torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2475 of 2870

4AT(H4SO)-16

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

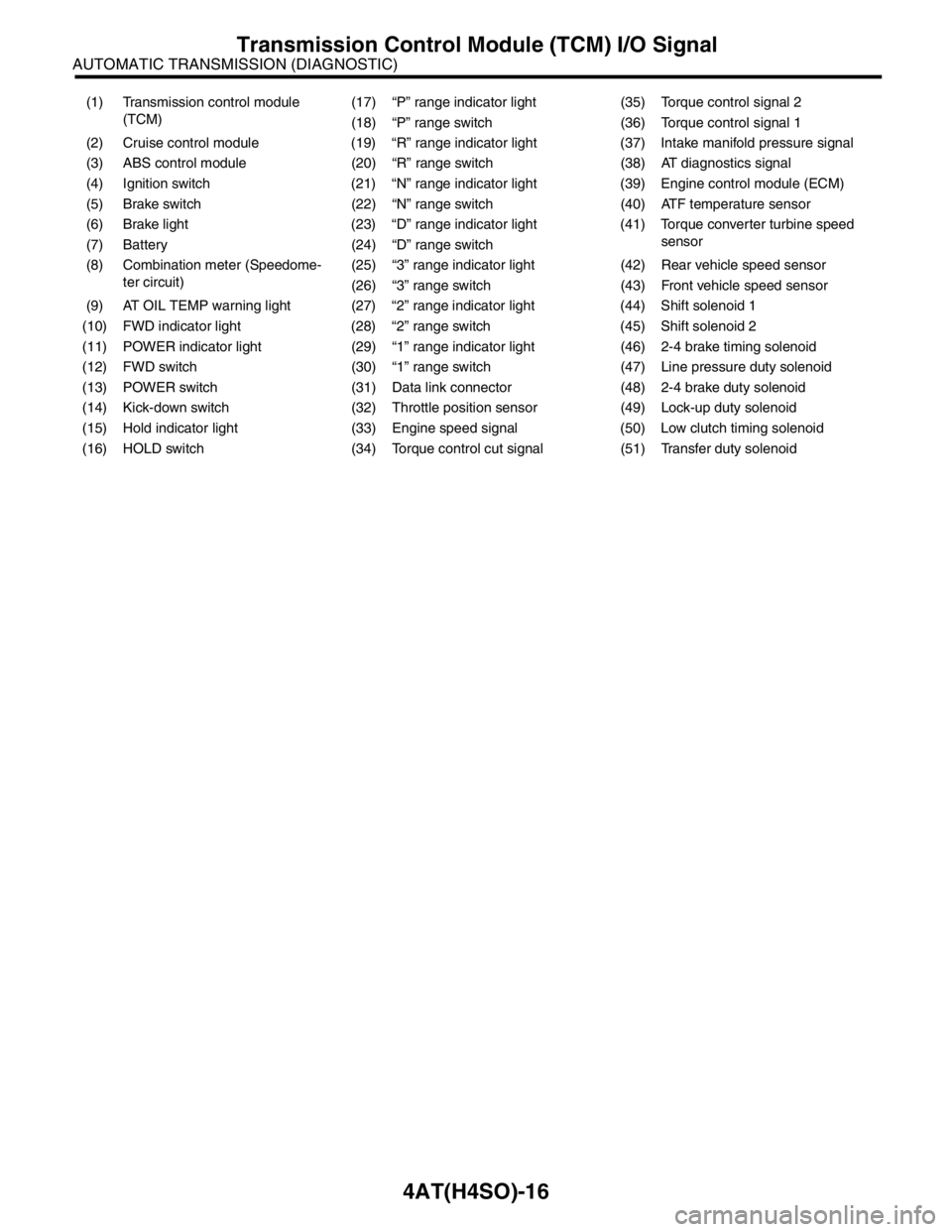

Transmission Control Module (TCM) I/O Signal

(1) Transmission control module

(TCM)(17) “P” range indicator light (35) Torque control signal 2

(18) “P” range switch (36) Torque control signal 1

(2) Cruise control module (19) “R” range indicator light (37) Intake manifold pressure signal

(3) ABS control module (20) “R” range switch (38) AT diagnostics signal

(4) Ignition switch (21) “N” range indicator light (39) Engine control module (ECM)

(5) Brake switch (22) “N” range switch (40) ATF temperature sensor

(6) Brake light (23) “D” range indicator light (41) Torque converter turbine speed

sensor

(7) Battery (24) “D” range switch

(8) Combination meter (Speedome-

ter circuit)(25) “3” range indicator light (42) Rear vehicle speed sensor

(26) “3” range switch (43) Front vehicle speed sensor

(9) AT OIL TEMP warning light (27) “2” range indicator light (44) Shift solenoid 1

(10) FWD indicator light (28) “2” range switch (45) Shift solenoid 2

(11) POWER indicator light (29) “1” range indicator light (46) 2-4 brake timing solenoid

(12) FWD switch (30) “1” range switch (47) Line pressure duty solenoid

(13) POWER switch (31) Data link connector (48) 2-4 brake duty solenoid

(14) Kick-down switch (32) Throttle position sensor (49) Lock-up duty solenoid

(15) Hold indicator light (33) Engine speed signal (50) Low clutch timing solenoid

(16) HOLD switch (34) Torque control cut signal (51) Transfer duty solenoid

Page 2477 of 2870

![SUBARU FORESTER 2004 Service Repair Manual 4AT(H4SO)-18

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Subaru Select Monitor

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the « SUBARU FORESTER 2004 Service Repair Manual 4AT(H4SO)-18

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Subaru Select Monitor

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «](/img/17/57426/w960_57426-2476.png)

4AT(H4SO)-18

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Subaru Select Monitor

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Transmission Control System} and press the

[YES] key.

3) Press the [YES] key after the information of transmission type is displayed.

4) On the «Transmission Diagnosis» display screen, select the {Current Data Display & Save} and press the

[YES] key.

5) On the «Data Display Menu» display screen, select the {Data Display} and press the [YES] key.

6) Using the scroll key, move the display screen up or down until desired data is shown.

A list of the support data is shown in the following table.

NOTE:

For detailed operation procedure, refer to the SUBARU SELECT MONITOR OPERATION MANUAL.

Contents Display Unit of measure

Battery voltage Battery Voltage V

Rear vehicle speed sensor signal Rear Wheel Speed km/h or MPH

Front vehicle speed sensor signal Front Wheel Speed km/h or MPH

Engine speed signal Engine Speed rpm

Automatic transmission fluid temperature signal ATF Temp.°C or °F

Throttle position signal Throttle Sensor Voltage V

Gear position Gear Position —

Line pressure control duty ratio Line Pressure Duty Ratio %

Lock up clutch control duty ratio Lock Up Duty Ratio %

Transfer clutch control duty ratio (AWD model) Transfer Duty Ratio %

Power supply for throttle position sensor Throttle Sensor Power V

Torque converter turbine speed signal Turbine Revolution Speed rpm

2-4 brake timing pressure control duty ratio Brake Clutch Duty Ratio %

Intake manifold pressure sensor voltage Mani. Pressure Voltage V

FWD switch signal FWD Switch ON or OFF

Stop light switch signal Stop Light Switch ON or OFF

Anti lock brake system signal ABS Signal ON or OFF

Cruise control system signal Cruise Control Signal ON or OFF

Parking range signal P Range Signal ON or OFF

Neutral range signal N Range Signal ON or OFF

Reverse range signal R Range Signal ON or OFF

Drive range signal D Range Signal ON or OFF

3rd range signal 3rd Range Signal ON or OFF

2nd range signal 2nd Range Signal ON or OFF

1st range signal 1st Range Signal ON or OFF

Shift control solenoid A Shift Solenoid #1 ON or OFF

Shift control solenoid B Shift Solenoid #2 ON or OFF

Torque control output signal #1 Torque Control Signal 1 ON or OFF

Torque control output signal #2 Torque Control Signal 2 ON or OFF

Torque control cut signal Torque Control Cut Sig. ON or OFF

2-4 brake timing control solenoid valve 2-4 Brake Timing Sol. ON or OFF

Low clutch timing control solenoid valve Low Clutch Timing Sol. ON or OFF

Automatic transmission diagnosis indicator lamp Diagnosis Lamp ON or OFF

Power mode switch signal Power Mode Switch ON or OFF

Hold mode switch signal Hold Mode Switch ON or OFF

Kick down switch signal Kick Down Switch ON or OFF

Automatic transmission fluid temperature lamp ATF Temperature Lamp ON or OFF

Page 2494 of 2870

4AT(H4SO)-35

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

List of Diagnostic Trouble Code (DTC)

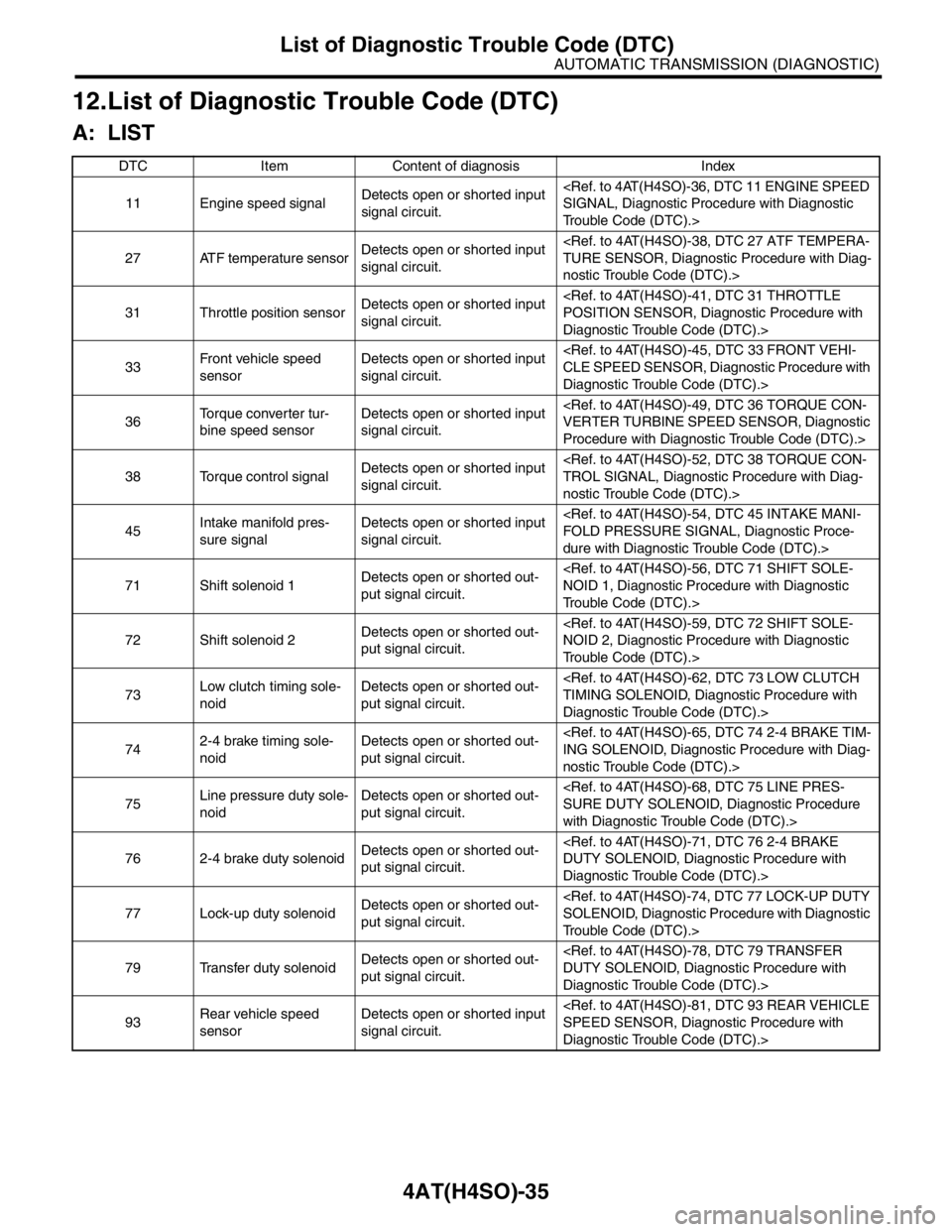

12.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Item Content of diagnosis Index

11 Engine speed signalDetects open or shorted input

signal circuit.

Trouble Code (DTC).>

27 ATF temperature sensorDetects open or shorted input

signal circuit.

nostic Trouble Code (DTC).>

31 Throttle position sensorDetects open or shorted input

signal circuit.

Diagnostic Trouble Code (DTC).>

33Front vehicle speed

sensorDetects open or shorted input

signal circuit.

Diagnostic Trouble Code (DTC).>

36Torque converter tur-

bine speed sensorDetects open or shorted input

signal circuit.

Procedure with Diagnostic Trouble Code (DTC).>

38 Torque control signalDetects open or shorted input

signal circuit.

nostic Trouble Code (DTC).>

45Intake manifold pres-

sure signalDetects open or shorted input

signal circuit.

dure with Diagnostic Trouble Code (DTC).>

71 Shift solenoid 1Detects open or shorted out-

put signal circuit.

Trouble Code (DTC).>

72 Shift solenoid 2Detects open or shorted out-

put signal circuit.

Trouble Code (DTC).>

73Low clutch timing sole-

noidDetects open or shorted out-

put signal circuit.

Diagnostic Trouble Code (DTC).>

742-4 brake timing sole-

noidDetects open or shorted out-

put signal circuit.

nostic Trouble Code (DTC).>

75Line pressure duty sole-

noidDetects open or shorted out-

put signal circuit.

with Diagnostic Trouble Code (DTC).>

76 2-4 brake duty solenoidDetects open or shorted out-

put signal circuit.

Diagnostic Trouble Code (DTC).>

77 Lock-up duty solenoidDetects open or shorted out-

put signal circuit.

Trouble Code (DTC).>

79 Transfer duty solenoidDetects open or shorted out-

put signal circuit.

Diagnostic Trouble Code (DTC).>

93Rear vehicle speed

sensorDetects open or shorted input

signal circuit.

Diagnostic Trouble Code (DTC).>

Page 2508 of 2870

4AT(H4SO)-49

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

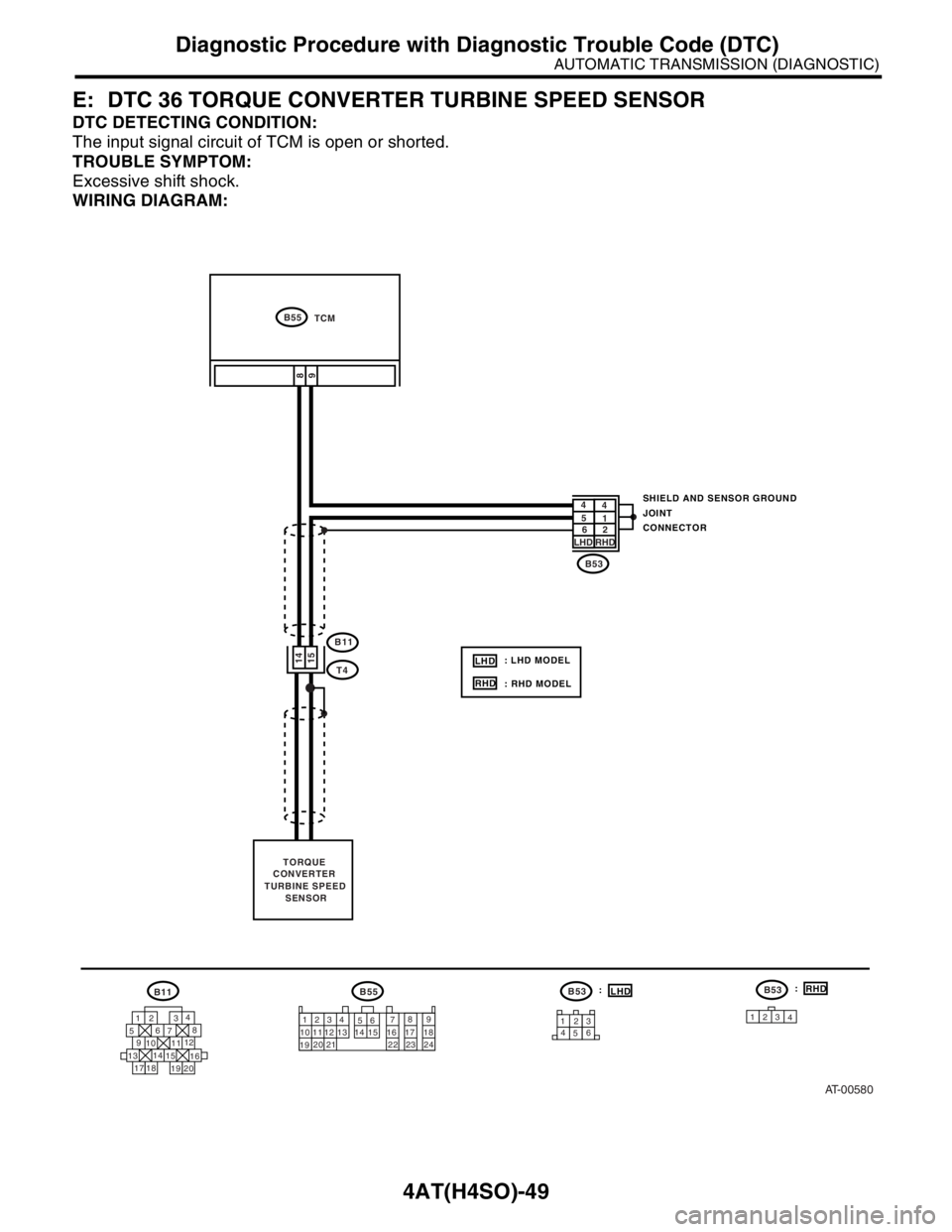

E: DTC 36 TORQUE CONVERTER TURBINE SPEED SENSOR

DTC DETECTING CONDITION:

The input signal circuit of TCM is open or shorted.

TROUBLE SYMPTOM:

Excessive shift shock.

WIRING DIAGRAM:

AT-00580

14

15

B11

B534

T4

TCMB55

8

9

1

2

RHD

SENSOR

LHD

RHD: LHD MODEL

: RHD MODEL

TORQUE

CONVERTER

TURBINE SPEED

B55

1234

56789

10 1112

13 14 15 16 17 18

192021

2223 24

B11

1

234

56

78

9

1314

15

20 19 1716 10 1112

18

B53

LHD4

5

6SHIELD AND SENSOR GROUND

JOINT

CONNECTOR

LHD :B53

123

4

:RHD

651

234

Page 2509 of 2870

4AT(H4SO)-50

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

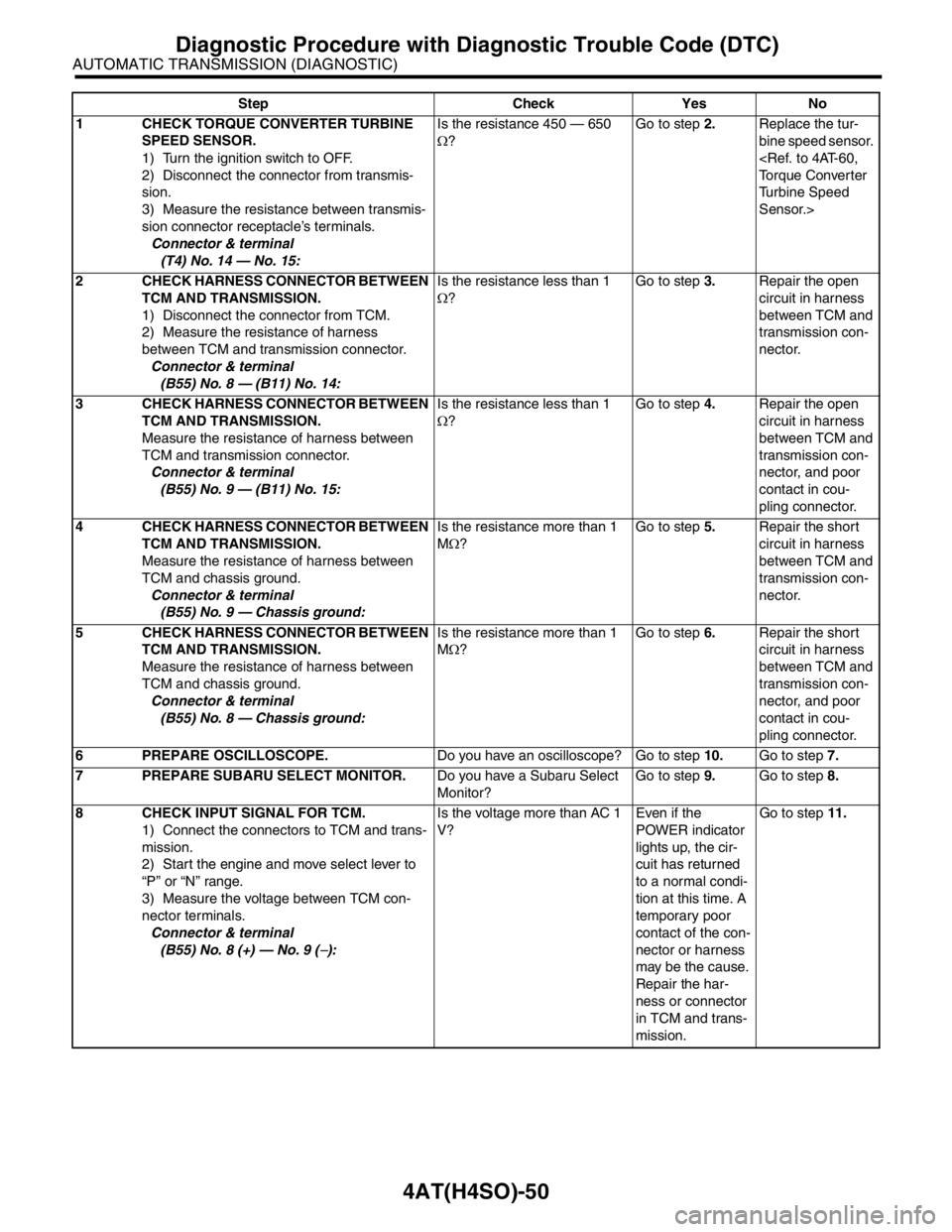

Step Check Yes No

1 CHECK TORQUE CONVERTER TURBINE

SPEED SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion.

3) Measure the resistance between transmis-

sion connector receptacle’s terminals.

Connector & terminal

(T4) No. 14 — No. 15:Is the resistance 450 — 650

Ω?Go to step 2.Replace the tur-

bine speed sensor.

Turbine Speed

Sensor.>

2 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Disconnect the connector from TCM.

2) Measure the resistance of harness

between TCM and transmission connector.

Connector & terminal

(B55) No. 8 — (B11) No. 14:Is the resistance less than 1

Ω?Go to step 3.Repair the open

circuit in harness

between TCM and

transmission con-

nector.

3 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM and transmission connector.

Connector & terminal

(B55) No. 9 — (B11) No. 15:Is the resistance less than 1

Ω?Go to step 4.Repair the open

circuit in harness

between TCM and

transmission con-

nector, and poor

contact in cou-

pling connector.

4 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM and chassis ground.

Connector & terminal

(B55) No. 9 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 5.Repair the short

circuit in harness

between TCM and

transmission con-

nector.

5 CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM and chassis ground.

Connector & terminal

(B55) No. 8 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 6.Repair the short

circuit in harness

between TCM and

transmission con-

nector, and poor

contact in cou-

pling connector.

6 PREPARE OSCILLOSCOPE.Do you have an oscilloscope? Go to step 10.Go to step 7.

7 PREPARE SUBARU SELECT MONITOR.Do you have a Subaru Select

Monitor?Go to step 9.Go to step 8.

8 CHECK INPUT SIGNAL FOR TCM.

1) Connect the connectors to TCM and trans-

mission.

2) Start the engine and move select lever to

“P” or “N” range.

3) Measure the voltage between TCM con-

nector terminals.

Connector & terminal

(B55) No. 8 (+) — No. 9 (

−):Is the voltage more than AC 1

V?Even if the

POWER indicator

lights up, the cir-

cuit has returned

to a normal condi-

tion at this time. A

temporary poor

contact of the con-

nector or harness

may be the cause.

Repair the har-

ness or connector

in TCM and trans-

mission.Go to step 11.

Page 2510 of 2870

4AT(H4SO)-51

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

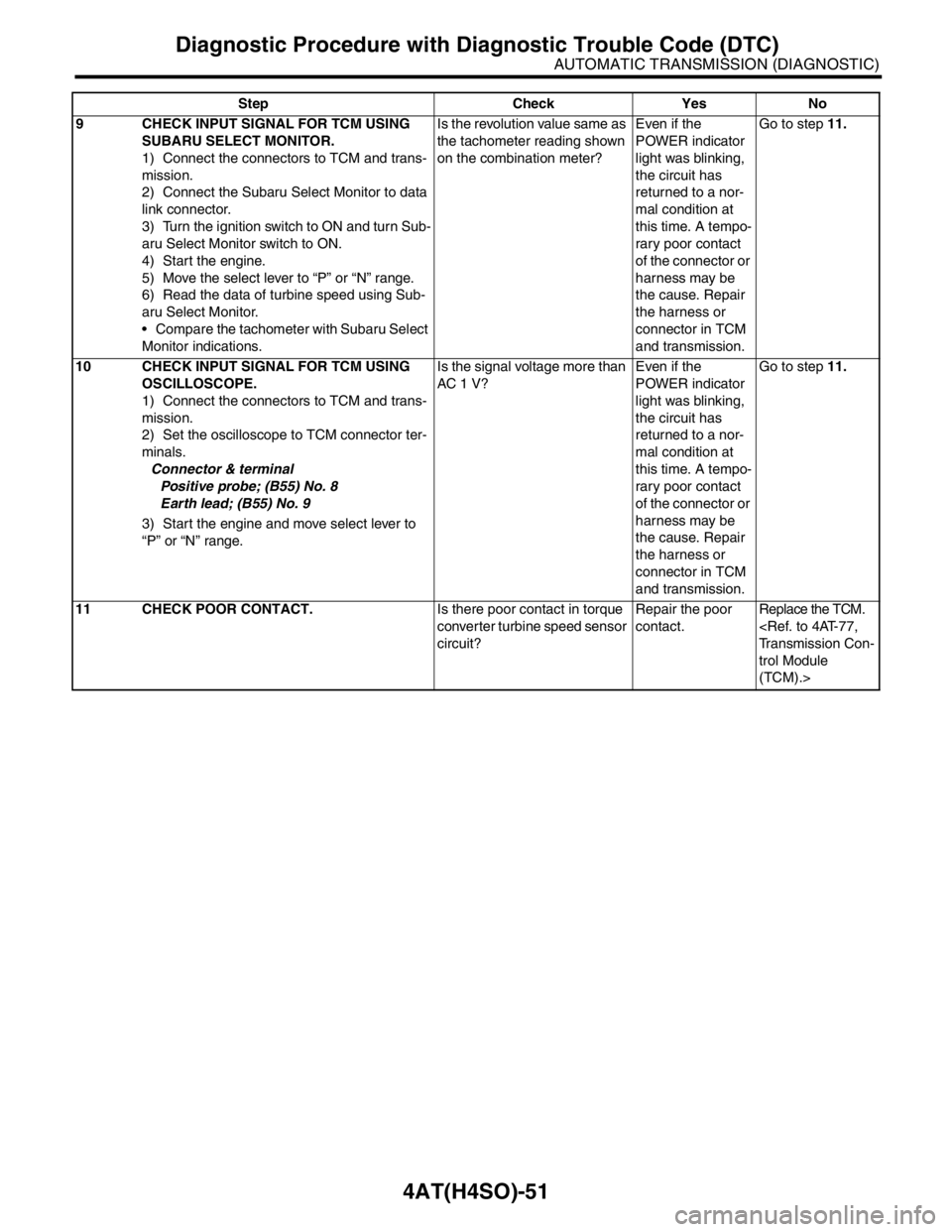

9 CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect the connectors to TCM and trans-

mission.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON and turn Sub-

aru Select Monitor switch to ON.

4) Start the engine.

5) Move the select lever to “P” or “N” range.

6) Read the data of turbine speed using Sub-

aru Select Monitor.

Compare the tachometer with Subaru Select

Monitor indications.Is the revolution value same as

the tachometer reading shown

on the combination meter?Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in TCM

and transmission.Go to step 11.

10 CHECK INPUT SIGNAL FOR TCM USING

OSCILLOSCOPE.

1) Connect the connectors to TCM and trans-

mission.

2) Set the oscilloscope to TCM connector ter-

minals.

Connector & terminal

Positive probe; (B55) No. 8

Earth lead; (B55) No. 9

3) Start the engine and move select lever to

“P” or “N” range.Is the signal voltage more than

AC 1 V?Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in TCM

and transmission.Go to step 11.

11 CHECK POOR CONTACT.Is there poor contact in torque

converter turbine speed sensor

circuit?Repair the poor

contact.Replace the TCM.

trol Module

(TCM).> Step Check Yes No

Page 2511 of 2870

4AT(H4SO)-52

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

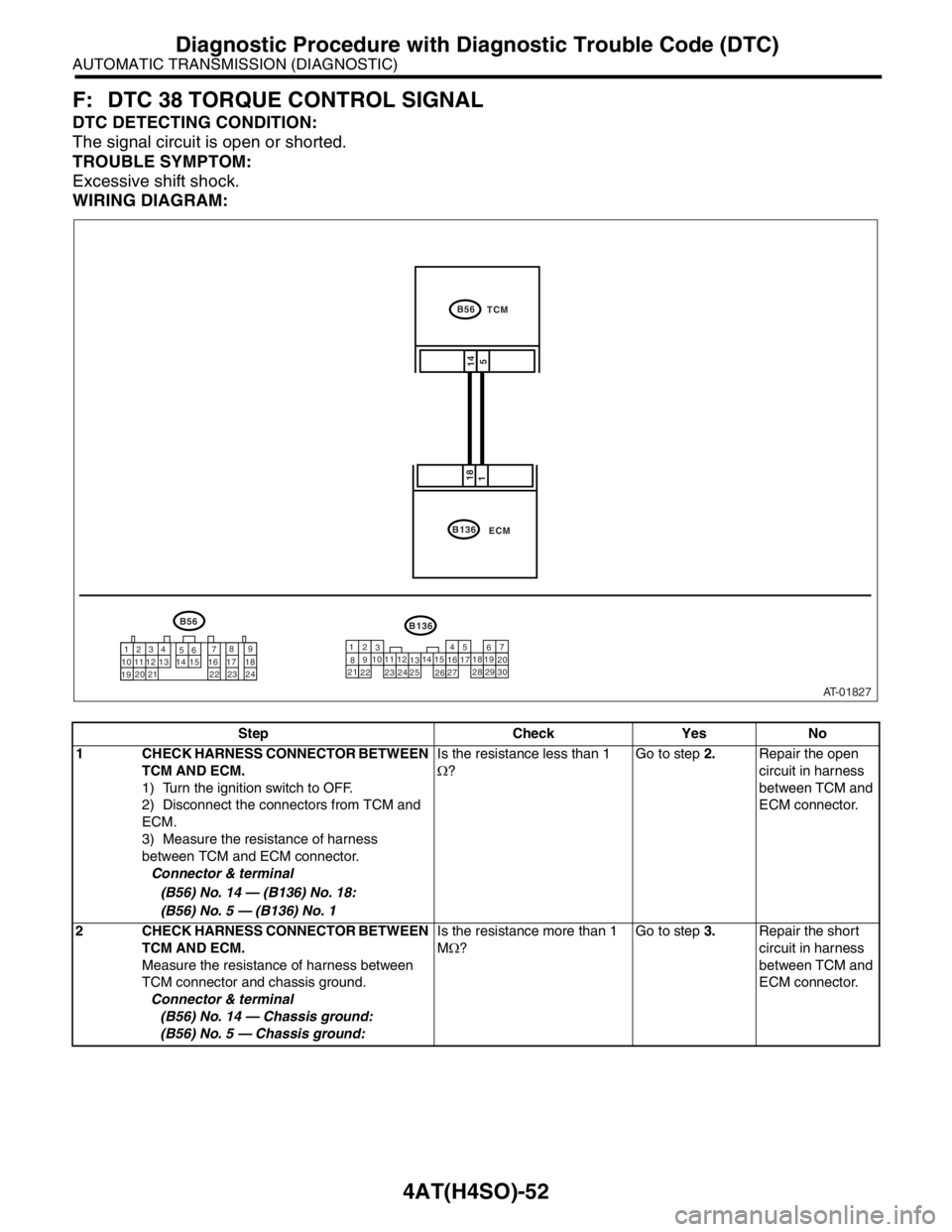

F: DTC 38 TORQUE CONTROL SIGNAL

DTC DETECTING CONDITION:

The signal circuit is open or shorted.

TROUBLE SYMPTOM:

Excessive shift shock.

WIRING DIAGRAM:

Step Check Yes No

1 CHECK HARNESS CONNECTOR BETWEEN

TCM AND ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

ECM.

3) Measure the resistance of harness

between TCM and ECM connector.

Connector & terminal

(B56) No. 14 — (B136) No. 18:

(B56) No. 5 — (B136) No. 1Is the resistance less than 1

Ω?Go to step 2.Repair the open

circuit in harness

between TCM and

ECM connector.

2 CHECK HARNESS CONNECTOR BETWEEN

TCM AND ECM.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B56) No. 14 — Chassis ground:

(B56) No. 5 — Chassis ground:Is the resistance more than 1

MΩ?Go to step 3.Repair the short

circuit in harness

between TCM and

ECM connector.

AT-01827

18

114

5

B56

B136

B136ECM

B56

TCM

1234

56789

10 1112

13 14 15 16 17 18

1920451712

89

20

213

1011 12

13

222314 15

242516

2667

18

19

2728

21

2223 24

2930

Page 2512 of 2870

4AT(H4SO)-53

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

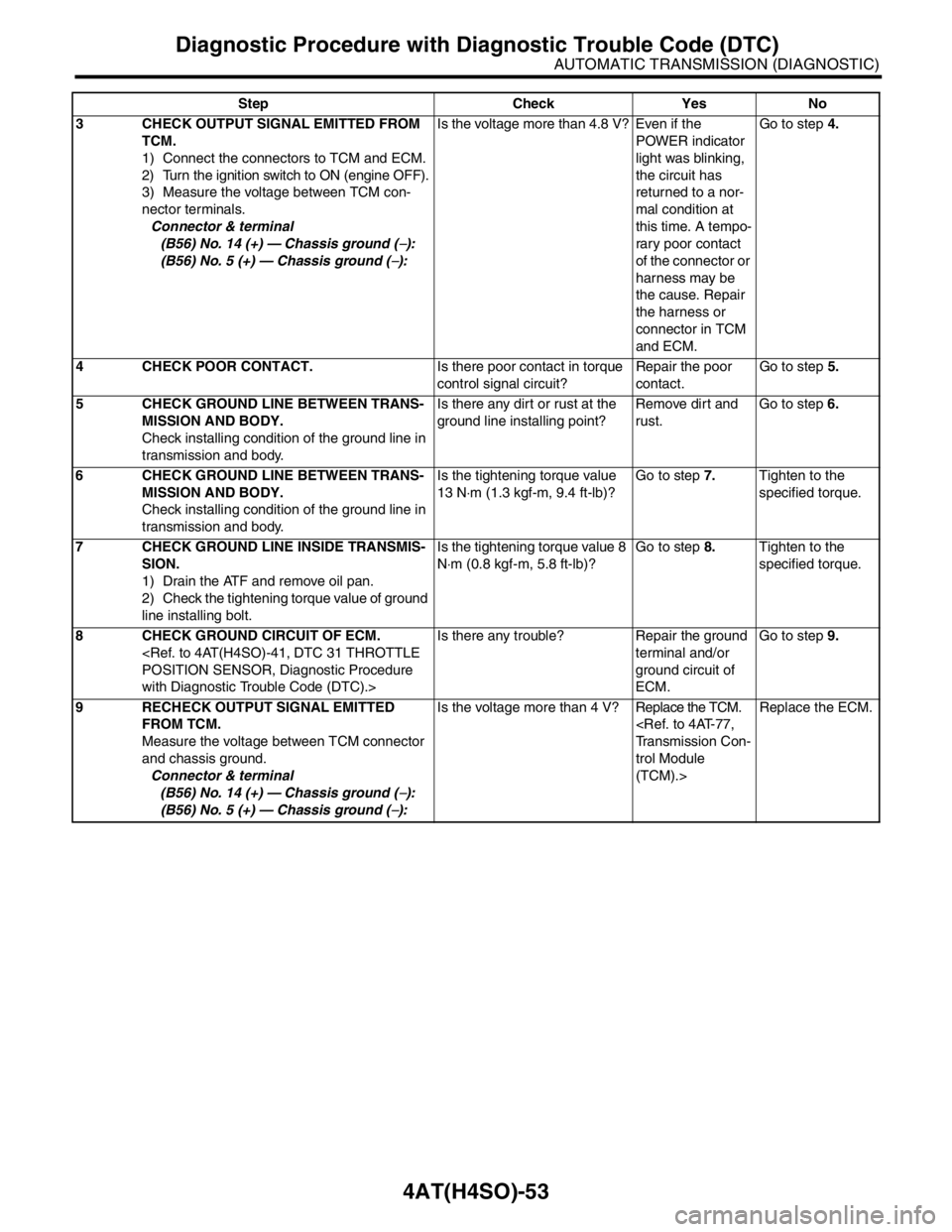

3 CHECK OUTPUT SIGNAL EMITTED FROM

TCM.

1) Connect the connectors to TCM and ECM.

2) Turn the ignition switch to ON (engine OFF).

3) Measure the voltage between TCM con-

nector terminals.

Connector & terminal

(B56) No. 14 (+) — Chassis ground (

−):

(B56) No. 5 (+) — Chassis ground (

−):Is the voltage more than 4.8 V? Even if the

POWER indicator

light was blinking,

the circuit has

returned to a nor-

mal condition at

this time. A tempo-

rary poor contact

of the connector or

harness may be

the cause. Repair

the harness or

connector in TCM

and ECM.Go to step 4.

4 CHECK POOR CONTACT.Is there poor contact in torque

control signal circuit?Repair the poor

contact.Go to step 5.

5 CHECK GROUND LINE BETWEEN TRANS-

MISSION AND BODY.

Check installing condition of the ground line in

transmission and body.Is there any dirt or rust at the

ground line installing point?Remove dirt and

rust.Go to step 6.

6 CHECK GROUND LINE BETWEEN TRANS-

MISSION AND BODY.

Check installing condition of the ground line in

transmission and body.Is the tightening torque value

13 N⋅m (1.3 kgf-m, 9.4 ft-lb)?Go to step 7.Tighten to the

specified torque.

7 CHECK GROUND LINE INSIDE TRANSMIS-

SION.

1) Drain the ATF and remove oil pan.

2) Check the tightening torque value of ground

line installing bolt.Is the tightening torque value 8

N⋅m (0.8 kgf-m, 5.8 ft-lb)?Go to step 8.Tighten to the

specified torque.

8 CHECK GROUND CIRCUIT OF ECM.

with Diagnostic Trouble Code (DTC).>Is there any trouble? Repair the ground

terminal and/or

ground circuit of

ECM.Go to step 9.

9 RECHECK OUTPUT SIGNAL EMITTED

FROM TCM.

Measure the voltage between TCM connector

and chassis ground.

Connector & terminal

(B56) No. 14 (+) — Chassis ground (

−):

(B56) No. 5 (+) — Chassis ground (

−):Is the voltage more than 4 V? Replace the TCM.

trol Module

(TCM).>Replace the ECM. Step Check Yes No

Page 2547 of 2870

4AT(H4SO)-88

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Diagnostic Procedure without Diagnostic Trouble Code (DTC)

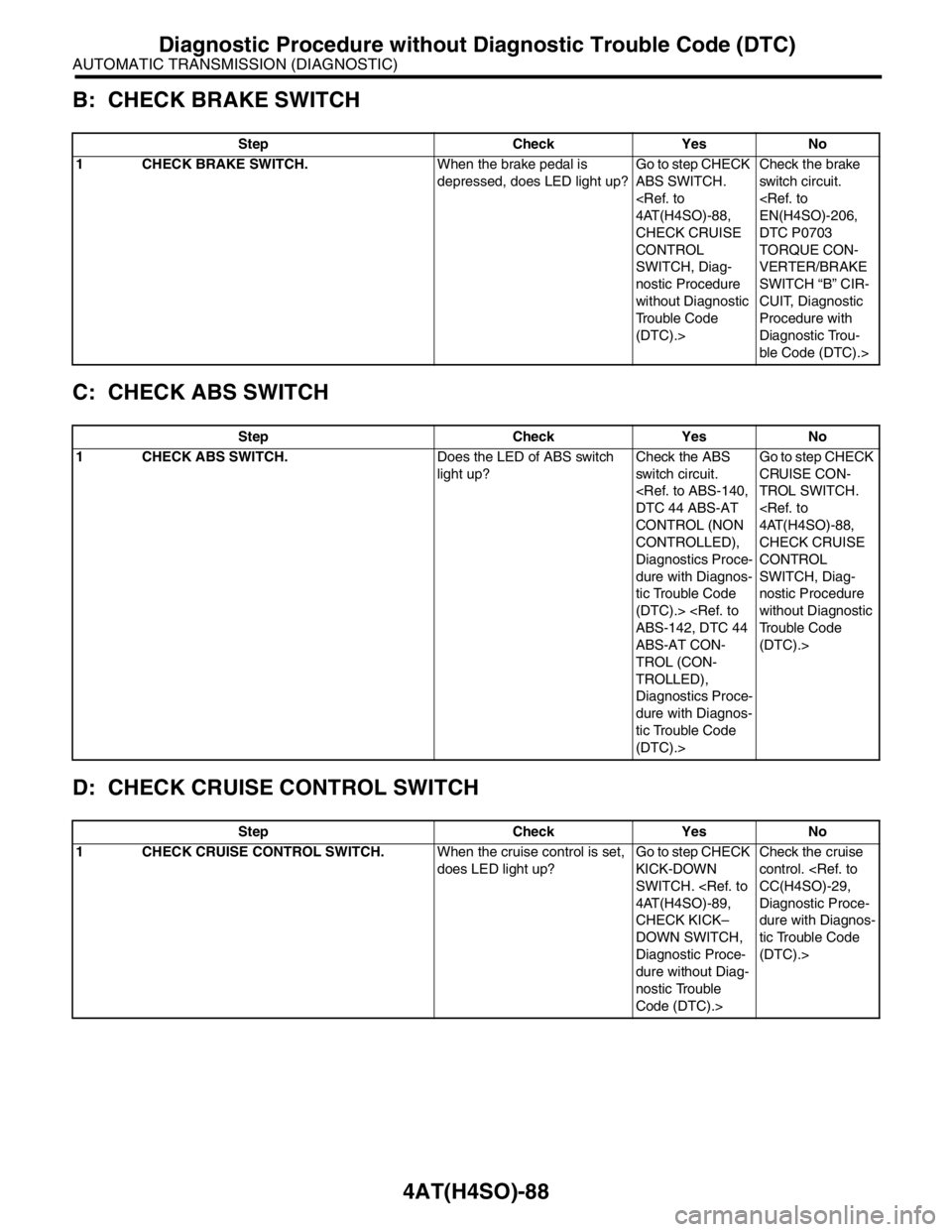

B: CHECK BRAKE SWITCH

C: CHECK ABS SWITCH

D: CHECK CRUISE CONTROL SWITCH

Step Check Yes No

1 CHECK BRAKE SWITCH.When the brake pedal is

depressed, does LED light up?Go to step CHECK

ABS SWITCH.

CHECK CRUISE

CONTROL

SWITCH, Diag-

nostic Procedure

without Diagnostic

Trouble Code

(DTC).>Check the brake

switch circuit.

DTC P0703

TORQUE CON-

VERTER/BRAKE

SWITCH “B” CIR-

CUIT, Diagnostic

Procedure with

Diagnostic Trou-

ble Code (DTC).>

Step Check Yes No

1 CHECK ABS SWITCH.Does the LED of ABS switch

light up?Check the ABS

switch circuit.

CONTROL (NON

CONTROLLED),

Diagnostics Proce-

dure with Diagnos-

tic Trouble Code

(DTC).>

ABS-AT CON-

TROL (CON-

TROLLED),

Diagnostics Proce-

dure with Diagnos-

tic Trouble Code

(DTC).>Go to step CHECK

CRUISE CON-

TROL SWITCH.

CHECK CRUISE

CONTROL

SWITCH, Diag-

nostic Procedure

without Diagnostic

Trouble Code

(DTC).>

Step Check Yes No

1 CHECK CRUISE CONTROL SWITCH.When the cruise control is set,

does LED light up?Go to step CHECK

KICK-DOWN

SWITCH.

CHECK KICK–

DOWN SWITCH,

Diagnostic Proce-

dure without Diag-

nostic Trouble

Code (DTC).>Check the cruise

control.

Diagnostic Proce-

dure with Diagnos-

tic Trouble Code

(DTC).>

Page 2570 of 2870

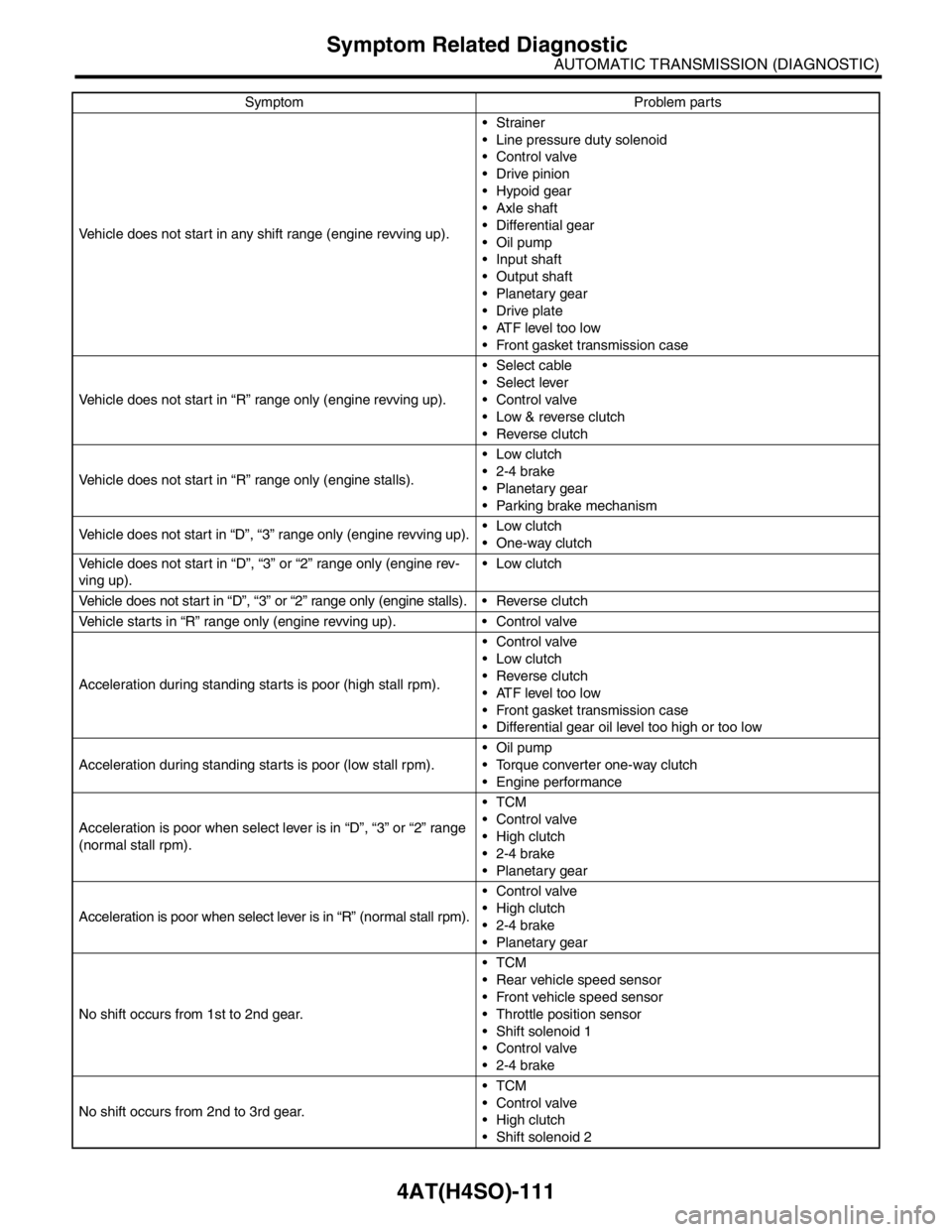

4AT(H4SO)-111

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Symptom Related Diagnostic

Vehicle does not start in any shift range (engine revving up). Strainer

Line pressure duty solenoid

Control valve

Drive pinion

Hypoid gear

Axle shaft

Differential gear

Oil pump

Input shaft

Output shaft

Planetary gear

Drive plate

ATF level too low

Front gasket transmission case

Vehicle does not start in “R” range only (engine revving up). Select cable

Select lever

Control valve

Low & reverse clutch

Reverse clutch

Vehicle does not start in “R” range only (engine stalls). Low clutch

2-4 brake

Planetary gear

Parking brake mechanism

Vehicle does not start in “D”, “3” range only (engine revving up). Low clutch

One-way clutch

Vehicle does not start in “D”, “3” or “2” range only (engine rev-

ving up). Low clutch

Vehicle does not start in “D”, “3” or “2” range only (engine stalls). Reverse clutch

Vehicle starts in “R” range only (engine revving up). Control valve

Acceleration during standing starts is poor (high stall rpm). Control valve

Low clutch

Reverse clutch

ATF level too low

Front gasket transmission case

Differential gear oil level too high or too low

Acceleration during standing starts is poor (low stall rpm). Oil pump

Torque converter one-way clutch

Engine performance

Acceleration is poor when select lever is in “D”, “3” or “2” range

(normal stall rpm).TCM

Control valve

High clutch

2-4 brake

Planetary gear

Acceleration is poor when select lever is in “R” (normal stall rpm). Control valve

High clutch

2-4 brake

Planetary gear

No shift occurs from 1st to 2nd gear.TCM

Rear vehicle speed sensor

Front vehicle speed sensor

Throttle position sensor

Shift solenoid 1

Control valve

2-4 brake

No shift occurs from 2nd to 3rd gear.TCM

Control valve

High clutch

Shift solenoid 2 Symptom Problem parts