torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2434 of 2870

4AT-120

AUTOMATIC TRANSMISSION

Front Differential

6) Hold the shaft of ST to avoid removing from dif-

ferential side retainer, and then remove the bearing

outer race.

ST 398527700 PULLER ASSY

NOTE:

Replace the bearing inner and outer races as a sin-

gle unit.

D: ASSEMBLY

1. DIFFERENTIAL CASE ASSEMBLY

1) Install the washer, differential bevel gear and dif-

ferential bevel pinion in the differential case (RH).

Insert the pinion shaft.

2) Install the straight pin in reverse direction.

3) Install the washer and differential bevel gear to

differential case (LH). Put the differential case (RH)

on the case, and then combine the both cases.4) Install the hypoid driven gear and secure by

tightening the bolt.

Tightening torque:

62 N

⋅m (6.3 kgf-m, 45.6 ft-lb)

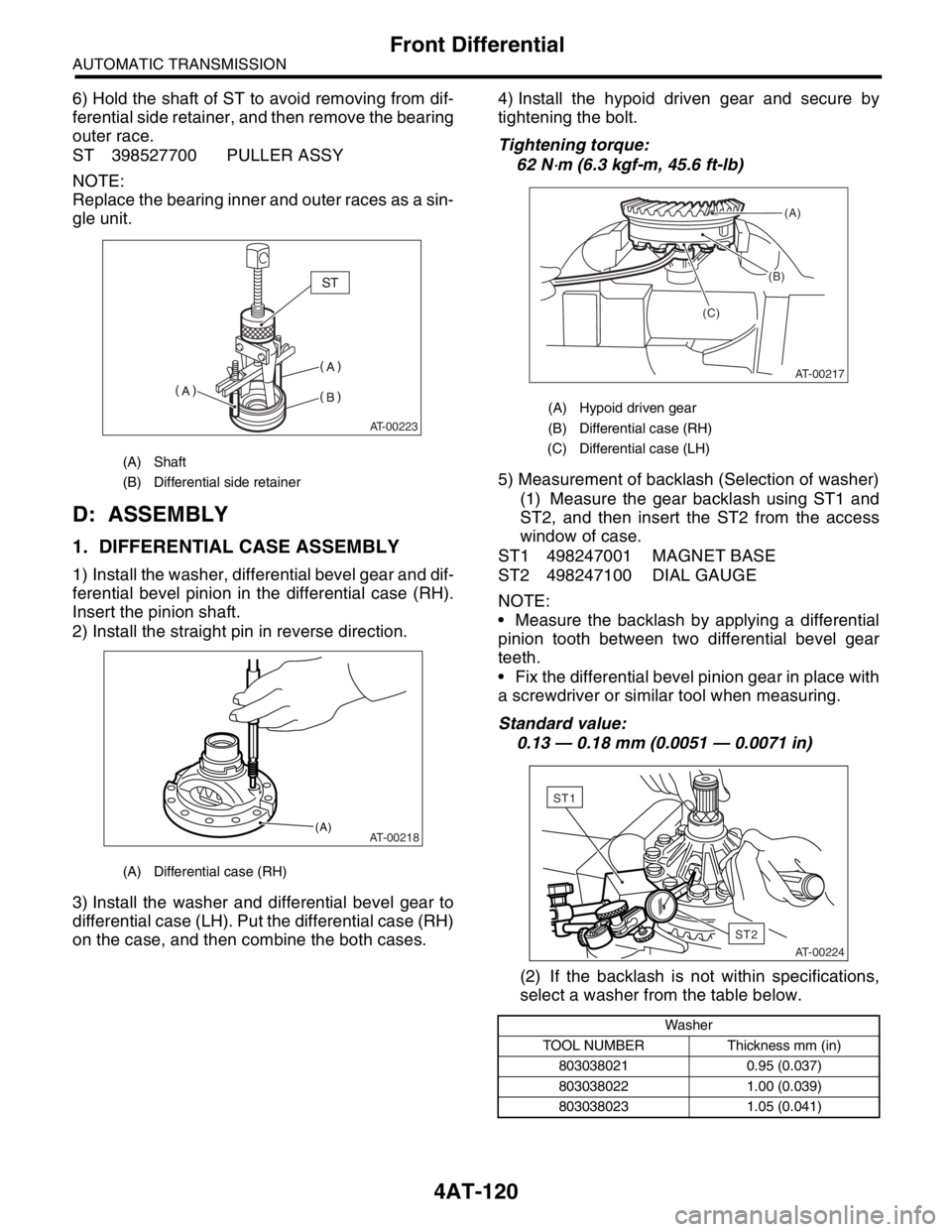

5) Measurement of backlash (Selection of washer)

(1) Measure the gear backlash using ST1 and

ST2, and then insert the ST2 from the access

window of case.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

NOTE:

Measure the backlash by applying a differential

pinion tooth between two differential bevel gear

teeth.

Fix the differential bevel pinion gear in place with

a screwdriver or similar tool when measuring.

Standard value:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

(2) If the backlash is not within specifications,

select a washer from the table below.

(A) Shaft

(B) Differential side retainer

(A) Differential case (RH)

AT-00223

AT-00218(A)

(A) Hypoid driven gear

(B) Differential case (RH)

(C) Differential case (LH)

Washer

TOOL NUMBER Thickness mm (in)

803038021 0.95 (0.037)

803038022 1.00 (0.039)

803038023 1.05 (0.041)

(B)

AT-00217

(A)

(C)

AT-00224

ST2

ST1

Page 2435 of 2870

4AT-121

AUTOMATIC TRANSMISSION

Front Differential

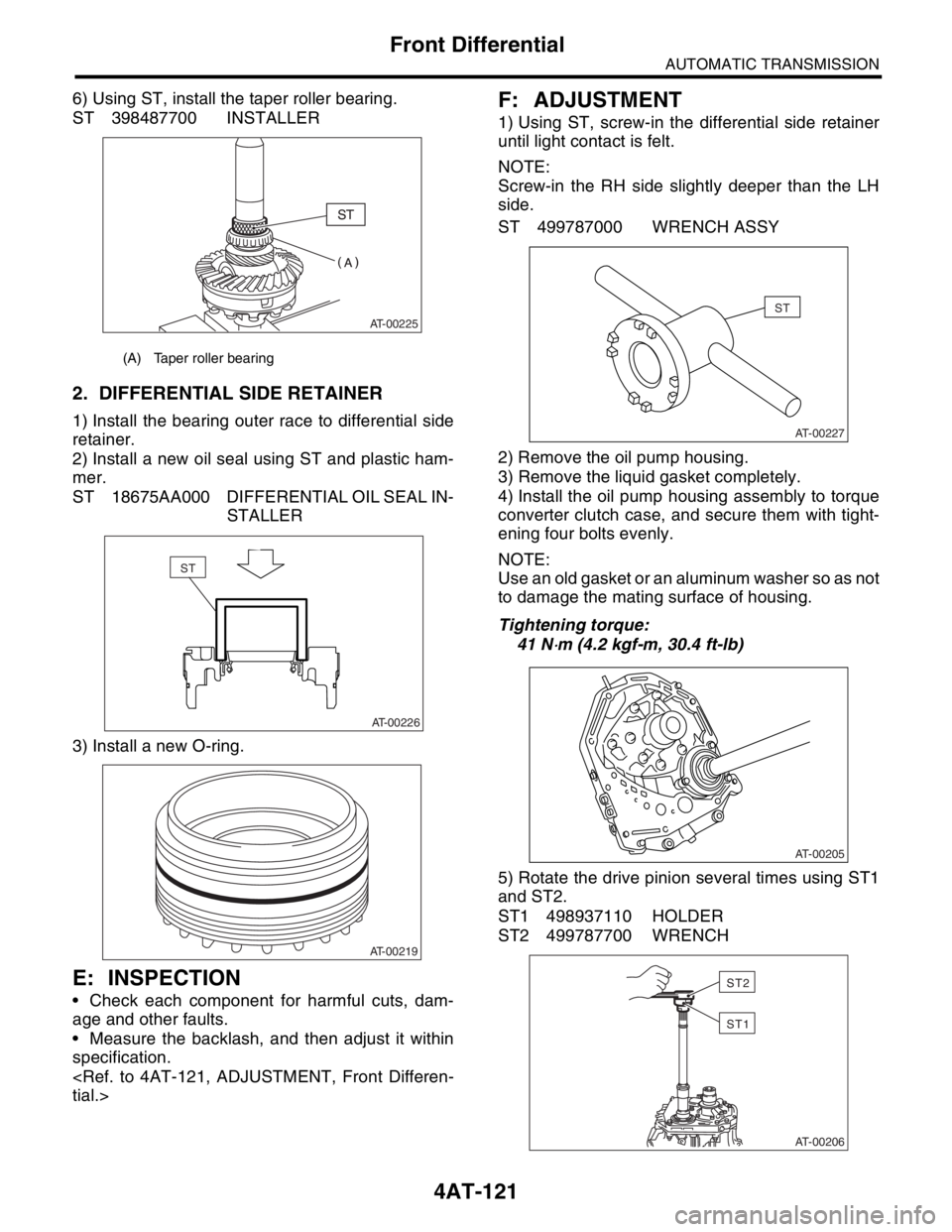

6) Using ST, install the taper roller bearing.

ST 398487700 INSTALLER

2. DIFFERENTIAL SIDE RETAINER

1) Install the bearing outer race to differential side

retainer.

2) Install a new oil seal using ST and plastic ham-

mer.

ST 18675AA000 DIFFERENTIAL OIL SEAL IN-

STALLER

3) Install a new O-ring.

E: INSPECTION

Check each component for harmful cuts, dam-

age and other faults.

Measure the backlash, and then adjust it within

specification.

F: ADJUSTMENT

1) Using ST, screw-in the differential side retainer

until light contact is felt.

NOTE:

Screw-in the RH side slightly deeper than the LH

side.

ST 499787000 WRENCH ASSY

2) Remove the oil pump housing.

3) Remove the liquid gasket completely.

4) Install the oil pump housing assembly to torque

converter clutch case, and secure them with tight-

ening four bolts evenly.

NOTE:

Use an old gasket or an aluminum washer so as not

to damage the mating surface of housing.

Tightening torque:

41 N

⋅m (4.2 kgf-m, 30.4 ft-lb)

5) Rotate the drive pinion several times using ST1

and ST2.

ST1 498937110 HOLDER

ST2 499787700 WRENCH

(A) Taper roller bearing

AT-00225

AT-00226

ST

AT-00219

AT-00227

ST

AT-00205

AT-00206

ST2

ST1

Page 2437 of 2870

4AT-123

AUTOMATIC TRANSMISSION

AT Main Case

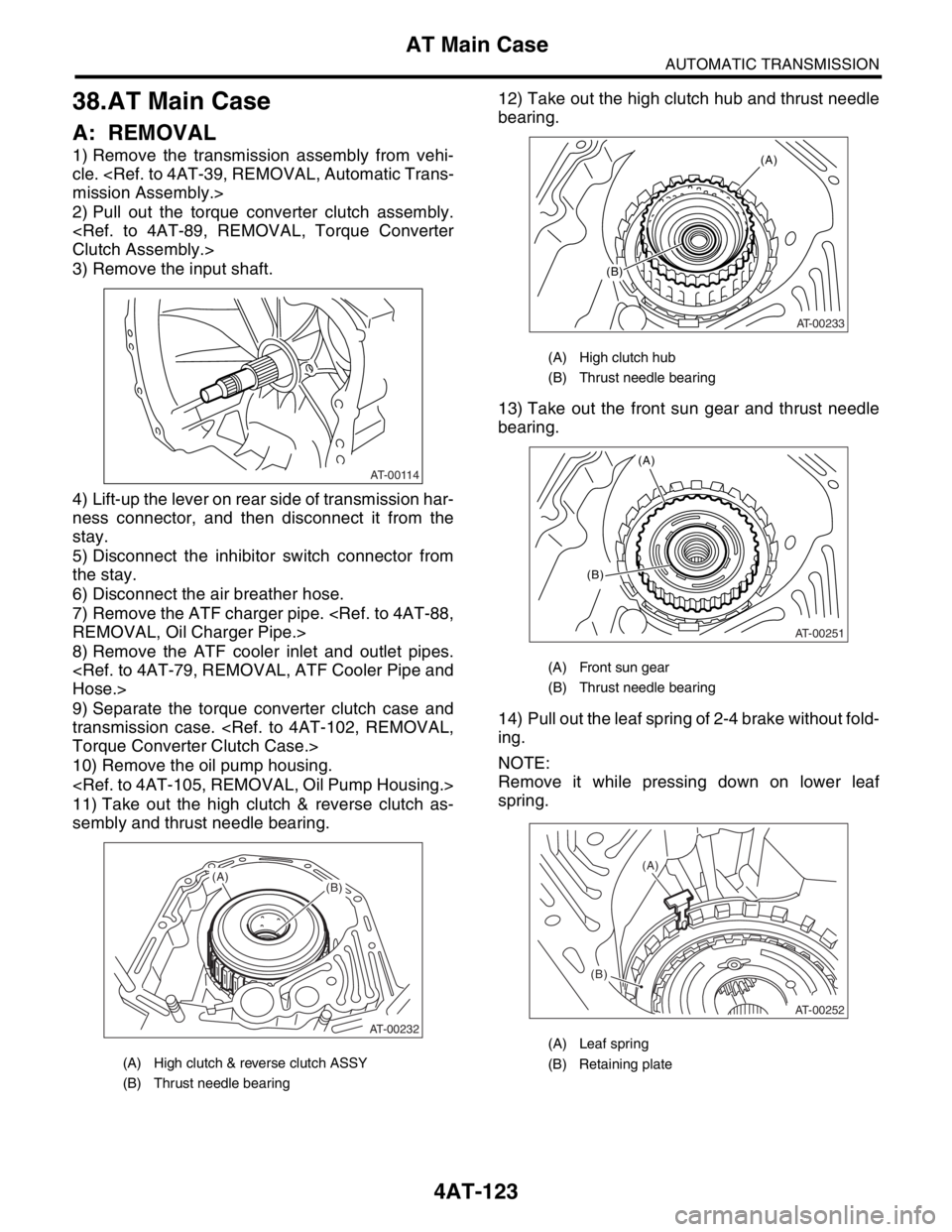

38.AT Main Case

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle.

2) Pull out the torque converter clutch assembly.

3) Remove the input shaft.

4) Lift-up the lever on rear side of transmission har-

ness connector, and then disconnect it from the

stay.

5) Disconnect the inhibitor switch connector from

the stay.

6) Disconnect the air breather hose.

7) Remove the ATF charger pipe.

8) Remove the ATF cooler inlet and outlet pipes.

9) Separate the torque converter clutch case and

transmission case.

10) Remove the oil pump housing.

11) Take out the high clutch & reverse clutch as-

sembly and thrust needle bearing.12) Take out the high clutch hub and thrust needle

bearing.

13) Take out the front sun gear and thrust needle

bearing.

14) Pull out the leaf spring of 2-4 brake without fold-

ing.

NOTE:

Remove it while pressing down on lower leaf

spring.

(A) High clutch & reverse clutch ASSY

(B) Thrust needle bearing

AT-00114

AT-00232

(B) (A)

(A) High clutch hub

(B) Thrust needle bearing

(A) Front sun gear

(B) Thrust needle bearing

(A) Leaf spring

(B) Retaining plate

AT-00233

(A)

(B)

AT-00251

(A)

(B)

AT-00252

(A)

(B)

Page 2440 of 2870

4AT-126

AUTOMATIC TRANSMISSION

AT Main Case

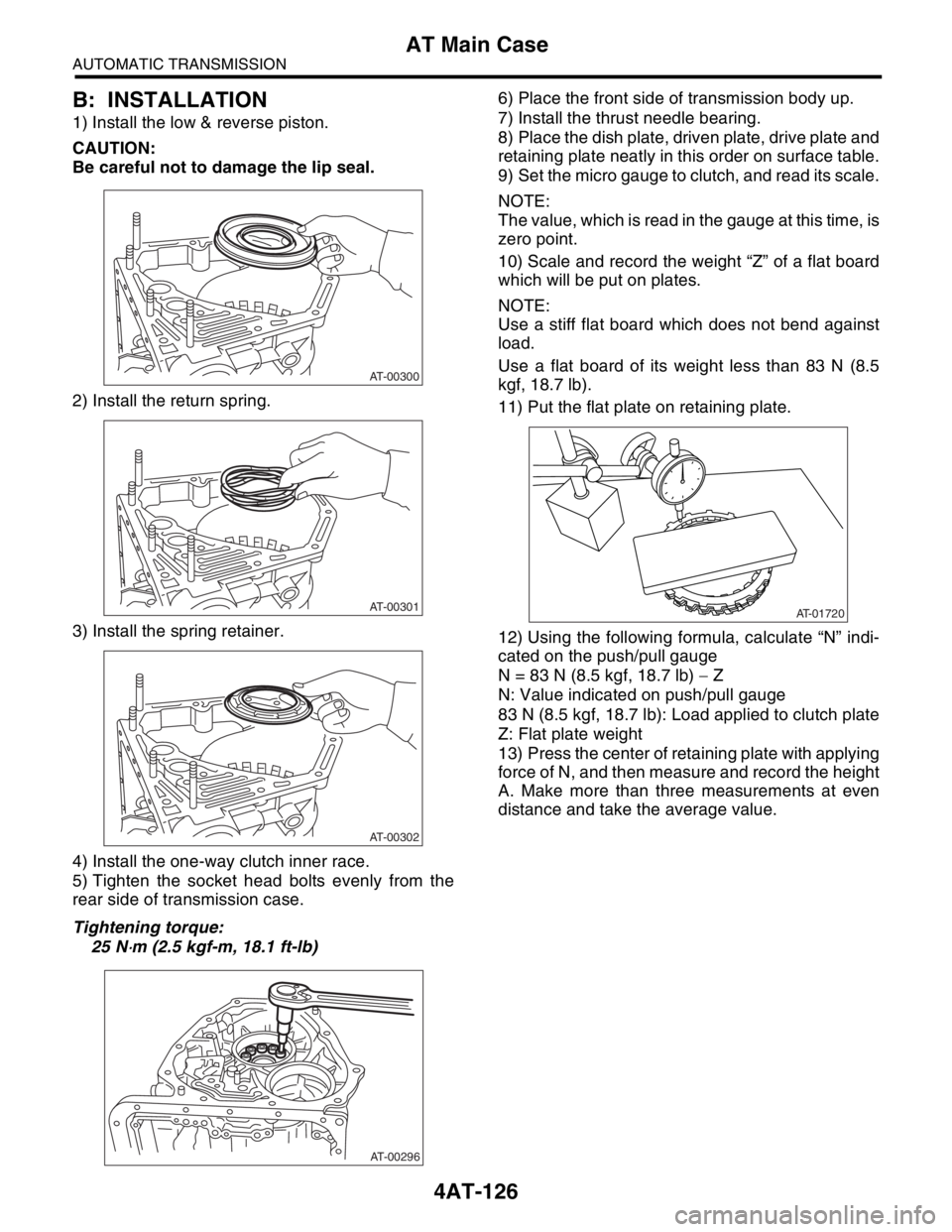

B: INSTALLATION

1) Install the low & reverse piston.

CAUTION:

Be careful not to damage the lip seal.

2) Install the return spring.

3) Install the spring retainer.

4) Install the one-way clutch inner race.

5) Tighten the socket head bolts evenly from the

rear side of transmission case.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)6) Place the front side of transmission body up.

7) Install the thrust needle bearing.

8) Place the dish plate, driven plate, drive plate and

retaining plate neatly in this order on surface table.

9) Set the micro gauge to clutch, and read its scale.

NOTE:

The value, which is read in the gauge at this time, is

zero point.

10) Scale and record the weight “Z” of a flat board

which will be put on plates.

NOTE:

Use a stiff flat board which does not bend against

load.

Use a flat board of its weight less than 83 N (8.5

kgf, 18.7 lb).

11) Put the flat plate on retaining plate.

12) Using the following formula, calculate “N” indi-

cated on the push/pull gauge

N = 83 N (8.5 kgf, 18.7 lb) − Z

N: Value indicated on push/pull gauge

83 N (8.5 kgf, 18.7 lb): Load applied to clutch plate

Z: Flat plate weight

13) Press the center of retaining plate with applying

force of N, and then measure and record the height

A. Make more than three measurements at even

distance and take the average value.

AT-00300

AT-00301

AT-00302

AT-00296

AT-01720

Page 2445 of 2870

4AT-131

AUTOMATIC TRANSMISSION

AT Main Case

35) Install the oil pump housing assembly with a

new gasket.

36) Install the torque converter clutch case assem-

bly into transmission case assembly.

Case.>

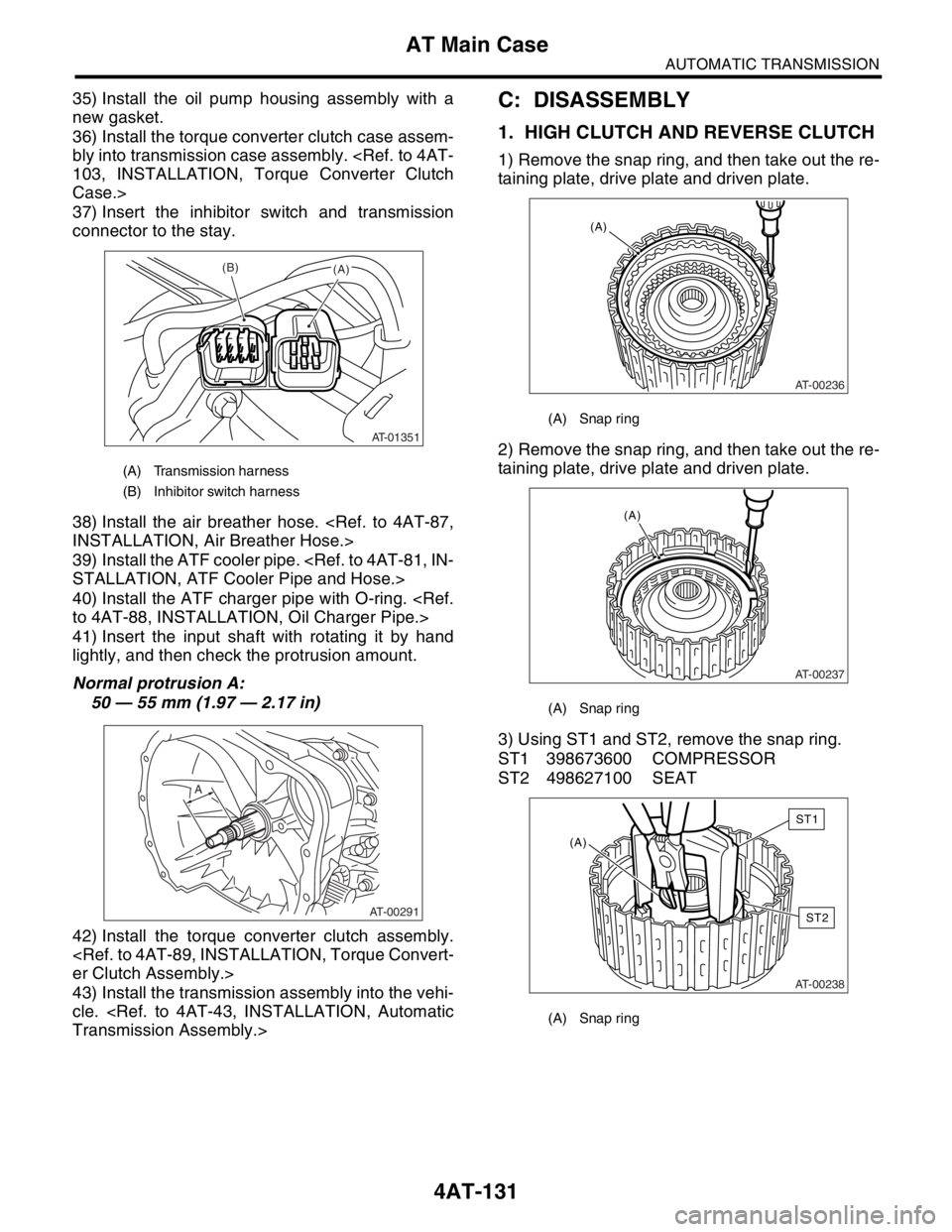

37) Insert the inhibitor switch and transmission

connector to the stay.

38) Install the air breather hose.

39) Install the ATF cooler pipe.

40) Install the ATF charger pipe with O-ring.

41) Insert the input shaft with rotating it by hand

lightly, and then check the protrusion amount.

Normal protrusion A:

50 — 55 mm (1.97 — 2.17 in)

42) Install the torque converter clutch assembly.

43) Install the transmission assembly into the vehi-

cle.

1. HIGH CLUTCH AND REVERSE CLUTCH

1) Remove the snap ring, and then take out the re-

taining plate, drive plate and driven plate.

2) Remove the snap ring, and then take out the re-

taining plate, drive plate and driven plate.

3) Using ST1 and ST2, remove the snap ring.

ST1 398673600 COMPRESSOR

ST2 498627100 SEAT

(A) Transmission harness

(B) Inhibitor switch harness

AT-01351

(B)(A)

AT-00291

A

(A) Snap ring

(A) Snap ring

(A) Snap ring

AT-00236

(A)

AT-00237

(A)

AT-00238

(A)

ST1

ST2

Page 2456 of 2870

4AT-142

AUTOMATIC TRANSMISSION

Transmission Control Device

39.Transmission Control Device

A: REMOVAL

1) Remove the transmission assembly from vehi-

cle.

2) Pull out the torque converter clutch assembly.

3) Remove the input shaft.

4) Lift-up the lever on rear side of transmission har-

ness connector, and then disconnect it from the

stay.

5) Disconnect the air breather hose.

6) Disconnect the inhibitor switch connector from

the stay.

7) Wrap vinyl tape around the nipple attached to

the air breather hose.

8) Remove the pitching stopper bracket.

9) Remove the inhibitor switch.

10) Remove the control valve body assembly.

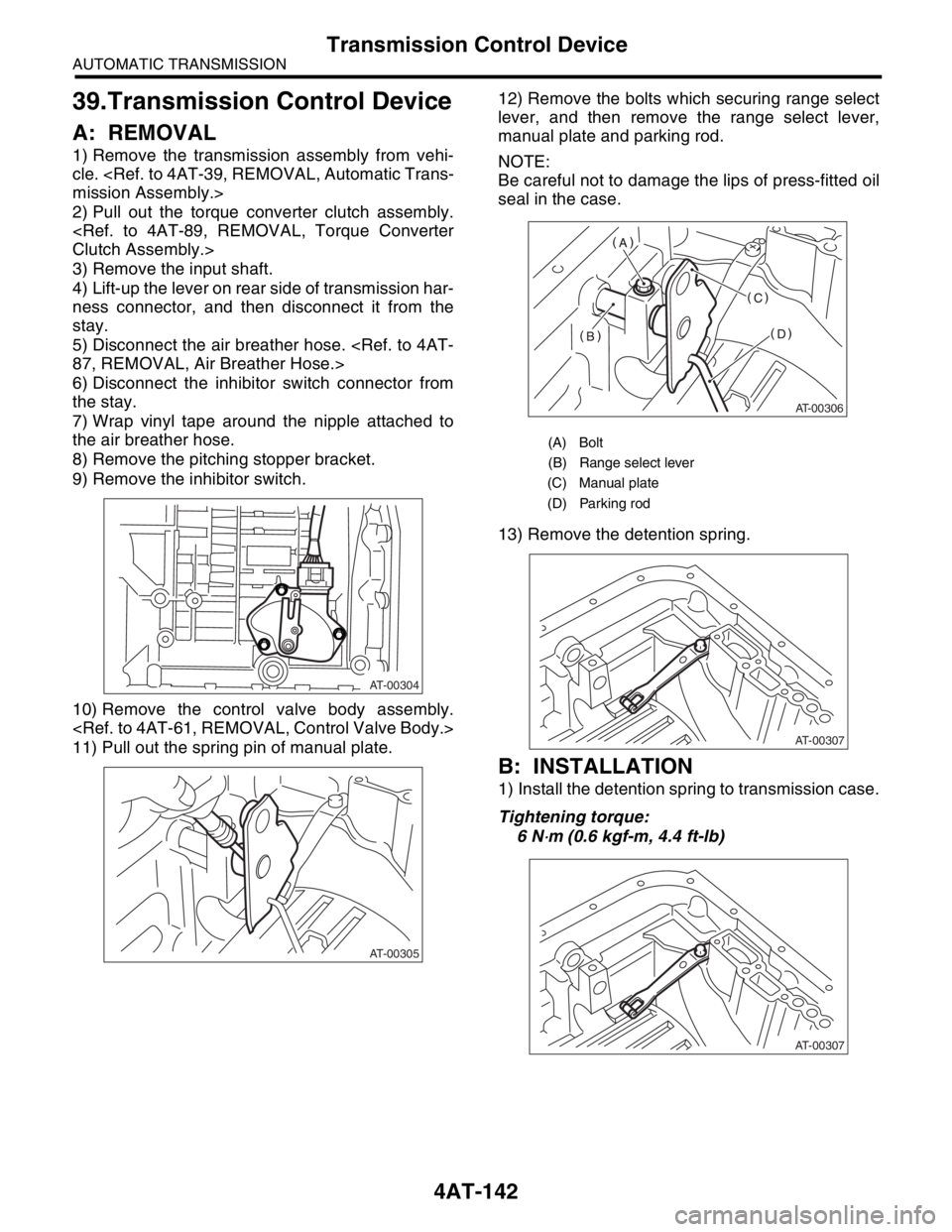

11) Pull out the spring pin of manual plate.12) Remove the bolts which securing range select

lever, and then remove the range select lever,

manual plate and parking rod.

NOTE:

Be careful not to damage the lips of press-fitted oil

seal in the case.

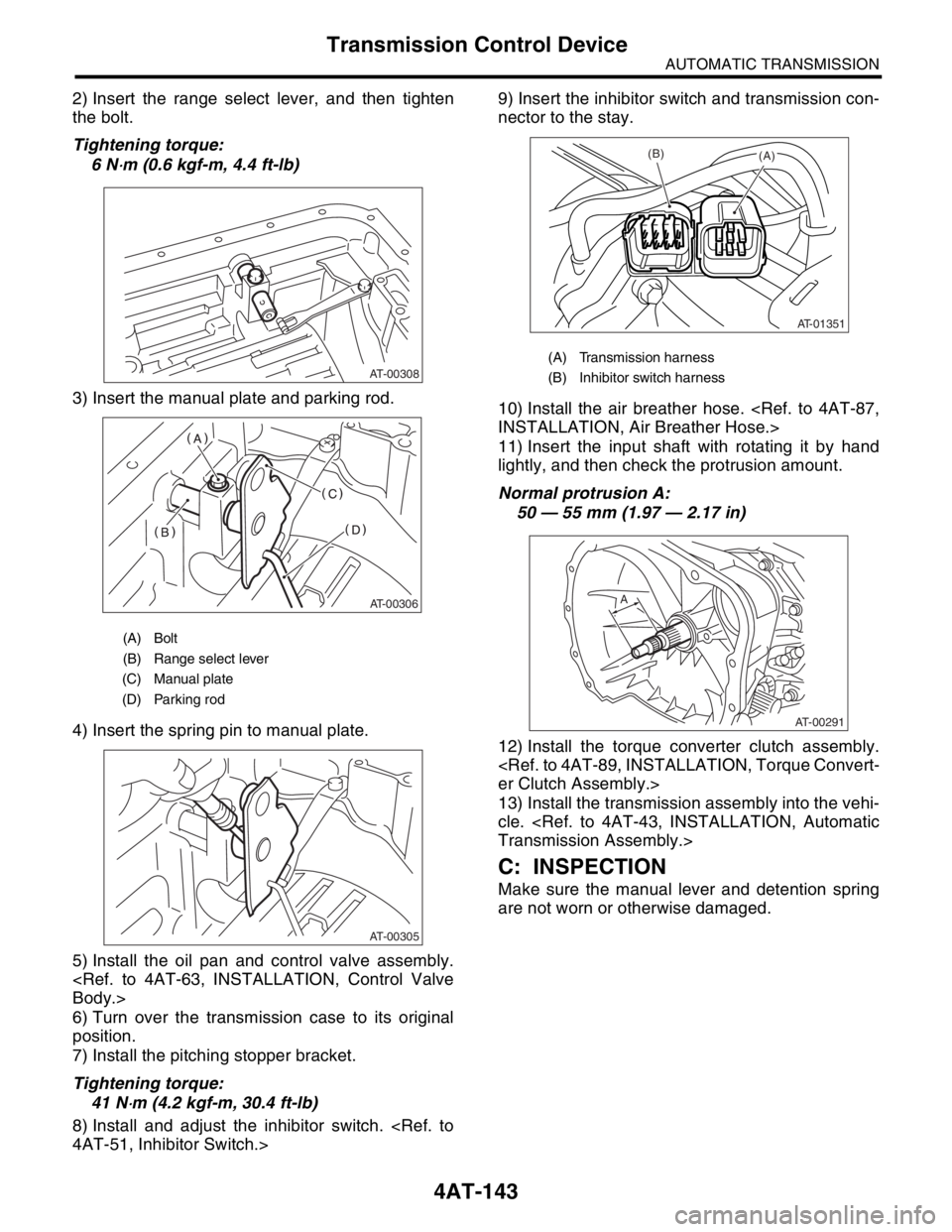

13) Remove the detention spring.

B: INSTALLATION

1) Install the detention spring to transmission case.

Tightening torque:

6 N

⋅m (0.6 kgf-m, 4.4 ft-lb)

AT-00304

AT-00305

(A) Bolt

(B) Range select lever

(C) Manual plate

(D) Parking rod

AT-00306

AT-00307

AT-00307

Page 2457 of 2870

4AT-143

AUTOMATIC TRANSMISSION

Transmission Control Device

2) Insert the range select lever, and then tighten

the bolt.

Tightening torque:

6 N

⋅m (0.6 kgf-m, 4.4 ft-lb)

3) Insert the manual plate and parking rod.

4) Insert the spring pin to manual plate.

5) Install the oil pan and control valve assembly.

6) Turn over the transmission case to its original

position.

7) Install the pitching stopper bracket.

Tightening torque:

41 N

⋅m (4.2 kgf-m, 30.4 ft-lb)

8) Install and adjust the inhibitor switch.

nector to the stay.

10) Install the air breather hose.

11) Insert the input shaft with rotating it by hand

lightly, and then check the protrusion amount.

Normal protrusion A:

50 — 55 mm (1.97 — 2.17 in)

12) Install the torque converter clutch assembly.

13) Install the transmission assembly into the vehi-

cle.

C: INSPECTION

Make sure the manual lever and detention spring

are not worn or otherwise damaged.

(A) Bolt

(B) Range select lever

(C) Manual plate

(D) Parking rod

AT-00308

AT-00306

AT-00305

(A) Transmission harness

(B) Inhibitor switch harness

AT-01351

(B)(A)

AT-00291

A

Page 2464 of 2870

4AT(H4SO)-5

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

General Description

3. General Description

A: CAUTION

Supplemental Restraint System “Airbag”

The airbag system wiring harness is routed near

the transmission control module (TCM).

CAUTION:

All airbag system wiring harness and con-

nectors are colored yellow. Do not use an elec-

trical test equipment on these circuit.

Be careful not to damage the airbag system wir-

ing harness when performing diagnostics and ser-

vicing the TCM.

Measurement

When measuring the voltage and resistance of

ECM, TCM or each sensor, use a tapered pin with

diameter of less than 0.64 mm (0.025 in) in order to

avoid poor contact. Do not insert the pin more than

0.65 mm (0.256 in).

B: INSPECTION

1. BATTERY

Measure the battery voltage and specific gravity of

electrolyte.

Standard voltage: 12 V or more

Specific gravity: Above 1.260

2. TRANSMISSION GROUND

Make sure that the ground terminal bolt is tightened

securely.

Chassis side

Tightening torque:

13 N

⋅m (1.3 kgf-m, 9.4 ft-lb)

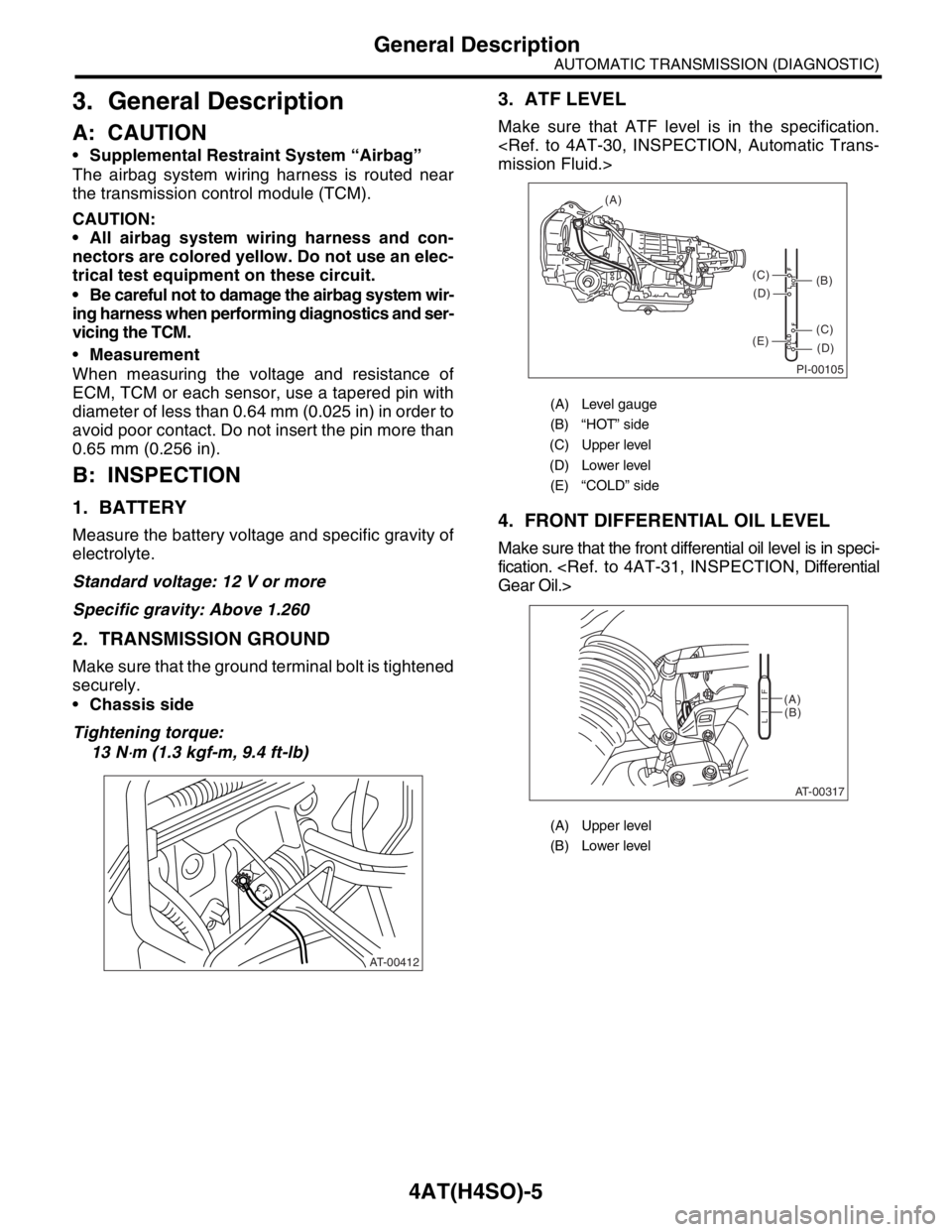

3. ATF LEVEL

Make sure that ATF level is in the specification.

4. FRONT DIFFERENTIAL OIL LEVEL

Make sure that the front differential oil level is in speci-

fication.

AT-00412

(A) Level gauge

(B) “HOT” side

(C) Upper level

(D) Lower level

(E) “COLD” side

(A) Upper level

(B) Lower level

PI-00105

COLD

LFHOT LF

(A)

(C)

(D)

(C)

(D)

(E)

(B)

AT-00317

(A)

(B)

LF

Page 2469 of 2870

4AT(H4SO)-10

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

Electrical Components Location

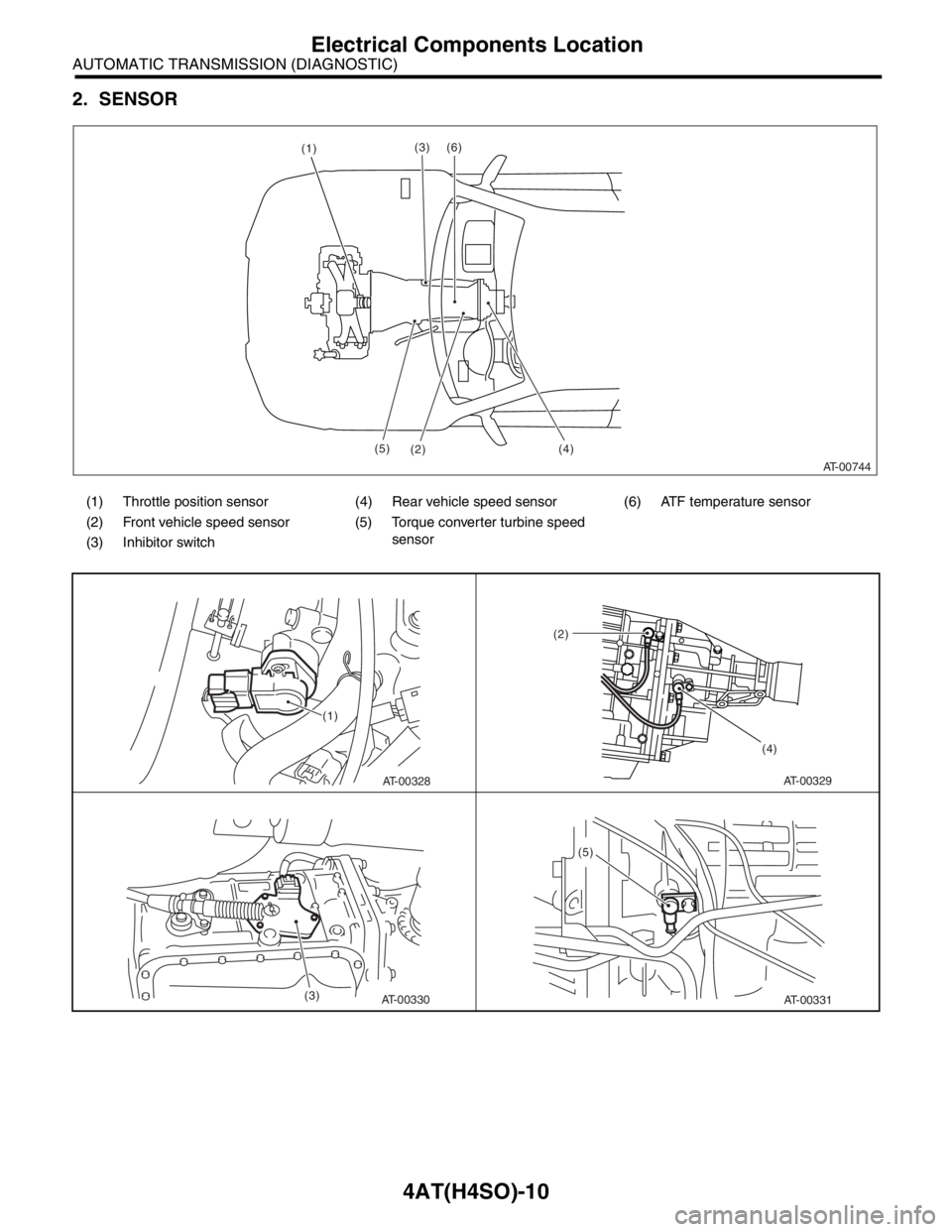

2. SENSOR

(1) Throttle position sensor (4) Rear vehicle speed sensor (6) ATF temperature sensor

(2) Front vehicle speed sensor (5) Torque converter turbine speed

sensor

(3) Inhibitor switch

AT-00744

(1)

(2)(3)

(4) (5)(6)

AT-00328 (1)

(2)

(4)

AT-00329

(3)

AT-00330

(5)

AT-00331

Page 2472 of 2870

4AT(H4SO)-13

AUTOMATIC TRANSMISSION (DIAGNOSTIC)

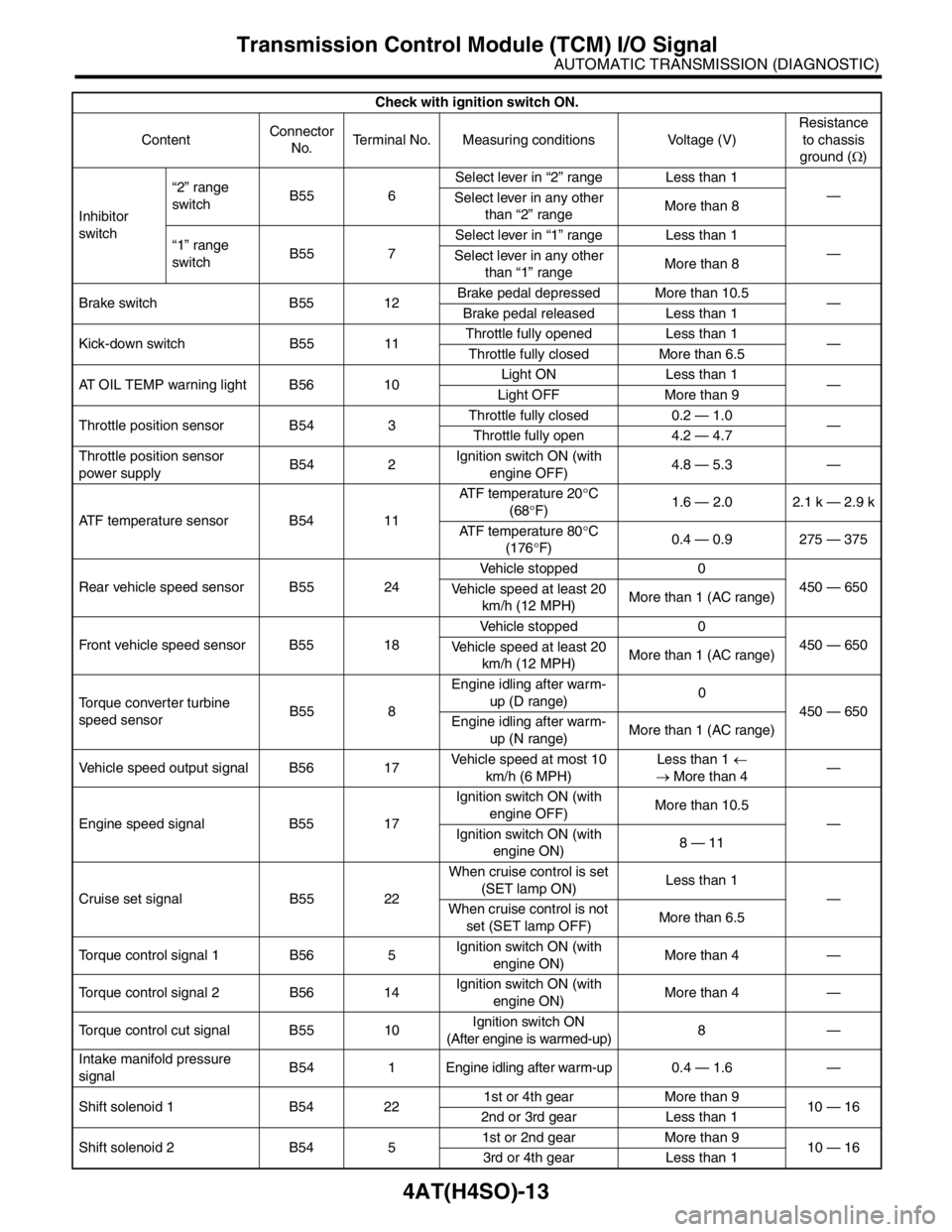

Transmission Control Module (TCM) I/O Signal

Inhibitor

switch“2” range

switchB55 6Select lever in “2” range Less than 1

—

Select lever in any other

than “2” rangeMore than 8

“1” range

switchB55 7Select lever in “1” range Less than 1

—

Select lever in any other

than “1” rangeMore than 8

Brake switch B55 12Brake pedal depressed More than 10.5

—

Brake pedal released Less than 1

Kick-down switch B55 11Throttle fully opened Less than 1

—

Throttle fully closed More than 6.5

AT OIL TEMP warning light B56 10Light ON Less than 1

—

Light OFF More than 9

Throttle position sensor B54 3Throttle fully closed 0.2 — 1.0

—

Throttle fully open 4.2 — 4.7

Throttle position sensor

power supplyB54 2Ignition switch ON (with

engine OFF)4.8 — 5.3 —

ATF temperature sensor B54 11ATF temperature 20°C

(68°F)1.6 — 2.0 2.1 k — 2.9 k

ATF temperature 80°C

(176°F)0.4 — 0.9 275 — 375

Rear vehicle speed sensor B55 24Vehicle stopped 0

450 — 650

Vehicle speed at least 20

km/h (12 MPH)More than 1 (AC range)

Front vehicle speed sensor B55 18Vehicle stopped 0

450 — 650

Vehicle speed at least 20

km/h (12 MPH)More than 1 (AC range)

Torque converter turbine

speed sensorB55 8Engine idling after warm-

up (D range)0

450 — 650

Engine idling after warm-

up (N range)More than 1 (AC range)

Vehicle speed output signal B56 17Vehicle speed at most 10

km/h (6 MPH)Less than 1 ←

→ More than 4—

Engine speed signal B55 17Ignition switch ON (with

engine OFF)More than 10.5

—

Ignition switch ON (with

engine ON)8 — 11

Cruise set signal B55 22When cruise control is set

(SET lamp ON)Less than 1

—

When cruise control is not

set (SET lamp OFF)More than 6.5

Torque control signal 1 B56 5Ignition switch ON (with

engine ON)More than 4 —

Torque control signal 2 B56 14Ignition switch ON (with

engine ON)More than 4 —

Torque control cut signal B55 10Ignition switch ON

(After engine is warmed-up)8—

Intake manifold pressure

signalB54 1 Engine idling after warm-up 0.4 — 1.6 —

Shift solenoid 1 B54 221st or 4th gear More than 9

10 — 16

2nd or 3rd gear Less than 1

Shift solenoid 2 B54 51st or 2nd gear More than 9

10 — 16

3rd or 4th gear Less than 1 Check with ignition switch ON.

ContentConnector

No.Terminal No. Measuring conditions Voltage (V)Resistance

to chassis

ground (Ω)