Steering Terminal SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 80 of 2453

AB(diag)-56

Diagnostic Chart with Trouble Code

AIRBAG SYSTEM (DIAGNOSTICS)

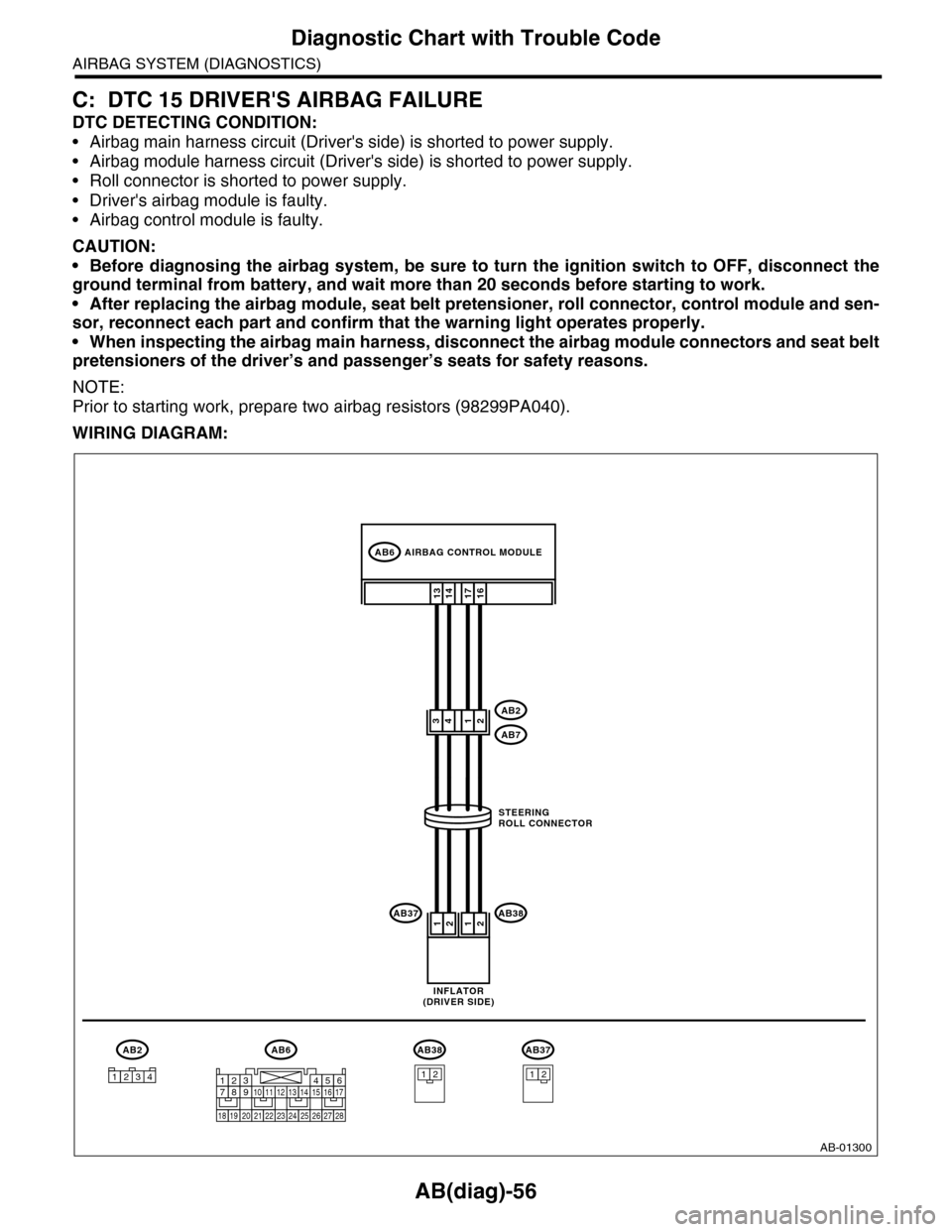

C: DTC 15 DRIVER'S AIRBAG FAILURE

DTC DETECTING CONDITION:

•Airbag main harness circuit (Driver's side) is shorted to power supply.

•Airbag module harness circuit (Driver's side) is shorted to power supply.

•Roll connector is shorted to power supply.

•Driver's airbag module is faulty.

•Airbag control module is faulty.

CAUTION:

•Before diagnosing the airbag system, be sure to turn the ignition switch to OFF, disconnect the

ground terminal from battery, and wait more than 20 seconds before starting to work.

•After replacing the airbag module, seat belt pretensioner, roll connector, control module and sen-

sor, reconnect each part and confirm that the warning light operates properly.

•When inspecting the airbag main harness, disconnect the airbag module connectors and seat belt

pretensioners of the driver’s and passenger’s seats for safety reasons.

NOTE:

Prior to starting work, prepare two airbag resistors (98299PA040).

WIRING DIAGRAM:

AB-01300

16171314

AB6

AB2

AB2

AB71234

AB6

AB381212

21

AB38

AB37

123421

AB37

1234567891011121314151617

1819202122232425262728

AIRBAG CONTROL MODULE

STEERINGROLL CONNECTOR

INFLATOR(DRIVER SIDE)

Page 87 of 2453

AB(diag)-63

Diagnostic Chart with Trouble Code

AIRBAG SYSTEM (DIAGNOSTICS)

This DTC is indicated when the front airbag module and the pretensioner are deployed.

Once this DTC is displayed, the memory cannot be cleared. Therefore replace the following parts.

•Airbag control module

•Driver's airbag module

•Passenger's airbag module

•Front sub sensor of both sides

•Front seat belt outer with pretensioner of both sides.

•Steering roll connector

•Occupant detection system (passenger’s seat cushion & frame assembly)

G: DTC 23 CONNECTOR TO AIRBAG ECU FAILURE

DTC DETECTING CONDITION:

Connection of (AB6), (AB17) and (AB18) to airbag control module is improper.

CAUTION:

Before diagnosing the airbag system, be sure to turn the ignition switch to OFF, disconnect the

ground terminal from battery, and wait more than 20 seconds before starting to work.

Step Check Yes No

1CHECK POOR CONTACTS OF CONNEC-

TORS (AB6), (AB17) AND (AB18).

1) Turn the ignition switch to OFF, disconnect

the battery ground cable, and wait more than

20 seconds.

2) Disconnect the connectors (AB6), (AB17)

and (AB18) from airbag control module.

Is there rust or damage on the

harness connector and the

control module connector?

Replace the airbag

control module.

Module.> Replace

the body harness

with the airbag

main harness or

replace the body

harness with the

side airbag har-

ness.

Go to step 2.

2CHECK POOR CONTACTS OF CONNEC-

TORS (AB6), (AB17) AND (AB18).

1) Reconnect the connector securely.

2) Connect the battery ground terminal and

turn the ignition switch to ON.

Does the airbag warning light

illuminate for 6 seconds and go

off?

Go to step 3.Replace the airbag

control module.

Module.>

3CHECK AIRBAG CONTROL MODULE.

1) Connect all the connectors.

2) Erase the memory.

3) Perform the inspection mode.

4) Read the DTC.

Is the same DTC displayed? Replace the airbag

control module.

Module.>

Go to step 4.

4CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC)”.

of Diagnostic Trou-

ble Code (DTC).>

Finish the diagno-

sis.

Page 138 of 2453

AB(diag)-114

Diagnostic Chart with Trouble Code

AIRBAG SYSTEM (DIAGNOSTICS)

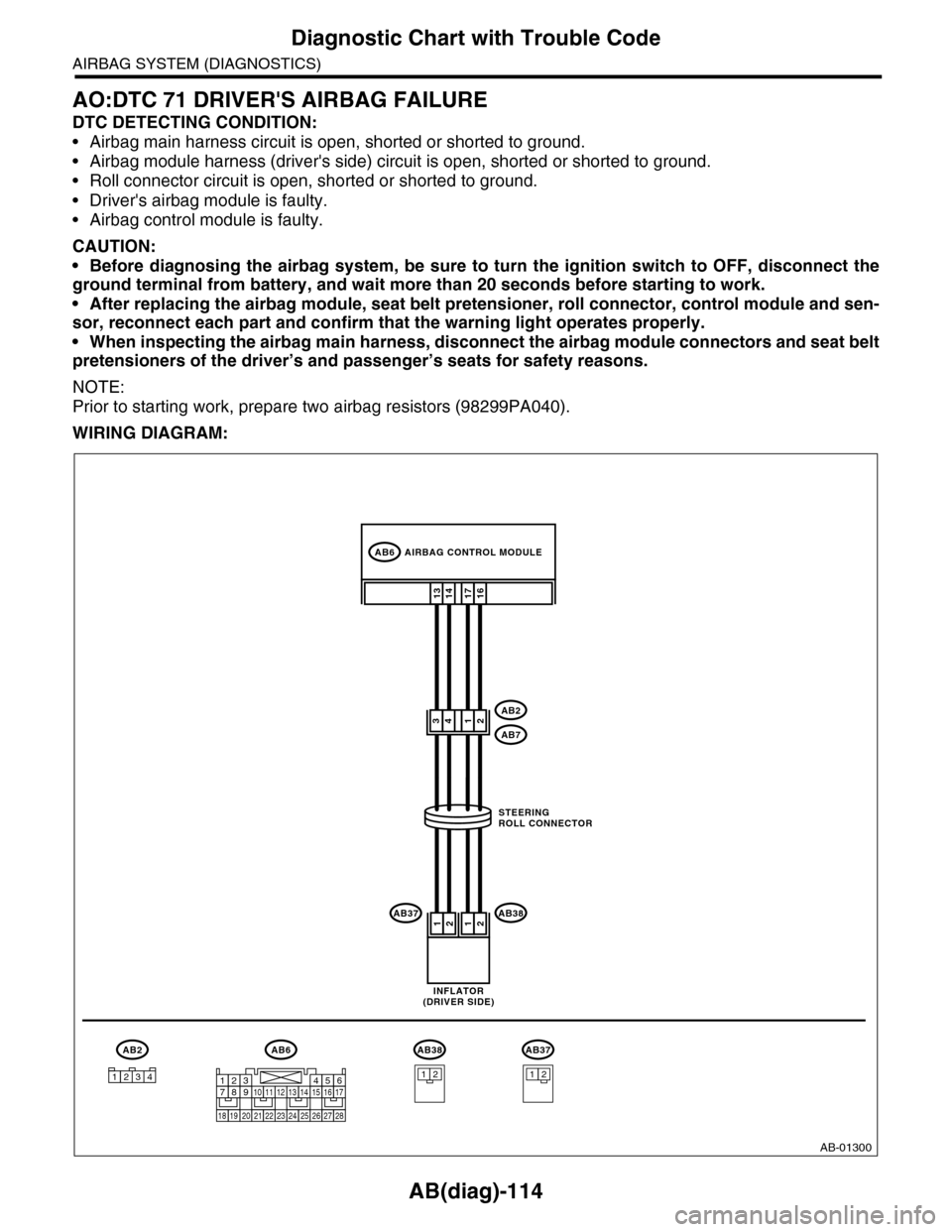

AO:DTC 71 DRIVER'S AIRBAG FAILURE

DTC DETECTING CONDITION:

•Airbag main harness circuit is open, shorted or shorted to ground.

•Airbag module harness (driver's side) circuit is open, shorted or shorted to ground.

•Roll connector circuit is open, shorted or shorted to ground.

•Driver's airbag module is faulty.

•Airbag control module is faulty.

CAUTION:

•Before diagnosing the airbag system, be sure to turn the ignition switch to OFF, disconnect the

ground terminal from battery, and wait more than 20 seconds before starting to work.

•After replacing the airbag module, seat belt pretensioner, roll connector, control module and sen-

sor, reconnect each part and confirm that the warning light operates properly.

•When inspecting the airbag main harness, disconnect the airbag module connectors and seat belt

pretensioners of the driver’s and passenger’s seats for safety reasons.

NOTE:

Prior to starting work, prepare two airbag resistors (98299PA040).

WIRING DIAGRAM:

AB-01300

16171314

AB6

AB2

AB2

AB71234

AB6

AB381212

21

AB38

AB37

123421

AB37

1234567891011121314151617

1819202122232425262728

AIRBAG CONTROL MODULE

STEERINGROLL CONNECTOR

INFLATOR(DRIVER SIDE)

Page 144 of 2453

AB(diag)-120

Diagnostic Chart with Trouble Code

AIRBAG SYSTEM (DIAGNOSTICS)

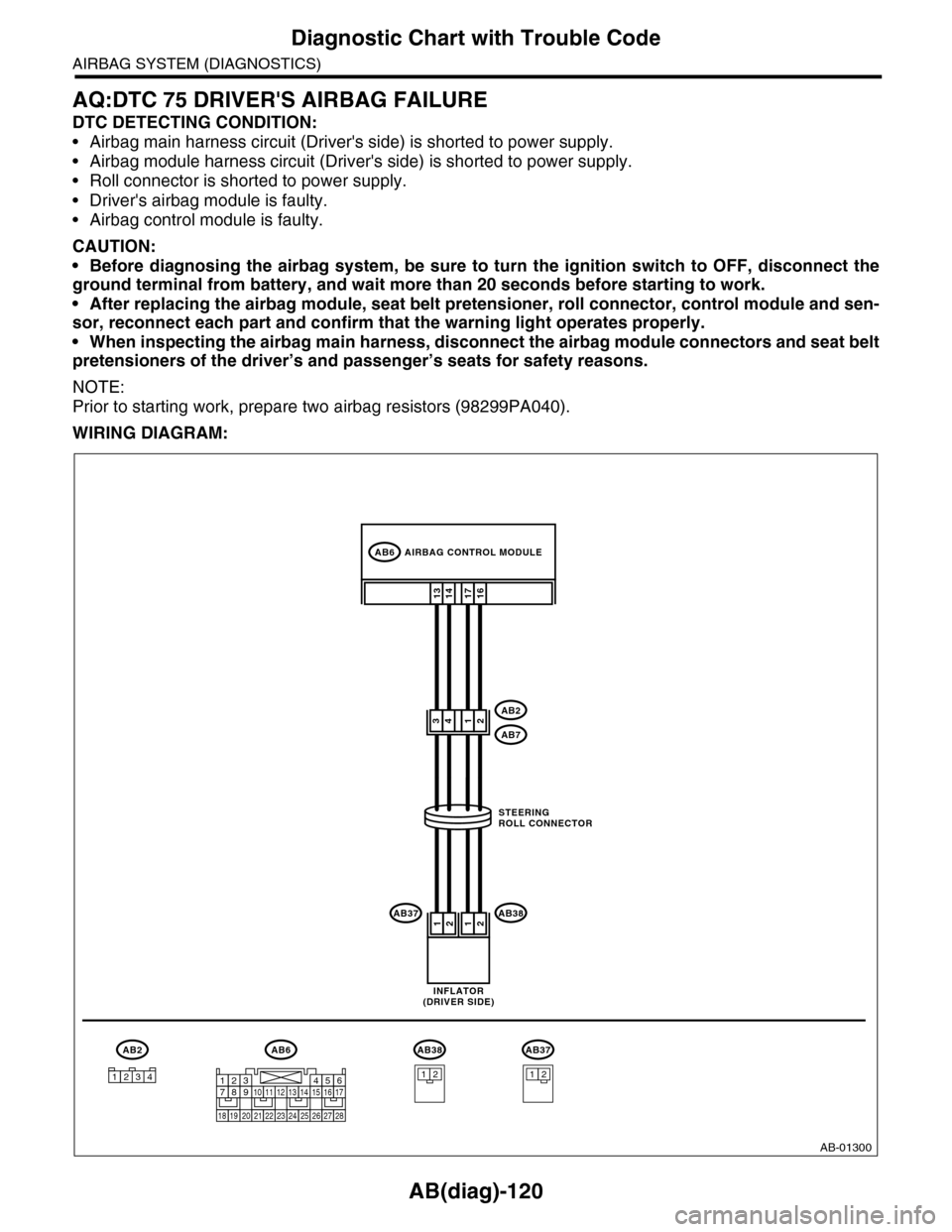

AQ:DTC 75 DRIVER'S AIRBAG FAILURE

DTC DETECTING CONDITION:

•Airbag main harness circuit (Driver's side) is shorted to power supply.

•Airbag module harness circuit (Driver's side) is shorted to power supply.

•Roll connector is shorted to power supply.

•Driver's airbag module is faulty.

•Airbag control module is faulty.

CAUTION:

•Before diagnosing the airbag system, be sure to turn the ignition switch to OFF, disconnect the

ground terminal from battery, and wait more than 20 seconds before starting to work.

•After replacing the airbag module, seat belt pretensioner, roll connector, control module and sen-

sor, reconnect each part and confirm that the warning light operates properly.

•When inspecting the airbag main harness, disconnect the airbag module connectors and seat belt

pretensioners of the driver’s and passenger’s seats for safety reasons.

NOTE:

Prior to starting work, prepare two airbag resistors (98299PA040).

WIRING DIAGRAM:

AB-01300

16171314

AB6

AB2

AB2

AB71234

AB6

AB381212

21

AB38

AB37

123421

AB37

1234567891011121314151617

1819202122232425262728

AIRBAG CONTROL MODULE

STEERINGROLL CONNECTOR

INFLATOR(DRIVER SIDE)

Page 167 of 2453

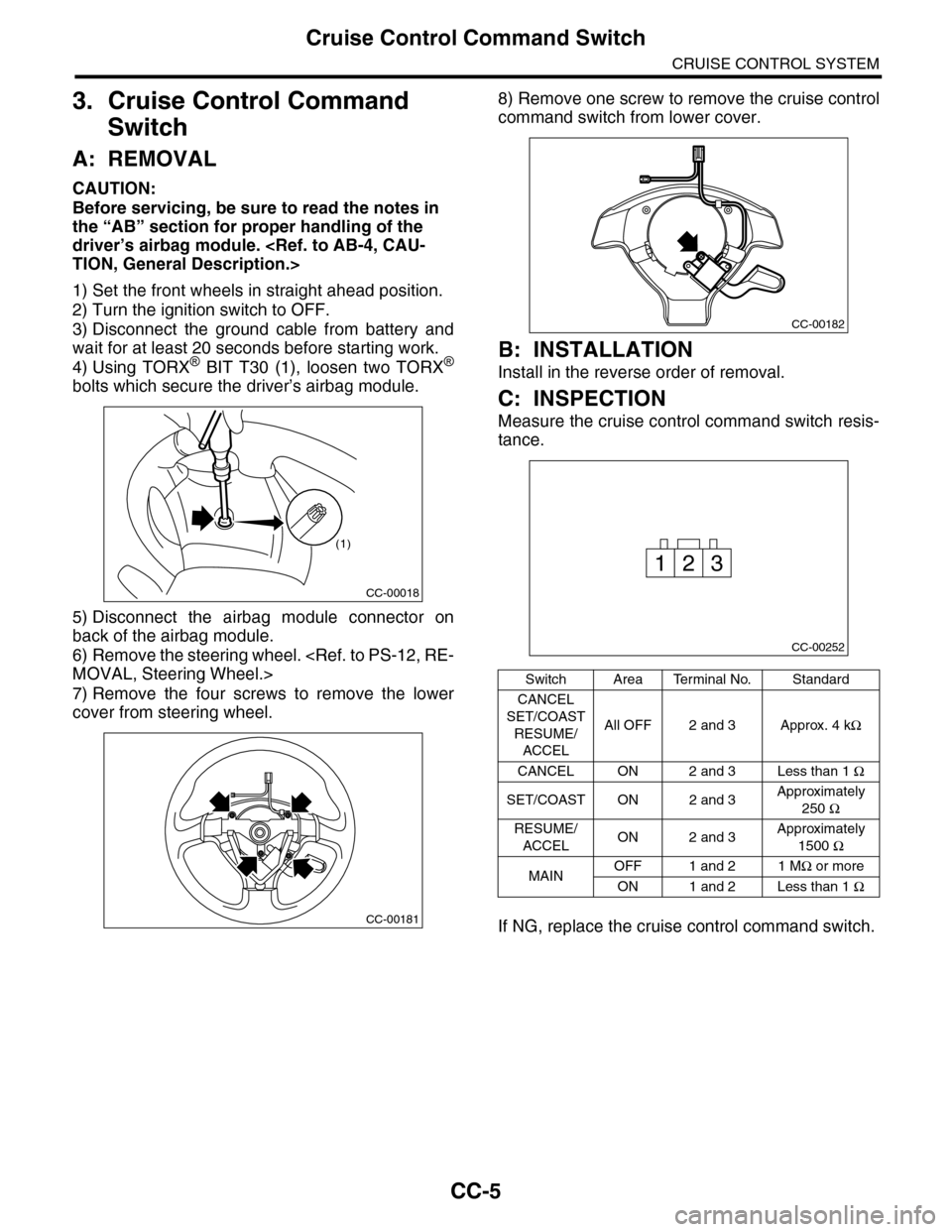

CC-5

Cruise Control Command Switch

CRUISE CONTROL SYSTEM

3. Cruise Control Command

Switch

A: REMOVAL

CAUTION:

Before servicing, be sure to read the notes in

the “AB” section for proper handling of the

driver’s airbag module.

1) Set the front wheels in straight ahead position.

2) Turn the ignition switch to OFF.

3) Disconnect the ground cable from battery and

wait for at least 20 seconds before starting work.

4) Using TORX® BIT T30 (1), loosen two TORX®

bolts which secure the driver’s airbag module.

5) Disconnect the airbag module connector on

back of the airbag module.

6) Remove the steering wheel.

7) Remove the four screws to remove the lower

cover from steering wheel.

8) Remove one screw to remove the cruise control

command switch from lower cover.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

Measure the cruise control command switch resis-

tance.

If NG, replace the cruise control command switch.

CC-00018

(1)

CC-00181

Switch Area Terminal No. Standard

CANCEL

SET/COAST

RESUME/

ACCEL

All OFF 2 and 3 Approx. 4 kΩ

CANCEL ON 2 and 3 Less than 1 Ω

SET/COAST ON 2 and 3Approximately

250 Ω

RESUME/

ACCELON 2 and 3Approximately

1500 Ω

MAINOFF 1 and 2 1 MΩ or more

ON 1 and 2 Less than 1 Ω

CC-00182

CC-00252

231

Page 180 of 2453

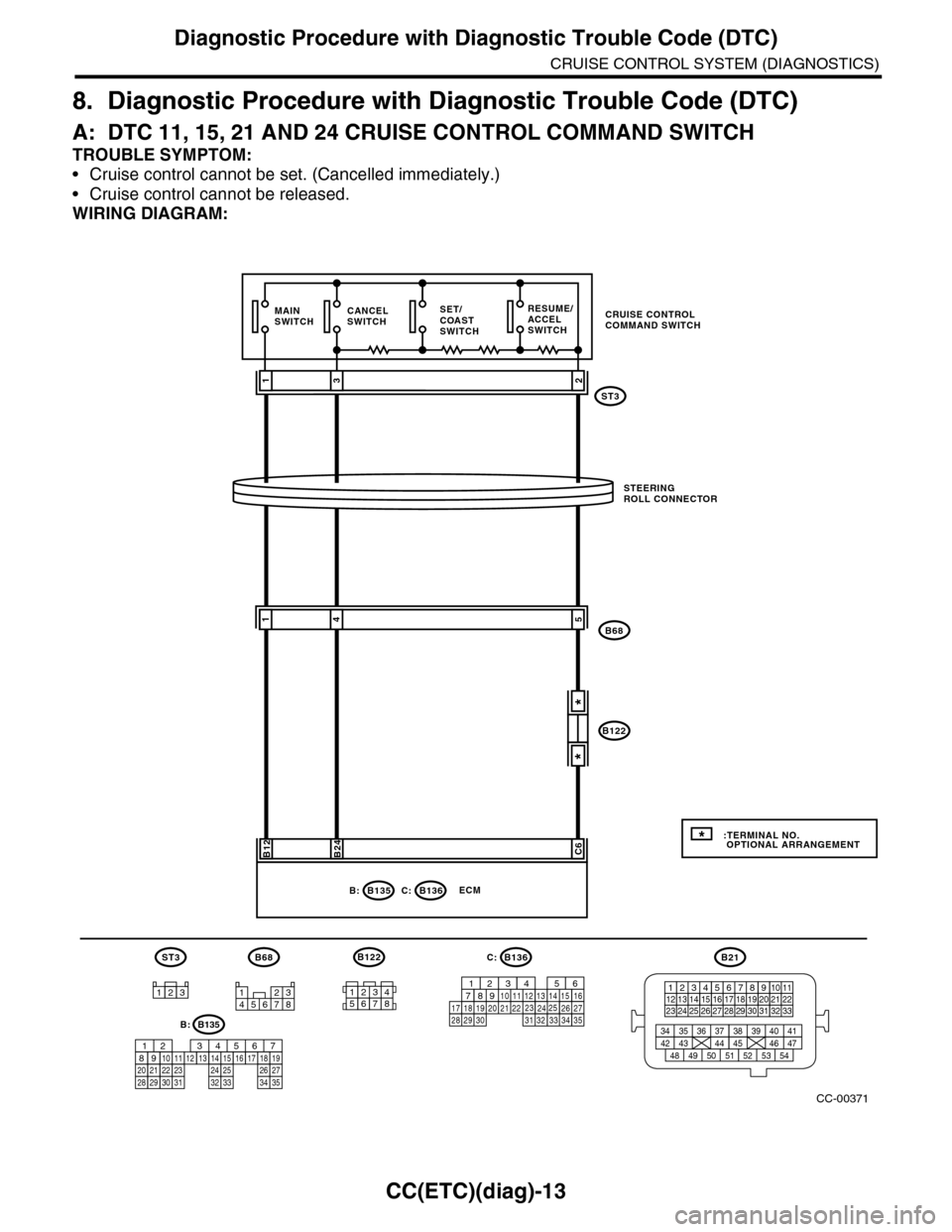

CC(ETC)(diag)-13

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

8. Diagnostic Procedure with Diagnostic Trouble Code (DTC)

A: DTC 11, 15, 21 AND 24 CRUISE CONTROL COMMAND SWITCH

TROUBLE SYMPTOM:

•Cruise control cannot be set. (Cancelled immediately.)

•Cruise control cannot be released.

WIRING DIAGRAM:

CC-00371

ST3

SET/COASTSWITCH

RESUME/ACCELSWITCH

CANCELSWITCH

B136C:ECM

B24

2

B68

STEERINGROLL CONNECTOR

31

MAINSWITCH

541

B12C6

*

*

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

12345678

B68

123

ST3B136

9

302928 3231201918 22211012111424343327261612345613231525871735

C:

* :TERMINAL NO. OPTIONAL ARRANGEMENT

B122

CRUISE CONTROLCOMMAND SWITCH

B135B:

B122

12345678

B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

B:

Page 181 of 2453

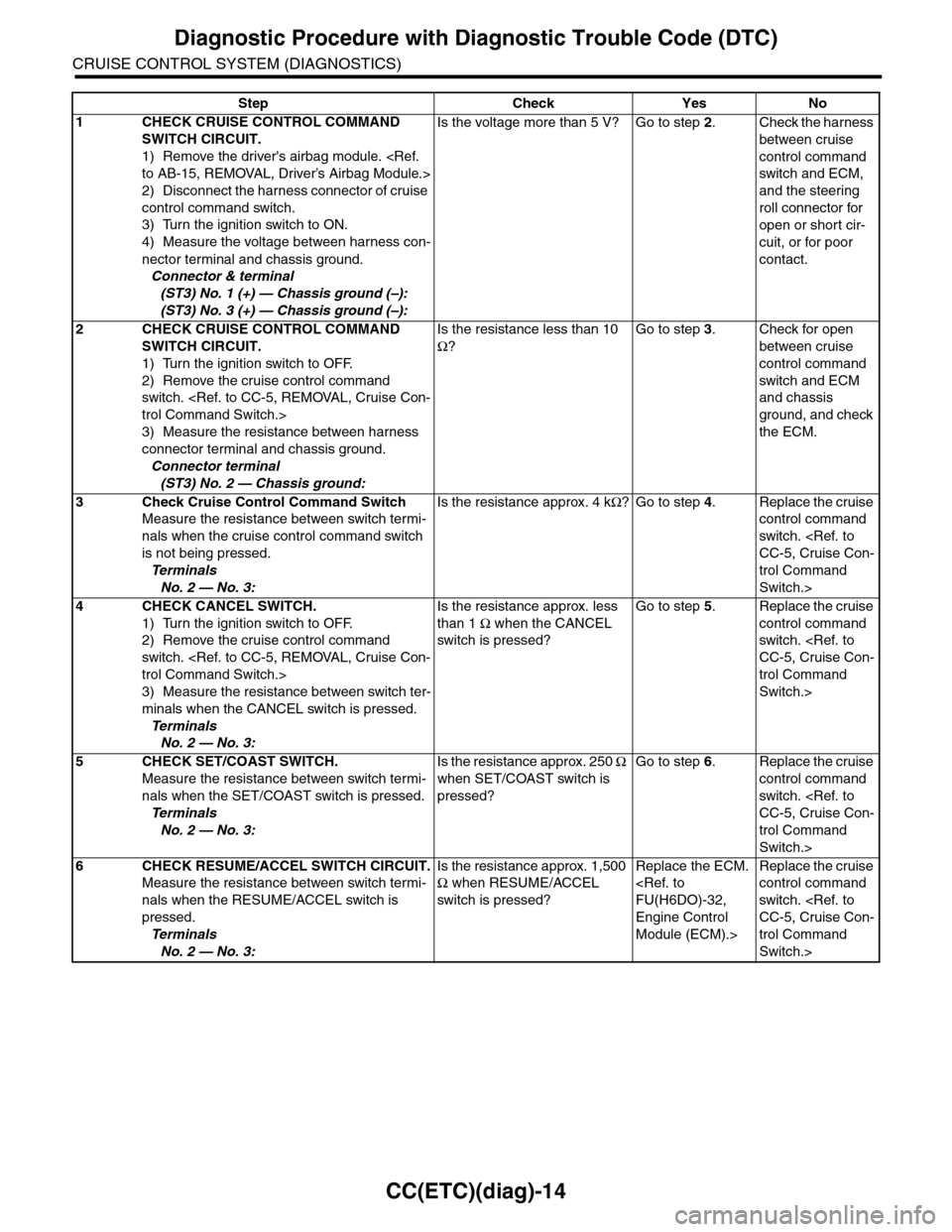

CC(ETC)(diag)-14

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

Step Check Yes No

1CHECK CRUISE CONTROL COMMAND

SWITCH CIRCUIT.

1) Remove the driver's airbag module.

2) Disconnect the harness connector of cruise

control command switch.

3) Turn the ignition switch to ON.

4) Measure the voltage between harness con-

nector terminal and chassis ground.

Connector & terminal

(ST3) No. 1 (+) — Chassis ground (–):

(ST3) No. 3 (+) — Chassis ground (–):

Is the voltage more than 5 V? Go to step 2.Check the harness

between cruise

control command

switch and ECM,

and the steering

roll connector for

open or short cir-

cuit, or for poor

contact.

2CHECK CRUISE CONTROL COMMAND

SWITCH CIRCUIT.

1) Turn the ignition switch to OFF.

2) Remove the cruise control command

switch.

3) Measure the resistance between harness

connector terminal and chassis ground.

Connector terminal

(ST3) No. 2 — Chassis ground:

Is the resistance less than 10

Ω?

Go to step 3.Check for open

between cruise

control command

switch and ECM

and chassis

ground, and check

the ECM.

3Check Cruise Control Command Switch

Measure the resistance between switch termi-

nals when the cruise control command switch

is not being pressed.

Te r m i n a l s

No. 2 — No. 3:

Is the resistance approx. 4 kΩ?Go to step 4.Replace the cruise

control command

switch.

trol Command

Switch.>

4CHECK CANCEL SWITCH.

1) Turn the ignition switch to OFF.

2) Remove the cruise control command

switch.

3) Measure the resistance between switch ter-

minals when the CANCEL switch is pressed.

Te r m i n a l s

No. 2 — No. 3:

Is the resistance approx. less

than 1 Ω when the CANCEL

switch is pressed?

Go to step 5.Replace the cruise

control command

switch.

trol Command

Switch.>

5CHECK SET/COAST SWITCH.

Measure the resistance between switch termi-

nals when the SET/COAST switch is pressed.

Te r m i n a l s

No. 2 — No. 3:

Is the resistance approx. 250 Ω

when SET/COAST switch is

pressed?

Go to step 6.Replace the cruise

control command

switch.

trol Command

Switch.>

6CHECK RESUME/ACCEL SWITCH CIRCUIT.

Measure the resistance between switch termi-

nals when the RESUME/ACCEL switch is

pressed.

Te r m i n a l s

No. 2 — No. 3:

Is the resistance approx. 1,500

Ω when RESUME/ACCEL

switch is pressed?

Replace the ECM.

Engine Control

Module (ECM).>

Replace the cruise

control command

switch.

trol Command

Switch.>

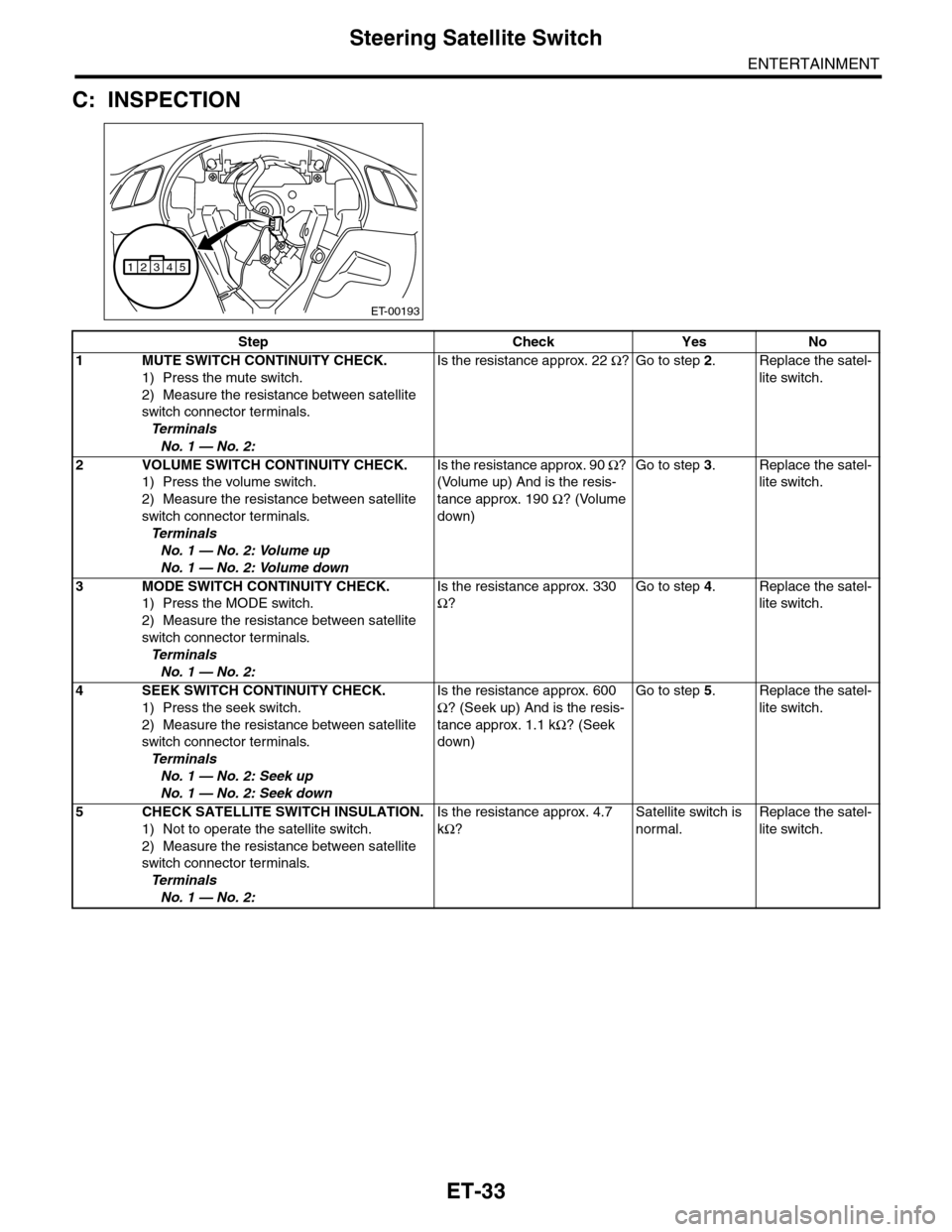

Page 218 of 2453

ET-33

Steering Satellite Switch

ENTERTAINMENT

C: INSPECTION

ET-00193

12345

Step Check Yes No

1MUTE SWITCH CONTINUITY CHECK.

1) Press the mute switch.

2) Measure the resistance between satellite

switch connector terminals.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance approx. 22 Ω?Go to step 2.Replace the satel-

lite switch.

2VOLUME SWITCH CONTINUITY CHECK.

1) Press the volume switch.

2) Measure the resistance between satellite

switch connector terminals.

Te r m i n a l s

No. 1 — No. 2: Volume up

No. 1 — No. 2: Volume down

Is the resistance approx. 90 Ω?

(Volume up) And is the resis-

tance approx. 190 Ω? (Volume

down)

Go to step 3.Replace the satel-

lite switch.

3MODE SWITCH CONTINUITY CHECK.

1) Press the MODE switch.

2) Measure the resistance between satellite

switch connector terminals.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance approx. 330

Ω?

Go to step 4.Replace the satel-

lite switch.

4SEEK SWITCH CONTINUITY CHECK.

1) Press the seek switch.

2) Measure the resistance between satellite

switch connector terminals.

Te r m i n a l s

No. 1 — No. 2: Seek up

No. 1 — No. 2: Seek down

Is the resistance approx. 600

Ω? (Seek up) And is the resis-

tance approx. 1.1 kΩ? (Seek

down)

Go to step 5.Replace the satel-

lite switch.

5CHECK SATELLITE SWITCH INSULATION.

1) Not to operate the satellite switch.

2) Measure the resistance between satellite

switch connector terminals.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance approx. 4.7

kΩ?

Satellite switch is

normal.

Replace the satel-

lite switch.

Page 502 of 2453

LAN(diag)-46

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

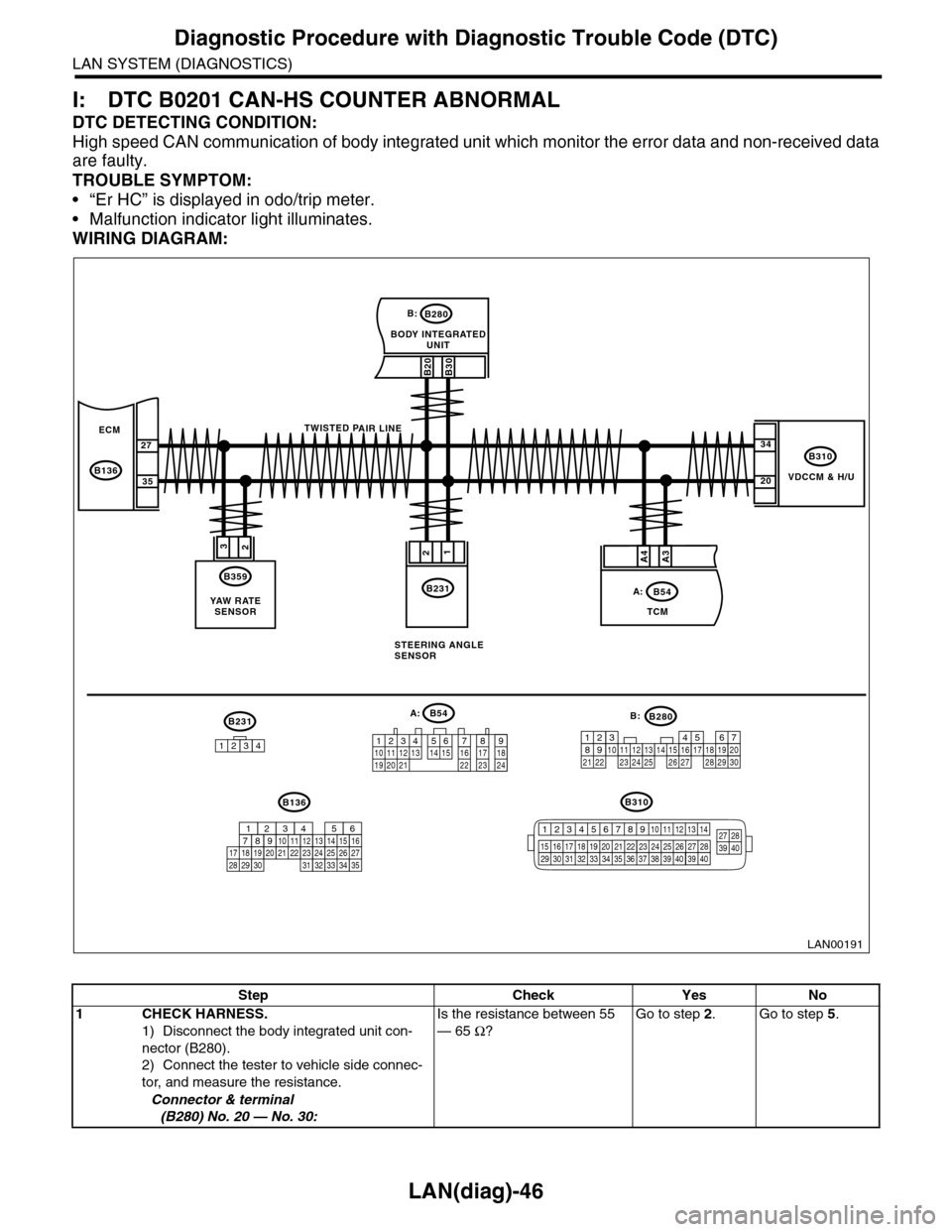

I: DTC B0201 CAN-HS COUNTER ABNORMAL

DTC DETECTING CONDITION:

High speed CAN communication of body integrated unit which monitor the error data and non-received data

are faulty.

TROUBLE SYMPTOM:

•“Er HC” is displayed in odo/trip meter.

•Malfunction indicator light illuminates.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Step Check Yes No

1CHECK HARNESS.

1) Disconnect the body integrated unit con-

nector (B280).

2) Connect the tester to vehicle side connec-

tor, and measure the resistance.

Connector & terminal

(B280) No. 20 — No. 30:

Is the resistance between 55

— 65 Ω?

Go to step 2.Go to step 5.

Page 503 of 2453

LAN(diag)-47

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

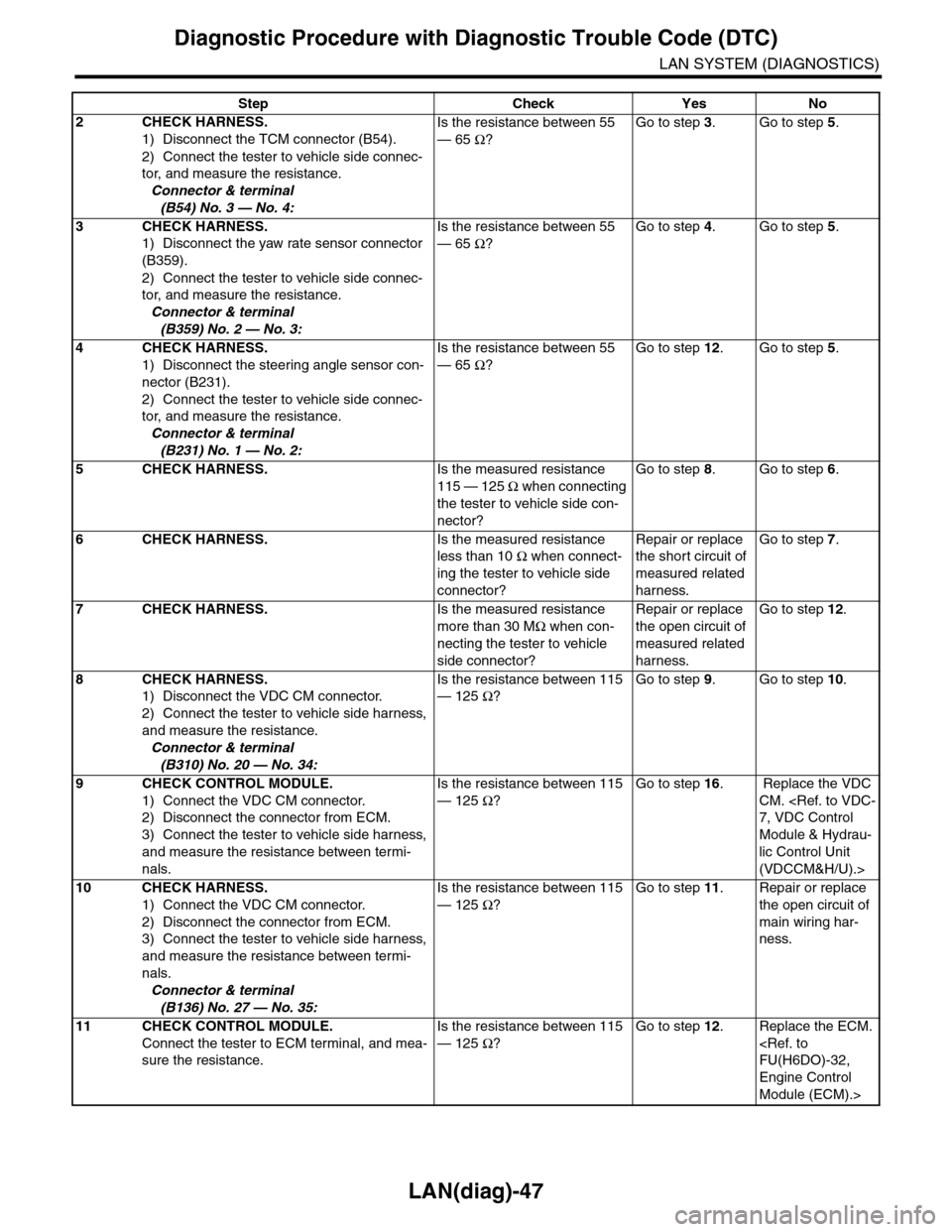

2CHECK HARNESS.

1) Disconnect the TCM connector (B54).

2) Connect the tester to vehicle side connec-

tor, and measure the resistance.

Connector & terminal

(B54) No. 3 — No. 4:

Is the resistance between 55

— 65 Ω?

Go to step 3.Go to step 5.

3CHECK HARNESS.

1) Disconnect the yaw rate sensor connector

(B359).

2) Connect the tester to vehicle side connec-

tor, and measure the resistance.

Connector & terminal

(B359) No. 2 — No. 3:

Is the resistance between 55

— 65 Ω?

Go to step 4.Go to step 5.

4CHECK HARNESS.

1) Disconnect the steering angle sensor con-

nector (B231).

2) Connect the tester to vehicle side connec-

tor, and measure the resistance.

Connector & terminal

(B231) No. 1 — No. 2:

Is the resistance between 55

— 65 Ω?

Go to step 12.Go to step 5.

5CHECK HARNESS.Is the measured resistance

115 — 125 Ω when connecting

the tester to vehicle side con-

nector?

Go to step 8.Go to step 6.

6CHECK HARNESS.Is the measured resistance

less than 10 Ω when connect-

ing the tester to vehicle side

connector?

Repair or replace

the short circuit of

measured related

harness.

Go to step 7.

7CHECK HARNESS.Is the measured resistance

more than 30 MΩ when con-

necting the tester to vehicle

side connector?

Repair or replace

the open circuit of

measured related

harness.

Go to step 12.

8CHECK HARNESS.

1) Disconnect the VDC CM connector.

2) Connect the tester to vehicle side harness,

and measure the resistance.

Connector & terminal

(B310) No. 20 — No. 34:

Is the resistance between 115

— 125 Ω?

Go to step 9.Go to step 10.

9CHECK CONTROL MODULE.

1) Connect the VDC CM connector.

2) Disconnect the connector from ECM.

3) Connect the tester to vehicle side harness,

and measure the resistance between termi-

nals.

Is the resistance between 115

— 125 Ω?

Go to step 16. Replace the VDC

CM.

Module & Hydrau-

lic Control Unit

(VDCCM&H/U).>

10 CHECK HARNESS.

1) Connect the VDC CM connector.

2) Disconnect the connector from ECM.

3) Connect the tester to vehicle side harness,

and measure the resistance between termi-

nals.

Connector & terminal

(B136) No. 27 — No. 35:

Is the resistance between 115

— 125 Ω?

Go to step 11.Repair or replace

the open circuit of

main wiring har-

ness.

11 CHECK CONTROL MODULE.

Connect the tester to ECM terminal, and mea-

sure the resistance.

Is the resistance between 115

— 125 Ω?

Go to step 12.Replace the ECM.

Engine Control

Module (ECM).>

Step Check Yes No