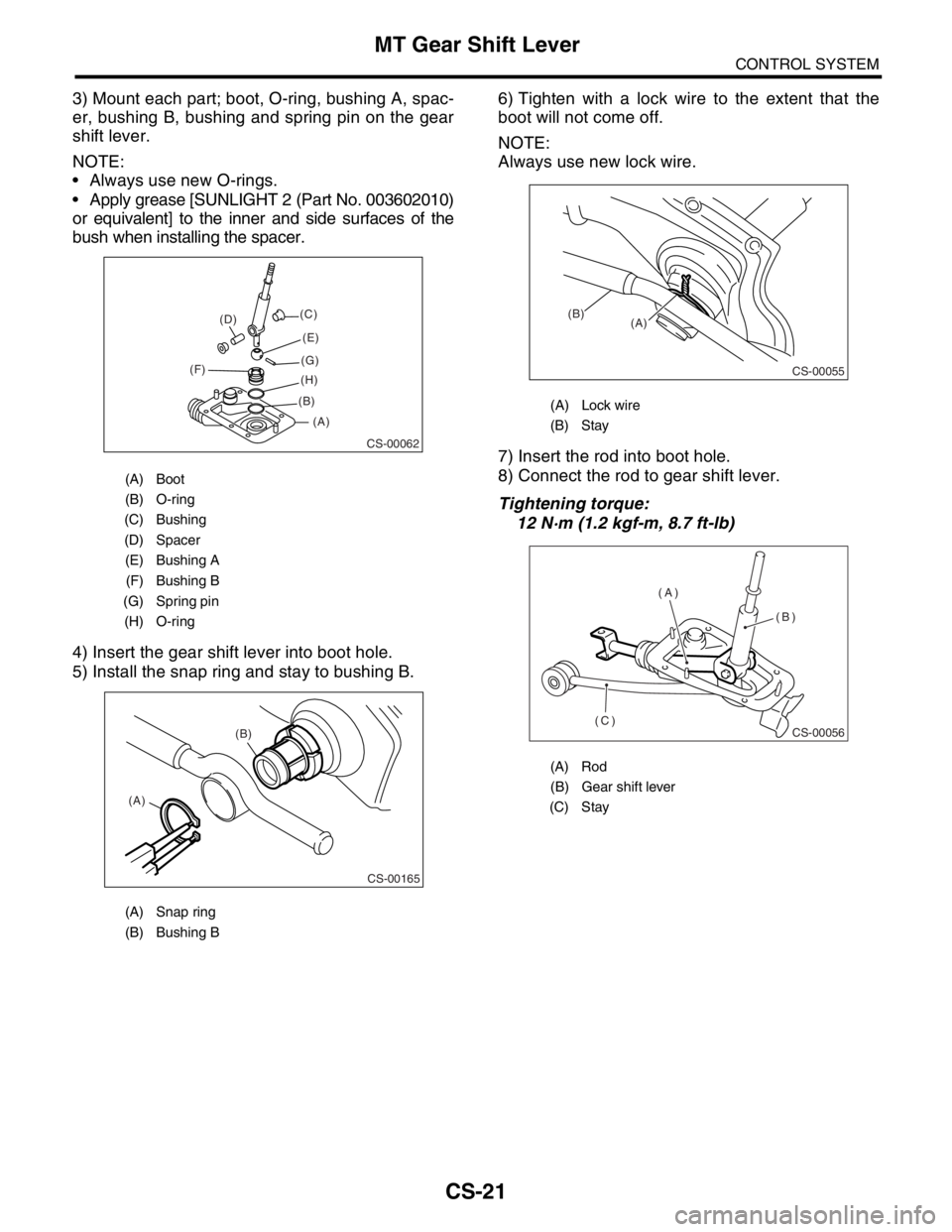

3) Mount each part; boot, O-ring, bushing A, spac-

er, bushing B, bushing and spring pin on the gear

shift lever.

NOTE:

Always use new O-rings.

Apply grease [SUNLIGHT 2 (Part No. 003602010)

or equivalent] to the inner and side surfaces of the

bush when installing the spacer.

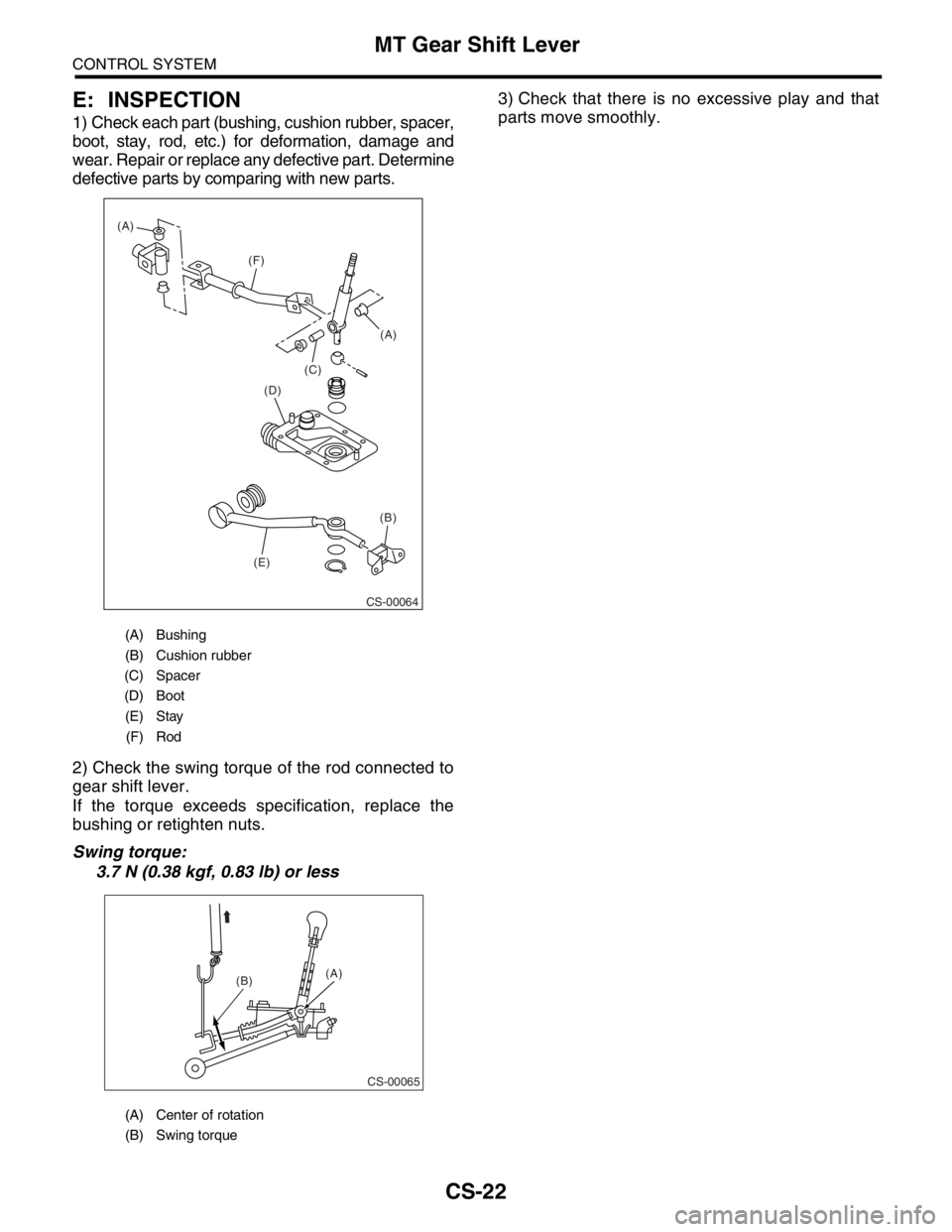

4) Insert the gear shift lever into boot hole.

5) Install the snap ring and stay to bushing B.6) Tighten with a lock wire to the extent that the

boot will not come off.

NOTE:

Always use new lock wire.

7) Insert the rod into boot hole.

8) Connect the rod to gear shift lever.

Tightening torque:

12 N·m (1.2 kgf-m, 8.7 ft-lb)

(A) Boot

(B) O-ring

(C) Bushing

(D) Spacer

(E) Bushing A

(F) Bushing B

(G) Spring pin

(H) O-ring

(A) Snap ring

(B) Bushing B

CS-00062

(F)(D)(C)

(E)

(G)

(H)

(B)

(A)

CS-00165

(A)(B)

(A) Lock wire

(B) Stay

(A) Rod

(B) Gear shift lever

(C) Stay

CS-00055

(B)

(A)

CS-00056

(A)

(B)

(C)

Page 2307 of 2870

CS-22

CONTROL SYSTEM

MT Gear Shift Lever

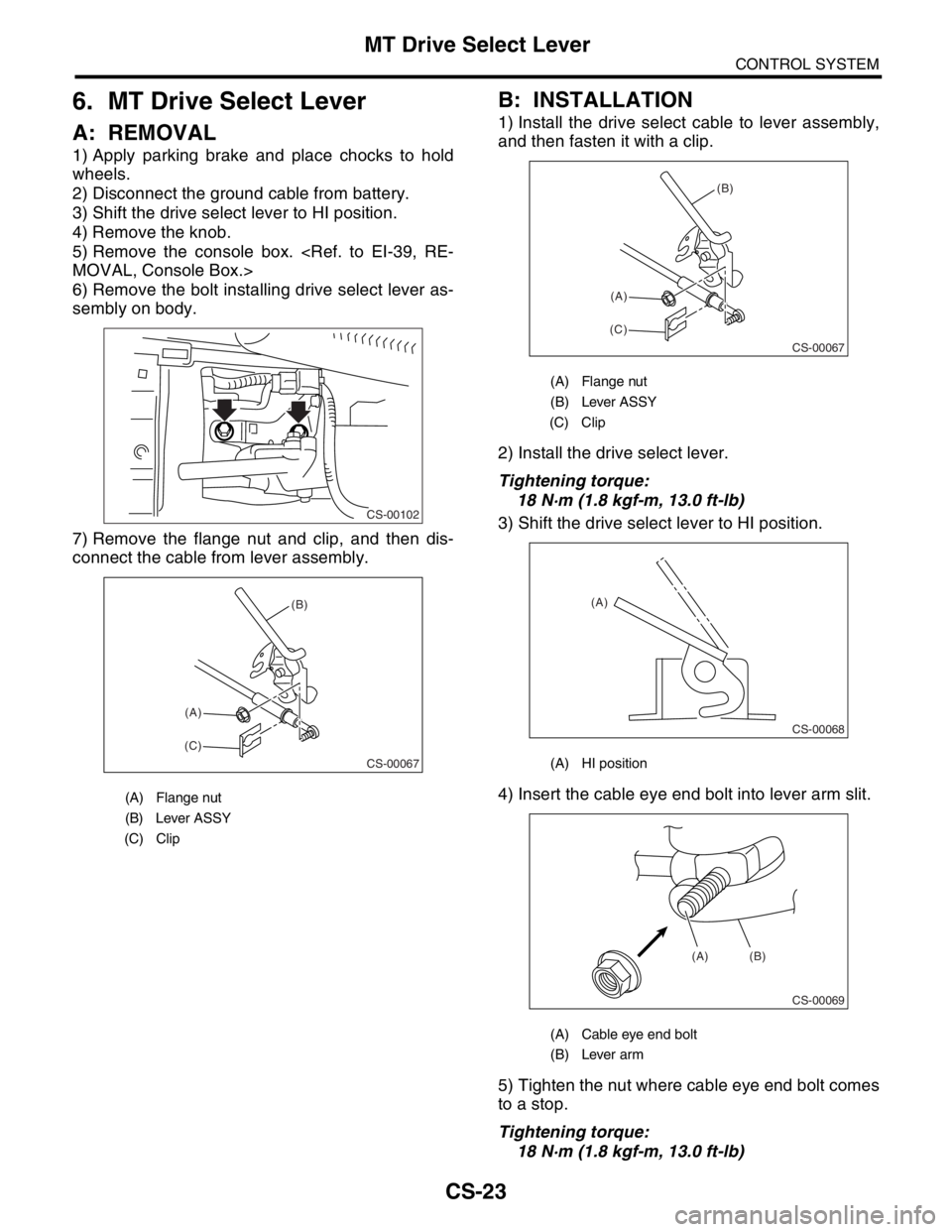

E: INSPECTION

1) Check each part (bushing, cushion rubber, spacer,

boot, stay, rod, etc.) for deformation, damage and

wear. Repair or replace any defective part. Determine

defective parts by comparing with new parts.

2) Check the swing torque of the rod connected to

gear shift lever.

If the torque exceeds specification, replace the

bushing or retighten nuts.

Swing torque:

3.7 N (0.38 kgf, 0.83 lb) or less3) Check that there is no excessive play and that

parts move smoothly.

(A) Bushing

(B) Cushion rubber

(C) Spacer

(D) Boot

(E) Stay

(F) Rod

(A) Center of rotation

(B) Swing torque

(C)

(D)(A) (F) (A)

CS-00064

(E)(B)

CS-00065

(A)

(B)

Page 2308 of 2870

CS-23

CONTROL SYSTEM

MT Drive Select Lever

6. MT Drive Select Lever

A: REMOVAL

1) Apply parking brake and place chocks to hold

wheels.

2) Disconnect the ground cable from battery.

3) Shift the drive select lever to HI position.

4) Remove the knob.

5) Remove the console box.

6) Remove the bolt installing drive select lever as-

sembly on body.

7) Remove the flange nut and clip, and then dis-

connect the cable from lever assembly.

B: INSTALLATION

1) Install the drive select cable to lever assembly,

and then fasten it with a clip.

2) Install the drive select lever.

Tightening torque:

18 N·m (1.8 kgf-m, 13.0 ft-lb)

3) Shift the drive select lever to HI position.

4) Insert the cable eye end bolt into lever arm slit.

5) Tighten the nut where cable eye end bolt comes

to a stop.

Tightening torque:

18 N·m (1.8 kgf-m, 13.0 ft-lb)

(A) Flange nut

(B) Lever ASSY

(C) Clip

CS-00102

CS-00067

(C)(A)(B)

(A) Flange nut

(B) Lever ASSY

(C) Clip

(A) HI position

(A) Cable eye end bolt

(B) Lever arm

CS-00067

(C)(A)(B)

CS-00068

(A)

CS-00069

(A) (B)

Page 2309 of 2870

CS-24

CONTROL SYSTEM

MT Drive Select Lever

6) Install in the reverse order of removal.

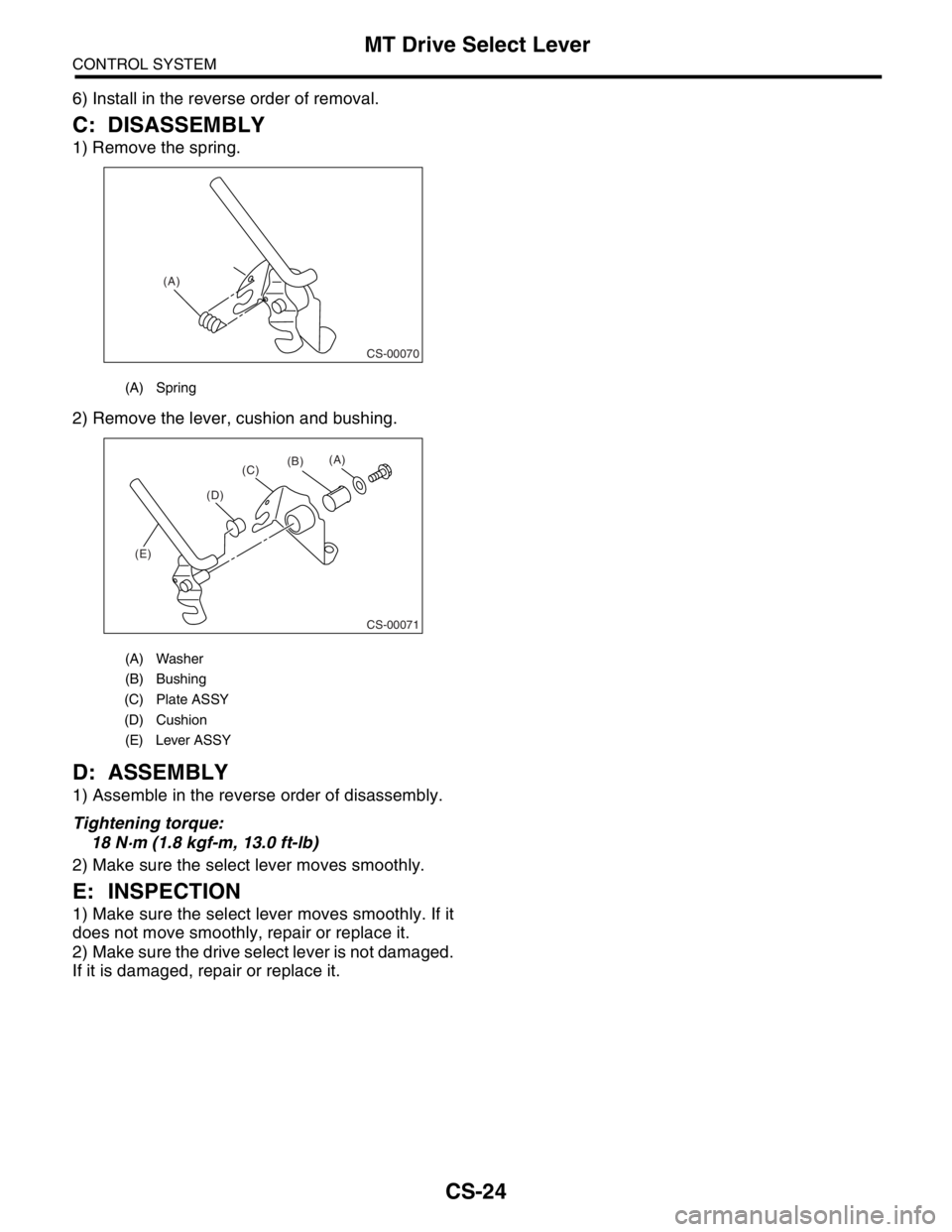

C: DISASSEMBLY

1) Remove the spring.

2) Remove the lever, cushion and bushing.

D: ASSEMBLY

1) Assemble in the reverse order of disassembly.

Tightening torque:

18 N·m (1.8 kgf-m, 13.0 ft-lb)

2) Make sure the select lever moves smoothly.

E: INSPECTION

1) Make sure the select lever moves smoothly. If it

does not move smoothly, repair or replace it.

2) Make sure the drive select lever is not damaged.

If it is damaged, repair or replace it.

(A) Spring

(A) Washer

(B) Bushing

(C) Plate ASSY

(D) Cushion

(E) Lever ASSY

CS-00070

(A)

CS-00071

(E)(C)

(D)(B)(A)

Page 2310 of 2870

CS-25

CONTROL SYSTEM

Drive Select Cable

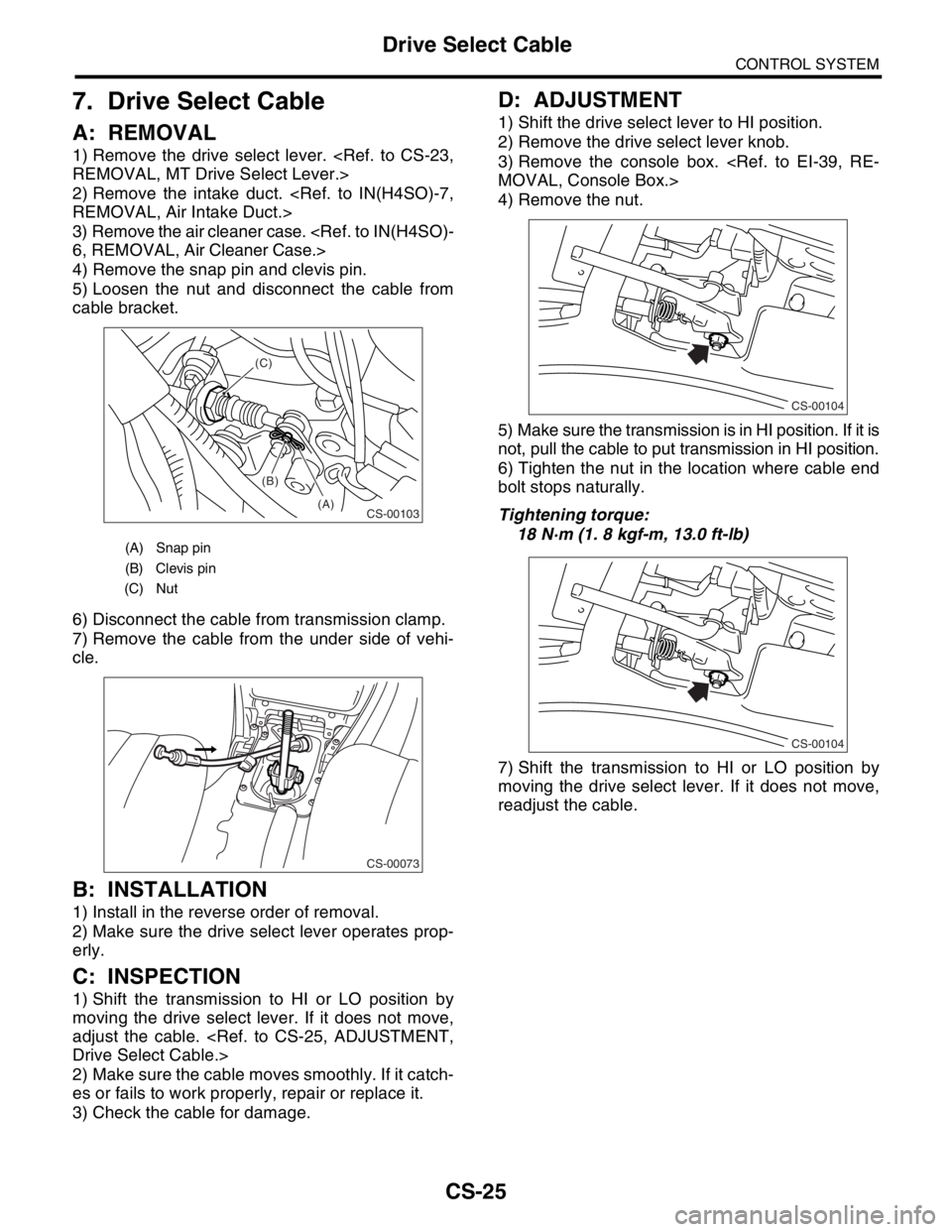

7. Drive Select Cable

A: REMOVAL

1) Remove the drive select lever.

2) Remove the intake duct.

3) Remove the air cleaner case.

4) Remove the snap pin and clevis pin.

5) Loosen the nut and disconnect the cable from

cable bracket.

6) Disconnect the cable from transmission clamp.

7) Remove the cable from the under side of vehi-

cle.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Make sure the drive select lever operates prop-

erly.

C: INSPECTION

1) Shift the transmission to HI or LO position by

moving the drive select lever. If it does not move,

adjust the cable.

2) Make sure the cable moves smoothly. If it catch-

es or fails to work properly, repair or replace it.

3) Check the cable for damage.

D: ADJUSTMENT

1) Shift the drive select lever to HI position.

2) Remove the drive select lever knob.

3) Remove the console box.

4) Remove the nut.

5) Make sure the transmission is in HI position. If it is

not, pull the cable to put transmission in HI position.

6) Tighten the nut in the location where cable end

bolt stops naturally.

Tightening torque:

18 N·m (1. 8 kgf-m, 13.0 ft-lb)

7) Shift the transmission to HI or LO position by

moving the drive select lever. If it does not move,

readjust the cable.

(A) Snap pin

(B) Clevis pin

(C) Nut

CS-00103(A) (B) (C)

CS-00073

CS-00104

CS-00104

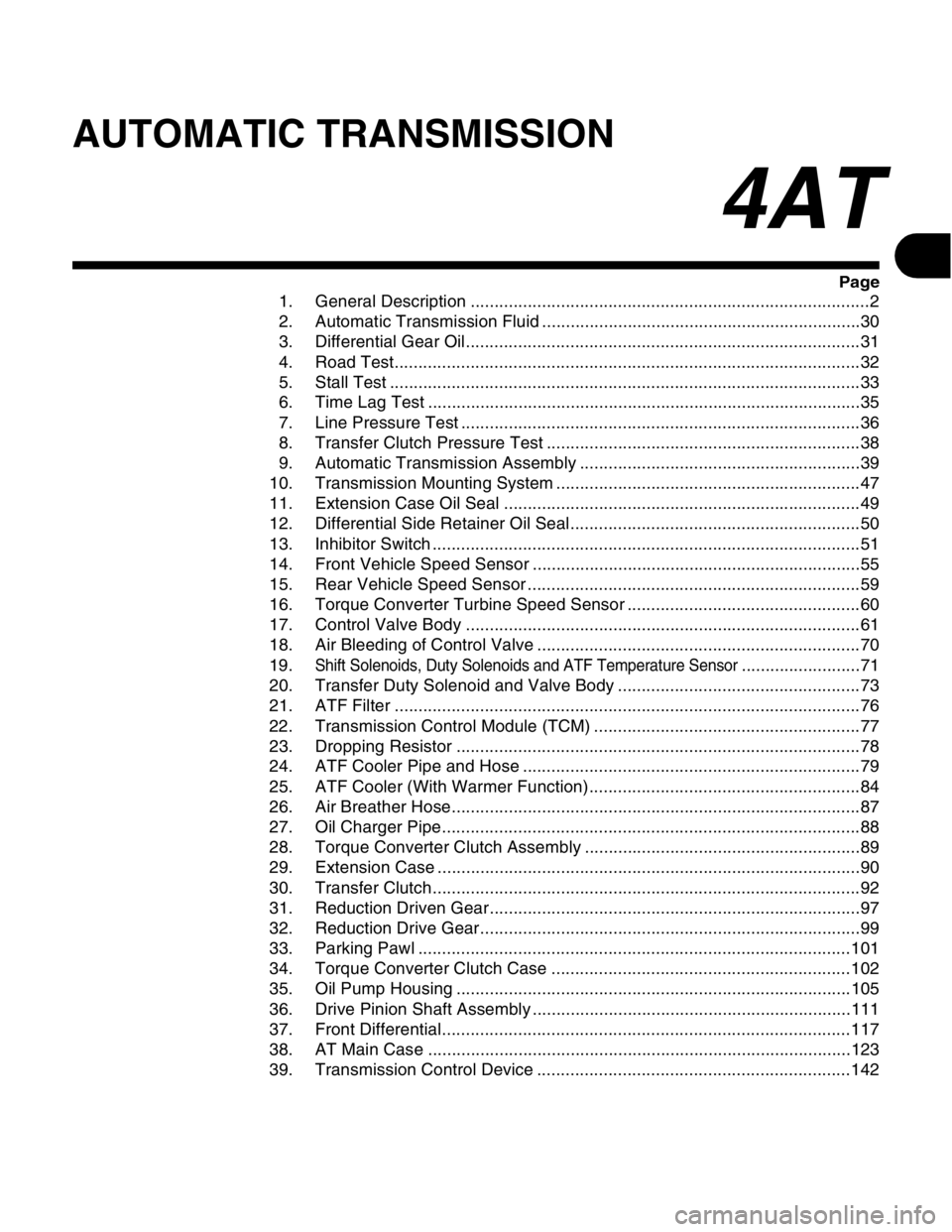

Page 2313 of 2870

AUTOMATIC TRANSMISSION

4AT

Page

1. General Description ....................................................................................2

2. Automatic Transmission Fluid ...................................................................30

3. Differential Gear Oil...................................................................................31

4. Road Test..................................................................................................32

5. Stall Test ...................................................................................................33

6. Time Lag Test ...........................................................................................35

7. Line Pressure Test ....................................................................................36

8. Transfer Clutch Pressure Test ..................................................................38

9. Automatic Transmission Assembly ...........................................................39

10. Transmission Mounting System ................................................................47

11. Extension Case Oil Seal ...........................................................................49

12. Differential Side Retainer Oil Seal.............................................................50

13. Inhibitor Switch ..........................................................................................51

14. Front Vehicle Speed Sensor .....................................................................55

15. Rear Vehicle Speed Sensor ......................................................................59

16. Torque Converter Turbine Speed Sensor .................................................60

17. Control Valve Body ...................................................................................61

18. Air Bleeding of Control Valve ....................................................................70

19.

Shift Solenoids, Duty Solenoids and ATF Temperature Sensor.........................71

20. Transfer Duty Solenoid and Valve Body ...................................................73

21. ATF Filter ..................................................................................................76

22. Transmission Control Module (TCM) ........................................................77

23. Dropping Resistor .....................................................................................78

24. ATF Cooler Pipe and Hose .......................................................................79

25. ATF Cooler (With Warmer Function).........................................................84

26. Air Breather Hose......................................................................................87

27. Oil Charger Pipe........................................................................................88

28. Torque Converter Clutch Assembly ..........................................................89

29. Extension Case .........................................................................................90

30. Transfer Clutch..........................................................................................92

31. Reduction Driven Gear..............................................................................97

32. Reduction Drive Gear................................................................................99

33. Parking Pawl ...........................................................................................101

34. Torque Converter Clutch Case ...............................................................102

35. Oil Pump Housing ...................................................................................105

36. Drive Pinion Shaft Assembly ...................................................................111

37. Front Differential......................................................................................117

38. AT Main Case .........................................................................................123

39. Transmission Control Device ..................................................................142

Page 2314 of 2870

4AT-2

AUTOMATIC TRANSMISSION

General Description

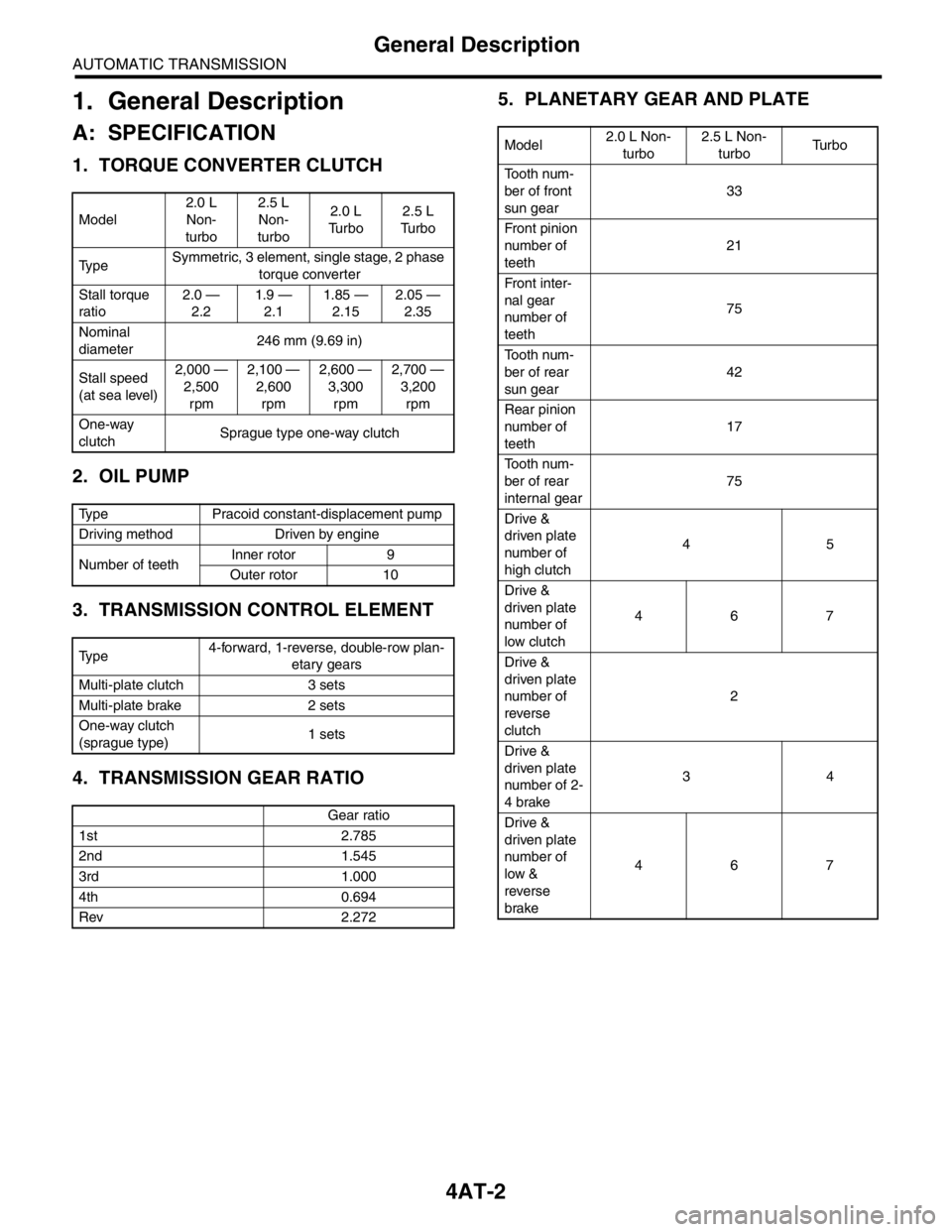

1. General Description

A: SPECIFICATION

1. TORQUE CONVERTER CLUTCH

2. OIL PUMP

3. TRANSMISSION CONTROL ELEMENT

4. TRANSMISSION GEAR RATIO5. PLANETARY GEAR AND PLATE

Model2.0 L

Non-

turbo2.5 L

Non-

turbo2.0 L

Tu r b o2.5 L

Tu r b o

Ty p eSymmetric, 3 element, single stage, 2 phase

torque converter

Stall torque

ratio2.0 —

2.21.9 —

2.11.85 —

2.152.05 —

2.35

Nominal

diameter246 mm (9.69 in)

Stall speed

(at sea level)2,000 —

2,500

rpm2,100 —

2,600

rpm2,600 —

3,300

rpm2,700 —

3,200

rpm

One-way

clutchSprague type one-way clutch

Type Pracoid constant-displacement pump

Driving method Driven by engine

Number of teethInner rotor 9

Outer rotor 10

Ty p e4-forward, 1-reverse, double-row plan-

etary gears

Multi-plate clutch 3 sets

Multi-plate brake 2 sets

One-way clutch

(sprague type)1 sets

Gear ratio

1st 2.785

2nd 1.545

3rd 1.000

4th 0.694

Rev 2.272

Model2.0 L Non-

turbo2.5 L Non-

turboTu r b o

Tooth num-

ber of front

sun gear33

Front pinion

number of

teeth21

Front inter-

nal gear

number of

teeth75

Tooth num-

ber of rear

sun gear42

Rear pinion

number of

teeth17

Tooth num-

ber of rear

internal gear75

Drive &

driven plate

number of

high clutch45

Drive &

driven plate

number of

low clutch467

Drive &

driven plate

number of

reverse

clutch2

Drive &

driven plate

number of 2-

4 brake34

Drive &

driven plate

number of

low &

reverse

brake467

Page 2317 of 2870

4AT-5

AUTOMATIC TRANSMISSION

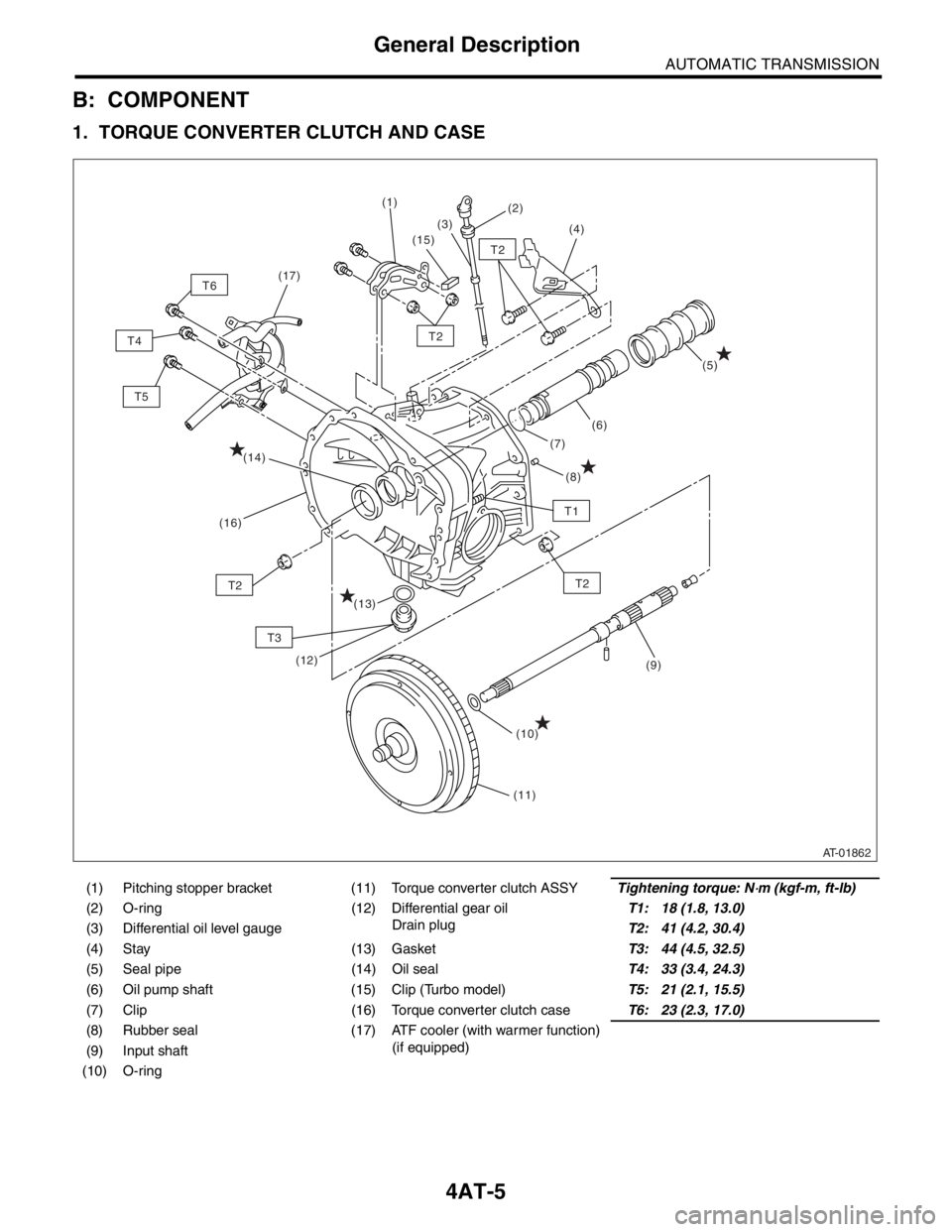

General Description

B: COMPONENT

1. TORQUE CONVERTER CLUTCH AND CASE

(1) Pitching stopper bracket (11) Torque converter clutch ASSYTightening torque: N⋅m (kgf-m, ft-lb)

(2) O-ring (12) Differential gear oil

Drain plugT1: 18 (1.8, 13.0)

(3) Differential oil level gaugeT2: 41 (4.2, 30.4)

(4) Stay (13) GasketT3: 44 (4.5, 32.5)

(5) Seal pipe (14) Oil sealT4: 33 (3.4, 24.3)

(6) Oil pump shaft (15) Clip (Turbo model)T5: 21 (2.1, 15.5)

(7) Clip (16) Torque converter clutch caseT6: 23 (2.3, 17.0)

(8) Rubber seal (17) ATF cooler (with warmer function)

(if equipped)

(9) Input shaft

(10) O-ring

AT-01862

T2

T2

T2T2

T3

T1

(8)

(11) (1)

(2)

(3)

(4)

(7)(5)

(6)

(10)(9)

(14)

(16)

(12)

(13)

(15)

T5 T4T6(17)

Page 2318 of 2870

4AT-6

AUTOMATIC TRANSMISSION

General Description

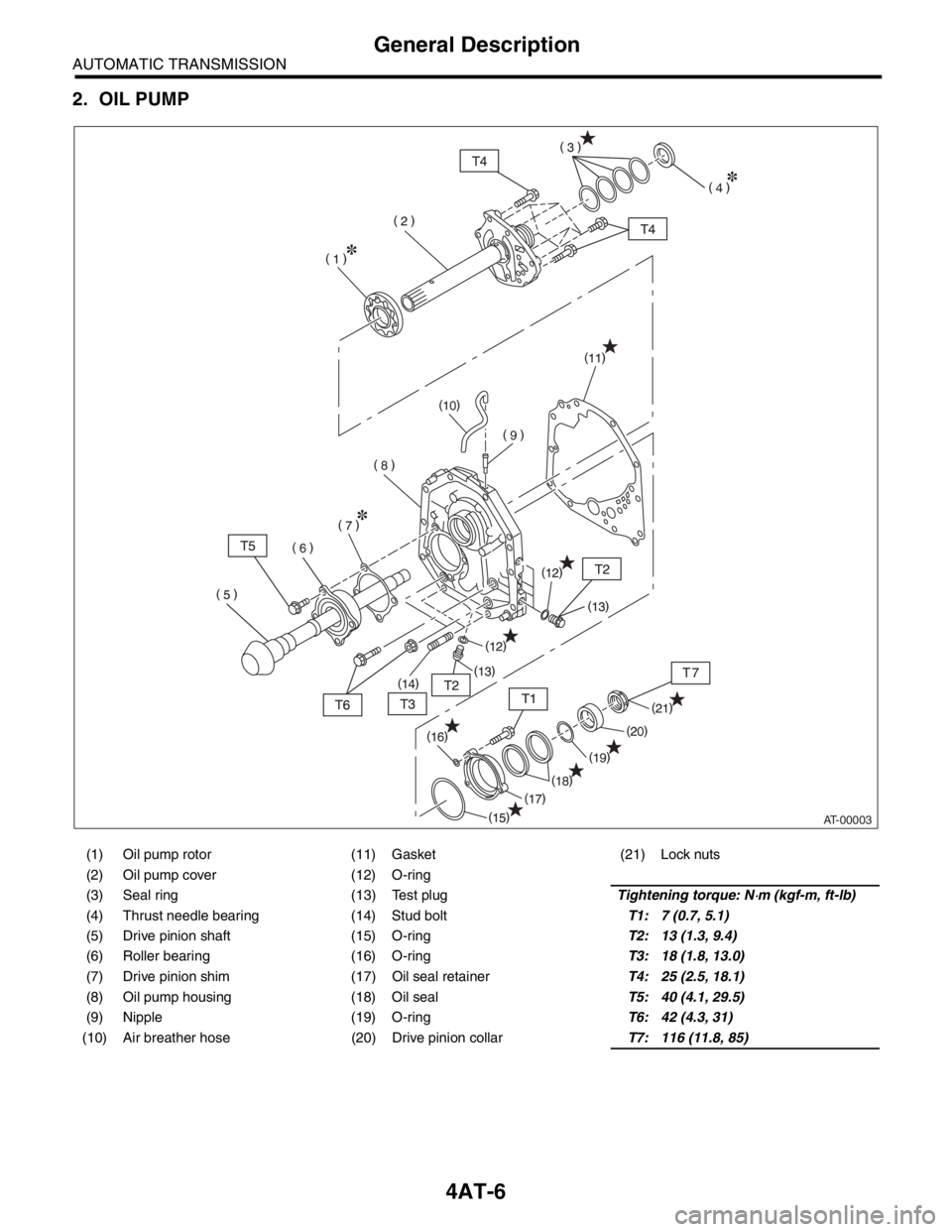

2. OIL PUMP

(1) Oil pump rotor (11) Gasket (21) Lock nuts

(2) Oil pump cover (12) O-ring

(3) Seal ring (13) Test plugTightening torque: N

⋅m (kgf-m, ft-lb)

(4) Thrust needle bearing (14) Stud boltT1: 7 (0.7, 5.1)

(5) Drive pinion shaft (15) O-ringT2: 13 (1.3, 9.4)

(6) Roller bearing (16) O-ringT3: 18 (1.8, 13.0)

(7) Drive pinion shim (17) Oil seal retainerT4: 25 (2.5, 18.1)

(8) Oil pump housing (18) Oil sealT5: 40 (4.1, 29.5)

(9) Nipple (19) O-ringT6: 42 (4.3, 31)

(10) Air breather hose (20) Drive pinion collarT7: 116 (11.8, 85)

AT-00003

Page 2320 of 2870

4AT-8

AUTOMATIC TRANSMISSION

General Description

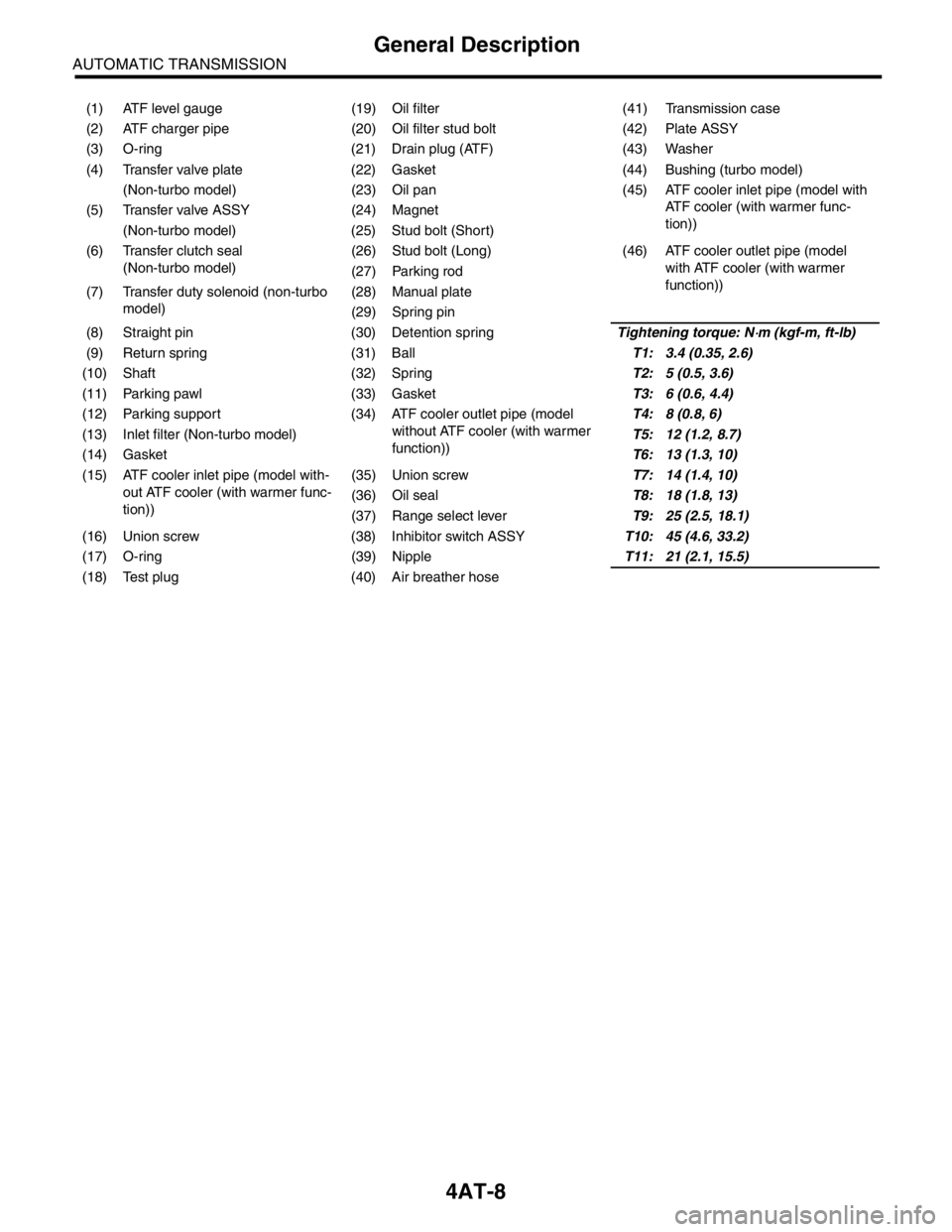

(1) ATF level gauge (19) Oil filter (41) Transmission case

(2) ATF charger pipe (20) Oil filter stud bolt (42) Plate ASSY

(3) O-ring (21) Drain plug (ATF) (43) Washer

(4) Transfer valve plate (22) Gasket (44) Bushing (turbo model)

(Non-turbo model) (23) Oil pan (45) ATF cooler inlet pipe (model with

ATF cooler (with warmer func-

tion)) (5) Transfer valve ASSY (24) Magnet

(Non-turbo model) (25) Stud bolt (Short)

(6) Transfer clutch seal

(Non-turbo model)(26) Stud bolt (Long) (46) ATF cooler outlet pipe (model

with ATF cooler (with warmer

function)) (27) Parking rod

(7) Transfer duty solenoid (non-turbo

model)(28) Manual plate

(29) Spring pin

(8) Straight pin (30) Detention springTightening torque: N

⋅m (kgf-m, ft-lb)

(9) Return spring (31) BallT1: 3.4 (0.35, 2.6)

(10) Shaft (32) SpringT2: 5 (0.5, 3.6)

(11) Parking pawl (33) GasketT3: 6 (0.6, 4.4)

(12) Parking support (34) ATF cooler outlet pipe (model

without ATF cooler (with warmer

function))T4: 8 (0.8, 6)

(13) Inlet filter (Non-turbo model)T5: 12 (1.2, 8.7)

(14) GasketT6: 13 (1.3, 10)

(15) ATF cooler inlet pipe (model with-

out ATF cooler (with warmer func-

tion))(35) Union screwT7: 14 (1.4, 10)

(36) Oil sealT8: 18 (1.8, 13)

(37) Range select leverT9: 25 (2.5, 18.1)

(16) Union screw (38) Inhibitor switch ASSYT10: 45 (4.6, 33.2)

(17) O-ring (39) NippleT11: 21 (2.1, 15.5)

(18) Test plug (40) Air breather hose