torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1968 of 2870

FU(H4DOTC 2.5)-38

FUEL INJECTION (FUEL SYSTEM)

Rear Oxygen Sensor

15.Rear Oxygen Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Lift-up the vehicle.

3) Disconnect the connector from the rear oxygen

sensor.

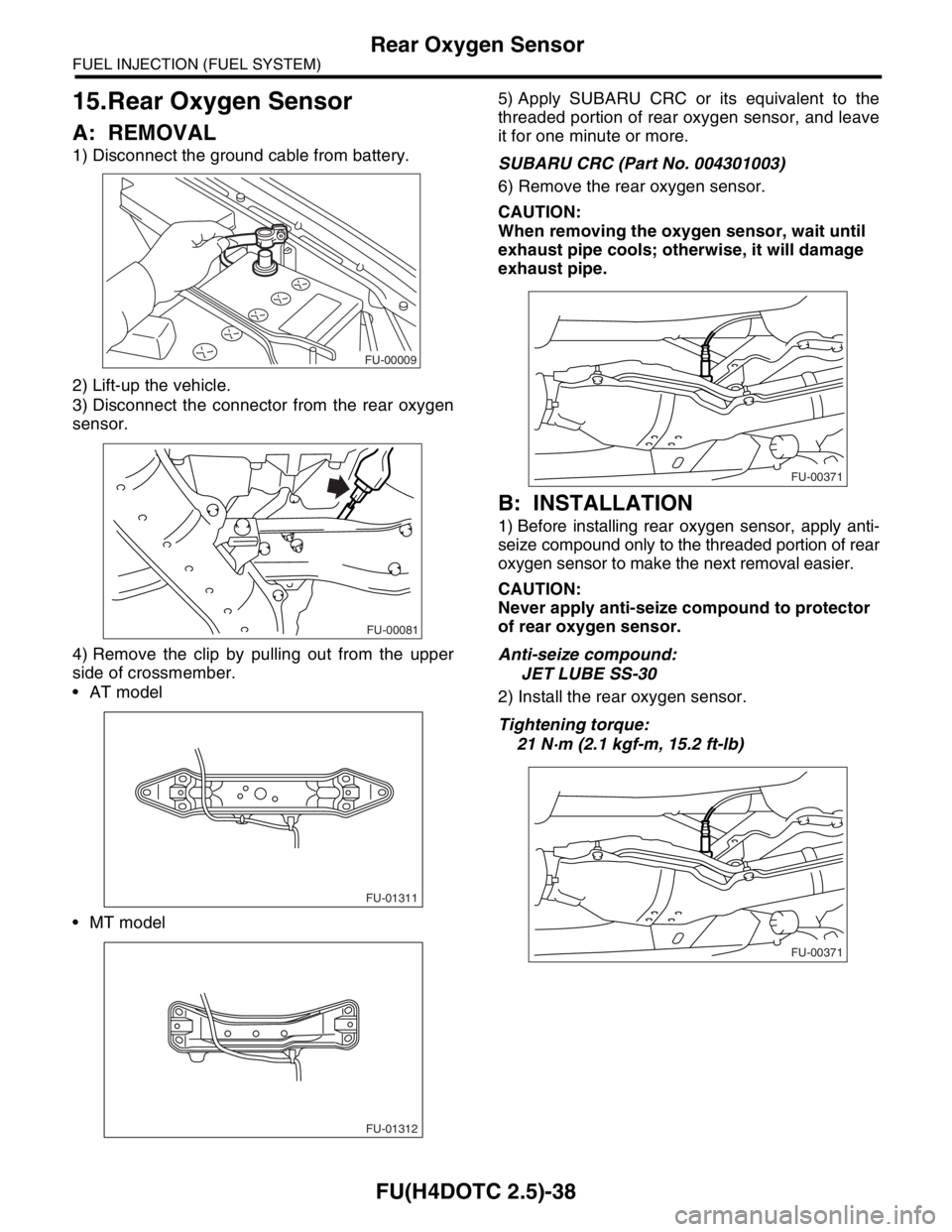

4) Remove the clip by pulling out from the upper

side of crossmember.

AT model

MT model5) Apply SUBARU CRC or its equivalent to the

threaded portion of rear oxygen sensor, and leave

it for one minute or more.

SUBARU CRC (Part No. 004301003)

6) Remove the rear oxygen sensor.

CAUTION:

When removing the oxygen sensor, wait until

exhaust pipe cools; otherwise, it will damage

exhaust pipe.

B: INSTALLATION

1) Before installing rear oxygen sensor, apply anti-

seize compound only to the threaded portion of rear

oxygen sensor to make the next removal easier.

CAUTION:

Never apply anti-seize compound to protector

of rear oxygen sensor.

Anti-seize compound:

JET LUBE SS-30

2) Install the rear oxygen sensor.

Tightening torque:

21 N·m (2.1 kgf-m, 15.2 ft-lb)

FU-00009

FU-00081

FU-01311

FU-01312

FU-00371

FU-00371

Page 1970 of 2870

FU(H4DOTC 2.5)-40

FUEL INJECTION (FUEL SYSTEM)

Exhaust Temperature Sensor

16.Exhaust Temperature Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the joint pipe.

3) Apply SUBARU CRC or its equivalent to the thread-

ed portion of exhaust temperature sensor, and leave it

for 1 minute or more.

SUBARU CRC (Part No. 004301003)

4) Remove the exhaust temperature sensor.

CAUTION:

When removing the exhaust temperature sen-

sor, wait until the exhaust pipe cools, otherwise

it will damage exhaust pipe.

B: INSTALLATION

1) Before installing the exhaust temperature sen-

sor, apply anti-seize compound only to the thread-

ed portion of exhaust temperature sensor to make

the next removal easier.

CAUTION:

Never apply anti-seize compound to the protec-

tor of exhaust temperature sensor.

Anti-seize compound:

SS-30 JET LUBE

2) Install the exhaust temperature sensor.

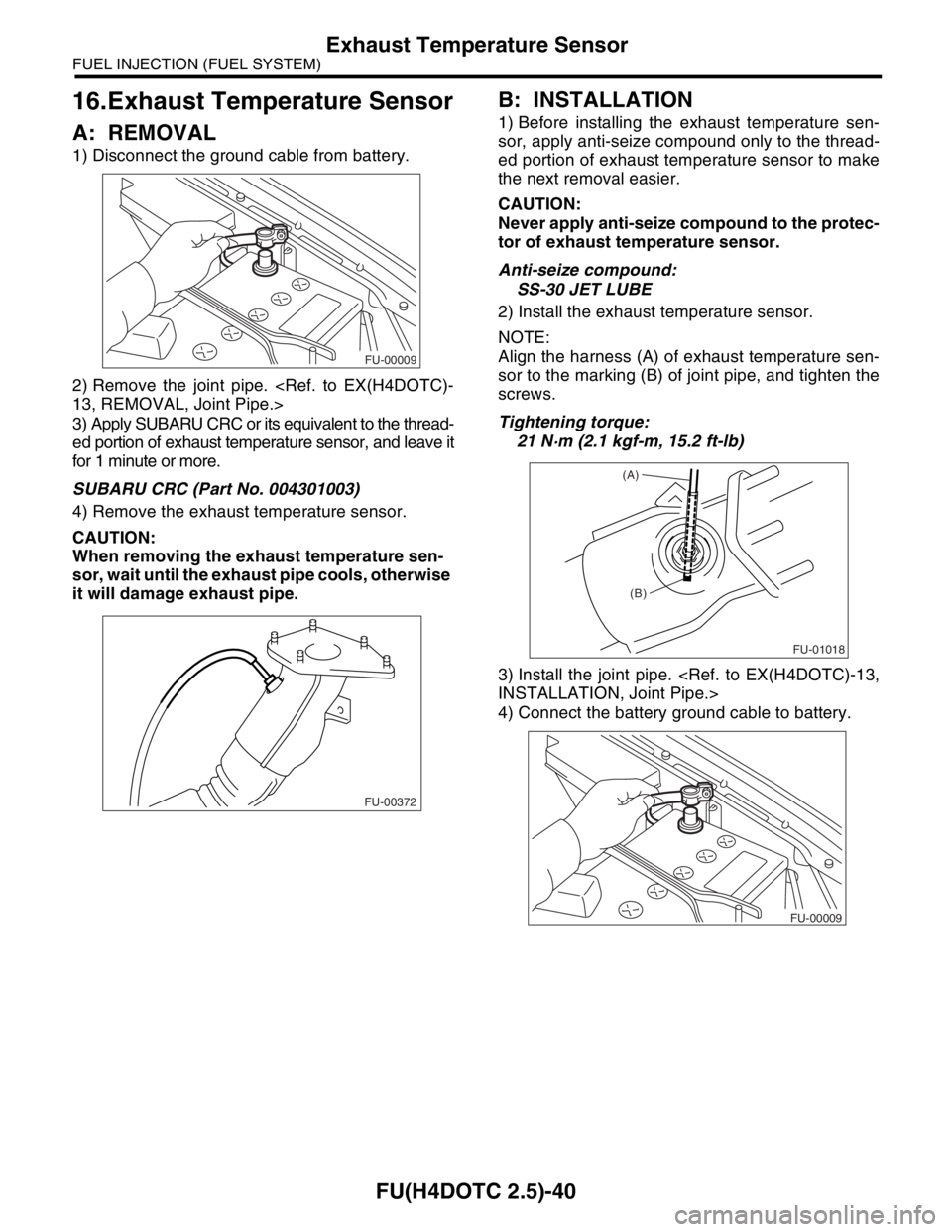

NOTE:

Align the harness (A) of exhaust temperature sen-

sor to the marking (B) of joint pipe, and tighten the

screws.

Tightening torque:

21 N·m (2.1 kgf-m, 15.2 ft-lb)

3) Install the joint pipe.

4) Connect the battery ground cable to battery.

FU-00009

FU-00372

FU-01018

(A)

(B)

FU-00009

Page 1975 of 2870

FU(H4DOTC 2.5)-45

FUEL INJECTION (FUEL SYSTEM)

Fuel

21.Fuel

A: OPERATION

1. RELEASING OF FUEL PRESSURE

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel on the floor.

1) Disconnect the connector from fuel pump relay.

2) Start the engine and run it until it stalls.

3) After the engine stalls, crank it for 5 more seconds.

4) Turn the ignition switch to OFF.

2. DRAINING FUEL

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel on the floor.

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Open the fuel filler flap lid and remove fuel filler

cap.

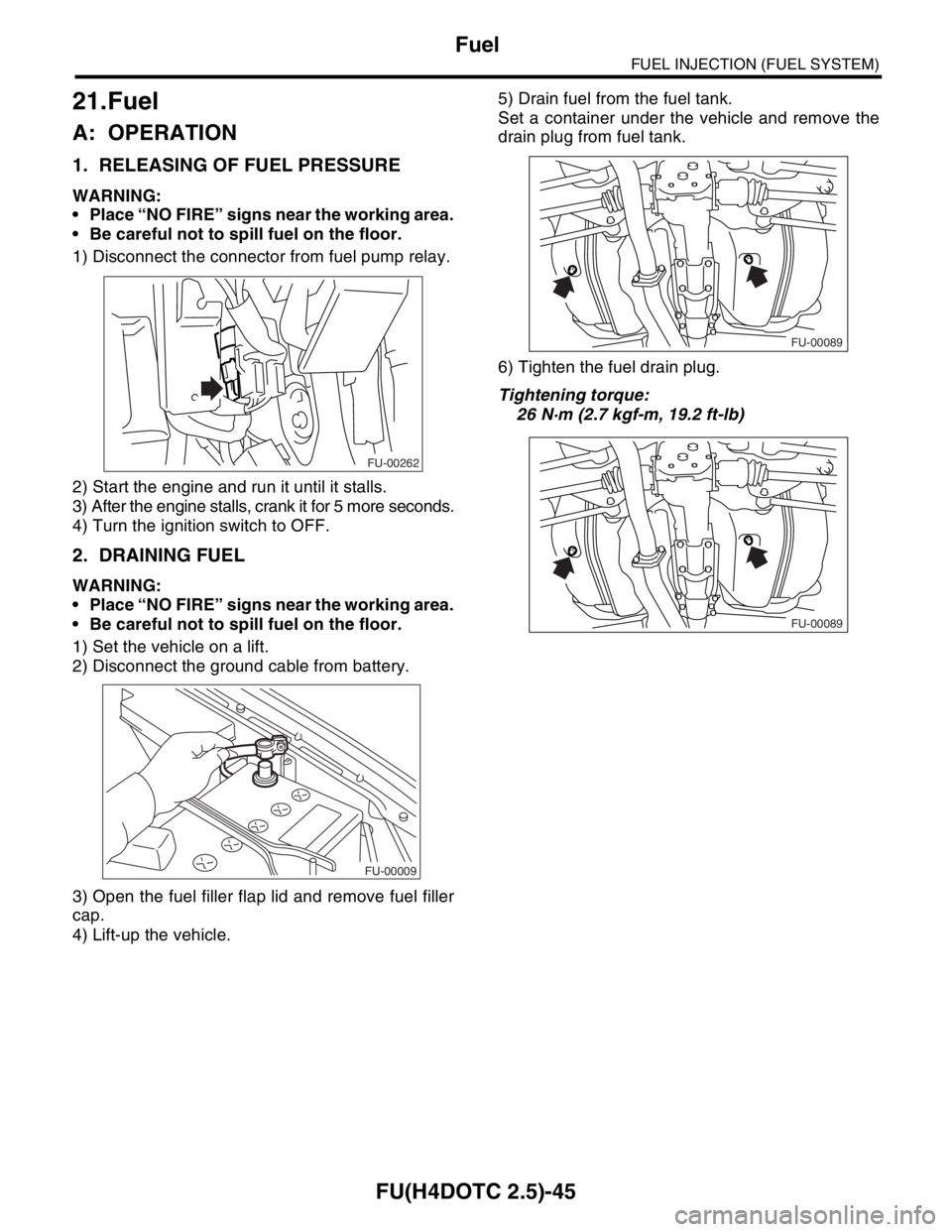

4) Lift-up the vehicle.5) Drain fuel from the fuel tank.

Set a container under the vehicle and remove the

drain plug from fuel tank.

6) Tighten the fuel drain plug.

Tightening torque:

26 N·m (2.7 kgf-m, 19.2 ft-lb)

FU-00262

FU-00009

FU-00089

FU-00089

Page 1977 of 2870

FU(H4DOTC 2.5)-47

FUEL INJECTION (FUEL SYSTEM)

Fuel Tank

2) Set the fuel tank and temporarily tighten the

bolts of fuel tank bands.

WARNING:

A helper is required to perform this work.

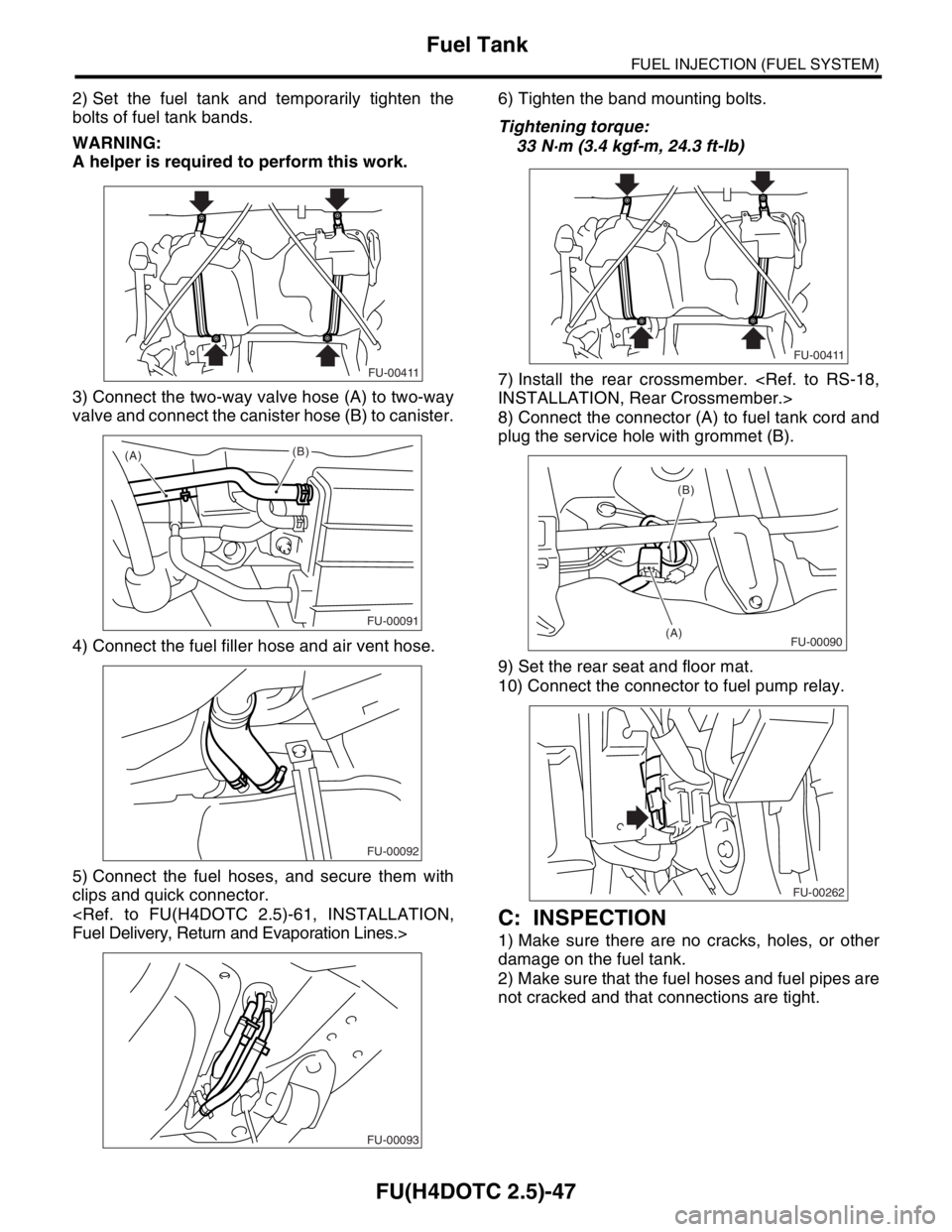

3) Connect the two-way valve hose (A) to two-way

valve and connect the canister hose (B) to canister.

4) Connect the fuel filler hose and air vent hose.

5) Connect the fuel hoses, and secure them with

clips and quick connector.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

7) Install the rear crossmember.

8) Connect the connector (A) to fuel tank cord and

plug the service hole with grommet (B).

9) Set the rear seat and floor mat.

10) Connect the connector to fuel pump relay.

C: INSPECTION

1) Make sure there are no cracks, holes, or other

damage on the fuel tank.

2) Make sure that the fuel hoses and fuel pipes are

not cracked and that connections are tight.

FU-00411

(A)(B)

FU-00091

FU-00092

FU-00093

FU-00411

(B)

(A)

FU-00090

FU-00262

Page 1978 of 2870

FU(H4DOTC 2.5)-48

FUEL INJECTION (FUEL SYSTEM)

Fuel Filler Pipe

23.Fuel Filler Pipe

A: REMOVAL

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel on the floor.

1) Set the vehicle on a lift.

2) Release the fuel pressure.

3) Open the fuel filler flap lid and remove fuel filler

cap.

4) Disconnect the ground cable from battery.

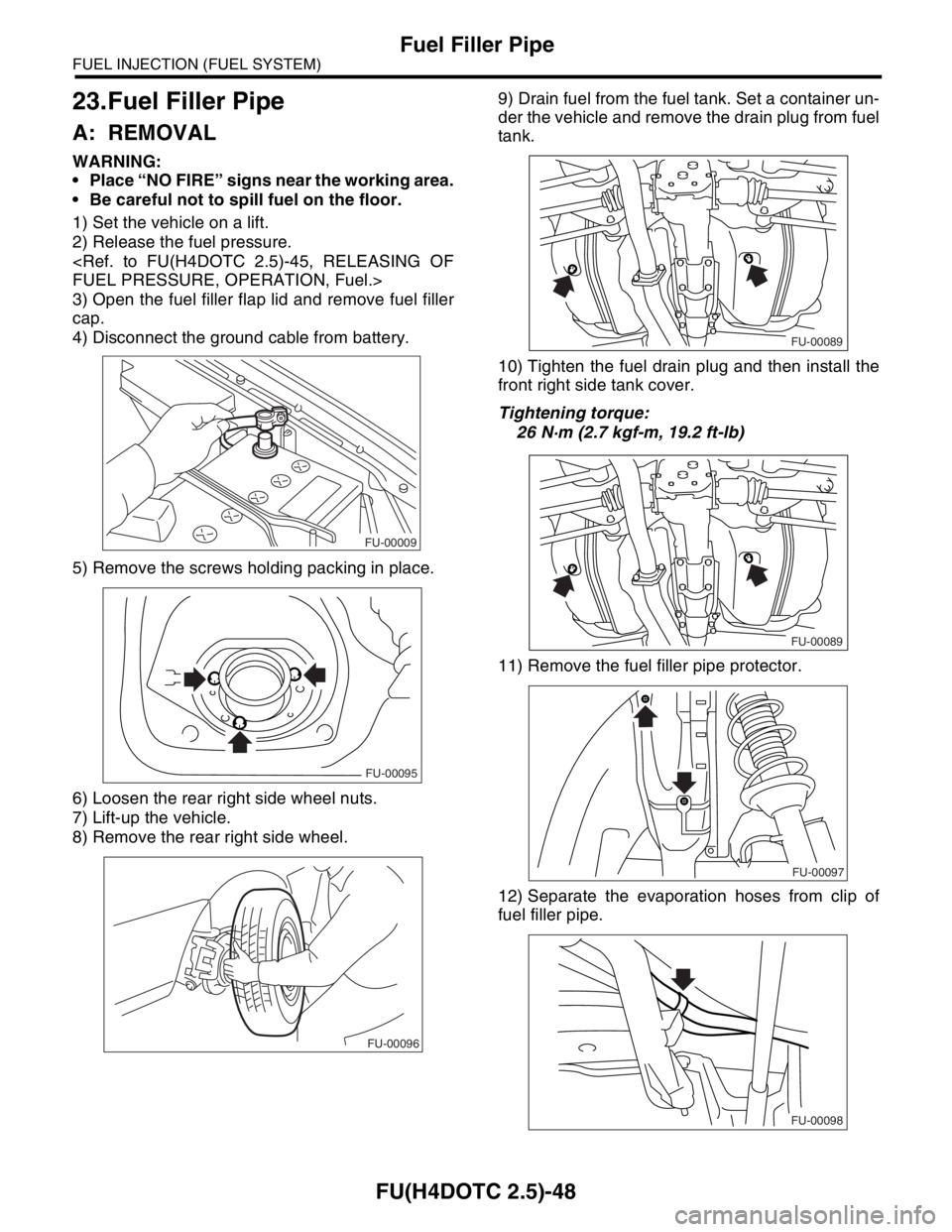

5) Remove the screws holding packing in place.

6) Loosen the rear right side wheel nuts.

7) Lift-up the vehicle.

8) Remove the rear right side wheel.9) Drain fuel from the fuel tank. Set a container un-

der the vehicle and remove the drain plug from fuel

tank.

10) Tighten the fuel drain plug and then install the

front right side tank cover.

Tightening torque:

26 N·m (2.7 kgf-m, 19.2 ft-lb)

11) Remove the fuel filler pipe protector.

12) Separate the evaporation hoses from clip of

fuel filler pipe.

FU-00009

FU-00095

FU-00096

FU-00089

FU-00089

FU-00097

FU-00098

Page 1980 of 2870

FU(H4DOTC 2.5)-50

FUEL INJECTION (FUEL SYSTEM)

Fuel Filler Pipe

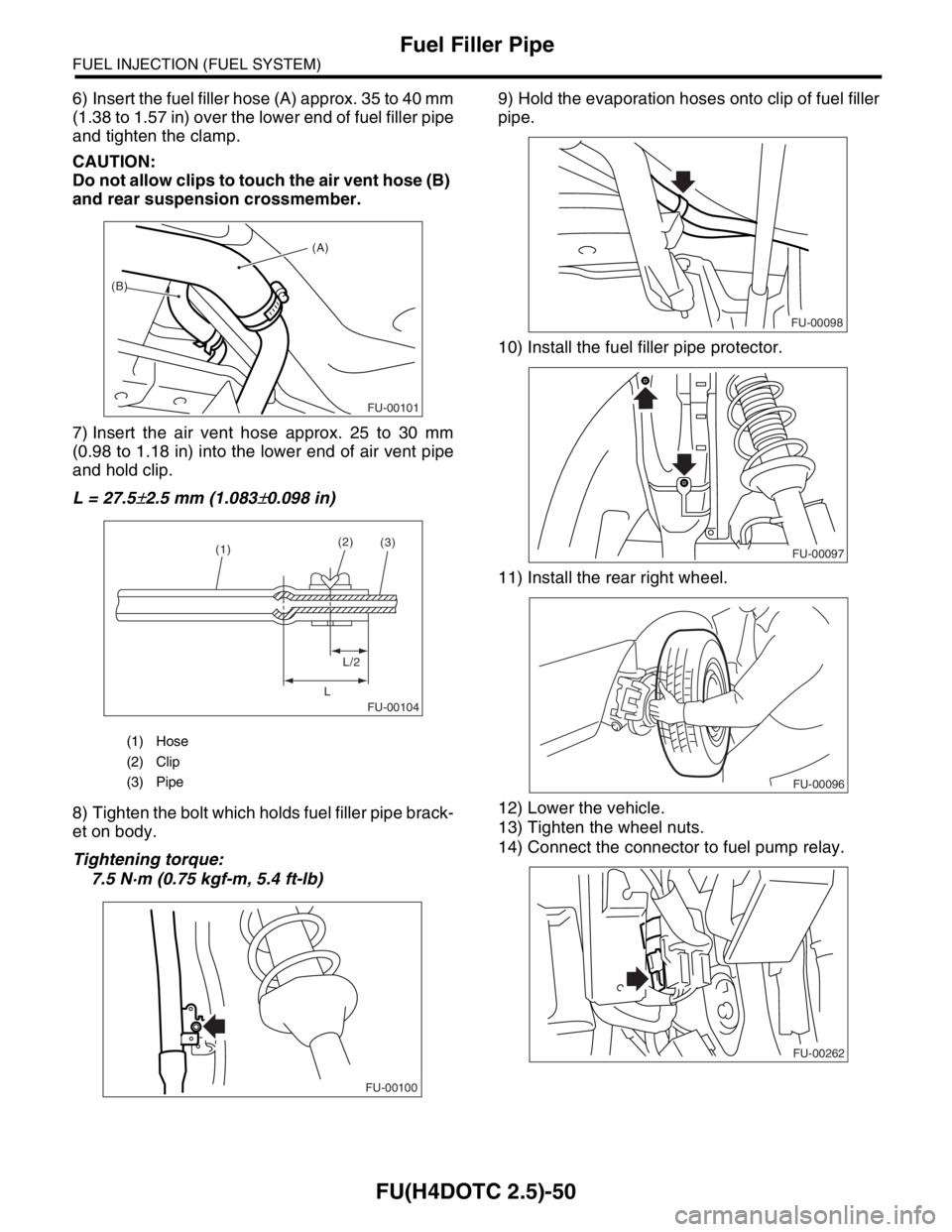

6) Insert the fuel filler hose (A) approx. 35 to 40 mm

(1.38 to 1.57 in) over the lower end of fuel filler pipe

and tighten the clamp.

CAUTION:

Do not allow clips to touch the air vent hose (B)

and rear suspension crossmember.

7) Insert the air vent hose approx. 25 to 30 mm

(0.98 to 1.18 in) into the lower end of air vent pipe

and hold clip.

L = 27.5

±2.5 mm (1.083±0.098 in)

8) Tighten the bolt which holds fuel filler pipe brack-

et on body.

Tightening torque:

7.5 N·m (0.75 kgf-m, 5.4 ft-lb)9) Hold the evaporation hoses onto clip of fuel filler

pipe.

10) Install the fuel filler pipe protector.

11) Install the rear right wheel.

12) Lower the vehicle.

13) Tighten the wheel nuts.

14) Connect the connector to fuel pump relay.

(1) Hose

(2) Clip

(3) Pipe

(A)

(B)

FU-00101

FU-00104

(1)(2)

L/2

L(3)

FU-00100

FU-00098

FU-00097

FU-00096

FU-00262

Page 1982 of 2870

FU(H4DOTC 2.5)-52

FUEL INJECTION (FUEL SYSTEM)

Fuel Pump

24.Fuel Pump

A: REMOVAL

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel on the floor.

NOTE:

Fuel pump assembly consists of fuel pump and fuel

level sensor.

1) Release the fuel pressure.

2) Open the fuel filler flap lid and remove fuel filler

cap.

3) Disconnect the ground cable from battery.

4) Lift-up the vehicle.

5) Drain fuel from the fuel tank. Set a container un-

der the vehicle and remove the drain plug from fuel

tank.

6) Tighten the fuel drain plug.

Tightening torque:

26 N

⋅m (2.7 kgf-m, 19.2 ft-lb)7) Raise the rear seat and turn floor mat up.

8) Remove the access hole lid.

9) Disconnect the connector from fuel pump.

10) Disconnect the quick connector and then dis-

connect fuel delivery hose.

11) Move the clips, and then disconnect the fuel re-

turn hose (A) and jet pump hose (B).

12) Remove the nuts which install fuel pump as-

sembly onto fuel tank.

13) Take off the fuel pump assembly from fuel tank.

FU-00009

FU-00089

FU-00089

FU-00105

FU-00106

FU-00376

(B)

(A)

FU-00108

Page 1983 of 2870

FU(H4DOTC 2.5)-53

FUEL INJECTION (FUEL SYSTEM)

Fuel Pump

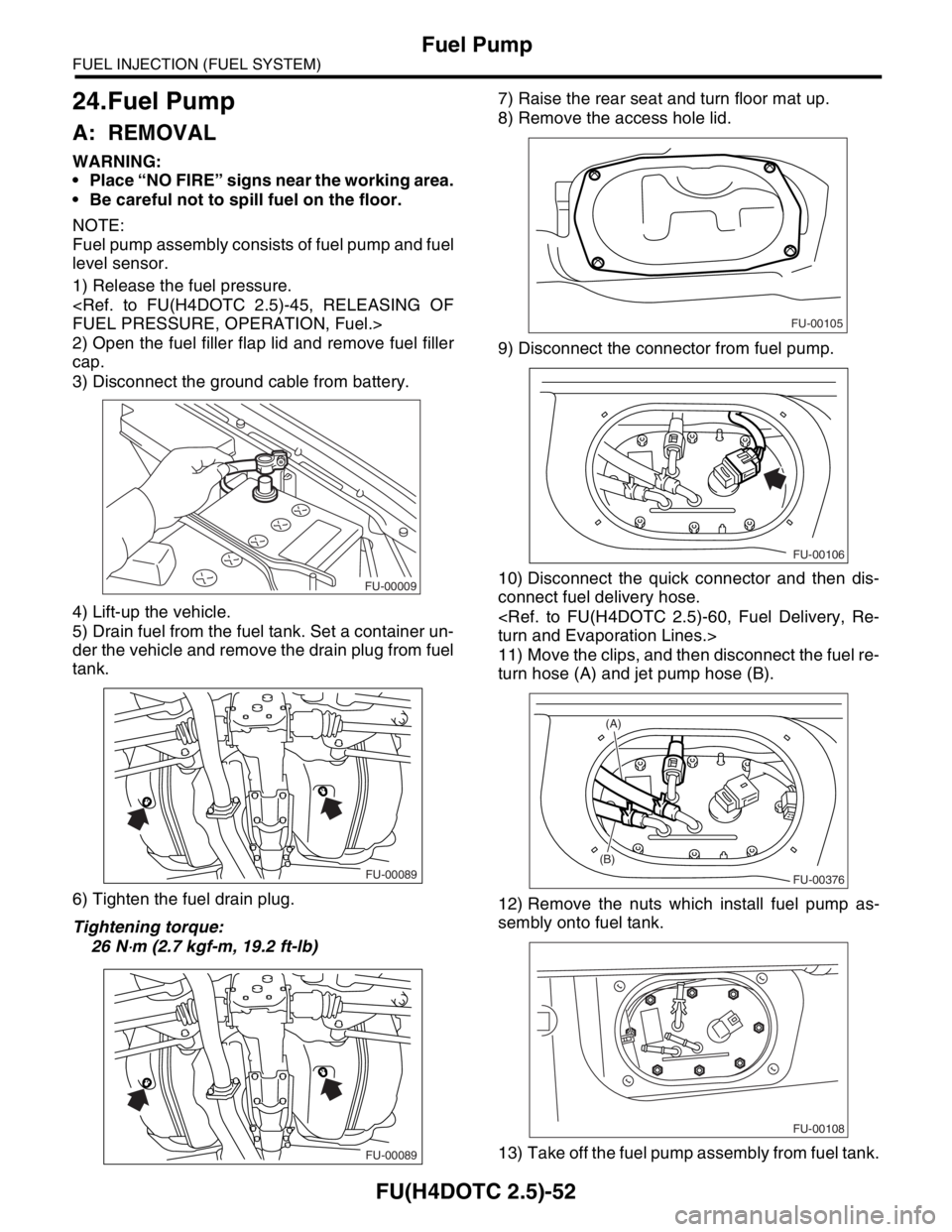

B: INSTALLATION

Install in the reverse order of removal. Do the fol-

lowing:

NOTE:

Replace the gaskets with new ones.

(1) Ensure sealing portion is free from fuel or for-

eign particles before installation.

(2) Tighten the nuts in alphabetical sequence

shown in the figure to specified torque.

Tightening torque:

4.4 N

⋅m (0.45 kgf-m, 3.3 ft-lb)

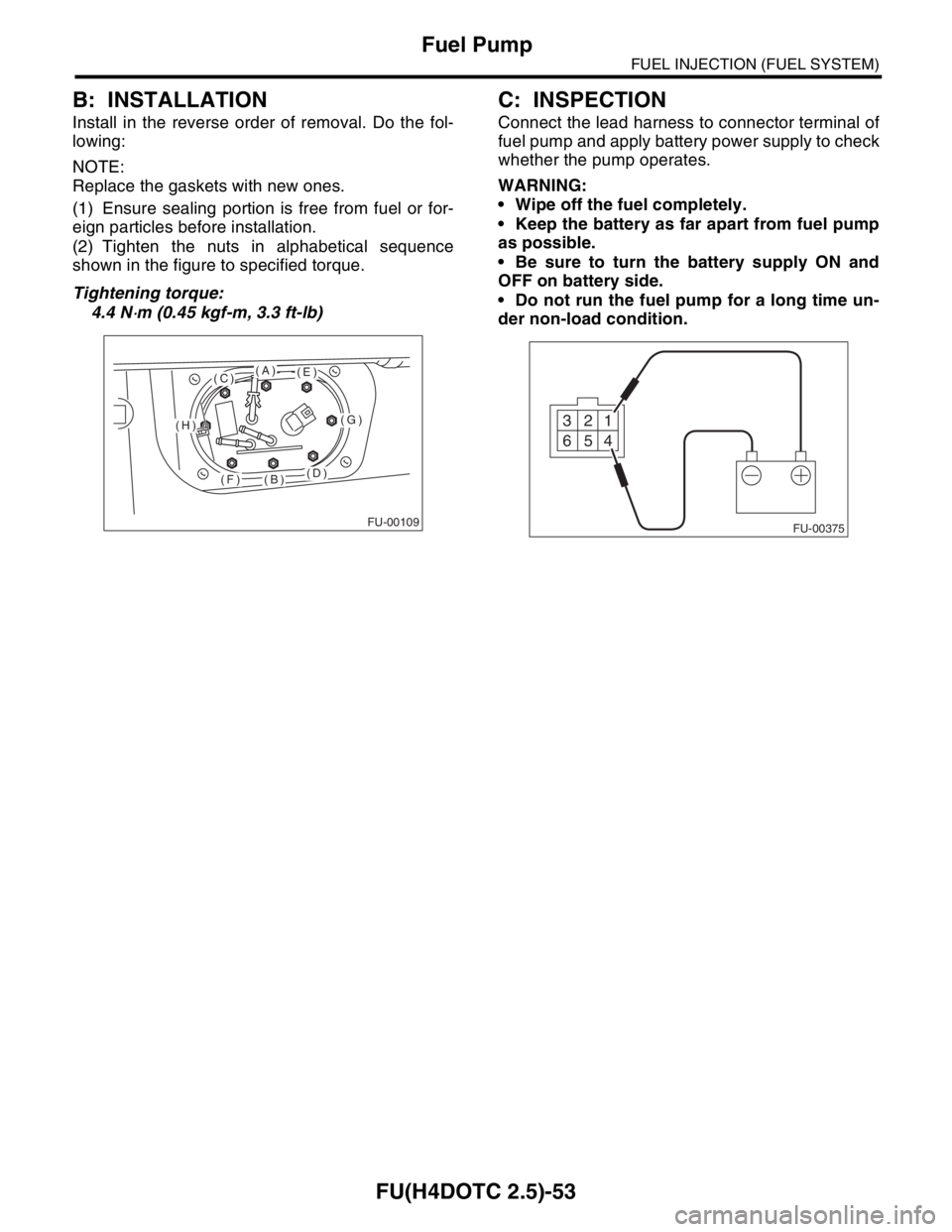

C: INSPECTION

Connect the lead harness to connector terminal of

fuel pump and apply battery power supply to check

whether the pump operates.

WARNING:

Wipe off the fuel completely.

Keep the battery as far apart from fuel pump

as possible.

Be sure to turn the battery supply ON and

OFF on battery side.

Do not run the fuel pump for a long time un-

der non-load condition.

FU-00109

(A)

(B)

(C)

(D)

(E)

(F)

(G)(H)

FU-003751 2 3

4 5 6

Page 1985 of 2870

FU(H4DOTC 2.5)-55

FUEL INJECTION (FUEL SYSTEM)

Fuel Sub Level Sensor

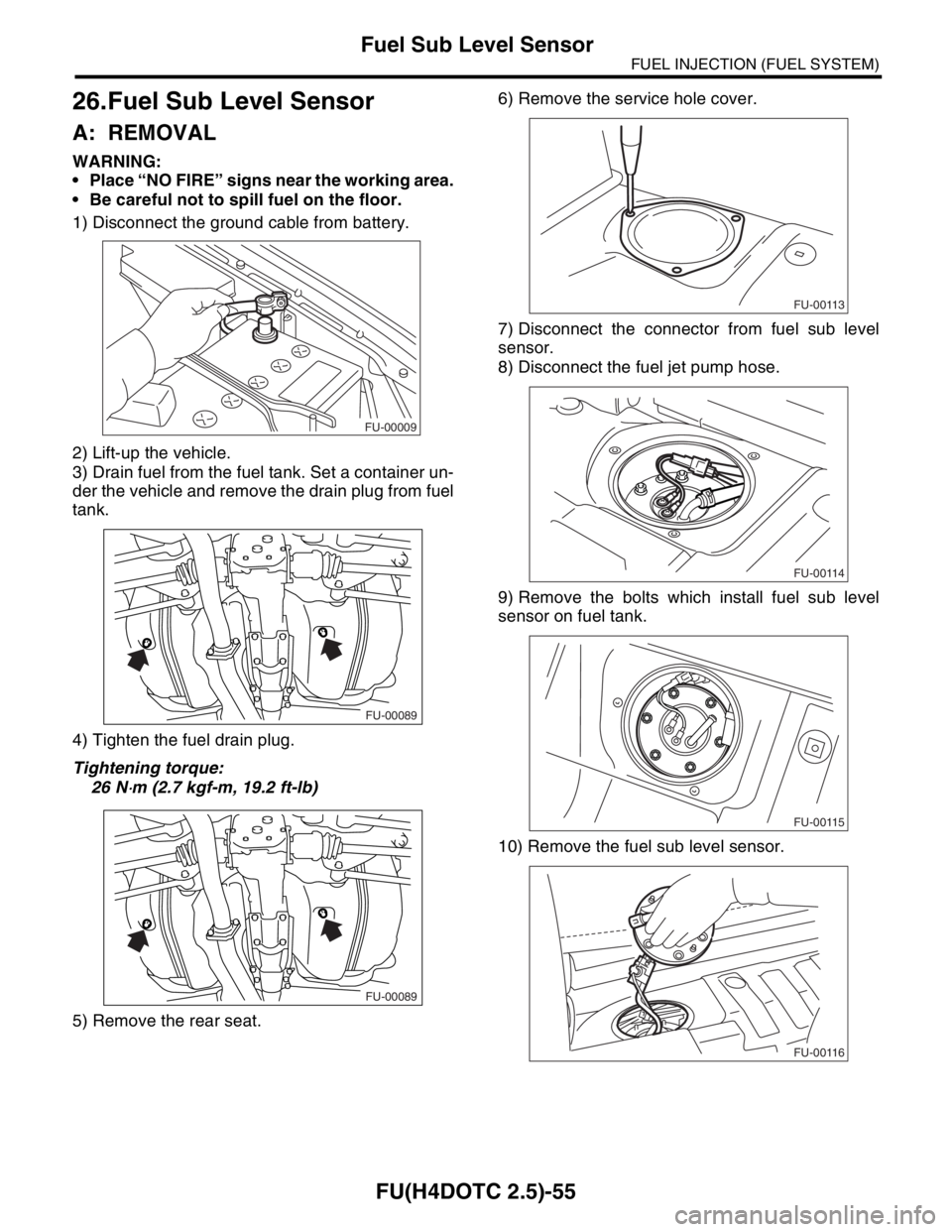

26.Fuel Sub Level Sensor

A: REMOVAL

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel on the floor.

1) Disconnect the ground cable from battery.

2) Lift-up the vehicle.

3) Drain fuel from the fuel tank. Set a container un-

der the vehicle and remove the drain plug from fuel

tank.

4) Tighten the fuel drain plug.

Tightening torque:

26 N

⋅m (2.7 kgf-m, 19.2 ft-lb)

5) Remove the rear seat.6) Remove the service hole cover.

7) Disconnect the connector from fuel sub level

sensor.

8) Disconnect the fuel jet pump hose.

9) Remove the bolts which install fuel sub level

sensor on fuel tank.

10) Remove the fuel sub level sensor.

FU-00009

FU-00089

FU-00089

FU-00113

FU-00114

FU-00115

FU-00116

Page 1986 of 2870

FU(H4DOTC 2.5)-56

FUEL INJECTION (FUEL SYSTEM)

Fuel Sub Level Sensor

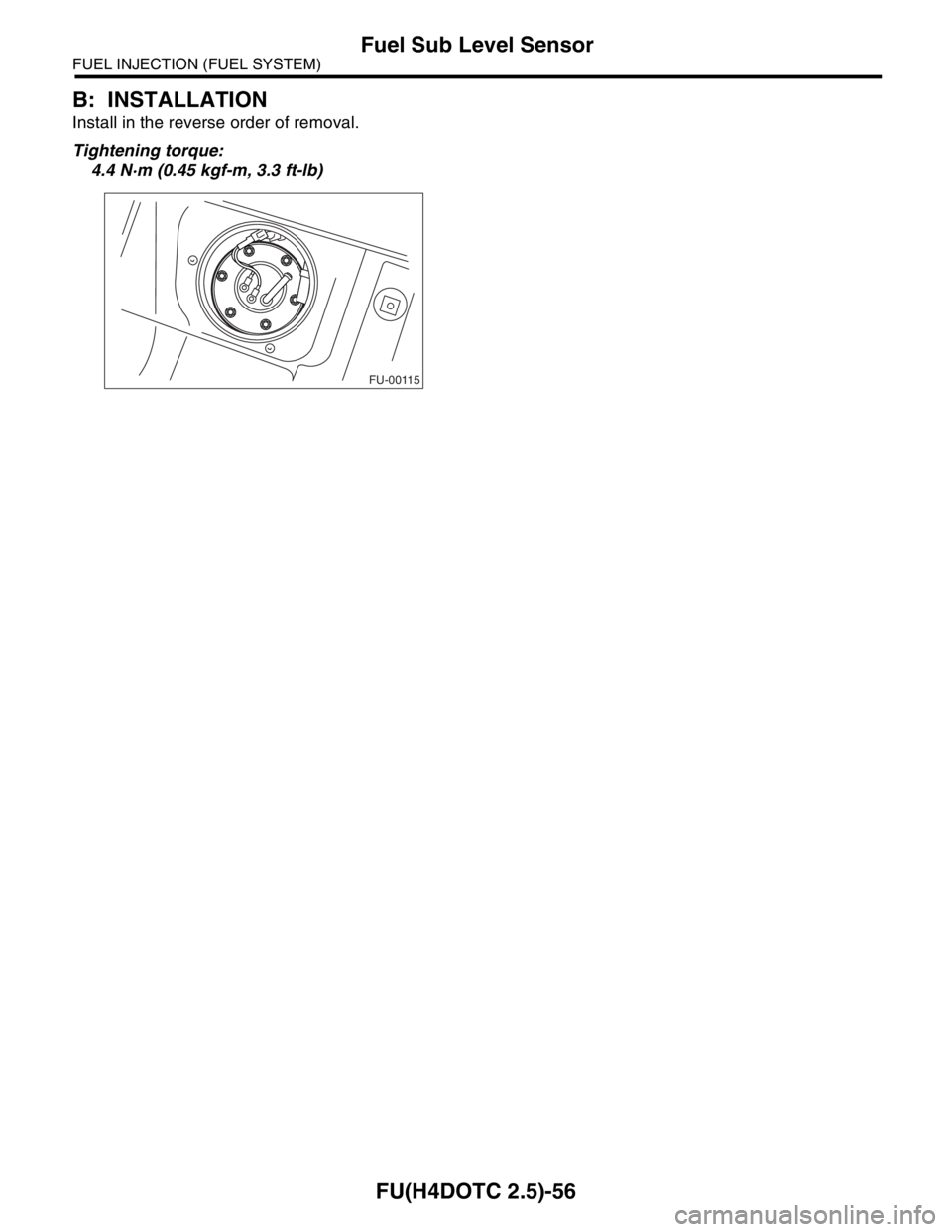

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

4.4 N·m (0.45 kgf-m, 3.3 ft-lb)

FU-00115