torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2399 of 2870

4AT-86

AUTOMATIC TRANSMISSION

ATF Cooler (With Warmer Function)

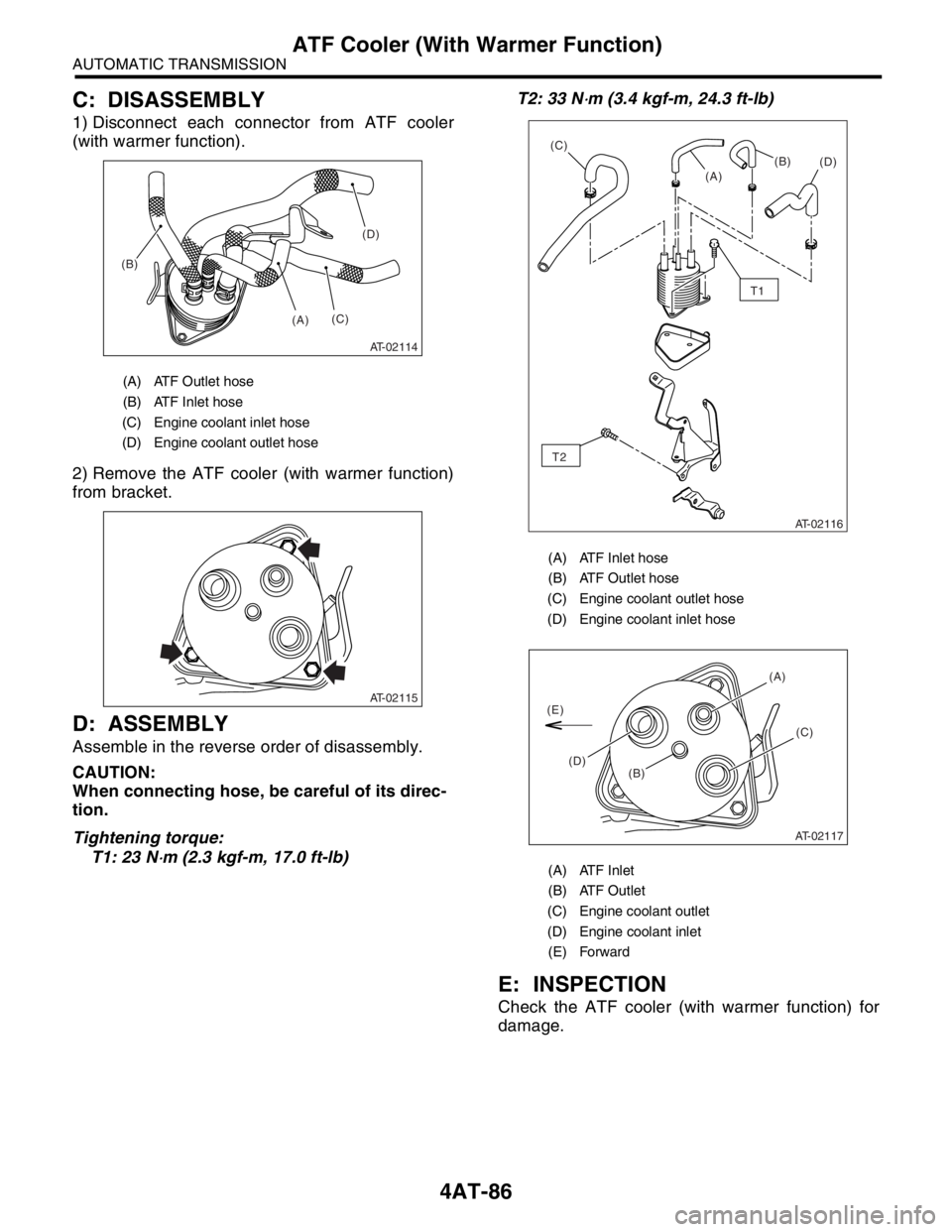

C: DISASSEMBLY

1) Disconnect each connector from ATF cooler

(with warmer function).

2) Remove the ATF cooler (with warmer function)

from bracket.

D: ASSEMBLY

Assemble in the reverse order of disassembly.

CAUTION:

When connecting hose, be careful of its direc-

tion.

Tightening torque:

T1: 23 N

⋅m (2.3 kgf-m, 17.0 ft-lb)T2: 33 N

⋅m (3.4 kgf-m, 24.3 ft-lb)

E: INSPECTION

Check the ATF cooler (with warmer function) for

damage.

(A) ATF Outlet hose

(B) ATF Inlet hose

(C) Engine coolant inlet hose

(D) Engine coolant outlet hose

AT-02114

(A) (B)(C)

(D)

AT-02115

(A) ATF Inlet hose

(B) ATF Outlet hose

(C) Engine coolant outlet hose

(D) Engine coolant inlet hose

(A) ATF Inlet

(B) ATF Outlet

(C) Engine coolant outlet

(D) Engine coolant inlet

(E) Forward

AT-02116

T1

T2

(B)

(D) (C)

(A)

AT-02117

(D)(B)(A)

(C)

(E)

Page 2401 of 2870

4AT-88

AUTOMATIC TRANSMISSION

Oil Charger Pipe

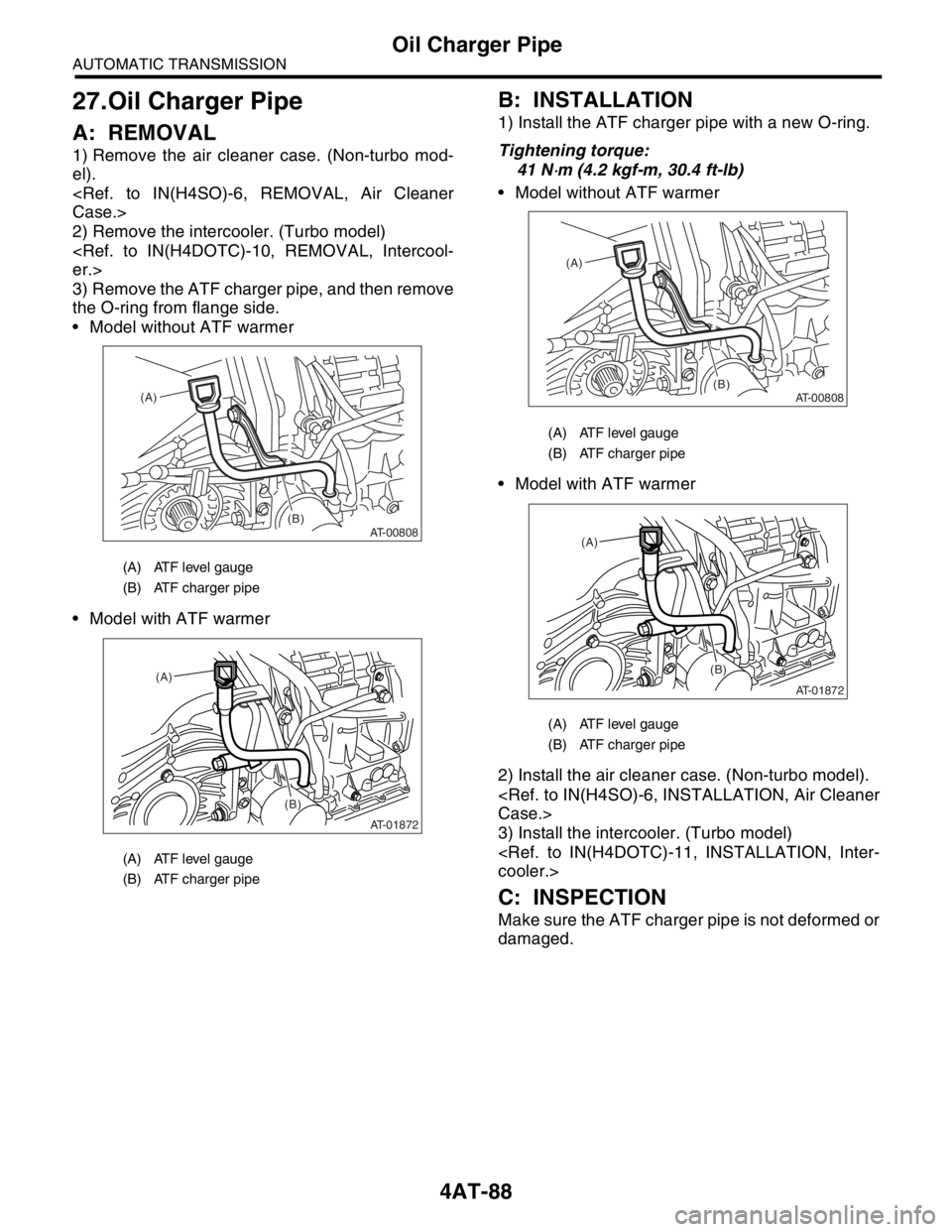

27.Oil Charger Pipe

A: REMOVAL

1) Remove the air cleaner case. (Non-turbo mod-

el).

2) Remove the intercooler. (Turbo model)

3) Remove the ATF charger pipe, and then remove

the O-ring from flange side.

Model without ATF warmer

Model with ATF warmer

B: INSTALLATION

1) Install the ATF charger pipe with a new O-ring.

Tightening torque:

41 N

⋅m (4.2 kgf-m, 30.4 ft-lb)

Model without ATF warmer

Model with ATF warmer

2) Install the air cleaner case. (Non-turbo model).

3) Install the intercooler. (Turbo model)

C: INSPECTION

Make sure the ATF charger pipe is not deformed or

damaged.

(A) ATF level gauge

(B) ATF charger pipe

(A) ATF level gauge

(B) ATF charger pipe

AT-00808

(A)

(B)

AT-01872

(B)

(A)

(A) ATF level gauge

(B) ATF charger pipe

(A) ATF level gauge

(B) ATF charger pipe

AT-00808

(A)

(B)

AT-01872

(B)

(A)

Page 2402 of 2870

4AT-89

AUTOMATIC TRANSMISSION

Torque Converter Clutch Assembly

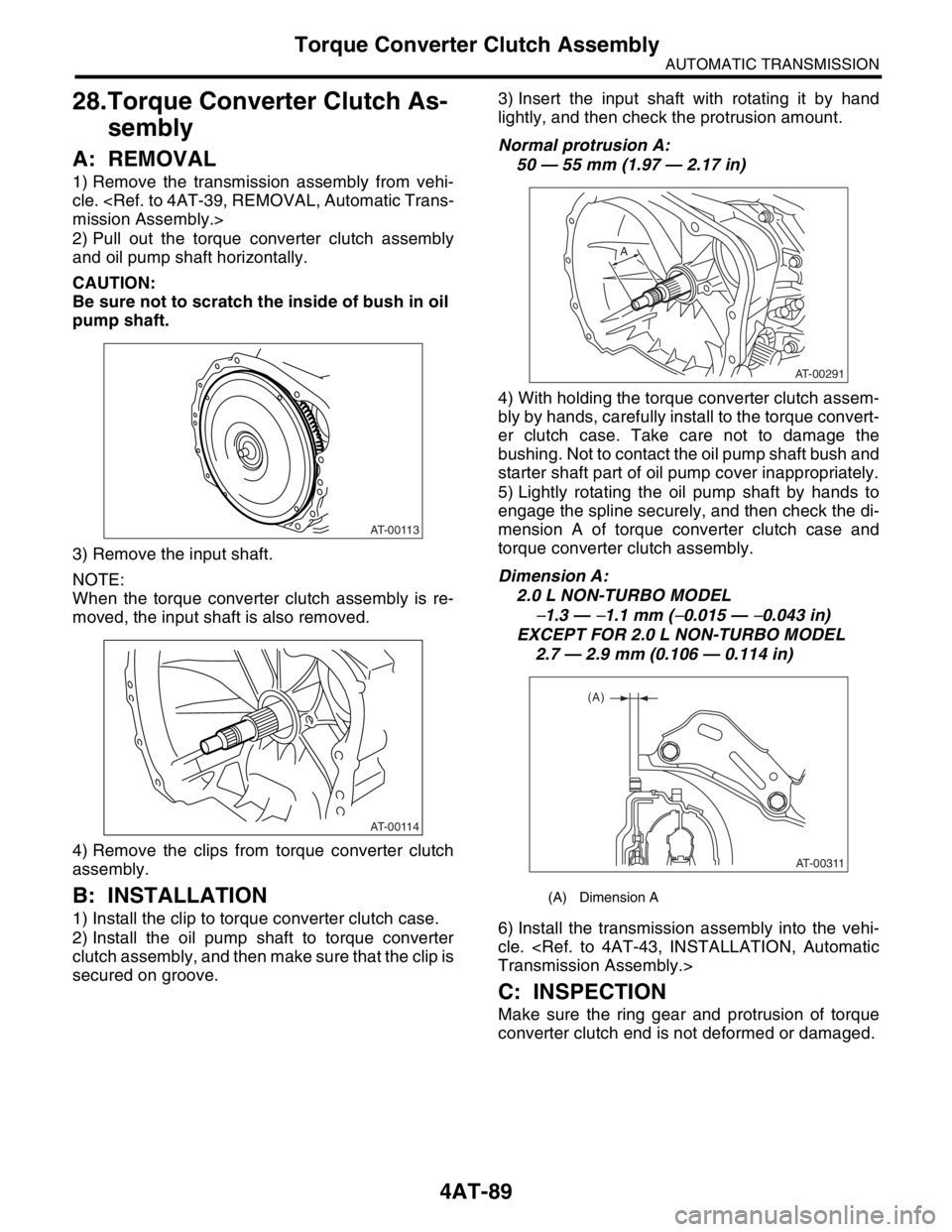

28.Torque Converter Clutch As-

sembly

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle.

2) Pull out the torque converter clutch assembly

and oil pump shaft horizontally.

CAUTION:

Be sure not to scratch the inside of bush in oil

pump shaft.

3) Remove the input shaft.

NOTE:

When the torque converter clutch assembly is re-

moved, the input shaft is also removed.

4) Remove the clips from torque converter clutch

assembly.

B: INSTALLATION

1) Install the clip to torque converter clutch case.

2) Install the oil pump shaft to torque converter

clutch assembly, and then make sure that the clip is

secured on groove.3) Insert the input shaft with rotating it by hand

lightly, and then check the protrusion amount.

Normal protrusion A:

50 — 55 mm (1.97 — 2.17 in)

4) With holding the torque converter clutch assem-

bly by hands, carefully install to the torque convert-

er clutch case. Take care not to damage the

bushing. Not to contact the oil pump shaft bush and

starter shaft part of oil pump cover inappropriately.

5) Lightly rotating the oil pump shaft by hands to

engage the spline securely, and then check the di-

mension A of torque converter clutch case and

torque converter clutch assembly.

Dimension A:

2.0 L NON-TURBO MODEL

−1.3 — −1.1 mm (−0.015 — −0.043 in)

EXCEPT FOR 2.0 L NON-TURBO MODEL

2.7 — 2.9 mm (0.106 — 0.114 in)

6) Install the transmission assembly into the vehi-

cle.

C: INSPECTION

Make sure the ring gear and protrusion of torque

converter clutch end is not deformed or damaged.

AT-00113

AT-00114

(A) Dimension A

AT-00291

A

AT-00311

(A)

Page 2403 of 2870

4AT-90

AUTOMATIC TRANSMISSION

Extension Case

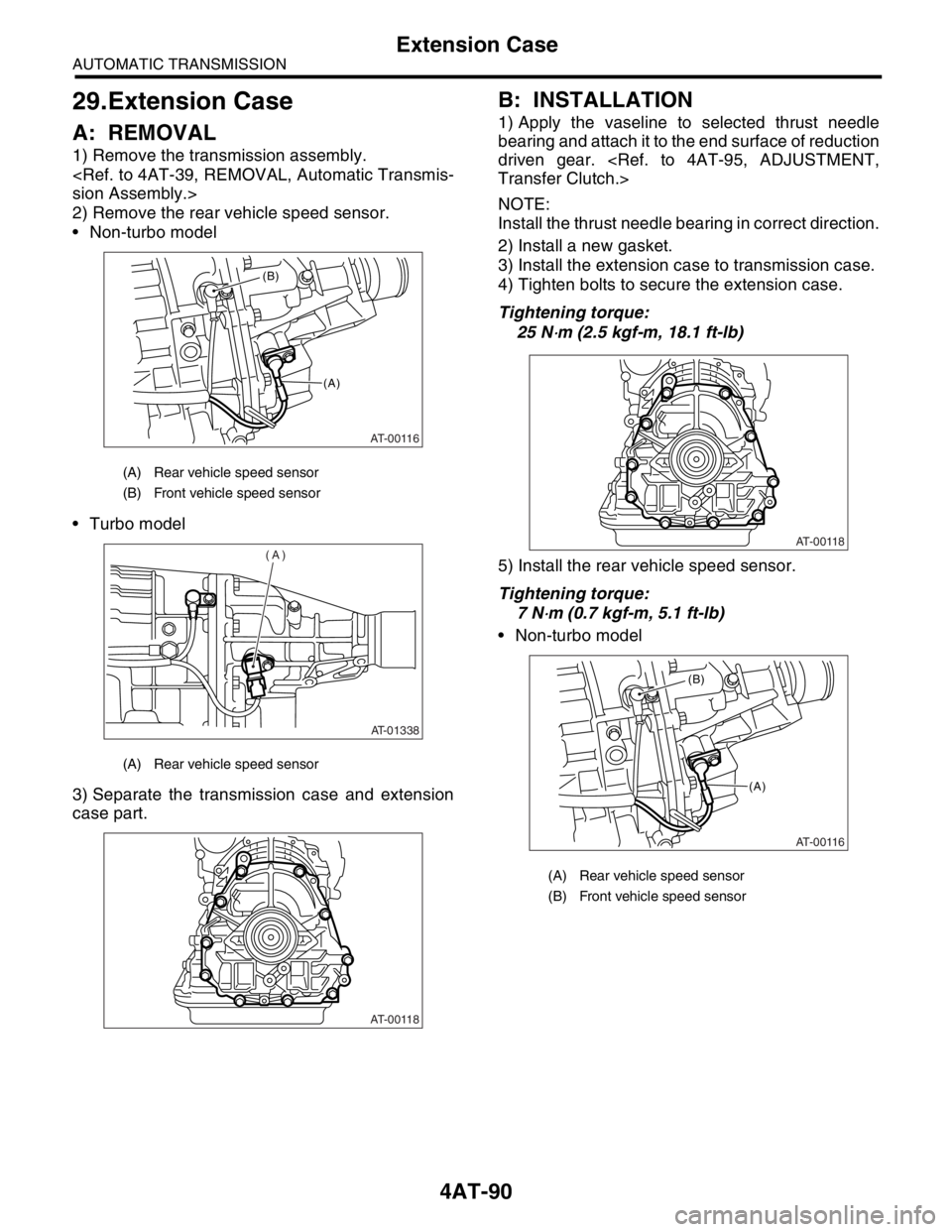

29.Extension Case

A: REMOVAL

1) Remove the transmission assembly.

2) Remove the rear vehicle speed sensor.

Non-turbo model

Turbo model

3) Separate the transmission case and extension

case part.

B: INSTALLATION

1) Apply the vaseline to selected thrust needle

bearing and attach it to the end surface of reduction

driven gear.

NOTE:

Install the thrust needle bearing in correct direction.

2) Install a new gasket.

3) Install the extension case to transmission case.

4) Tighten bolts to secure the extension case.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

5) Install the rear vehicle speed sensor.

Tightening torque:

7 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

Non-turbo model

(A) Rear vehicle speed sensor

(B) Front vehicle speed sensor

(A) Rear vehicle speed sensor

AT-00116

(B)

(A)

AT-01338

(A)

AT-00118

(A) Rear vehicle speed sensor

(B) Front vehicle speed sensor

AT-00118

AT-00116

(B)

(A)

Page 2405 of 2870

4AT-92

AUTOMATIC TRANSMISSION

Transfer Clutch

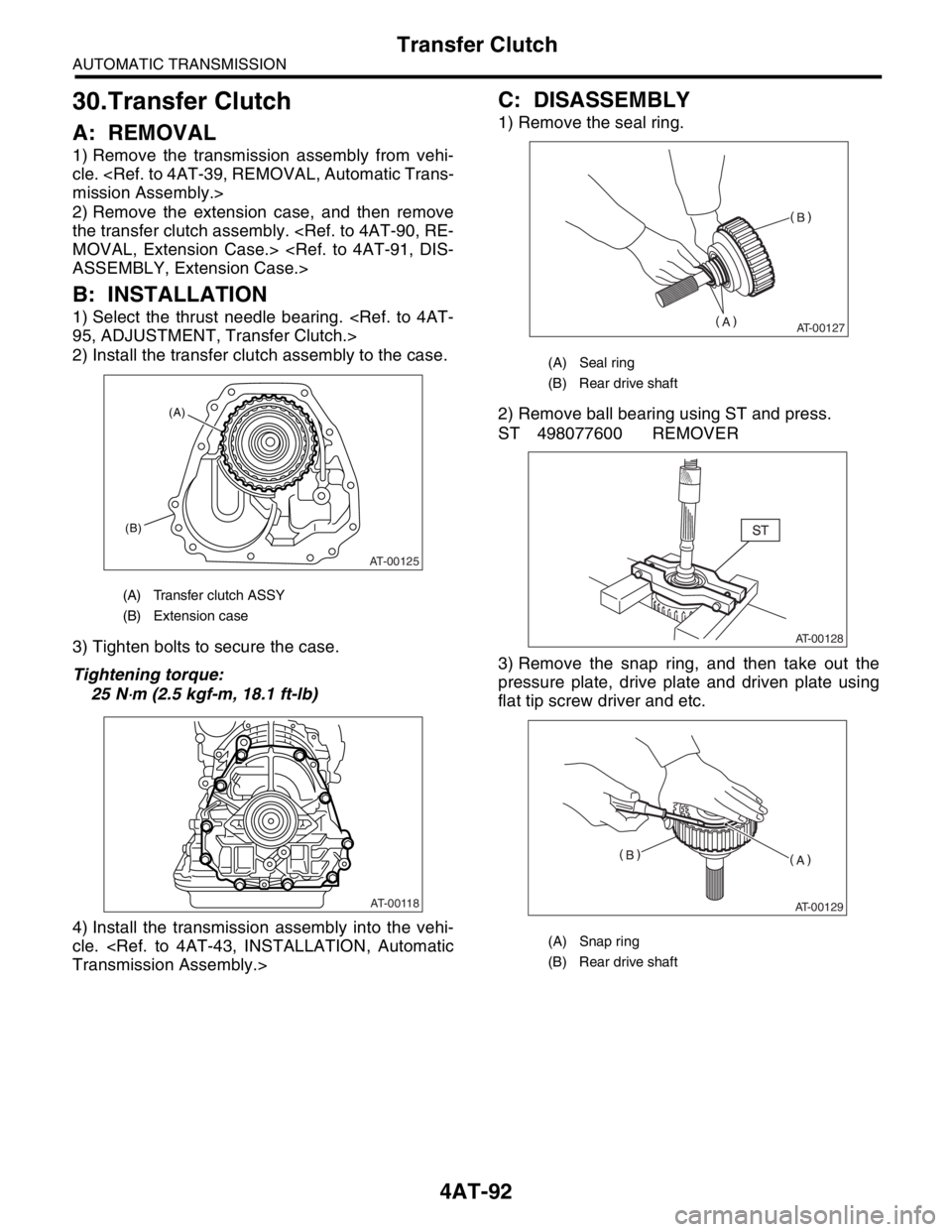

30.Transfer Clutch

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle.

2) Remove the extension case, and then remove

the transfer clutch assembly.

B: INSTALLATION

1) Select the thrust needle bearing.

2) Install the transfer clutch assembly to the case.

3) Tighten bolts to secure the case.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

4) Install the transmission assembly into the vehi-

cle.

C: DISASSEMBLY

1) Remove the seal ring.

2) Remove ball bearing using ST and press.

ST 498077600 REMOVER

3) Remove the snap ring, and then take out the

pressure plate, drive plate and driven plate using

flat tip screw driver and etc.

(A) Transfer clutch ASSY

(B) Extension case

AT-00125

(A)

(B)

AT-00118

(A) Seal ring

(B) Rear drive shaft

(A) Snap ring

(B) Rear drive shaft

AT-00127

AT-00128

AT-00129

Page 2411 of 2870

4AT-97

AUTOMATIC TRANSMISSION

Reduction Driven Gear

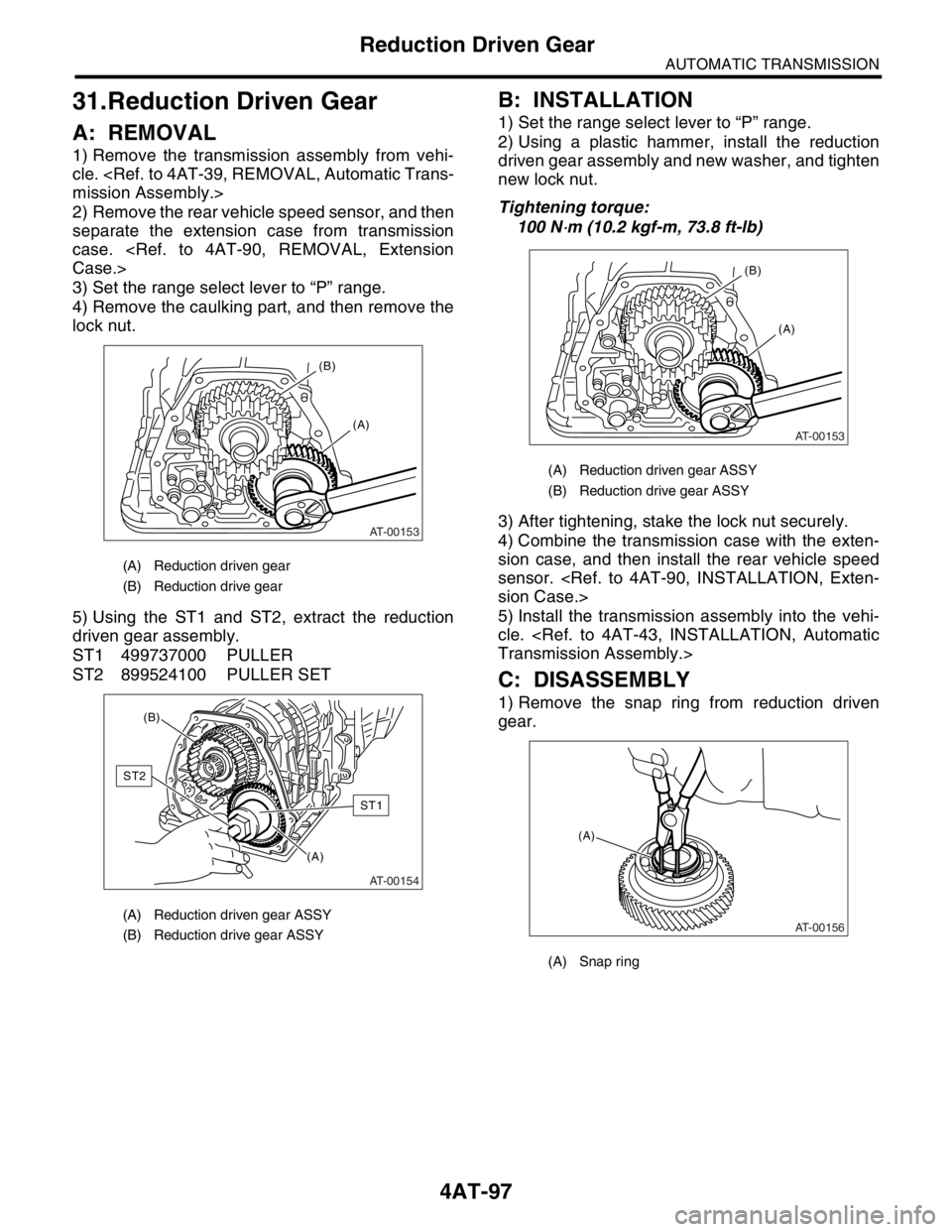

31.Reduction Driven Gear

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle.

2) Remove the rear vehicle speed sensor, and then

separate the extension case from transmission

case.

3) Set the range select lever to “P” range.

4) Remove the caulking part, and then remove the

lock nut.

5) Using the ST1 and ST2, extract the reduction

driven gear assembly.

ST1 499737000 PULLER

ST2 899524100 PULLER SET

B: INSTALLATION

1) Set the range select lever to “P” range.

2) Using a plastic hammer, install the reduction

driven gear assembly and new washer, and tighten

new lock nut.

Tightening torque:

100 N

⋅m (10.2 kgf-m, 73.8 ft-lb)

3) After tightening, stake the lock nut securely.

4) Combine the transmission case with the exten-

sion case, and then install the rear vehicle speed

sensor.

5) Install the transmission assembly into the vehi-

cle.

C: DISASSEMBLY

1) Remove the snap ring from reduction driven

gear.

(A) Reduction driven gear

(B) Reduction drive gear

(A) Reduction driven gear ASSY

(B) Reduction drive gear ASSY

AT-00153

(A) (B)

AT-00154

(A) (B)

ST1

ST2

(A) Reduction driven gear ASSY

(B) Reduction drive gear ASSY

(A) Snap ring

AT-00153

(A) (B)

AT-00156

(A)

Page 2416 of 2870

4AT-102

AUTOMATIC TRANSMISSION

Torque Converter Clutch Case

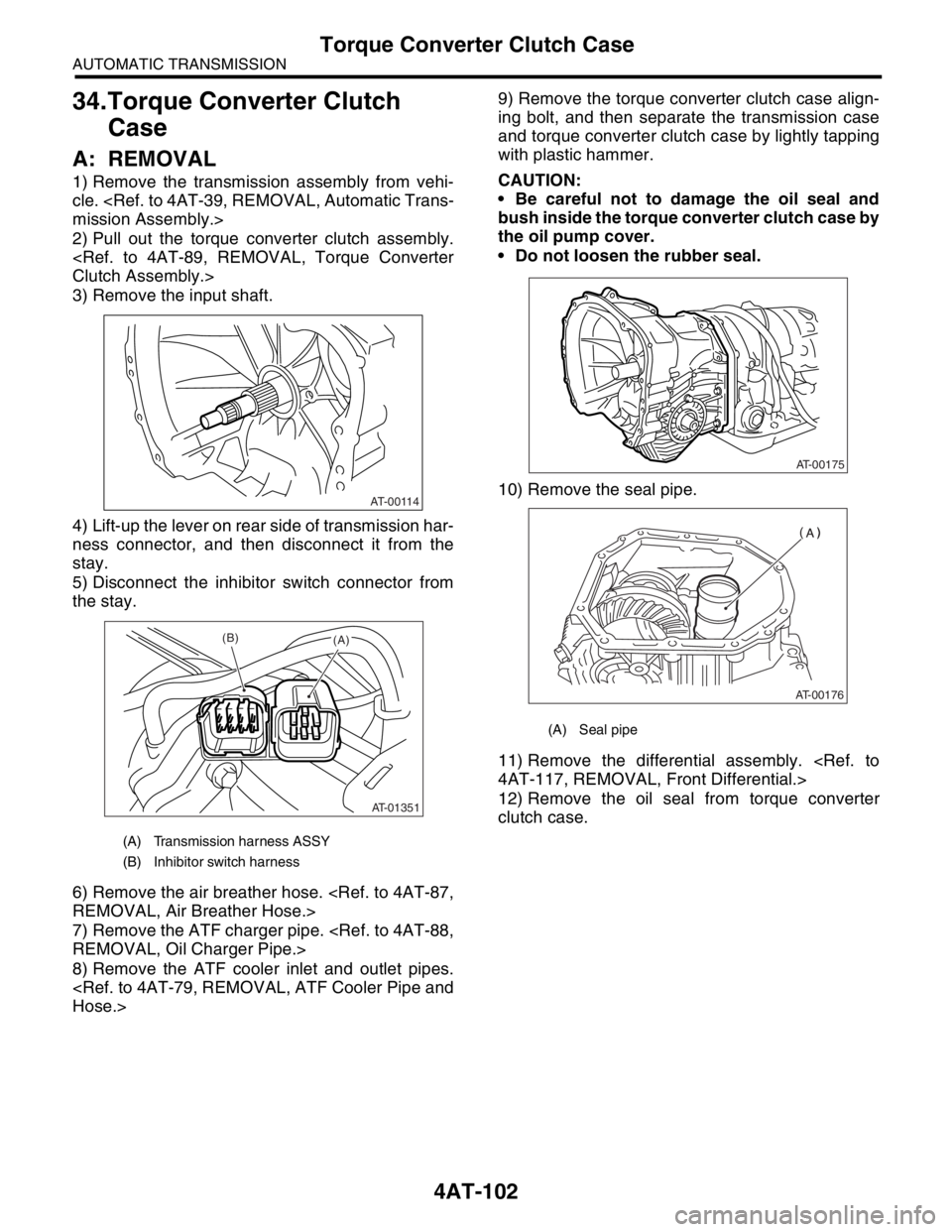

34.Torque Converter Clutch

Case

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle.

2) Pull out the torque converter clutch assembly.

3) Remove the input shaft.

4) Lift-up the lever on rear side of transmission har-

ness connector, and then disconnect it from the

stay.

5) Disconnect the inhibitor switch connector from

the stay.

6) Remove the air breather hose.

7) Remove the ATF charger pipe.

8) Remove the ATF cooler inlet and outlet pipes.

ing bolt, and then separate the transmission case

and torque converter clutch case by lightly tapping

with plastic hammer.

CAUTION:

Be careful not to damage the oil seal and

bush inside the torque converter clutch case by

the oil pump cover.

Do not loosen the rubber seal.

10) Remove the seal pipe.

11) Remove the differential assembly.

12) Remove the oil seal from torque converter

clutch case.

(A) Transmission harness ASSY

(B) Inhibitor switch harness

AT-00114

AT-01351

(B)(A)

(A) Seal pipe

AT-00175

AT-00176

Page 2417 of 2870

4AT-103

AUTOMATIC TRANSMISSION

Torque Converter Clutch Case

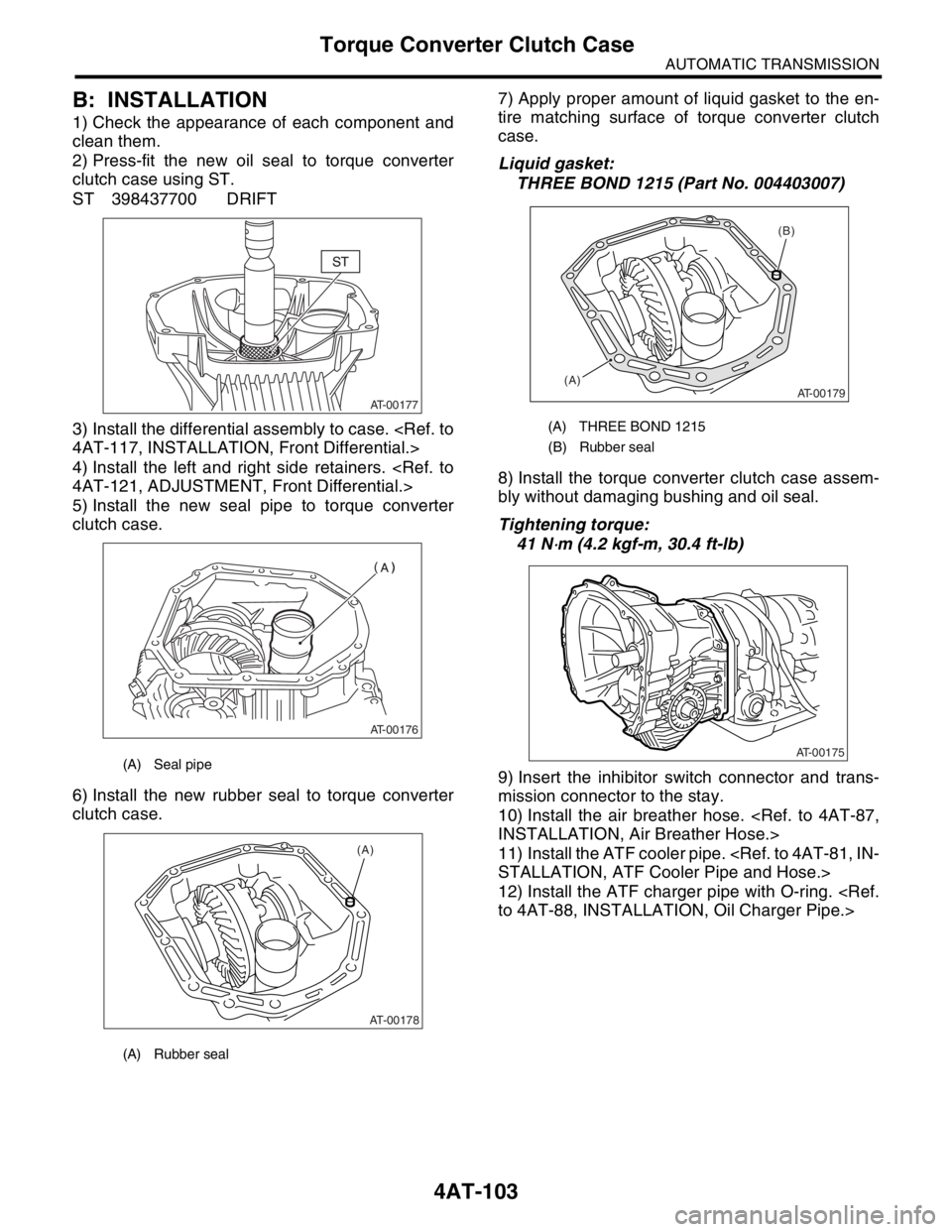

B: INSTALLATION

1) Check the appearance of each component and

clean them.

2) Press-fit the new oil seal to torque converter

clutch case using ST.

ST 398437700 DRIFT

3) Install the differential assembly to case.

4) Install the left and right side retainers.

5) Install the new seal pipe to torque converter

clutch case.

6) Install the new rubber seal to torque converter

clutch case.7) Apply proper amount of liquid gasket to the en-

tire matching surface of torque converter clutch

case.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007)

8) Install the torque converter clutch case assem-

bly without damaging bushing and oil seal.

Tightening torque:

41 N

⋅m (4.2 kgf-m, 30.4 ft-lb)

9) Insert the inhibitor switch connector and trans-

mission connector to the stay.

10) Install the air breather hose.

11) Install the ATF cooler pipe.

12) Install the ATF charger pipe with O-ring.

(A) Seal pipe

(A) Rubber seal

AT-00177

AT-00176

AT-00178

(A)

(A) THREE BOND 1215

(B) Rubber seal

(B)

(A)

AT-00179

AT-00175

Page 2418 of 2870

4AT-104

AUTOMATIC TRANSMISSION

Torque Converter Clutch Case

13) Insert the input shaft with rotating it by hand

lightly, and then check the protrusion amount.

Normal protrusion A:

50 — 55 mm (1.97 — 2.17 in)

14) Install the torque converter clutch assembly.

15) Install the transmission assembly into the vehi-

cle.

C: INSPECTION

Measure the backlash, and then adjust it within

specification.

AT-00291

A

Page 2419 of 2870

4AT-105

AUTOMATIC TRANSMISSION

Oil Pump Housing

35.Oil Pump Housing

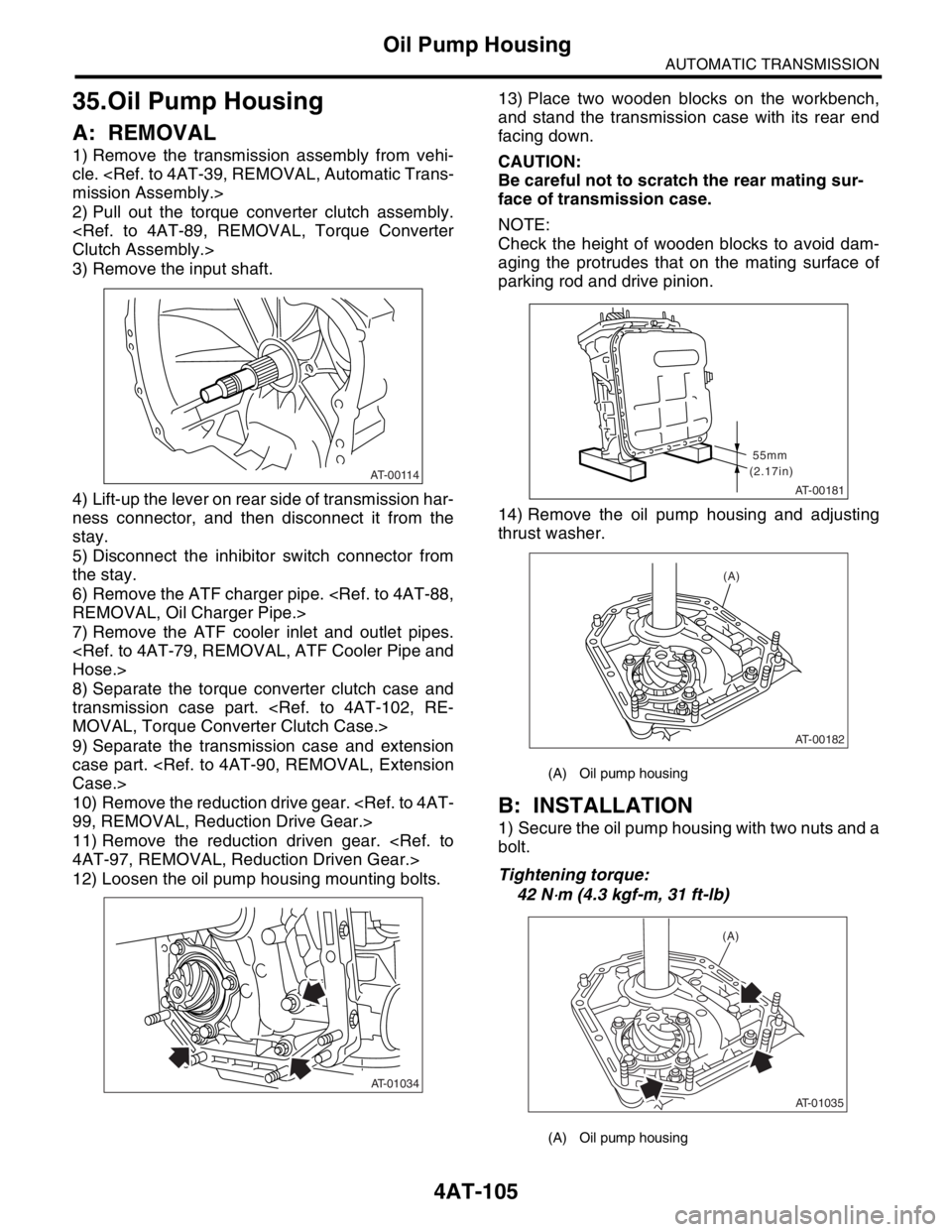

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle.

2) Pull out the torque converter clutch assembly.

3) Remove the input shaft.

4) Lift-up the lever on rear side of transmission har-

ness connector, and then disconnect it from the

stay.

5) Disconnect the inhibitor switch connector from

the stay.

6) Remove the ATF charger pipe.

7) Remove the ATF cooler inlet and outlet pipes.

8) Separate the torque converter clutch case and

transmission case part.

9) Separate the transmission case and extension

case part.

10) Remove the reduction drive gear.

11) Remove the reduction driven gear.

12) Loosen the oil pump housing mounting bolts.13) Place two wooden blocks on the workbench,

and stand the transmission case with its rear end

facing down.

CAUTION:

Be careful not to scratch the rear mating sur-

face of transmission case.

NOTE:

Check the height of wooden blocks to avoid dam-

aging the protrudes that on the mating surface of

parking rod and drive pinion.

14) Remove the oil pump housing and adjusting

thrust washer.

B: INSTALLATION

1) Secure the oil pump housing with two nuts and a

bolt.

Tightening torque:

42 N

⋅m (4.3 kgf-m, 31 ft-lb)

AT-00114

AT-01034

(A) Oil pump housing

(A) Oil pump housing

AT-00181

(2.17in)55mm

AT-00182

(A)

AT-01035

(A)