lock SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 870 of 2870

MECHANICAL

ME(H4SO)

Page

1. General Description ....................................................................................2

2. Compression .............................................................................................25

3. Idle Speed .................................................................................................26

4. Ignition Timing ...........................................................................................27

5. Intake Manifold Vacuum............................................................................28

6. Engine Oil Pressure ..................................................................................29

7. Fuel Pressure ............................................................................................30

8. Valve Clearance ........................................................................................31

9. Engine Assembly ......................................................................................34

10. Engine Mounting .......................................................................................41

11. Preparation for Overhaul ...........................................................................42

12. V-belt .........................................................................................................43

13. Crank Pulley ..............................................................................................45

14. Timing Belt Cover......................................................................................47

15. Timing Belt ................................................................................................48

16. Cam Sprocket ...........................................................................................53

17. Crank Sprocket .........................................................................................55

18. Valve Rocker Assembly ............................................................................56

19. Camshaft ...................................................................................................58

20. Cylinder Head ...........................................................................................62

21. Cylinder Block ...........................................................................................69

22. Engine Trouble in General ........................................................................91

23. Engine Noise .............................................................................................96

Page 872 of 2870

ME(H4SO)-3

MECHANICAL

General Description

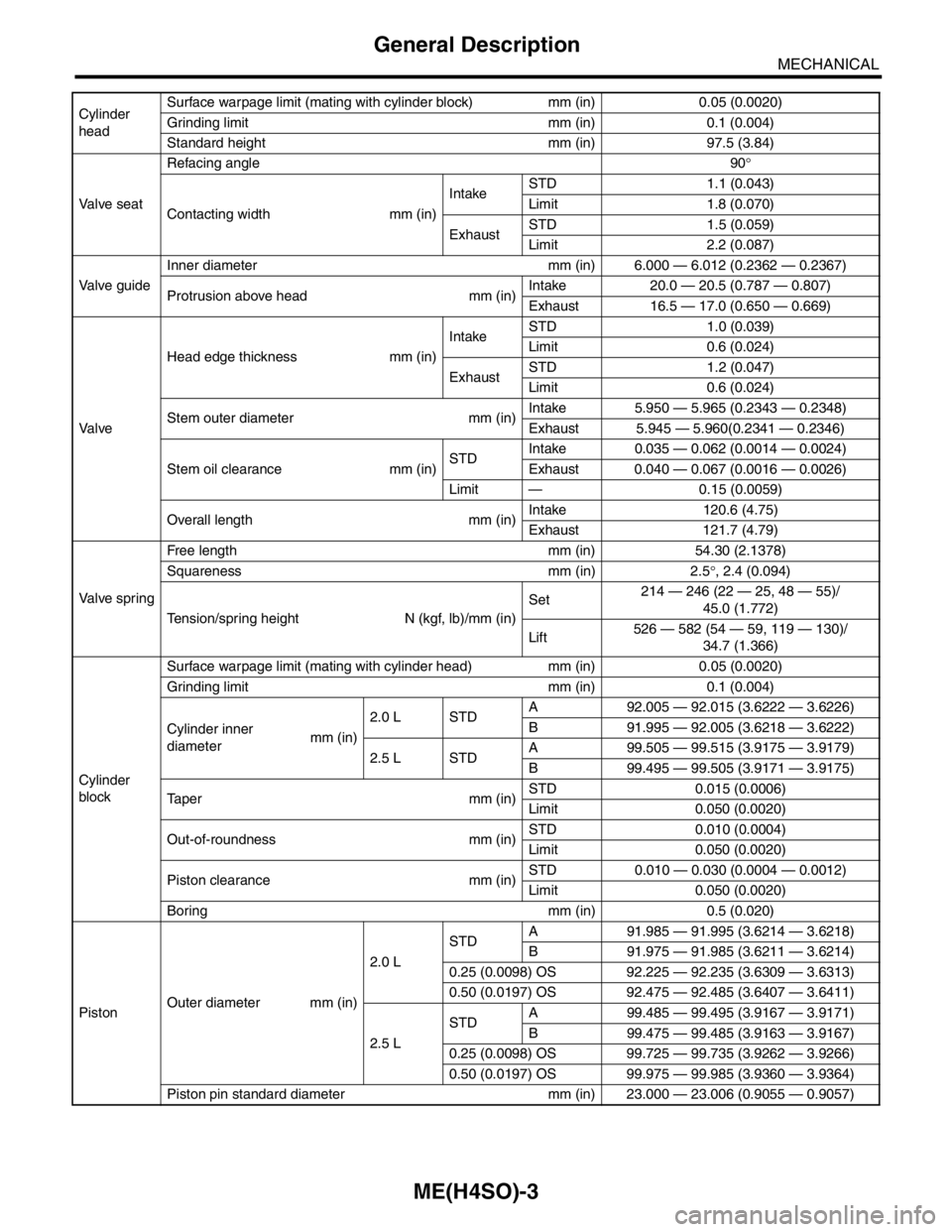

Cylinder

headSurface warpage limit (mating with cylinder block) mm (in) 0.05 (0.0020)

Grinding limit mm (in) 0.1 (0.004)

Standard height mm (in) 97.5 (3.84)

Va l ve s e a tRefacing angle90°

Contacting width mm (in)IntakeSTD 1.1 (0.043)

Limit 1.8 (0.070)

ExhaustSTD 1.5 (0.059)

Limit 2.2 (0.087)

Valve guideInner diameter mm (in) 6.000 — 6.012 (0.2362 — 0.2367)

Protrusion above head mm (in)Intake 20.0 — 20.5 (0.787 — 0.807)

Exhaust 16.5 — 17.0 (0.650 — 0.669)

Va l veHead edge thickness mm (in)IntakeSTD 1.0 (0.039)

Limit 0.6 (0.024)

ExhaustSTD 1.2 (0.047)

Limit 0.6 (0.024)

Stem outer diameter mm (in)Intake 5.950 — 5.965 (0.2343 — 0.2348)

Exhaust 5.945 — 5.960(0.2341 — 0.2346)

Stem oil clearance mm (in)STDIntake 0.035 — 0.062 (0.0014 — 0.0024)

Exhaust 0.040 — 0.067 (0.0016 — 0.0026)

Limit — 0.15 (0.0059)

Overall length mm (in)Intake 120.6 (4.75)

Exhaust 121.7 (4.79)

Valve springFree length mm (in) 54.30 (2.1378)

Squareness mm (in) 2.5°, 2.4 (0.094)

Tension/spring height N (kgf, lb)/mm (in)Set214 — 246 (22 — 25, 48 — 55)/

45.0 (1.772)

Lift526 — 582 (54 — 59, 119 — 130)/

34.7 (1.366)

Cylinder

blockSurface warpage limit (mating with cylinder head) mm (in) 0.05 (0.0020)

Grinding limit mm (in) 0.1 (0.004)

Cylinder inner

diametermm (in)2.0 L STDA 92.005 — 92.015 (3.6222 — 3.6226)

B 91.995 — 92.005 (3.6218 — 3.6222)

2.5 L STDA 99.505 — 99.515 (3.9175 — 3.9179)

B 99.495 — 99.505 (3.9171 — 3.9175)

Ta p e r m m ( i n )STD 0.015 (0.0006)

Limit 0.050 (0.0020)

Out-of-roundness mm (in)STD 0.010 (0.0004)

Limit 0.050 (0.0020)

Piston clearance mm (in)STD 0.010 — 0.030 (0.0004 — 0.0012)

Limit 0.050 (0.0020)

Boring mm (in) 0.5 (0.020)

PistonOuter diameter mm (in)2.0 LSTDA 91.985 — 91.995 (3.6214 — 3.6218)

B 91.975 — 91.985 (3.6211 — 3.6214)

0.25 (0.0098) OS 92.225 — 92.235 (3.6309 — 3.6313)

0.50 (0.0197) OS 92.475 — 92.485 (3.6407 — 3.6411)

2.5 LSTDA 99.485 — 99.495 (3.9167 — 3.9171)

B 99.475 — 99.485 (3.9163 — 3.9167)

0.25 (0.0098) OS 99.725 — 99.735 (3.9262 — 3.9266)

0.50 (0.0197) OS 99.975 — 99.985 (3.9360 — 3.9364)

Piston pin standard diameter mm (in) 23.000 — 23.006 (0.9055 — 0.9057)

Page 879 of 2870

ME(H4SO)-10

MECHANICAL

General Description

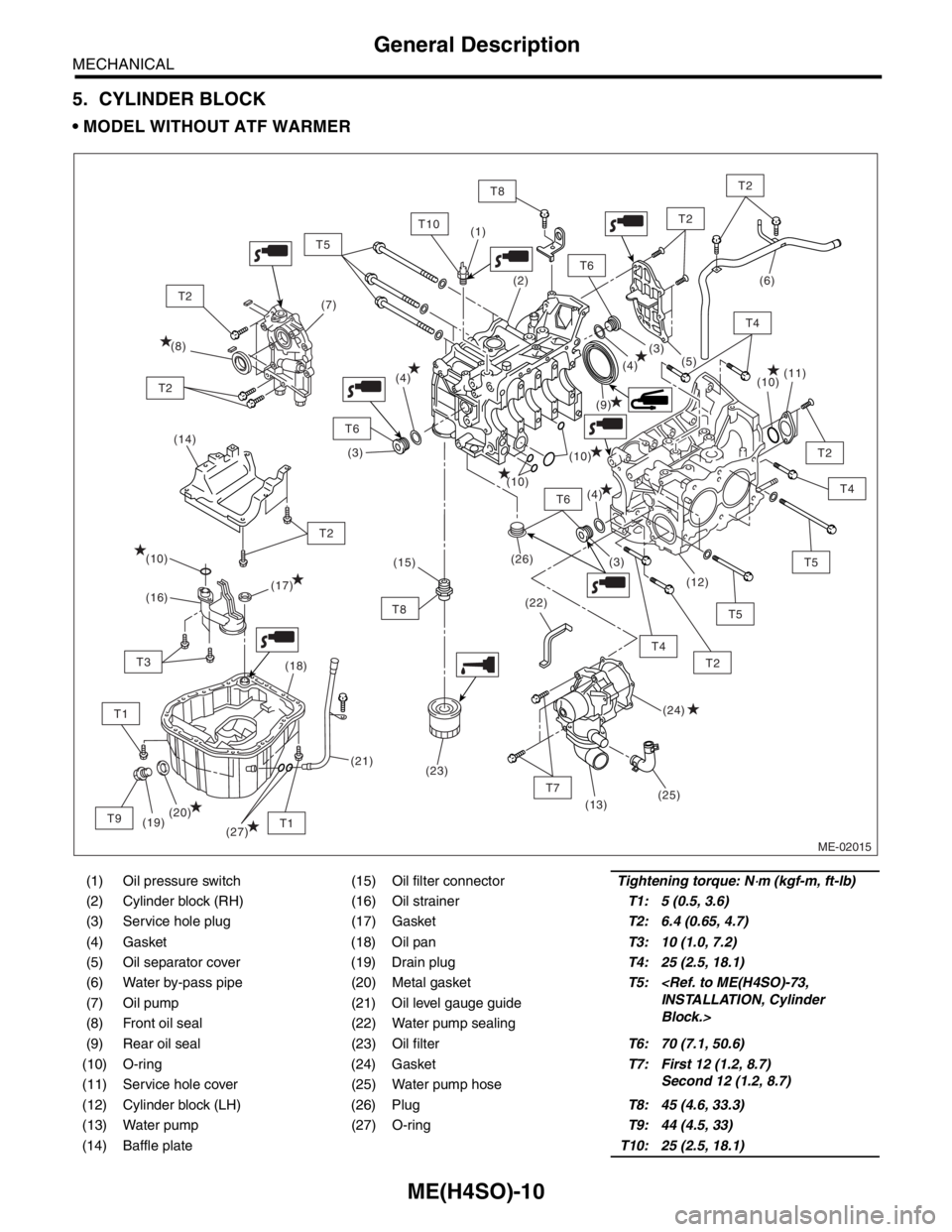

5. CYLINDER BLOCK

MODEL WITHOUT ATF WARMER

(1) Oil pressure switch (15) Oil filter connectorTightening torque: N⋅m (kgf-m, ft-lb)

(2) Cylinder block (RH) (16) Oil strainerT1: 5 (0.5, 3.6)

(3) Service hole plug (17) GasketT2: 6.4 (0.65, 4.7)

(4) Gasket (18) Oil panT3: 10 (1.0, 7.2)

(5) Oil separator cover (19) Drain plugT4: 25 (2.5, 18.1)

(6) Water by-pass pipe (20) Metal gasketT5:

Block.> (7) Oil pump (21) Oil level gauge guide

(8) Front oil seal (22) Water pump sealing

(9) Rear oil seal (23) Oil filterT6: 70 (7.1, 50.6)

(10) O-ring (24) GasketT7: First 12 (1.2, 8.7)

Second 12 (1.2, 8.7)

(11) Service hole cover (25) Water pump hose

(12) Cylinder block (LH) (26) PlugT8: 45 (4.6, 33.3)

(13) Water pump (27) O-ringT9: 44 (4.5, 33)

(14) Baffle plateT10: 25 (2.5, 18.1)

ME-02015

(14)

T6

T7

T2

T2

T4

T8

T4

T5

T2

T6

T6

T10

T1

T2

T8

T1

T3

T9

T2

T2

(9) (8)(7)(6)

(10)

(10)

(10)

(26)

(22)(11)

(12)

(13)

(19)(18)

(20)(17)

(16)

(24) (10)

(25)(5)

(4)

(4)

(4)(3)

(3)

(3) (2) (1)

(21)(15)

(23)

T5

T2

T5

T4

(27)

Page 880 of 2870

ME(H4SO)-11

MECHANICAL

General Description

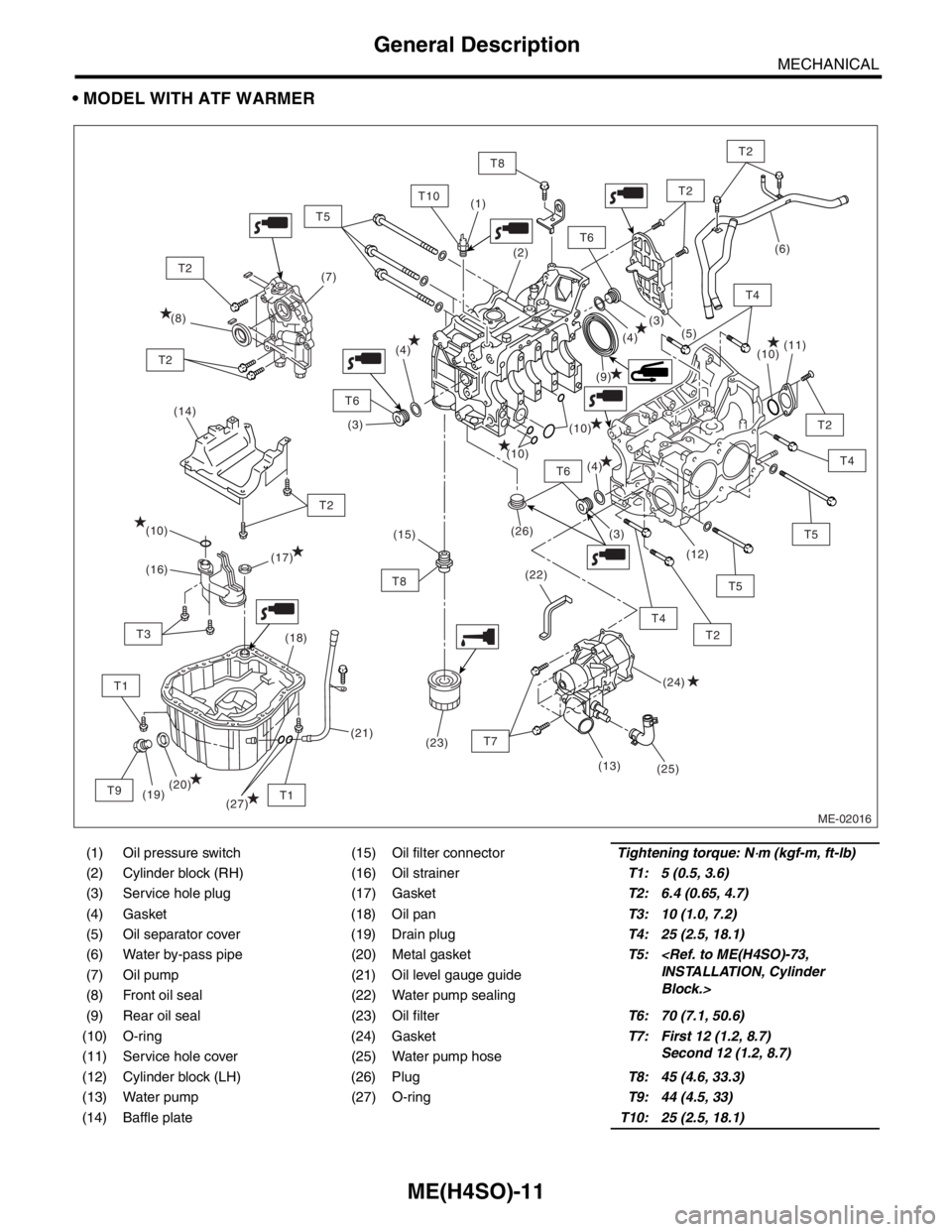

MODEL WITH ATF WARMER

(1) Oil pressure switch (15) Oil filter connectorTightening torque: N⋅m (kgf-m, ft-lb)

(2) Cylinder block (RH) (16) Oil strainerT1: 5 (0.5, 3.6)

(3) Service hole plug (17) GasketT2: 6.4 (0.65, 4.7)

(4) Gasket (18) Oil panT3: 10 (1.0, 7.2)

(5) Oil separator cover (19) Drain plugT4: 25 (2.5, 18.1)

(6) Water by-pass pipe (20) Metal gasketT5:

Block.> (7) Oil pump (21) Oil level gauge guide

(8) Front oil seal (22) Water pump sealing

(9) Rear oil seal (23) Oil filterT6: 70 (7.1, 50.6)

(10) O-ring (24) GasketT7: First 12 (1.2, 8.7)

Second 12 (1.2, 8.7)

(11) Service hole cover (25) Water pump hose

(12) Cylinder block (LH) (26) PlugT8: 45 (4.6, 33.3)

(13) Water pump (27) O-ringT9: 44 (4.5, 33)

(14) Baffle plateT10: 25 (2.5, 18.1)

ME-02016

(14)

T6

T2

T2

T4

T8

T5

T2

T6

T6

T10

T1

T2

T8

T1

T3

T9

T2

T2

(9) (8)(7)

(10)

(10)

(10)

(26)

(22)(11)

(12)

(19)(18)

(20)(17)

(16)

(24) (10)

(25)(5)

(4)

(4)

(4)(3)

(3)

(3) (2) (1)

(21)(15)

(23)

T5

T2

T5

T4

(27)

T7

(13)

(6)

T4

Page 898 of 2870

ME(H4SO)-29

MECHANICAL

Engine Oil Pressure

6. Engine Oil Pressure

A: INSPECTION

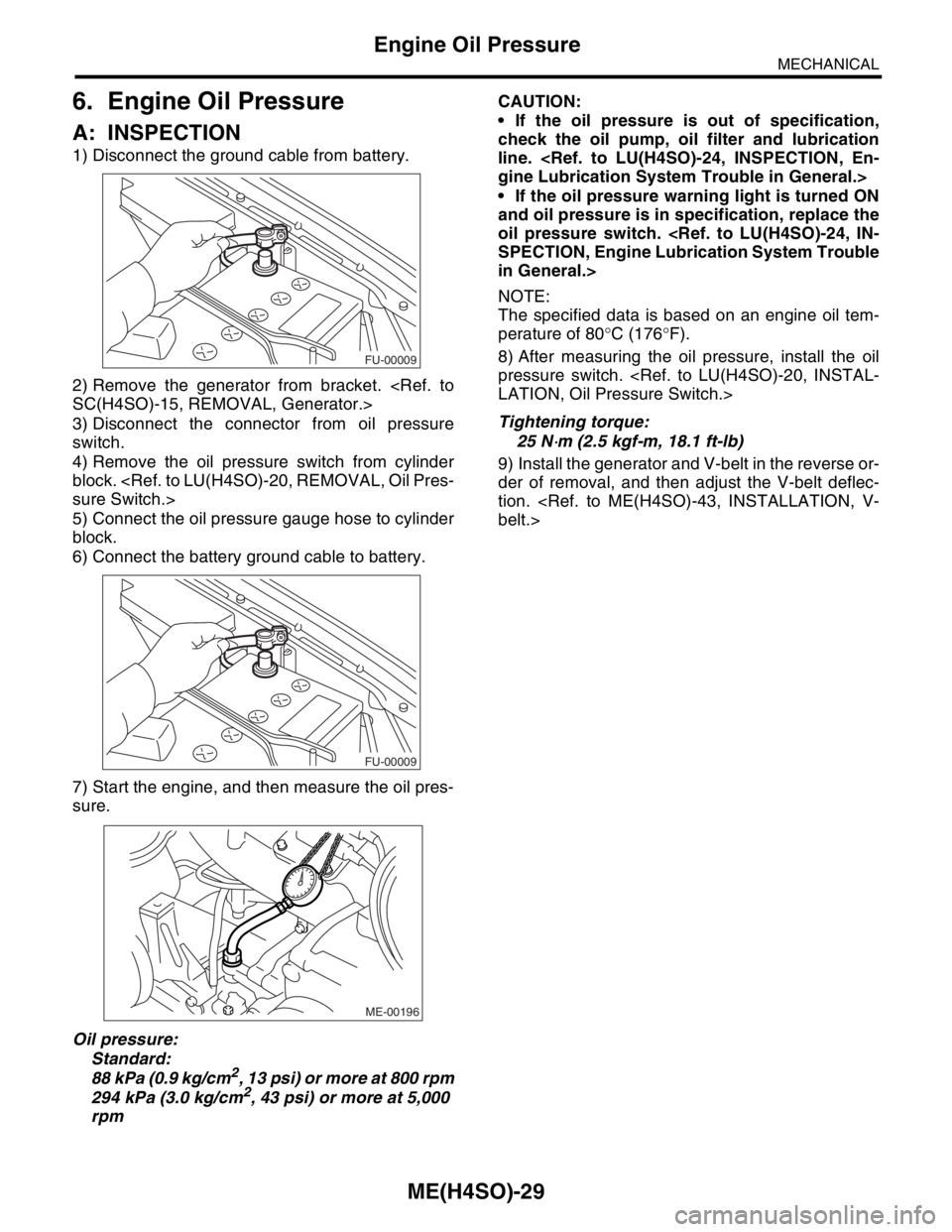

1) Disconnect the ground cable from battery.

2) Remove the generator from bracket.

3) Disconnect the connector from oil pressure

switch.

4) Remove the oil pressure switch from cylinder

block.

5) Connect the oil pressure gauge hose to cylinder

block.

6) Connect the battery ground cable to battery.

7) Start the engine, and then measure the oil pres-

sure.

Oil pressure:

Standard:

88 kPa (0.9 kg/cm

2, 13 psi) or more at 800 rpm

294 kPa (3.0 kg/cm2, 43 psi) or more at 5,000

rpmCAUTION:

If the oil pressure is out of specification,

check the oil pump, oil filter and lubrication

line.

If the oil pressure warning light is turned ON

and oil pressure is in specification, replace the

oil pressure switch.

in General.>

NOTE:

The specified data is based on an engine oil tem-

perature of 80°C (176°F).

8) After measuring the oil pressure, install the oil

pressure switch.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

9) Install the generator and V-belt in the reverse or-

der of removal, and then adjust the V-belt deflec-

tion.

FU-00009

FU-00009

ME-00196

Page 900 of 2870

ME(H4SO)-31

MECHANICAL

Valve Clearance

8. Valve Clearance

A: INSPECTION

NOTE:

Inspection and adjustment of the valve clearance

should be performed while engine is cold.

1) Set the vehicle on a lift.

2) Lift-up the vehicle.

3) Remove the under cover.

4) Lower the vehicle.

5) Disconnect the ground cable from battery.

6) Remove the belt cover (LH).

7) When inspecting the #1 and #3 cylinders:

(1) Disconnect the spark plug cords from spark

plugs RH side.

(2) Disconnect the PCV hose from rocker cover

(RH).

(3) Remove the bolts, and then remove the

rocker cover (RH).

8) When inspecting the #2 and #4 cylinders:

(1) Disconnect the spark plug cords from spark

plugs (LH Side)

(2) Disconnect the PCV hose from rocker cover

(LH).

(3) Remove the bolts, and then remove the

rocker cover (LH).

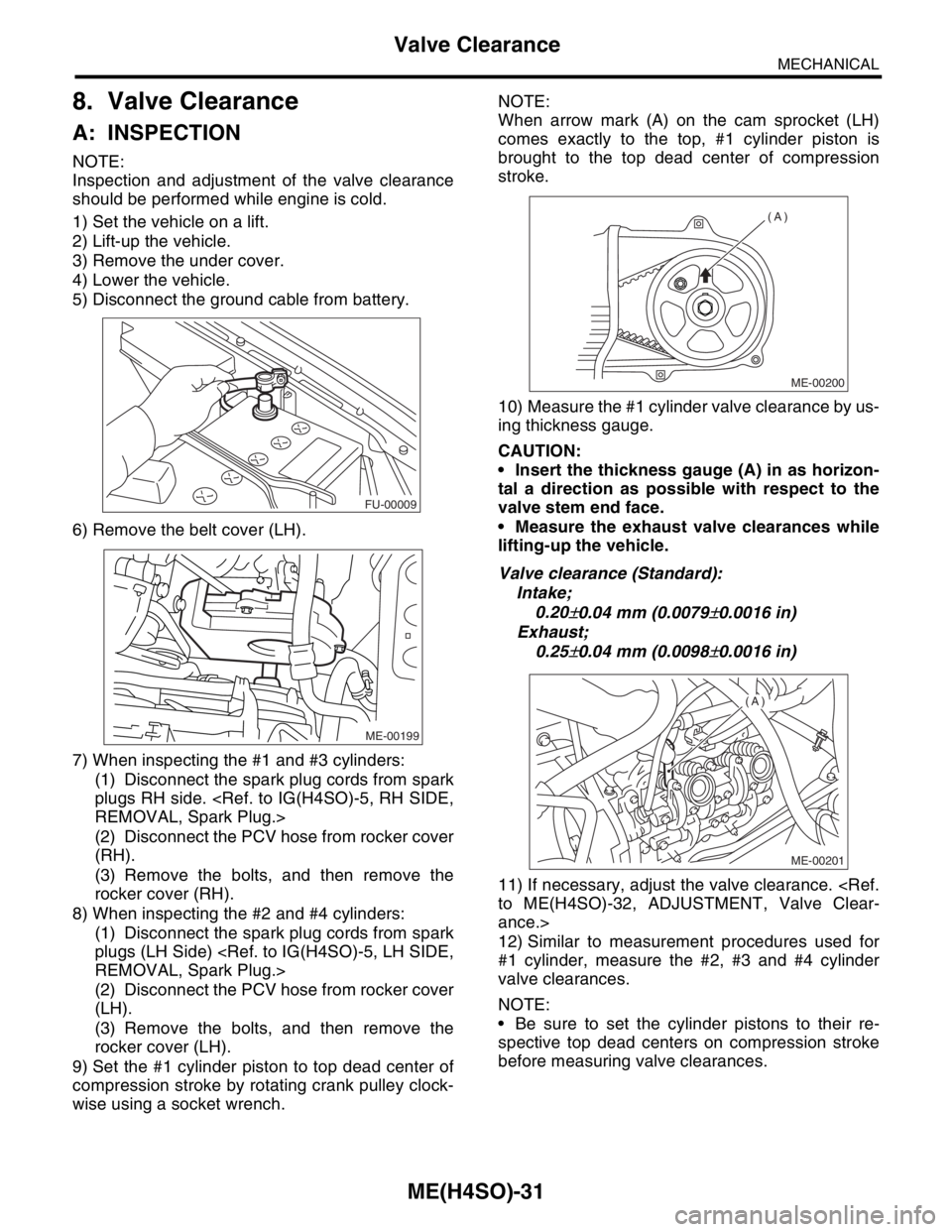

9) Set the #1 cylinder piston to top dead center of

compression stroke by rotating crank pulley clock-

wise using a socket wrench.NOTE:

When arrow mark (A) on the cam sprocket (LH)

comes exactly to the top, #1 cylinder piston is

brought to the top dead center of compression

stroke.

10) Measure the #1 cylinder valve clearance by us-

ing thickness gauge.

CAUTION:

Insert the thickness gauge (A) in as horizon-

tal a direction as possible with respect to the

valve stem end face.

Measure the exhaust valve clearances while

lifting-up the vehicle.

Valve clearance (Standard):

Intake;

0.20

±0.04 mm (0.0079±0.0016 in)

Exhaust;

0.25

±0.04 mm (0.0098±0.0016 in)

11) If necessary, adjust the valve clearance.

ance.>

12) Similar to measurement procedures used for

#1 cylinder, measure the #2, #3 and #4 cylinder

valve clearances.

NOTE:

Be sure to set the cylinder pistons to their re-

spective top dead centers on compression stroke

before measuring valve clearances.

FU-00009

ME-00199

ME-00200

(A)

ME-00201

(A)

Page 901 of 2870

ME(H4SO)-32

MECHANICAL

Valve Clearance

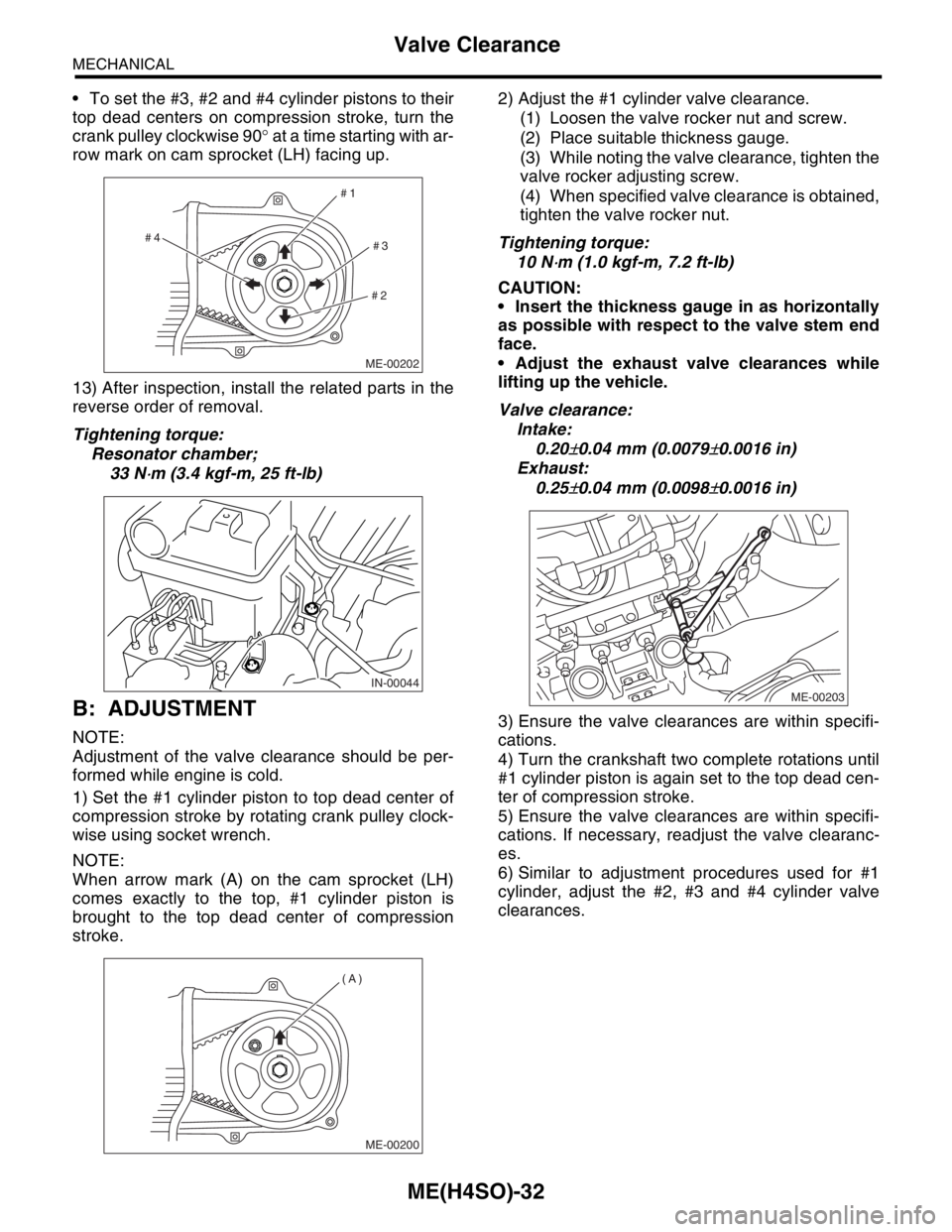

To set the #3, #2 and #4 cylinder pistons to their

top dead centers on compression stroke, turn the

crank pulley clockwise 90° at a time starting with ar-

row mark on cam sprocket (LH) facing up.

13) After inspection, install the related parts in the

reverse order of removal.

Tightening torque:

Resonator chamber;

33 N

⋅m (3.4 kgf-m, 25 ft-lb)

B: ADJUSTMENT

NOTE:

Adjustment of the valve clearance should be per-

formed while engine is cold.

1) Set the #1 cylinder piston to top dead center of

compression stroke by rotating crank pulley clock-

wise using socket wrench.

NOTE:

When arrow mark (A) on the cam sprocket (LH)

comes exactly to the top, #1 cylinder piston is

brought to the top dead center of compression

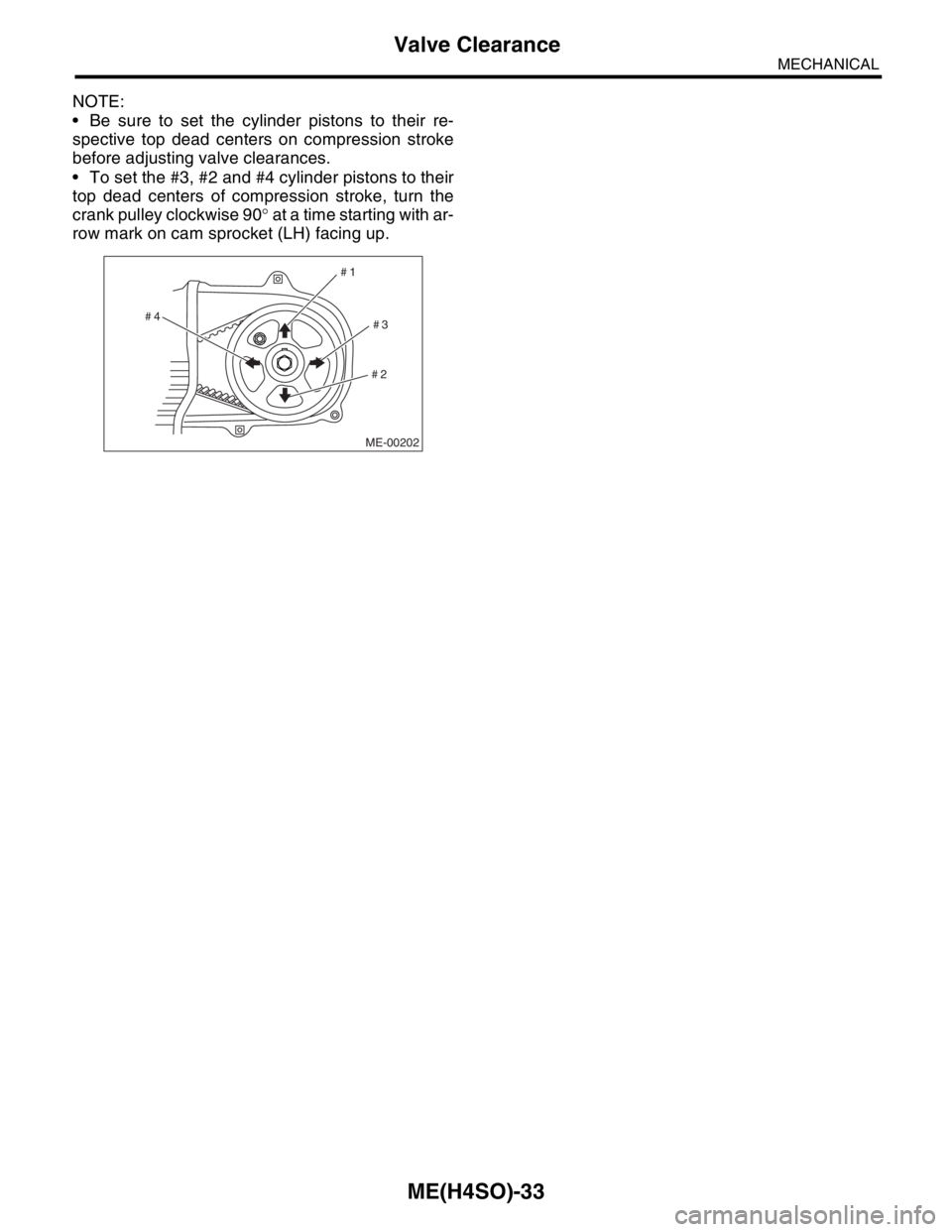

stroke.2) Adjust the #1 cylinder valve clearance.

(1) Loosen the valve rocker nut and screw.

(2) Place suitable thickness gauge.

(3) While noting the valve clearance, tighten the

valve rocker adjusting screw.

(4) When specified valve clearance is obtained,

tighten the valve rocker nut.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

CAUTION:

Insert the thickness gauge in as horizontally

as possible with respect to the valve stem end

face.

Adjust the exhaust valve clearances while

lifting up the vehicle.

Valve clearance:

Intake:

0.20

±0.04 mm (0.0079±0.0016 in)

Exhaust:

0.25

±0.04 mm (0.0098±0.0016 in)

3) Ensure the valve clearances are within specifi-

cations.

4) Turn the crankshaft two complete rotations until

#1 cylinder piston is again set to the top dead cen-

ter of compression stroke.

5) Ensure the valve clearances are within specifi-

cations. If necessary, readjust the valve clearanc-

es.

6) Similar to adjustment procedures used for #1

cylinder, adjust the #2, #3 and #4 cylinder valve

clearances.

ME-00202

#1

#2#3 #4

IN-00044

ME-00200

(A)

ME-00203

Page 902 of 2870

ME(H4SO)-33

MECHANICAL

Valve Clearance

NOTE:

Be sure to set the cylinder pistons to their re-

spective top dead centers on compression stroke

before adjusting valve clearances.

To set the #3, #2 and #4 cylinder pistons to their

top dead centers of compression stroke, turn the

crank pulley clockwise 90° at a time starting with ar-

row mark on cam sprocket (LH) facing up.

ME-00202

#1

#2#3 #4

Page 905 of 2870

ME(H4SO)-36

MECHANICAL

Engine Assembly

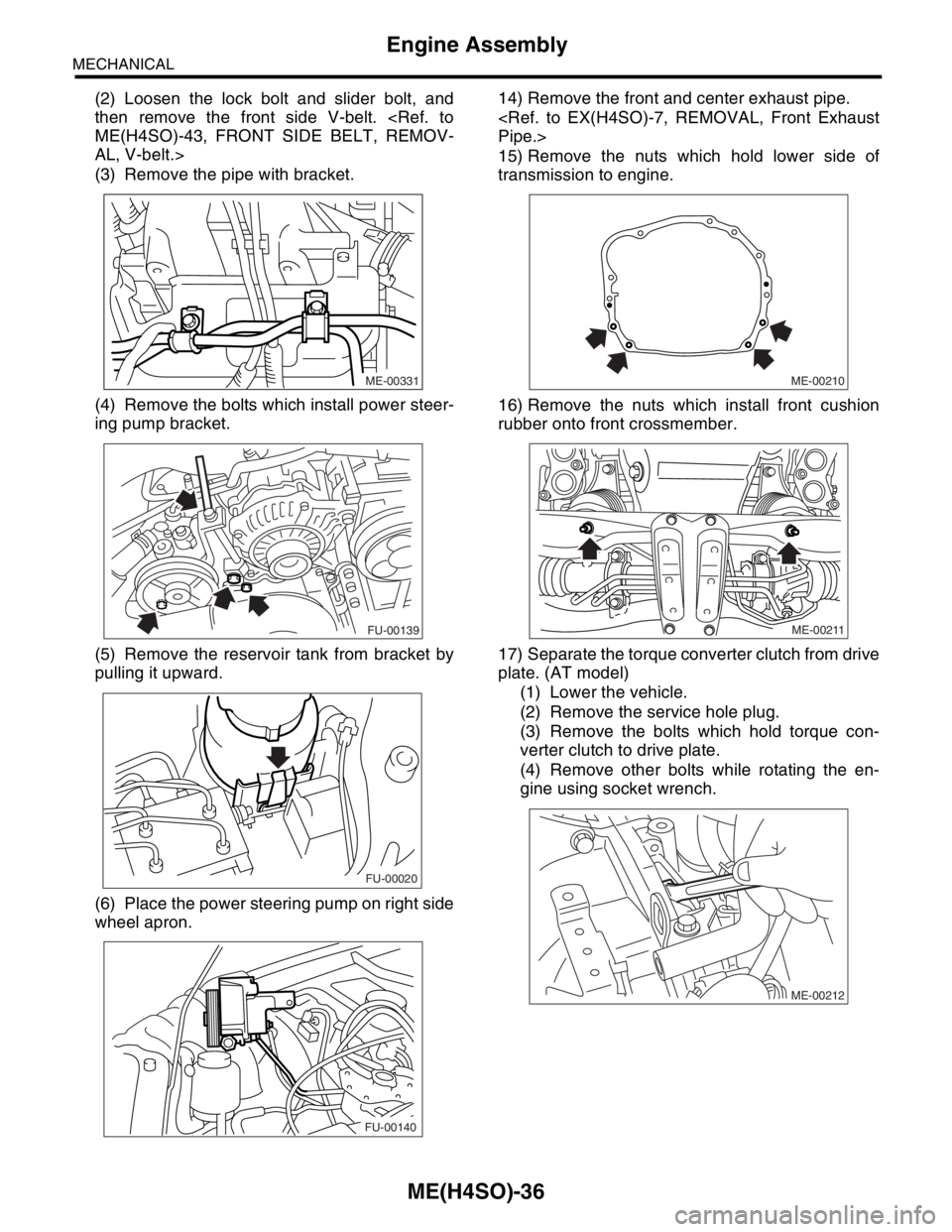

(2) Loosen the lock bolt and slider bolt, and

then remove the front side V-belt.

AL, V-belt.>

(3) Remove the pipe with bracket.

(4) Remove the bolts which install power steer-

ing pump bracket.

(5) Remove the reservoir tank from bracket by

pulling it upward.

(6) Place the power steering pump on right side

wheel apron.14) Remove the front and center exhaust pipe.

15) Remove the nuts which hold lower side of

transmission to engine.

16) Remove the nuts which install front cushion

rubber onto front crossmember.

17) Separate the torque converter clutch from drive

plate. (AT model)

(1) Lower the vehicle.

(2) Remove the service hole plug.

(3) Remove the bolts which hold torque con-

verter clutch to drive plate.

(4) Remove other bolts while rotating the en-

gine using socket wrench.

ME-00331

FU-00139

FU-00020

FU-00140ME-00210

ME-00211

ME-00212

Page 912 of 2870

ME(H4SO)-43

MECHANICAL

V-belt

12.V-belt

A: REMOVAL

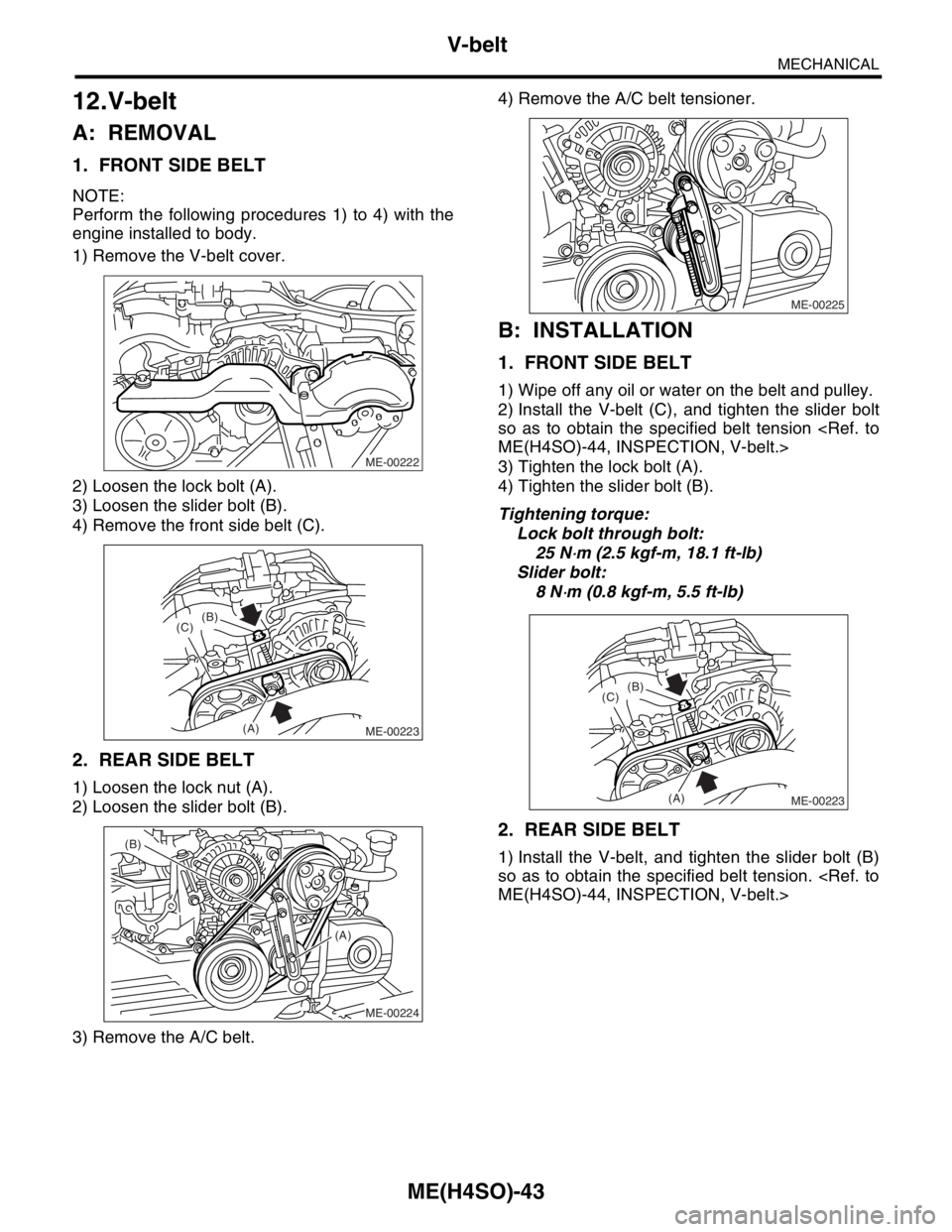

1. FRONT SIDE BELT

NOTE:

Perform the following procedures 1) to 4) with the

engine installed to body.

1) Remove the V-belt cover.

2) Loosen the lock bolt (A).

3) Loosen the slider bolt (B).

4) Remove the front side belt (C).

2. REAR SIDE BELT

1) Loosen the lock nut (A).

2) Loosen the slider bolt (B).

3) Remove the A/C belt.4) Remove the A/C belt tensioner.

B: INSTALLATION

1. FRONT SIDE BELT

1) Wipe off any oil or water on the belt and pulley.

2) Install the V-belt (C), and tighten the slider bolt

so as to obtain the specified belt tension

3) Tighten the lock bolt (A).

4) Tighten the slider bolt (B).

Tightening torque:

Lock bolt through bolt:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

Slider bolt:

8 N

⋅m (0.8 kgf-m, 5.5 ft-lb)

2. REAR SIDE BELT

1) Install the V-belt, and tighten the slider bolt (B)

so as to obtain the specified belt tension.

ME-00222

ME-00223

(B)

(C)

(A)

ME-00224

(A) (B)

ME-00225

ME-00223

(B)

(C)

(A)