SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 341 of 1456

5) Disconnect connector from idle air control sole-

noid valve.

S2M0099

6) Disconnect PCV hose (A) and pressure regula-

tor vacuum hose (B).

H2M2440A

7) Disconnect air by-pass hose from idle air con-

trol solenoid valve.

S2M0100

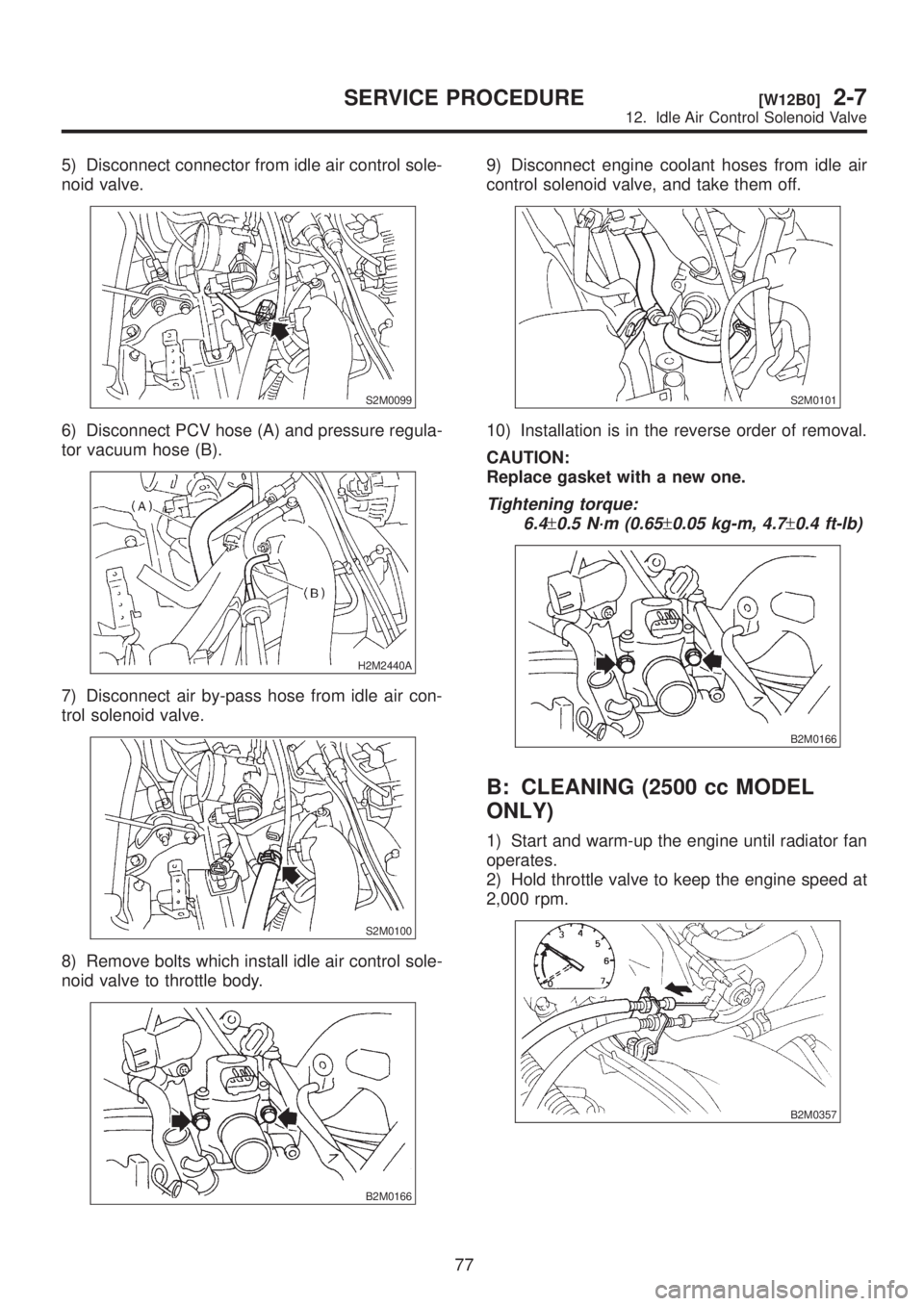

8) Remove bolts which install idle air control sole-

noid valve to throttle body.

B2M0166

9) Disconnect engine coolant hoses from idle air

control solenoid valve, and take them off.

S2M0101

10) Installation is in the reverse order of removal.

CAUTION:

Replace gasket with a new one.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

B2M0166

B: CLEANING (2500 cc MODEL

ONLY)

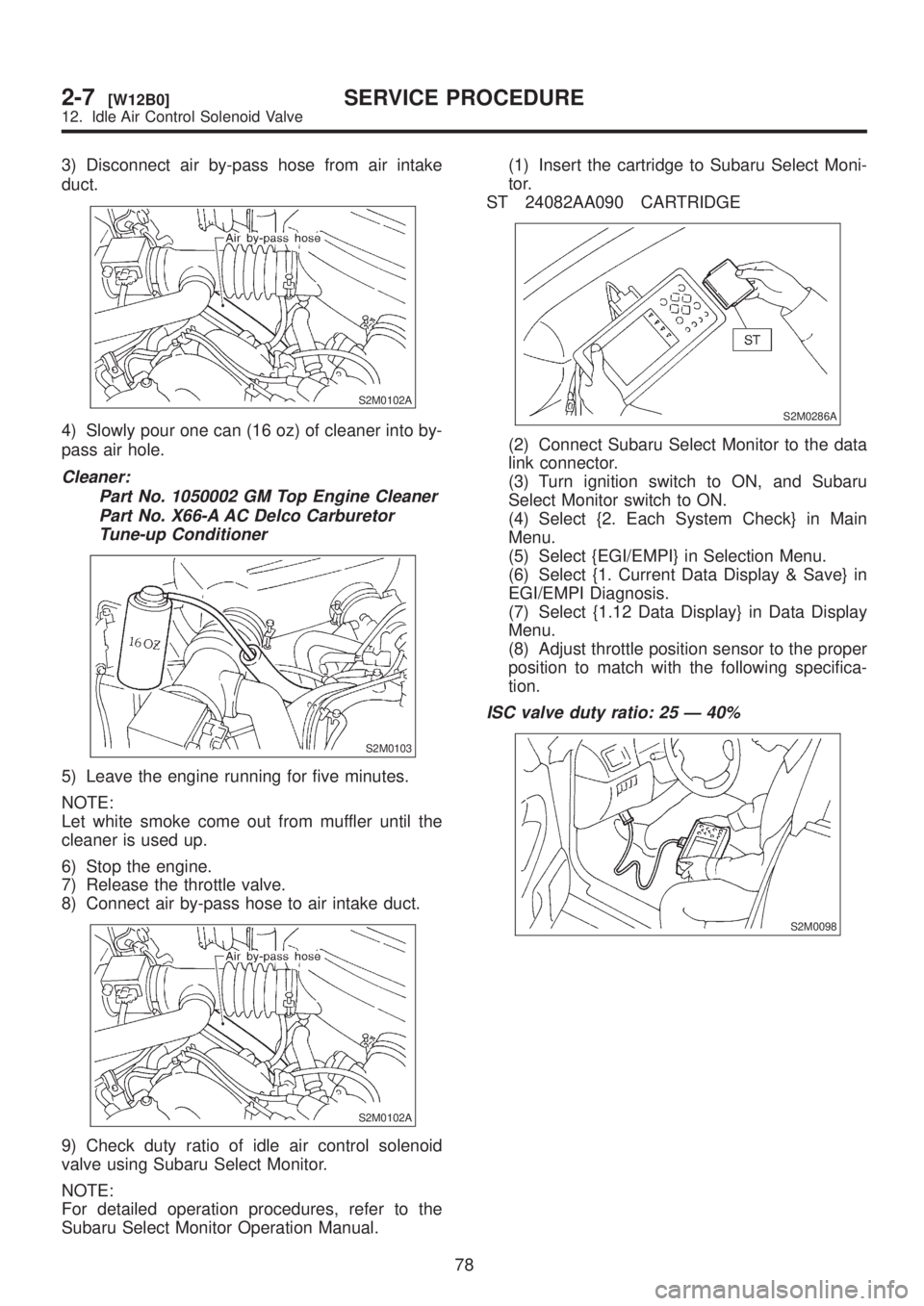

1) Start and warm-up the engine until radiator fan

operates.

2) Hold throttle valve to keep the engine speed at

2,000 rpm.

B2M0357

77

[W12B0]2-7SERVICE PROCEDURE

12. Idle Air Control Solenoid Valve

Page 342 of 1456

3) Disconnect air by-pass hose from air intake

duct.

S2M0102A

4) Slowly pour one can (16 oz) of cleaner into by-

pass air hole.

Cleaner:

Part No. 1050002 GM Top Engine Cleaner

Part No. X66-A AC Delco Carburetor

Tune-up Conditioner

S2M0103

5) Leave the engine running for five minutes.

NOTE:

Let white smoke come out from muffler until the

cleaner is used up.

6) Stop the engine.

7) Release the throttle valve.

8) Connect air by-pass hose to air intake duct.

S2M0102A

9) Check duty ratio of idle air control solenoid

valve using Subaru Select Monitor.

NOTE:

For detailed operation procedures, refer to the

Subaru Select Monitor Operation Manual.(1) Insert the cartridge to Subaru Select Moni-

tor.

ST 24082AA090 CARTRIDGE

S2M0286A

(2) Connect Subaru Select Monitor to the data

link connector.

(3) Turn ignition switch to ON, and Subaru

Select Monitor switch to ON.

(4) Select {2. Each System Check} in Main

Menu.

(5) Select {EGI/EMPI} in Selection Menu.

(6) Select {1. Current Data Display & Save} in

EGI/EMPI Diagnosis.

(7) Select {1.12 Data Display} in Data Display

Menu.

(8) Adjust throttle position sensor to the proper

position to match with the following specifica-

tion.

ISC valve duty ratio: 25 Ð 40%

S2M0098

78

2-7[W12B0]SERVICE PROCEDURE

12. Idle Air Control Solenoid Valve

Page 343 of 1456

13. Pressure Sources

Switching Solenoid Valve (AT

model)

A: REMOVAL AND INSTALLATION

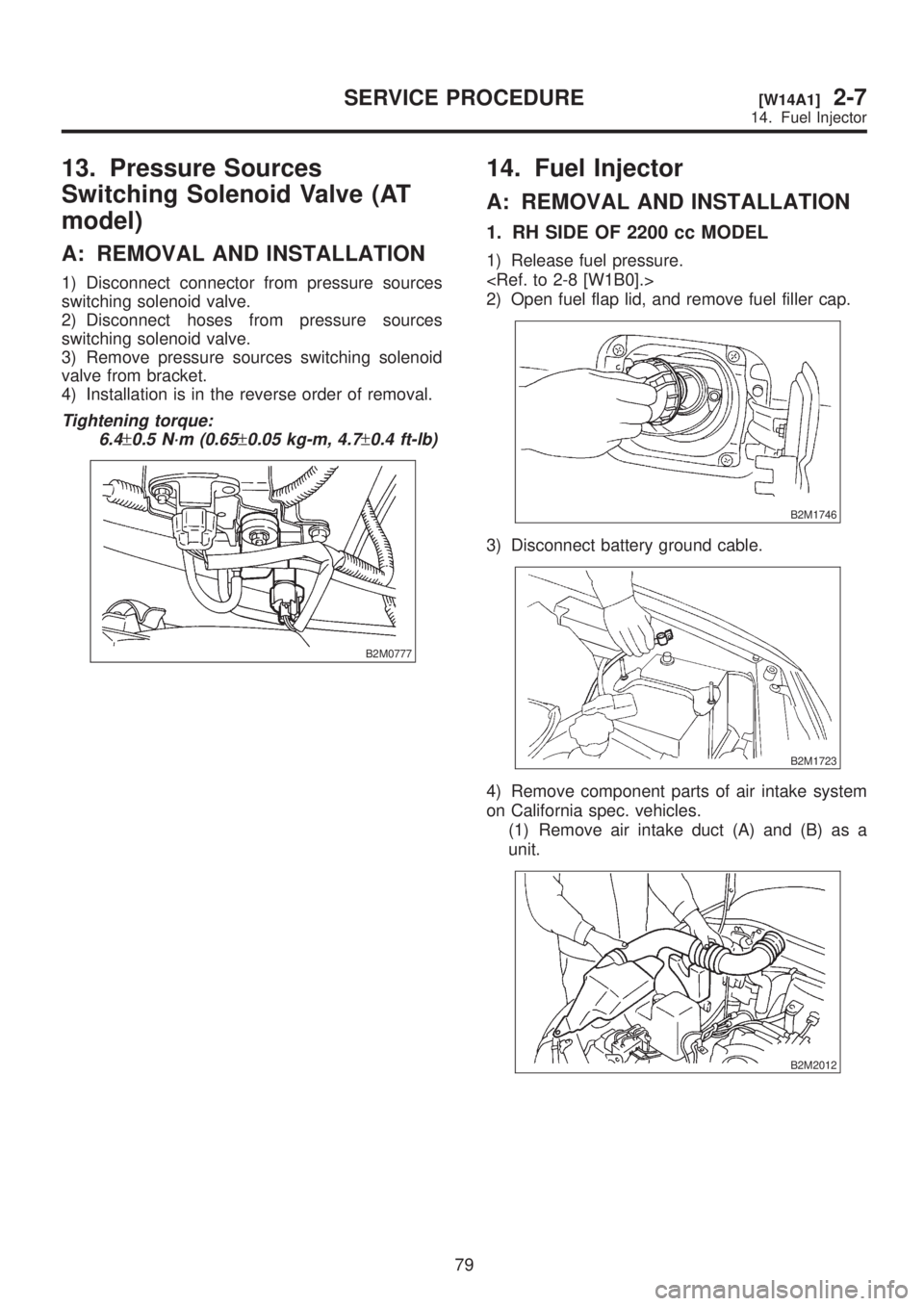

1) Disconnect connector from pressure sources

switching solenoid valve.

2) Disconnect hoses from pressure sources

switching solenoid valve.

3) Remove pressure sources switching solenoid

valve from bracket.

4) Installation is in the reverse order of removal.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

B2M0777

14. Fuel Injector

A: REMOVAL AND INSTALLATION

1. RH SIDE OF 2200 cc MODEL

1) Release fuel pressure.

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Remove component parts of air intake system

on California spec. vehicles.

(1) Remove air intake duct (A) and (B) as a

unit.

B2M2012

79

[W14A1]2-7SERVICE PROCEDURE

14. Fuel Injector

Page 344 of 1456

13. Pressure Sources

Switching Solenoid Valve (AT

model)

A: REMOVAL AND INSTALLATION

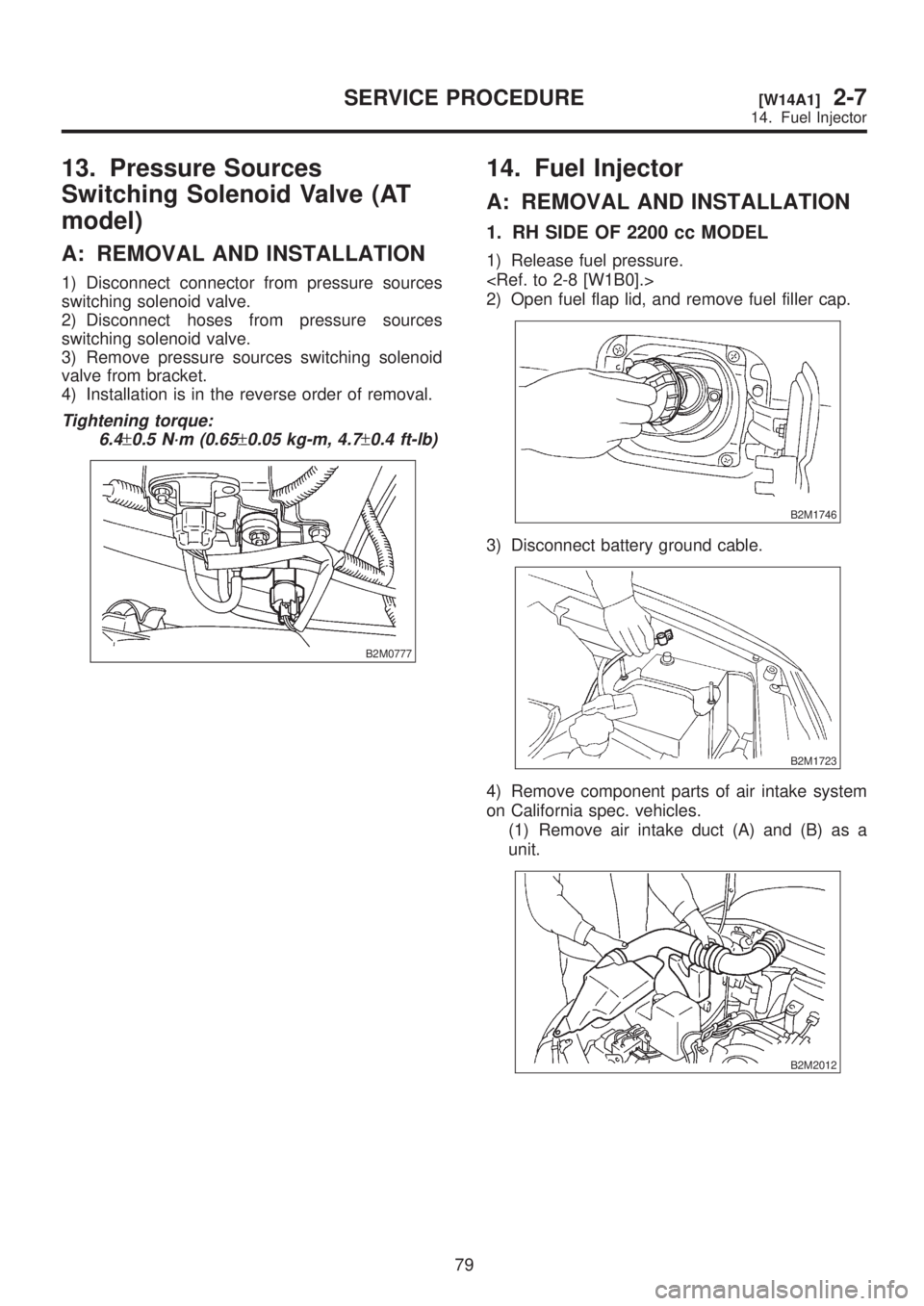

1) Disconnect connector from pressure sources

switching solenoid valve.

2) Disconnect hoses from pressure sources

switching solenoid valve.

3) Remove pressure sources switching solenoid

valve from bracket.

4) Installation is in the reverse order of removal.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

B2M0777

14. Fuel Injector

A: REMOVAL AND INSTALLATION

1. RH SIDE OF 2200 cc MODEL

1) Release fuel pressure.

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Remove component parts of air intake system

on California spec. vehicles.

(1) Remove air intake duct (A) and (B) as a

unit.

B2M2012

79

[W14A1]2-7SERVICE PROCEDURE

14. Fuel Injector

Page 345 of 1456

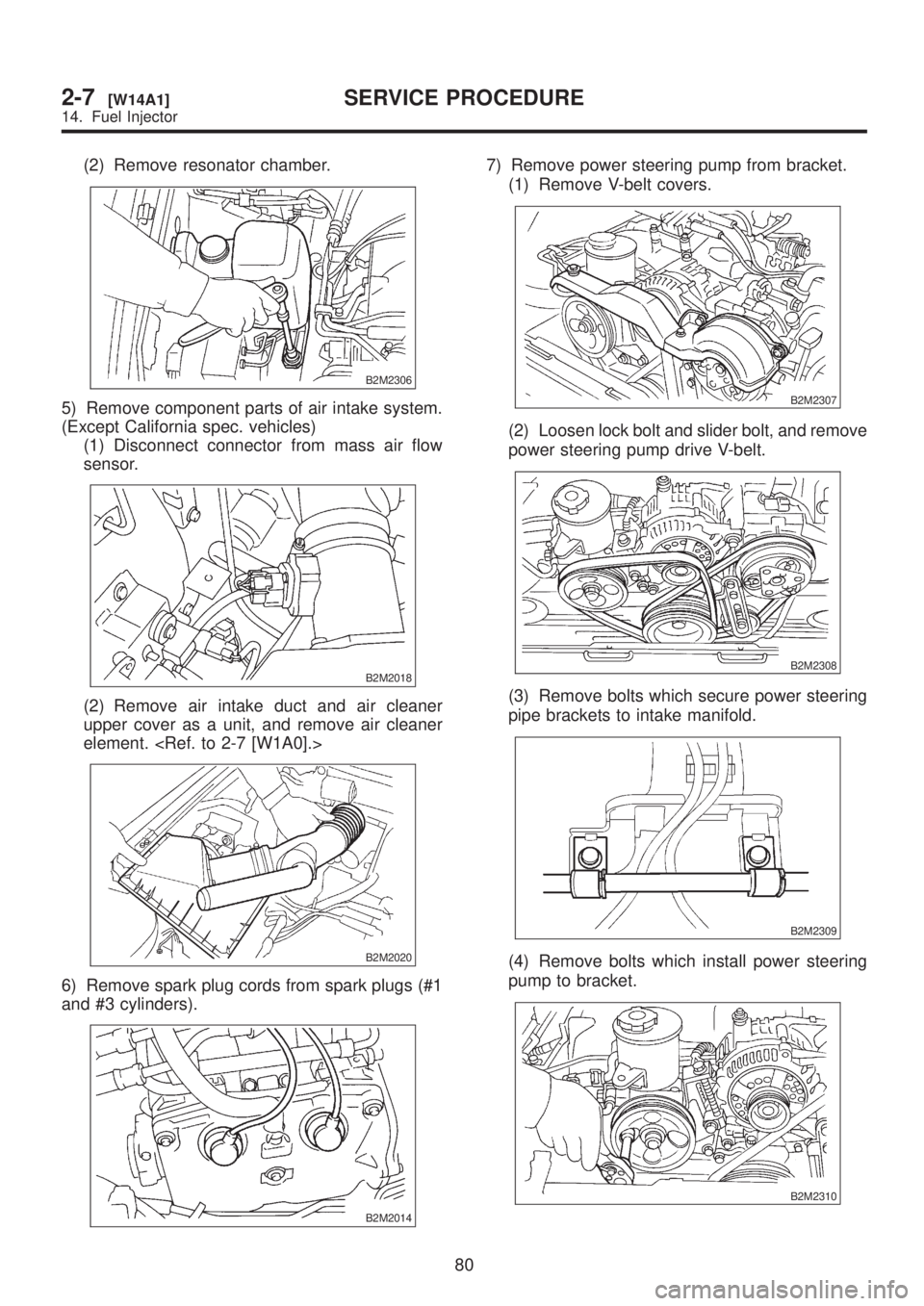

(2) Remove resonator chamber.

B2M2306

5) Remove component parts of air intake system.

(Except California spec. vehicles)

(1) Disconnect connector from mass air flow

sensor.

B2M2018

(2) Remove air intake duct and air cleaner

upper cover as a unit, and remove air cleaner

element.

B2M2020

6) Remove spark plug cords from spark plugs (#1

and #3 cylinders).

B2M2014

7) Remove power steering pump from bracket.

(1) Remove V-belt covers.

B2M2307

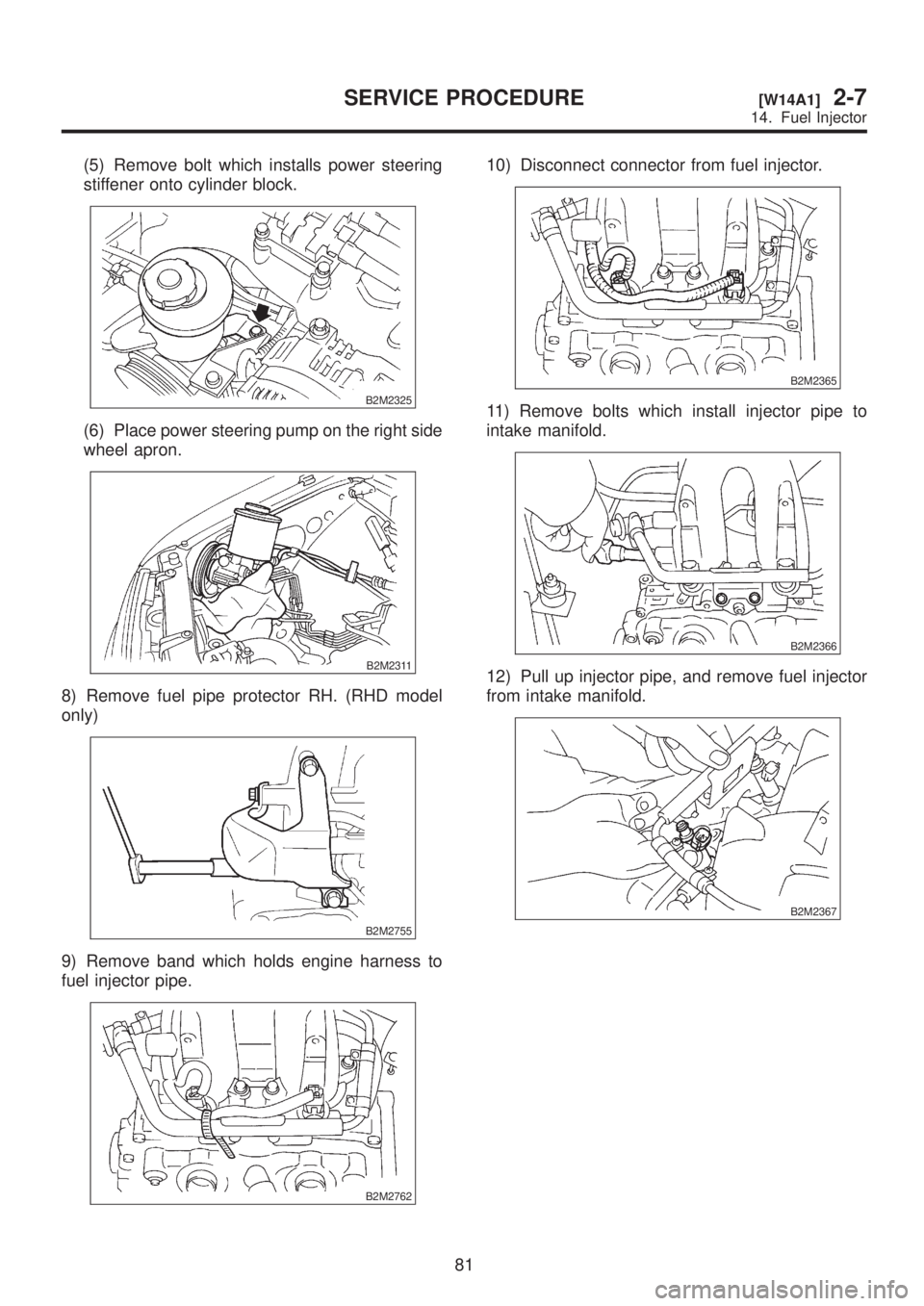

(2) Loosen lock bolt and slider bolt, and remove

power steering pump drive V-belt.

B2M2308

(3) Remove bolts which secure power steering

pipe brackets to intake manifold.

B2M2309

(4) Remove bolts which install power steering

pump to bracket.

B2M2310

80

2-7[W14A1]SERVICE PROCEDURE

14. Fuel Injector

Page 346 of 1456

(5) Remove bolt which installs power steering

stiffener onto cylinder block.

B2M2325

(6) Place power steering pump on the right side

wheel apron.

B2M2311

8) Remove fuel pipe protector RH. (RHD model

only)

B2M2755

9) Remove band which holds engine harness to

fuel injector pipe.

B2M2762

10) Disconnect connector from fuel injector.

B2M2365

11) Remove bolts which install injector pipe to

intake manifold.

B2M2366

12) Pull up injector pipe, and remove fuel injector

from intake manifold.

B2M2367

81

[W14A1]2-7SERVICE PROCEDURE

14. Fuel Injector

Page 347 of 1456

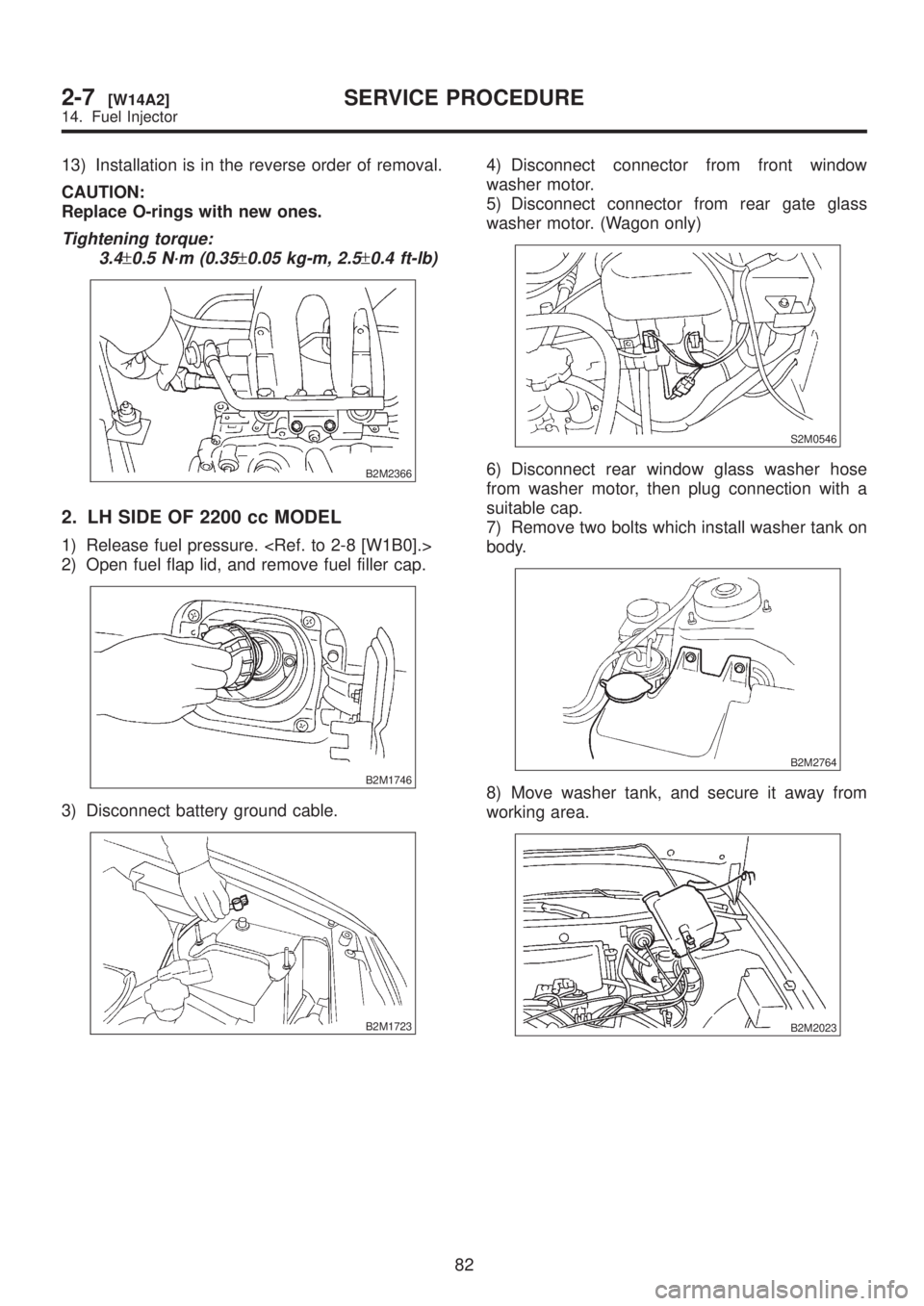

13) Installation is in the reverse order of removal.

CAUTION:

Replace O-rings with new ones.

Tightening torque:

3.4

±0.5 N´m (0.35±0.05 kg-m, 2.5±0.4 ft-lb)

B2M2366

2. LH SIDE OF 2200 cc MODEL

1) Release fuel pressure.

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Disconnect connector from front window

washer motor.

5) Disconnect connector from rear gate glass

washer motor. (Wagon only)

S2M0546

6) Disconnect rear window glass washer hose

from washer motor, then plug connection with a

suitable cap.

7) Remove two bolts which install washer tank on

body.

B2M2764

8) Move washer tank, and secure it away from

working area.

B2M2023

82

2-7[W14A2]SERVICE PROCEDURE

14. Fuel Injector

Page 348 of 1456

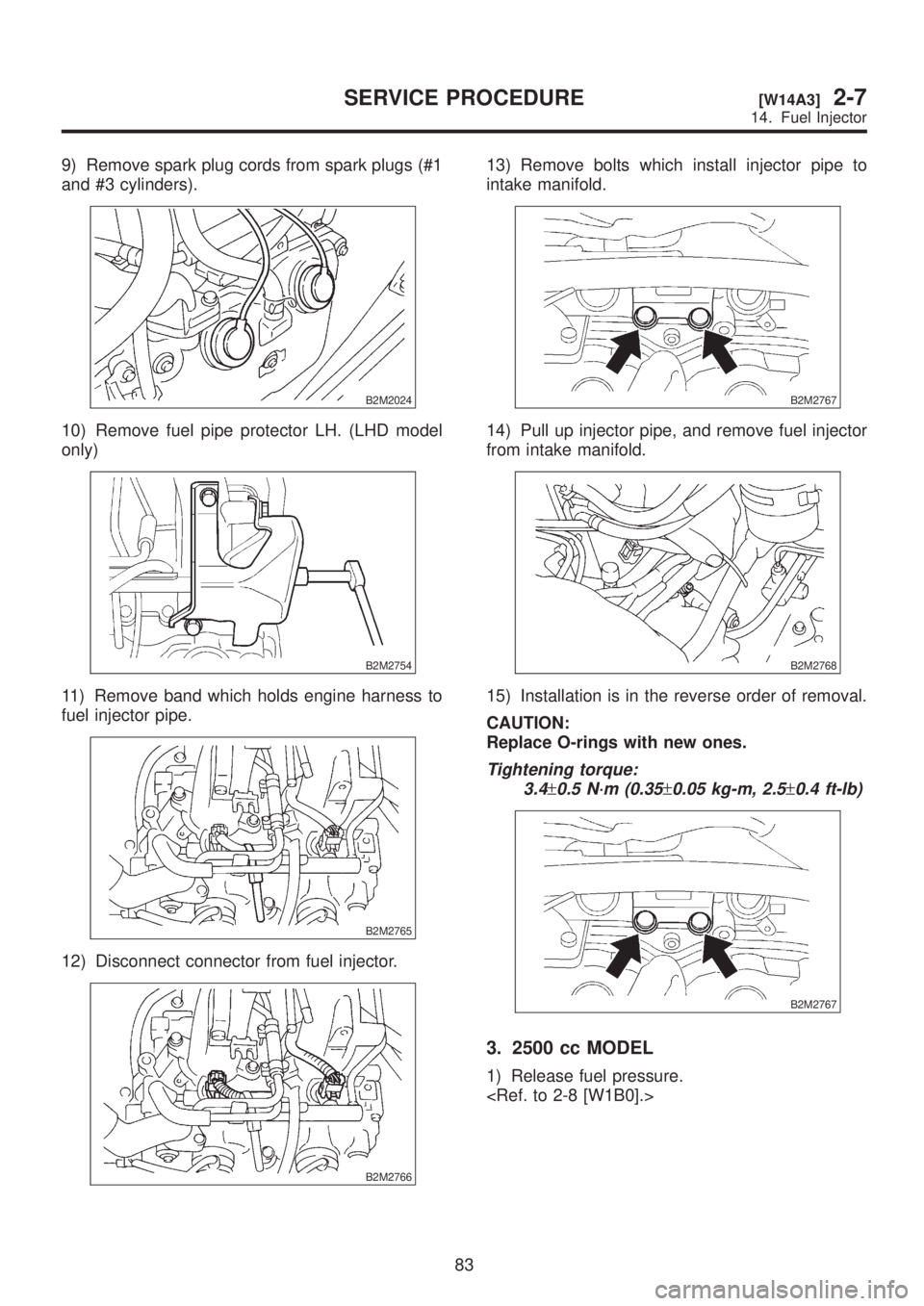

9) Remove spark plug cords from spark plugs (#1

and #3 cylinders).

B2M2024

10) Remove fuel pipe protector LH. (LHD model

only)

B2M2754

11) Remove band which holds engine harness to

fuel injector pipe.

B2M2765

12) Disconnect connector from fuel injector.

B2M2766

13) Remove bolts which install injector pipe to

intake manifold.

B2M2767

14) Pull up injector pipe, and remove fuel injector

from intake manifold.

B2M2768

15) Installation is in the reverse order of removal.

CAUTION:

Replace O-rings with new ones.

Tightening torque:

3.4

±0.5 N´m (0.35±0.05 kg-m, 2.5±0.4 ft-lb)

B2M2767

3. 2500 cc MODEL

1) Release fuel pressure.

83

[W14A3]2-7SERVICE PROCEDURE

14. Fuel Injector

Page 349 of 1456

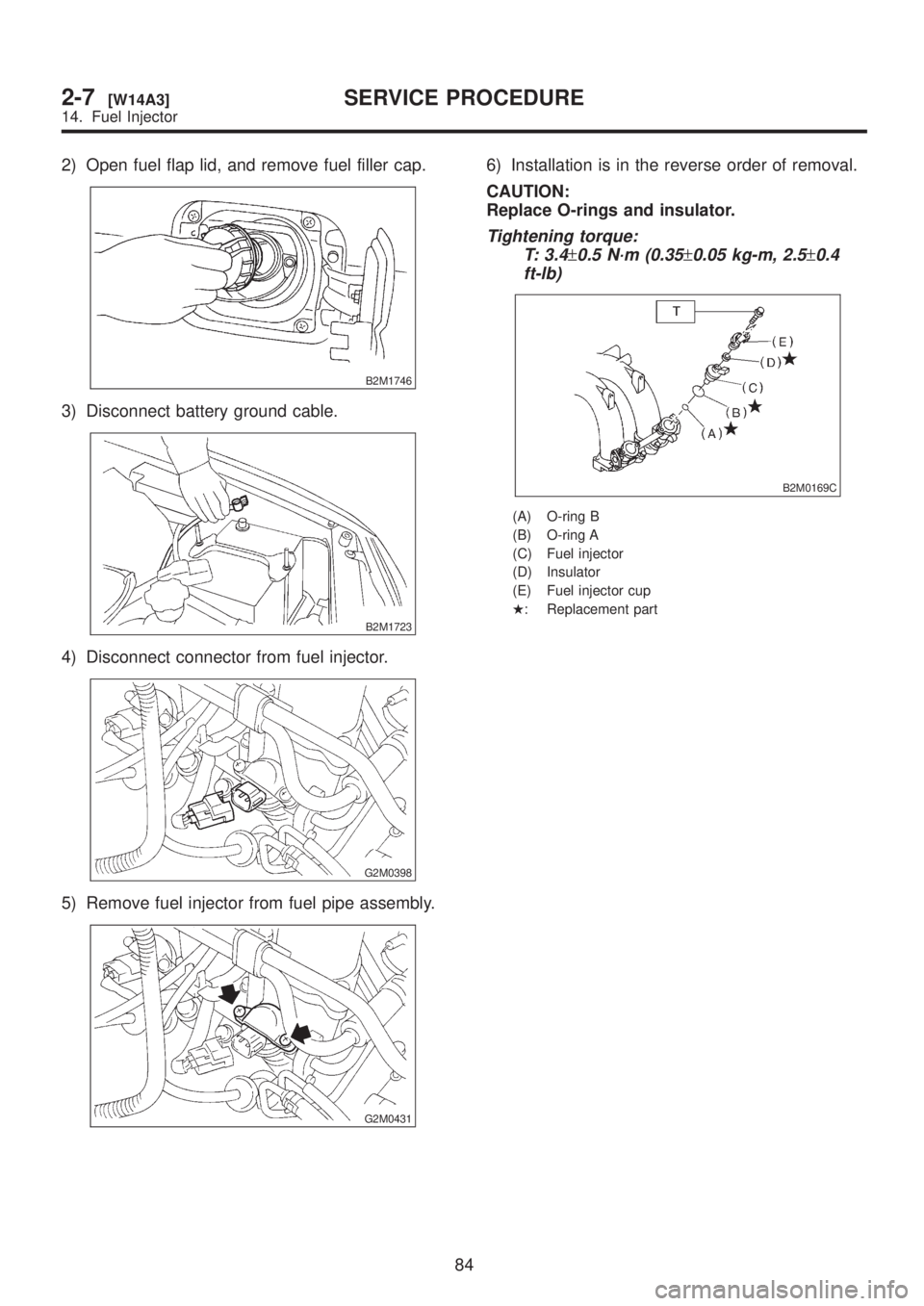

2) Open fuel flap lid, and remove fuel filler cap.

B2M1746

3) Disconnect battery ground cable.

B2M1723

4) Disconnect connector from fuel injector.

G2M0398

5) Remove fuel injector from fuel pipe assembly.

G2M0431

6) Installation is in the reverse order of removal.

CAUTION:

Replace O-rings and insulator.

Tightening torque:

T: 3.4

±0.5 N´m (0.35±0.05 kg-m, 2.5±0.4

ft-lb)

B2M0169C

(A) O-ring B

(B) O-ring A

(C) Fuel injector

(D) Insulator

(E) Fuel injector cup

H: Replacement part

84

2-7[W14A3]SERVICE PROCEDURE

14. Fuel Injector

Page 350 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 15. Engine Control Module

A: REMOVAL AND INSTALLATION

1. 2200 cc MODEL

1) Disconnect battery ground cable.

B2M1723

2) Remove side sill front cover.

<Ref. to 5-3 [W5A1].>

B2M0672A

3) Detach floor mat o SUBARU LEGACY 1999 Service Repair Manual 15. Engine Control Module

A: REMOVAL AND INSTALLATION

1. 2200 cc MODEL

1) Disconnect battery ground cable.

B2M1723

2) Remove side sill front cover.

<Ref. to 5-3 [W5A1].>

B2M0672A

3) Detach floor mat o](/img/17/57435/w960_57435-349.png)

15. Engine Control Module

A: REMOVAL AND INSTALLATION

1. 2200 cc MODEL

1) Disconnect battery ground cable.

B2M1723

2) Remove side sill front cover.

B2M0672A

3) Detach floor mat of front passenger seat.

B2M0673A

4) Remove protect cover.

B2M0674

5) Remove nuts which hold ECM to bracket.

B2M2368

6) Remove clip from bracket.

B2M2369A

7) Disconnect ECM connectors.

B2M2370

8) Take out ECM.

B2M2371A

9) Installation is in the reverse order of removal.

CAUTION:

When replacing ECM, be careful not to use the

wrong spec. ECM to avoid any damage to the

fuel injection system.

85

[W15A1]2-7SERVICE PROCEDURE

15. Engine Control Module