lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 750 of 2870

PM-13

PERIODIC MAINTENANCE SERVICE

Timing Belt

7. Timing Belt

A: REPLACEMENT

1. NON-TURBO MODEL

1) Remove the radiator fan and air conditioner fan.

2) Shield the radiator from any damage using card-

board and blanket.

3) Remove the V-belt cover.

4) Remove the V-belts.

5) Remove the air conditioning compressor V-belt

tensioner.

6) To lock the crankshaft, use ST. Remove the pul-

ley bolt.

ST 499977100 CRANK PULLEY WRENCH

7) Remove the crank pulley.

8) Remove the left side belt cover.

9) Remove the front timing belt cover.

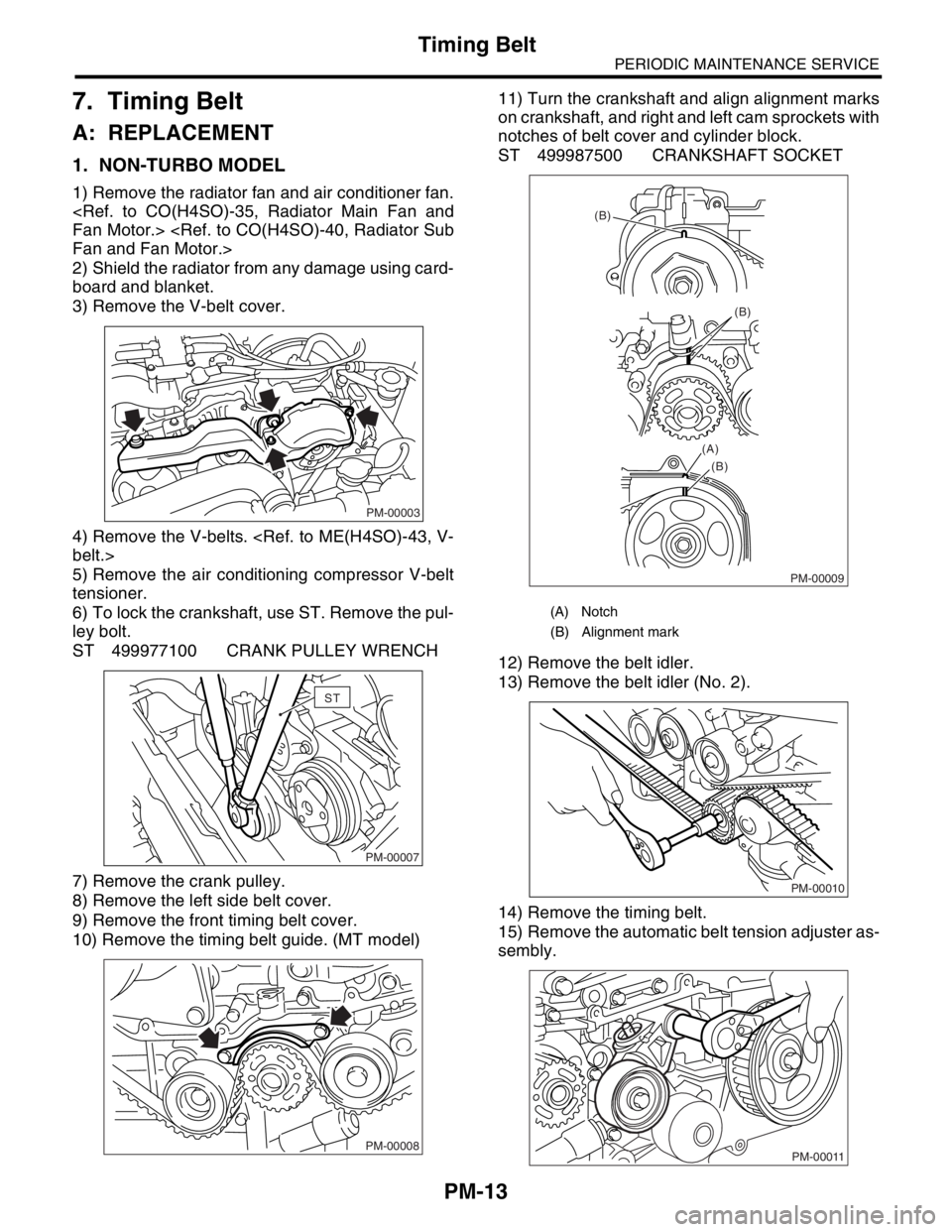

10) Remove the timing belt guide. (MT model)11) Turn the crankshaft and align alignment marks

on crankshaft, and right and left cam sprockets with

notches of belt cover and cylinder block.

ST 499987500 CRANKSHAFT SOCKET

12) Remove the belt idler.

13) Remove the belt idler (No. 2).

14) Remove the timing belt.

15) Remove the automatic belt tension adjuster as-

sembly.

PM-00003

PM-00007

ST

PM-00008

(A) Notch

(B) Alignment mark

PM-00009

(B)

(B)

(B) (A)

PM-00010

PM-00011

Page 751 of 2870

PM-14

PERIODIC MAINTENANCE SERVICE

Timing Belt

16) Install in the reverse order of removal.

2. TURBO MODEL

1) Remove the radiator fan and air conditioner fan.

2) Protect the radiator with cardboard and blanket.

3) Remove the V-belts.

4) Remove the air conditioning compressor drive

belt tensioner.

5) To lock the crankshaft use ST. Remove the pul-

ley bolt.

ST 499977300 CRANK PULLEY WRENCH

6) Remove the crank pulley.

7) Remove the air conditioning compressor drive

belt tensioner.

8) Remove the belt cover (LH).

9) Remove the belt cover (RH).

10) Remove the front belt cover.11) Remove the timing belt guide. (MT model)

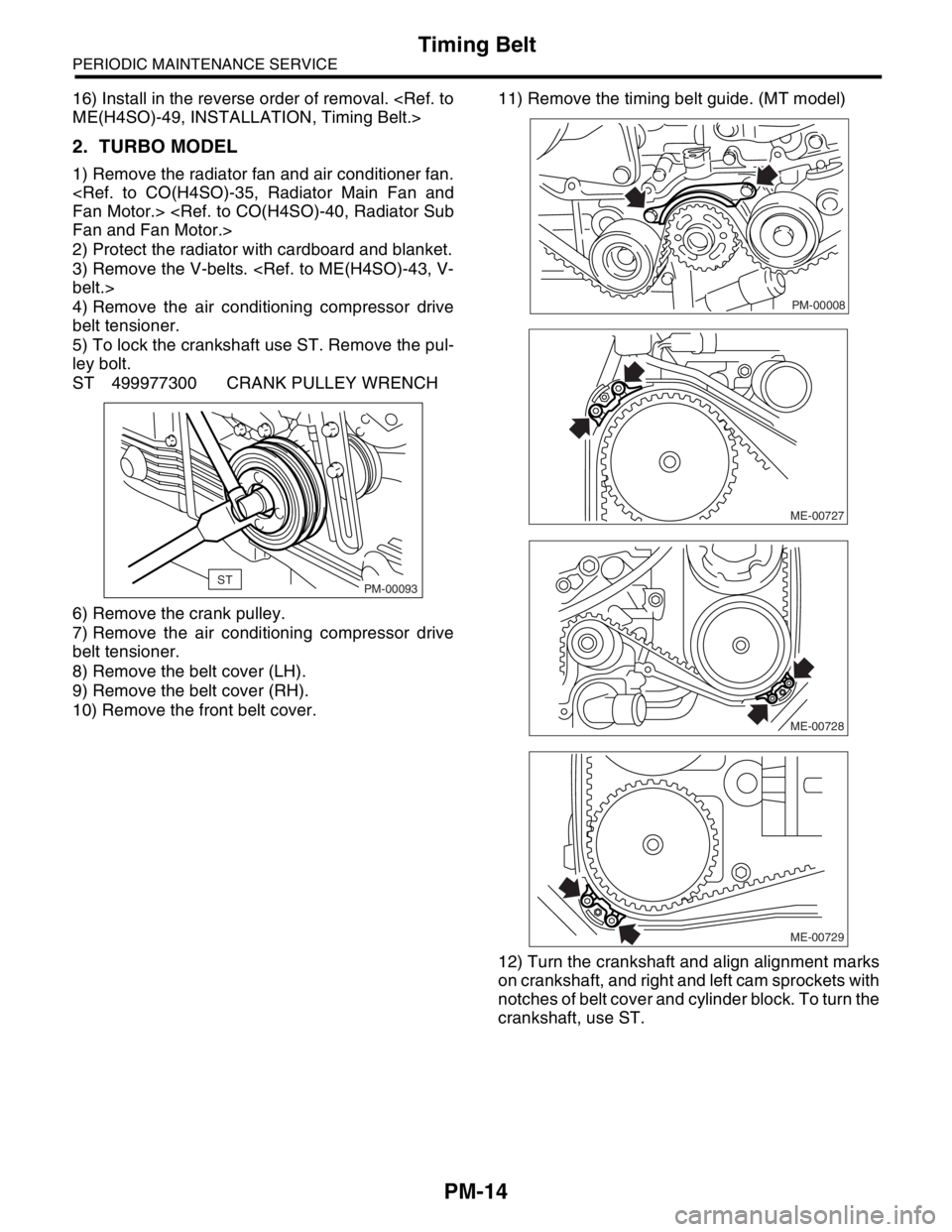

12) Turn the crankshaft and align alignment marks

on crankshaft, and right and left cam sprockets with

notches of belt cover and cylinder block. To turn the

crankshaft, use ST.

STPM-00093

PM-00008

ME-00727

ME-00728

ME-00729

Page 762 of 2870

PM-25

PERIODIC MAINTENANCE SERVICE

Hill-holder System

15.Hill-holder System

A: INSPECTION AND ADJUSTMENT

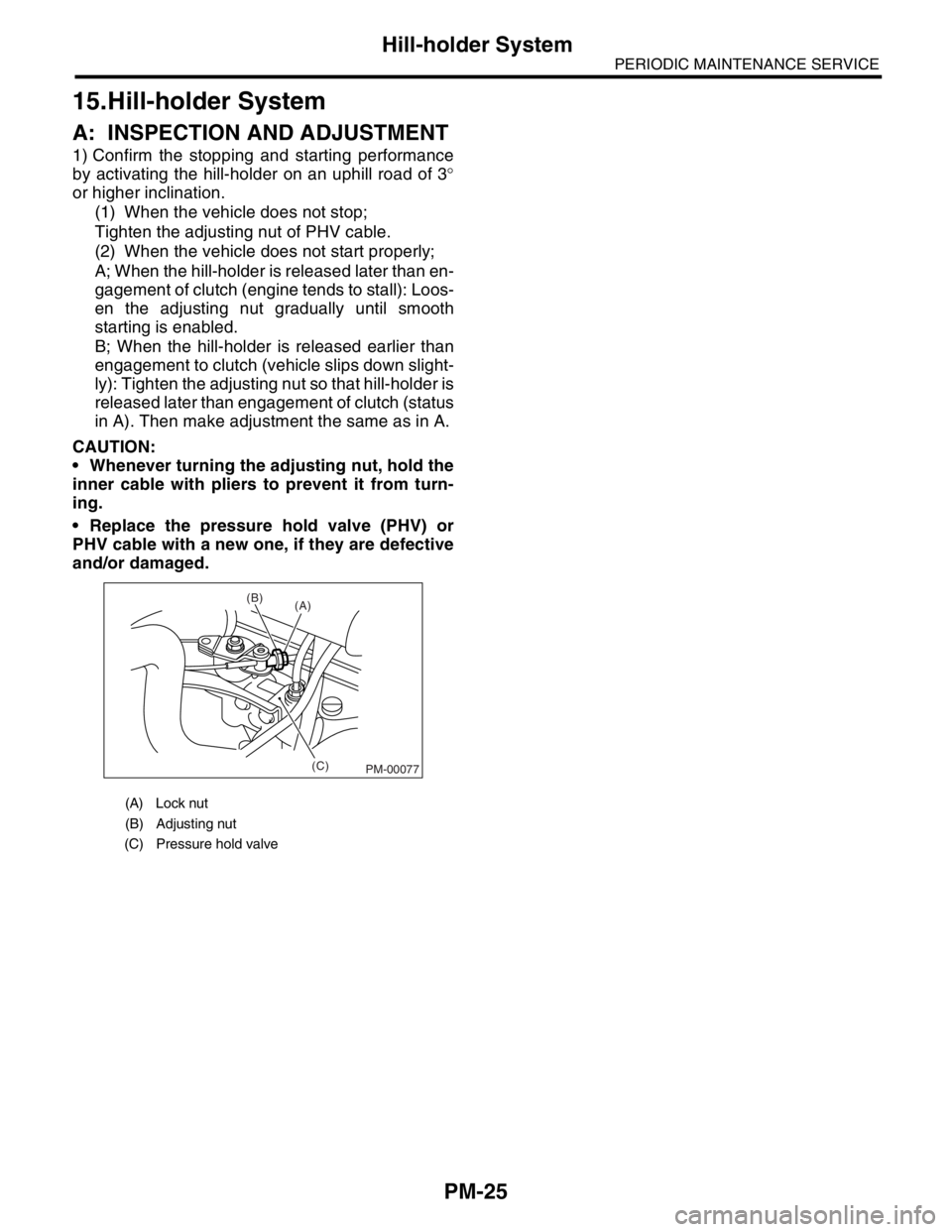

1) Confirm the stopping and starting performance

by activating the hill-holder on an uphill road of 3°

or higher inclination.

(1) When the vehicle does not stop;

Tighten the adjusting nut of PHV cable.

(2) When the vehicle does not start properly;

A; When the hill-holder is released later than en-

gagement of clutch (engine tends to stall): Loos-

en the adjusting nut gradually until smooth

starting is enabled.

B; When the hill-holder is released earlier than

engagement to clutch (vehicle slips down slight-

ly): Tighten the adjusting nut so that hill-holder is

released later than engagement of clutch (status

in A). Then make adjustment the same as in A.

CAUTION:

Whenever turning the adjusting nut, hold the

inner cable with pliers to prevent it from turn-

ing.

Replace the pressure hold valve (PHV) or

PHV cable with a new one, if they are defective

and/or damaged.

(A) Lock nut

(B) Adjusting nut

(C) Pressure hold valve

(C) (B)

(A)

PM-00077

Page 768 of 2870

PM-31

PERIODIC MAINTENANCE SERVICE

Brake Line

(4) If there is no free play between clevis pin

and clevis, turn the brake switch adjusting nut

until the clearance between stopper and screw

of brake switch becomes 0.3 mm (0.012 in).

3) Check the pedal stroke.

While the engine is idling, depress the brake pedal

with a 490 N (50 kgf, 110 lb) load and measure the

distance between brake pedal and steering wheel.

With the brake pedal released, measure the dis-

tance between pedal and steering wheel again.

The difference between the two measurements

must be less than specified value. If the distance is

more than specified value, there is possibility of air

inside the hydraulic unit.

Brake pedal reserve distance: A

For Australia model

105 mm (4.13 in)/ 490 N (50 kgf , 110 lb) or less

Except for Australia model

90 mm (3.54 in)/ 490 N (50 kgf , 110 lb) or less4) Check to see if air is in the hydraulic brake line

by the feel of pedal operation. If air appears to exist

in the line, bleed it from the system.

5) Check for even operation of all brakes, using a

brake tester or by driving the vehicle for a short dis-

tance on a straight road.

2. BRAKE SERVO SYSTEM

1) With the engine off, depress the brake pedal

several times applying the same pedal force: Make

sure the travel distance should not change.

2) With the brake pedal depressed, start the en-

gine: Make sure the pedal should move slightly to-

ward the floor.

3) With the brake pedal depressed, stop the engine

and keep the pedal depressed for 30 seconds:

Make sure the pedal height should not change.

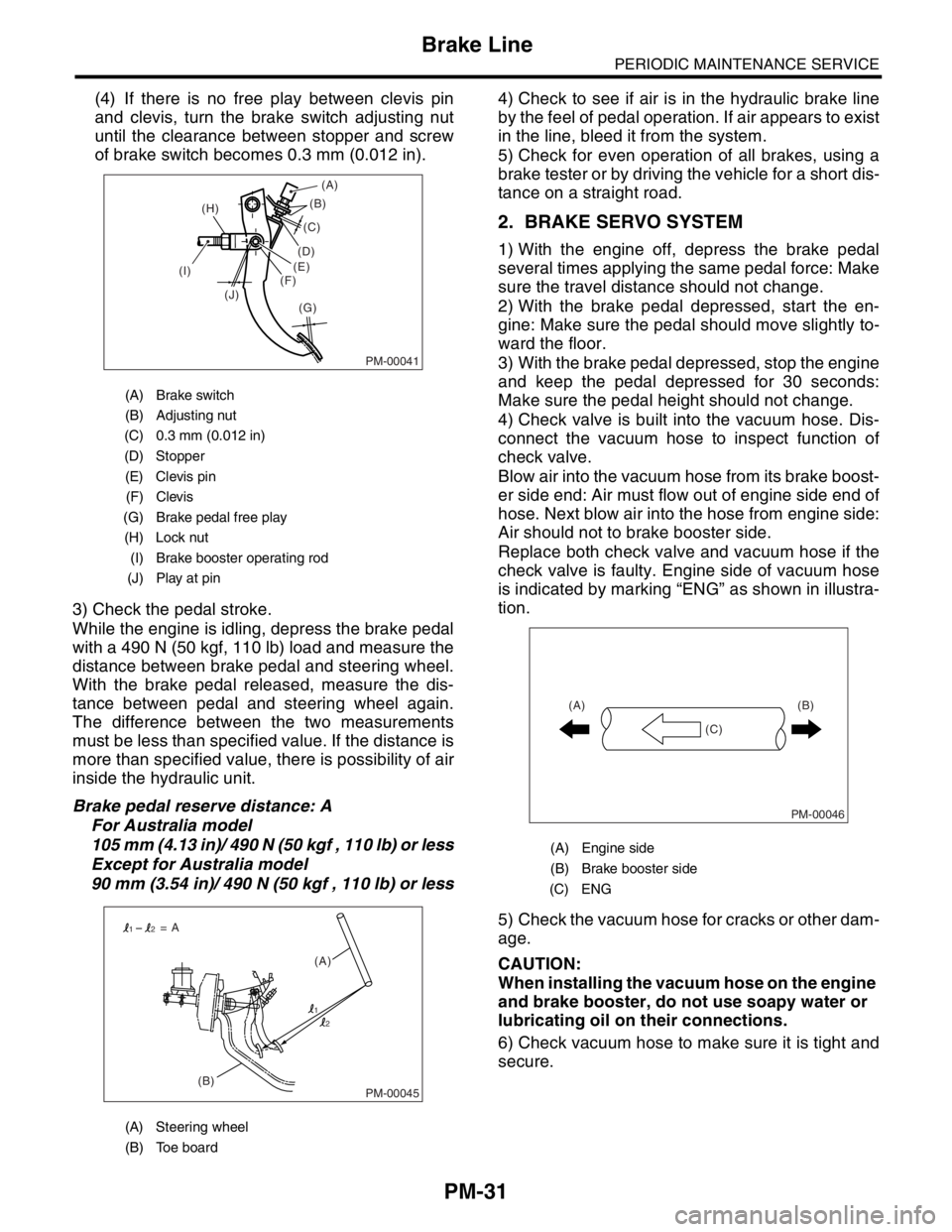

4) Check valve is built into the vacuum hose. Dis-

connect the vacuum hose to inspect function of

check valve.

Blow air into the vacuum hose from its brake boost-

er side end: Air must flow out of engine side end of

hose. Next blow air into the hose from engine side:

Air should not to brake booster side.

Replace both check valve and vacuum hose if the

check valve is faulty. Engine side of vacuum hose

is indicated by marking “ENG” as shown in illustra-

tion.

5) Check the vacuum hose for cracks or other dam-

age.

CAUTION:

When installing the vacuum hose on the engine

and brake booster, do not use soapy water or

lubricating oil on their connections.

6) Check vacuum hose to make sure it is tight and

secure.

(A) Brake switch

(B) Adjusting nut

(C) 0.3 mm (0.012 in)

(D) Stopper

(E) Clevis pin

(F) Clevis

(G) Brake pedal free play

(H) Lock nut

(I) Brake booster operating rod

(J) Play at pin

(A) Steering wheel

(B) Toe board

PM-00041

(B)

(G) (H)

(I)

(J)(C)

(D)

(E)

(F)(A)

PM-00045(B)(A) = A

1

12

2

(A) Engine side

(B) Brake booster side

(C) ENG

PM-00046

(B)

(C) (A)

Page 772 of 2870

PM-35

PERIODIC MAINTENANCE SERVICE

Brake Linings and Drums

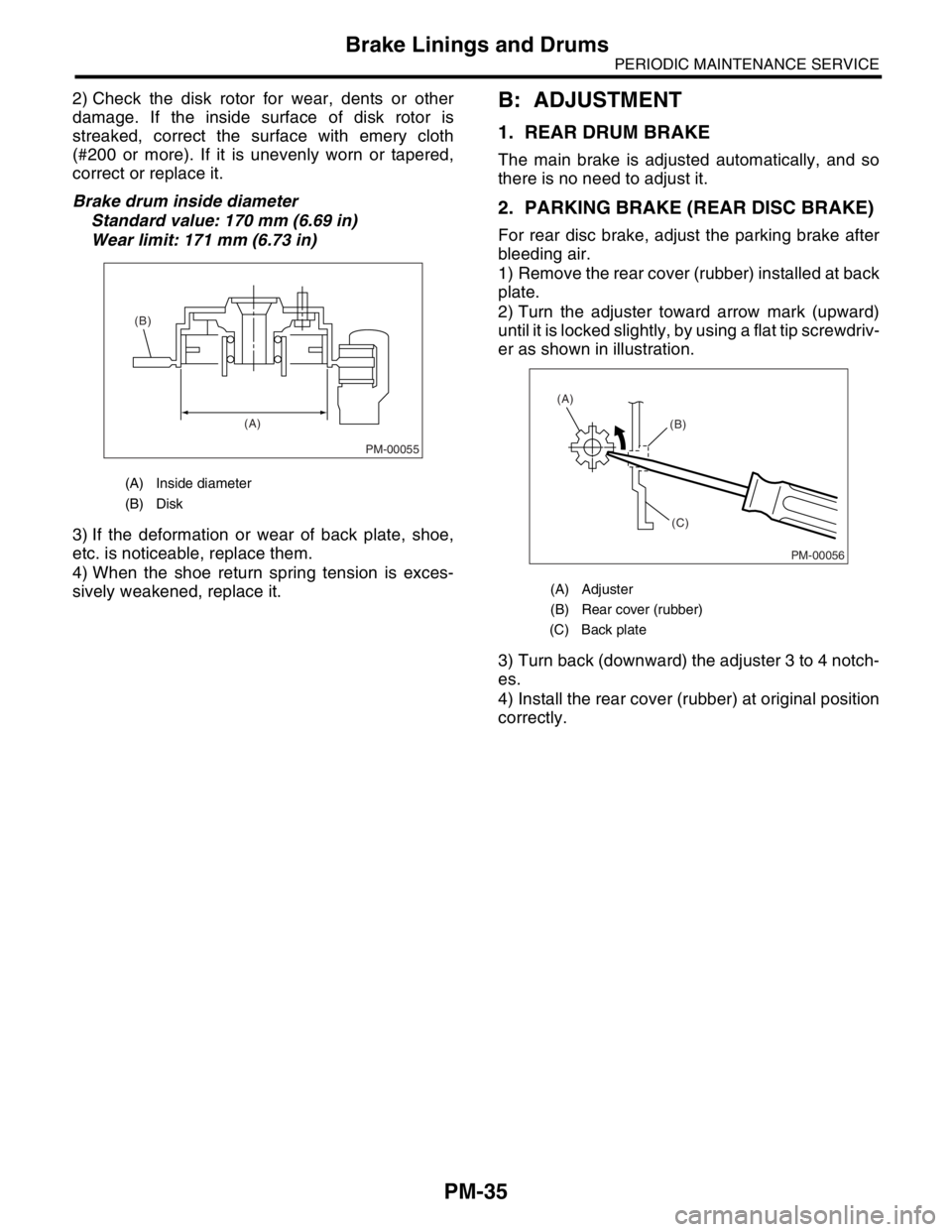

2) Check the disk rotor for wear, dents or other

damage. If the inside surface of disk rotor is

streaked, correct the surface with emery cloth

(#200 or more). If it is unevenly worn or tapered,

correct or replace it.

Brake drum inside diameter

Standard value: 170 mm (6.69 in)

Wear limit: 171 mm (6.73 in)

3) If the deformation or wear of back plate, shoe,

etc. is noticeable, replace them.

4) When the shoe return spring tension is exces-

sively weakened, replace it.B: ADJUSTMENT

1. REAR DRUM BRAKE

The main brake is adjusted automatically, and so

there is no need to adjust it.

2. PARKING BRAKE (REAR DISC BRAKE)

For rear disc brake, adjust the parking brake after

bleeding air.

1) Remove the rear cover (rubber) installed at back

plate.

2) Turn the adjuster toward arrow mark (upward)

until it is locked slightly, by using a flat tip screwdriv-

er as shown in illustration.

3) Turn back (downward) the adjuster 3 to 4 notch-

es.

4) Install the rear cover (rubber) at original position

correctly.

(A) Inside diameter

(B) Disk

PM-00055

(A) (B)

(A) Adjuster

(B) Rear cover (rubber)

(C) Back plate

PM-00056

(B)

(C) (A)

Page 774 of 2870

PM-37

PERIODIC MAINTENANCE SERVICE

Suspension

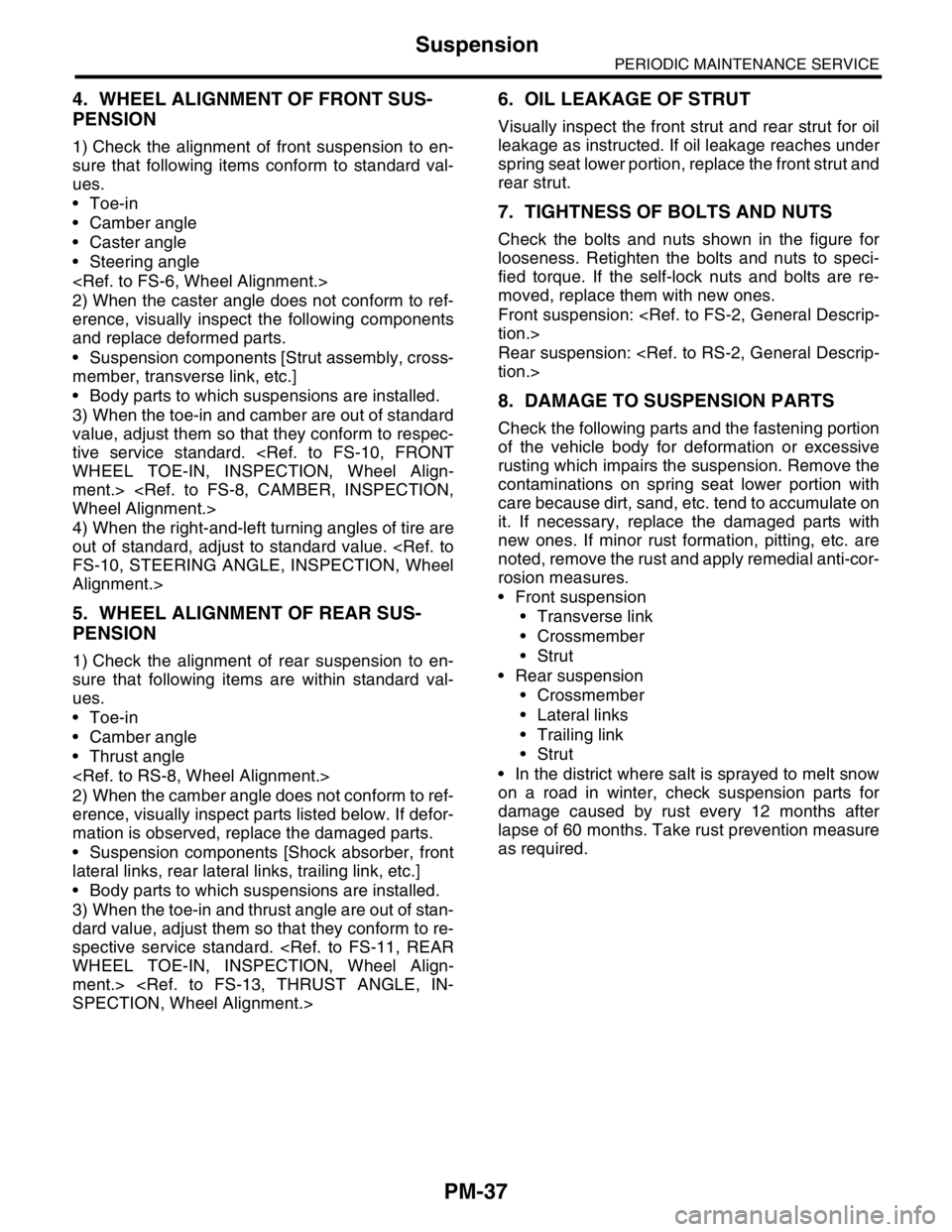

4. WHEEL ALIGNMENT OF FRONT SUS-

PENSION

1) Check the alignment of front suspension to en-

sure that following items conform to standard val-

ues.

Toe-in

Camber angle

Caster angle

Steering angle

2) When the caster angle does not conform to ref-

erence, visually inspect the following components

and replace deformed parts.

Suspension components [Strut assembly, cross-

member, transverse link, etc.]

Body parts to which suspensions are installed.

3) When the toe-in and camber are out of standard

value, adjust them so that they conform to respec-

tive service standard.

ment.>

4) When the right-and-left turning angles of tire are

out of standard, adjust to standard value.

Alignment.>

5. WHEEL ALIGNMENT OF REAR SUS-

PENSION

1) Check the alignment of rear suspension to en-

sure that following items are within standard val-

ues.

Toe-in

Camber angle

Thrust angle

2) When the camber angle does not conform to ref-

erence, visually inspect parts listed below. If defor-

mation is observed, replace the damaged parts.

Suspension components [Shock absorber, front

lateral links, rear lateral links, trailing link, etc.]

Body parts to which suspensions are installed.

3) When the toe-in and thrust angle are out of stan-

dard value, adjust them so that they conform to re-

spective service standard.

ment.>

6. OIL LEAKAGE OF STRUT

Visually inspect the front strut and rear strut for oil

leakage as instructed. If oil leakage reaches under

spring seat lower portion, replace the front strut and

rear strut.

7. TIGHTNESS OF BOLTS AND NUTS

Check the bolts and nuts shown in the figure for

looseness. Retighten the bolts and nuts to speci-

fied torque. If the self-lock nuts and bolts are re-

moved, replace them with new ones.

Front suspension:

Rear suspension:

8. DAMAGE TO SUSPENSION PARTS

Check the following parts and the fastening portion

of the vehicle body for deformation or excessive

rusting which impairs the suspension. Remove the

contaminations on spring seat lower portion with

care because dirt, sand, etc. tend to accumulate on

it. If necessary, replace the damaged parts with

new ones. If minor rust formation, pitting, etc. are

noted, remove the rust and apply remedial anti-cor-

rosion measures.

Front suspension

Transverse link

Crossmember

Strut

Rear suspension

Crossmember

Lateral links

Trailing link

Strut

In the district where salt is sprayed to melt snow

on a road in winter, check suspension parts for

damage caused by rust every 12 months after

lapse of 60 months. Take rust prevention measure

as required.

Page 775 of 2870

PM-38

PERIODIC MAINTENANCE SERVICE

Wheel Bearing

23.Wheel Bearing

A: INSPECTION

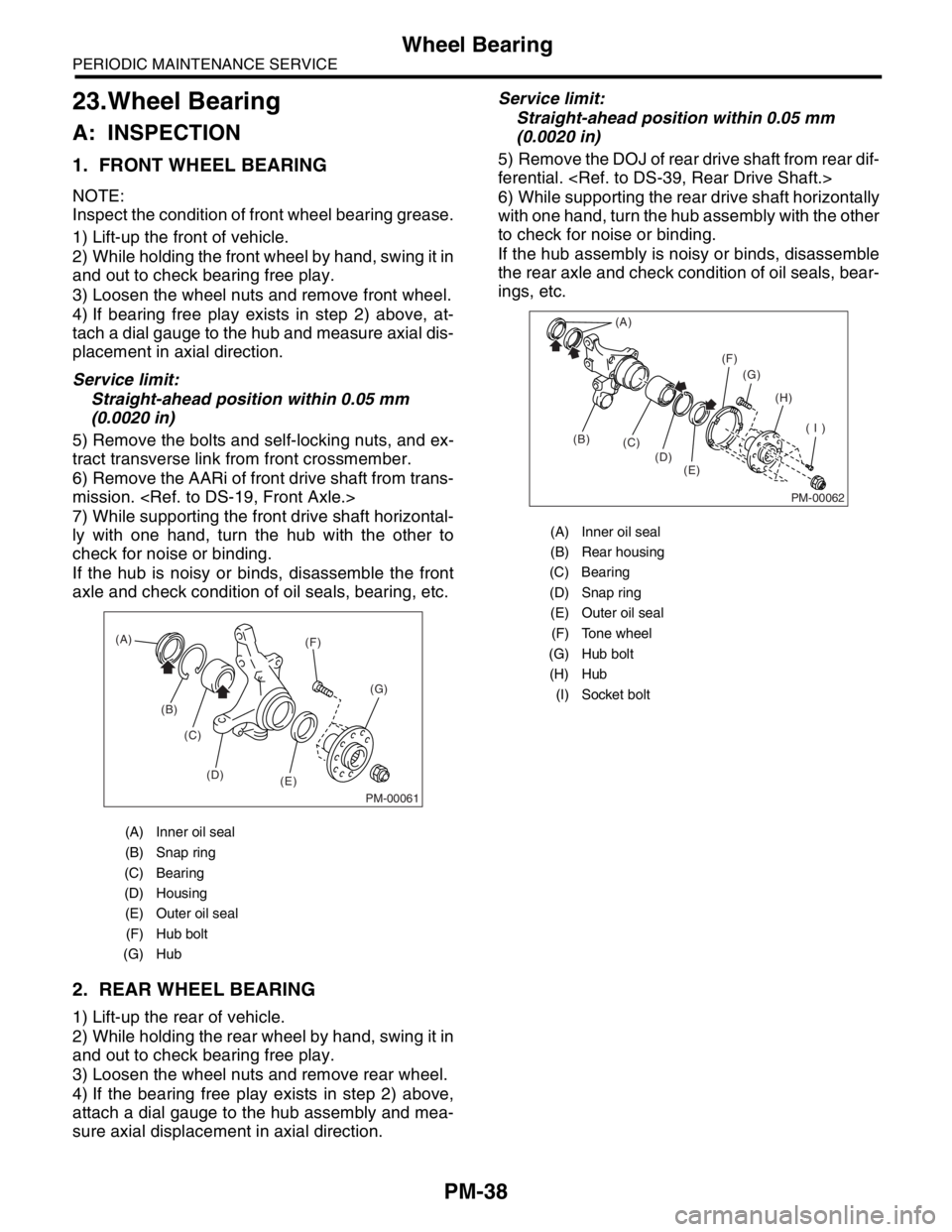

1. FRONT WHEEL BEARING

NOTE:

Inspect the condition of front wheel bearing grease.

1) Lift-up the front of vehicle.

2) While holding the front wheel by hand, swing it in

and out to check bearing free play.

3) Loosen the wheel nuts and remove front wheel.

4) If bearing free play exists in step 2) above, at-

tach a dial gauge to the hub and measure axial dis-

placement in axial direction.

Service limit:

Straight-ahead position within 0.05 mm

(0.0020 in)

5) Remove the bolts and self-locking nuts, and ex-

tract transverse link from front crossmember.

6) Remove the AARi of front drive shaft from trans-

mission.

7) While supporting the front drive shaft horizontal-

ly with one hand, turn the hub with the other to

check for noise or binding.

If the hub is noisy or binds, disassemble the front

axle and check condition of oil seals, bearing, etc.

2. REAR WHEEL BEARING

1) Lift-up the rear of vehicle.

2) While holding the rear wheel by hand, swing it in

and out to check bearing free play.

3) Loosen the wheel nuts and remove rear wheel.

4) If the bearing free play exists in step 2) above,

attach a dial gauge to the hub assembly and mea-

sure axial displacement in axial direction.Service limit:

Straight-ahead position within 0.05 mm

(0.0020 in)

5) Remove the DOJ of rear drive shaft from rear dif-

ferential.

6) While supporting the rear drive shaft horizontally

with one hand, turn the hub assembly with the other

to check for noise or binding.

If the hub assembly is noisy or binds, disassemble

the rear axle and check condition of oil seals, bear-

ings, etc.

(A) Inner oil seal

(B) Snap ring

(C) Bearing

(D) Housing

(E) Outer oil seal

(F) Hub bolt

(G) Hub

PM-00061

(A)

(B)

(C)

(D)

(E)(G) (F)

(A) Inner oil seal

(B) Rear housing

(C) Bearing

(D) Snap ring

(E) Outer oil seal

(F) Tone wheel

(G) Hub bolt

(H) Hub

(I) Socket bolt

PM-00062

(A)

(B)

(C)

(D)

(E)(G)

(H)

( I ) (F)

Page 779 of 2870

PM-42

PERIODIC MAINTENANCE SERVICE

Steering System (Power Steering)

(2) Retighten the adjusting screw to 7.4 N·m

(0.75 kgf-m, 5.4 ft-lb) and back off 25°.

(3) Apply Liquid gasket to at least 1/3 of entire

perimeter of adjusting screw thread.

(4) Install the lock nut. While holding the adjust-

ing screw with a wrench, tighten the lock nut us-

ing ST.

ST 926230000 SPANNER

Tightening torque (Lock nut):

39 N·m (4.0 kgf-m, 29 ft-lb)

Hold the adjusting screw with a wrench to pre-

vent it from turning it, while tightening the lock

nut.

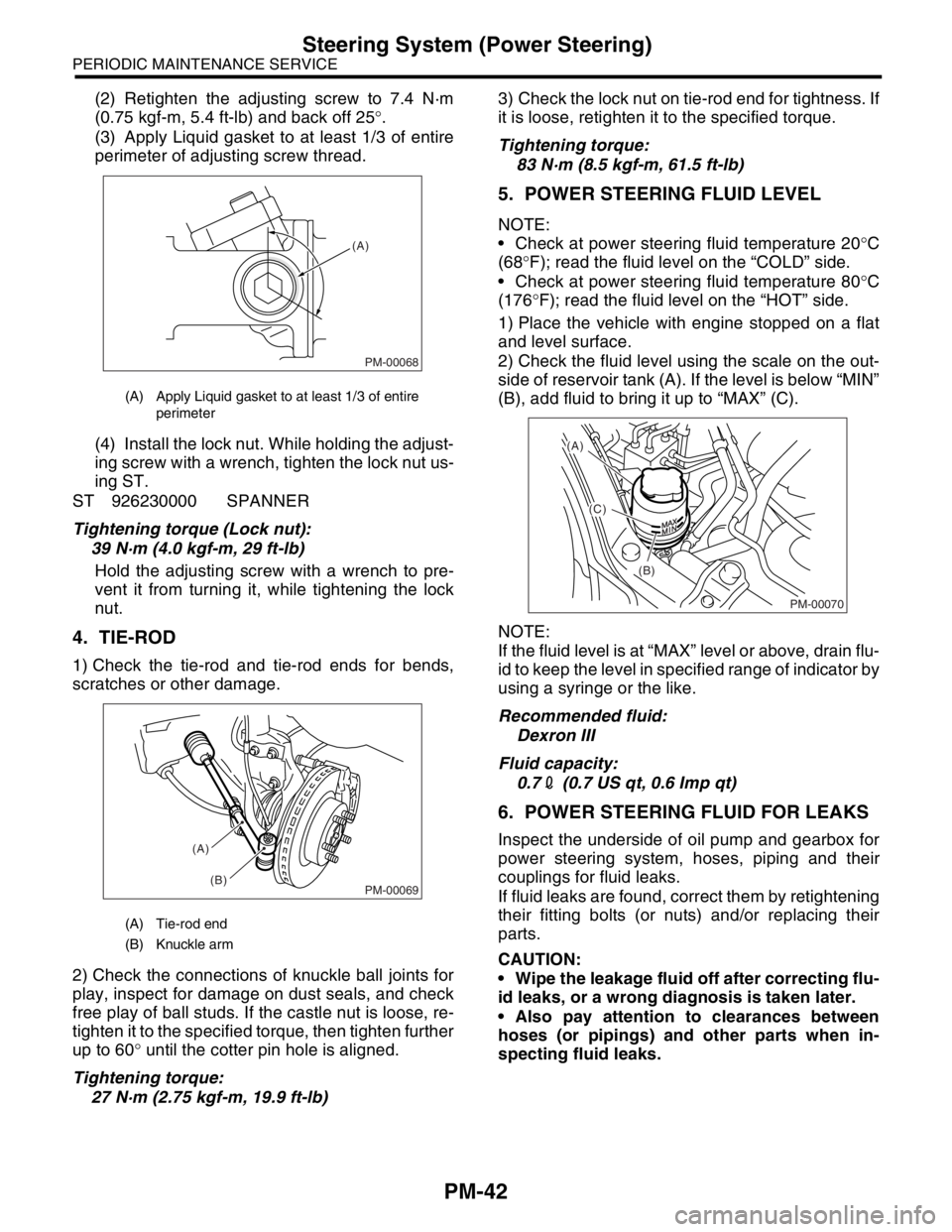

4. TIE-ROD

1) Check the tie-rod and tie-rod ends for bends,

scratches or other damage.

2) Check the connections of knuckle ball joints for

play, inspect for damage on dust seals, and check

free play of ball studs. If the castle nut is loose, re-

tighten it to the specified torque, then tighten further

up to 60° until the cotter pin hole is aligned.

Tightening torque:

27 N·m (2.75 kgf-m, 19.9 ft-lb)3) Check the lock nut on tie-rod end for tightness. If

it is loose, retighten it to the specified torque.

Tightening torque:

83 N·m (8.5 kgf-m, 61.5 ft-lb)

5. POWER STEERING FLUID LEVEL

NOTE:

Check at power steering fluid temperature 20°C

(68°F); read the fluid level on the “COLD” side.

Check at power steering fluid temperature 80°C

(176°F); read the fluid level on the “HOT” side.

1) Place the vehicle with engine stopped on a flat

and level surface.

2) Check the fluid level using the scale on the out-

side of reservoir tank (A). If the level is below “MIN”

(B), add fluid to bring it up to “MAX” (C).

NOTE:

If the fluid level is at “MAX” level or above, drain flu-

id to keep the level in specified range of indicator by

using a syringe or the like.

Recommended fluid:

Dexron III

Fluid capacity:

0.72 (0.7 US qt, 0.6 Imp qt)

6. POWER STEERING FLUID FOR LEAKS

Inspect the underside of oil pump and gearbox for

power steering system, hoses, piping and their

couplings for fluid leaks.

If fluid leaks are found, correct them by retightening

their fitting bolts (or nuts) and/or replacing their

parts.

CAUTION:

Wipe the leakage fluid off after correcting flu-

id leaks, or a wrong diagnosis is taken later.

Also pay attention to clearances between

hoses (or pipings) and other parts when in-

specting fluid leaks.

(A) Apply Liquid gasket to at least 1/3 of entire

perimeter

(A) Tie-rod end

(B) Knuckle arm

PM-00068

(A)

PM-00069

(A)

(B)

PM-00070

(A)

(C)

(B)

Page 808 of 2870

FU(H4SO)-26

FUEL INJECTION (FUEL SYSTEM)

Crankshaft Position Sensor

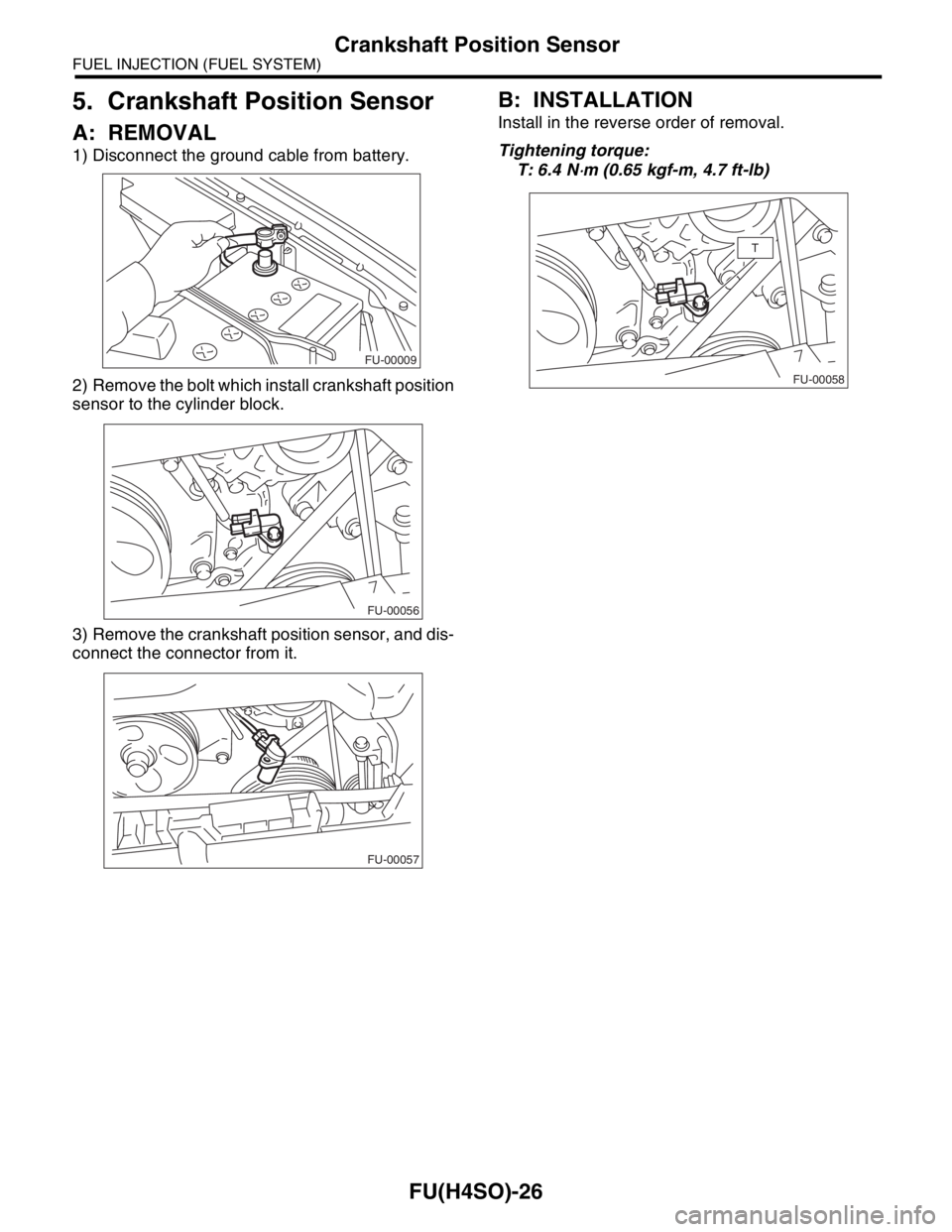

5. Crankshaft Position Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the bolt which install crankshaft position

sensor to the cylinder block.

3) Remove the crankshaft position sensor, and dis-

connect the connector from it.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

T: 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

FU-00009

FU-00056

FU-00057

FU-00058

T

Page 810 of 2870

FU(H4SO)-28

FUEL INJECTION (FUEL SYSTEM)

Knock Sensor

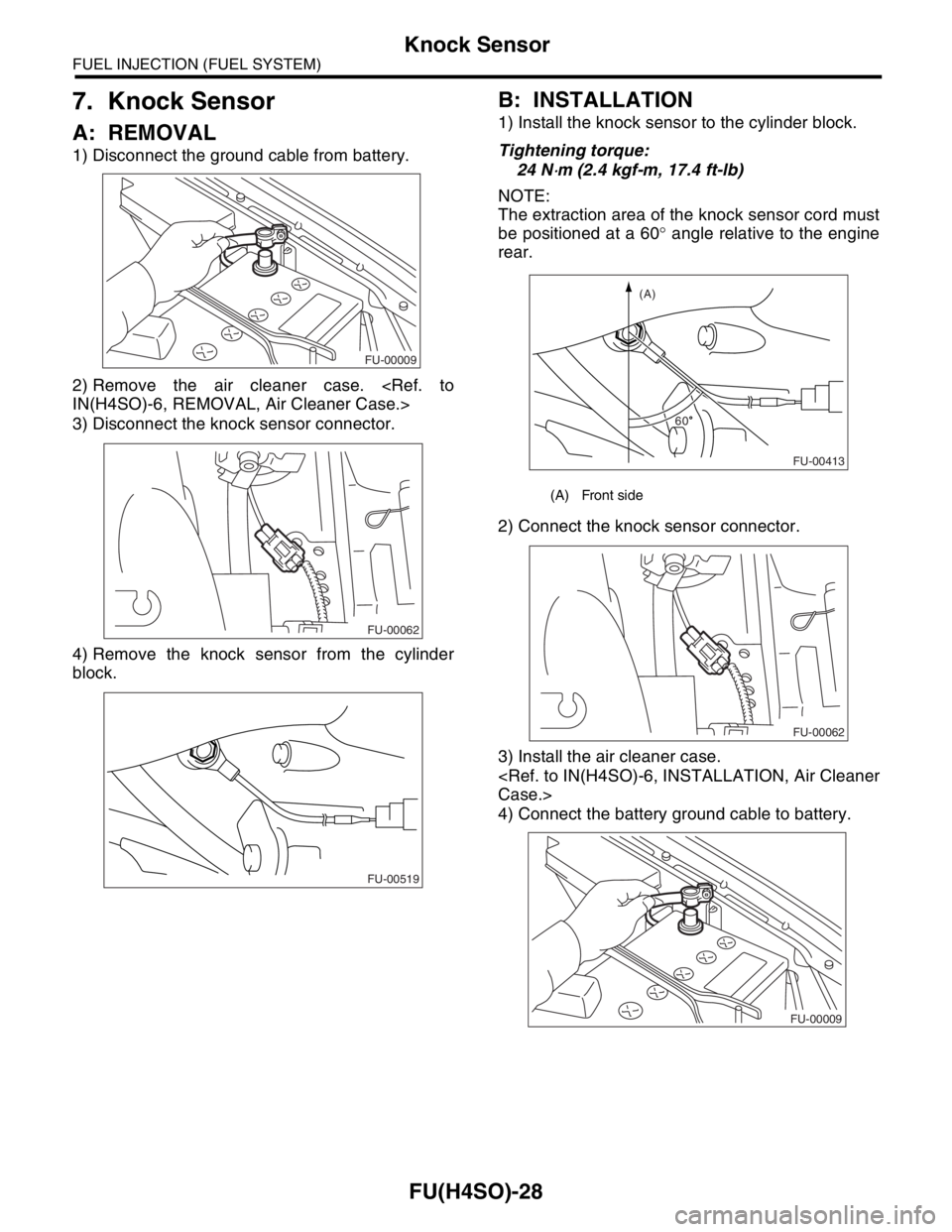

7. Knock Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air cleaner case.

3) Disconnect the knock sensor connector.

4) Remove the knock sensor from the cylinder

block.

B: INSTALLATION

1) Install the knock sensor to the cylinder block.

Tightening torque:

24 N

⋅m (2.4 kgf-m, 17.4 ft-lb)

NOTE:

The extraction area of the knock sensor cord must

be positioned at a 60° angle relative to the engine

rear.

2) Connect the knock sensor connector.

3) Install the air cleaner case.

4) Connect the battery ground cable to battery.

FU-00009

FU-00062

FU-00519

(A) Front side

FU-00413

(A)

60

FU-00062

FU-00009