torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2342 of 2870

4AT-30

AUTOMATIC TRANSMISSION

Automatic Transmission Fluid

2. Automatic Transmission Flu-

id

A: INSPECTION

NOTE:

The level of ATF varies with fluid temperature. Pay

attention to the ATF temperature when checking

ATF level.

1) Raise the ATF temperature by driving a distance

of 5 to 10 km (3 to 6 miles). Otherwise, idle the en-

gine to raise ATF temperature to 70 — 80°C (158

— 176°F) on Subaru Select Monitor.

TION, Subaru Select Monitor.>

2) Make sure the vehicle is level.

3) After selecting all positions (P, R, N, D, 3, 2, 1),

set the select lever in “P” range. Measure the ATF

level with engine idling for one or two minutes.

4) Make sure that ATF level is above the center of

upper level and lower level at HOT side.

If the ATF level is below the lower level, check for

leaks in the transmission. If there are leaks, it is

necessary to repair or replace gasket, oil seals,

plugs or other parts.

5) If the ATF level is below the center between up-

per level and lower level, add the recommended

ATF until the fluid level is found above the center

between upper level and lower level marks.

CAUTION:

Use care not to exceed the upper level.

Remember that the addition of ATF to the up-

per limit mark when the transmission is cold

will overfilling of ATF, causing a transmission

failure.

6) Check ATF level after raising ATF temperature

to 70 — 80°C (158 — 176°F) by running the vehicle

or by idling the engine again.

B: REPLACEMENT

1) Lift-up the vehicle.2) Drain the ATF completely.

CAUTION:

Directly after the engine has been running, the

ATF is hot. Be careful not to burn yourself.

3) Replace the gasket with new one, and then tight-

en the drain plug (ATF).

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

4) Lower the vehicle.

5) Pour ATF from the ATF charge pipe.

Recommended fluid:

DEXRON III type automatic transmission flu-

id

Capacity:

Fill the same amount of ATF drained from

drain plug hole.

CAPACITY WHEN TRANSMISSION IS OVER-

HAULED:

2.0 L NON-TURBO MODEL

8.4 — 8.72 (8.9 — 9.2 US qt, 7.4 — 7.7 Imp

qt)

EXCEPT 2.0 L NON-TURBO MODEL

9.3 — 9.62 (9.8 — 10.1 US qt, 8.2 — 8.4 Imp

qt)

6) Check the level and leaks of ATF.

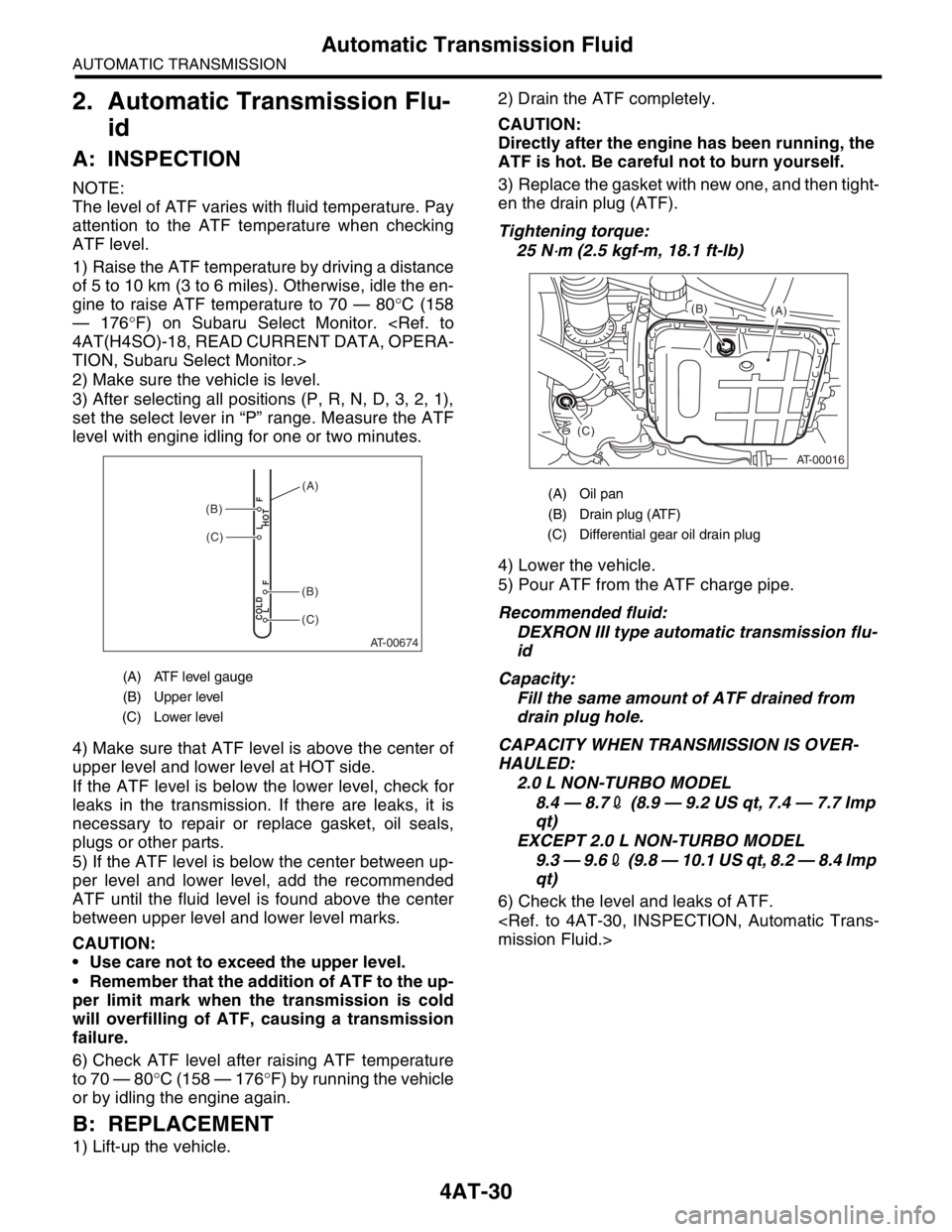

(A) ATF level gauge

(B) Upper level

(C) Lower level

AT-00674

COLD

LFHOT LF

(C)

(C)

(B)

(B)

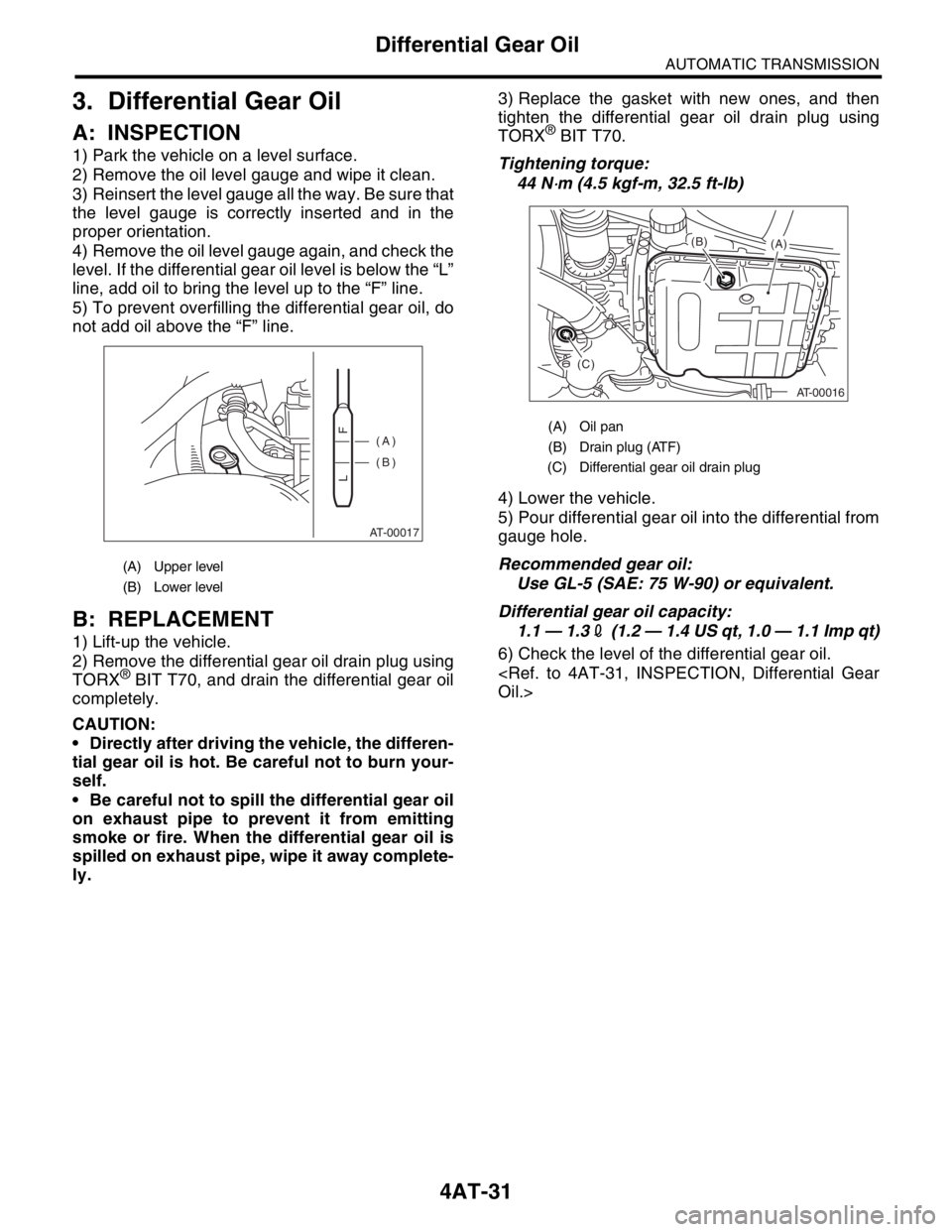

(A)(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

Page 2343 of 2870

4AT-31

AUTOMATIC TRANSMISSION

Differential Gear Oil

3. Differential Gear Oil

A: INSPECTION

1) Park the vehicle on a level surface.

2) Remove the oil level gauge and wipe it clean.

3) Reinsert the level gauge all the way. Be sure that

the level gauge is correctly inserted and in the

proper orientation.

4) Remove the oil level gauge again, and check the

level. If the differential gear oil level is below the “L”

line, add oil to bring the level up to the “F” line.

5) To prevent overfilling the differential gear oil, do

not add oil above the “F” line.

B: REPLACEMENT

1) Lift-up the vehicle.

2) Remove the differential gear oil drain plug using

TORX

® BIT T70, and drain the differential gear oil

completely.

CAUTION:

Directly after driving the vehicle, the differen-

tial gear oil is hot. Be careful not to burn your-

self.

Be careful not to spill the differential gear oil

on exhaust pipe to prevent it from emitting

smoke or fire. When the differential gear oil is

spilled on exhaust pipe, wipe it away complete-

ly.3) Replace the gasket with new ones, and then

tighten the differential gear oil drain plug using

TORX

® BIT T70.

Tightening torque:

44 N

⋅m (4.5 kgf-m, 32.5 ft-lb)

4) Lower the vehicle.

5) Pour differential gear oil into the differential from

gauge hole.

Recommended gear oil:

Use GL-5 (SAE: 75 W-90) or equivalent.

Differential gear oil capacity:

1.1 — 1.32 (1.2 — 1.4 US qt, 1.0 — 1.1 Imp qt)

6) Check the level of the differential gear oil.

(A) Upper level

(B) Lower level

AT-00017

(A)

(B)

LF

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

Page 2345 of 2870

4AT-33

AUTOMATIC TRANSMISSION

Stall Test

5. Stall Test

A: INSPECTION

NOTE:

The stall test is of extreme importance in diagnos-

ing the condition of the automatic transmission and

the engine. It should be conducted to measure the

engine stall speeds in “R” and “2” ranges (when

HOLD switch is ON).

Purposes of the stall test:

To check the operation of the automatic trans-

mission clutch.

To check the operation of the torque converter

clutch.

To check engine performance.

1) Check that the throttle valve opens fully.

2) Check that the engine oil level is correct.

3) Check that the coolant level is correct.

4) Check that the ATF level is correct.

5) Check that the differential gear oil level is cor-

rect.

6) Increase ATF temperature to 70 — 80°C (158 —

176°F) by idling the engine for approximately 30

minutes (with select lever set to “N” or “P”).

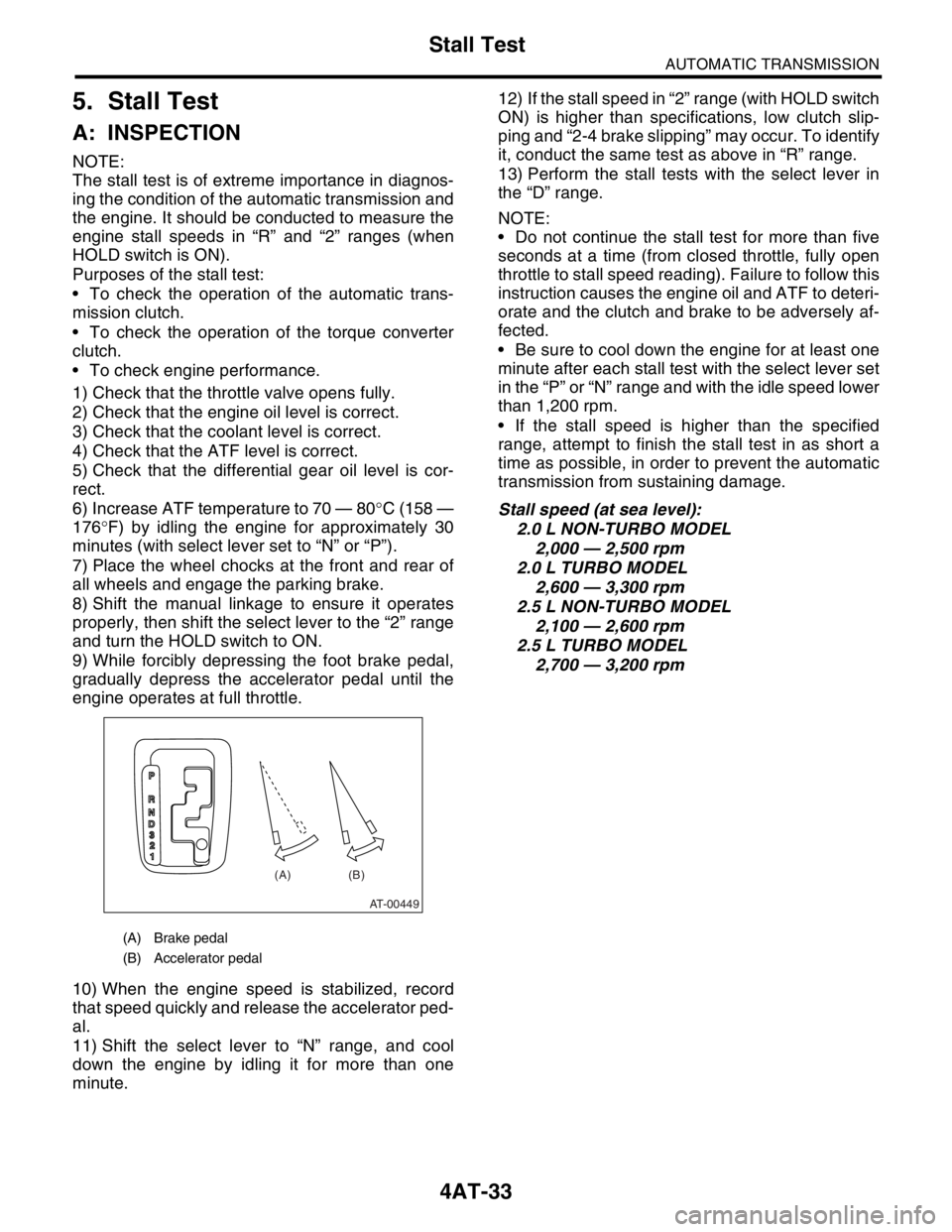

7) Place the wheel chocks at the front and rear of

all wheels and engage the parking brake.

8) Shift the manual linkage to ensure it operates

properly, then shift the select lever to the “2” range

and turn the HOLD switch to ON.

9) While forcibly depressing the foot brake pedal,

gradually depress the accelerator pedal until the

engine operates at full throttle.

10) When the engine speed is stabilized, record

that speed quickly and release the accelerator ped-

al.

11) Shift the select lever to “N” range, and cool

down the engine by idling it for more than one

minute.12) If the stall speed in “2” range (with HOLD switch

ON) is higher than specifications, low clutch slip-

ping and “2-4 brake slipping” may occur. To identify

it, conduct the same test as above in “R” range.

13) Perform the stall tests with the select lever in

the “D” range.

NOTE:

Do not continue the stall test for more than five

seconds at a time (from closed throttle, fully open

throttle to stall speed reading). Failure to follow this

instruction causes the engine oil and ATF to deteri-

orate and the clutch and brake to be adversely af-

fected.

Be sure to cool down the engine for at least one

minute after each stall test with the select lever set

in the “P” or “N” range and with the idle speed lower

than 1,200 rpm.

If the stall speed is higher than the specified

range, attempt to finish the stall test in as short a

time as possible, in order to prevent the automatic

transmission from sustaining damage.

Stall speed (at sea level):

2.0 L NON-TURBO MODEL

2,000 — 2,500 rpm

2.0 L TURBO MODEL

2,600 — 3,300 rpm

2.5 L NON-TURBO MODEL

2,100 — 2,600 rpm

2.5 L TURBO MODEL

2,700 — 3,200 rpm

(A) Brake pedal

(B) Accelerator pedal

(A) (B)

P

R

N

D

3

2

1

AT-00449

Page 2346 of 2870

4AT-34

AUTOMATIC TRANSMISSION

Stall Test

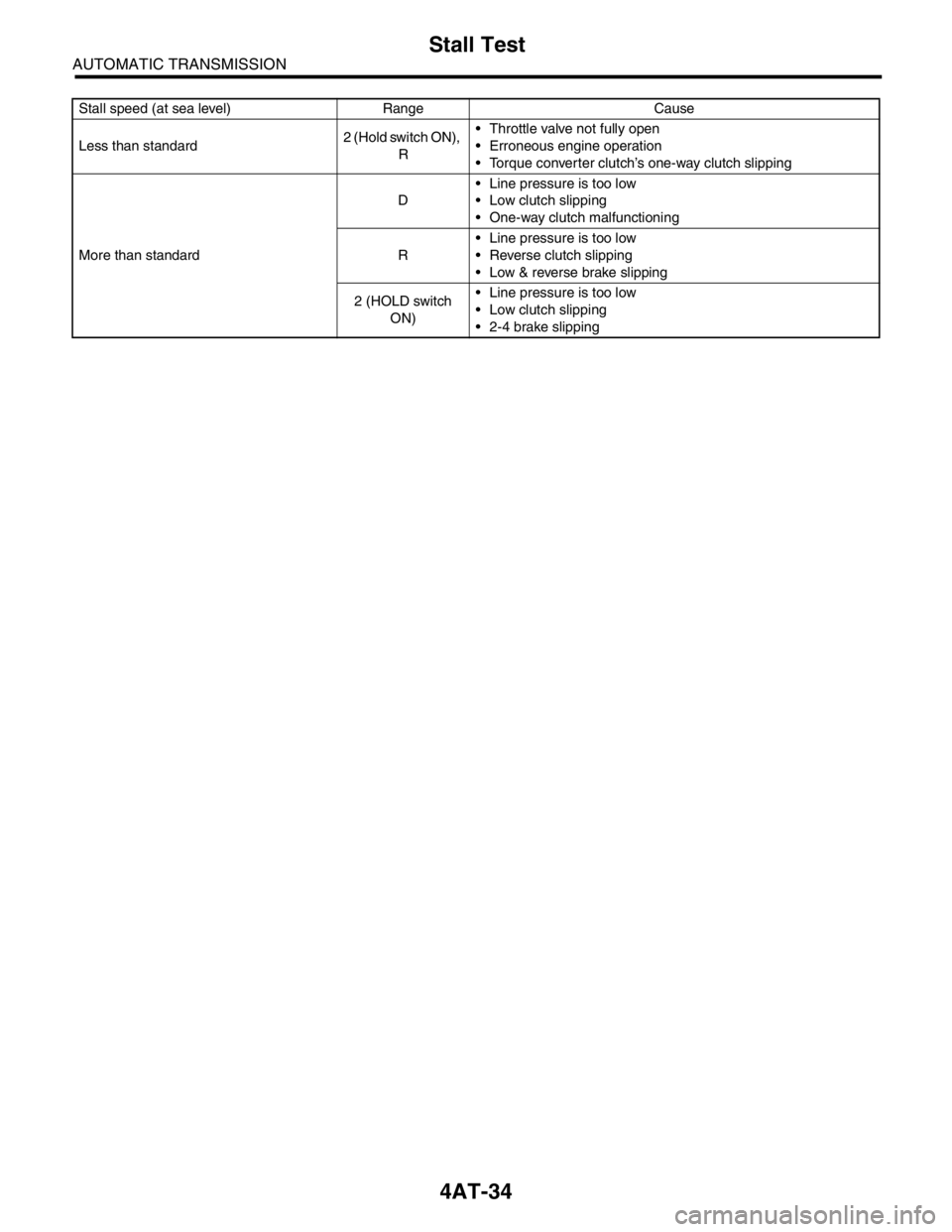

Stall speed (at sea level) Range Cause

Less than standard2 (Hold switch ON),

R Throttle valve not fully open

Erroneous engine operation

Torque converter clutch’s one-way clutch slipping

More than standardD Line pressure is too low

Low clutch slipping

One-way clutch malfunctioning

R Line pressure is too low

Reverse clutch slipping

Low & reverse brake slipping

2 (HOLD switch

ON) Line pressure is too low

Low clutch slipping

2-4 brake slipping

Page 2352 of 2870

4AT-40

AUTOMATIC TRANSMISSION

Automatic Transmission Assembly

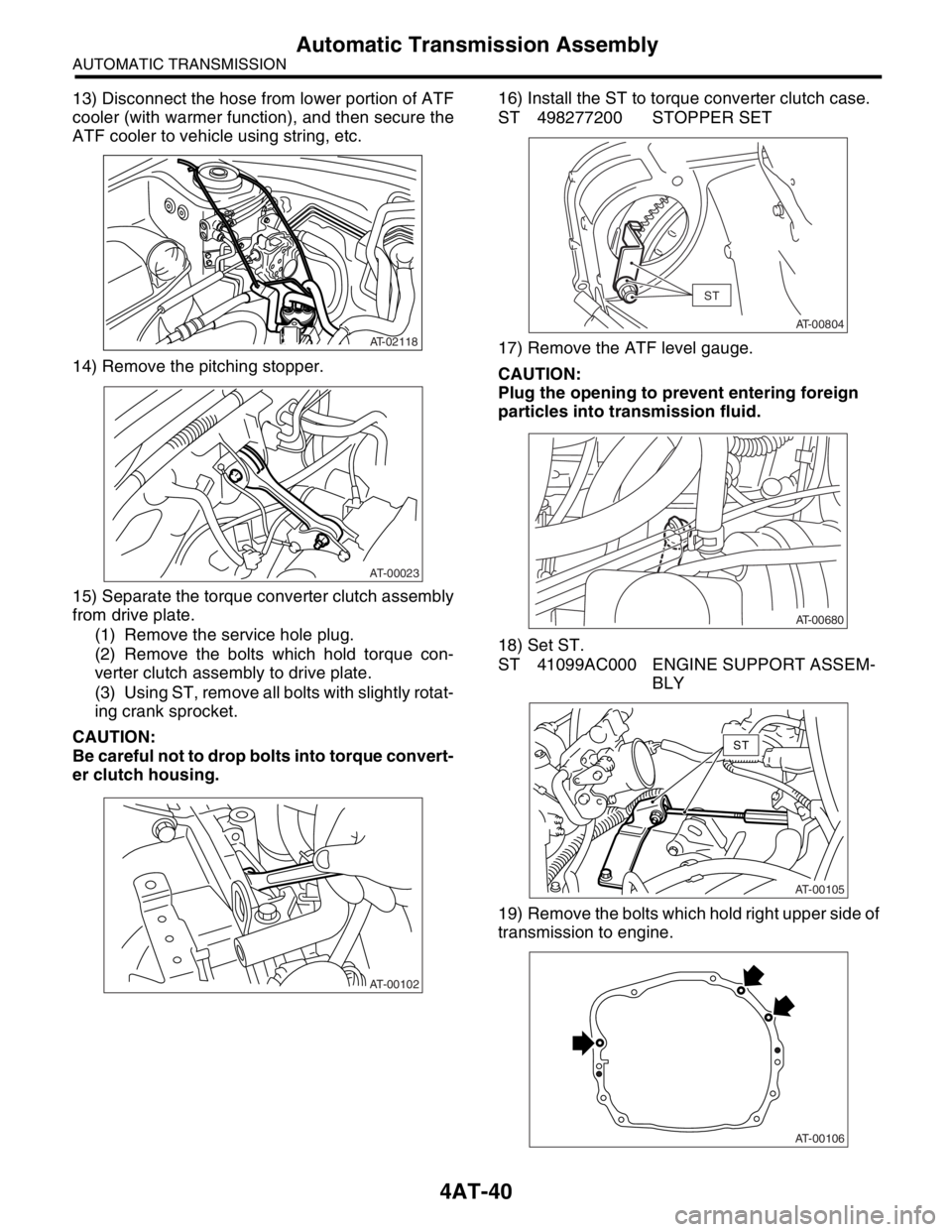

13) Disconnect the hose from lower portion of ATF

cooler (with warmer function), and then secure the

ATF cooler to vehicle using string, etc.

14) Remove the pitching stopper.

15) Separate the torque converter clutch assembly

from drive plate.

(1) Remove the service hole plug.

(2) Remove the bolts which hold torque con-

verter clutch assembly to drive plate.

(3) Using ST, remove all bolts with slightly rotat-

ing crank sprocket.

CAUTION:

Be careful not to drop bolts into torque convert-

er clutch housing.16) Install the ST to torque converter clutch case.

ST 498277200 STOPPER SET

17) Remove the ATF level gauge.

CAUTION:

Plug the opening to prevent entering foreign

particles into transmission fluid.

18) Set ST.

ST 41099AC000 ENGINE SUPPORT ASSEM-

BLY

19) Remove the bolts which hold right upper side of

transmission to engine.

AT-02118

AT-00023

AT-00102

AT-00804

ST

AT-00680

AT-00105

ST

AT-00106

Page 2354 of 2870

4AT-42

AUTOMATIC TRANSMISSION

Automatic Transmission Assembly

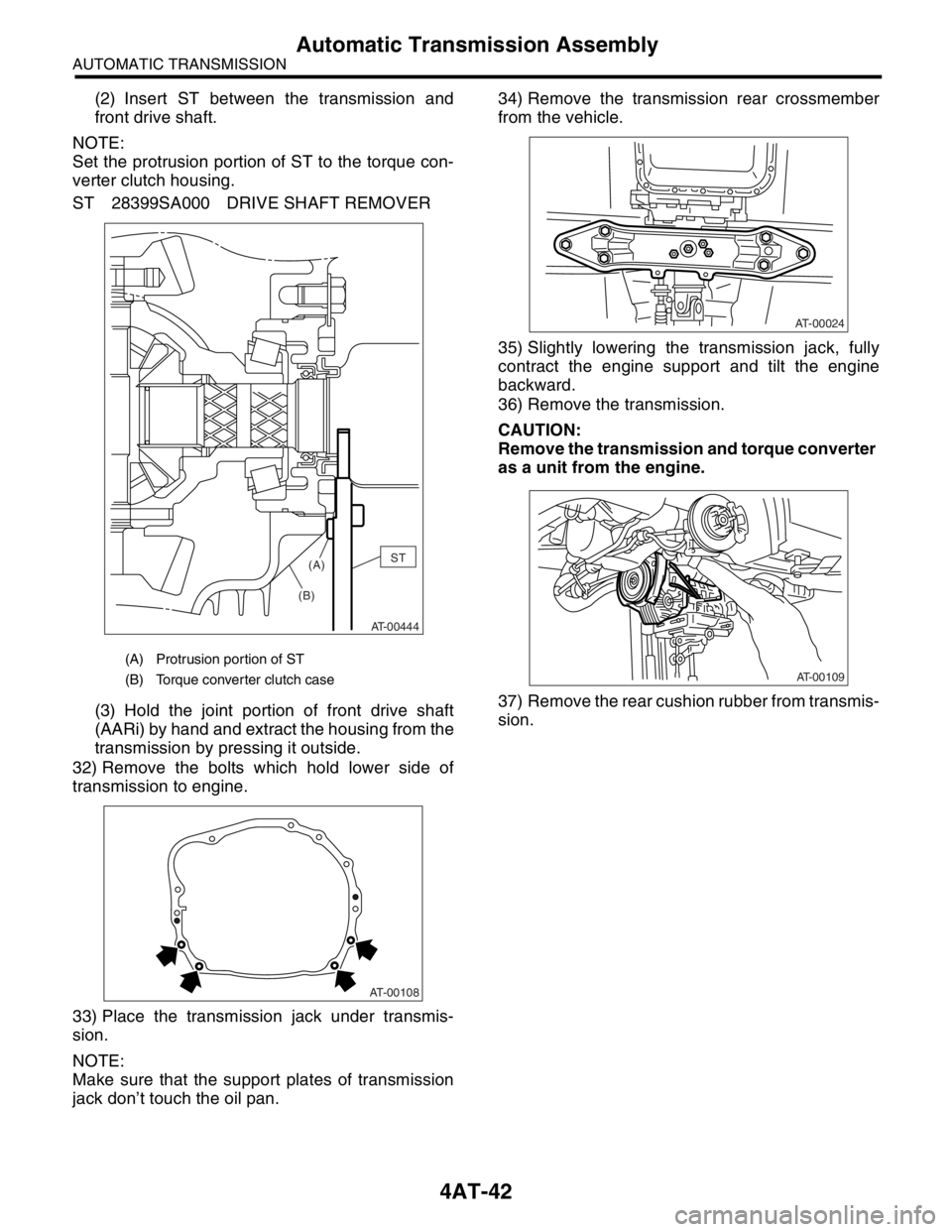

(2) Insert ST between the transmission and

front drive shaft.

NOTE:

Set the protrusion portion of ST to the torque con-

verter clutch housing.

ST 28399SA000 DRIVE SHAFT REMOVER

(3) Hold the joint portion of front drive shaft

(AARi) by hand and extract the housing from the

transmission by pressing it outside.

32) Remove the bolts which hold lower side of

transmission to engine.

33) Place the transmission jack under transmis-

sion.

NOTE:

Make sure that the support plates of transmission

jack don’t touch the oil pan.34) Remove the transmission rear crossmember

from the vehicle.

35) Slightly lowering the transmission jack, fully

contract the engine support and tilt the engine

backward.

36) Remove the transmission.

CAUTION:

Remove the transmission and torque converter

as a unit from the engine.

37) Remove the rear cushion rubber from transmis-

sion.

(A) Protrusion portion of ST

(B) Torque converter clutch case

AT-00444

ST

(A)

(B)

AT-00108

AT-00024

AT-00109

Page 2355 of 2870

4AT-43

AUTOMATIC TRANSMISSION

Automatic Transmission Assembly

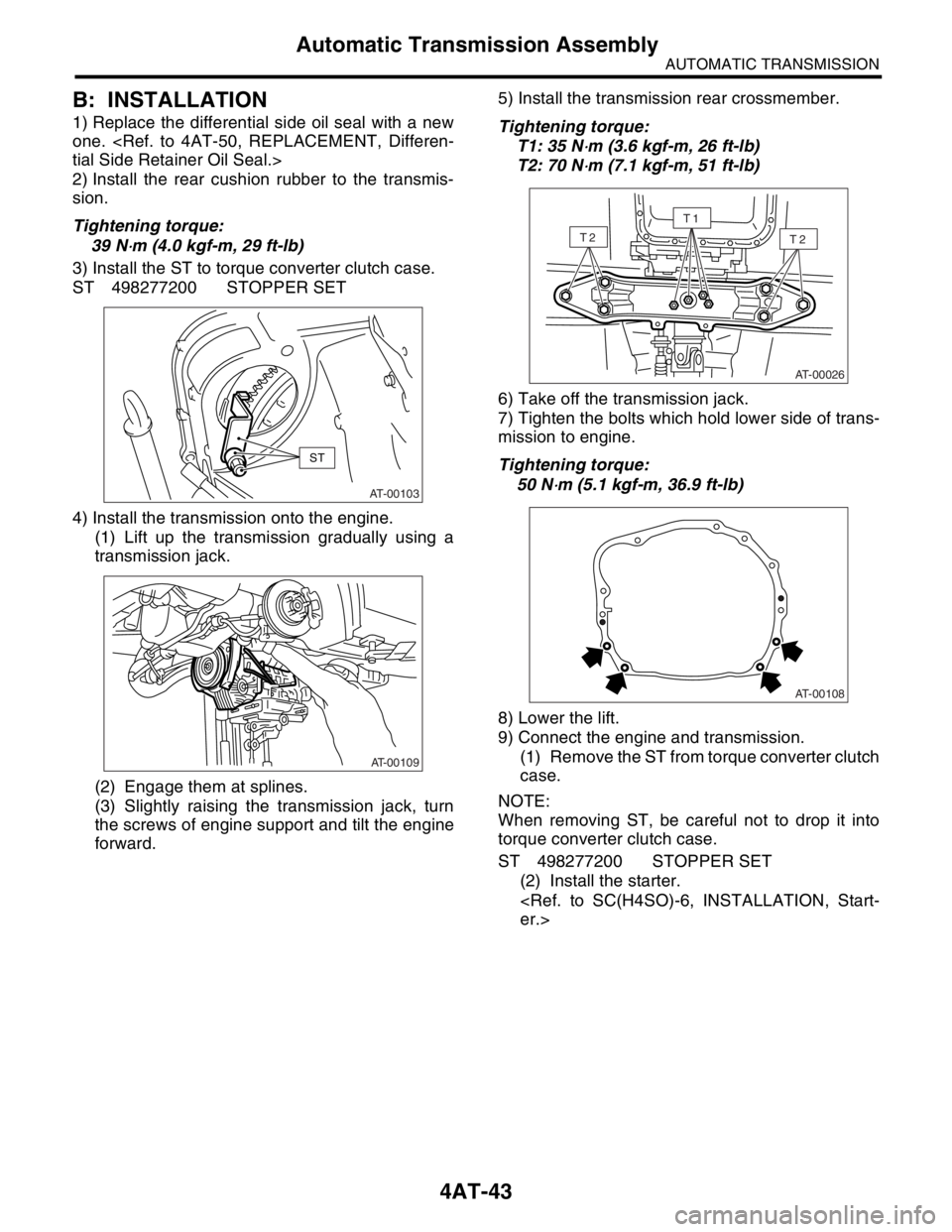

B: INSTALLATION

1) Replace the differential side oil seal with a new

one.

2) Install the rear cushion rubber to the transmis-

sion.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 29 ft-lb)

3) Install the ST to torque converter clutch case.

ST 498277200 STOPPER SET

4) Install the transmission onto the engine.

(1) Lift up the transmission gradually using a

transmission jack.

(2) Engage them at splines.

(3) Slightly raising the transmission jack, turn

the screws of engine support and tilt the engine

forward.5) Install the transmission rear crossmember.

Tightening torque:

T1: 35 N

⋅m (3.6 kgf-m, 26 ft-lb)

T2: 70 N

⋅m (7.1 kgf-m, 51 ft-lb)

6) Take off the transmission jack.

7) Tighten the bolts which hold lower side of trans-

mission to engine.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 36.9 ft-lb)

8) Lower the lift.

9) Connect the engine and transmission.

(1) Remove the ST from torque converter clutch

case.

NOTE:

When removing ST, be careful not to drop it into

torque converter clutch case.

ST 498277200 STOPPER SET

(2) Install the starter.

ST

AT-00109

AT-00026

T2T2

T1

AT-00108

Page 2356 of 2870

4AT-44

AUTOMATIC TRANSMISSION

Automatic Transmission Assembly

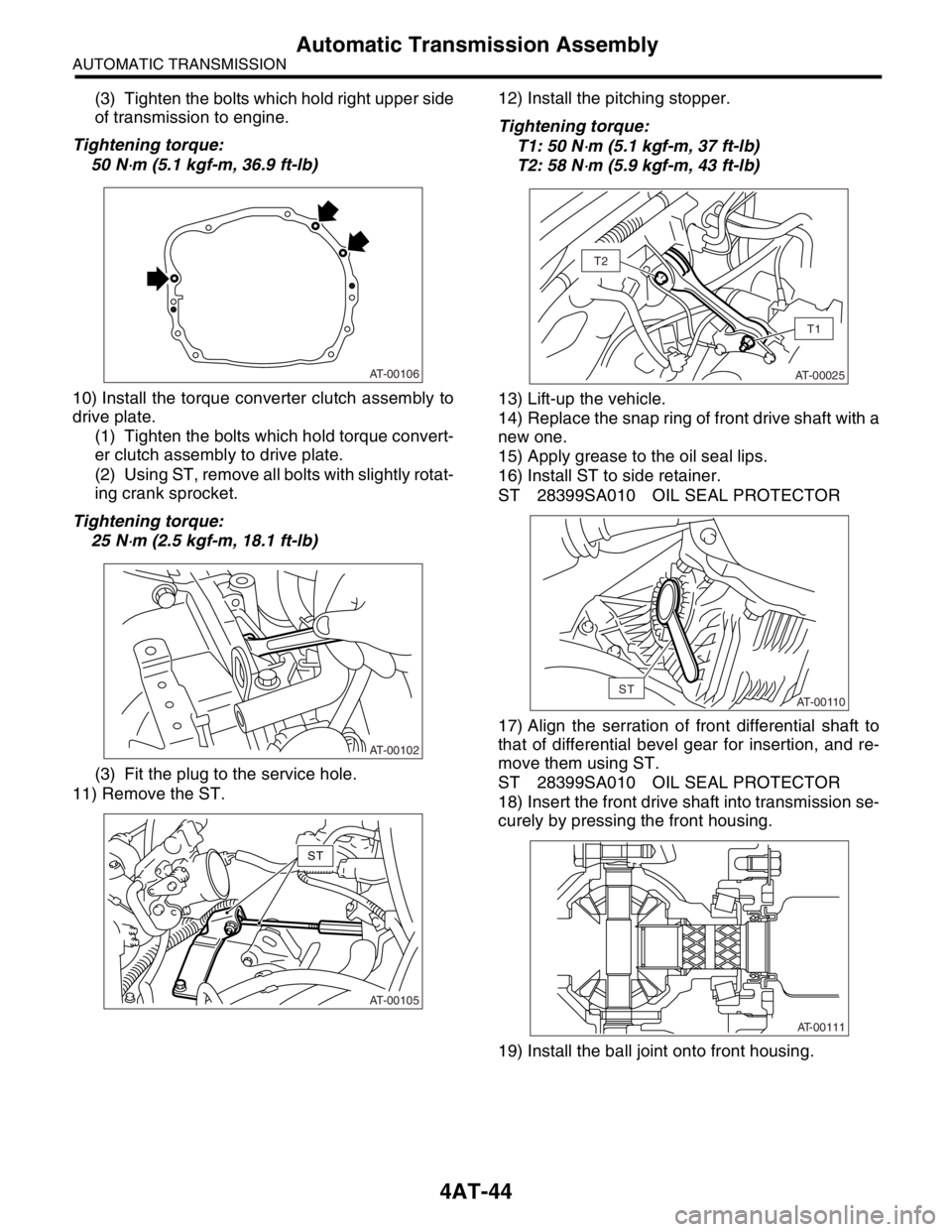

(3) Tighten the bolts which hold right upper side

of transmission to engine.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 36.9 ft-lb)

10) Install the torque converter clutch assembly to

drive plate.

(1) Tighten the bolts which hold torque convert-

er clutch assembly to drive plate.

(2) Using ST, remove all bolts with slightly rotat-

ing crank sprocket.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(3) Fit the plug to the service hole.

11) Remove the ST.12) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅m (5.1 kgf-m, 37 ft-lb)

T2: 58 N

⋅m (5.9 kgf-m, 43 ft-lb)

13) Lift-up the vehicle.

14) Replace the snap ring of front drive shaft with a

new one.

15) Apply grease to the oil seal lips.

16) Install ST to side retainer.

ST 28399SA010 OIL SEAL PROTECTOR

17) Align the serration of front differential shaft to

that of differential bevel gear for insertion, and re-

move them using ST.

ST 28399SA010 OIL SEAL PROTECTOR

18) Insert the front drive shaft into transmission se-

curely by pressing the front housing.

19) Install the ball joint onto front housing.

AT-00106

AT-00102

AT-00105

ST

AT-00025

T1

T2

AT-00110ST

AT-00111

Page 2357 of 2870

4AT-45

AUTOMATIC TRANSMISSION

Automatic Transmission Assembly

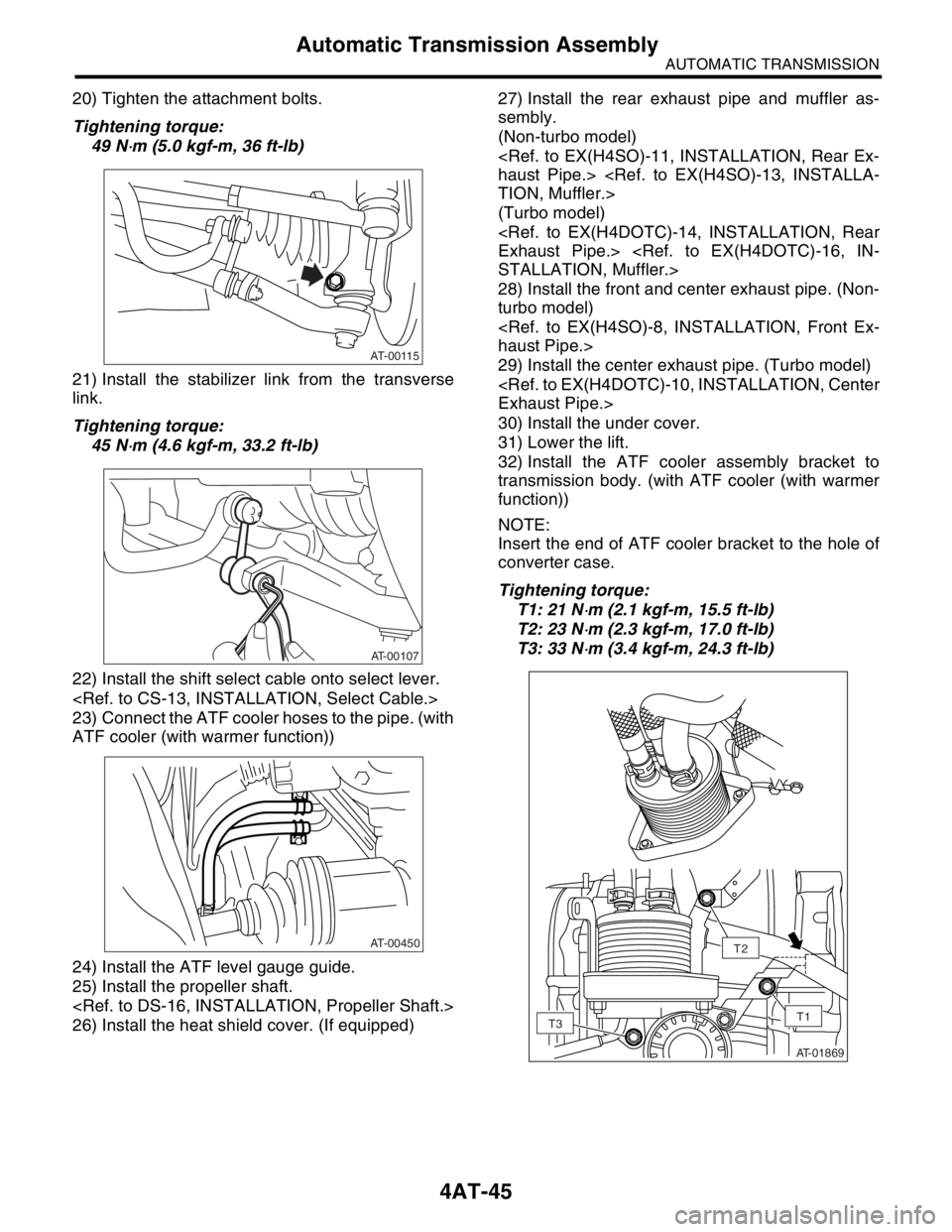

20) Tighten the attachment bolts.

Tightening torque:

49 N

⋅m (5.0 kgf-m, 36 ft-lb)

21) Install the stabilizer link from the transverse

link.

Tightening torque:

45 N

⋅m (4.6 kgf-m, 33.2 ft-lb)

22) Install the shift select cable onto select lever.

23) Connect the ATF cooler hoses to the pipe. (with

ATF cooler (with warmer function))

24) Install the ATF level gauge guide.

25) Install the propeller shaft.

26) Install the heat shield cover. (If equipped)27) Install the rear exhaust pipe and muffler as-

sembly.

(Non-turbo model)

(Turbo model)

28) Install the front and center exhaust pipe. (Non-

turbo model)

29) Install the center exhaust pipe. (Turbo model)

30) Install the under cover.

31) Lower the lift.

32) Install the ATF cooler assembly bracket to

transmission body. (with ATF cooler (with warmer

function))

NOTE:

Insert the end of ATF cooler bracket to the hole of

converter case.

Tightening torque:

T1: 21 N

⋅m (2.1 kgf-m, 15.5 ft-lb)

T2: 23 N

⋅m (2.3 kgf-m, 17.0 ft-lb)

T3: 33 N

⋅m (3.4 kgf-m, 24.3 ft-lb)

AT-00115

AT-00107

AT-00450

AT-01869

T2

T1T3

Page 2358 of 2870

4AT-46

AUTOMATIC TRANSMISSION

Automatic Transmission Assembly

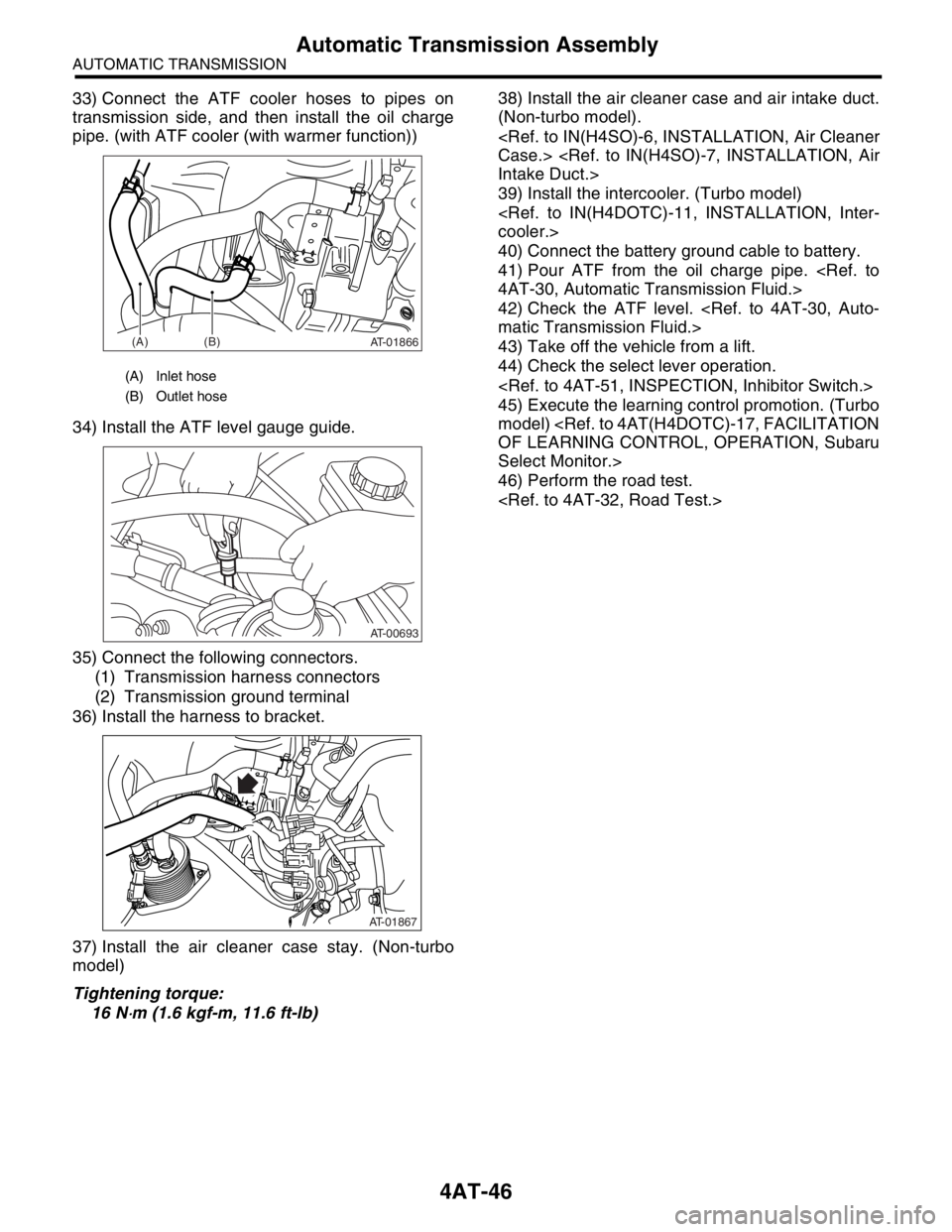

33) Connect the ATF cooler hoses to pipes on

transmission side, and then install the oil charge

pipe. (with ATF cooler (with warmer function))

34) Install the ATF level gauge guide.

35) Connect the following connectors.

(1) Transmission harness connectors

(2) Transmission ground terminal

36) Install the harness to bracket.

37) Install the air cleaner case stay. (Non-turbo

model)

Tightening torque:

16 N

⋅m (1.6 kgf-m, 11.6 ft-lb)38) Install the air cleaner case and air intake duct.

(Non-turbo model).

39) Install the intercooler. (Turbo model)

40) Connect the battery ground cable to battery.

41) Pour ATF from the oil charge pipe.

42) Check the ATF level.

43) Take off the vehicle from a lift.

44) Check the select lever operation.

45) Execute the learning control promotion. (Turbo

model)

Select Monitor.>

46) Perform the road test.

(A) Inlet hose

(B) Outlet hose

AT-01866(A)(B)

AT-00693

AT-01867