lock SUBARU FORESTER 2004 Service Manual Online

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 551 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

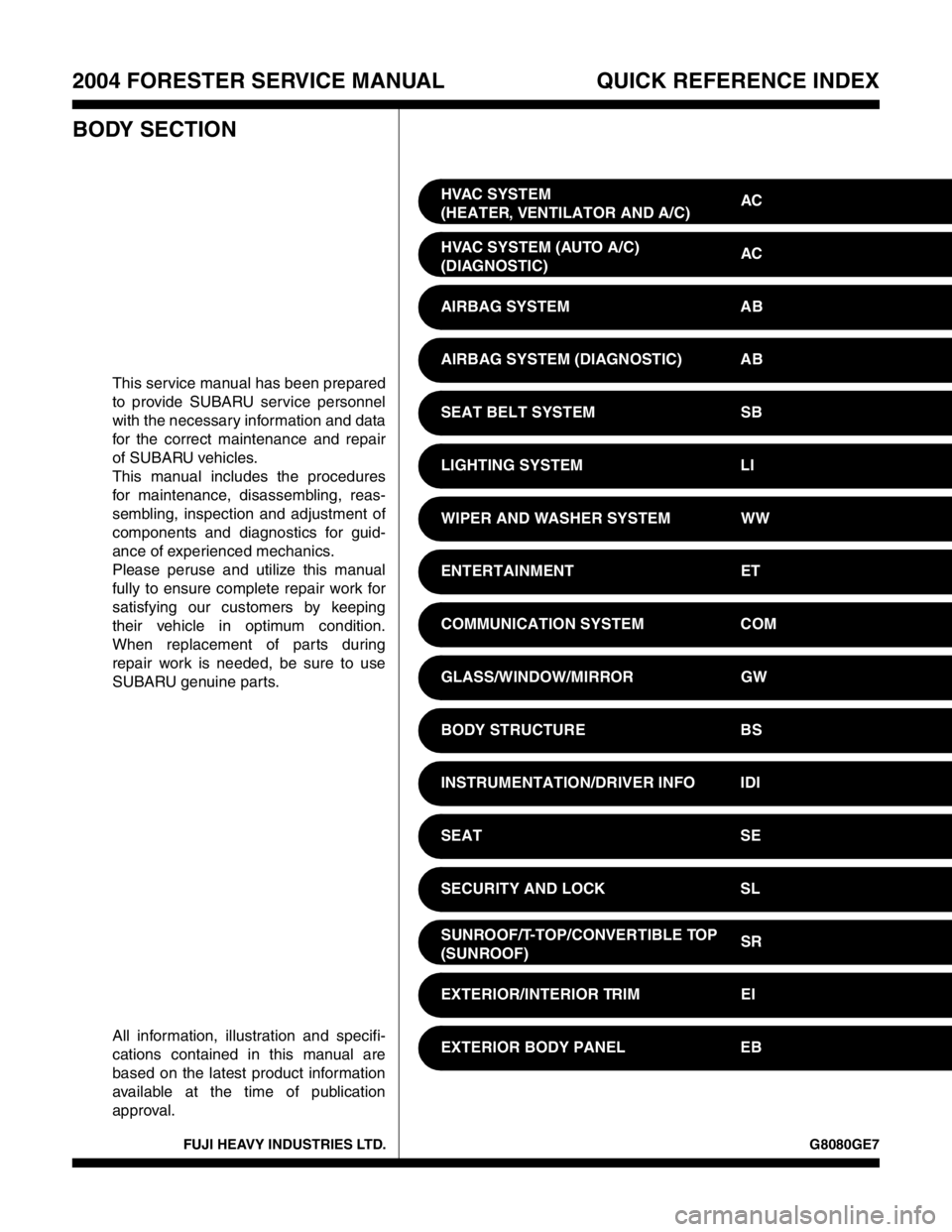

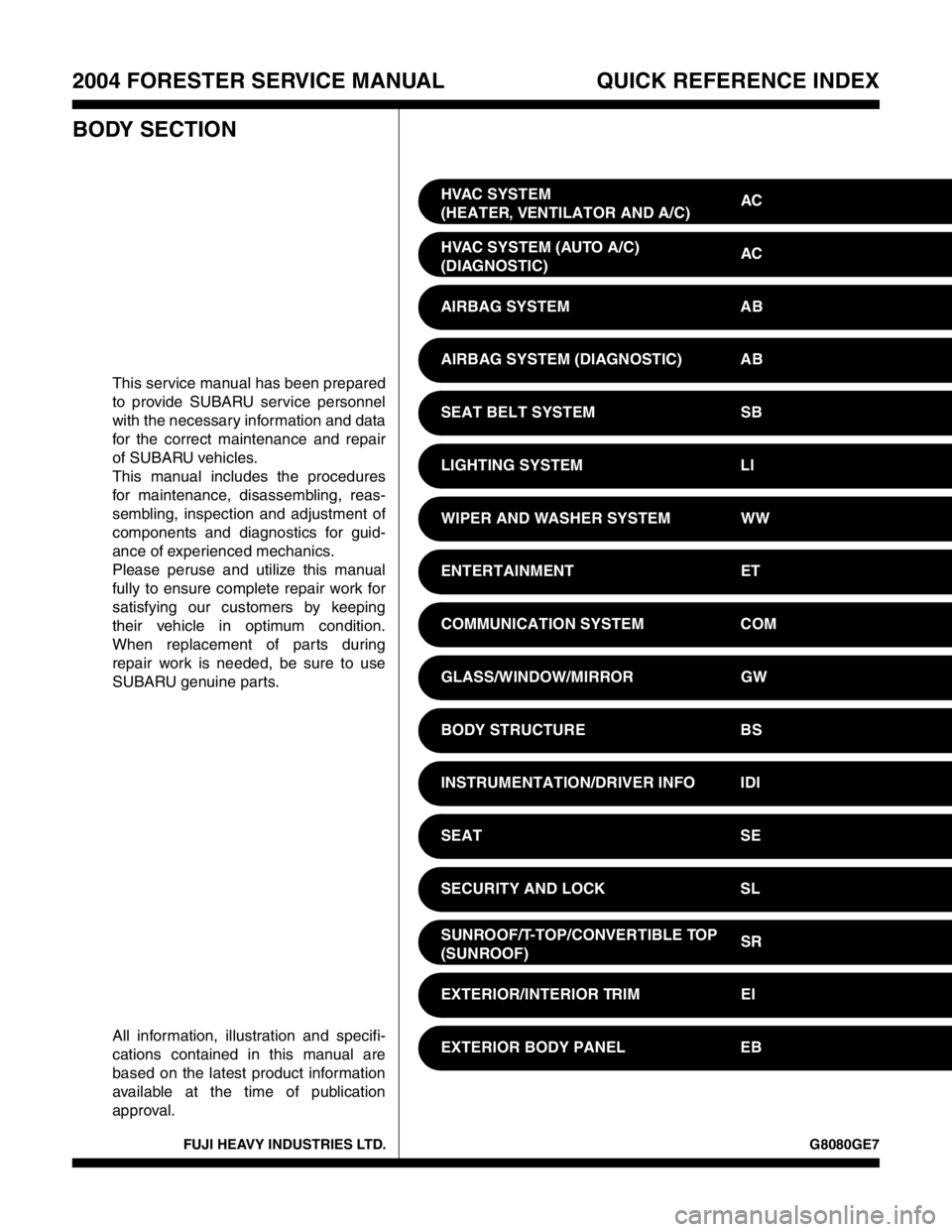

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 567 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

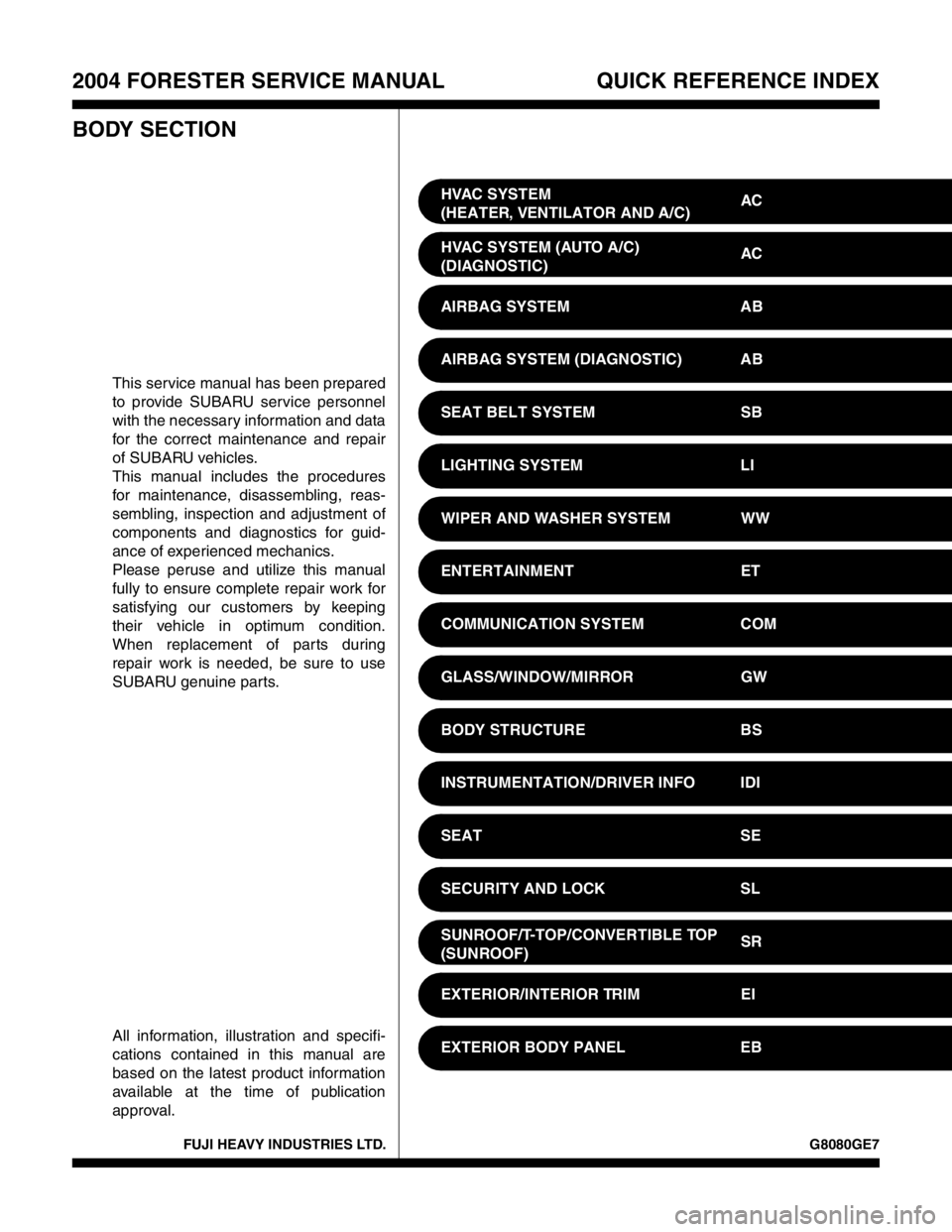

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 607 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

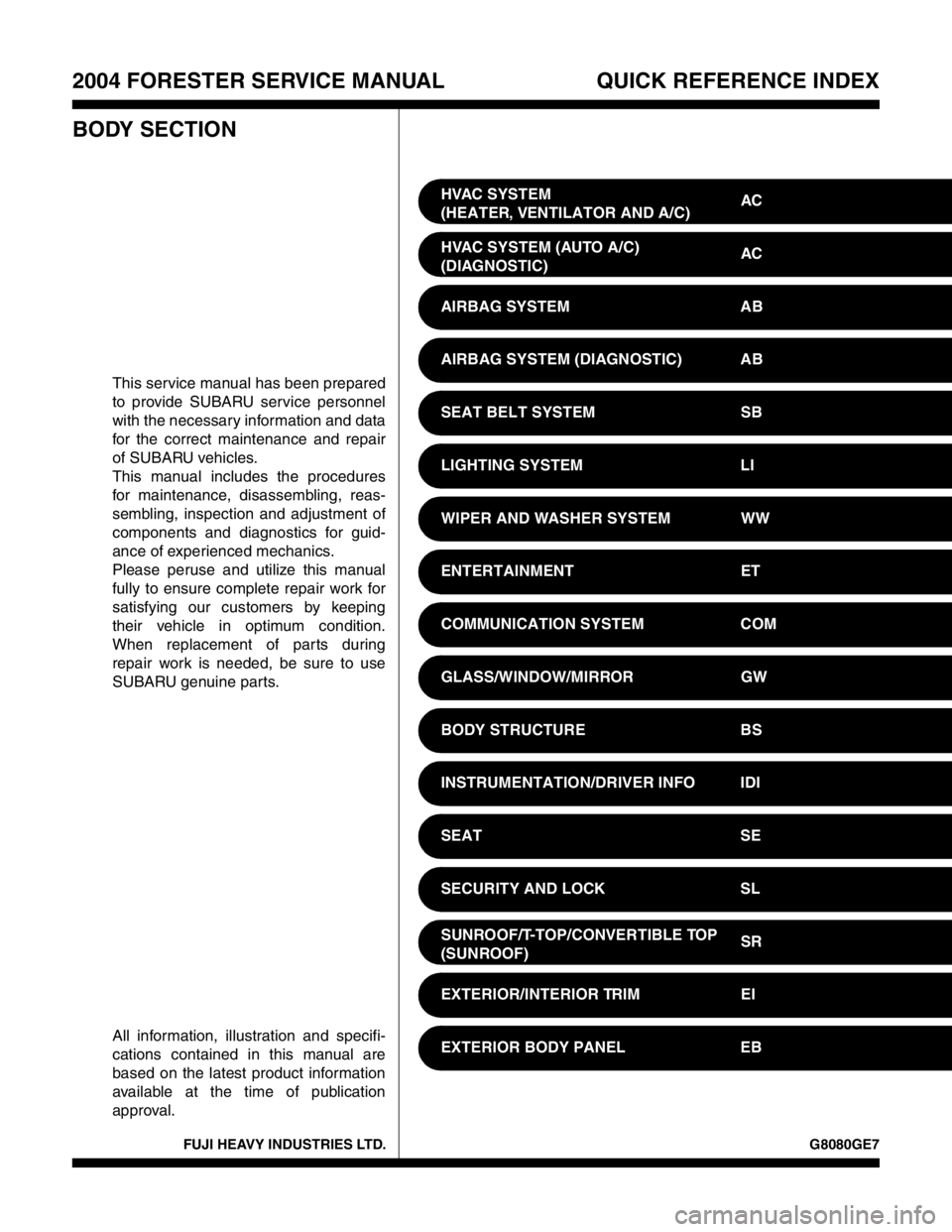

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 611 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

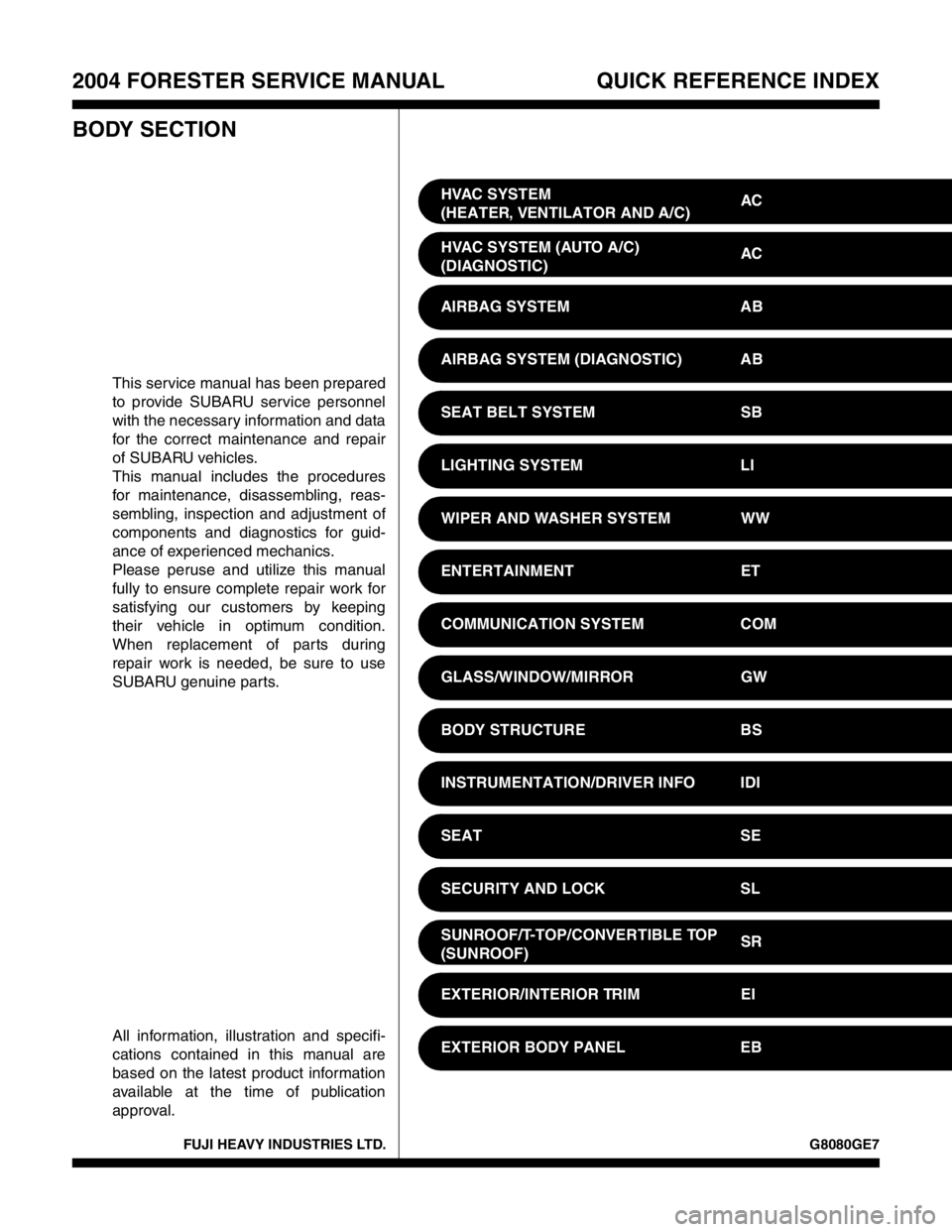

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 641 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE7

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

BODY SECTION

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.HVAC SYSTEM

(HEATER, VENTILATOR AND A/C)AC

HVAC SYSTEM (AUTO A/C)

(DIAGNOSTIC)AC

AIRBAG SYSTEM AB

AIRBAG SYSTEM (DIAGNOSTIC) AB

SEAT BELT SYSTEM SB

LIGHTING SYSTEM LI

WIPER AND WASHER SYSTEM WW

ENTERTAINMENT ET

COMMUNICATION SYSTEM COM

GLASS/WINDOW/MIRROR GW

BODY STRUCTURE BS

INSTRUMENTATION/DRIVER INFO IDI

SEAT SE

SECURITY AND LOCK SL

SUNROOF/T-TOP/CONVERTIBLE TOP

(SUNROOF)SR

EXTERIOR/INTERIOR TRIM EI

EXTERIOR BODY PANEL EB

Page 661 of 2870

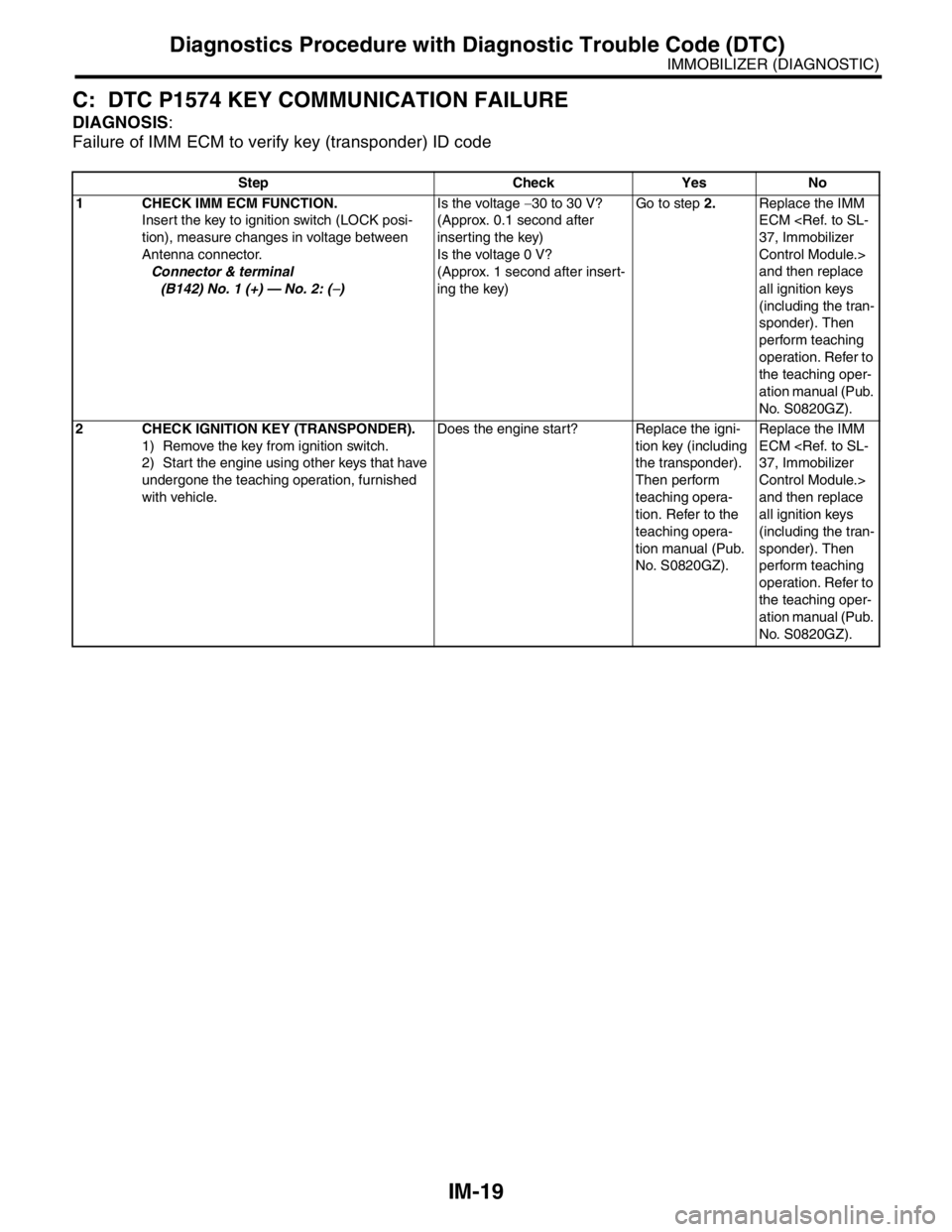

IM-19

IMMOBILIZER (DIAGNOSTIC)

Diagnostics Procedure with Diagnostic Trouble Code (DTC)

C: DTC P1574 KEY COMMUNICATION FAILURE

DIAGNOSIS:

Failure of IMM ECM to verify key (transponder) ID code

Step Check Yes No

1 CHECK IMM ECM FUNCTION.

Insert the key to ignition switch (LOCK posi-

tion), measure changes in voltage between

Antenna connector.

Connector & terminal

(B142) No. 1 (+) — No. 2: (

−)Is the voltage −30 to 30 V?

(Approx. 0.1 second after

inserting the key)

Is the voltage 0 V?

(Approx. 1 second after insert-

ing the key)Go to step 2.Replace the IMM

ECM

Control Module.>

and then replace

all ignition keys

(including the tran-

sponder). Then

perform teaching

operation. Refer to

the teaching oper-

ation manual (Pub.

No. S0820GZ).

2 CHECK IGNITION KEY (TRANSPONDER).

1) Remove the key from ignition switch.

2) Start the engine using other keys that have

undergone the teaching operation, furnished

with vehicle.Does the engine start? Replace the igni-

tion key (including

the transponder).

Then perform

teaching opera-

tion. Refer to the

teaching opera-

tion manual (Pub.

No. S0820GZ).Replace the IMM

ECM

Control Module.>

and then replace

all ignition keys

(including the tran-

sponder). Then

perform teaching

operation. Refer to

the teaching oper-

ation manual (Pub.

No. S0820GZ).

Page 687 of 2870

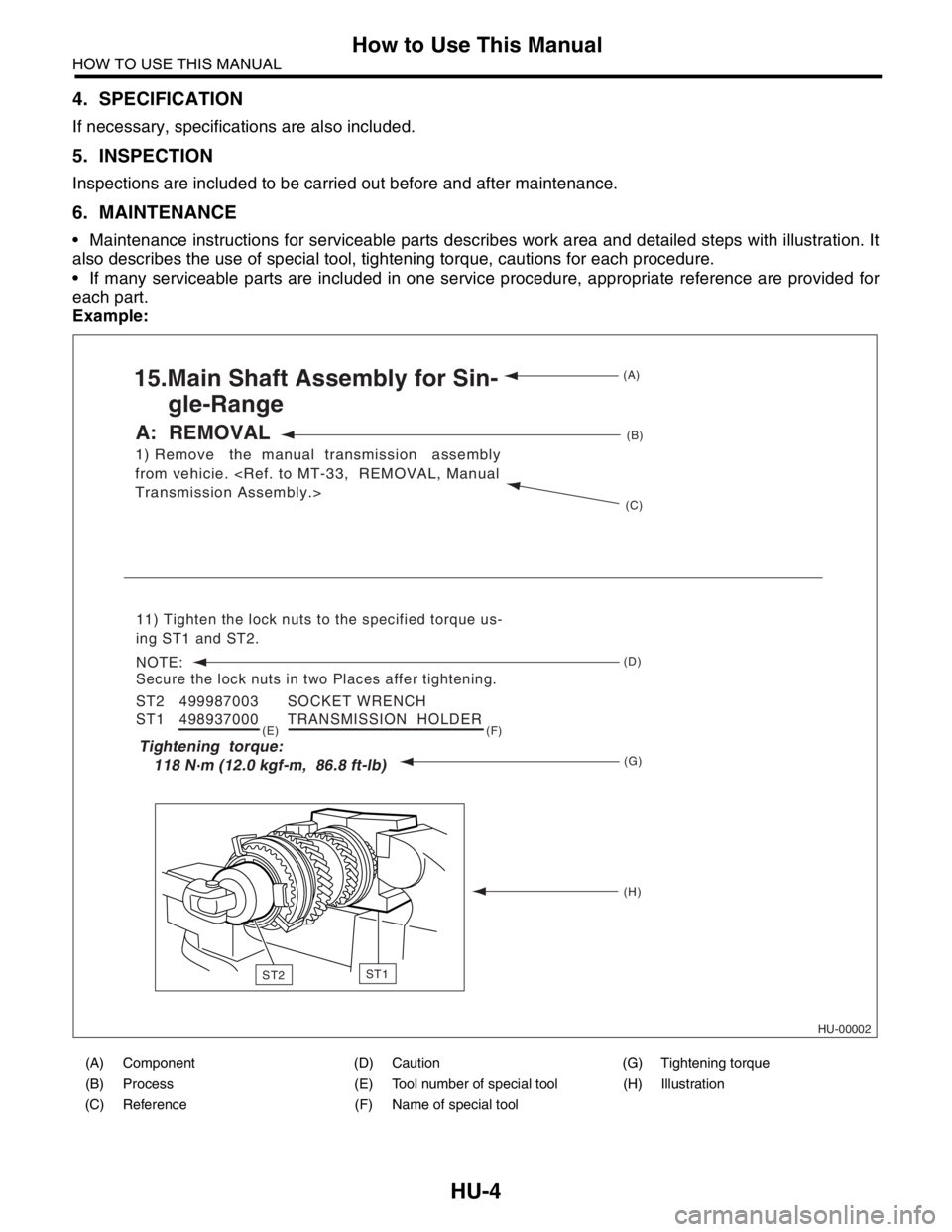

HU-4

HOW TO USE THIS MANUAL

How to Use This Manual

4. SPECIFICATION

If necessary, specifications are also included.

5. INSPECTION

Inspections are included to be carried out before and after maintenance.

6. MAINTENANCE

• Maintenance instructions for serviceable parts describes work area and detailed steps with illustration. It

also describes the use of special tool, tightening torque, cautions for each procedure.

If many serviceable parts are included in one service procedure, appropriate reference are provided for

each part.

Example:

(A) Component (D) Caution (G) Tightening torque

(B) Process (E) Tool number of special tool (H) Illustration

(C) Reference (F) Name of special tool

HU-00002

1) Remove the manual transmission assembly

from vehicie.

15.Main Shaft Assembly for Sin-

gle-Range

A: REMOVAL

11) Tighten the lock nuts to the specified torque us-

ing ST1 and ST2.

NOTE:

Secure the lock nuts in two Places affer tightening.

ST2 499987003 SOCKET WRENCH

ST1 498937000 TRANSMISSION HOLDER

(A)

(B)

(C)

(D)

(G) (E) (F)

(H)

Tightening torque:

118 N m (12.0 kgf-m, 86.8 ft-lb)

ST1ST2

Page 692 of 2870

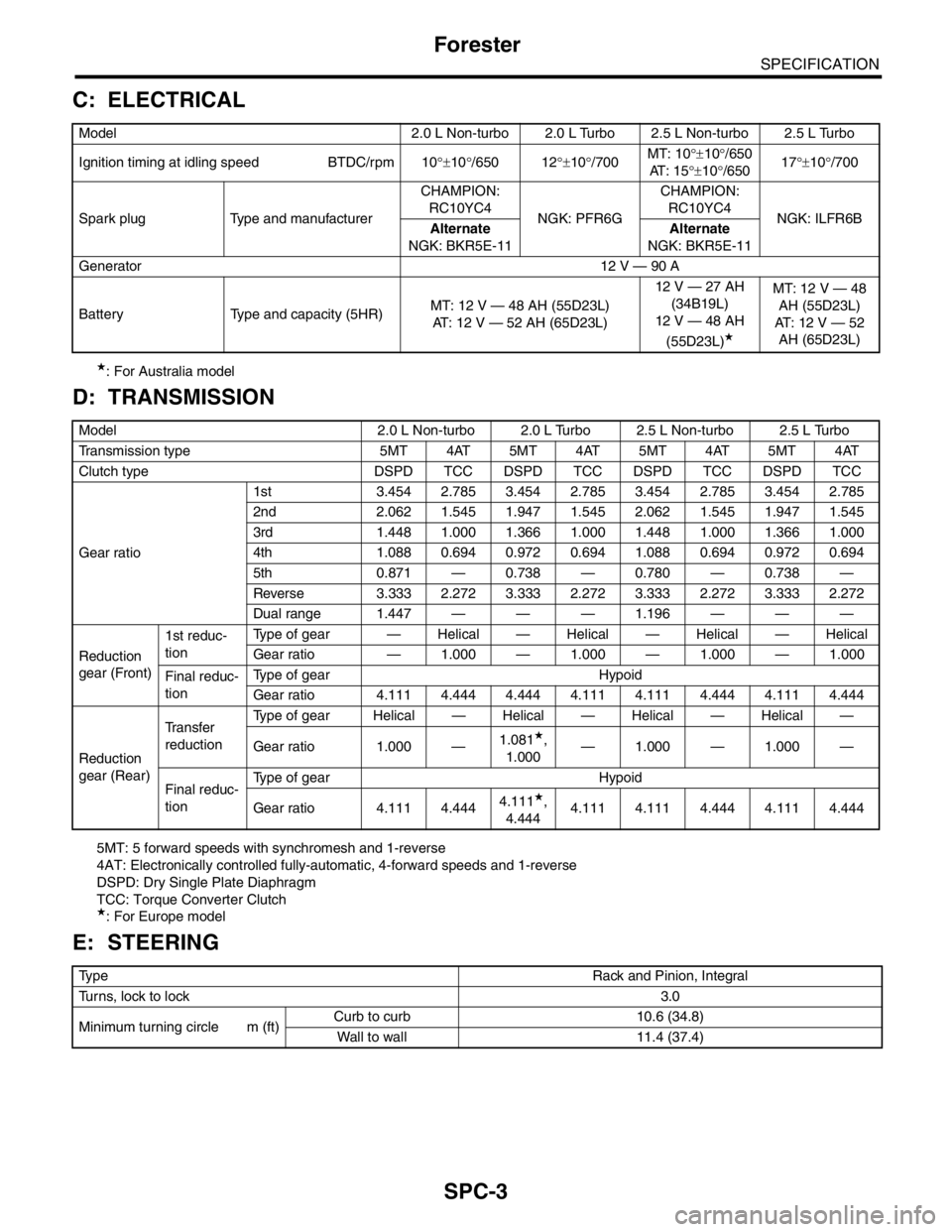

SPC-3

SPECIFICATION

Forester

C: ELECTRICAL

★: For Australia model

D: TRANSMISSION

5MT: 5 forward speeds with synchromesh and 1-reverse

4AT: Electronically controlled fully-automatic, 4-forward speeds and 1-reverse

DSPD: Dry Single Plate Diaphragm

TCC: Torque Converter Clutch

★: For Europe model

E: STEERING

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Ignition timing at idling speed BTDC/rpm 10°±10°/650 12°±10°/700MT: 10°±10°/650

AT : 1 5°±10°/65017°±10°/700

Spark plug Type and manufacturerCHAMPION:

RC10YC4

NGK: PFR6GCHAMPION:

RC10YC4

NGK: ILFR6B

Alternate

NGK: BKR5E-11Alternate

NGK: BKR5E-11

Generator12 V — 90 A

Battery Type and capacity (5HR)MT: 12 V — 48 AH (55D23L)

AT: 12 V — 52 AH (65D23L)12 V — 27 AH

(34B19L)

12 V — 48 AH

(55D23L)

★

MT: 12 V — 48

AH (55D23L)

AT: 12 V — 52

AH (65D23L)

Model 2.0 L Non-turbo 2.0 L Turbo 2.5 L Non-turbo 2.5 L Turbo

Transmission type 5MT 4AT 5MT 4AT 5MT 4AT 5MT 4AT

Clutch type DSPD TCC DSPD TCC DSPD TCC DSPD TCC

Gear ratio1st 3.454 2.785 3.454 2.785 3.454 2.785 3.454 2.785

2nd 2.062 1.545 1.947 1.545 2.062 1.545 1.947 1.545

3rd 1.448 1.000 1.366 1.000 1.448 1.000 1.366 1.000

4th 1.088 0.694 0.972 0.694 1.088 0.694 0.972 0.694

5th 0.871 — 0.738 — 0.780 — 0.738 —

Reverse 3.333 2.272 3.333 2.272 3.333 2.272 3.333 2.272

Dual range 1.447 — — — 1.196 — — —

Reduction

gear (Front)1st reduc-

tionType of gear — Helical — Helical — Helical — Helical

Gear ratio — 1.000 — 1.000 — 1.000 — 1.000

Final reduc-

tionType of gear Hypoid

Gear ratio 4.111 4.444 4.444 4.111 4.111 4.444 4.111 4.444

Reduction

gear (Rear)Transfer

reductionType of gear Helical — Helical — Helical — Helical —

Gear ratio 1.000 —1.081

★,

1.000— 1.000 — 1.000 —

Final reduc-

tionType of gear Hypoid

Gear ratio 4.111 4.4444.111

★,

4.4444.111 4.111 4.444 4.111 4.444

Ty p eRack and Pinion, Integral

Turns, lock to lock3.0

Minimum turning circle m (ft)Curb to curb 10.6 (34.8)

Wall to wall 11.4 (37.4)

Page 726 of 2870

PI-3

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

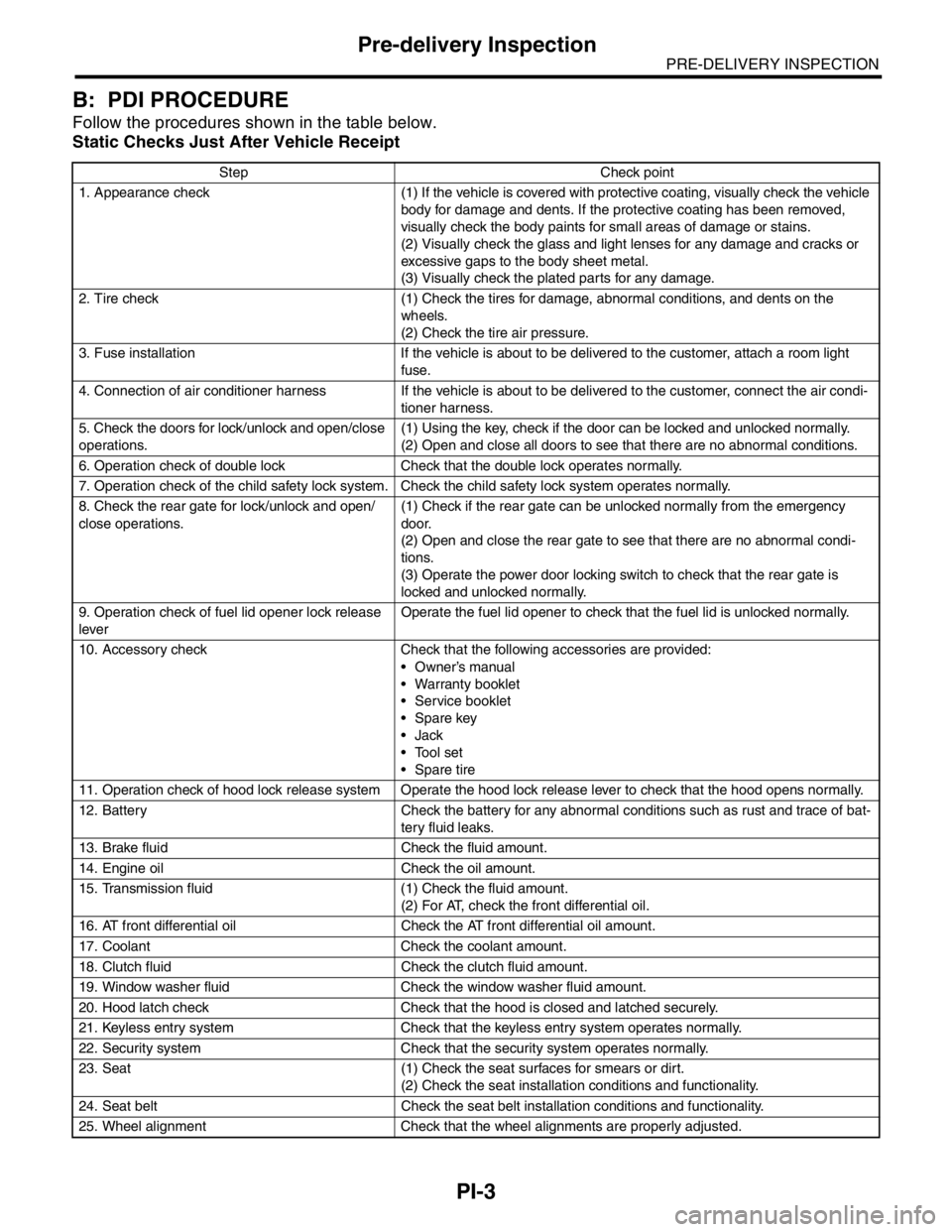

B: PDI PROCEDURE

Follow the procedures shown in the table below.

Static Checks Just After Vehicle Receipt

Step Check point

1. Appearance check (1) If the vehicle is covered with protective coating, visually check the vehicle

body for damage and dents. If the protective coating has been removed,

visually check the body paints for small areas of damage or stains.

(2) Visually check the glass and light lenses for any damage and cracks or

excessive gaps to the body sheet metal.

(3) Visually check the plated parts for any damage.

2. Tire check (1) Check the tires for damage, abnormal conditions, and dents on the

wheels.

(2) Check the tire air pressure.

3. Fuse installation If the vehicle is about to be delivered to the customer, attach a room light

fuse.

4. Connection of air conditioner harness If the vehicle is about to be delivered to the customer, connect the air condi-

tioner harness.

5. Check the doors for lock/unlock and open/close

operations.(1) Using the key, check if the door can be locked and unlocked normally.

(2) Open and close all doors to see that there are no abnormal conditions.

6. Operation check of double lock Check that the double lock operates normally.

7. Operation check of the child safety lock system. Check the child safety lock system operates normally.

8. Check the rear gate for lock/unlock and open/

close operations.(1) Check if the rear gate can be unlocked normally from the emergency

door.

(2) Open and close the rear gate to see that there are no abnormal condi-

tions.

(3) Operate the power door locking switch to check that the rear gate is

locked and unlocked normally.

9. Operation check of fuel lid opener lock release

leverOperate the fuel lid opener to check that the fuel lid is unlocked normally.

10. Accessory check Check that the following accessories are provided:

Owner’s manual

Warranty booklet

Service booklet

Spare key

Jack

Tool set

Spare tire

11. Operation check of hood lock release system Operate the hood lock release lever to check that the hood opens normally.

12. Battery Check the battery for any abnormal conditions such as rust and trace of bat-

tery fluid leaks.

13. Brake fluid Check the fluid amount.

14. Engine oil Check the oil amount.

15. Transmission fluid (1) Check the fluid amount.

(2) For AT, check the front differential oil.

16. AT front differential oil Check the AT front differential oil amount.

17. Coolant Check the coolant amount.

18. Clutch fluid Check the clutch fluid amount.

19. Window washer fluid Check the window washer fluid amount.

20. Hood latch check Check that the hood is closed and latched securely.

21. Keyless entry system Check that the keyless entry system operates normally.

22. Security system Check that the security system operates normally.

23. Seat (1) Check the seat surfaces for smears or dirt.

(2) Check the seat installation conditions and functionality.

24. Seat belt Check the seat belt installation conditions and functionality.

25. Wheel alignment Check that the wheel alignments are properly adjusted.

Page 727 of 2870

PI-4

PRE-DELIVERY INSPECTION

Pre-delivery Inspection

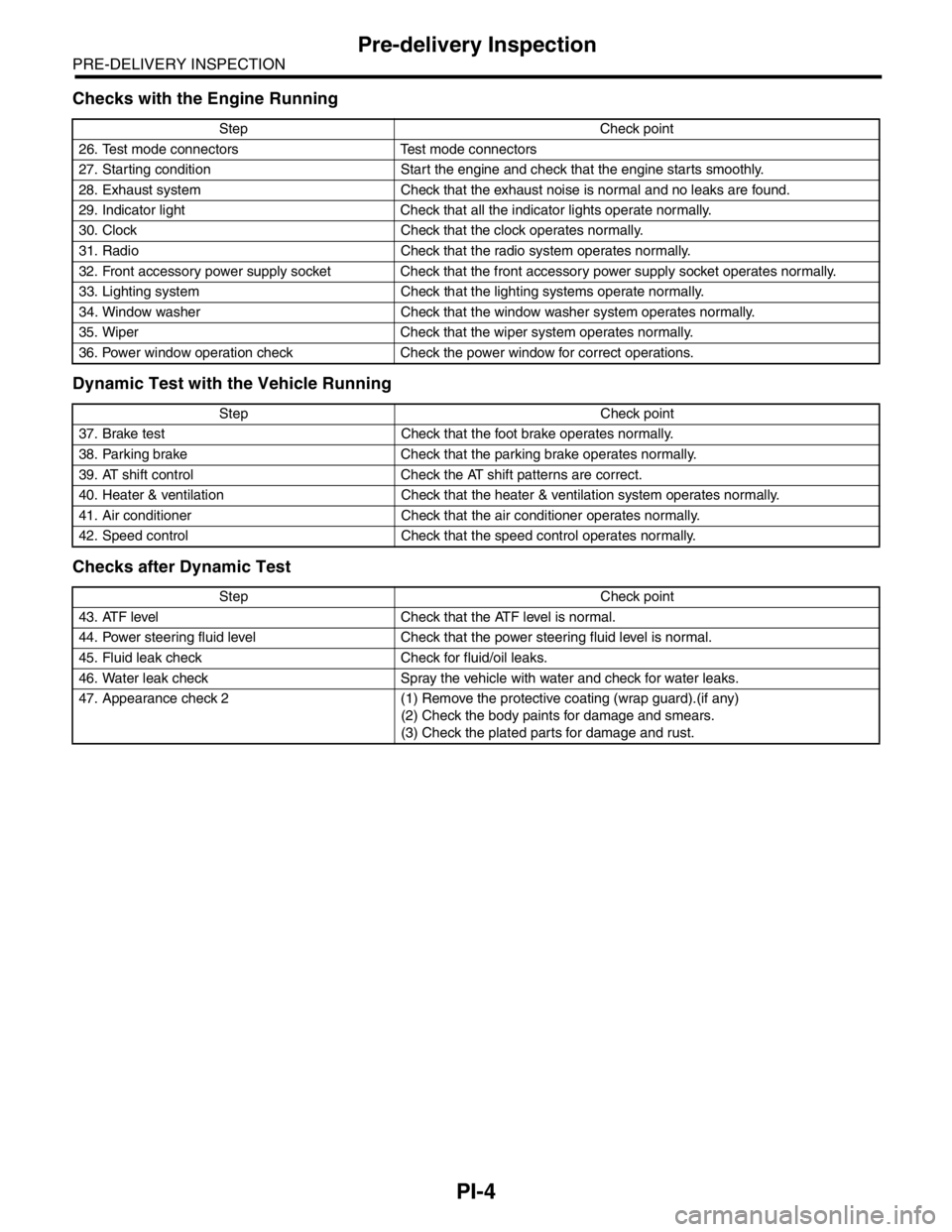

Checks with the Engine Running

Dynamic Test with the Vehicle Running

Checks after Dynamic Test

Step Check point

26. Test mode connectors Test mode connectors

27. Starting condition Start the engine and check that the engine starts smoothly.

28. Exhaust system Check that the exhaust noise is normal and no leaks are found.

29. Indicator light Check that all the indicator lights operate normally.

30. Clock Check that the clock operates normally.

31. Radio Check that the radio system operates normally.

32. Front accessory power supply socket Check that the front accessory power supply socket operates normally.

33. Lighting system Check that the lighting systems operate normally.

34. Window washer Check that the window washer system operates normally.

35. Wiper Check that the wiper system operates normally.

36. Power window operation check Check the power window for correct operations.

Step Check point

37. Brake test Check that the foot brake operates normally.

38. Parking brake Check that the parking brake operates normally.

39. AT shift control Check the AT shift patterns are correct.

40. Heater & ventilation Check that the heater & ventilation system operates normally.

41. Air conditioner Check that the air conditioner operates normally.

42. Speed control Check that the speed control operates normally.

Step Check point

43. ATF level Check that the ATF level is normal.

44. Power steering fluid level Check that the power steering fluid level is normal.

45. Fluid leak check Check for fluid/oil leaks.

46. Water leak check Spray the vehicle with water and check for water leaks.

47. Appearance check 2 (1) Remove the protective coating (wrap guard).(if any)

(2) Check the body paints for damage and smears.

(3) Check the plated parts for damage and rust.