SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 331 of 1456

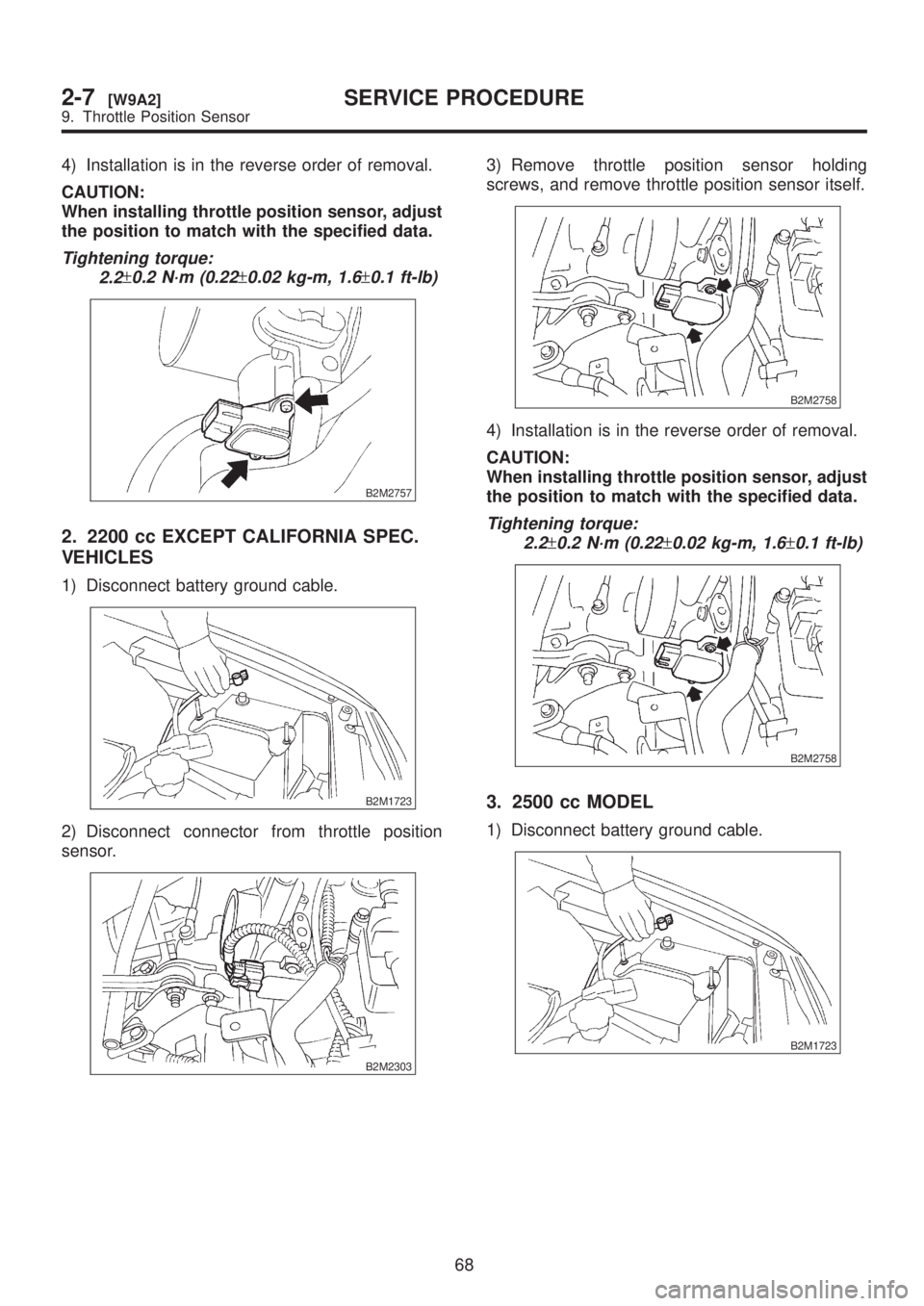

4) Installation is in the reverse order of removal.

CAUTION:

When installing throttle position sensor, adjust

the position to match with the specified data.

Tightening torque:

2.2

±0.2 N´m (0.22±0.02 kg-m, 1.6±0.1 ft-lb)

B2M2757

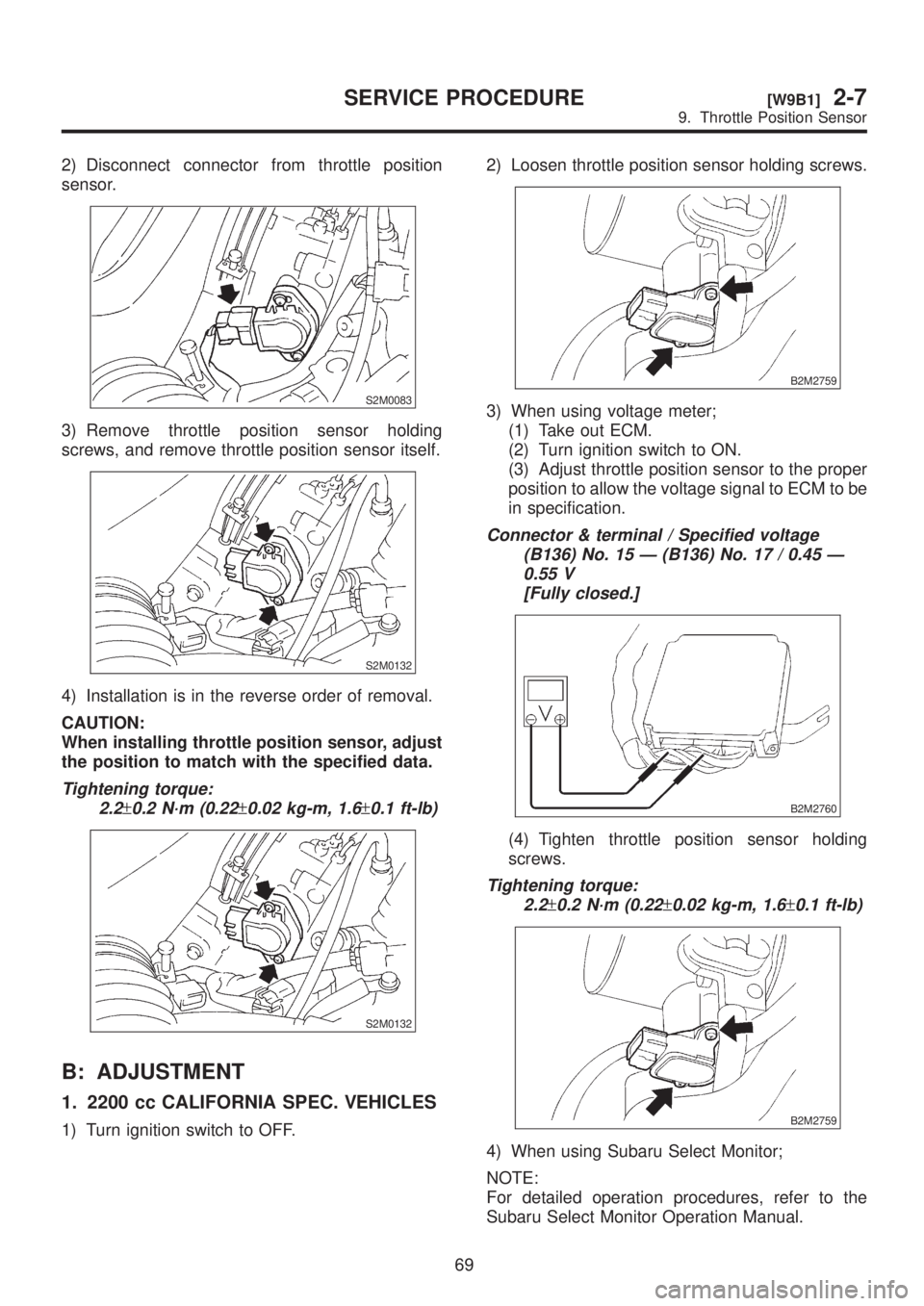

2. 2200 cc EXCEPT CALIFORNIA SPEC.

VEHICLES

1) Disconnect battery ground cable.

B2M1723

2) Disconnect connector from throttle position

sensor.

B2M2303

3) Remove throttle position sensor holding

screws, and remove throttle position sensor itself.

B2M2758

4) Installation is in the reverse order of removal.

CAUTION:

When installing throttle position sensor, adjust

the position to match with the specified data.

Tightening torque:

2.2

±0.2 N´m (0.22±0.02 kg-m, 1.6±0.1 ft-lb)

B2M2758

3. 2500 cc MODEL

1) Disconnect battery ground cable.

B2M1723

68

2-7[W9A2]SERVICE PROCEDURE

9. Throttle Position Sensor

Page 332 of 1456

2) Disconnect connector from throttle position

sensor.

S2M0083

3) Remove throttle position sensor holding

screws, and remove throttle position sensor itself.

S2M0132

4) Installation is in the reverse order of removal.

CAUTION:

When installing throttle position sensor, adjust

the position to match with the specified data.

Tightening torque:

2.2

±0.2 N´m (0.22±0.02 kg-m, 1.6±0.1 ft-lb)

S2M0132

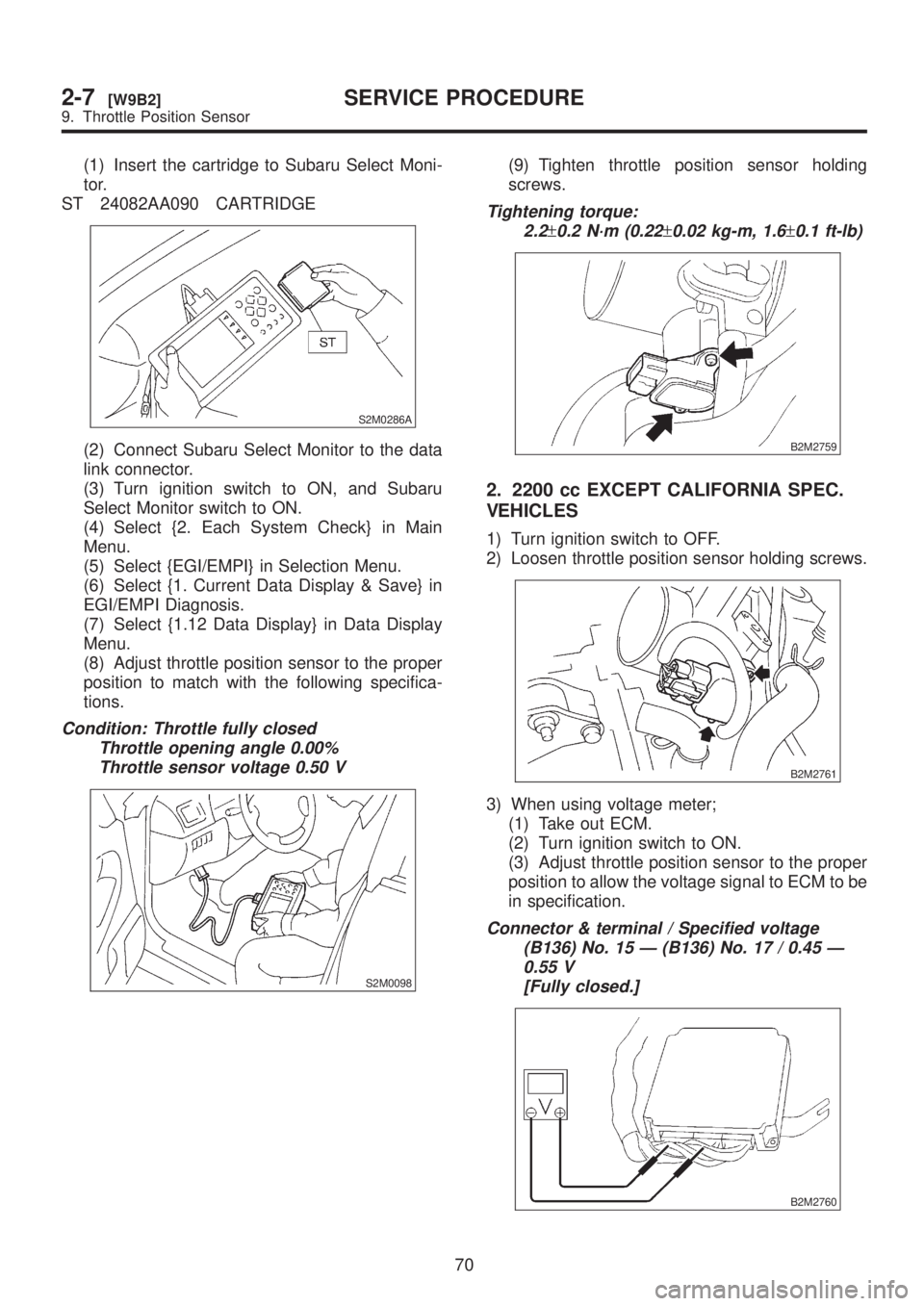

B: ADJUSTMENT

1. 2200 cc CALIFORNIA SPEC. VEHICLES

1) Turn ignition switch to OFF.2) Loosen throttle position sensor holding screws.

B2M2759

3) When using voltage meter;

(1) Take out ECM.

(2) Turn ignition switch to ON.

(3) Adjust throttle position sensor to the proper

position to allow the voltage signal to ECM to be

in specification.

Connector & terminal / Specified voltage

(B136) No. 15 Ð (B136) No. 17 / 0.45 Ð

0.55 V

[Fully closed.]

B2M2760

(4) Tighten throttle position sensor holding

screws.

Tightening torque:

2.2

±0.2 N´m (0.22±0.02 kg-m, 1.6±0.1 ft-lb)

B2M2759

4) When using Subaru Select Monitor;

NOTE:

For detailed operation procedures, refer to the

Subaru Select Monitor Operation Manual.

69

[W9B1]2-7SERVICE PROCEDURE

9. Throttle Position Sensor

Page 333 of 1456

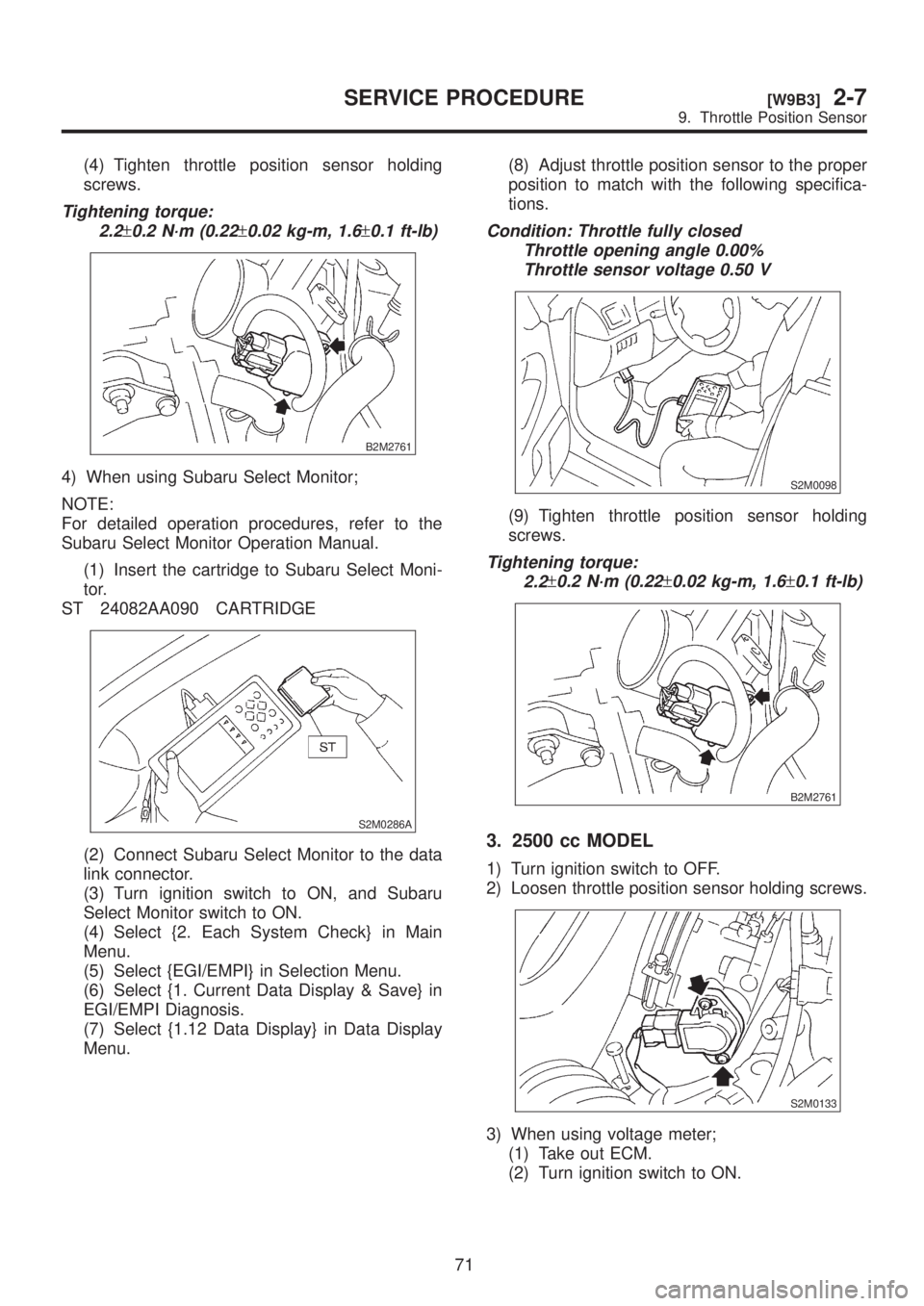

(1) Insert the cartridge to Subaru Select Moni-

tor.

ST 24082AA090 CARTRIDGE

S2M0286A

(2) Connect Subaru Select Monitor to the data

link connector.

(3) Turn ignition switch to ON, and Subaru

Select Monitor switch to ON.

(4) Select {2. Each System Check} in Main

Menu.

(5) Select {EGI/EMPI} in Selection Menu.

(6) Select {1. Current Data Display & Save} in

EGI/EMPI Diagnosis.

(7) Select {1.12 Data Display} in Data Display

Menu.

(8) Adjust throttle position sensor to the proper

position to match with the following specifica-

tions.

Condition: Throttle fully closed

Throttle opening angle 0.00%

Throttle sensor voltage 0.50 V

S2M0098

(9) Tighten throttle position sensor holding

screws.

Tightening torque:

2.2

±0.2 N´m (0.22±0.02 kg-m, 1.6±0.1 ft-lb)

B2M2759

2. 2200 cc EXCEPT CALIFORNIA SPEC.

VEHICLES

1) Turn ignition switch to OFF.

2) Loosen throttle position sensor holding screws.

B2M2761

3) When using voltage meter;

(1) Take out ECM.

(2) Turn ignition switch to ON.

(3) Adjust throttle position sensor to the proper

position to allow the voltage signal to ECM to be

in specification.

Connector & terminal / Specified voltage

(B136) No. 15 Ð (B136) No. 17 / 0.45 Ð

0.55 V

[Fully closed.]

B2M2760

70

2-7[W9B2]SERVICE PROCEDURE

9. Throttle Position Sensor

Page 334 of 1456

(4) Tighten throttle position sensor holding

screws.

Tightening torque:

2.2

±0.2 N´m (0.22±0.02 kg-m, 1.6±0.1 ft-lb)

B2M2761

4) When using Subaru Select Monitor;

NOTE:

For detailed operation procedures, refer to the

Subaru Select Monitor Operation Manual.

(1) Insert the cartridge to Subaru Select Moni-

tor.

ST 24082AA090 CARTRIDGE

S2M0286A

(2) Connect Subaru Select Monitor to the data

link connector.

(3) Turn ignition switch to ON, and Subaru

Select Monitor switch to ON.

(4) Select {2. Each System Check} in Main

Menu.

(5) Select {EGI/EMPI} in Selection Menu.

(6) Select {1. Current Data Display & Save} in

EGI/EMPI Diagnosis.

(7) Select {1.12 Data Display} in Data Display

Menu.(8) Adjust throttle position sensor to the proper

position to match with the following specifica-

tions.

Condition: Throttle fully closed

Throttle opening angle 0.00%

Throttle sensor voltage 0.50 V

S2M0098

(9) Tighten throttle position sensor holding

screws.

Tightening torque:

2.2

±0.2 N´m (0.22±0.02 kg-m, 1.6±0.1 ft-lb)

B2M2761

3. 2500 cc MODEL

1) Turn ignition switch to OFF.

2) Loosen throttle position sensor holding screws.

S2M0133

3) When using voltage meter;

(1) Take out ECM.

(2) Turn ignition switch to ON.

71

[W9B3]2-7SERVICE PROCEDURE

9. Throttle Position Sensor

Page 335 of 1456

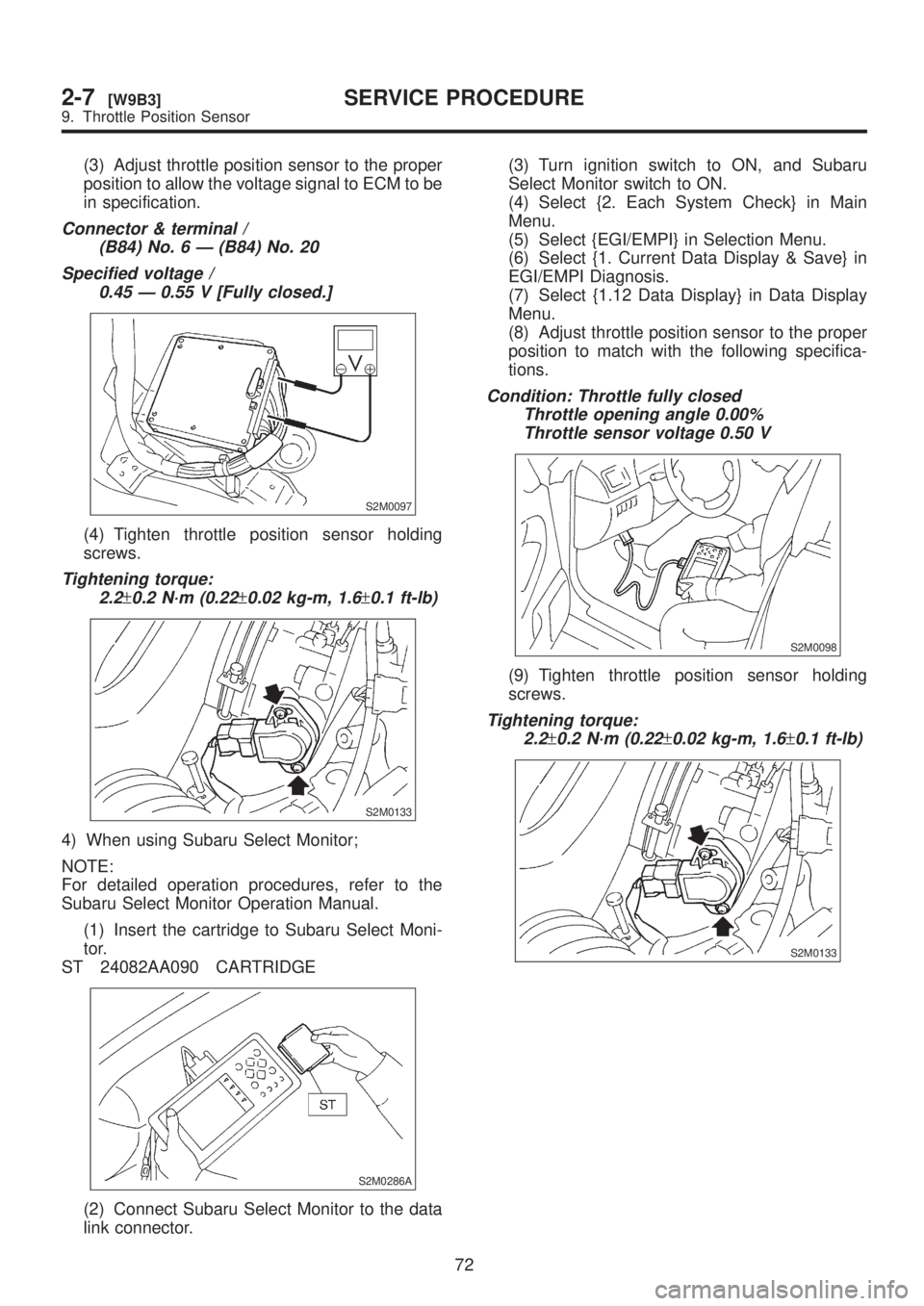

(3) Adjust throttle position sensor to the proper

position to allow the voltage signal to ECM to be

in specification.

Connector & terminal /

(B84) No. 6 Ð (B84) No. 20

Specified voltage /

0.45 Ð 0.55 V [Fully closed.]

S2M0097

(4) Tighten throttle position sensor holding

screws.

Tightening torque:

2.2

±0.2 N´m (0.22±0.02 kg-m, 1.6±0.1 ft-lb)

S2M0133

4) When using Subaru Select Monitor;

NOTE:

For detailed operation procedures, refer to the

Subaru Select Monitor Operation Manual.

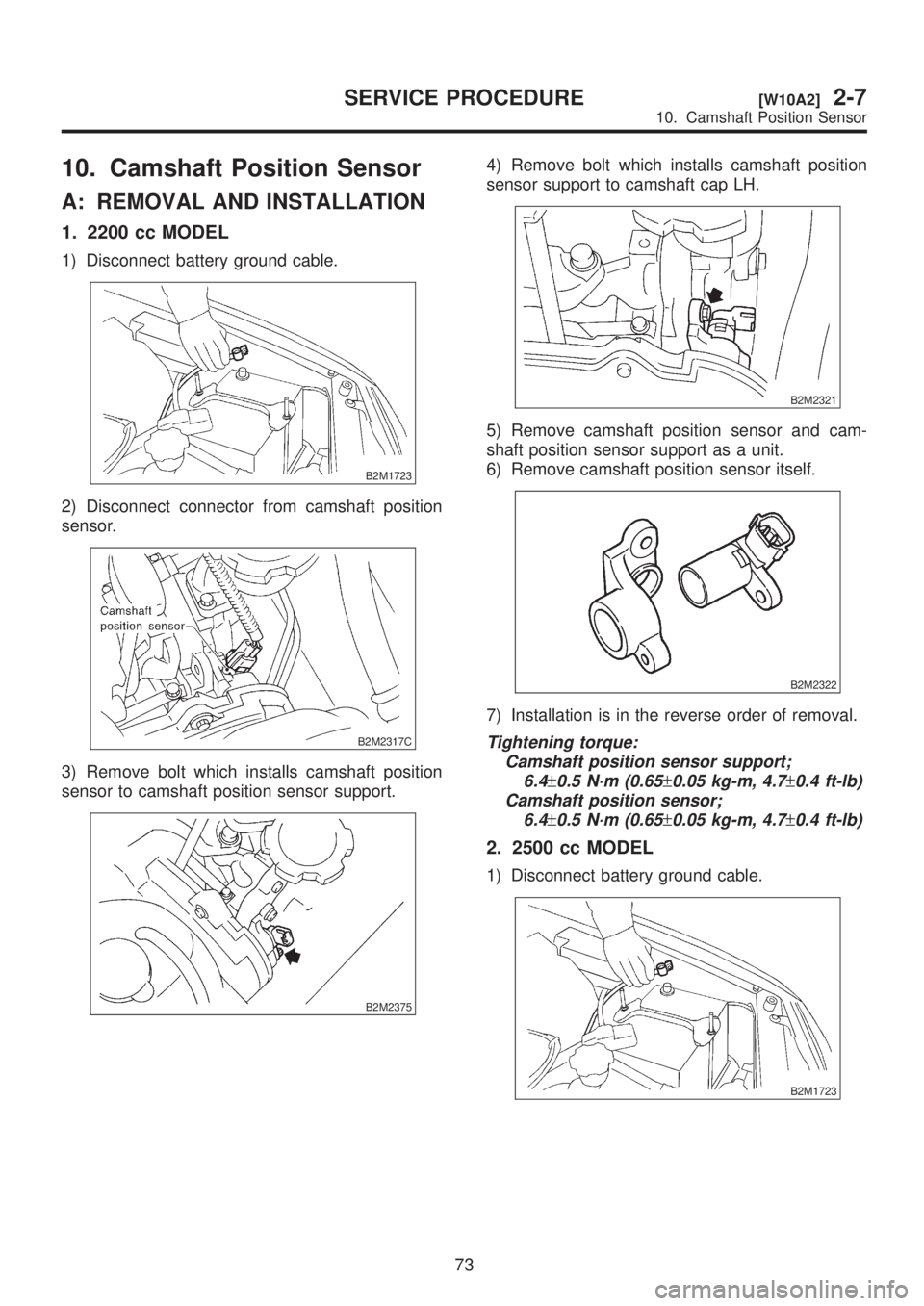

(1) Insert the cartridge to Subaru Select Moni-

tor.

ST 24082AA090 CARTRIDGE

S2M0286A

(2) Connect Subaru Select Monitor to the data

link connector.(3) Turn ignition switch to ON, and Subaru

Select Monitor switch to ON.

(4) Select {2. Each System Check} in Main

Menu.

(5) Select {EGI/EMPI} in Selection Menu.

(6) Select {1. Current Data Display & Save} in

EGI/EMPI Diagnosis.

(7) Select {1.12 Data Display} in Data Display

Menu.

(8) Adjust throttle position sensor to the proper

position to match with the following specifica-

tions.

Condition: Throttle fully closed

Throttle opening angle 0.00%

Throttle sensor voltage 0.50 V

S2M0098

(9) Tighten throttle position sensor holding

screws.

Tightening torque:

2.2

±0.2 N´m (0.22±0.02 kg-m, 1.6±0.1 ft-lb)

S2M0133

72

2-7[W9B3]SERVICE PROCEDURE

9. Throttle Position Sensor

Page 336 of 1456

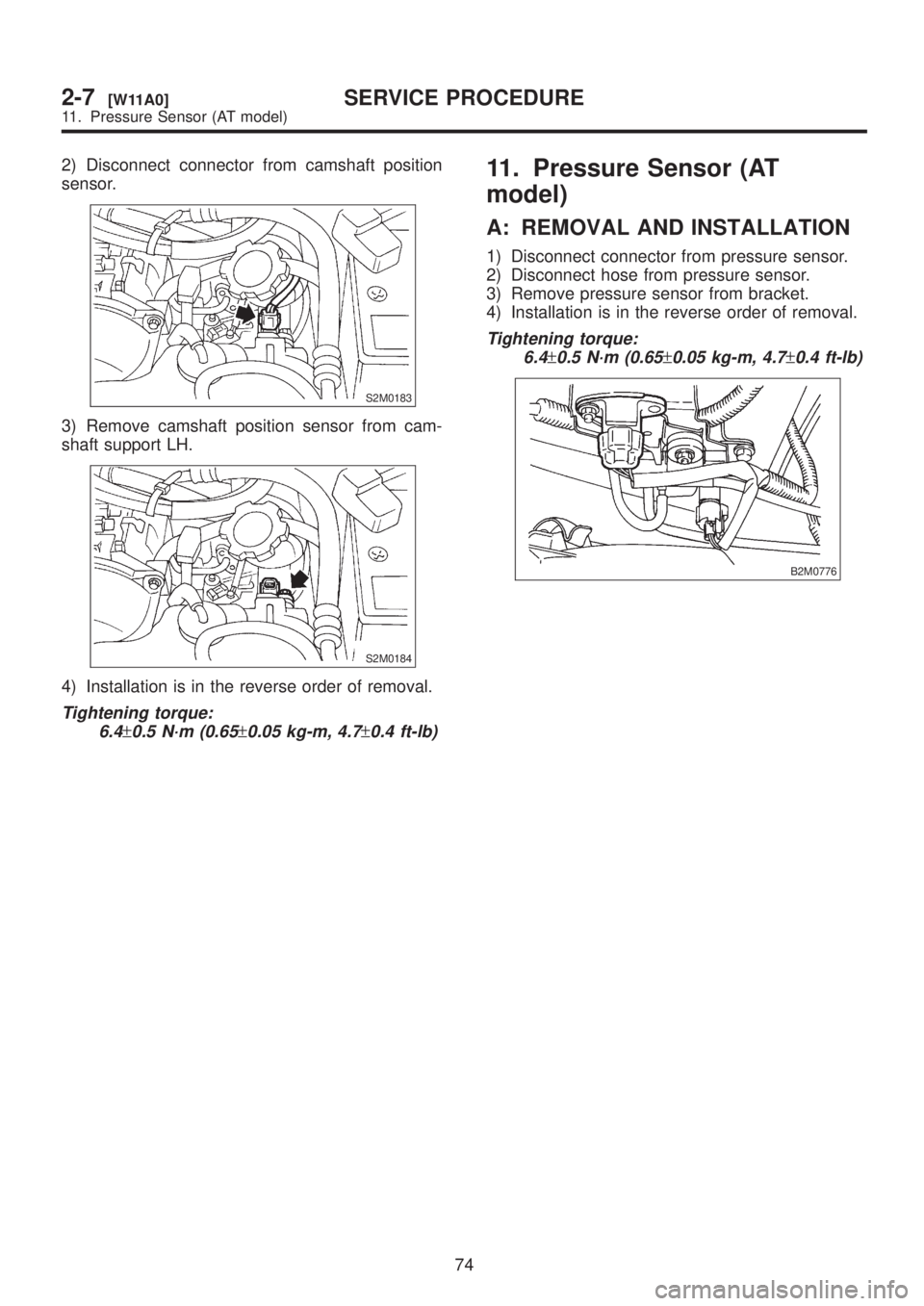

10. Camshaft Position Sensor

A: REMOVAL AND INSTALLATION

1. 2200 cc MODEL

1) Disconnect battery ground cable.

B2M1723

2) Disconnect connector from camshaft position

sensor.

B2M2317C

3) Remove bolt which installs camshaft position

sensor to camshaft position sensor support.

B2M2375

4) Remove bolt which installs camshaft position

sensor support to camshaft cap LH.

B2M2321

5) Remove camshaft position sensor and cam-

shaft position sensor support as a unit.

6) Remove camshaft position sensor itself.

B2M2322

7) Installation is in the reverse order of removal.

Tightening torque:

Camshaft position sensor support;

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

Camshaft position sensor;

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

2. 2500 cc MODEL

1) Disconnect battery ground cable.

B2M1723

73

[W10A2]2-7SERVICE PROCEDURE

10. Camshaft Position Sensor

Page 337 of 1456

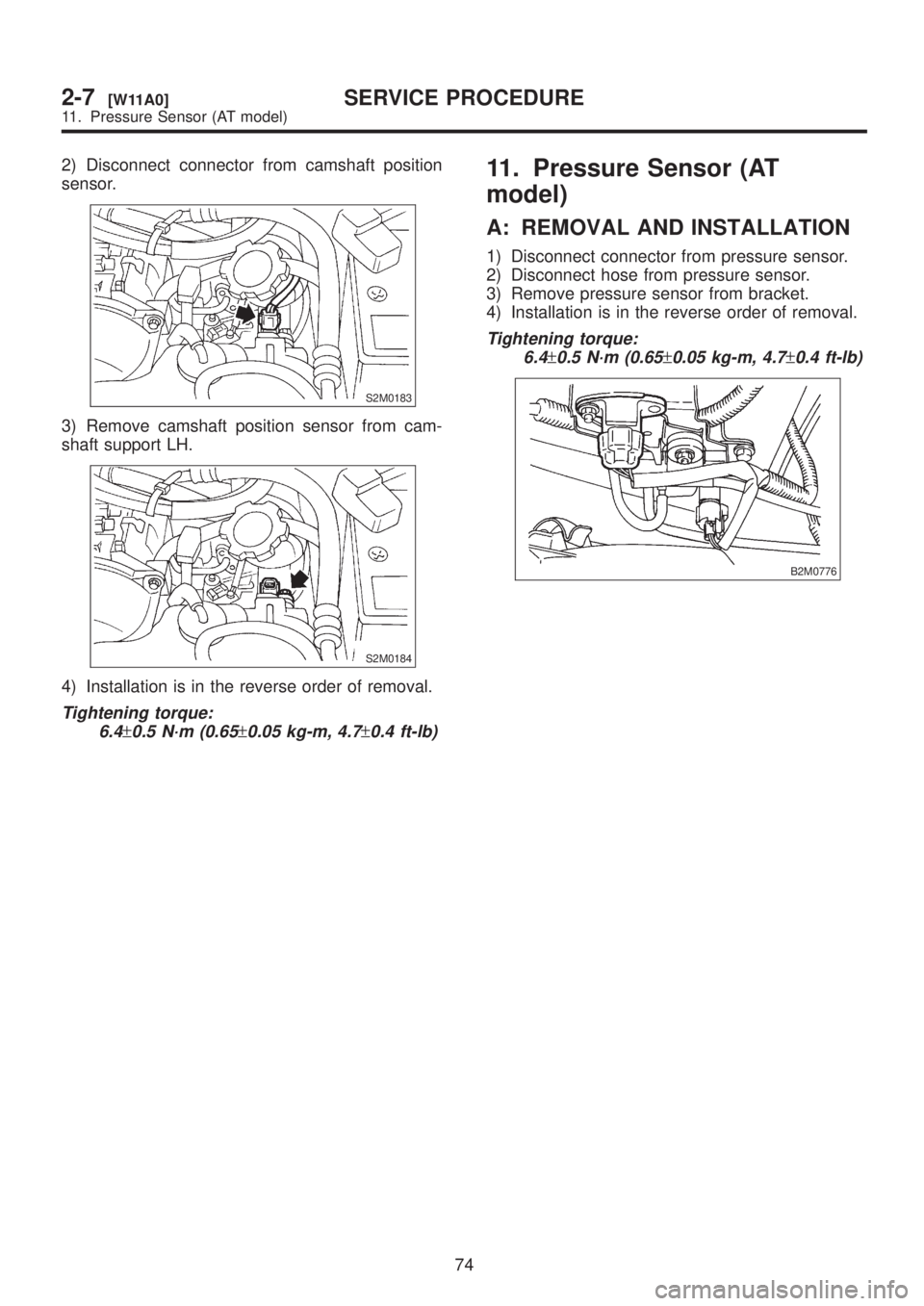

2) Disconnect connector from camshaft position

sensor.

S2M0183

3) Remove camshaft position sensor from cam-

shaft support LH.

S2M0184

4) Installation is in the reverse order of removal.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

11. Pressure Sensor (AT

model)

A: REMOVAL AND INSTALLATION

1) Disconnect connector from pressure sensor.

2) Disconnect hose from pressure sensor.

3) Remove pressure sensor from bracket.

4) Installation is in the reverse order of removal.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

B2M0776

74

2-7[W11A0]SERVICE PROCEDURE

11. Pressure Sensor (AT model)

Page 338 of 1456

2) Disconnect connector from camshaft position

sensor.

S2M0183

3) Remove camshaft position sensor from cam-

shaft support LH.

S2M0184

4) Installation is in the reverse order of removal.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

11. Pressure Sensor (AT

model)

A: REMOVAL AND INSTALLATION

1) Disconnect connector from pressure sensor.

2) Disconnect hose from pressure sensor.

3) Remove pressure sensor from bracket.

4) Installation is in the reverse order of removal.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

B2M0776

74

2-7[W11A0]SERVICE PROCEDURE

11. Pressure Sensor (AT model)

Page 339 of 1456

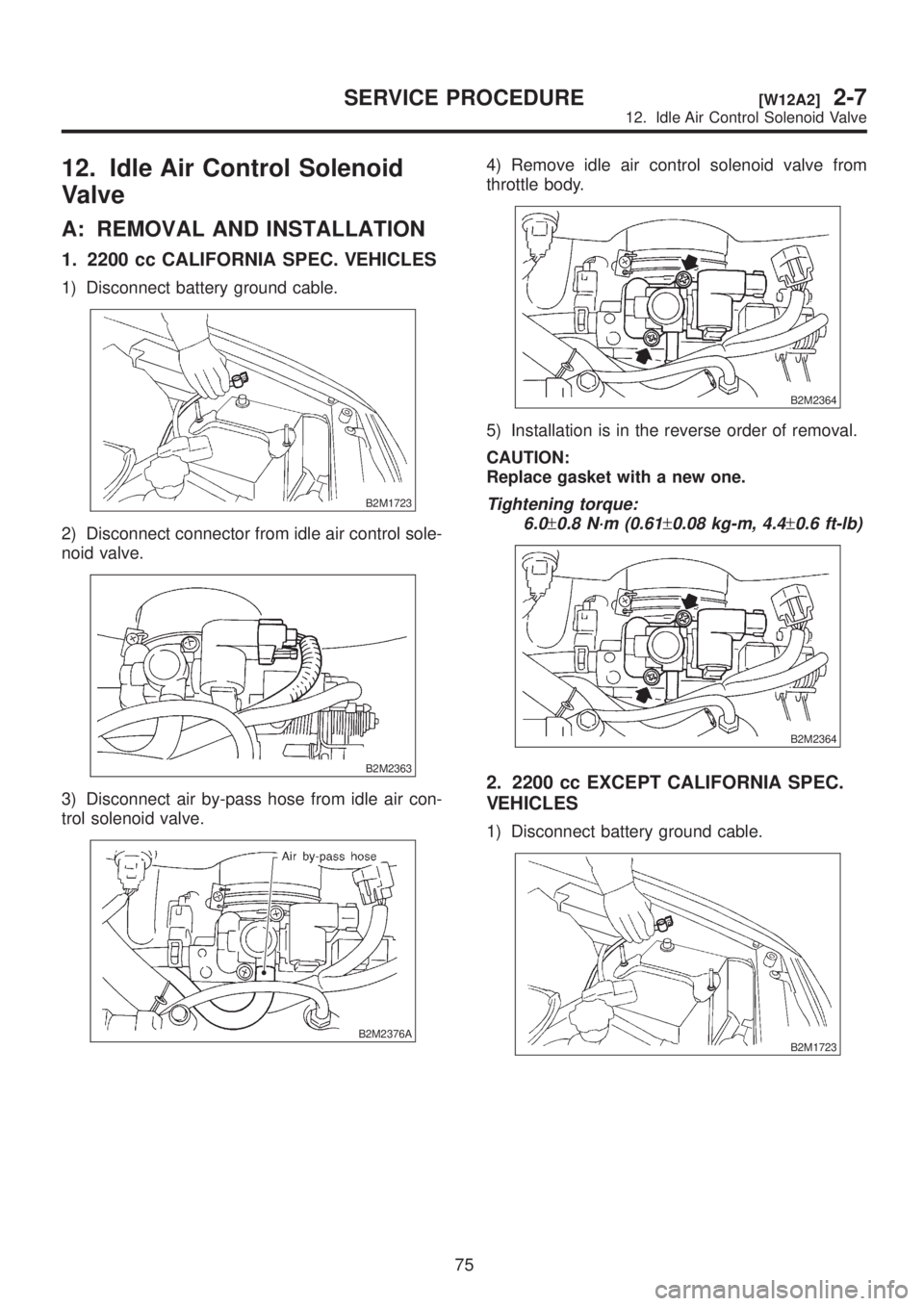

12. Idle Air Control Solenoid

Valve

A: REMOVAL AND INSTALLATION

1. 2200 cc CALIFORNIA SPEC. VEHICLES

1) Disconnect battery ground cable.

B2M1723

2) Disconnect connector from idle air control sole-

noid valve.

B2M2363

3) Disconnect air by-pass hose from idle air con-

trol solenoid valve.

B2M2376A

4) Remove idle air control solenoid valve from

throttle body.

B2M2364

5) Installation is in the reverse order of removal.

CAUTION:

Replace gasket with a new one.

Tightening torque:

6.0

±0.8 N´m (0.61±0.08 kg-m, 4.4±0.6 ft-lb)

B2M2364

2. 2200 cc EXCEPT CALIFORNIA SPEC.

VEHICLES

1) Disconnect battery ground cable.

B2M1723

75

[W12A2]2-7SERVICE PROCEDURE

12. Idle Air Control Solenoid Valve

Page 340 of 1456

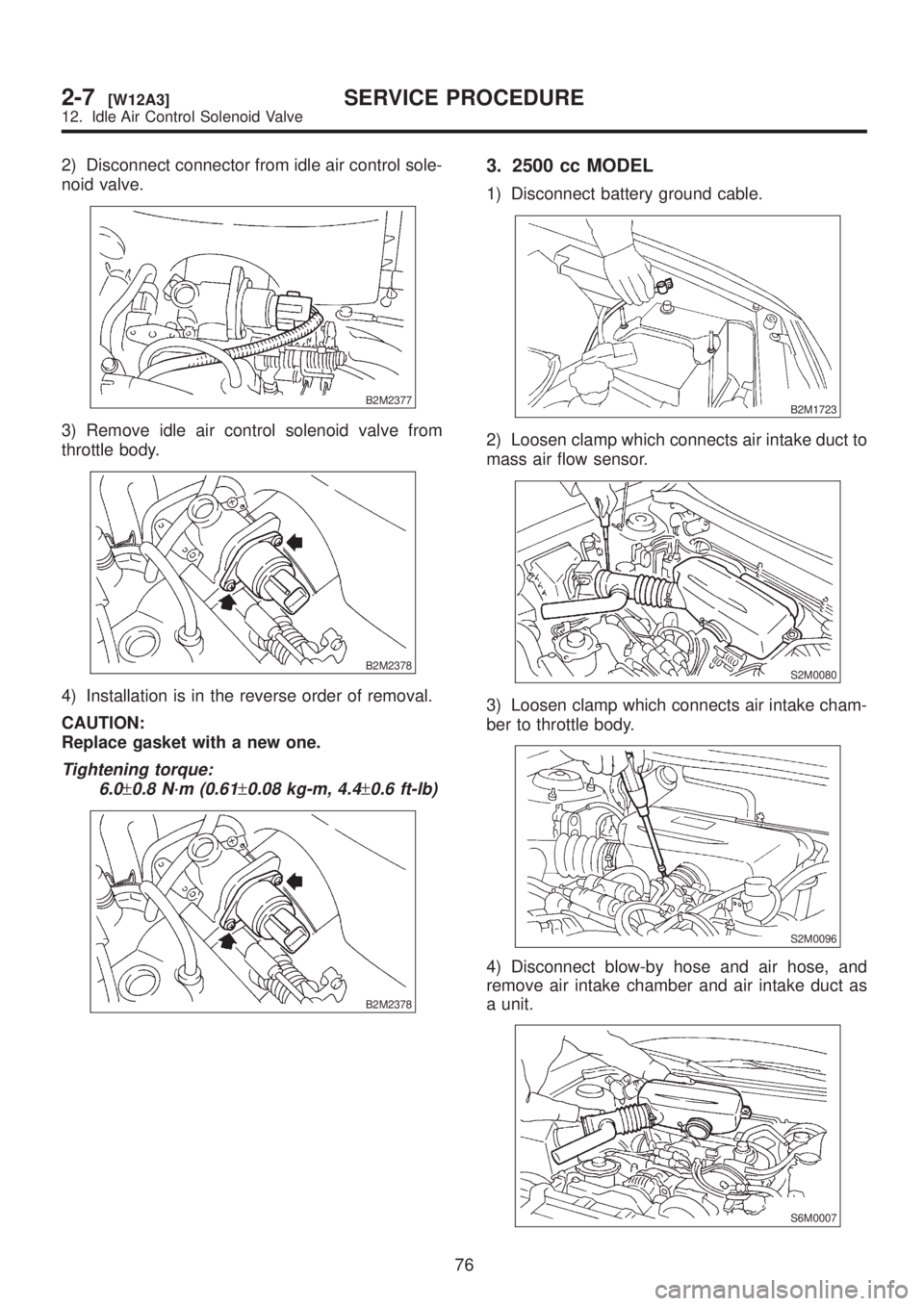

2) Disconnect connector from idle air control sole-

noid valve.

B2M2377

3) Remove idle air control solenoid valve from

throttle body.

B2M2378

4) Installation is in the reverse order of removal.

CAUTION:

Replace gasket with a new one.

Tightening torque:

6.0

±0.8 N´m (0.61±0.08 kg-m, 4.4±0.6 ft-lb)

B2M2378

3. 2500 cc MODEL

1) Disconnect battery ground cable.

B2M1723

2) Loosen clamp which connects air intake duct to

mass air flow sensor.

S2M0080

3) Loosen clamp which connects air intake cham-

ber to throttle body.

S2M0096

4) Disconnect blow-by hose and air hose, and

remove air intake chamber and air intake duct as

a unit.

S6M0007

76

2-7[W12A3]SERVICE PROCEDURE

12. Idle Air Control Solenoid Valve