torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2359 of 2870

4AT-47

AUTOMATIC TRANSMISSION

Transmission Mounting System

10.Transmission Mounting Sys-

tem

A: REMOVAL

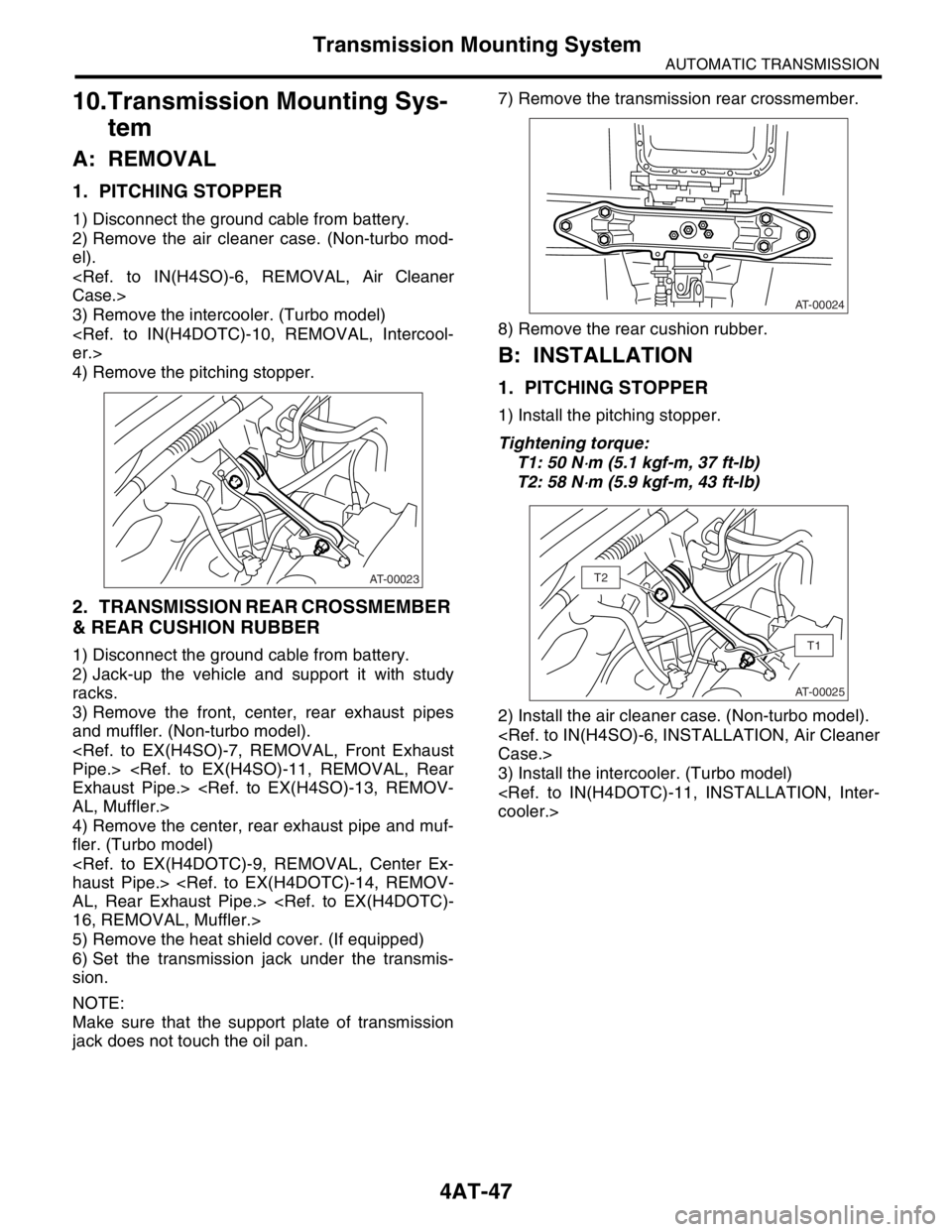

1. PITCHING STOPPER

1) Disconnect the ground cable from battery.

2) Remove the air cleaner case. (Non-turbo mod-

el).

3) Remove the intercooler. (Turbo model)

4) Remove the pitching stopper.

2. TRANSMISSION REAR CROSSMEMBER

& REAR CUSHION RUBBER

1) Disconnect the ground cable from battery.

2) Jack-up the vehicle and support it with study

racks.

3) Remove the front, center, rear exhaust pipes

and muffler. (Non-turbo model).

4) Remove the center, rear exhaust pipe and muf-

fler. (Turbo model)

5) Remove the heat shield cover. (If equipped)

6) Set the transmission jack under the transmis-

sion.

NOTE:

Make sure that the support plate of transmission

jack does not touch the oil pan.7) Remove the transmission rear crossmember.

8) Remove the rear cushion rubber.

B: INSTALLATION

1. PITCHING STOPPER

1) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅m (5.1 kgf-m, 37 ft-lb)

T2: 58 N

⋅m (5.9 kgf-m, 43 ft-lb)

2) Install the air cleaner case. (Non-turbo model).

3) Install the intercooler. (Turbo model)

AT-00023

AT-00024

AT-00025

T1

T2

Page 2360 of 2870

4AT-48

AUTOMATIC TRANSMISSION

Transmission Mounting System

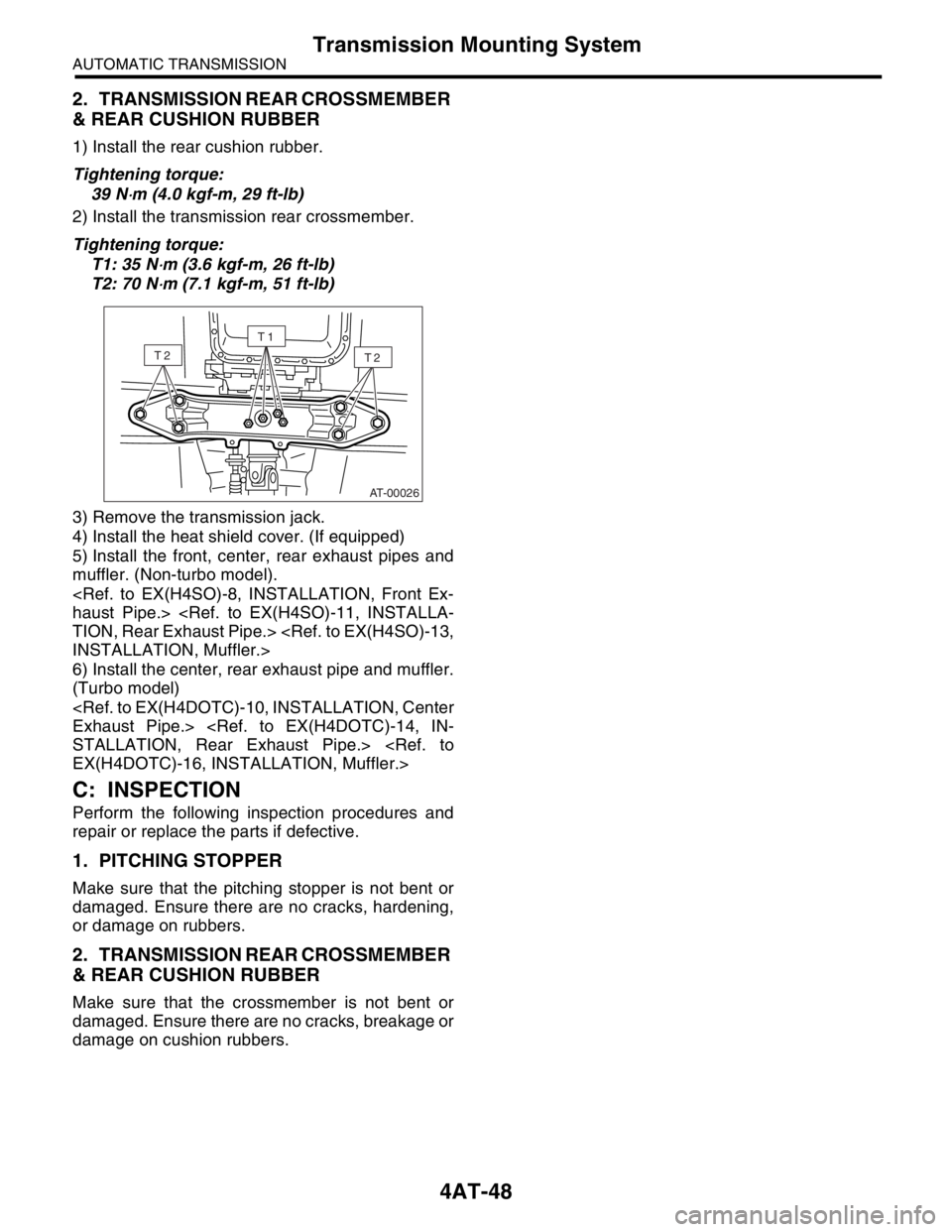

2. TRANSMISSION REAR CROSSMEMBER

& REAR CUSHION RUBBER

1) Install the rear cushion rubber.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 29 ft-lb)

2) Install the transmission rear crossmember.

Tightening torque:

T1: 35 N

⋅m (3.6 kgf-m, 26 ft-lb)

T2: 70 N

⋅m (7.1 kgf-m, 51 ft-lb)

3) Remove the transmission jack.

4) Install the heat shield cover. (If equipped)

5) Install the front, center, rear exhaust pipes and

muffler. (Non-turbo model).

6) Install the center, rear exhaust pipe and muffler.

(Turbo model)

C: INSPECTION

Perform the following inspection procedures and

repair or replace the parts if defective.

1. PITCHING STOPPER

Make sure that the pitching stopper is not bent or

damaged. Ensure there are no cracks, hardening,

or damage on rubbers.

2. TRANSMISSION REAR CROSSMEMBER

& REAR CUSHION RUBBER

Make sure that the crossmember is not bent or

damaged. Ensure there are no cracks, breakage or

damage on cushion rubbers.

AT-00026

T2T2

T1

Page 2362 of 2870

4AT-49

AUTOMATIC TRANSMISSION

Extension Case Oil Seal

11.Extension Case Oil Seal

A: INSPECTION

Make sure that the ATF does not leak from the joint

of transmission and propeller shaft. If so, replace

the oil seal.

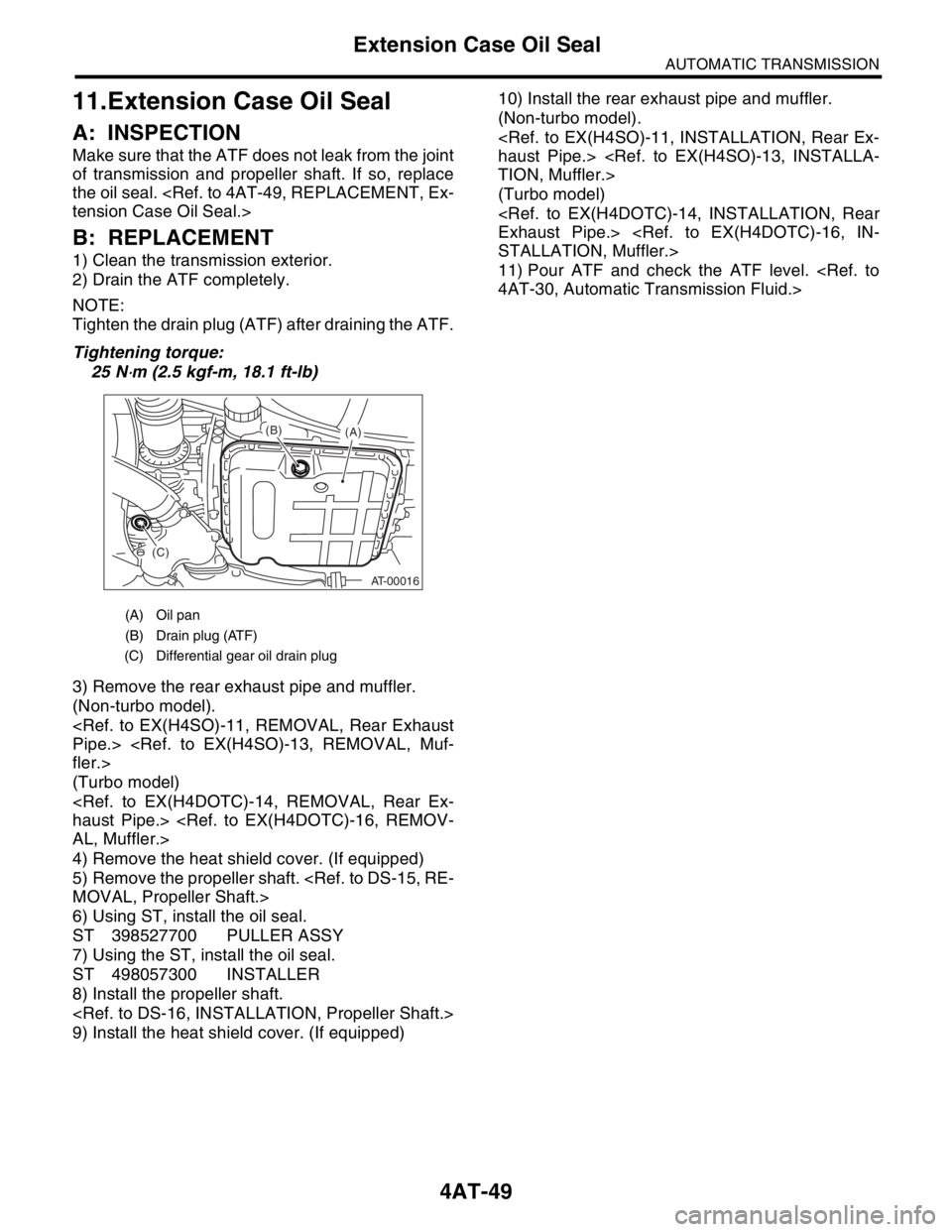

B: REPLACEMENT

1) Clean the transmission exterior.

2) Drain the ATF completely.

NOTE:

Tighten the drain plug (ATF) after draining the ATF.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

3) Remove the rear exhaust pipe and muffler.

(Non-turbo model).

(Turbo model)

4) Remove the heat shield cover. (If equipped)

5) Remove the propeller shaft.

6) Using ST, install the oil seal.

ST 398527700 PULLER ASSY

7) Using the ST, install the oil seal.

ST 498057300 INSTALLER

8) Install the propeller shaft.

9) Install the heat shield cover. (If equipped)10) Install the rear exhaust pipe and muffler.

(Non-turbo model).

(Turbo model)

11) Pour ATF and check the ATF level.

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

Page 2363 of 2870

4AT-50

AUTOMATIC TRANSMISSION

Differential Side Retainer Oil Seal

12.Differential Side Retainer Oil

Seal

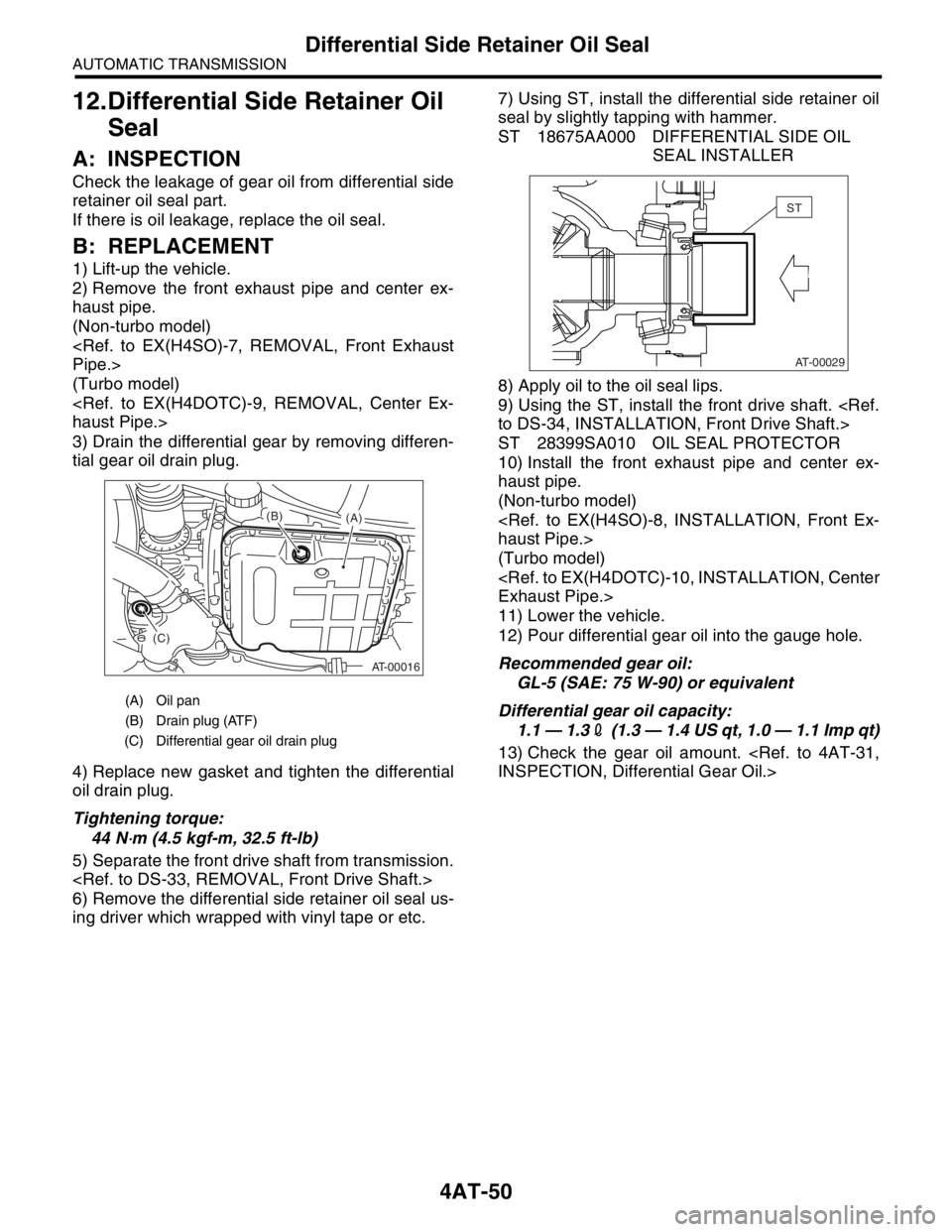

A: INSPECTION

Check the leakage of gear oil from differential side

retainer oil seal part.

If there is oil leakage, replace the oil seal.

B: REPLACEMENT

1) Lift-up the vehicle.

2) Remove the front exhaust pipe and center ex-

haust pipe.

(Non-turbo model)

(Turbo model)

3) Drain the differential gear by removing differen-

tial gear oil drain plug.

4) Replace new gasket and tighten the differential

oil drain plug.

Tightening torque:

44 N

⋅m (4.5 kgf-m, 32.5 ft-lb)

5) Separate the front drive shaft from transmission.

6) Remove the differential side retainer oil seal us-

ing driver which wrapped with vinyl tape or etc.7) Using ST, install the differential side retainer oil

seal by slightly tapping with hammer.

ST 18675AA000 DIFFERENTIAL SIDE OIL

SEAL INSTALLER

8) Apply oil to the oil seal lips.

9) Using the ST, install the front drive shaft.

ST 28399SA010 OIL SEAL PROTECTOR

10) Install the front exhaust pipe and center ex-

haust pipe.

(Non-turbo model)

(Turbo model)

11) Lower the vehicle.

12) Pour differential gear oil into the gauge hole.

Recommended gear oil:

GL-5 (SAE: 75 W-90) or equivalent

Differential gear oil capacity:

1.1 — 1.32 (1.3 — 1.4 US qt, 1.0 — 1.1 Imp qt)

13) Check the gear oil amount.

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

AT-00029

ST

Page 2365 of 2870

4AT-52

AUTOMATIC TRANSMISSION

Inhibitor Switch

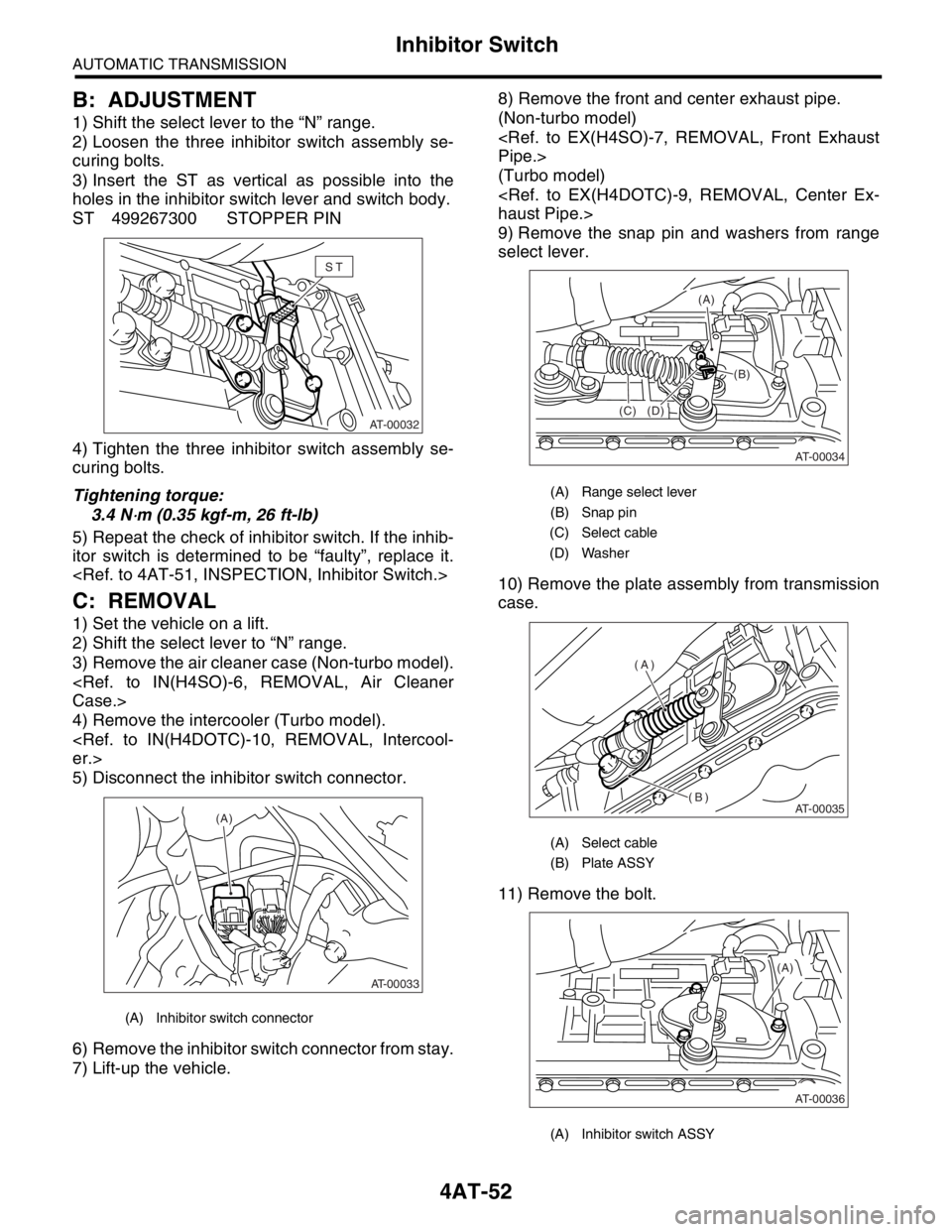

B: ADJUSTMENT

1) Shift the select lever to the “N” range.

2) Loosen the three inhibitor switch assembly se-

curing bolts.

3) Insert the ST as vertical as possible into the

holes in the inhibitor switch lever and switch body.

ST 499267300 STOPPER PIN

4) Tighten the three inhibitor switch assembly se-

curing bolts.

Tightening torque:

3.4 N

⋅m (0.35 kgf-m, 26 ft-lb)

5) Repeat the check of inhibitor switch. If the inhib-

itor switch is determined to be “faulty”, replace it.

C: REMOVAL

1) Set the vehicle on a lift.

2) Shift the select lever to “N” range.

3) Remove the air cleaner case (Non-turbo model).

4) Remove the intercooler (Turbo model).

5) Disconnect the inhibitor switch connector.

6) Remove the inhibitor switch connector from stay.

7) Lift-up the vehicle.8) Remove the front and center exhaust pipe.

(Non-turbo model)

(Turbo model)

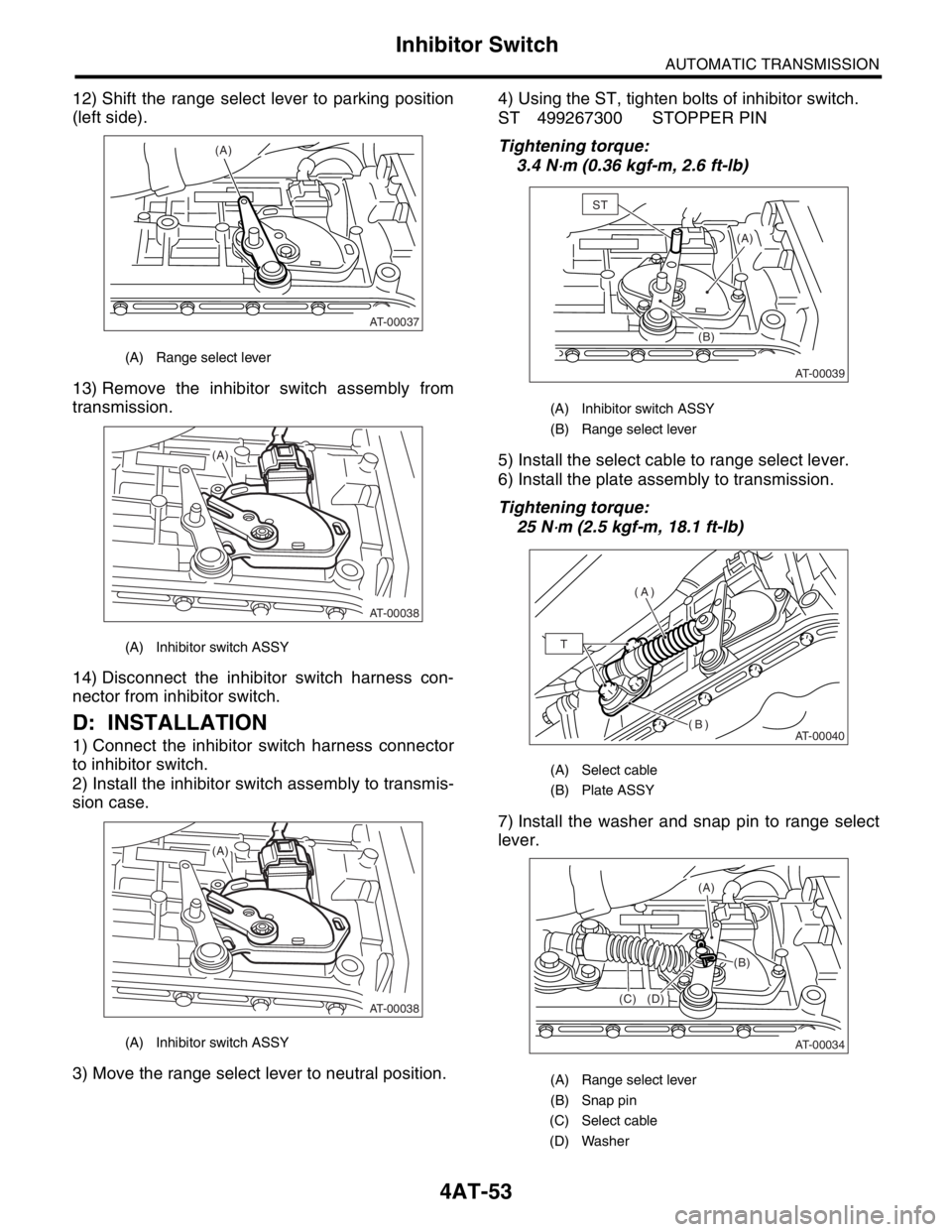

9) Remove the snap pin and washers from range

select lever.

10) Remove the plate assembly from transmission

case.

11) Remove the bolt.

(A) Inhibitor switch connector

ST

AT-00032

AT-00033

(A)

(A) Range select lever

(B) Snap pin

(C) Select cable

(D) Washer

(A) Select cable

(B) Plate ASSY

(A) Inhibitor switch ASSY

AT-00034

(C)(B) (A)

(D)

AT-00035

(A)

(B)

(A)

AT-00036

Page 2366 of 2870

4AT-53

AUTOMATIC TRANSMISSION

Inhibitor Switch

12) Shift the range select lever to parking position

(left side).

13) Remove the inhibitor switch assembly from

transmission.

14) Disconnect the inhibitor switch harness con-

nector from inhibitor switch.

D: INSTALLATION

1) Connect the inhibitor switch harness connector

to inhibitor switch.

2) Install the inhibitor switch assembly to transmis-

sion case.

3) Move the range select lever to neutral position.4) Using the ST, tighten bolts of inhibitor switch.

ST 499267300 STOPPER PIN

Tightening torque:

3.4 N

⋅m (0.36 kgf-m, 2.6 ft-lb)

5) Install the select cable to range select lever.

6) Install the plate assembly to transmission.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

7) Install the washer and snap pin to range select

lever.

(A) Range select lever

(A) Inhibitor switch ASSY

(A) Inhibitor switch ASSY

(A)

AT-00037

AT-00038

(A)

AT-00038

(A)

(A) Inhibitor switch ASSY

(B) Range select lever

(A) Select cable

(B) Plate ASSY

(A) Range select lever

(B) Snap pin

(C) Select cable

(D) Washer

(A)

AT-00039

(B)

ST

AT-00040

(A)

(B)

T

AT-00034

(C)(B) (A)

(D)

Page 2368 of 2870

4AT-55

AUTOMATIC TRANSMISSION

Front Vehicle Speed Sensor

14.Front Vehicle Speed Sensor

A: REMOVAL

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Remove the air cleaner case. (Non-turbo mod-

el).

4) Remove the intercooler. (Turbo model)

5) Disconnect the transmission connector.

6) Remove the pitching stopper.

7) Remove the transmission connector from the

stay.

8) Lift-up the vehicle.9) Clean the transmission exterior.

10) Drain the ATF completely.

NOTE:

Tighten the drain plug (ATF) after draining the ATF.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

11) Remove the front, center, rear, exhaust pipes

and muffler. (Non-turbo model).

12) Remove the center, rear exhaust pipe and muf-

fler. (Turbo model)

13) Remove the heat shield cover. (If equipped)

14) Remove the propeller shaft.

15) Place the transmission jack under transmis-

sion.

NOTE:

Make sure that the support plate of transmission

jack does not touch the oil pan.

16) Remove the transmission rear crossmember

bolt.

(A) Transmission connector

AT-00041

AT-00042

(A)

(A) Oil pan

(B) Drain plug (ATF)

(C) Differential gear oil drain plug

AT-00016

(A) (B)

(C)

AT-00043

Page 2369 of 2870

4AT-56

AUTOMATIC TRANSMISSION

Front Vehicle Speed Sensor

17) Lower the transmission jack.

NOTE:

Do not separate the transmission jack and trans-

mission.

18) Remove the ATF cooler inlet and outlet pipes.

CAUTION:

When removing the outlet pipe, be careful not

to lose the ball and spring used with retaining

screw.

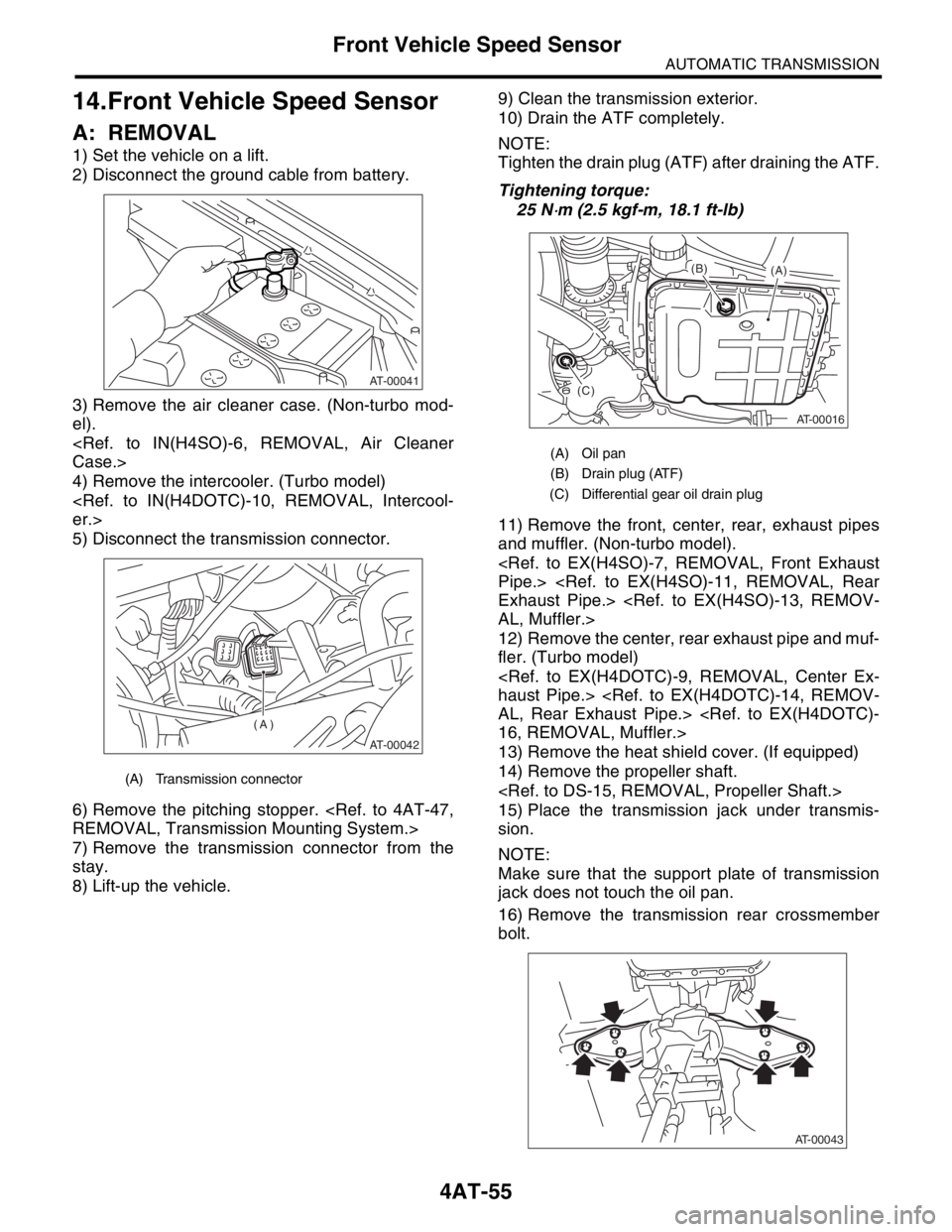

19) Remove the front vehicle speed sensor and

torque converter turbine speed sensor.

20) Remove the rear vehicle speed sensor. (Non-

turbo model)21) Disconnect the connector from rear vehicle

speed sensor. (Turbo model)

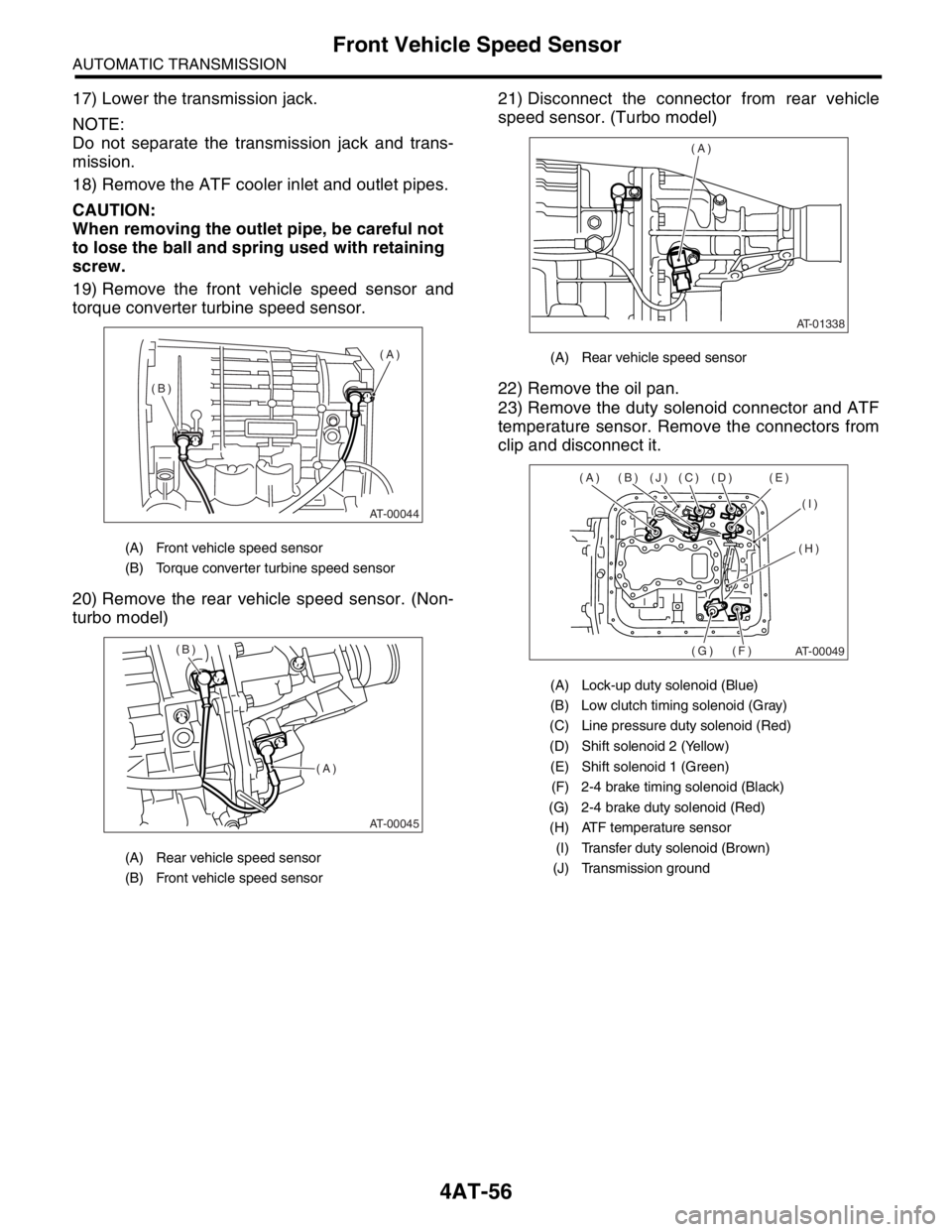

22) Remove the oil pan.

23) Remove the duty solenoid connector and ATF

temperature sensor. Remove the connectors from

clip and disconnect it.

(A) Front vehicle speed sensor

(B) Torque converter turbine speed sensor

(A) Rear vehicle speed sensor

(B) Front vehicle speed sensor

AT-00044

(A)

(B)

AT-00045

(A) (B)

(A) Rear vehicle speed sensor

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

(H) ATF temperature sensor

(I) Transfer duty solenoid (Brown)

(J) Transmission ground

AT-01338

(A)

AT-00049

(A) (B) (J) (C) (D) (E)

(I)

(H)

(F) (G)

Page 2370 of 2870

4AT-57

AUTOMATIC TRANSMISSION

Front Vehicle Speed Sensor

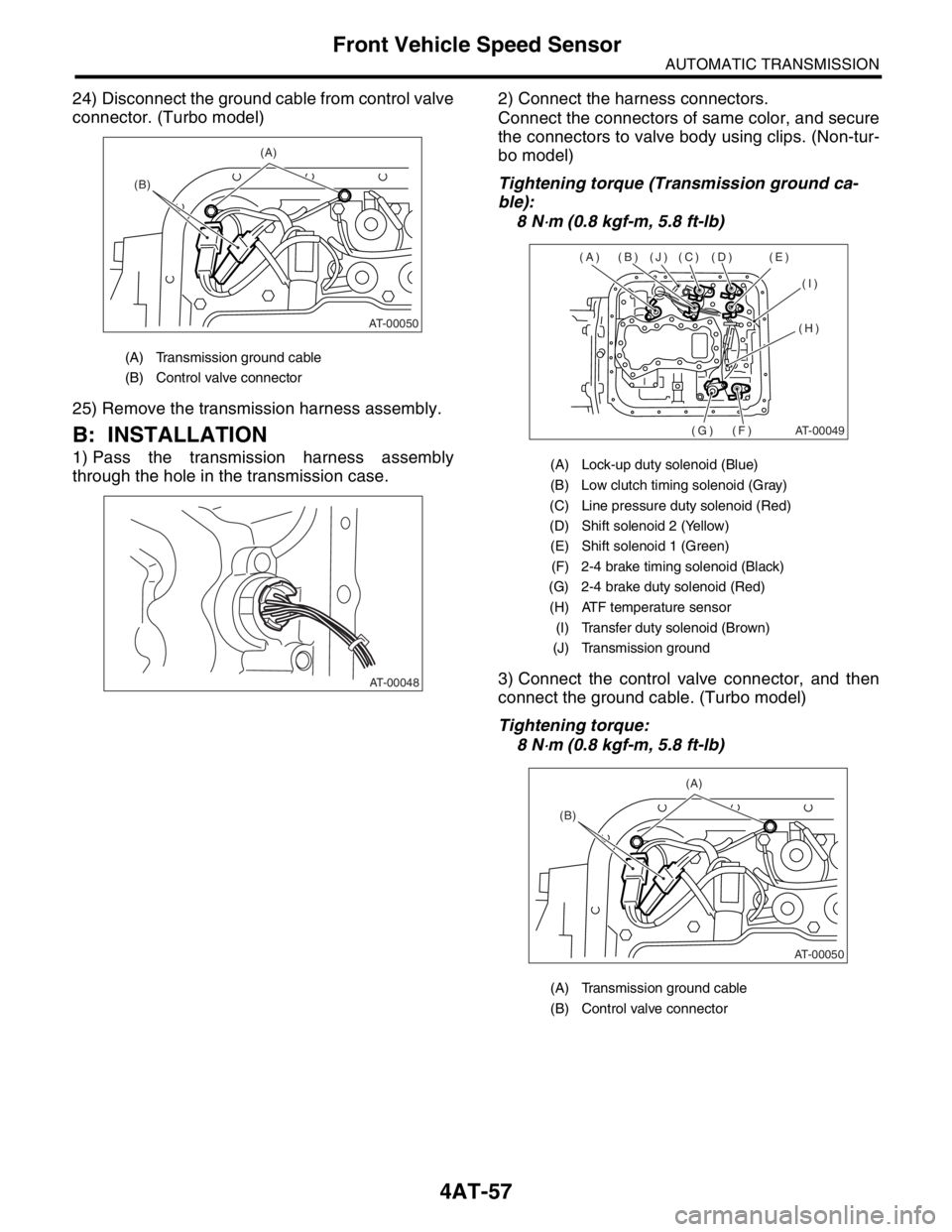

24) Disconnect the ground cable from control valve

connector. (Turbo model)

25) Remove the transmission harness assembly.

B: INSTALLATION

1) Pass the transmission harness assembly

through the hole in the transmission case.2) Connect the harness connectors.

Connect the connectors of same color, and secure

the connectors to valve body using clips. (Non-tur-

bo model)

Tightening torque (Transmission ground ca-

ble):

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

3) Connect the control valve connector, and then

connect the ground cable. (Turbo model)

Tightening torque:

8 N

⋅m (0.8 kgf-m, 5.8 ft-lb)

(A) Transmission ground cable

(B) Control valve connector

AT-00050

(B)

(A)

AT-00048

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 2 (Yellow)

(E) Shift solenoid 1 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid (Red)

(H) ATF temperature sensor

(I) Transfer duty solenoid (Brown)

(J) Transmission ground

(A) Transmission ground cable

(B) Control valve connector

AT-00049

(A) (B) (J) (C) (D) (E)

(I)

(H)

(F) (G)

AT-00050

(B)

(A)

Page 2371 of 2870

4AT-58

AUTOMATIC TRANSMISSION

Front Vehicle Speed Sensor

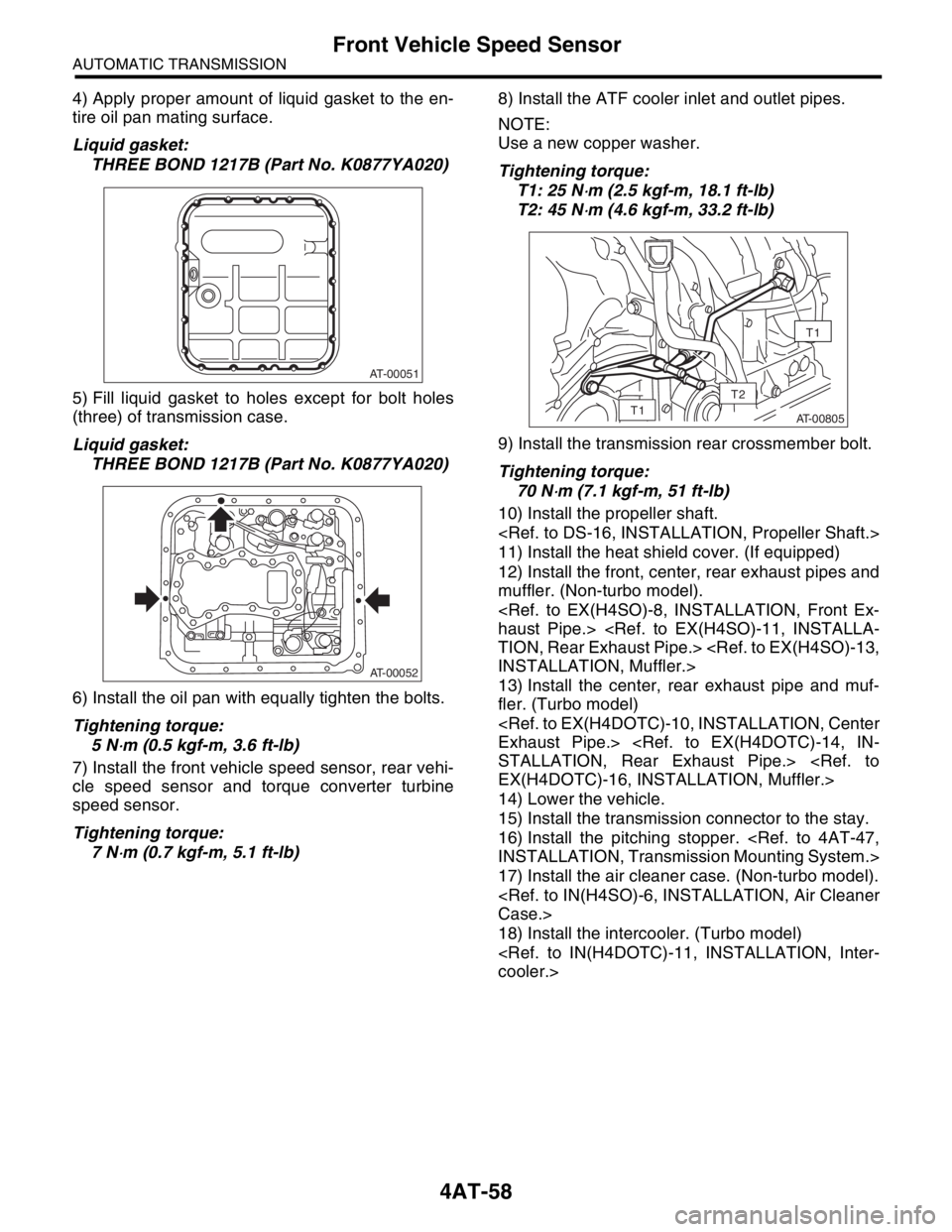

4) Apply proper amount of liquid gasket to the en-

tire oil pan mating surface.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

5) Fill liquid gasket to holes except for bolt holes

(three) of transmission case.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

6) Install the oil pan with equally tighten the bolts.

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

7) Install the front vehicle speed sensor, rear vehi-

cle speed sensor and torque converter turbine

speed sensor.

Tightening torque:

7 N

⋅m (0.7 kgf-m, 5.1 ft-lb)8) Install the ATF cooler inlet and outlet pipes.

NOTE:

Use a new copper washer.

Tightening torque:

T1: 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

T2: 45 N

⋅m (4.6 kgf-m, 33.2 ft-lb)

9) Install the transmission rear crossmember bolt.

Tightening torque:

70 N

⋅m (7.1 kgf-m, 51 ft-lb)

10) Install the propeller shaft.

11) Install the heat shield cover. (If equipped)

12) Install the front, center, rear exhaust pipes and

muffler. (Non-turbo model).

13) Install the center, rear exhaust pipe and muf-

fler. (Turbo model)

14) Lower the vehicle.

15) Install the transmission connector to the stay.

16) Install the pitching stopper.

17) Install the air cleaner case. (Non-turbo model).

18) Install the intercooler. (Turbo model)

AT-00051

AT-00052

AT-00805

T1

T1

T2