torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1987 of 2870

FU(H4DOTC 2.5)-57

FUEL INJECTION (FUEL SYSTEM)

Fuel Filter

27.Fuel Filter

A: REMOVAL

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel on the floor.

1) Release the fuel pressure.

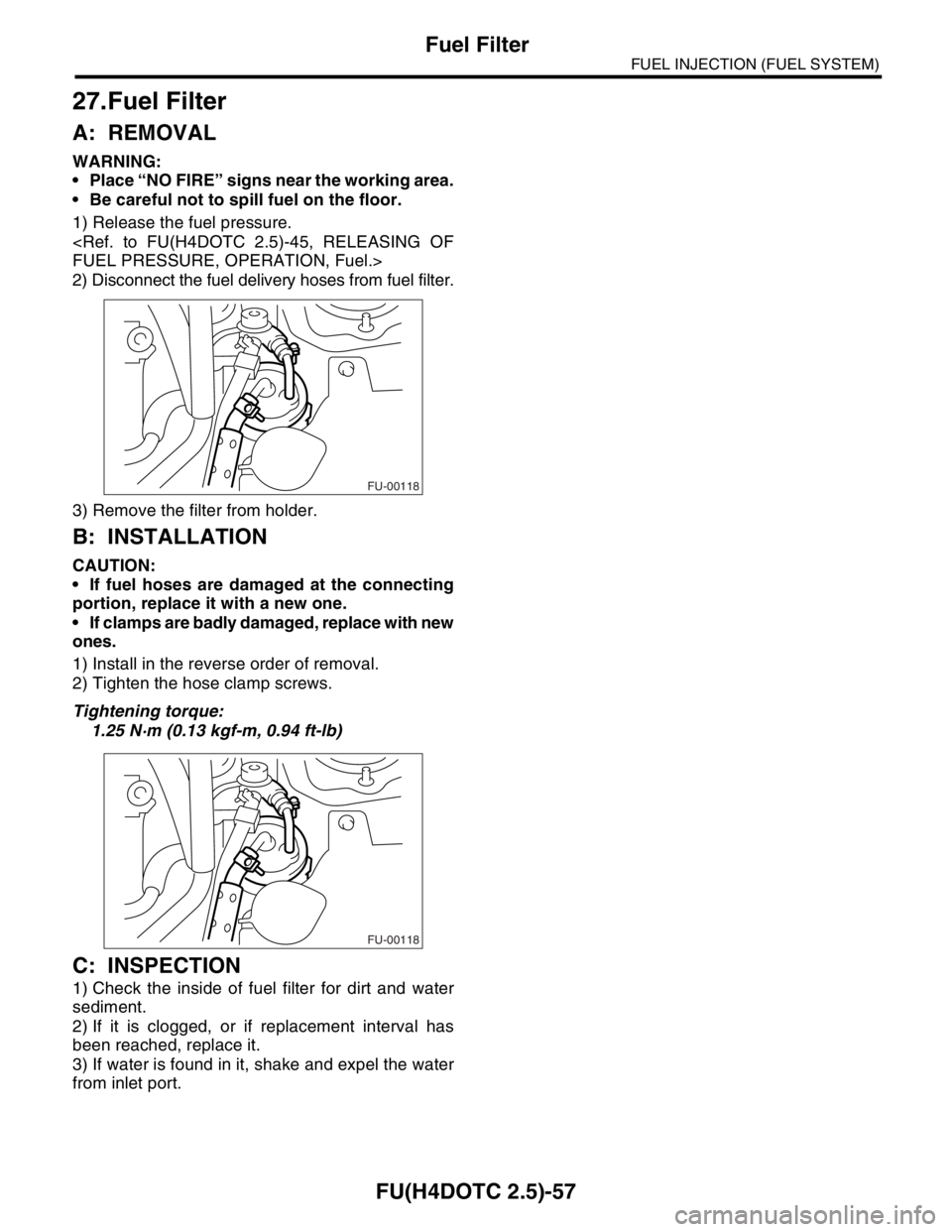

2) Disconnect the fuel delivery hoses from fuel filter.

3) Remove the filter from holder.

B: INSTALLATION

CAUTION:

If fuel hoses are damaged at the connecting

portion, replace it with a new one.

If clamps are badly damaged, replace with new

ones.

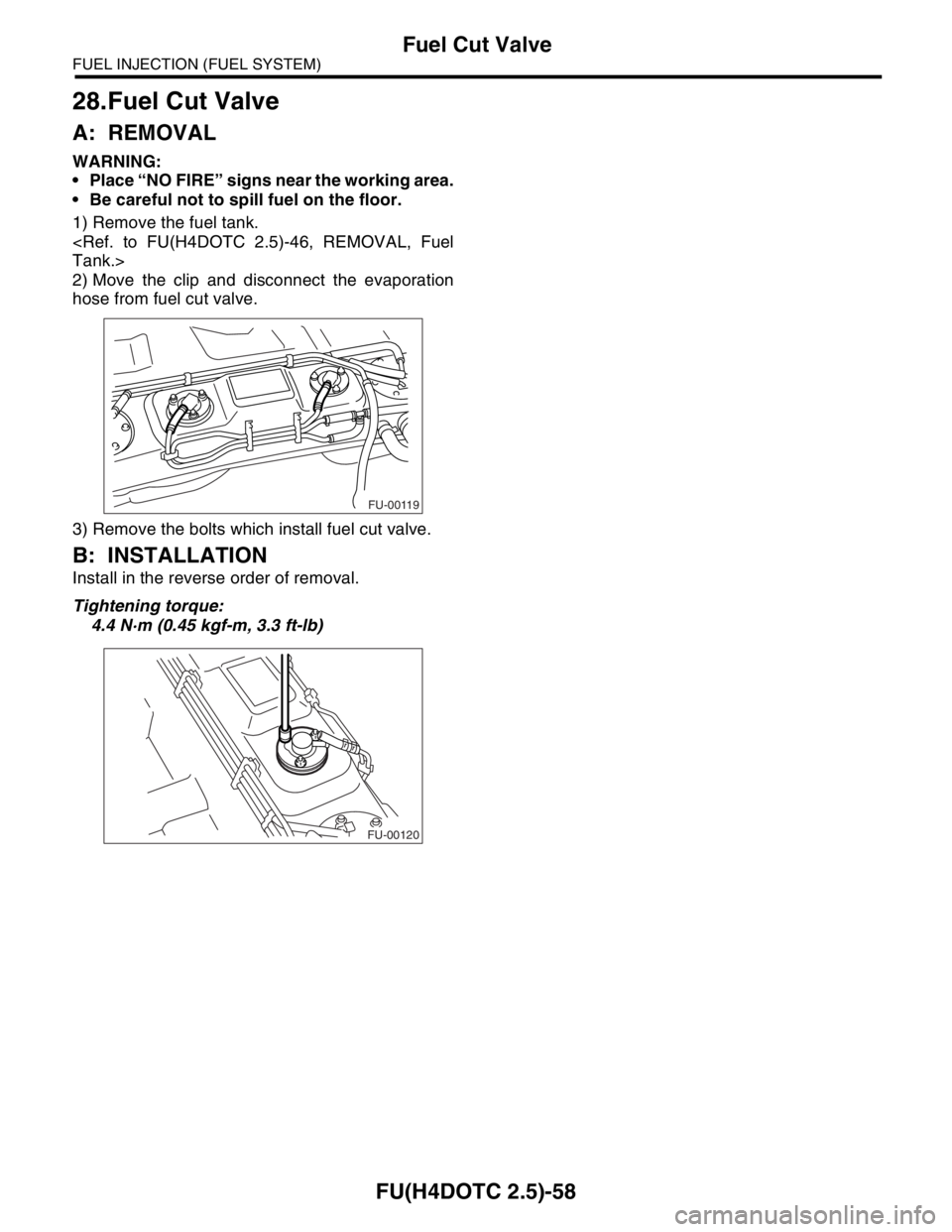

1) Install in the reverse order of removal.

2) Tighten the hose clamp screws.

Tightening torque:

1.25 N·m (0.13 kgf-m, 0.94 ft-lb)

C: INSPECTION

1) Check the inside of fuel filter for dirt and water

sediment.

2) If it is clogged, or if replacement interval has

been reached, replace it.

3) If water is found in it, shake and expel the water

from inlet port.

FU-00118

FU-00118

Page 1988 of 2870

FU(H4DOTC 2.5)-58

FUEL INJECTION (FUEL SYSTEM)

Fuel Cut Valve

28.Fuel Cut Valve

A: REMOVAL

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel on the floor.

1) Remove the fuel tank.

2) Move the clip and disconnect the evaporation

hose from fuel cut valve.

3) Remove the bolts which install fuel cut valve.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

4.4 N·m (0.45 kgf-m, 3.3 ft-lb)

FU-00119

FU-00120

Page 2015 of 2870

SP(H4DOTC 2.5)-2

SPEED CONTROL SYSTEM

General Description

1. General Description

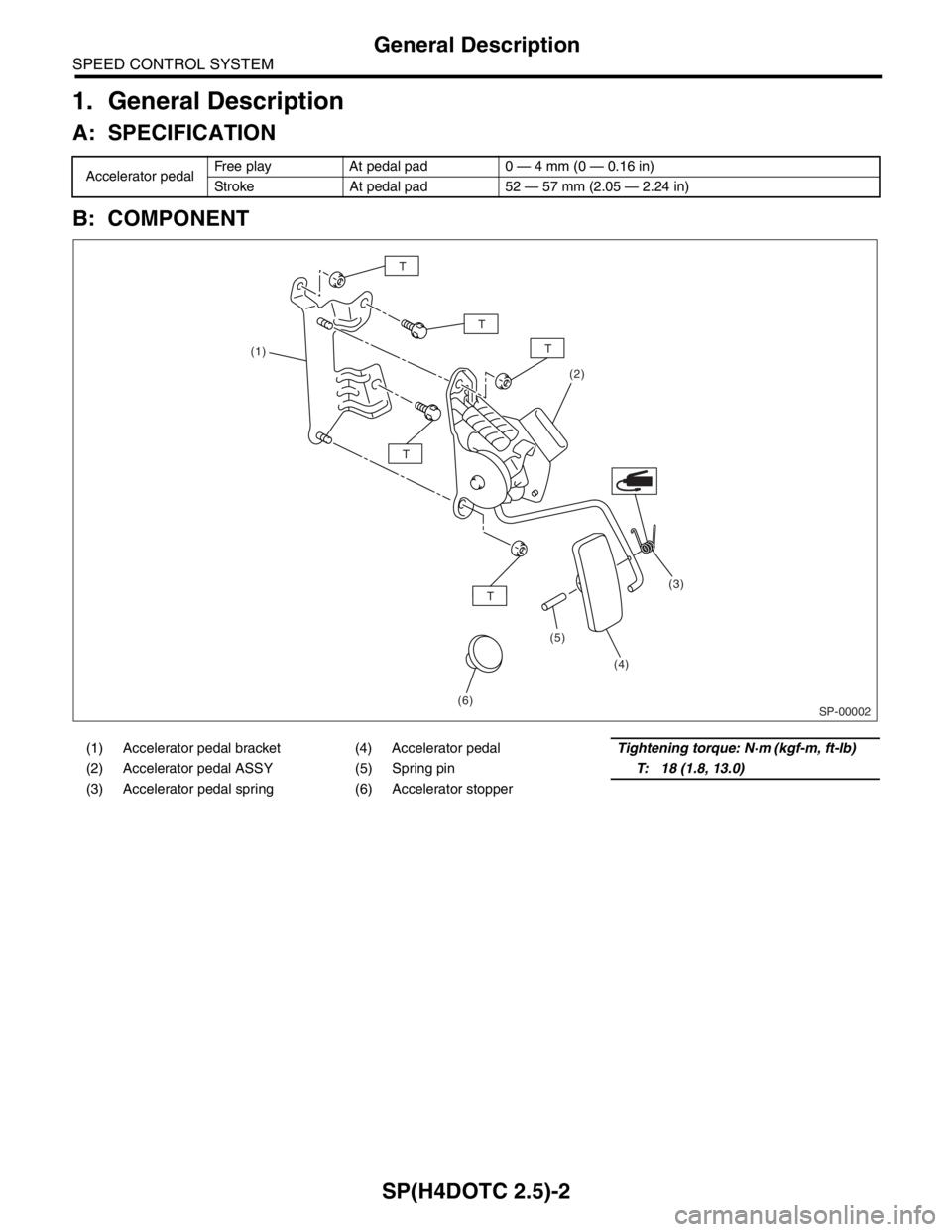

A: SPECIFICATION

B: COMPONENT

Accelerator pedalFree play At pedal pad 0 — 4 mm (0 — 0.16 in)

Stroke At pedal pad 52 — 57 mm (2.05 — 2.24 in)

(1) Accelerator pedal bracket (4) Accelerator pedalTightening torque: N·m (kgf-m, ft-lb)

(2) Accelerator pedal ASSY (5) Spring pinT: 18 (1.8, 13.0)

(3) Accelerator pedal spring (6) Accelerator stopper

(6)

(1)

(2)

(5)(3)

(4)

SP-00002

T

T

T

T

T

Page 2016 of 2870

SP(H4DOTC 2.5)-3

SPEED CONTROL SYSTEM

General Description

C: CAUTION

Wear work clothing, including a cap, protective

goggles, and protective shoes during operation.

Remove contamination, including dirt and corro-

sion, before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust and dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement.

Be careful not to burn your hands, because each

part in the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

Page 2017 of 2870

SP(H4DOTC 2.5)-4

SPEED CONTROL SYSTEM

Accelerator Pedal

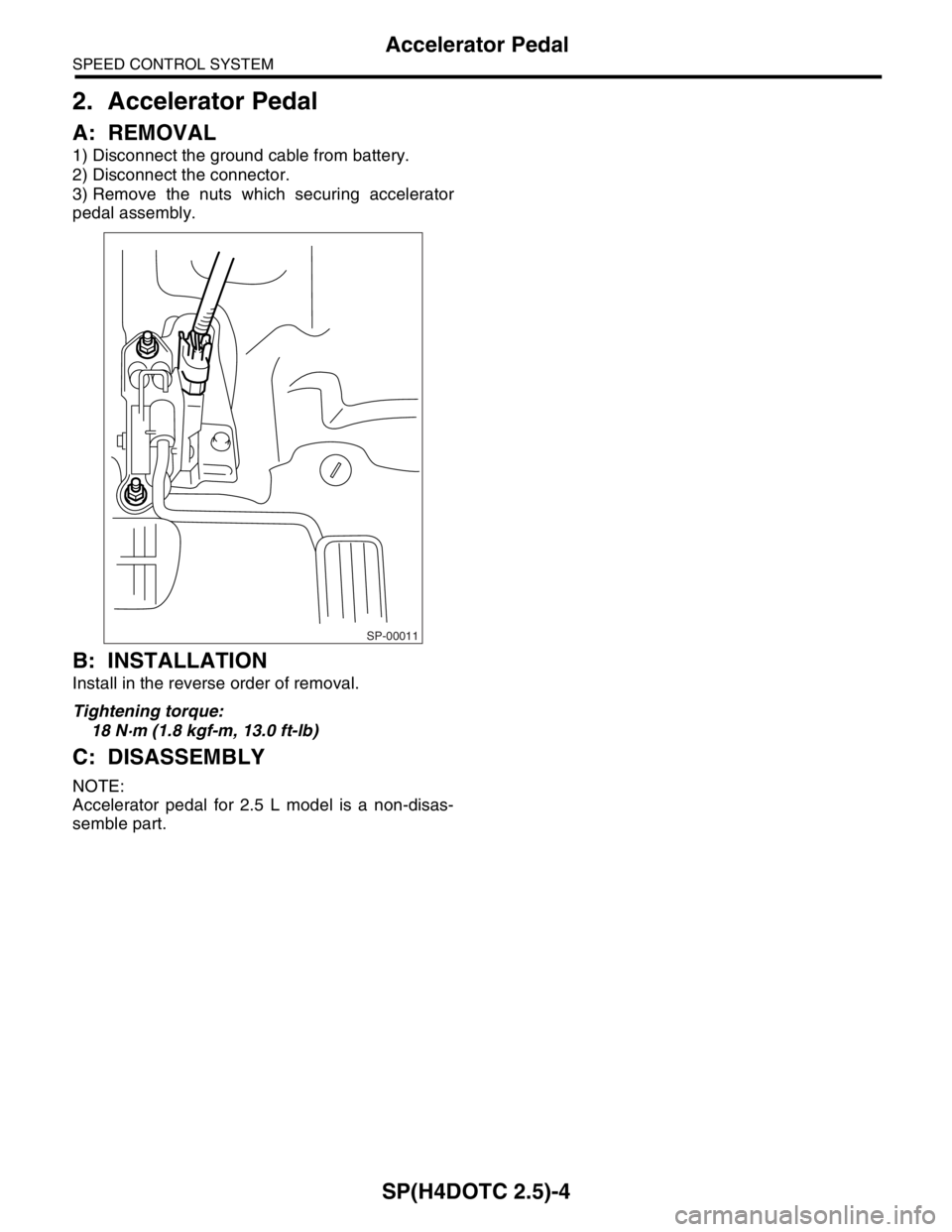

2. Accelerator Pedal

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Disconnect the connector.

3) Remove the nuts which securing accelerator

pedal assembly.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

18 N·m (1.8 kgf-m, 13.0 ft-lb)

C: DISASSEMBLY

NOTE:

Accelerator pedal for 2.5 L model is a non-disas-

semble part.

SP-00011

Page 2053 of 2870

EN(H4DOTC 2.5)-29

ENGINE (DIAGNOSTIC)

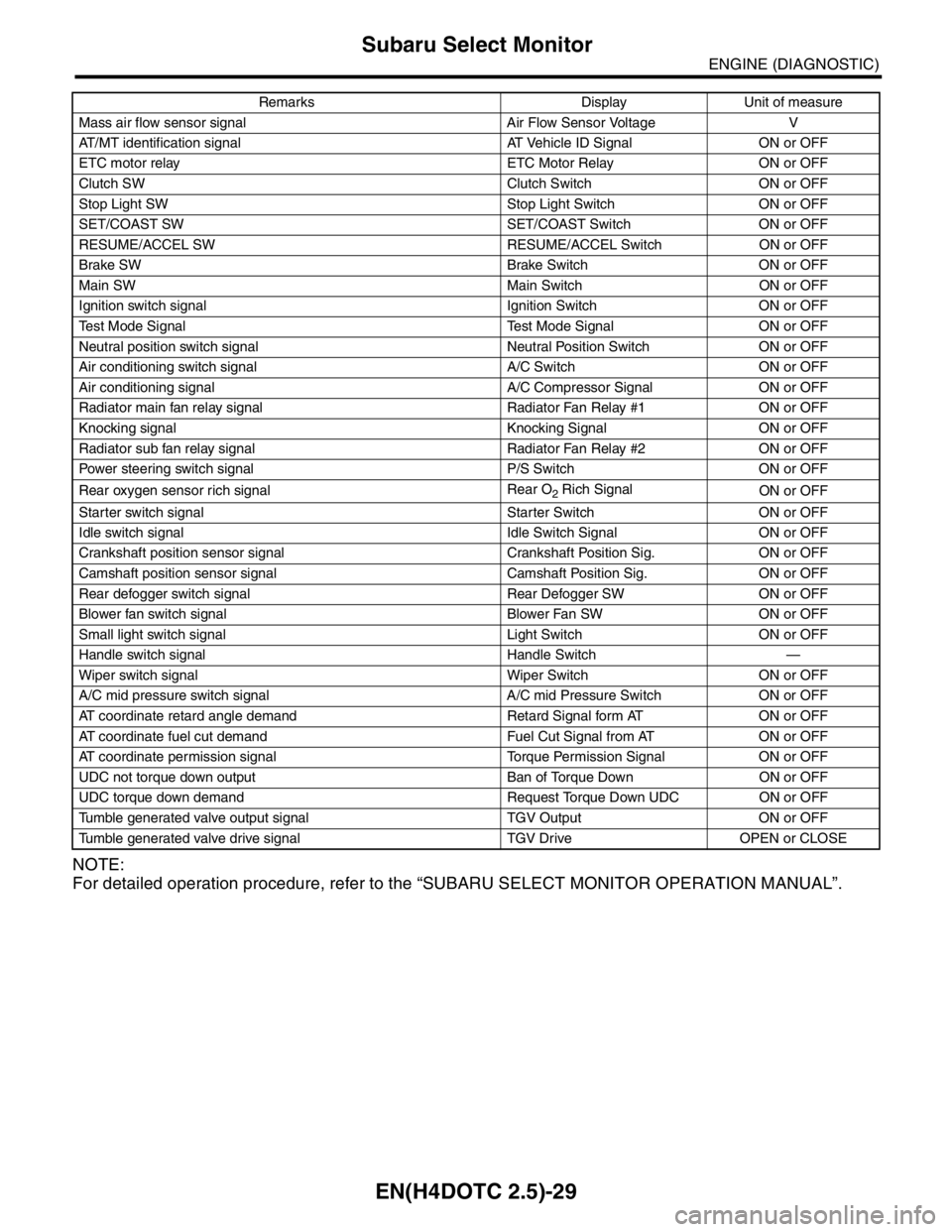

Subaru Select Monitor

NOTE:

For detailed operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MANUAL”.

Mass air flow sensor signal Air Flow Sensor Voltage V

AT/MT identification signal AT Vehicle ID Signal ON or OFF

ETC motor relay ETC Motor Relay ON or OFF

Clutch SW Clutch Switch ON or OFF

Stop Light SW Stop Light Switch ON or OFF

SET/COAST SW SET/COAST Switch ON or OFF

RESUME/ACCEL SW RESUME/ACCEL Switch ON or OFF

Brake SW Brake Switch ON or OFF

Main SW Main Switch ON or OFF

Ignition switch signal Ignition Switch ON or OFF

Test Mode Signal Test Mode Signal ON or OFF

Neutral position switch signal Neutral Position Switch ON or OFF

Air conditioning switch signal A/C Switch ON or OFF

Air conditioning signal A/C Compressor Signal ON or OFF

Radiator main fan relay signal Radiator Fan Relay #1 ON or OFF

Knocking signal Knocking Signal ON or OFF

Radiator sub fan relay signal Radiator Fan Relay #2 ON or OFF

Power steering switch signal P/S Switch ON or OFF

Rear oxygen sensor rich signalRear O

2 Rich Signal

ON or OFF

Starter switch signal Starter Switch ON or OFF

Idle switch signal Idle Switch Signal ON or OFF

Crankshaft position sensor signal Crankshaft Position Sig. ON or OFF

Camshaft position sensor signal Camshaft Position Sig. ON or OFF

Rear defogger switch signal Rear Defogger SW ON or OFF

Blower fan switch signal Blower Fan SW ON or OFF

Small light switch signal Light Switch ON or OFF

Handle switch signal Handle Switch —

Wiper switch signal Wiper Switch ON or OFF

A/C mid pressure switch signal A/C mid Pressure Switch ON or OFF

AT coordinate retard angle demand Retard Signal form AT ON or OFF

AT coordinate fuel cut demand Fuel Cut Signal from AT ON or OFF

AT coordinate permission signal Torque Permission Signal ON or OFF

UDC not torque down output Ban of Torque Down ON or OFF

UDC torque down demand Request Torque Down UDC ON or OFF

Tumble generated valve output signal TGV Output ON or OFF

Tumble generated valve drive signal TGV Drive OPEN or CLOSERemarks Display Unit of measure

Page 2056 of 2870

![SUBARU FORESTER 2004 Service Repair Manual EN(H4DOTC 2.5)-32

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the � SUBARU FORESTER 2004 Service Repair Manual EN(H4DOTC 2.5)-32

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the �](/img/17/57426/w960_57426-2055.png)

EN(H4DOTC 2.5)-32

ENGINE (DIAGNOSTIC)

Subaru Select Monitor

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Engine} and press the [YES] key.

3) Press the [YES] key after the information of engine type was displayed.

4) On the «Engine Diagnosis» screen, select the {Current Data Display/Save}, and then press the [YES] key.

5) On the «Data Display» screen, select the {Data & LED Display} and press the [YES] key.

6) Using the scroll key, move the display screen up or down until the desired data is shown.

A list of the support data is shown in the following table.

Description Display Message LED “ON” requirements

Ignition switch signal Ignition Switch ON or OFF When ignition switch is ON.

Test Mode Signal Test Mode Signal ON or OFF When test mode connector is connected.

Neutral position switch signal Neutral Position Switch ON or OFF When neutral position signal is entered.

Air conditioning switch signal A/C Switch ON or OFF When air conditioning switch is ON.

Air conditioning relay signal A/C Compressor Signal ON or OFF When air conditioning relay is in function.

Radiator main fan relay signal Radiator Fan Relay #1 ON or OFF When radiator main fan relay is in function.

Knocking signal Knocking Signal ON or OFF When knocking signal is input.

Radiator sub fan relay signal Radiator Fan Relay #2 ON or OFF When radiator sub fan relay is in function.

Rear oxygen sensor rich signalRear O

2 Rich Signal

ON or OFFWhen rear oxygen sensor mixture ratio is

rich.

Starter switch signal Starter Switch Signal ON or OFF When starter switch signal is entered.

Idle switch signal Idle Switch Signal ON or OFF When idle switch signal is entered.

Crankshaft position sensor signal Crankshaft Position Signal ON or OFFWhen crankshaft position sensor signal is

input.

Camshaft position sensor signal Camshaft Position Signal ON or OFFWhen camshaft position sensor signal is

entered.

Power steering switch signal P/S Switch ON or OFF When power steering switch is entered.

Rear defogger switch signal Rear Defogger Switch ON or OFF When rear defogger switch is ON.

Blower fan switch signal Blower Fan Switch ON or OFF When blower fan switch is ON.

Small light switch signal Light Switch ON or OFF When small light switch is ON.

Tumble generated valve actuator

signalTGV Output ON or OFF When TGV actuator signal is entered.

Tumble generated valve drive sig-

nalTGV DriveClose or

OpenWhen TGV moves and valve opens.

Handle switch signal Handle SWLow Input

or High

InputIlluminates in Low Input.

AT/MT identification terminal AT Vehicle ID Signal ON or OFF ON (AT model).

Wiper switch signal Wiper Switch ON or OFF When wiper switch is turned to ON.

A/C mid pressure switch signal A/C Mid Pressure Switch ON or OFFWhen A/C mid pressure switch is turned to

ON.

AT coordinate retard angle

demandRetard Signal from AT ON or OFF When AT retard angle signal is exists.

AT coordinate fuel cut demand Fuel Cut Signal from AT ON or OFFWhen AT coordinate fuel cut demand signal

is exists.

AT coordinate permission signal Torque Permission Signal ON or OFFWhen AT coordinate permission signal is

exists.

VDC not torque down out put Ban of Torque Down ON or OFFWhen VDC not torque down output signal is

exists.

VDC torque down demand Request Torque Down VDC ON or OFFWhen VDC torque down demand signal is

exists.

ETC motor relay signal ETC Motor Relay ON or OFFWhen electronic throttle control relay is in

function.

Clutch switch signal Clutch Switch ON or OFF When clutch switch is ON.

Stop switch signal Stop Light Switch ON or OFF When stop light switch is ON.

Page 2282 of 2870

EN(H4DOTC 2.5)-258

ENGINE (DIAGNOSTIC)

General Diagnostic Table

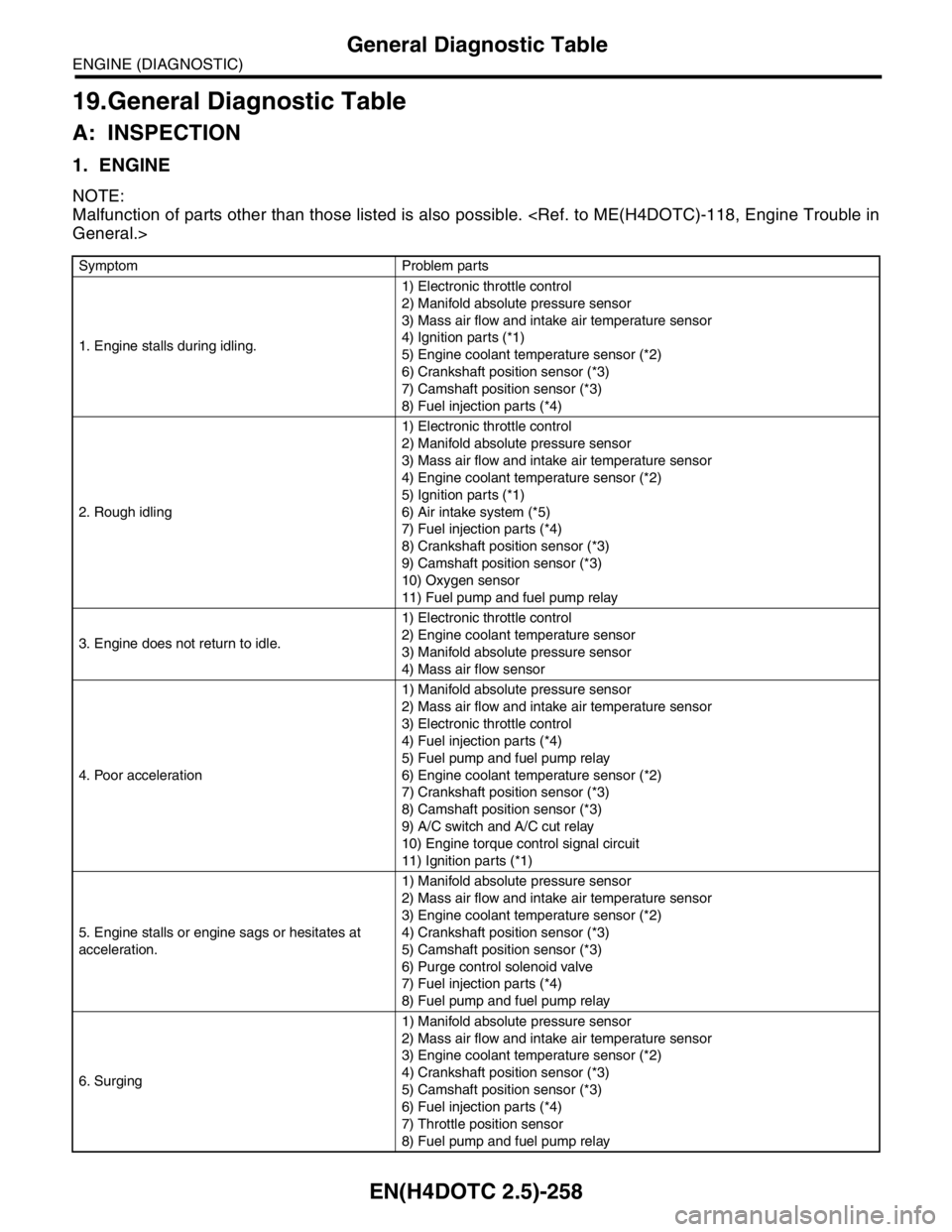

19.General Diagnostic Table

A: INSPECTION

1. ENGINE

NOTE:

Malfunction of parts other than those listed is also possible.

Symptom Problem parts

1. Engine stalls during idling.1) Electronic throttle control

2) Manifold absolute pressure sensor

3) Mass air flow and intake air temperature sensor

4) Ignition parts (*1)

5) Engine coolant temperature sensor (*2)

6) Crankshaft position sensor (*3)

7) Camshaft position sensor (*3)

8) Fuel injection parts (*4)

2. Rough idling1) Electronic throttle control

2) Manifold absolute pressure sensor

3) Mass air flow and intake air temperature sensor

4) Engine coolant temperature sensor (*2)

5) Ignition parts (*1)

6) Air intake system (*5)

7) Fuel injection parts (*4)

8) Crankshaft position sensor (*3)

9) Camshaft position sensor (*3)

10) Oxygen sensor

11) Fuel pump and fuel pump relay

3. Engine does not return to idle.1) Electronic throttle control

2) Engine coolant temperature sensor

3) Manifold absolute pressure sensor

4) Mass air flow sensor

4. Poor acceleration1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Electronic throttle control

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay

6) Engine coolant temperature sensor (*2)

7) Crankshaft position sensor (*3)

8) Camshaft position sensor (*3)

9) A/C switch and A/C cut relay

10) Engine torque control signal circuit

11) Ignition parts (*1)

5. Engine stalls or engine sags or hesitates at

acceleration.1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Purge control solenoid valve

7) Fuel injection parts (*4)

8) Fuel pump and fuel pump relay

6. Surging1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Fuel injection parts (*4)

7) Throttle position sensor

8) Fuel pump and fuel pump relay

Page 2287 of 2870

CS-2

CONTROL SYSTEM

General Description

1. General Description

A: SPECIFICATION

Item Specification

Swing torque of rod against lever N (kgf, Ib) 3.7 (0.38, 0.83) or less

Page 2288 of 2870

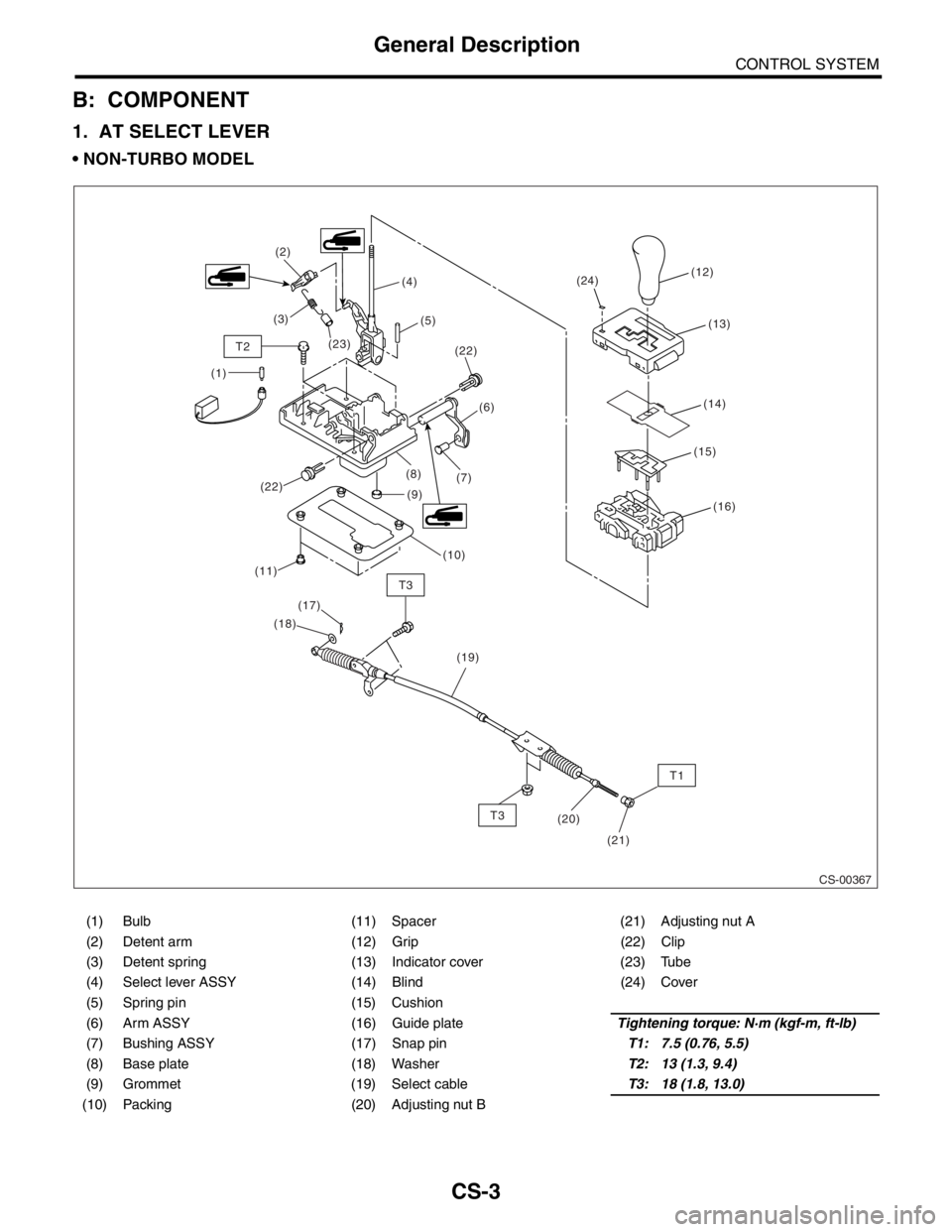

CS-3

CONTROL SYSTEM

General Description

B: COMPONENT

1. AT SELECT LEVER

NON-TURBO MODEL

CS-00367

T3

T2

T3

T1

(10) (22)

(9) (8)

(7)(6) (5) (4) (2)

(3)

(1)(22)(12)

(13)

(15)

(16)

(21) (20) (19) (17)

(14)

(11)

(18)

(23)

(24)

(1) Bulb (11) Spacer (21) Adjusting nut A

(2) Detent arm (12) Grip (22) Clip

(3) Detent spring (13) Indicator cover (23) Tube

(4) Select lever ASSY (14) Blind (24) Cover

(5) Spring pin (15) Cushion

(6) Arm ASSY (16) Guide plateTightening torque: N·m (kgf-m, ft-lb)

(7) Bushing ASSY (17) Snap pinT1: 7.5 (0.76, 5.5)

(8) Base plate (18) WasherT2: 13 (1.3, 9.4)

(9) Grommet (19) Select cableT3: 18 (1.8, 13.0)

(10) Packing (20) Adjusting nut B