SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 851 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 12) Feed the specified fluid and discharge air.

NOTE:

Never start the engine before feeding the fluid; otherwise vane pump might be seized up.

B4M0674A

58

4-3[W7C2]SERVICE PROCEDURE

7. Pipe Assembly ( SUBARU LEGACY 1999 Service Repair Manual 12) Feed the specified fluid and discharge air.

NOTE:

Never start the engine before feeding the fluid; otherwise vane pump might be seized up.

B4M0674A

58

4-3[W7C2]SERVICE PROCEDURE

7. Pipe Assembly (](/img/17/57435/w960_57435-850.png)

12) Feed the specified fluid and discharge air.

NOTE:

Never start the engine before feeding the fluid; otherwise vane pump might be seized up.

B4M0674A

58

4-3[W7C2]SERVICE PROCEDURE

7. Pipe Assembly (Power Steering System)

Page 852 of 1456

8. Oil Pump (Power Steering

System)

A: REMOVAL

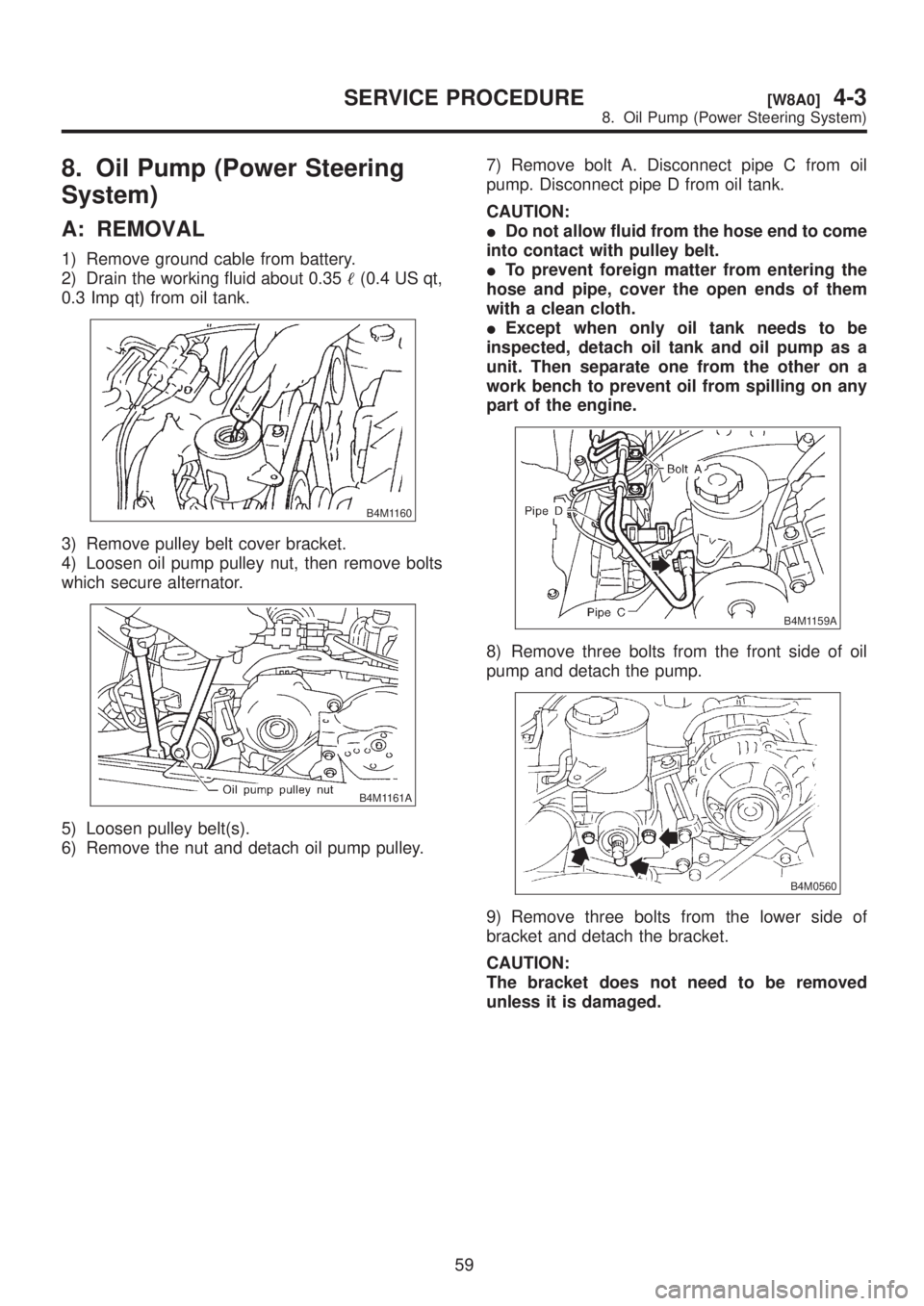

1) Remove ground cable from battery.

2) Drain the working fluid about 0.35(0.4 US qt,

0.3 Imp qt) from oil tank.

B4M1160

3) Remove pulley belt cover bracket.

4) Loosen oil pump pulley nut, then remove bolts

which secure alternator.

B4M1161A

5) Loosen pulley belt(s).

6) Remove the nut and detach oil pump pulley.7) Remove bolt A. Disconnect pipe C from oil

pump. Disconnect pipe D from oil tank.

CAUTION:

IDo not allow fluid from the hose end to come

into contact with pulley belt.

ITo prevent foreign matter from entering the

hose and pipe, cover the open ends of them

with a clean cloth.

IExcept when only oil tank needs to be

inspected, detach oil tank and oil pump as a

unit. Then separate one from the other on a

work bench to prevent oil from spilling on any

part of the engine.

B4M1159A

8) Remove three bolts from the front side of oil

pump and detach the pump.

B4M0560

9) Remove three bolts from the lower side of

bracket and detach the bracket.

CAUTION:

The bracket does not need to be removed

unless it is damaged.

59

[W8A0]4-3SERVICE PROCEDURE

8. Oil Pump (Power Steering System)

Page 853 of 1456

10) Place oil pump in a vise, remove two bolts

from oil tank and detach oil tank.

CAUTION:

Do not place oil pump directly in the vise; use

soft pads and hold oil pump lightly to protect

the pump.

B4M0561A

11) Remove O-ring from oil pump.

12) Remove stay from oil pump. (2500 cc model

only)

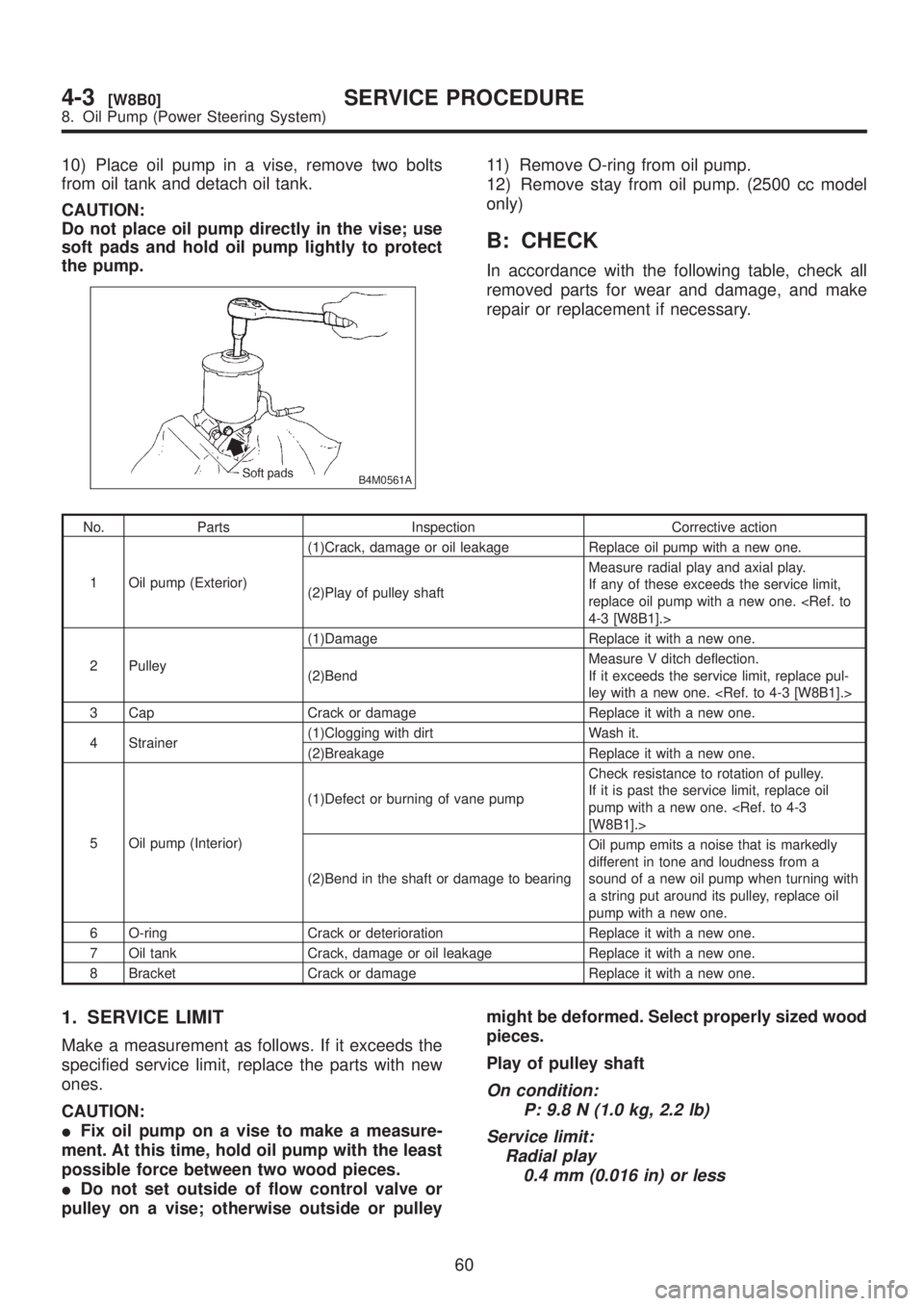

B: CHECK

In accordance with the following table, check all

removed parts for wear and damage, and make

repair or replacement if necessary.

No. Parts Inspection Corrective action

1 Oil pump (Exterior)(1)Crack, damage or oil leakage Replace oil pump with a new one.

(2)Play of pulley shaftMeasure radial play and axial play.

If any of these exceeds the service limit,

replace oil pump with a new one.

2 Pulley(1)Damage Replace it with a new one.

(2)BendMeasure V ditch deflection.

If it exceeds the service limit, replace pul-

ley with a new one.

3 Cap Crack or damage Replace it with a new one.

4 Strainer(1)Clogging with dirt Wash it.

(2)Breakage Replace it with a new one.

5 Oil pump (Interior)(1)Defect or burning of vane pumpCheck resistance to rotation of pulley.

If it is past the service limit, replace oil

pump with a new one.

(2)Bend in the shaft or damage to bearingOil pump emits a noise that is markedly

different in tone and loudness from a

sound of a new oil pump when turning with

a string put around its pulley, replace oil

pump with a new one.

6 O-ring Crack or deterioration Replace it with a new one.

7 Oil tank Crack, damage or oil leakage Replace it with a new one.

8 Bracket Crack or damage Replace it with a new one.

1. SERVICE LIMIT

Make a measurement as follows. If it exceeds the

specified service limit, replace the parts with new

ones.

CAUTION:

IFix oil pump on a vise to make a measure-

ment. At this time, hold oil pump with the least

possible force between two wood pieces.

IDo not set outside of flow control valve or

pulley on a vise; otherwise outside or pulleymight be deformed. Select properly sized wood

pieces.

Play of pulley shaft

On condition:

P: 9.8 N (1.0 kg, 2.2 lb)

Service limit:

Radial play

0.4 mm (0.016 in) or less

60

4-3[W8B0]SERVICE PROCEDURE

8. Oil Pump (Power Steering System)

Page 854 of 1456

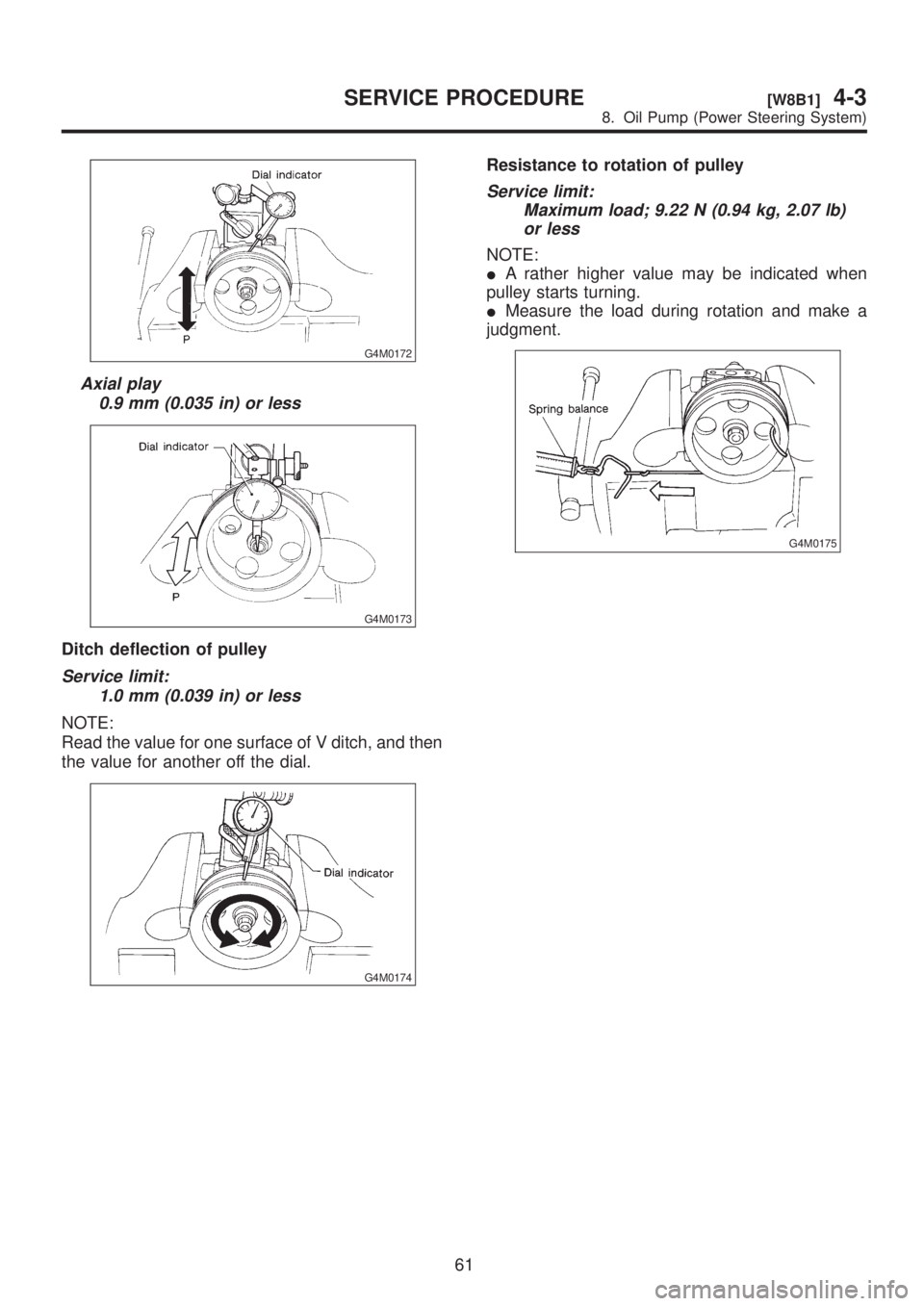

G4M0172

Axial play

0.9 mm (0.035 in) or less

G4M0173

Ditch deflection of pulley

Service limit:

1.0 mm (0.039 in) or less

NOTE:

Read the value for one surface of V ditch, and then

the value for another off the dial.

G4M0174

Resistance to rotation of pulley

Service limit:

Maximum load; 9.22 N (0.94 kg, 2.07 lb)

or less

NOTE:

IA rather higher value may be indicated when

pulley starts turning.

IMeasure the load during rotation and make a

judgment.

G4M0175

61

[W8B1]4-3SERVICE PROCEDURE

8. Oil Pump (Power Steering System)

Page 855 of 1456

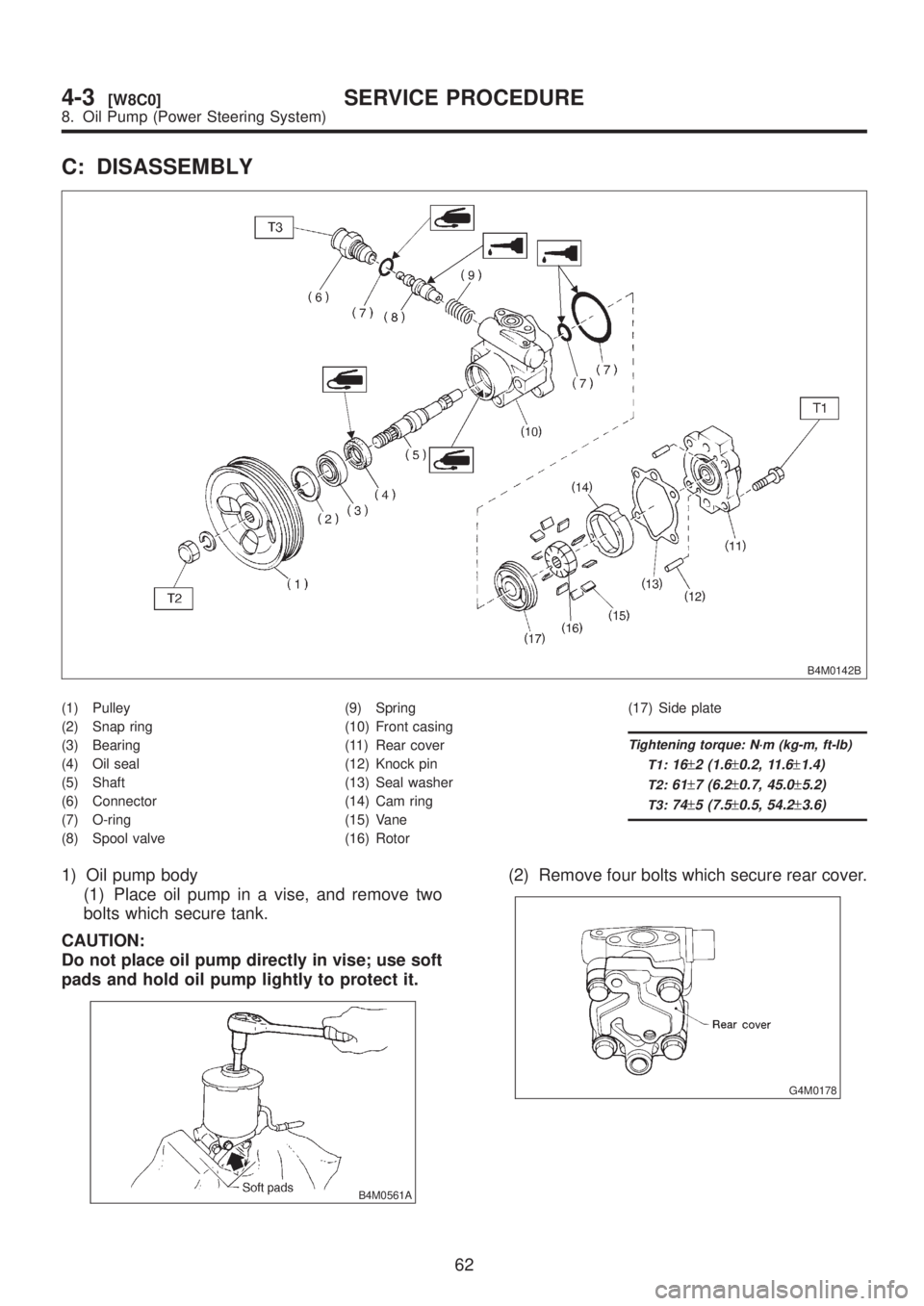

C: DISASSEMBLY

B4M0142B

(1) Pulley

(2) Snap ring

(3) Bearing

(4) Oil seal

(5) Shaft

(6) Connector

(7) O-ring

(8) Spool valve(9) Spring

(10) Front casing

(11) Rear cover

(12) Knock pin

(13) Seal washer

(14) Cam ring

(15) Vane

(16) Rotor(17) Side plate

Tightening torque: N´m (kg-m, ft-lb)

T1:

16±2 (1.6±0.2, 11.6±1.4)

T2:61±7 (6.2±0.7, 45.0±5.2)

T3:74±5 (7.5±0.5, 54.2±3.6)

1) Oil pump body

(1) Place oil pump in a vise, and remove two

bolts which secure tank.

CAUTION:

Do not place oil pump directly in vise; use soft

pads and hold oil pump lightly to protect it.

B4M0561A

(2) Remove four bolts which secure rear cover.

G4M0178

62

4-3[W8C0]SERVICE PROCEDURE

8. Oil Pump (Power Steering System)

Page 856 of 1456

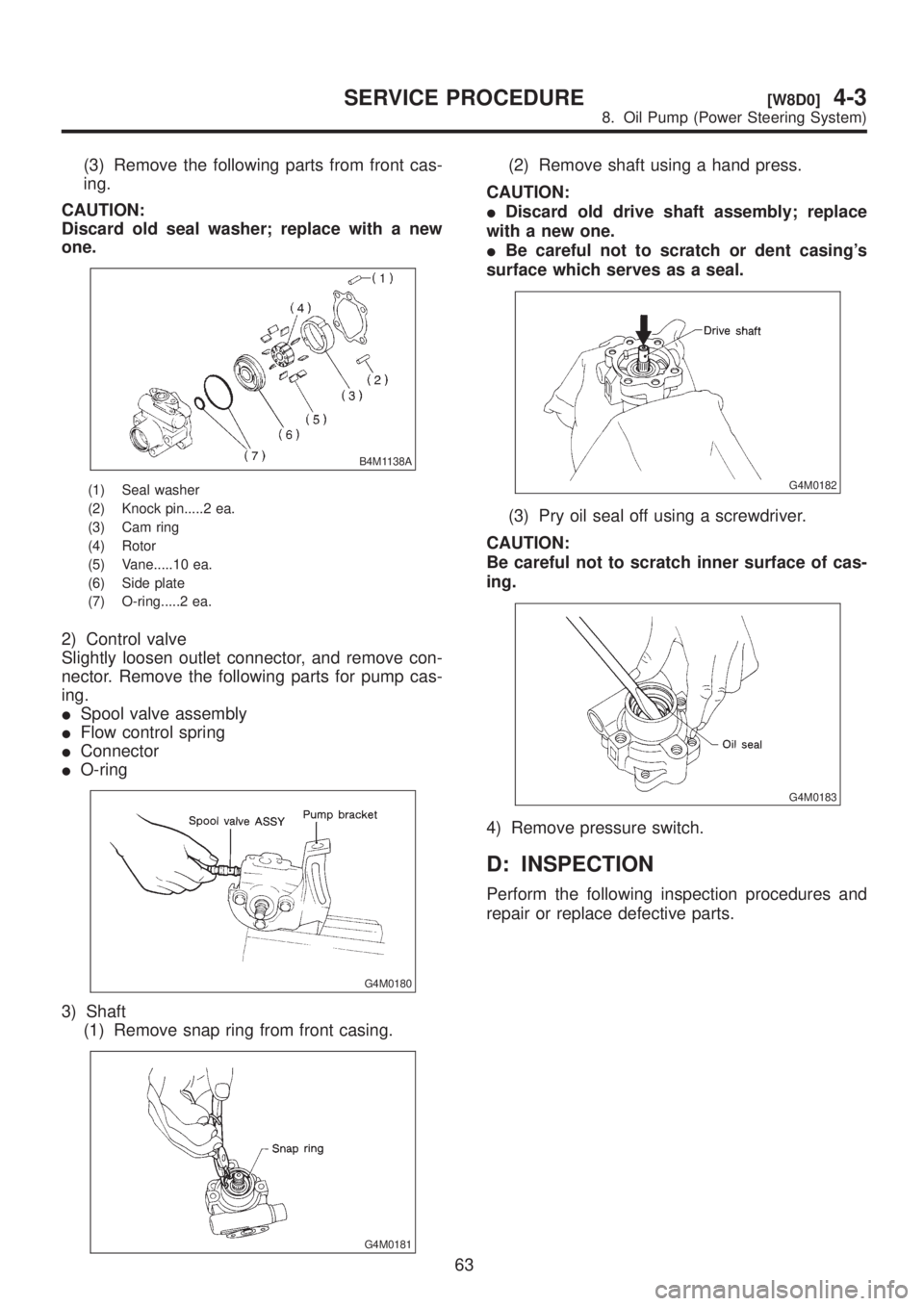

(3) Remove the following parts from front cas-

ing.

CAUTION:

Discard old seal washer; replace with a new

one.

B4M1138A

(1) Seal washer

(2) Knock pin.....2 ea.

(3) Cam ring

(4) Rotor

(5) Vane.....10 ea.

(6) Side plate

(7) O-ring.....2 ea.

2) Control valve

Slightly loosen outlet connector, and remove con-

nector. Remove the following parts for pump cas-

ing.

ISpool valve assembly

IFlow control spring

IConnector

IO-ring

G4M0180

3) Shaft

(1) Remove snap ring from front casing.

G4M0181

(2) Remove shaft using a hand press.

CAUTION:

IDiscard old drive shaft assembly; replace

with a new one.

IBe careful not to scratch or dent casing's

surface which serves as a seal.

G4M0182

(3) Pry oil seal off using a screwdriver.

CAUTION:

Be careful not to scratch inner surface of cas-

ing.

G4M0183

4) Remove pressure switch.

D: INSPECTION

Perform the following inspection procedures and

repair or replace defective parts.

63

[W8D0]4-3SERVICE PROCEDURE

8. Oil Pump (Power Steering System)

Page 857 of 1456

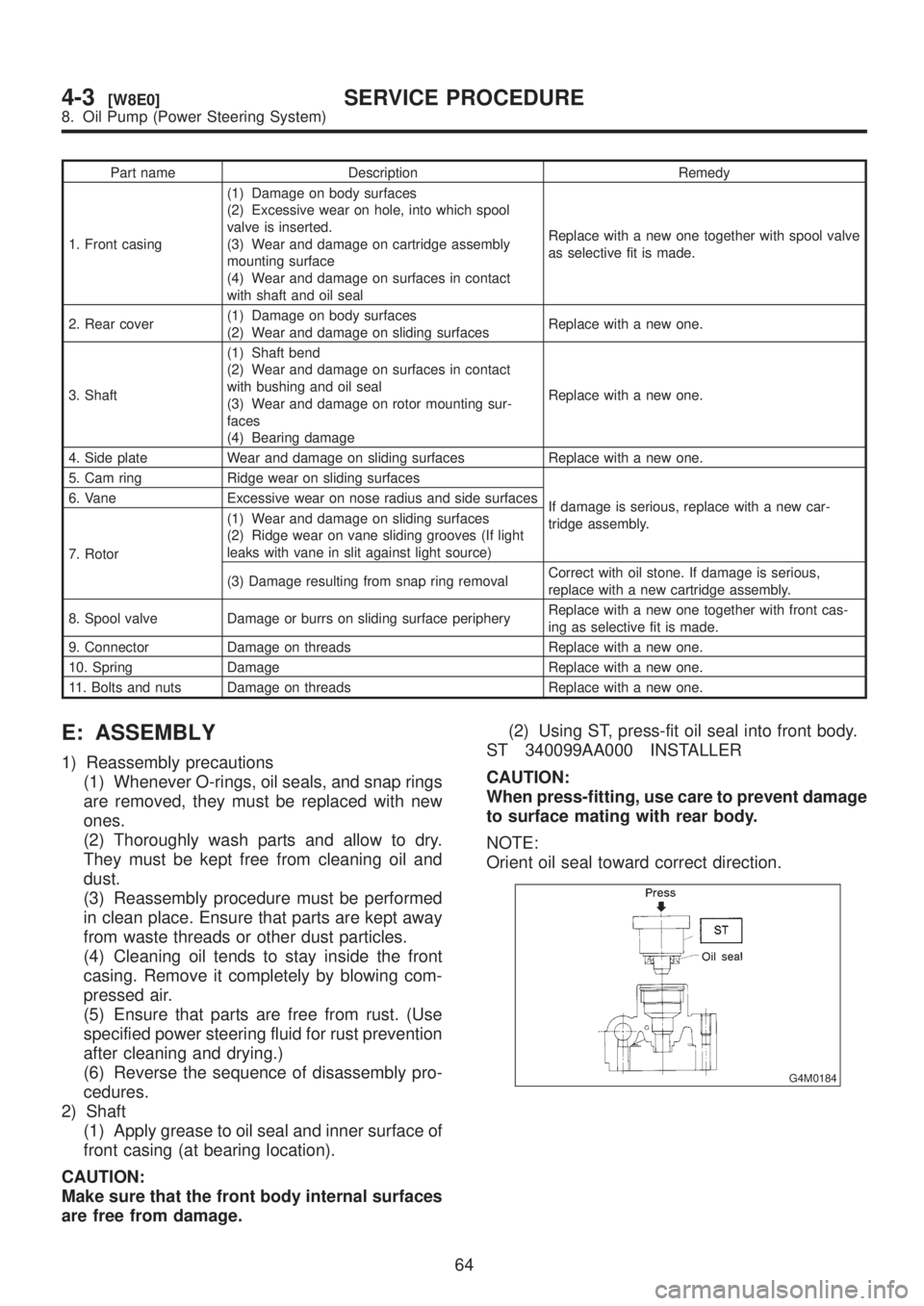

Part name Description Remedy

1. Front casing(1) Damage on body surfaces

(2) Excessive wear on hole, into which spool

valve is inserted.

(3) Wear and damage on cartridge assembly

mounting surface

(4) Wear and damage on surfaces in contact

with shaft and oil sealReplace with a new one together with spool valve

as selective fit is made.

2. Rear cover(1) Damage on body surfaces

(2) Wear and damage on sliding surfacesReplace with a new one.

3. Shaft(1) Shaft bend

(2) Wear and damage on surfaces in contact

with bushing and oil seal

(3) Wear and damage on rotor mounting sur-

faces

(4) Bearing damageReplace with a new one.

4. Side plate Wear and damage on sliding surfaces Replace with a new one.

5. Cam ring Ridge wear on sliding surfaces

If damage is serious, replace with a new car-

tridge assembly. 6. Vane Excessive wear on nose radius and side surfaces

7. Rotor(1) Wear and damage on sliding surfaces

(2) Ridge wear on vane sliding grooves (If light

leaks with vane in slit against light source)

(3) Damage resulting from snap ring removalCorrect with oil stone. If damage is serious,

replace with a new cartridge assembly.

8. Spool valve Damage or burrs on sliding surface peripheryReplace with a new one together with front cas-

ing as selective fit is made.

9. Connector Damage on threads Replace with a new one.

10. Spring Damage Replace with a new one.

11. Bolts and nuts Damage on threads Replace with a new one.

E: ASSEMBLY

1) Reassembly precautions

(1) Whenever O-rings, oil seals, and snap rings

are removed, they must be replaced with new

ones.

(2) Thoroughly wash parts and allow to dry.

They must be kept free from cleaning oil and

dust.

(3) Reassembly procedure must be performed

in clean place. Ensure that parts are kept away

from waste threads or other dust particles.

(4) Cleaning oil tends to stay inside the front

casing. Remove it completely by blowing com-

pressed air.

(5) Ensure that parts are free from rust. (Use

specified power steering fluid for rust prevention

after cleaning and drying.)

(6) Reverse the sequence of disassembly pro-

cedures.

2) Shaft

(1) Apply grease to oil seal and inner surface of

front casing (at bearing location).

CAUTION:

Make sure that the front body internal surfaces

are free from damage.(2) Using ST, press-fit oil seal into front body.

ST 340099AA000 INSTALLER

CAUTION:

When press-fitting, use care to prevent damage

to surface mating with rear body.

NOTE:

Orient oil seal toward correct direction.

G4M0184

64

4-3[W8E0]SERVICE PROCEDURE

8. Oil Pump (Power Steering System)

Page 858 of 1456

(3) Using ST, press-fit shaft assembly into front

body and mount snap ring.

ST 340099AA020 INSTALLER

NOTE:

Turn snap ring to ensure that it fits right into the

groove.

G4M0185

3) Cartridge assembly

(1) Apply specified power steering fluid to

O-rings and fit them into front casing.

(2) Install side plate to front casing.

CAUTION:

Use care not to let side plate gall.

G4M0186

(3) Mount rotor onto shaft.

(4) Install 10 vanes into rotor with their nose

radius facing toward cam ring.

(5) Install cam ring to front casing, securing

with knock pins.

CAUTION:

Do not use hammer to fit knock pins in posi-

tion.

G4M0187

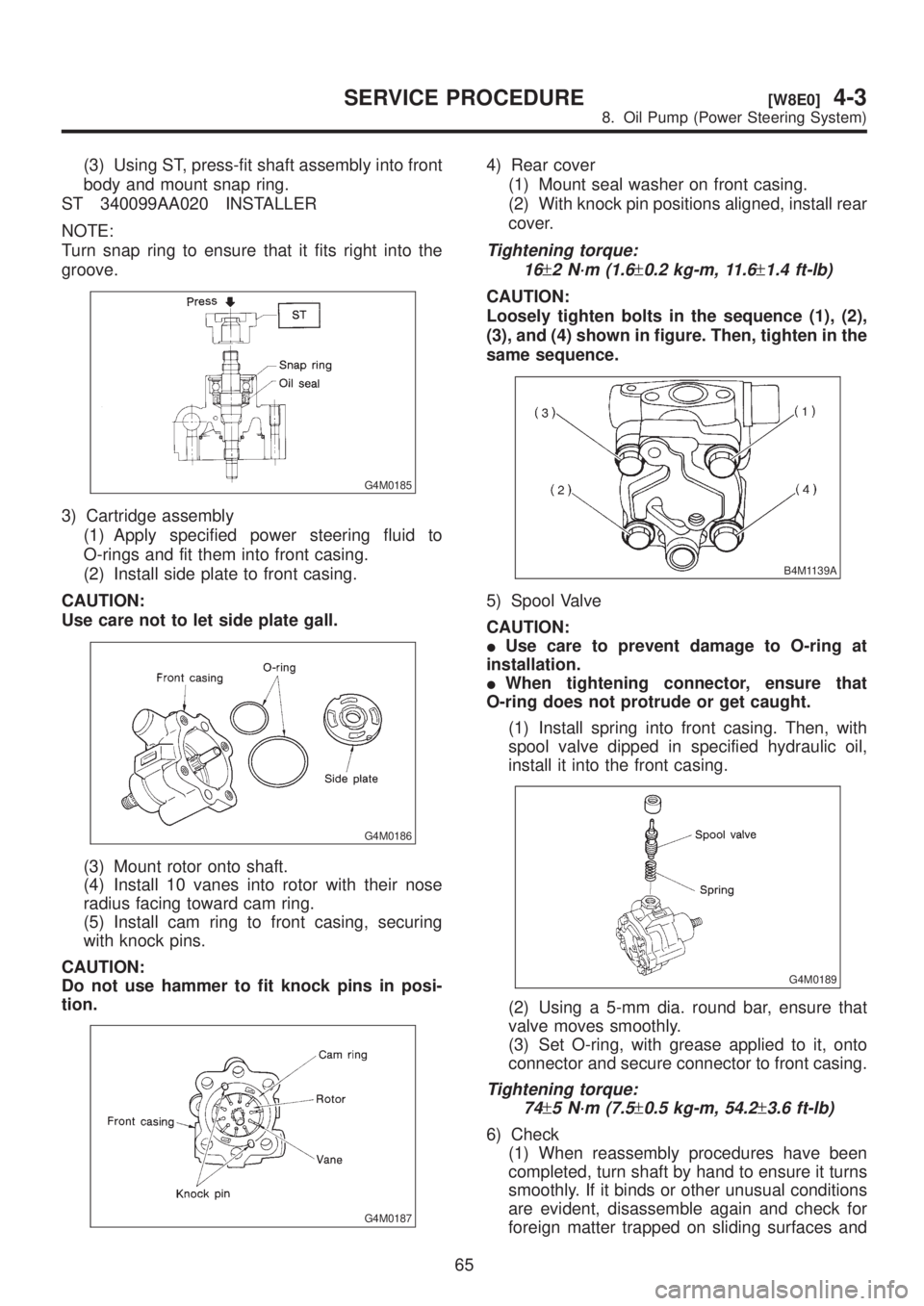

4) Rear cover

(1) Mount seal washer on front casing.

(2) With knock pin positions aligned, install rear

cover.

Tightening torque:

16

±2 N´m (1.6±0.2 kg-m, 11.6±1.4 ft-lb)

CAUTION:

Loosely tighten bolts in the sequence (1), (2),

(3), and (4) shown in figure. Then, tighten in the

same sequence.

B4M1139A

5) Spool Valve

CAUTION:

IUse care to prevent damage to O-ring at

installation.

IWhen tightening connector, ensure that

O-ring does not protrude or get caught.

(1) Install spring into front casing. Then, with

spool valve dipped in specified hydraulic oil,

install it into the front casing.

G4M0189

(2) Using a 5-mm dia. round bar, ensure that

valve moves smoothly.

(3) Set O-ring, with grease applied to it, onto

connector and secure connector to front casing.

Tightening torque:

74

±5 N´m (7.5±0.5 kg-m, 54.2±3.6 ft-lb)

6) Check

(1) When reassembly procedures have been

completed, turn shaft by hand to ensure it turns

smoothly. If it binds or other unusual conditions

are evident, disassemble again and check for

foreign matter trapped on sliding surfaces and

65

[W8E0]4-3SERVICE PROCEDURE

8. Oil Pump (Power Steering System)

Page 859 of 1456

improper installation. Eliminate the cause of

trouble.

(2) Check followings by referring to ªCHECKº

article.

IExcessive play in pulley shaft

IDitch deflection of pulley

IResistance to rotation of pulley

IMeasurement of generated oil pressure

F: INSTALLATION

1) Install bracket on engine.

Tightening torque:

22

±2 N´m (2.2±0.2 kg-m, 15.9±1.4 ft-lb)

2) Install oil pump on oil tank as follows outside

the vehicle:

NOTE:

Prior to installation, make sure that all oil is

removed from oil pump, oil tank and pipe.

3) Place oil pump in vise.

CAUTION:

Do not place oil pump directly in vise; use soft

pads and hold oil pump lightly to protect it.

4) Install O-ring on oil pump.

CAUTION:

Discard old O-ring and replace with a new one.

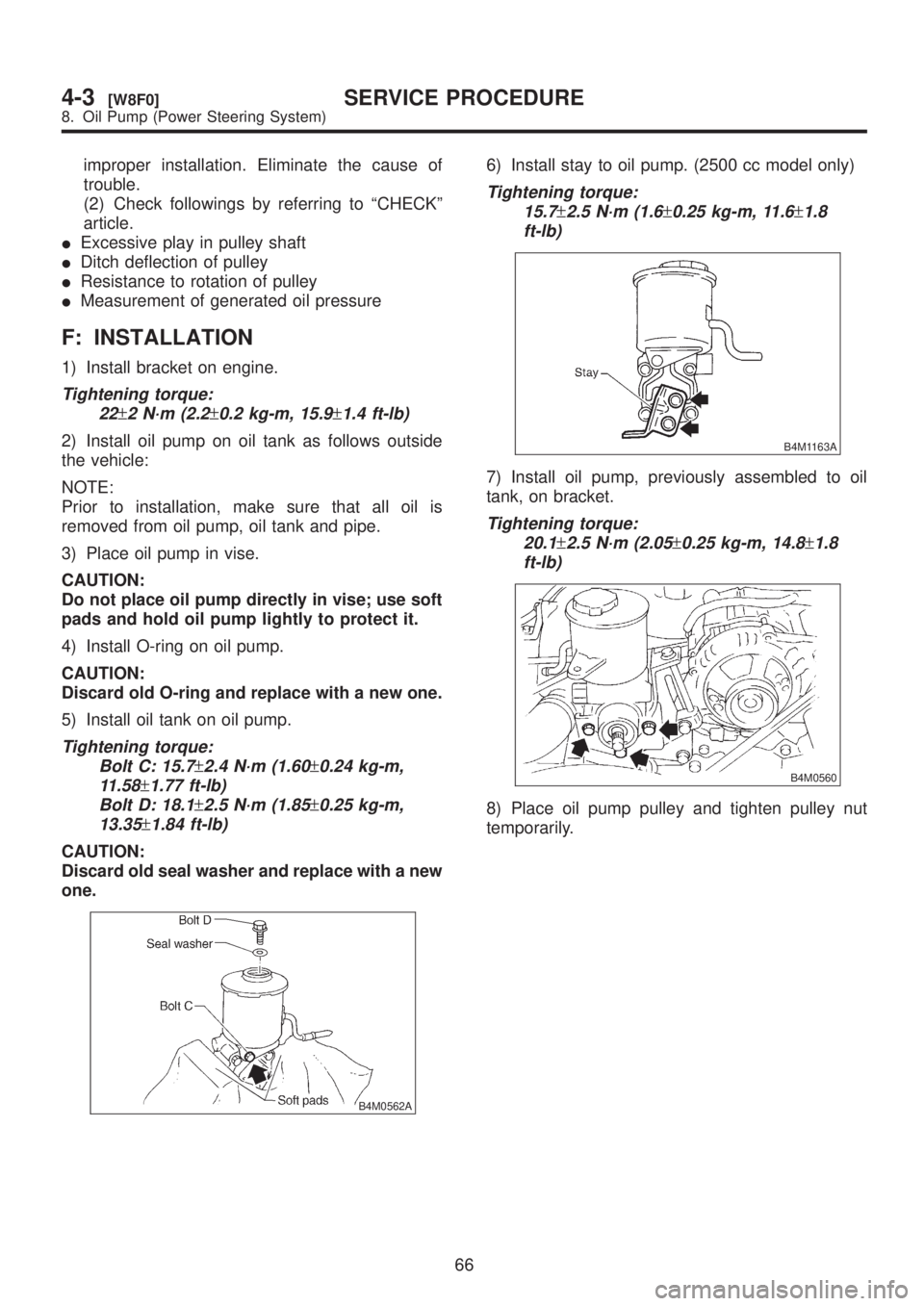

5) Install oil tank on oil pump.

Tightening torque:

Bolt C: 15.7

±2.4 N´m (1.60±0.24 kg-m,

11.58

±1.77 ft-lb)

Bolt D: 18.1

±2.5 N´m (1.85±0.25 kg-m,

13.35

±1.84 ft-lb)

CAUTION:

Discard old seal washer and replace with a new

one.

B4M0562A

6) Install stay to oil pump. (2500 cc model only)

Tightening torque:

15.7

±2.5 N´m (1.6±0.25 kg-m, 11.6±1.8

ft-lb)

B4M1163A

7) Install oil pump, previously assembled to oil

tank, on bracket.

Tightening torque:

20.1

±2.5 N´m (2.05±0.25 kg-m, 14.8±1.8

ft-lb)

B4M0560

8) Place oil pump pulley and tighten pulley nut

temporarily.

66

4-3[W8F0]SERVICE PROCEDURE

8. Oil Pump (Power Steering System)

Page 860 of 1456

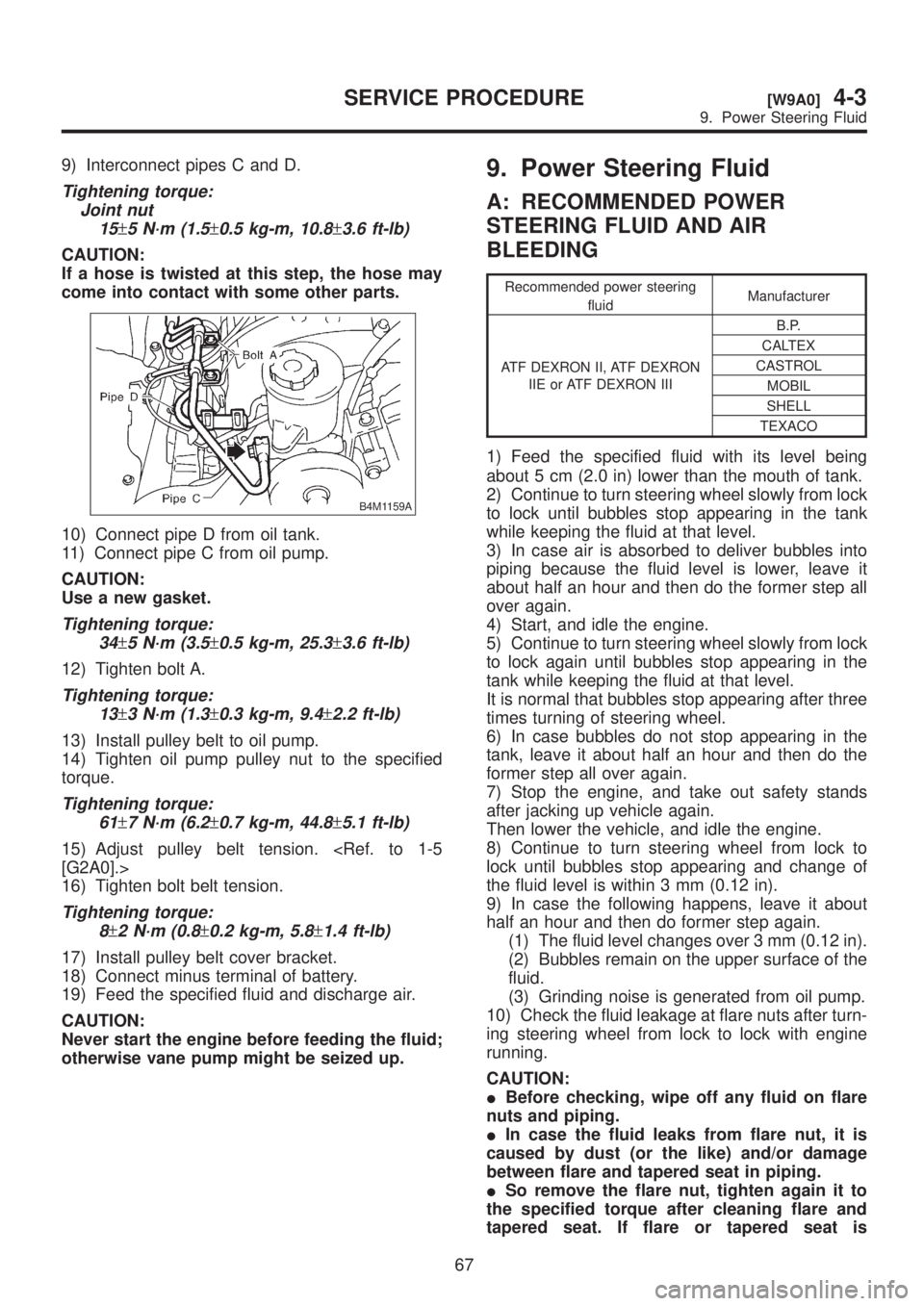

9) Interconnect pipes C and D.

Tightening torque:

Joint nut

15

±5 N´m (1.5±0.5 kg-m, 10.8±3.6 ft-lb)

CAUTION:

If a hose is twisted at this step, the hose may

come into contact with some other parts.

B4M1159A

10) Connect pipe D from oil tank.

11) Connect pipe C from oil pump.

CAUTION:

Use a new gasket.

Tightening torque:

34

±5 N´m (3.5±0.5 kg-m, 25.3±3.6 ft-lb)

12) Tighten bolt A.

Tightening torque:

13

±3 N´m (1.3±0.3 kg-m, 9.4±2.2 ft-lb)

13) Install pulley belt to oil pump.

14) Tighten oil pump pulley nut to the specified

torque.

Tightening torque:

61

±7 N´m (6.2±0.7 kg-m, 44.8±5.1 ft-lb)

15) Adjust pulley belt tension.

16) Tighten bolt belt tension.

Tightening torque:

8

±2 N´m (0.8±0.2 kg-m, 5.8±1.4 ft-lb)

17) Install pulley belt cover bracket.

18) Connect minus terminal of battery.

19) Feed the specified fluid and discharge air.

CAUTION:

Never start the engine before feeding the fluid;

otherwise vane pump might be seized up.

9. Power Steering Fluid

A: RECOMMENDED POWER

STEERING FLUID AND AIR

BLEEDING

Recommended power steering

fluidManufacturer

ATF DEXRON II, ATF DEXRON

IIE or ATF DEXRON IIIB.P.

CALTEX

CASTROL

MOBIL

SHELL

TEXACO

1) Feed the specified fluid with its level being

about 5 cm (2.0 in) lower than the mouth of tank.

2) Continue to turn steering wheel slowly from lock

to lock until bubbles stop appearing in the tank

while keeping the fluid at that level.

3) In case air is absorbed to deliver bubbles into

piping because the fluid level is lower, leave it

about half an hour and then do the former step all

over again.

4) Start, and idle the engine.

5) Continue to turn steering wheel slowly from lock

to lock again until bubbles stop appearing in the

tank while keeping the fluid at that level.

It is normal that bubbles stop appearing after three

times turning of steering wheel.

6) In case bubbles do not stop appearing in the

tank, leave it about half an hour and then do the

former step all over again.

7) Stop the engine, and take out safety stands

after jacking up vehicle again.

Then lower the vehicle, and idle the engine.

8) Continue to turn steering wheel from lock to

lock until bubbles stop appearing and change of

the fluid level is within 3 mm (0.12 in).

9) In case the following happens, leave it about

half an hour and then do former step again.

(1) The fluid level changes over 3 mm (0.12 in).

(2) Bubbles remain on the upper surface of the

fluid.

(3) Grinding noise is generated from oil pump.

10) Check the fluid leakage at flare nuts after turn-

ing steering wheel from lock to lock with engine

running.

CAUTION:

IBefore checking, wipe off any fluid on flare

nuts and piping.

IIn case the fluid leaks from flare nut, it is

caused by dust (or the like) and/or damage

between flare and tapered seat in piping.

ISo remove the flare nut, tighten again it to

the specified torque after cleaning flare and

tapered seat. If flare or tapered seat is

67

[W9A0]4-3SERVICE PROCEDURE

9. Power Steering Fluid