SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 811 of 1456

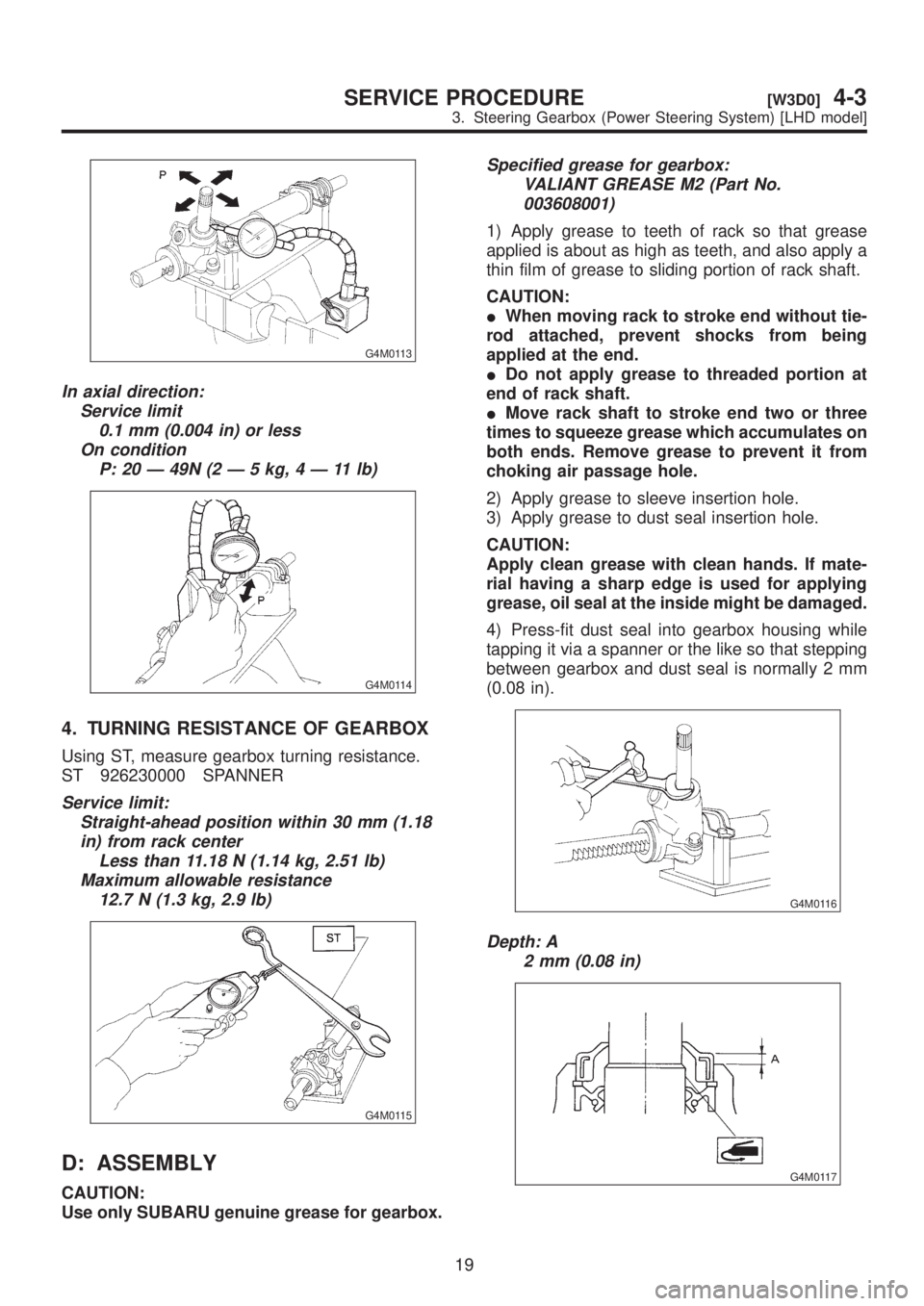

G4M0113

In axial direction:

Service limit

0.1 mm (0.004 in) or less

On condition

P:20Ð49N(2Ð5kg,4Ð11lb)

G4M0114

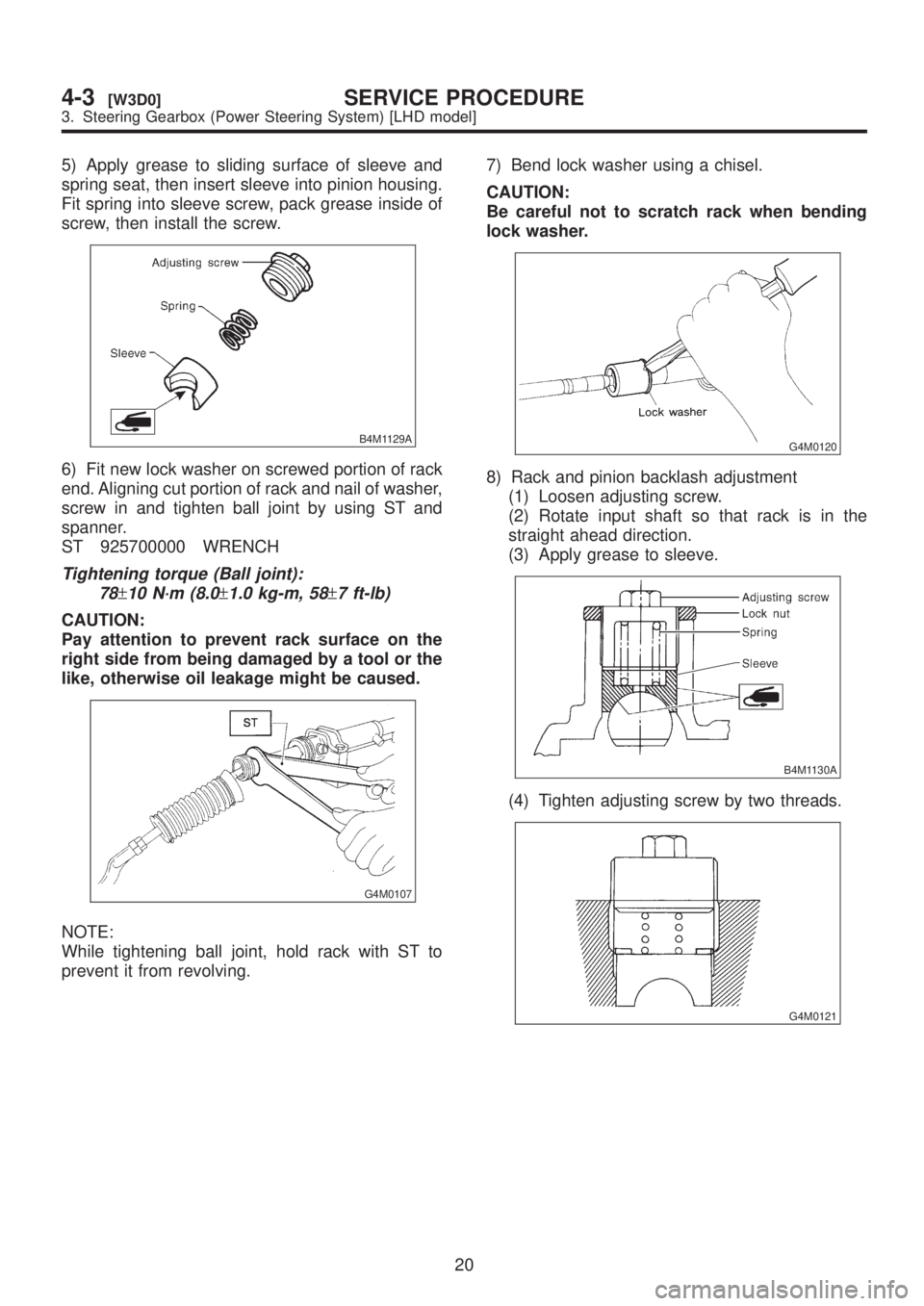

4. TURNING RESISTANCE OF GEARBOX

Using ST, measure gearbox turning resistance.

ST 926230000 SPANNER

Service limit:

Straight-ahead position within 30 mm (1.18

in) from rack center

Less than 11.18 N (1.14 kg, 2.51 lb)

Maximum allowable resistance

12.7 N (1.3 kg, 2.9 lb)

G4M0115

D: ASSEMBLY

CAUTION:

Use only SUBARU genuine grease for gearbox.

Specified grease for gearbox:

VALIANT GREASE M2 (Part No.

003608001)

1) Apply grease to teeth of rack so that grease

applied is about as high as teeth, and also apply a

thin film of grease to sliding portion of rack shaft.

CAUTION:

IWhen moving rack to stroke end without tie-

rod attached, prevent shocks from being

applied at the end.

IDo not apply grease to threaded portion at

end of rack shaft.

IMove rack shaft to stroke end two or three

times to squeeze grease which accumulates on

both ends. Remove grease to prevent it from

choking air passage hole.

2) Apply grease to sleeve insertion hole.

3) Apply grease to dust seal insertion hole.

CAUTION:

Apply clean grease with clean hands. If mate-

rial having a sharp edge is used for applying

grease, oil seal at the inside might be damaged.

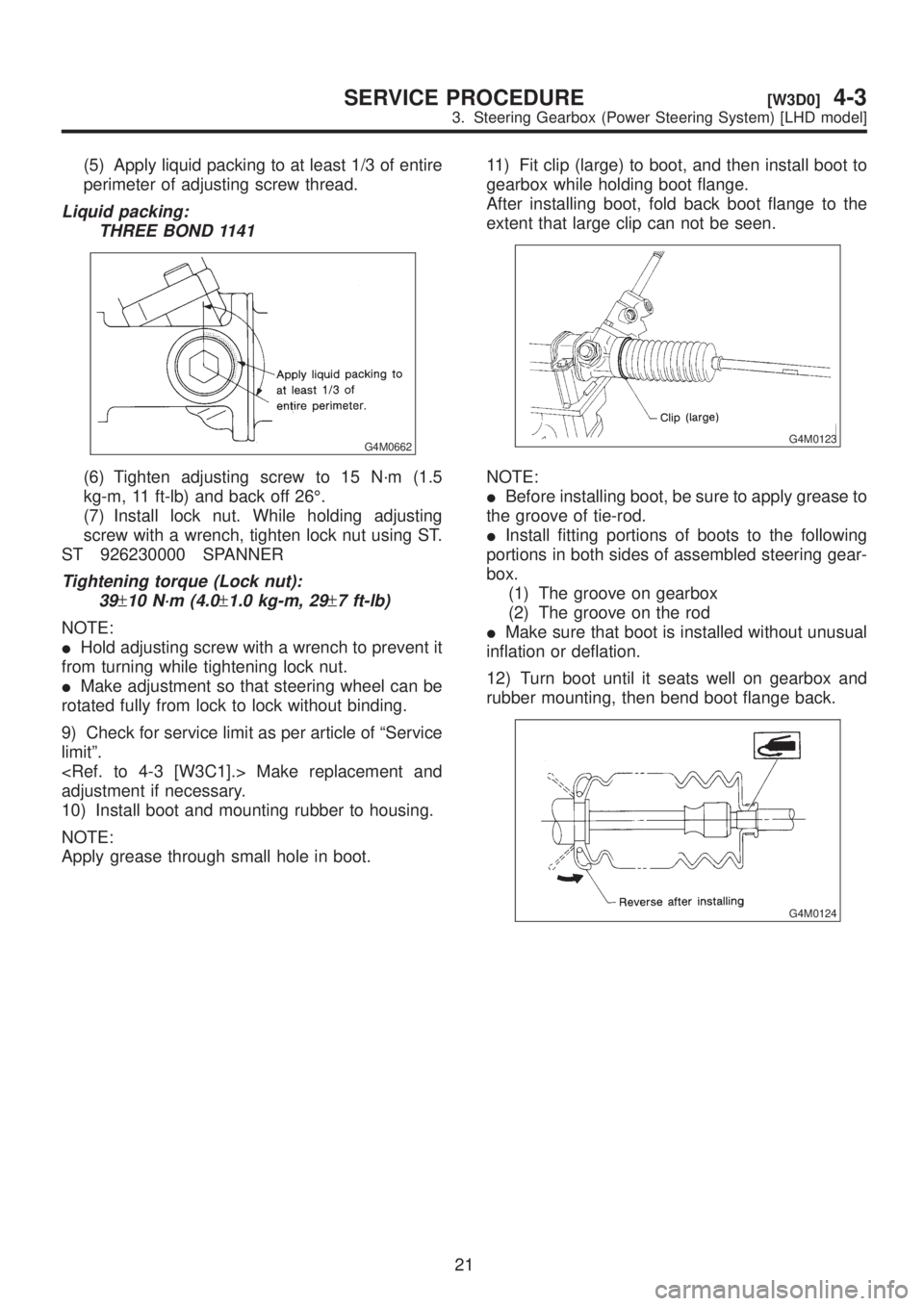

4) Press-fit dust seal into gearbox housing while

tapping it via a spanner or the like so that stepping

between gearbox and dust seal is normally 2 mm

(0.08 in).

G4M0116

Depth: A

2 mm (0.08 in)

G4M0117

19

[W3D0]4-3SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 812 of 1456

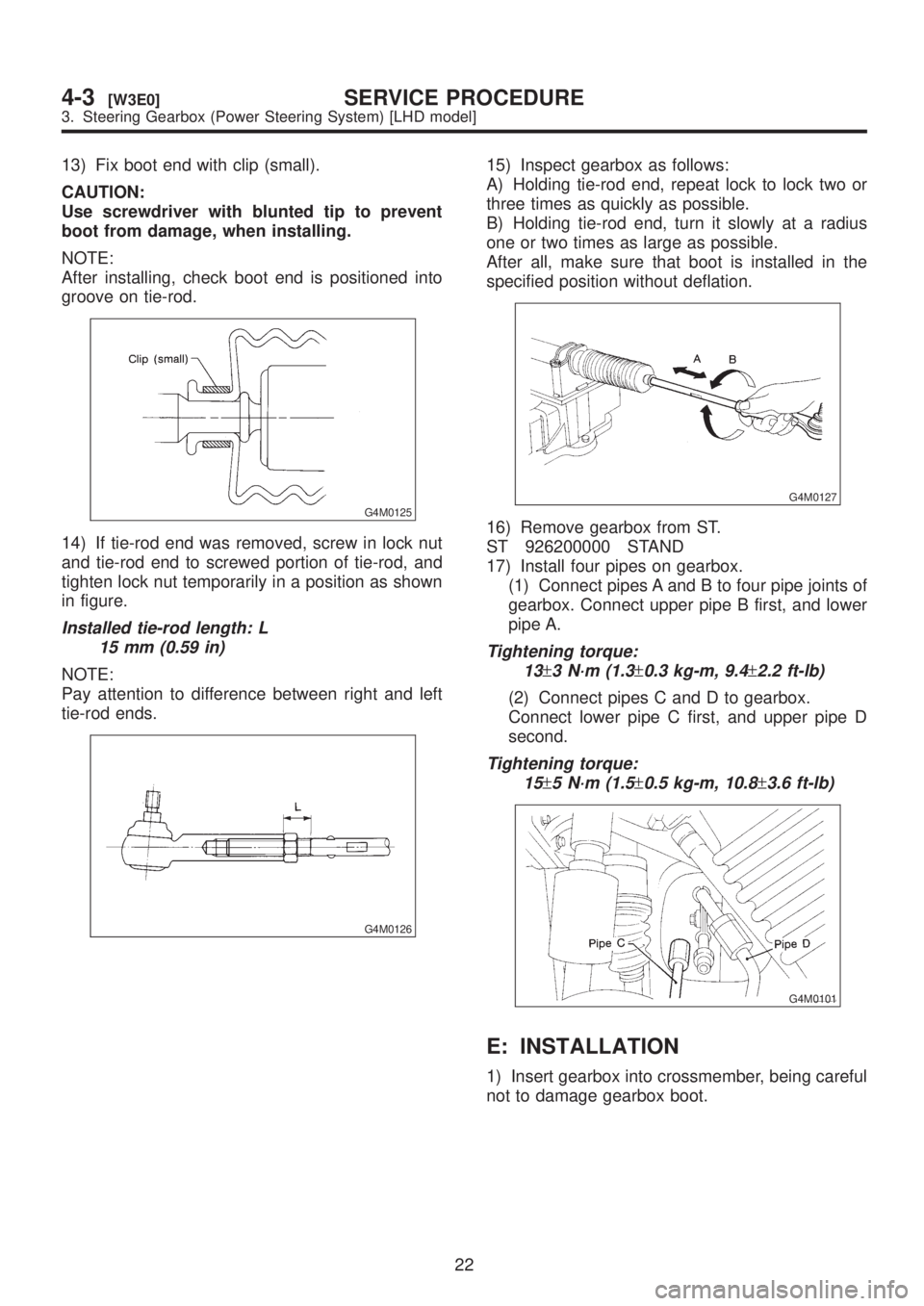

5) Apply grease to sliding surface of sleeve and

spring seat, then insert sleeve into pinion housing.

Fit spring into sleeve screw, pack grease inside of

screw, then install the screw.

B4M1129A

6) Fit new lock washer on screwed portion of rack

end. Aligning cut portion of rack and nail of washer,

screw in and tighten ball joint by using ST and

spanner.

ST 925700000 WRENCH

Tightening torque (Ball joint):

78

±10 N´m (8.0±1.0 kg-m, 58±7 ft-lb)

CAUTION:

Pay attention to prevent rack surface on the

right side from being damaged by a tool or the

like, otherwise oil leakage might be caused.

G4M0107

NOTE:

While tightening ball joint, hold rack with ST to

prevent it from revolving.7) Bend lock washer using a chisel.

CAUTION:

Be careful not to scratch rack when bending

lock washer.

G4M0120

8) Rack and pinion backlash adjustment

(1) Loosen adjusting screw.

(2) Rotate input shaft so that rack is in the

straight ahead direction.

(3) Apply grease to sleeve.

B4M1130A

(4) Tighten adjusting screw by two threads.

G4M0121

20

4-3[W3D0]SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 813 of 1456

(5) Apply liquid packing to at least 1/3 of entire

perimeter of adjusting screw thread.

Liquid packing:

THREE BOND 1141

G4M0662

(6) Tighten adjusting screw to 15 N´m (1.5

kg-m, 11 ft-lb) and back off 26É.

(7) Install lock nut. While holding adjusting

screw with a wrench, tighten lock nut using ST.

ST 926230000 SPANNER

Tightening torque (Lock nut):

39

±10 N´m (4.0±1.0 kg-m, 29±7 ft-lb)

NOTE:

IHold adjusting screw with a wrench to prevent it

from turning while tightening lock nut.

IMake adjustment so that steering wheel can be

rotated fully from lock to lock without binding.

9) Check for service limit as per article of ªService

limitº.

adjustment if necessary.

10) Install boot and mounting rubber to housing.

NOTE:

Apply grease through small hole in boot.11) Fit clip (large) to boot, and then install boot to

gearbox while holding boot flange.

After installing boot, fold back boot flange to the

extent that large clip can not be seen.

G4M0123

NOTE:

IBefore installing boot, be sure to apply grease to

the groove of tie-rod.

IInstall fitting portions of boots to the following

portions in both sides of assembled steering gear-

box.

(1) The groove on gearbox

(2) The groove on the rod

IMake sure that boot is installed without unusual

inflation or deflation.

12) Turn boot until it seats well on gearbox and

rubber mounting, then bend boot flange back.

G4M0124

21

[W3D0]4-3SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 814 of 1456

13) Fix boot end with clip (small).

CAUTION:

Use screwdriver with blunted tip to prevent

boot from damage, when installing.

NOTE:

After installing, check boot end is positioned into

groove on tie-rod.

G4M0125

14) If tie-rod end was removed, screw in lock nut

and tie-rod end to screwed portion of tie-rod, and

tighten lock nut temporarily in a position as shown

in figure.

Installed tie-rod length: L

15 mm (0.59 in)

NOTE:

Pay attention to difference between right and left

tie-rod ends.

G4M0126

15) Inspect gearbox as follows:

A) Holding tie-rod end, repeat lock to lock two or

three times as quickly as possible.

B) Holding tie-rod end, turn it slowly at a radius

one or two times as large as possible.

After all, make sure that boot is installed in the

specified position without deflation.

G4M0127

16) Remove gearbox from ST.

ST 926200000 STAND

17) Install four pipes on gearbox.

(1) Connect pipes A and B to four pipe joints of

gearbox. Connect upper pipe B first, and lower

pipe A.

Tightening torque:

13

±3 N´m (1.3±0.3 kg-m, 9.4±2.2 ft-lb)

(2) Connect pipes C and D to gearbox.

Connect lower pipe C first, and upper pipe D

second.

Tightening torque:

15

±5 N´m (1.5±0.5 kg-m, 10.8±3.6 ft-lb)

G4M0101

E: INSTALLATION

1) Insert gearbox into crossmember, being careful

not to damage gearbox boot.

22

4-3[W3E0]SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 815 of 1456

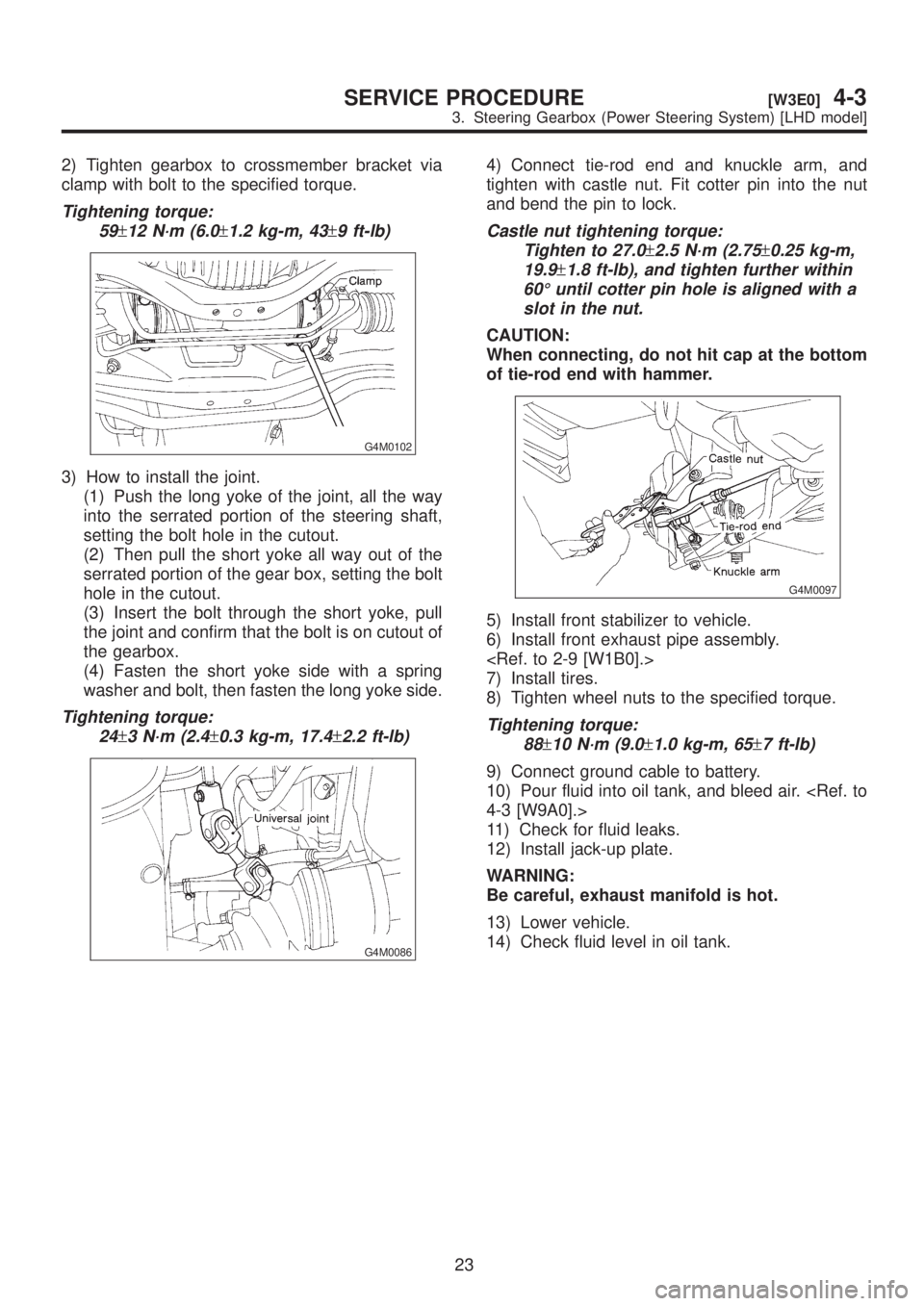

2) Tighten gearbox to crossmember bracket via

clamp with bolt to the specified torque.

Tightening torque:

59

±12 N´m (6.0±1.2 kg-m, 43±9 ft-lb)

G4M0102

3) How to install the joint.

(1) Push the long yoke of the joint, all the way

into the serrated portion of the steering shaft,

setting the bolt hole in the cutout.

(2) Then pull the short yoke all way out of the

serrated portion of the gear box, setting the bolt

hole in the cutout.

(3) Insert the bolt through the short yoke, pull

the joint and confirm that the bolt is on cutout of

the gearbox.

(4) Fasten the short yoke side with a spring

washer and bolt, then fasten the long yoke side.

Tightening torque:

24

±3 N´m (2.4±0.3 kg-m, 17.4±2.2 ft-lb)

G4M0086

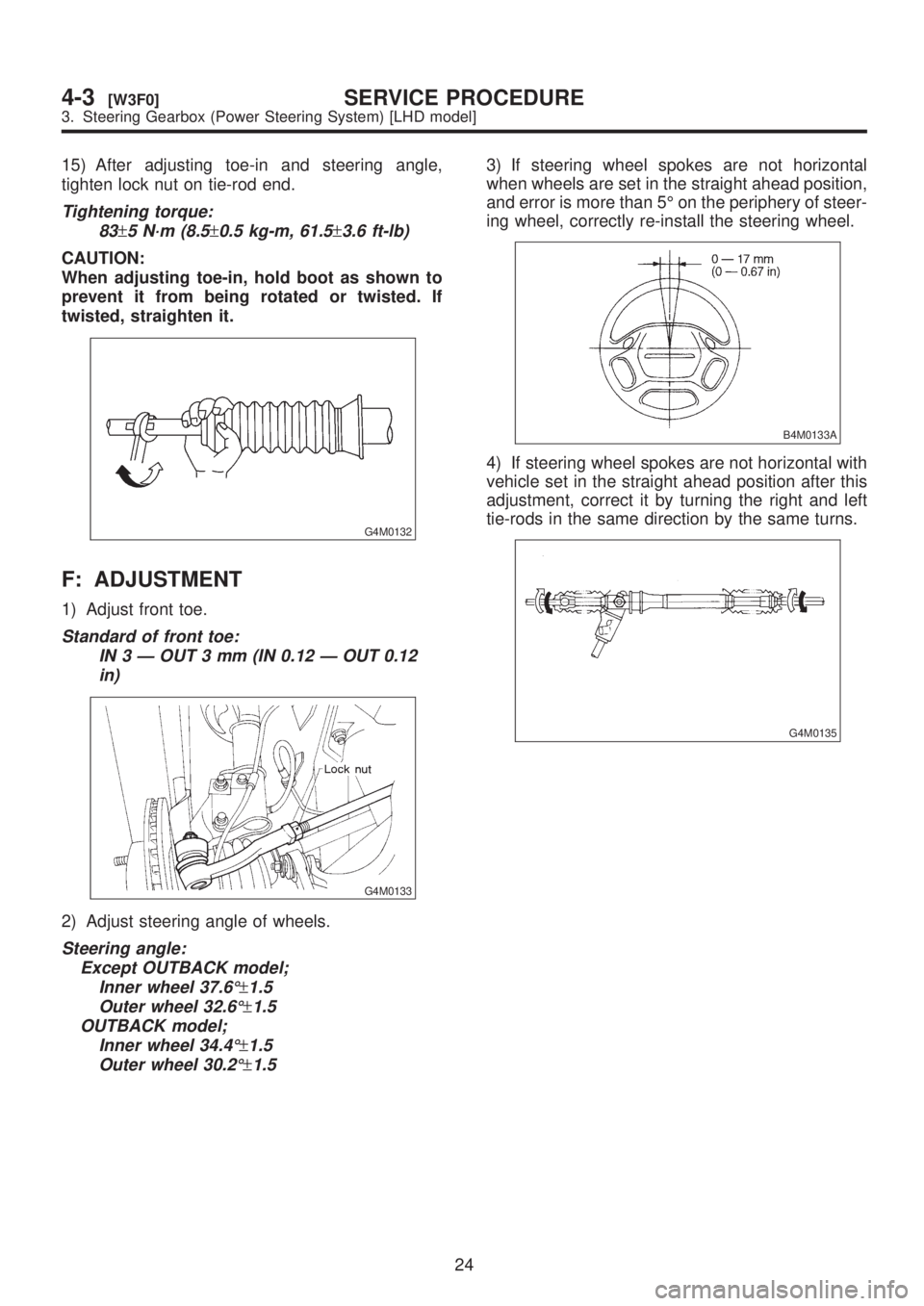

4) Connect tie-rod end and knuckle arm, and

tighten with castle nut. Fit cotter pin into the nut

and bend the pin to lock.

Castle nut tightening torque:

Tighten to 27.0

±2.5 N´m (2.75±0.25 kg-m,

19.9

±1.8 ft-lb), and tighten further within

60É until cotter pin hole is aligned with a

slot in the nut.

CAUTION:

When connecting, do not hit cap at the bottom

of tie-rod end with hammer.

G4M0097

5) Install front stabilizer to vehicle.

6) Install front exhaust pipe assembly.

7) Install tires.

8) Tighten wheel nuts to the specified torque.

Tightening torque:

88

±10 N´m (9.0±1.0 kg-m, 65±7 ft-lb)

9) Connect ground cable to battery.

10) Pour fluid into oil tank, and bleed air.

11) Check for fluid leaks.

12) Install jack-up plate.

WARNING:

Be careful, exhaust manifold is hot.

13) Lower vehicle.

14) Check fluid level in oil tank.

23

[W3E0]4-3SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 816 of 1456

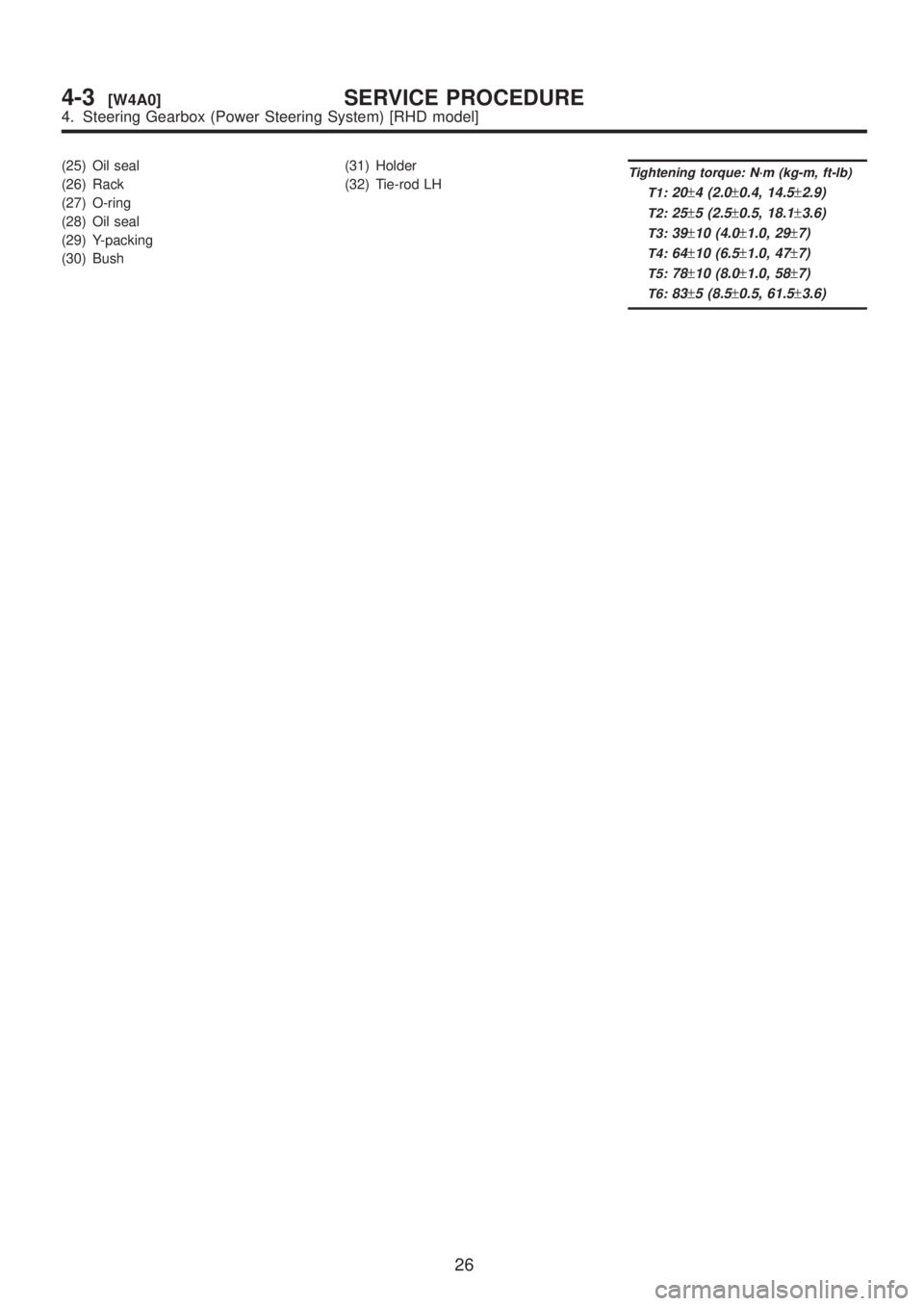

15) After adjusting toe-in and steering angle,

tighten lock nut on tie-rod end.

Tightening torque:

83

±5 N´m (8.5±0.5 kg-m, 61.5±3.6 ft-lb)

CAUTION:

When adjusting toe-in, hold boot as shown to

prevent it from being rotated or twisted. If

twisted, straighten it.

G4M0132

F: ADJUSTMENT

1) Adjust front toe.

Standard of front toe:

IN 3 Ð OUT 3 mm (IN 0.12 Ð OUT 0.12

in)

G4M0133

2) Adjust steering angle of wheels.

Steering angle:

Except OUTBACK model;

Inner wheel 37.6É

±1.5

Outer wheel 32.6É

±1.5

OUTBACK model;

Inner wheel 34.4É

±1.5

Outer wheel 30.2É

±1.5

3) If steering wheel spokes are not horizontal

when wheels are set in the straight ahead position,

and error is more than 5É on the periphery of steer-

ing wheel, correctly re-install the steering wheel.

B4M0133A

4) If steering wheel spokes are not horizontal with

vehicle set in the straight ahead position after this

adjustment, correct it by turning the right and left

tie-rods in the same direction by the same turns.

G4M0135

24

4-3[W3F0]SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 817 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 4. Steering Gearbox (Power

Steering System) [RHD model]

A: REMOVAL

NOTE:

For disassembly and assembly of gearbox unit,

refer to section Control Valve (Power Steering

Gearbox) [RHD model]. <Ref. to 4-3 SUBARU LEGACY 1999 Service Repair Manual 4. Steering Gearbox (Power

Steering System) [RHD model]

A: REMOVAL

NOTE:

For disassembly and assembly of gearbox unit,

refer to section Control Valve (Power Steering

Gearbox) [RHD model]. <Ref. to 4-3](/img/17/57435/w960_57435-816.png)

4. Steering Gearbox (Power

Steering System) [RHD model]

A: REMOVAL

NOTE:

For disassembly and assembly of gearbox unit,

refer to section Control Valve (Power Steering

Gearbox) [RHD model].

B4M0666B

(1) Dust cover

(2) Valve housing

(3) Y-packing

(4) Ball-bearing

(5) Spacer

(6) Pinion

(7) Shim

(8) Dust seal(9) Clip

(10) Tie-rod end

(11) Clip

(12) Boot

(13) Wire

(14) Tie-rod RH

(15) Lock washer

(16) Sleeve(17) Spring

(18) Adjusting screw

(19) Lock nut

(20) Pipe A

(21) Pipe B

(22) Adapter

(23) Housing ASSY

(24) Back-up washer

25

[W4A0]4-3SERVICE PROCEDURE

4. Steering Gearbox (Power Steering System) [RHD model]

Page 818 of 1456

(25) Oil seal

(26) Rack

(27) O-ring

(28) Oil seal

(29) Y-packing

(30) Bush(31) Holder

(32) Tie-rod LHTightening torque: N´m (kg-m, ft-lb)

T1:

20±4 (2.0±0.4, 14.5±2.9)

T2:25±5 (2.5±0.5, 18.1±3.6)

T3:39±10 (4.0±1.0, 29±7)

T4:64±10 (6.5±1.0, 47±7)

T5:78±10 (8.0±1.0, 58±7)

T6:83±5 (8.5±0.5, 61.5±3.6)

26

4-3[W4A0]SERVICE PROCEDURE

4. Steering Gearbox (Power Steering System) [RHD model]

Page 819 of 1456

1) Disconnect battery negative terminal.

2) Disconnect both oxygen sensor and exhaust

gas temperature warning sensor connectors from

front exhaust pipe assembly.

WARNING:

Be careful as exhaust pipe is hot.

3) Raise vehicle with a jack and remove front

wheel.

4) Disconnect front exhaust pipe assembly.

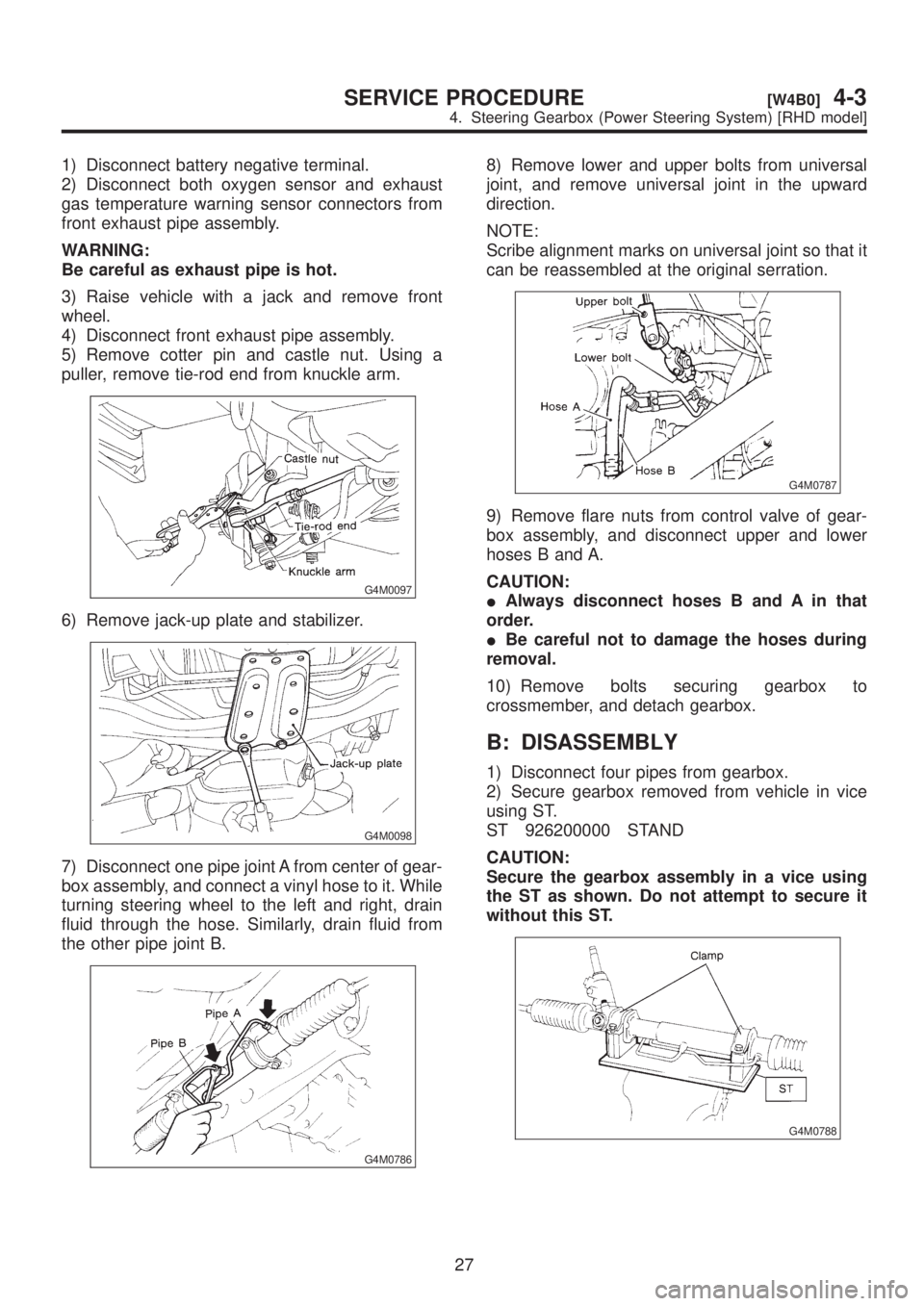

5) Remove cotter pin and castle nut. Using a

puller, remove tie-rod end from knuckle arm.

G4M0097

6) Remove jack-up plate and stabilizer.

G4M0098

7) Disconnect one pipe joint A from center of gear-

box assembly, and connect a vinyl hose to it. While

turning steering wheel to the left and right, drain

fluid through the hose. Similarly, drain fluid from

the other pipe joint B.

G4M0786

8) Remove lower and upper bolts from universal

joint, and remove universal joint in the upward

direction.

NOTE:

Scribe alignment marks on universal joint so that it

can be reassembled at the original serration.

G4M0787

9) Remove flare nuts from control valve of gear-

box assembly, and disconnect upper and lower

hoses B and A.

CAUTION:

IAlways disconnect hoses B and A in that

order.

IBe careful not to damage the hoses during

removal.

10) Remove bolts securing gearbox to

crossmember, and detach gearbox.

B: DISASSEMBLY

1) Disconnect four pipes from gearbox.

2) Secure gearbox removed from vehicle in vice

using ST.

ST 926200000 STAND

CAUTION:

Secure the gearbox assembly in a vice using

the ST as shown. Do not attempt to secure it

without this ST.

G4M0788

27

[W4B0]4-3SERVICE PROCEDURE

4. Steering Gearbox (Power Steering System) [RHD model]

Page 820 of 1456

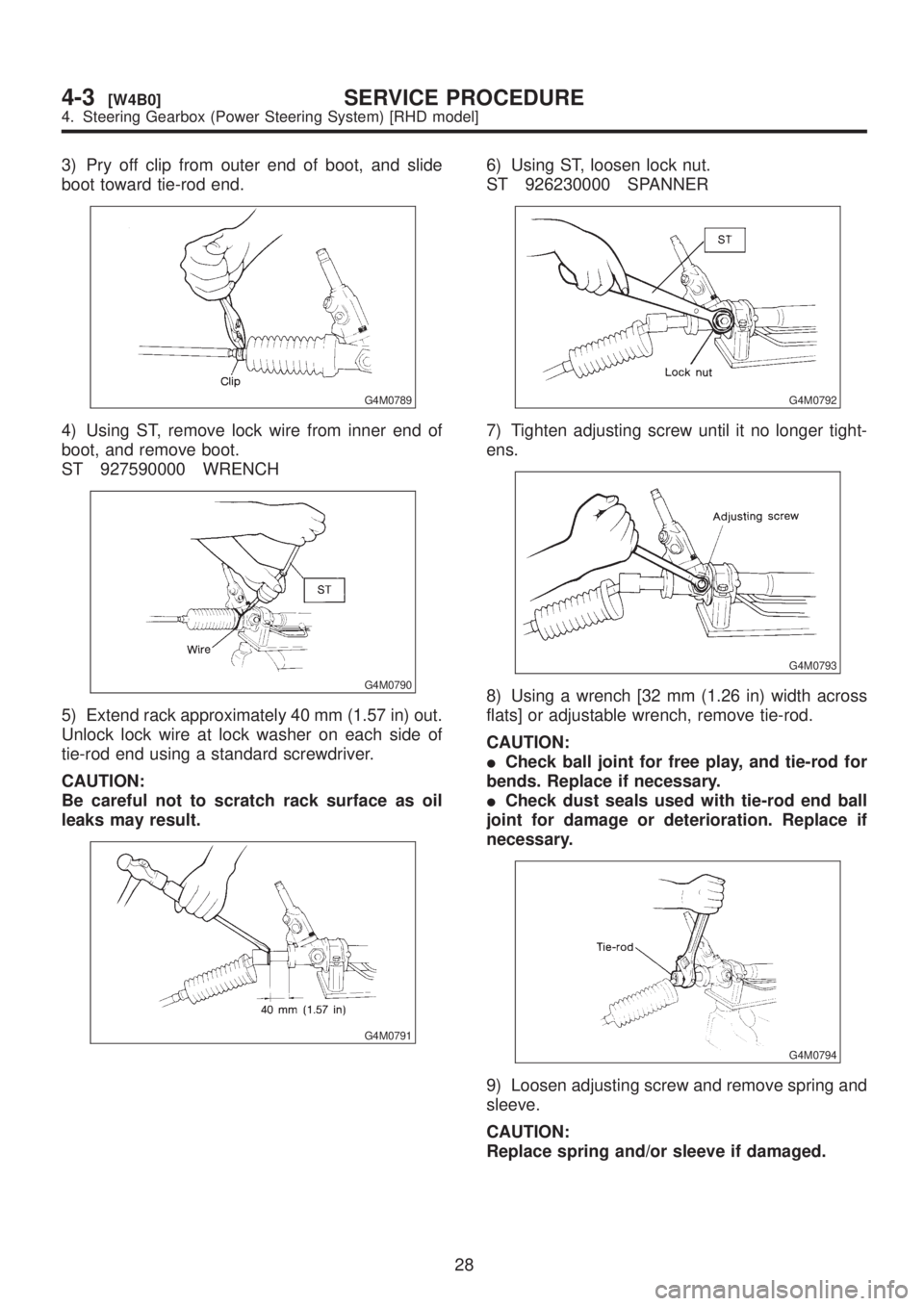

3) Pry off clip from outer end of boot, and slide

boot toward tie-rod end.

G4M0789

4) Using ST, remove lock wire from inner end of

boot, and remove boot.

ST 927590000 WRENCH

G4M0790

5) Extend rack approximately 40 mm (1.57 in) out.

Unlock lock wire at lock washer on each side of

tie-rod end using a standard screwdriver.

CAUTION:

Be careful not to scratch rack surface as oil

leaks may result.

G4M0791

6) Using ST, loosen lock nut.

ST 926230000 SPANNER

G4M0792

7) Tighten adjusting screw until it no longer tight-

ens.

G4M0793

8) Using a wrench [32 mm (1.26 in) width across

flats] or adjustable wrench, remove tie-rod.

CAUTION:

ICheck ball joint for free play, and tie-rod for

bends. Replace if necessary.

ICheck dust seals used with tie-rod end ball

joint for damage or deterioration. Replace if

necessary.

G4M0794

9) Loosen adjusting screw and remove spring and

sleeve.

CAUTION:

Replace spring and/or sleeve if damaged.

28

4-3[W4B0]SERVICE PROCEDURE

4. Steering Gearbox (Power Steering System) [RHD model]