lock SUBARU FORESTER 2004 Service Manual PDF

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 462 of 2870

SL-42

SECURITY AND LOCK

Keyless Transmitter

Page 463 of 2870

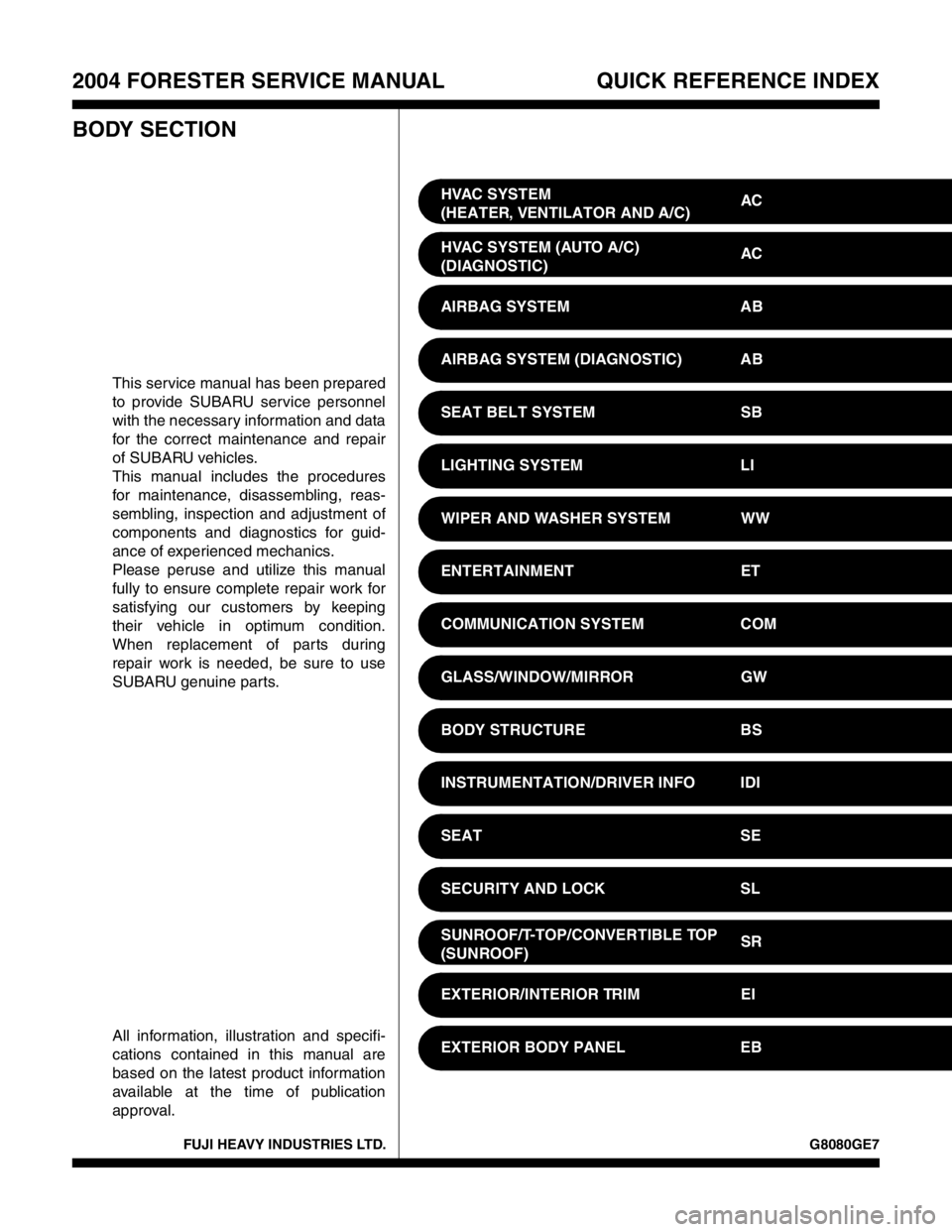

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 475 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 501 of 2870

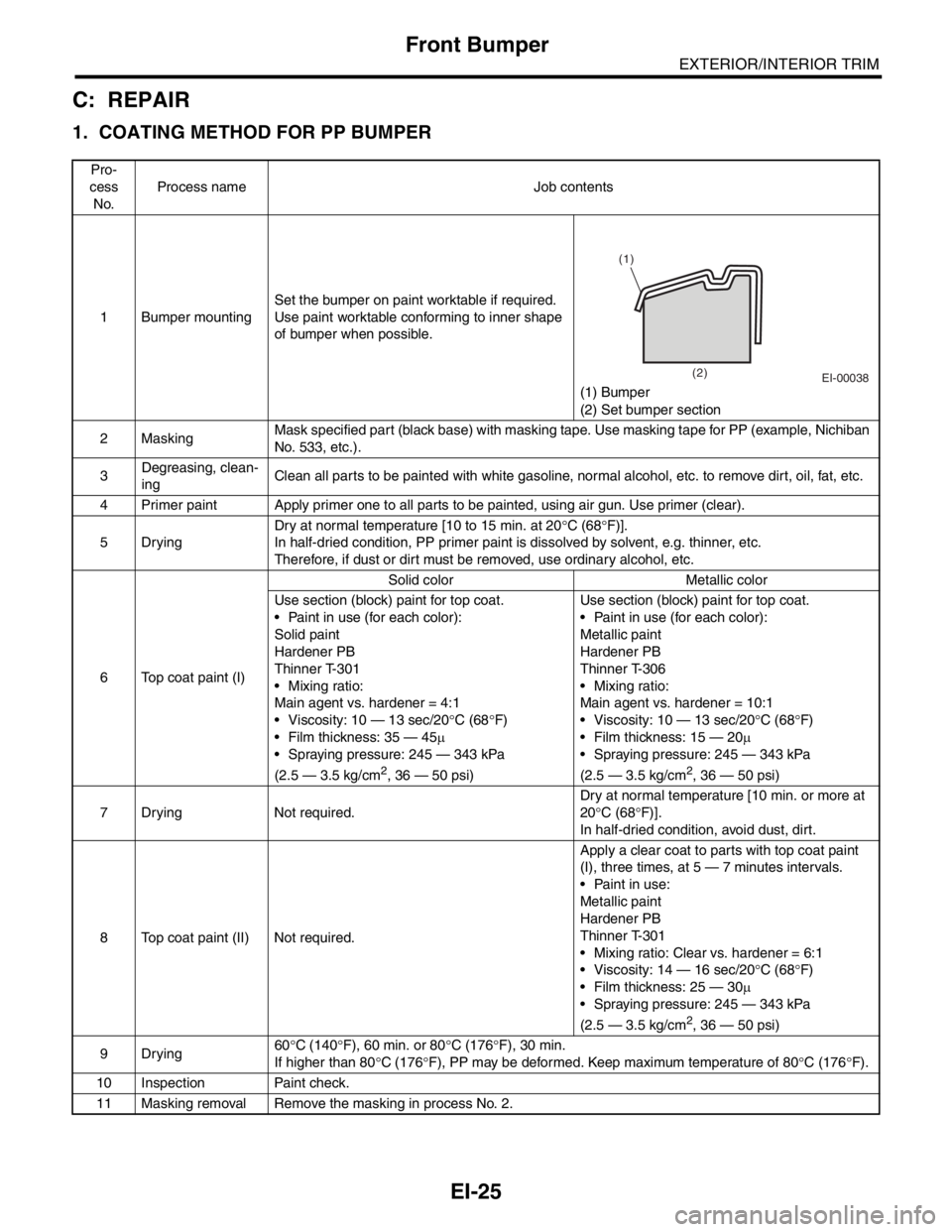

EI-25

EXTERIOR/INTERIOR TRIM

Front Bumper

C: REPAIR

1. COATING METHOD FOR PP BUMPER

Pro-

cess

No.Process name Job contents

1 Bumper mountingSet the bumper on paint worktable if required.

Use paint worktable conforming to inner shape

of bumper when possible.

(1) Bumper

(2) Set bumper section

2MaskingMask specified part (black base) with masking tape. Use masking tape for PP (example, Nichiban

No. 533, etc.).

3Degreasing, clean-

ingClean all parts to be painted with white gasoline, normal alcohol, etc. to remove dirt, oil, fat, etc.

4 Primer paint Apply primer one to all parts to be painted, using air gun. Use primer (clear).

5DryingDry at normal temperature [10 to 15 min. at 20°C (68°F)].

In half-dried condition, PP primer paint is dissolved by solvent, e.g. thinner, etc.

Therefore, if dust or dirt must be removed, use ordinary alcohol, etc.

6 Top coat paint (I)Solid color Metallic color

Use section (block) paint for top coat.

Paint in use (for each color):

Solid paint

Hardener PB

Thinner T-301

Mixing ratio:

Main agent vs. hardener = 4:1

Viscosity: 10 — 13 sec/20°C (68°F)

Film thickness: 35 — 45µ

Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm

2, 36 — 50 psi)Use section (block) paint for top coat.

Paint in use (for each color):

Metallic paint

Hardener PB

Thinner T-306

Mixing ratio:

Main agent vs. hardener = 10:1

Viscosity: 10 — 13 sec/20°C (68°F)

Film thickness: 15 — 20µ

Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

7 Drying Not required.Dry at normal temperature [10 min. or more at

20°C (68°F)].

In half-dried condition, avoid dust, dirt.

8 Top coat paint (II) Not required.Apply a clear coat to parts with top coat paint

(I), three times, at 5 — 7 minutes intervals.

Paint in use:

Metallic paint

Hardener PB

Thinner T-301

Mixing ratio: Clear vs. hardener = 6:1

Viscosity: 14 — 16 sec/20°C (68°F)

Film thickness: 25 — 30µ

Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm

2, 36 — 50 psi)

9Drying60°C (140°F), 60 min. or 80°C (176°F), 30 min.

If higher than 80°C (176°F), PP may be deformed. Keep maximum temperature of 80°C (176°F).

10 Inspection Paint check.

11 Masking removal Remove the masking in process No. 2.

EI-00038

(1)

(2)

Page 505 of 2870

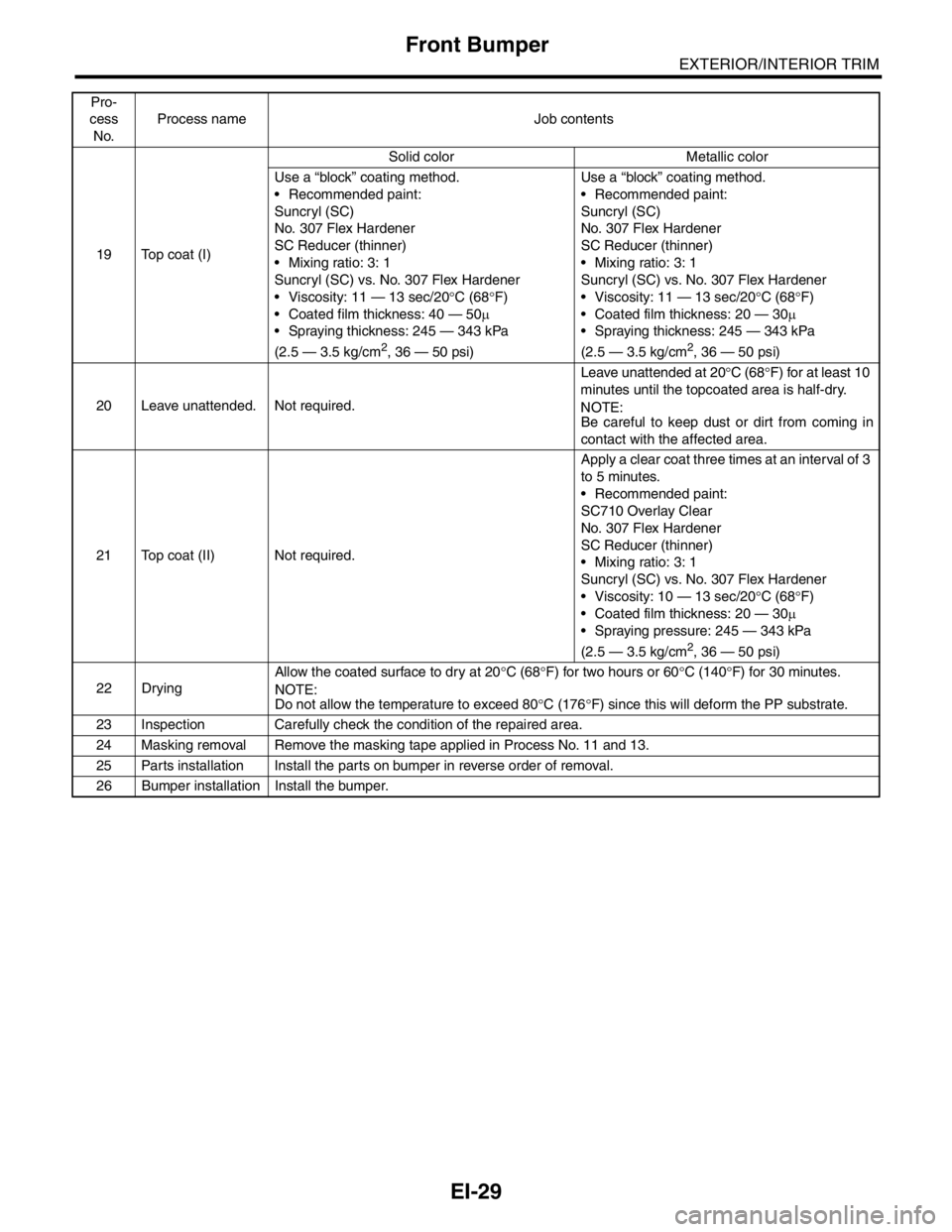

EI-29

EXTERIOR/INTERIOR TRIM

Front Bumper

19 Top coat (I)Solid color Metallic color

Use a “block” coating method.

Recommended paint:

Suncryl (SC)

No. 307 Flex Hardener

SC Reducer (thinner)

Mixing ratio: 3: 1

Suncryl (SC) vs. No. 307 Flex Hardener

Viscosity: 11 — 13 sec/20°C (68°F)

Coated film thickness: 40 — 50µ

Spraying thickness: 245 — 343 kPa

(2.5 — 3.5 kg/cm

2, 36 — 50 psi)Use a “block” coating method.

Recommended paint:

Suncryl (SC)

No. 307 Flex Hardener

SC Reducer (thinner)

Mixing ratio: 3: 1

Suncryl (SC) vs. No. 307 Flex Hardener

Viscosity: 11 — 13 sec/20°C (68°F)

Coated film thickness: 20 — 30µ

Spraying thickness: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

20 Leave unattended. Not required.Leave unattended at 20°C (68°F) for at least 10

minutes until the topcoated area is half-dry.

N

OTE:

Be careful to keep dust or dirt from coming in

contact with the affected area.

21 Top coat (II) Not required.Apply a clear coat three times at an interval of 3

to 5 minutes.

Recommended paint:

SC710 Overlay Clear

No. 307 Flex Hardener

SC Reducer (thinner)

Mixing ratio: 3: 1

Suncryl (SC) vs. No. 307 Flex Hardener

Viscosity: 10 — 13 sec/20°C (68°F)

Coated film thickness: 20 — 30µ

Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm

2, 36 — 50 psi)

22 DryingAllow the coated surface to dry at 20°C (68°F) for two hours or 60°C (140°F) for 30 minutes.

NOTE:

Do not allow the temperature to exceed 80°C (176°F) since this will deform the PP substrate.

23 Inspection Carefully check the condition of the repaired area.

24 Masking removal Remove the masking tape applied in Process No. 11 and 13.

25 Parts installation Install the parts on bumper in reverse order of removal.

26 Bumper installation Install the bumper. Pro-

cess

No.Process name Job contents

Page 527 of 2870

EI-51

EXTERIOR/INTERIOR TRIM

Instrument Panel Center Compartment

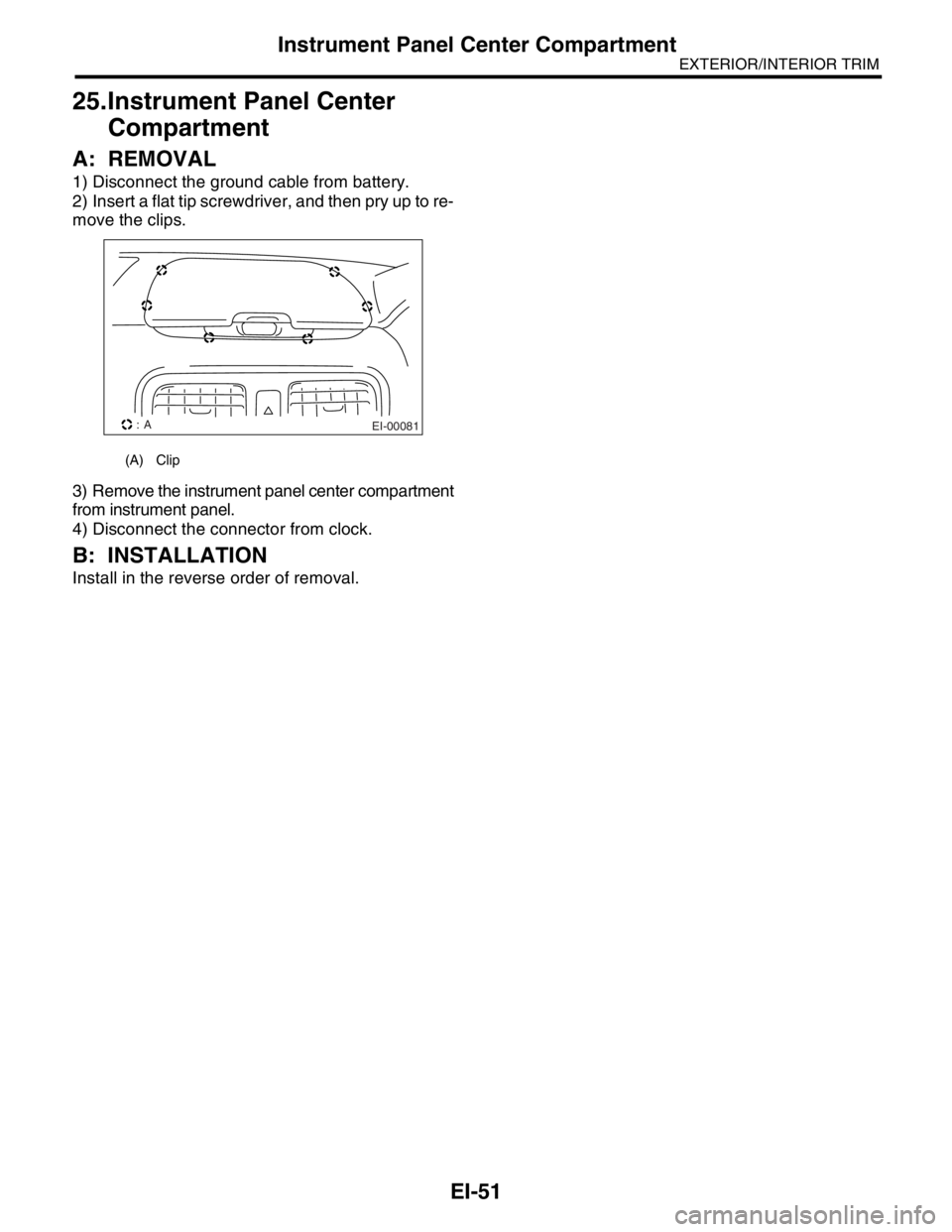

25.Instrument Panel Center

Compartment

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Insert a flat tip screwdriver, and then pry up to re-

move the clips.

3) Remove the instrument panel center compartment

from instrument panel.

4) Disconnect the connector from clock.

B: INSTALLATION

Install in the reverse order of removal.

(A) Clip

EI-00081: A

Page 529 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 539 of 2870

EB-9

EXTERIOR BODY PANEL

Front Hood Panel

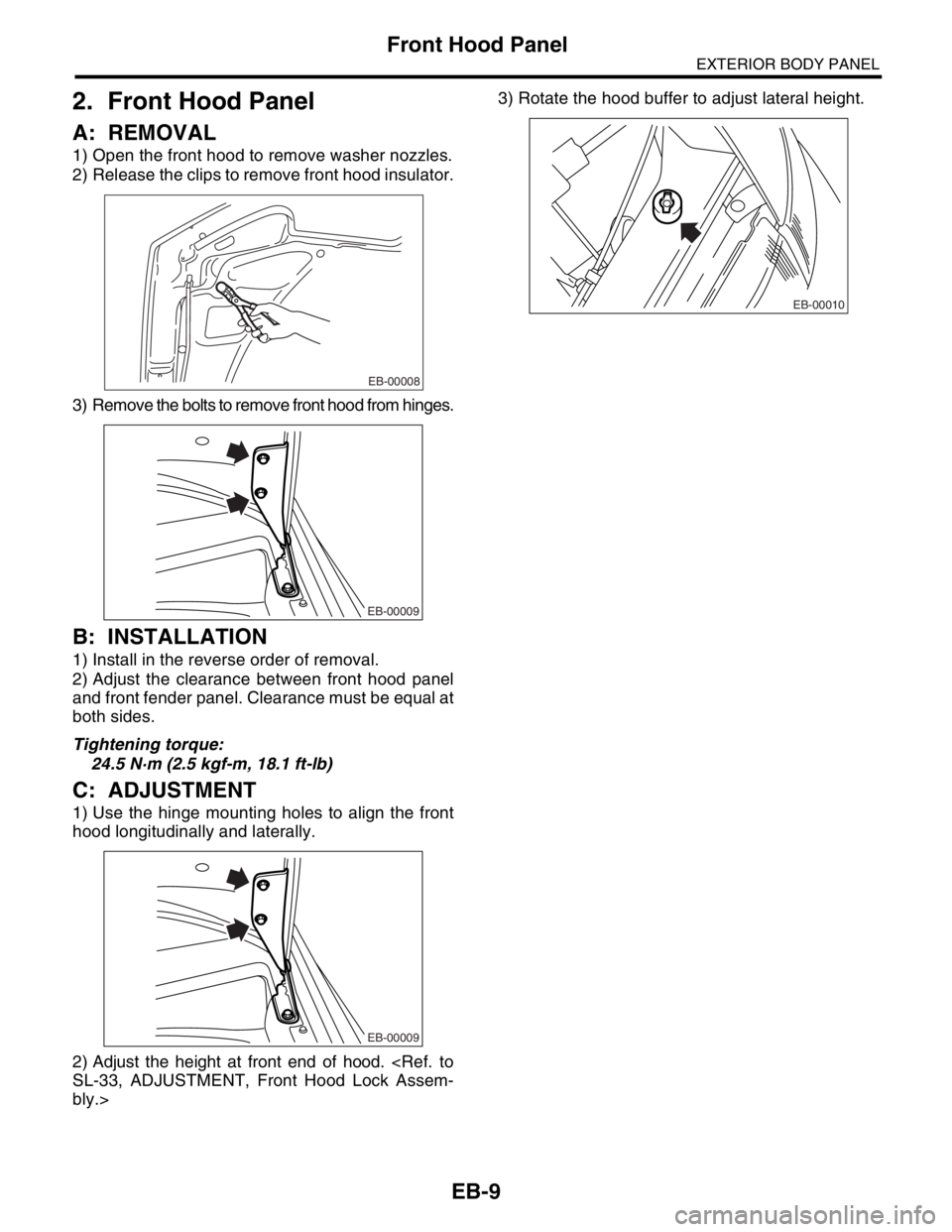

2. Front Hood Panel

A: REMOVAL

1) Open the front hood to remove washer nozzles.

2) Release the clips to remove front hood insulator.

3) Remove the bolts to remove front hood from hinges.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Adjust the clearance between front hood panel

and front fender panel. Clearance must be equal at

both sides.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

C: ADJUSTMENT

1) Use the hinge mounting holes to align the front

hood longitudinally and laterally.

2) Adjust the height at front end of hood.

bly.>3) Rotate the hood buffer to adjust lateral height.

EB-00008

EB-00009

EB-00009

EB-00010

Page 541 of 2870

EB-11

EXTERIOR BODY PANEL

Front Door Panel

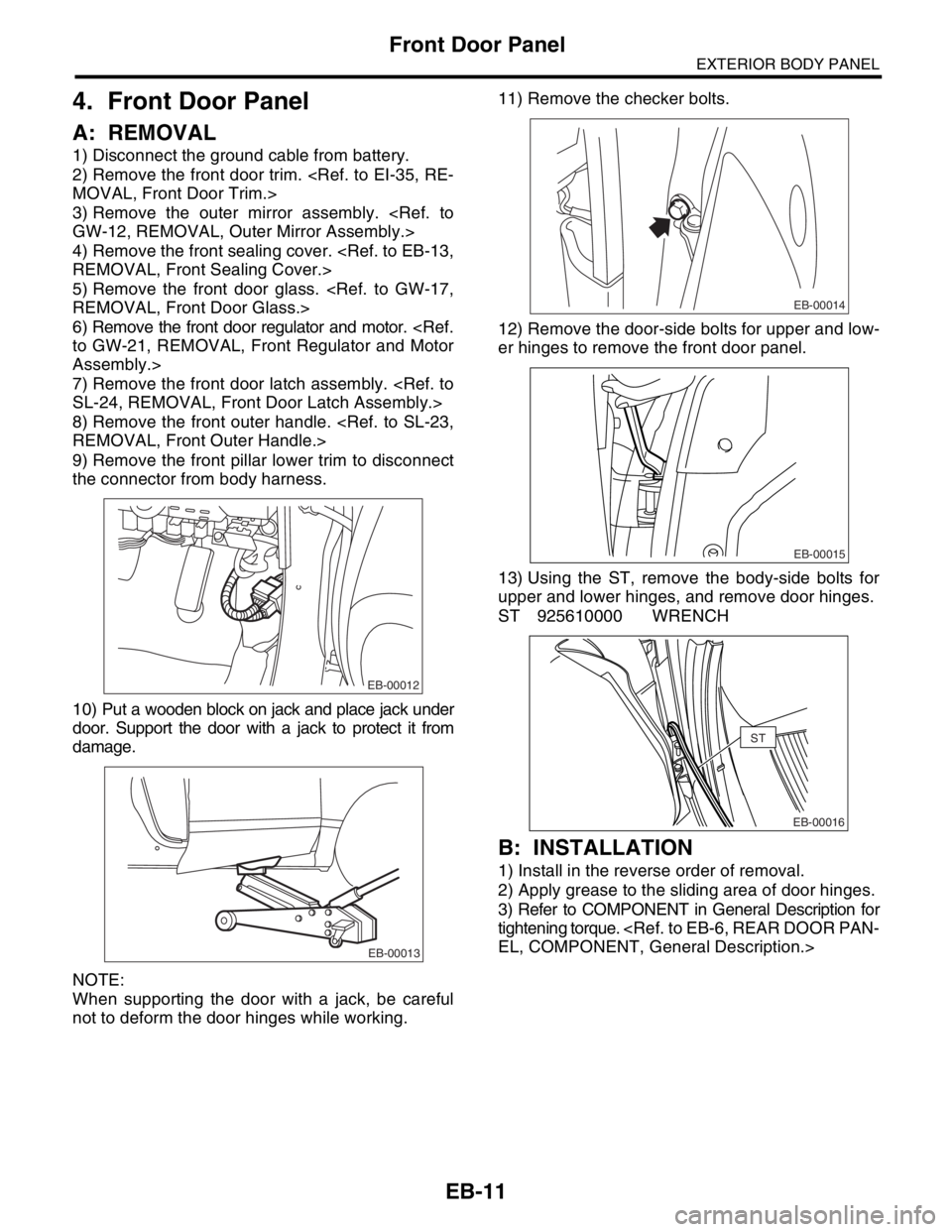

4. Front Door Panel

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the front door trim.

3) Remove the outer mirror assembly.

4) Remove the front sealing cover.

5) Remove the front door glass.

6) Remove the front door regulator and motor.

Assembly.>

7) Remove the front door latch assembly.

8) Remove the front outer handle.

9) Remove the front pillar lower trim to disconnect

the connector from body harness.

10) Put a wooden block on jack and place jack under

door. Support the door with a jack to protect it from

damage.

NOTE:

When supporting the door with a jack, be careful

not to deform the door hinges while working.11) Remove the checker bolts.

12) Remove the door-side bolts for upper and low-

er hinges to remove the front door panel.

13) Using the ST, remove the body-side bolts for

upper and lower hinges, and remove door hinges.

ST 925610000 WRENCH

B: INSTALLATION

1) Install in the reverse order of removal.

2) Apply grease to the sliding area of door hinges.

3) Refer to COMPONENT in General Description for

tightening torque.

EB-00012

EB-00013

EB-00014

EB-00015

EB-00016

ST

Page 544 of 2870

EB-14

EXTERIOR BODY PANEL

Rear Door Panel

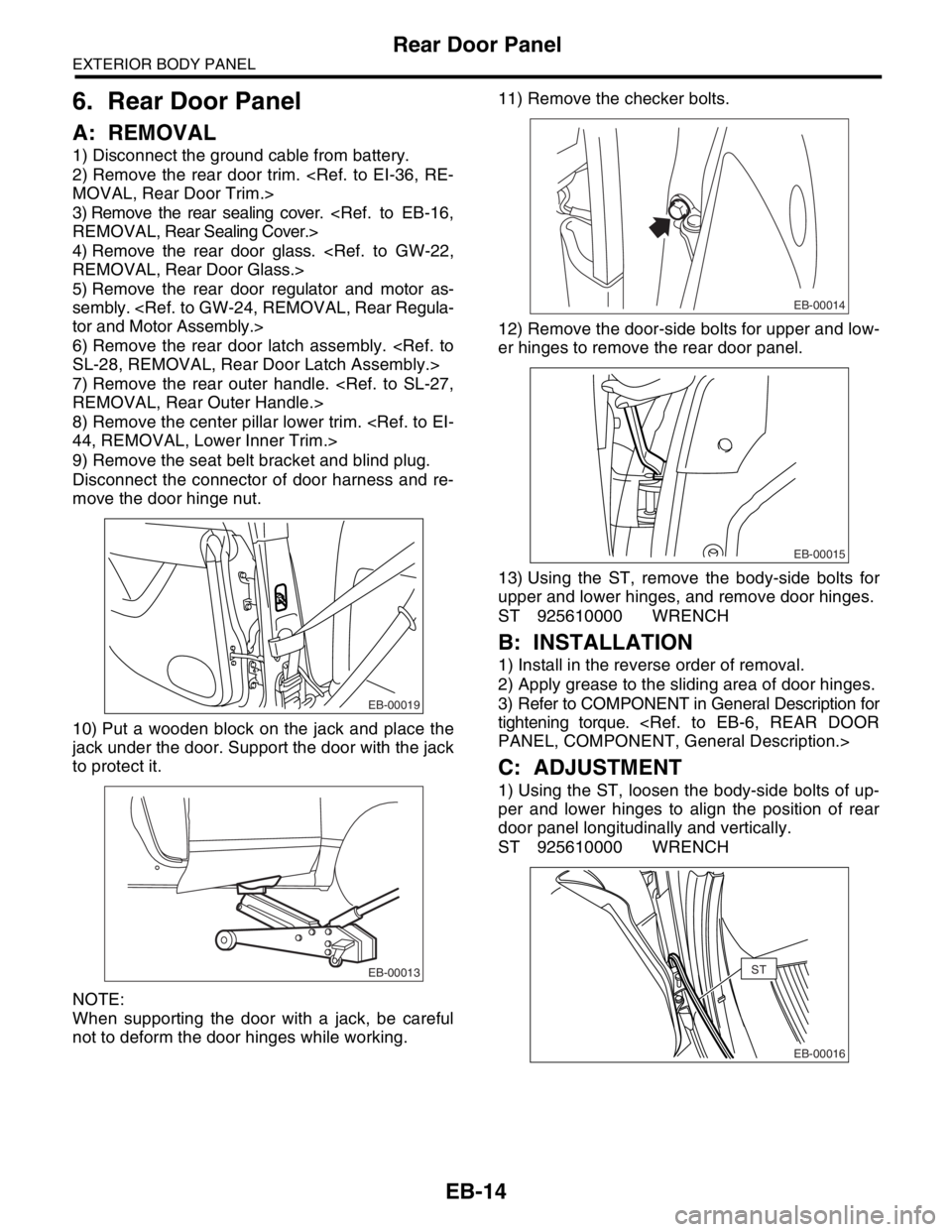

6. Rear Door Panel

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the rear door trim.

3) Remove the rear sealing cover.

4) Remove the rear door glass.

5) Remove the rear door regulator and motor as-

sembly.

6) Remove the rear door latch assembly.

7) Remove the rear outer handle.

8) Remove the center pillar lower trim.

9) Remove the seat belt bracket and blind plug.

Disconnect the connector of door harness and re-

move the door hinge nut.

10) Put a wooden block on the jack and place the

jack under the door. Support the door with the jack

to protect it.

NOTE:

When supporting the door with a jack, be careful

not to deform the door hinges while working.11) Remove the checker bolts.

12) Remove the door-side bolts for upper and low-

er hinges to remove the rear door panel.

13) Using the ST, remove the body-side bolts for

upper and lower hinges, and remove door hinges.

ST 925610000 WRENCH

B: INSTALLATION

1) Install in the reverse order of removal.

2) Apply grease to the sliding area of door hinges.

3) Refer to COMPONENT in General Description for

tightening torque.

C: ADJUSTMENT

1) Using the ST, loosen the body-side bolts of up-

per and lower hinges to align the position of rear

door panel longitudinally and vertically.

ST 925610000 WRENCH

EB-00019

EB-00013

EB-00014

EB-00015

EB-00016

ST