SUBARU LEGACY 1999 Service Manual PDF

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 71 of 1456

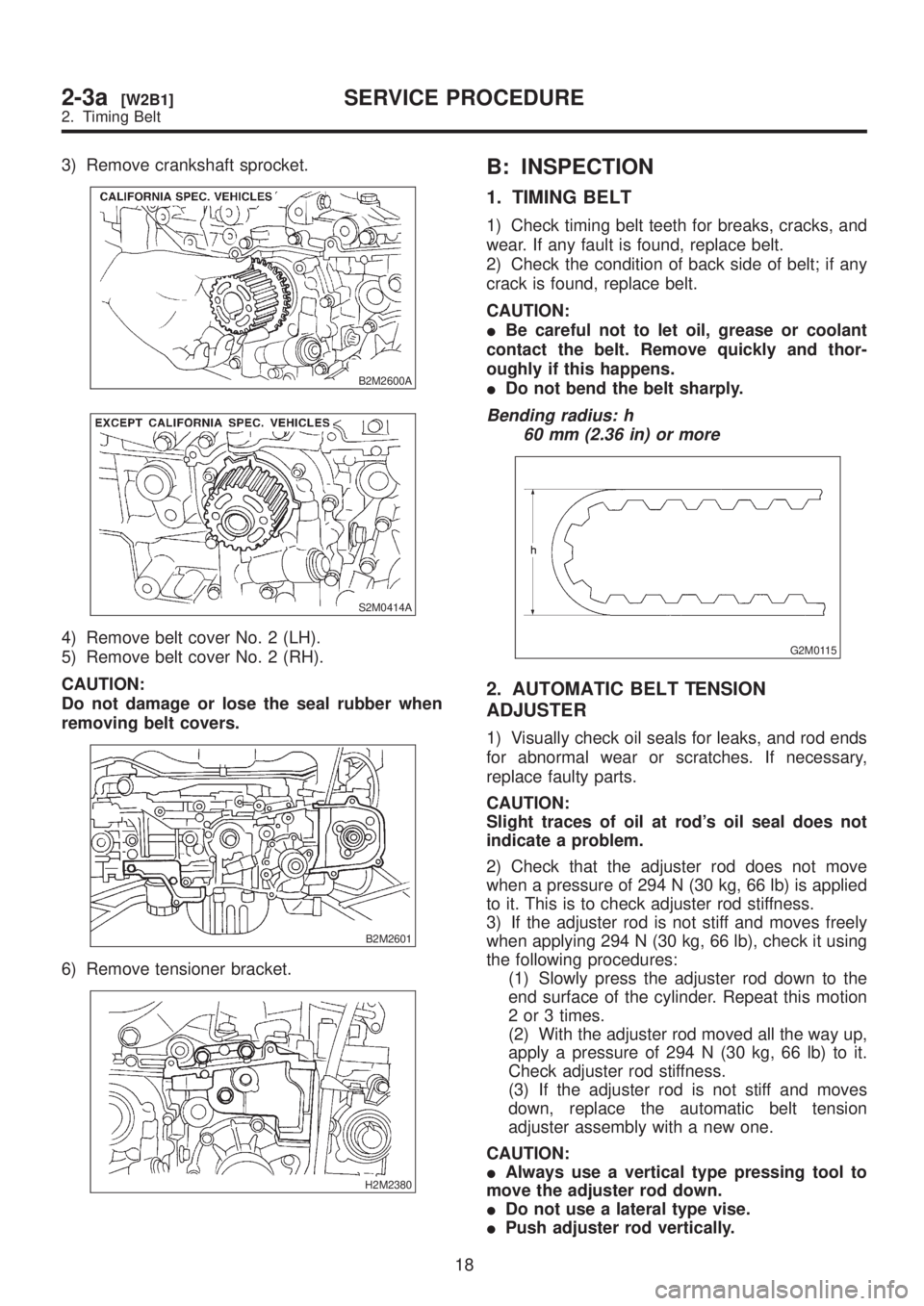

3) Remove crankshaft sprocket.

B2M2600A

S2M0414A

4) Remove belt cover No. 2 (LH).

5) Remove belt cover No. 2 (RH).

CAUTION:

Do not damage or lose the seal rubber when

removing belt covers.

B2M2601

6) Remove tensioner bracket.

H2M2380

B: INSPECTION

1. TIMING BELT

1) Check timing belt teeth for breaks, cracks, and

wear. If any fault is found, replace belt.

2) Check the condition of back side of belt; if any

crack is found, replace belt.

CAUTION:

IBe careful not to let oil, grease or coolant

contact the belt. Remove quickly and thor-

oughly if this happens.

IDo not bend the belt sharply.

Bending radius: h

60 mm (2.36 in) or more

G2M0115

2. AUTOMATIC BELT TENSION

ADJUSTER

1) Visually check oil seals for leaks, and rod ends

for abnormal wear or scratches. If necessary,

replace faulty parts.

CAUTION:

Slight traces of oil at rod's oil seal does not

indicate a problem.

2) Check that the adjuster rod does not move

when a pressure of 294 N (30 kg, 66 lb) is applied

to it. This is to check adjuster rod stiffness.

3) If the adjuster rod is not stiff and moves freely

when applying 294 N (30 kg, 66 lb), check it using

the following procedures:

(1) Slowly press the adjuster rod down to the

end surface of the cylinder. Repeat this motion

2 or 3 times.

(2) With the adjuster rod moved all the way up,

apply a pressure of 294 N (30 kg, 66 lb) to it.

Check adjuster rod stiffness.

(3) If the adjuster rod is not stiff and moves

down, replace the automatic belt tension

adjuster assembly with a new one.

CAUTION:

IAlways use a vertical type pressing tool to

move the adjuster rod down.

IDo not use a lateral type vise.

IPush adjuster rod vertically.

18

2-3a[W2B1]SERVICE PROCEDURE

2. Timing Belt

Page 72 of 1456

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

5.7

±0.5 mm (0.224±0.020 in)

H2M2381A

3. BELT TENSION PULLEY

1) Check mating surfaces of timing belt and con-

tact point of adjuster rod for abnormal wear or

scratches. Replace automatic belt tension adjuster

assembly if faulty.

2) Check tension pulley for smooth rotation.

Replace if noise or excessive play is noted.

3) Check tension pulley for grease leakage.

4. BELT IDLER

1) Check belt idler for smooth rotation. Replace if

noise or excessive play is noted.

2) Check belt outer contacting surfaces of idler

pulley for abnormal wear and scratches.

3) Check belt idler for grease leakage.

5. CAMSHAFT AND CRANKSHAFT

SPROCKET

1) Check sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between

sprocket and key.

3) Check crankshaft sprocket notch for sensor for

damage and contamination of foreign matter.

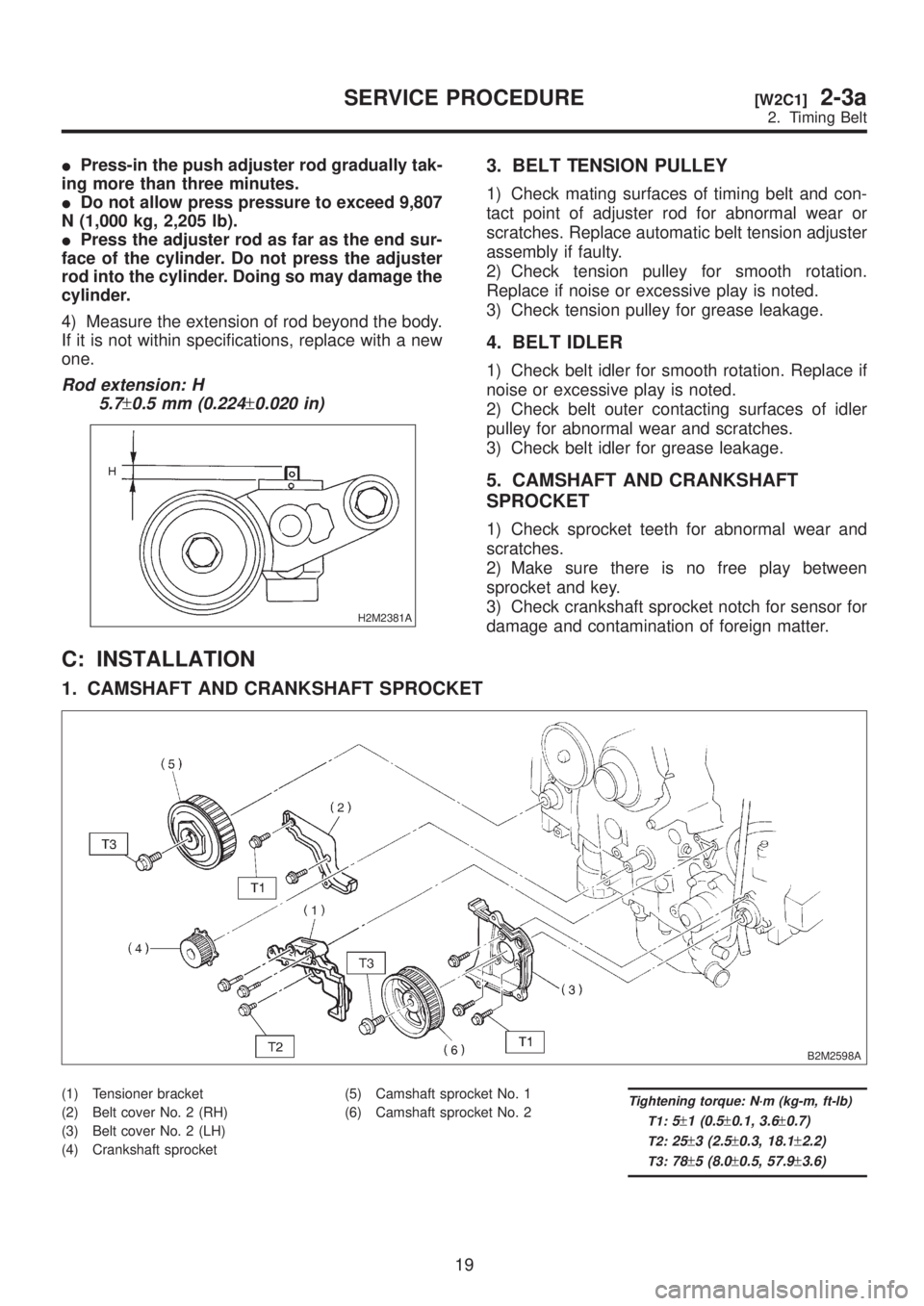

C: INSTALLATION

1. CAMSHAFT AND CRANKSHAFT SPROCKET

B2M2598A

(1) Tensioner bracket

(2) Belt cover No. 2 (RH)

(3) Belt cover No. 2 (LH)

(4) Crankshaft sprocket(5) Camshaft sprocket No. 1

(6) Camshaft sprocket No. 2Tightening torque: N´m (kg-m, ft-lb)

T1:

5±1 (0.5±0.1, 3.6±0.7)

T2:25±3 (2.5±0.3, 18.1±2.2)

T3:78±5 (8.0±0.5, 57.9±3.6)

19

[W2C1]2-3aSERVICE PROCEDURE

2. Timing Belt

Page 73 of 1456

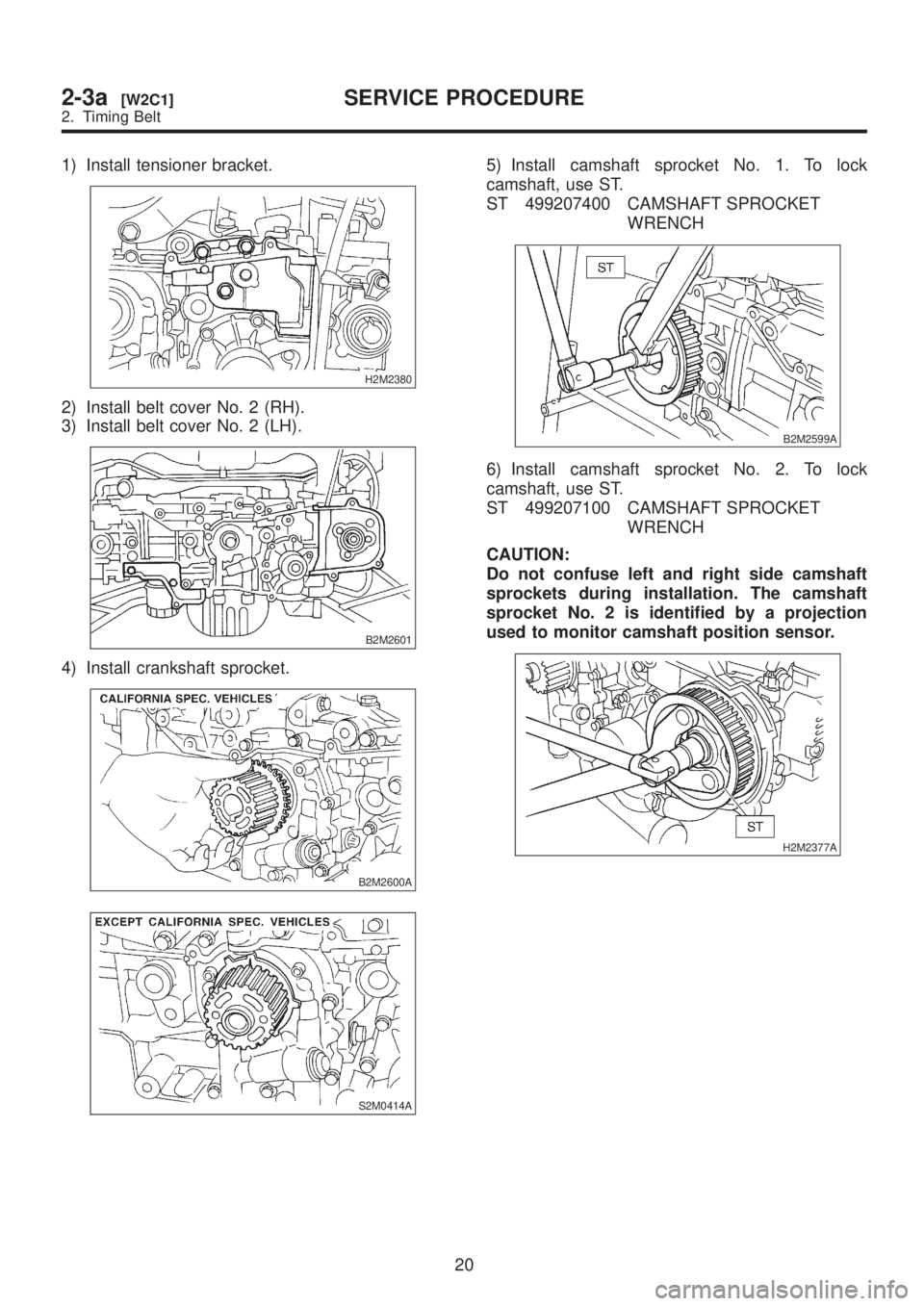

1) Install tensioner bracket.

H2M2380

2) Install belt cover No. 2 (RH).

3) Install belt cover No. 2 (LH).

B2M2601

4) Install crankshaft sprocket.

B2M2600A

S2M0414A

5) Install camshaft sprocket No. 1. To lock

camshaft, use ST.

ST 499207400 CAMSHAFT SPROCKET

WRENCH

B2M2599A

6) Install camshaft sprocket No. 2. To lock

camshaft, use ST.

ST 499207100 CAMSHAFT SPROCKET

WRENCH

CAUTION:

Do not confuse left and right side camshaft

sprockets during installation. The camshaft

sprocket No. 2 is identified by a projection

used to monitor camshaft position sensor.

H2M2377A

20

2-3a[W2C1]SERVICE PROCEDURE

2. Timing Belt

Page 74 of 1456

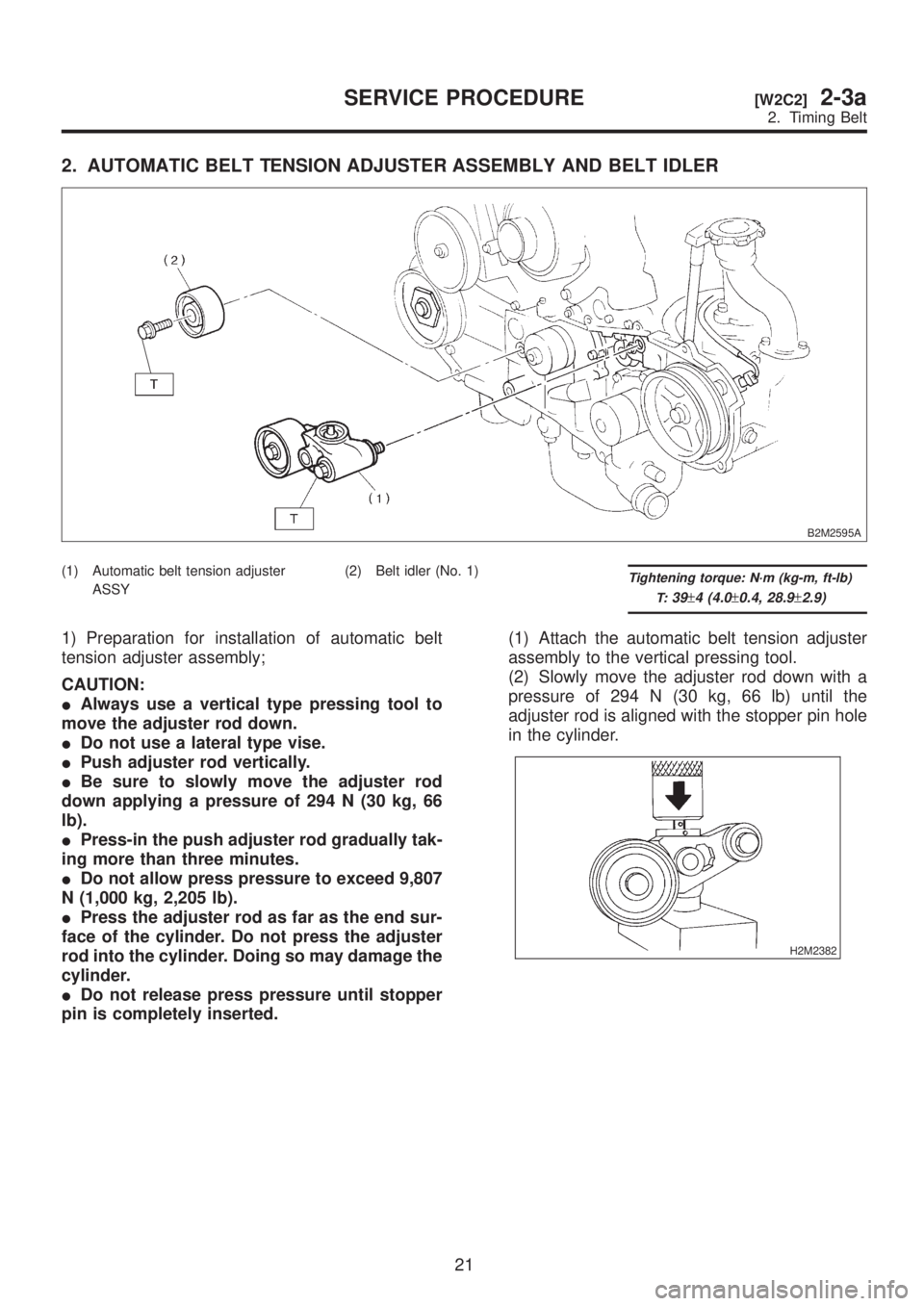

2. AUTOMATIC BELT TENSION ADJUSTER ASSEMBLY AND BELT IDLER

B2M2595A

(1) Automatic belt tension adjuster

ASSY(2) Belt idler (No. 1)Tightening torque: N´m (kg-m, ft-lb)

T:

39±4 (4.0±0.4, 28.9±2.9)

1) Preparation for installation of automatic belt

tension adjuster assembly;

CAUTION:

IAlways use a vertical type pressing tool to

move the adjuster rod down.

IDo not use a lateral type vise.

IPush adjuster rod vertically.

IBe sure to slowly move the adjuster rod

down applying a pressure of 294 N (30 kg, 66

lb).

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

IDo not release press pressure until stopper

pin is completely inserted.(1) Attach the automatic belt tension adjuster

assembly to the vertical pressing tool.

(2) Slowly move the adjuster rod down with a

pressure of 294 N (30 kg, 66 lb) until the

adjuster rod is aligned with the stopper pin hole

in the cylinder.

H2M2382

21

[W2C2]2-3aSERVICE PROCEDURE

2. Timing Belt

Page 75 of 1456

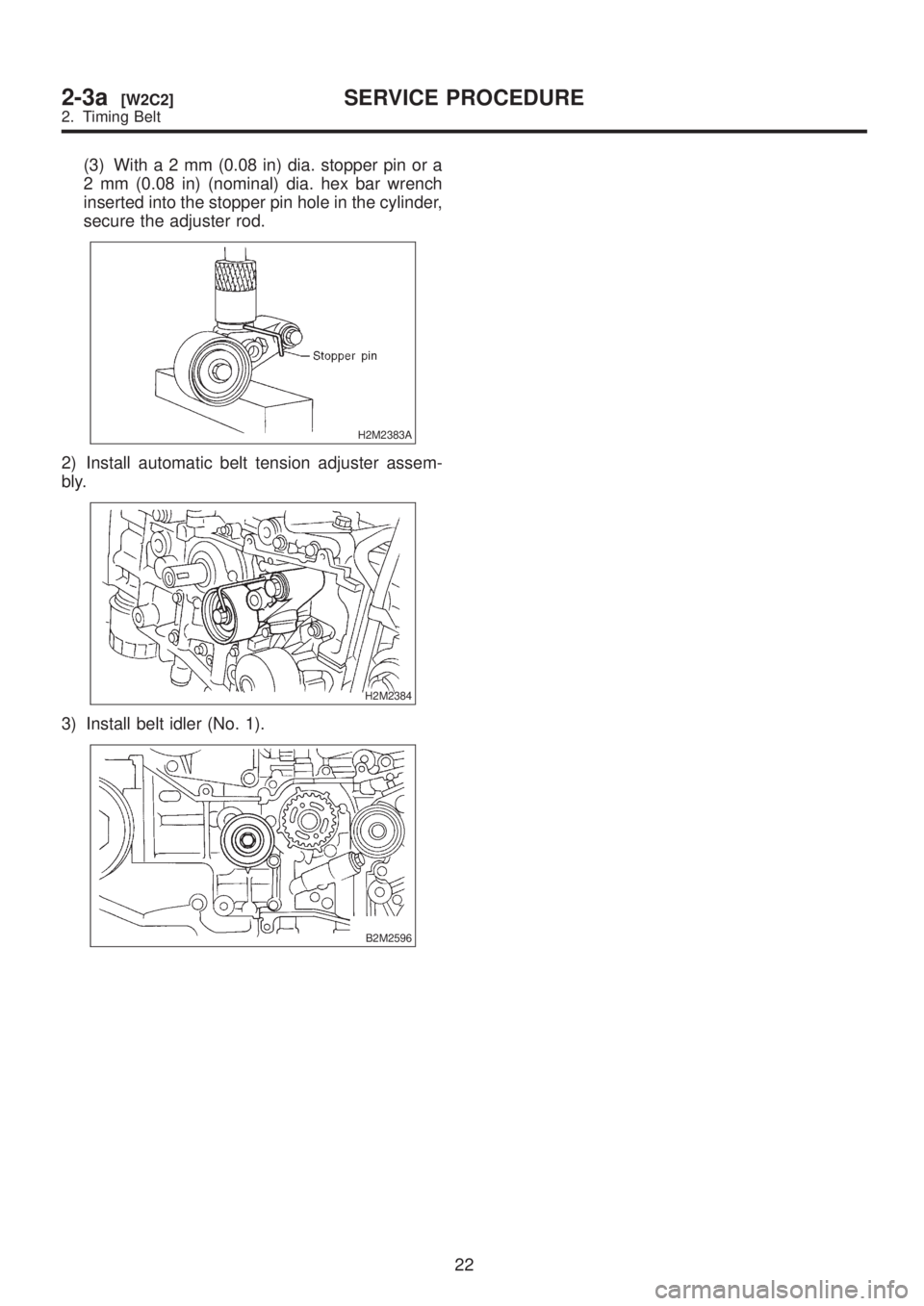

(3) Witha2mm(0.08 in) dia. stopper pin or a

2 mm (0.08 in) (nominal) dia. hex bar wrench

inserted into the stopper pin hole in the cylinder,

secure the adjuster rod.

H2M2383A

2) Install automatic belt tension adjuster assem-

bly.

H2M2384

3) Install belt idler (No. 1).

B2M2596

22

2-3a[W2C2]SERVICE PROCEDURE

2. Timing Belt

Page 76 of 1456

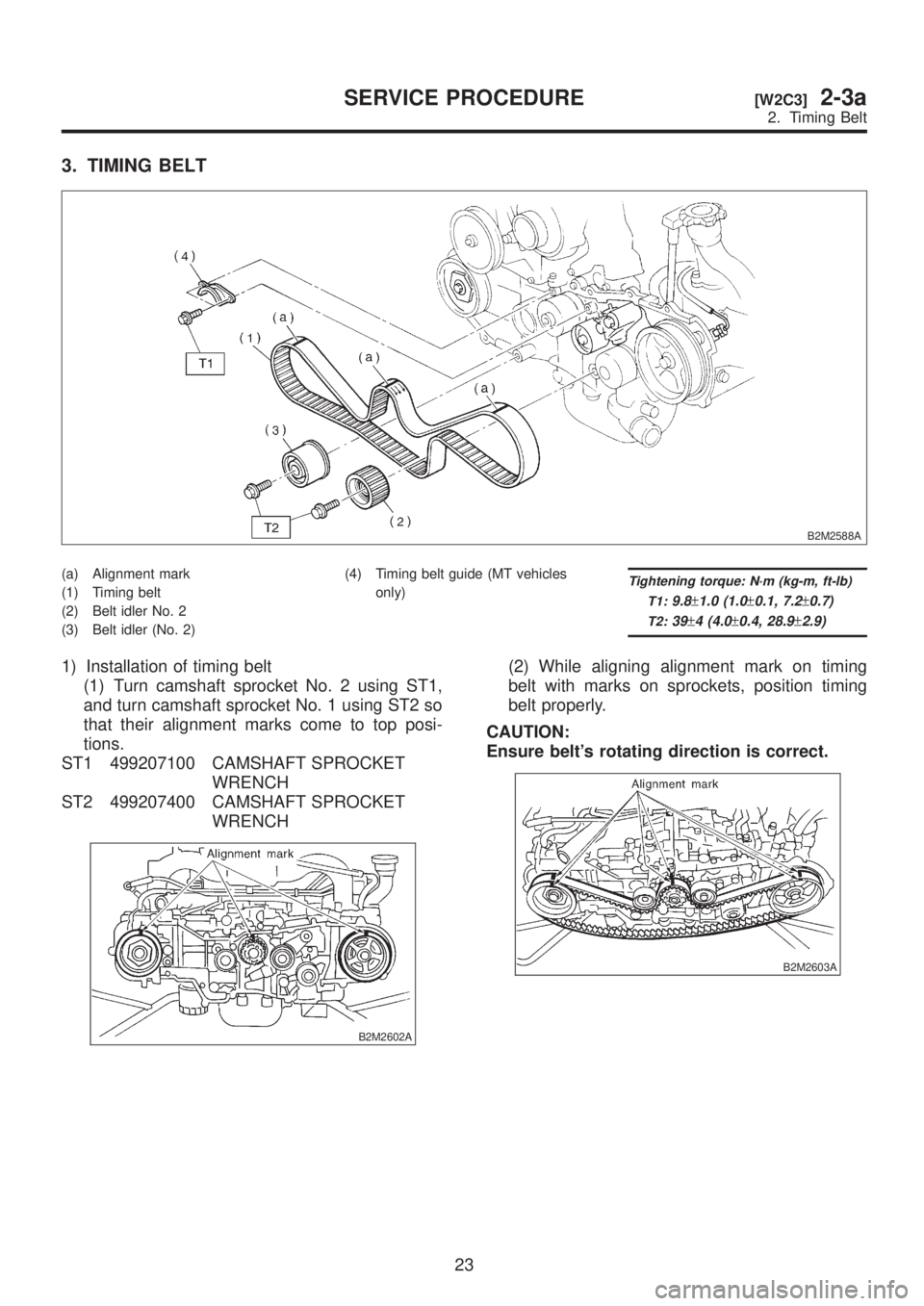

3. TIMING BELT

B2M2588A

(a) Alignment mark

(1) Timing belt

(2) Belt idler No. 2

(3) Belt idler (No. 2)(4) Timing belt guide (MT vehicles

only)Tightening torque: N´m (kg-m, ft-lb)

T1:

9.8±1.0 (1.0±0.1, 7.2±0.7)

T2:39±4 (4.0±0.4, 28.9±2.9)

1) Installation of timing belt

(1) Turn camshaft sprocket No. 2 using ST1,

and turn camshaft sprocket No. 1 using ST2 so

that their alignment marks come to top posi-

tions.

ST1 499207100 CAMSHAFT SPROCKET

WRENCH

ST2 499207400 CAMSHAFT SPROCKET

WRENCH

B2M2602A

(2) While aligning alignment mark on timing

belt with marks on sprockets, position timing

belt properly.

CAUTION:

Ensure belt's rotating direction is correct.

B2M2603A

23

[W2C3]2-3aSERVICE PROCEDURE

2. Timing Belt

Page 77 of 1456

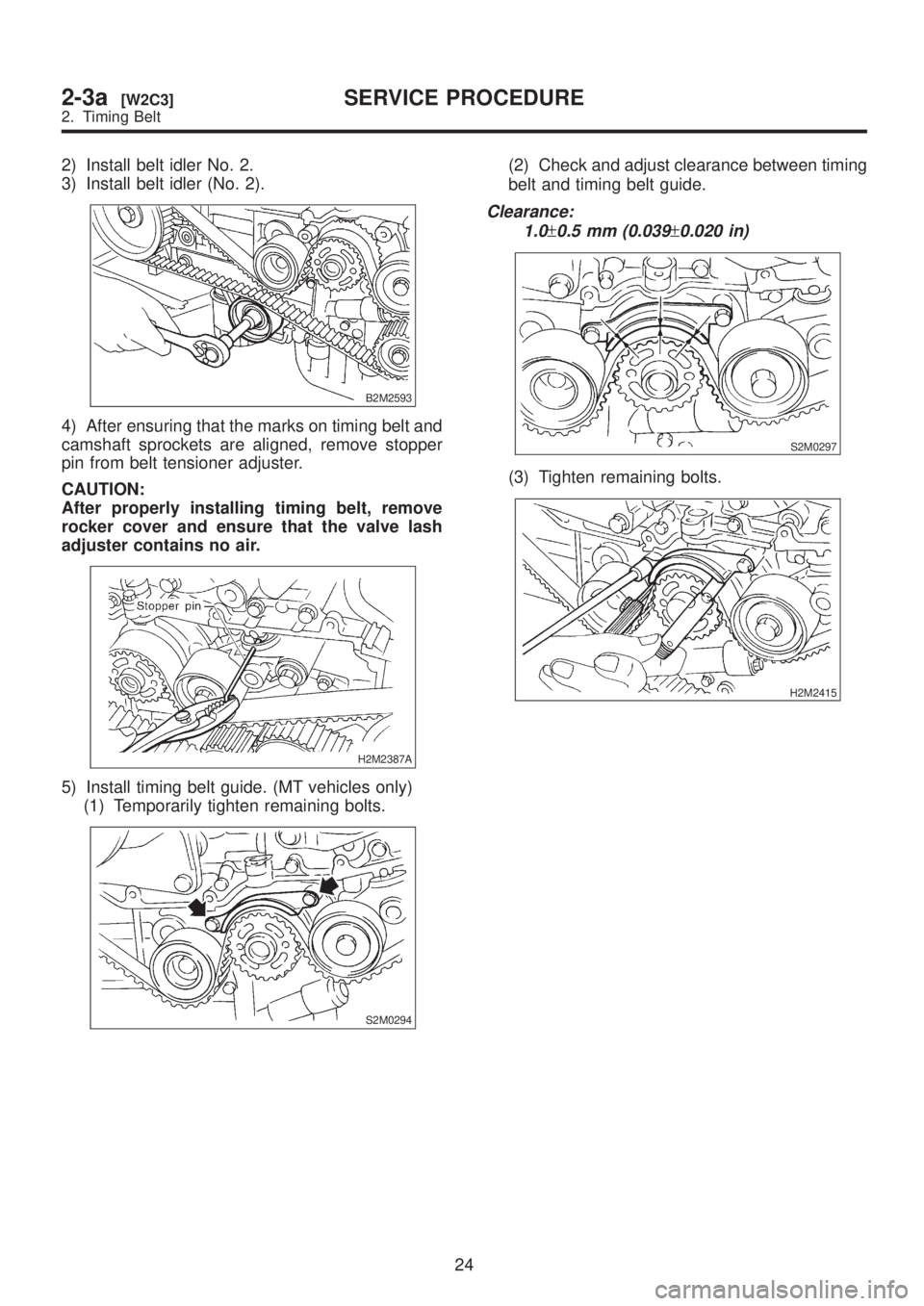

2) Install belt idler No. 2.

3) Install belt idler (No. 2).

B2M2593

4) After ensuring that the marks on timing belt and

camshaft sprockets are aligned, remove stopper

pin from belt tensioner adjuster.

CAUTION:

After properly installing timing belt, remove

rocker cover and ensure that the valve lash

adjuster contains no air.

H2M2387A

5) Install timing belt guide. (MT vehicles only)

(1) Temporarily tighten remaining bolts.

S2M0294

(2) Check and adjust clearance between timing

belt and timing belt guide.

Clearance:

1.0

±0.5 mm (0.039±0.020 in)

S2M0297

(3) Tighten remaining bolts.

H2M2415

24

2-3a[W2C3]SERVICE PROCEDURE

2. Timing Belt

Page 78 of 1456

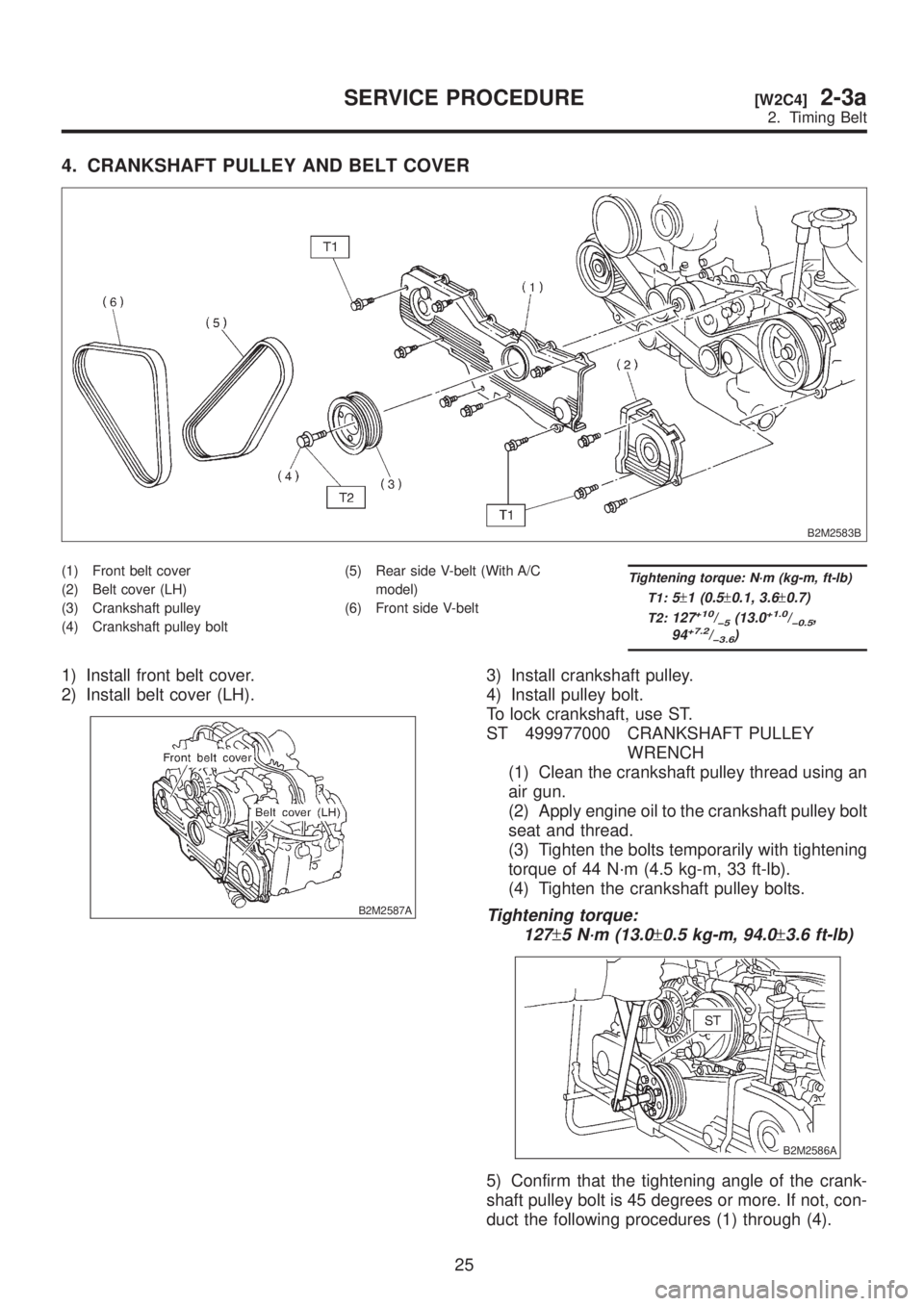

4. CRANKSHAFT PULLEY AND BELT COVER

B2M2583B

(1) Front belt cover

(2) Belt cover (LH)

(3) Crankshaft pulley

(4) Crankshaft pulley bolt(5) Rear side V-belt (With A/C

model)

(6) Front side V-beltTightening torque: N´m (kg-m, ft-lb)

T1:

5±1 (0.5±0.1, 3.6±0.7)

T2:127+10/þ5(13.0+1.0/þ0.5,

94+7.2/þ3.6)

1) Install front belt cover.

2) Install belt cover (LH).

B2M2587A

3) Install crankshaft pulley.

4) Install pulley bolt.

To lock crankshaft, use ST.

ST 499977000 CRANKSHAFT PULLEY

WRENCH

(1) Clean the crankshaft pulley thread using an

air gun.

(2) Apply engine oil to the crankshaft pulley bolt

seat and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N´m (4.5 kg-m, 33 ft-lb).

(4) Tighten the crankshaft pulley bolts.

Tightening torque:

127

±5 N´m (13.0±0.5 kg-m, 94.0±3.6 ft-lb)

B2M2586A

5) Confirm that the tightening angle of the crank-

shaft pulley bolt is 45 degrees or more. If not, con-

duct the following procedures (1) through (4).

25

[W2C4]2-3aSERVICE PROCEDURE

2. Timing Belt

Page 79 of 1456

(1) Replace the crankshaft pulley bolts and

clean them.

Crankshaft pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Tighten the bolts temporarily with tightening

torque of 44 N´m (4.5 kg-m, 33 ft-lb).

(4) Tighten the crankshaft pulley bolts keeping

them in an angle between 45 degrees and 60

degrees.

CAUTION:

Conduct the tightening procedures by confirm-

ing the turning angle of the crankshaft pulley

bolt referring to the gauge indicated on the belt

cover.

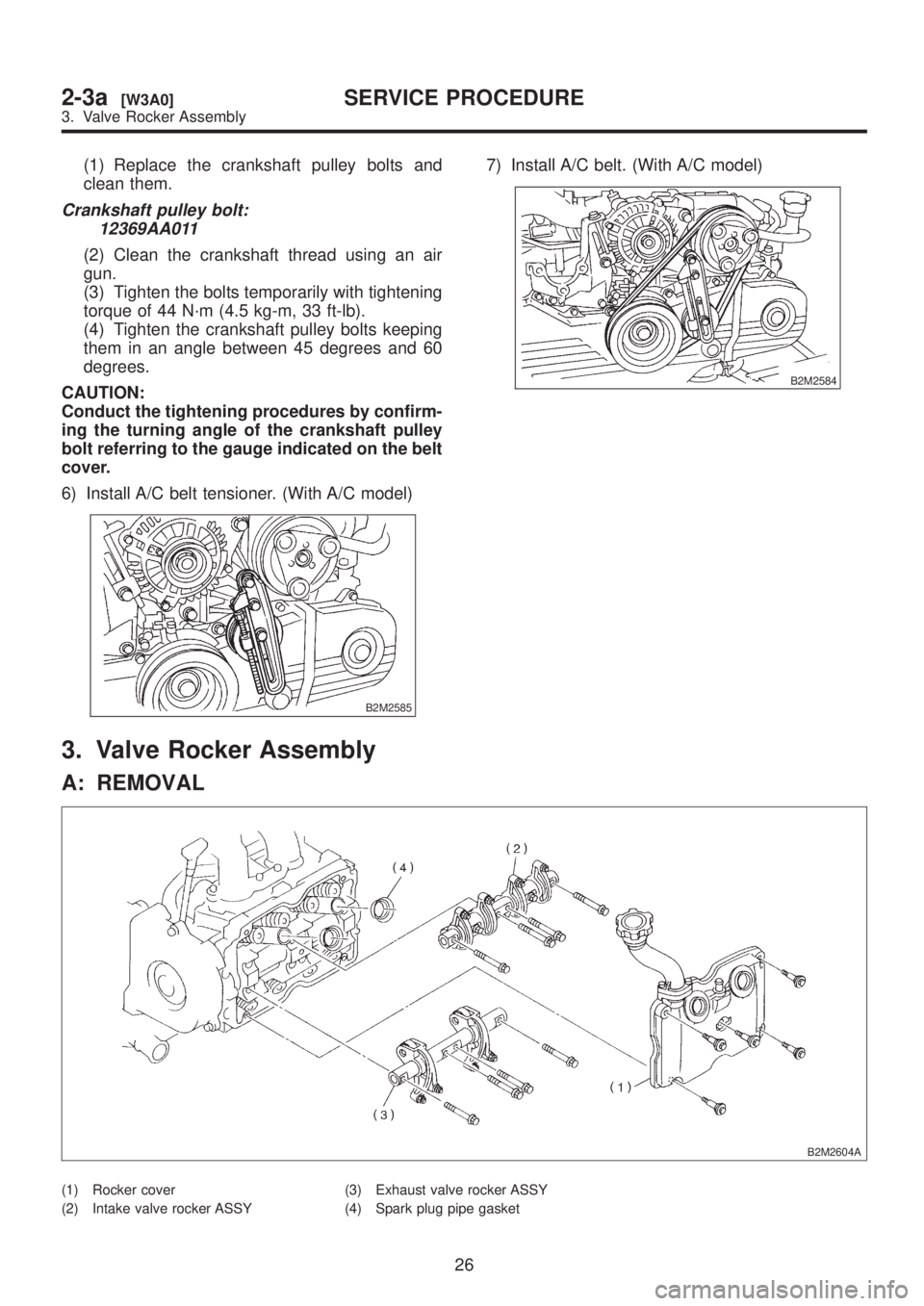

6) Install A/C belt tensioner. (With A/C model)

B2M2585

7) Install A/C belt. (With A/C model)

B2M2584

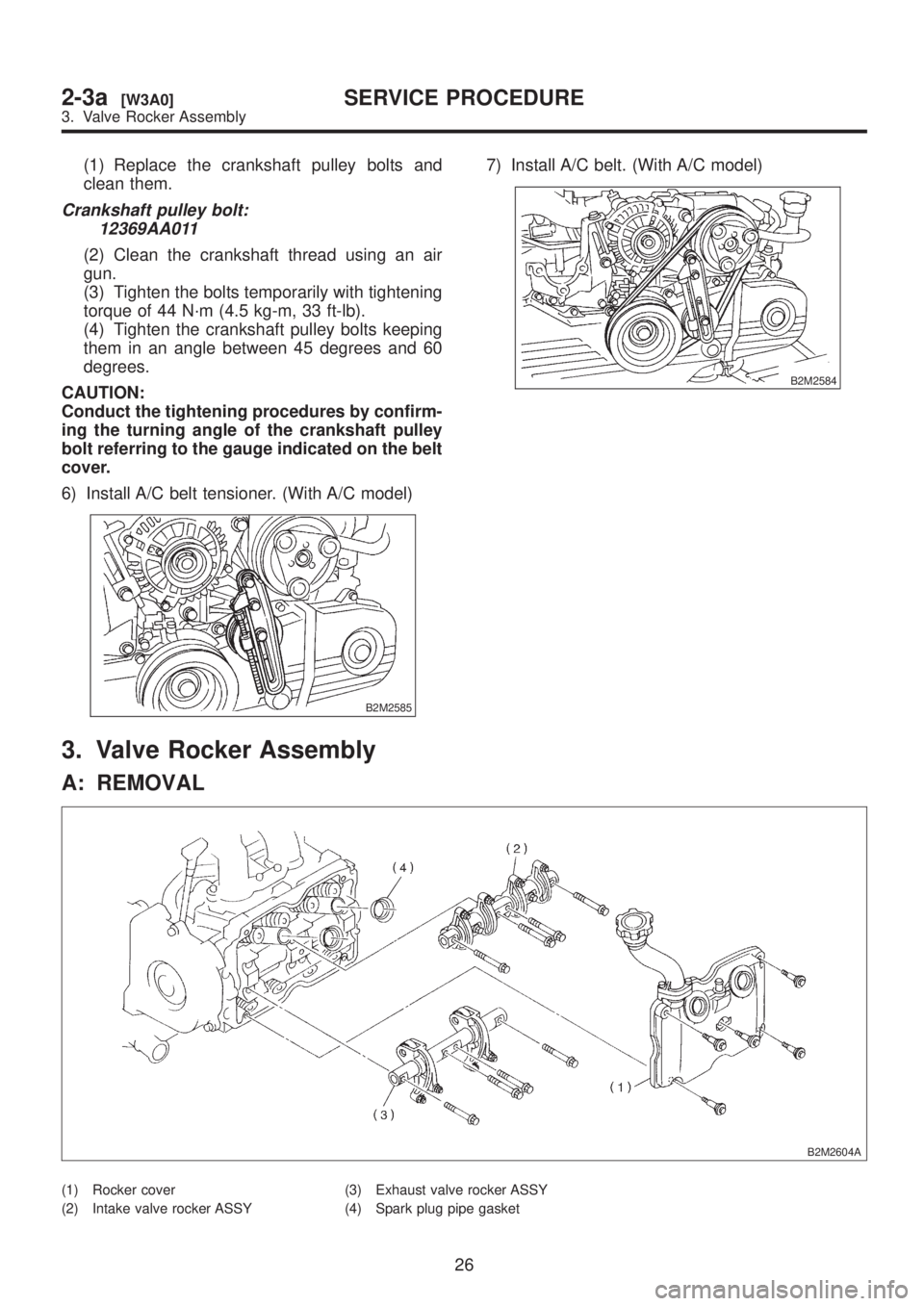

3. Valve Rocker Assembly

A: REMOVAL

B2M2604A

(1) Rocker cover

(2) Intake valve rocker ASSY(3) Exhaust valve rocker ASSY

(4) Spark plug pipe gasket

26

2-3a[W3A0]SERVICE PROCEDURE

3. Valve Rocker Assembly

Page 80 of 1456

(1) Replace the crankshaft pulley bolts and

clean them.

Crankshaft pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Tighten the bolts temporarily with tightening

torque of 44 N´m (4.5 kg-m, 33 ft-lb).

(4) Tighten the crankshaft pulley bolts keeping

them in an angle between 45 degrees and 60

degrees.

CAUTION:

Conduct the tightening procedures by confirm-

ing the turning angle of the crankshaft pulley

bolt referring to the gauge indicated on the belt

cover.

6) Install A/C belt tensioner. (With A/C model)

B2M2585

7) Install A/C belt. (With A/C model)

B2M2584

3. Valve Rocker Assembly

A: REMOVAL

B2M2604A

(1) Rocker cover

(2) Intake valve rocker ASSY(3) Exhaust valve rocker ASSY

(4) Spark plug pipe gasket

26

2-3a[W3A0]SERVICE PROCEDURE

3. Valve Rocker Assembly