check engine light SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 418 of 2453

IM (diag)-2

Basic Diagnostic Procedure

IMMOBILIZER (DIAGNOSTICS)

1. Basic Diagnostic Procedure

A: PROCEDURE

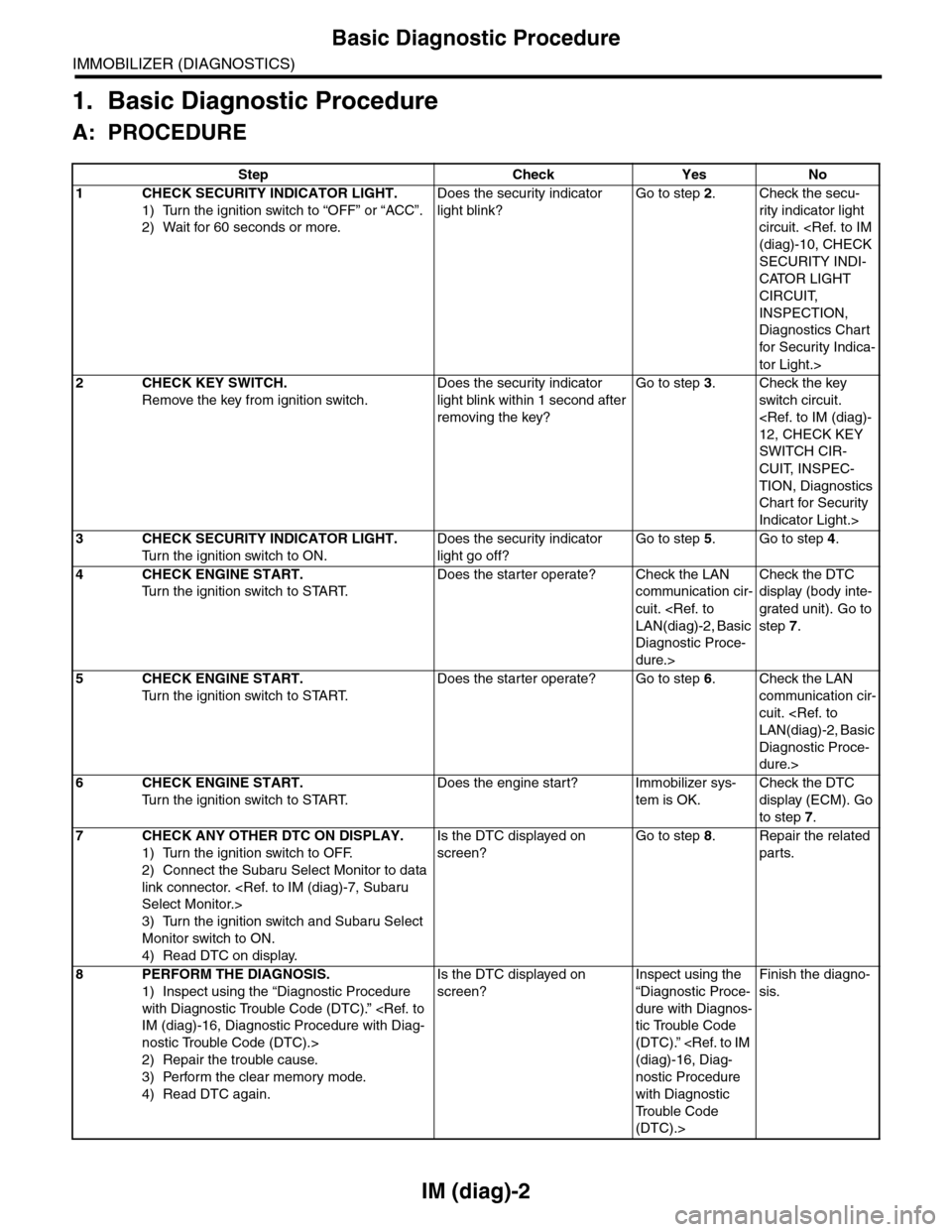

Step Check Yes No

1CHECK SECURITY INDICATOR LIGHT.

1) Turn the ignition switch to “OFF” or “ACC”.

2) Wait for 60 seconds or more.

Does the security indicator

light blink?

Go to step 2.Check the secu-

rity indicator light

circuit.

SECURITY INDI-

CATOR LIGHT

CIRCUIT,

INSPECTION,

Diagnostics Chart

for Secur ity Indica-

tor Light.>

2CHECK KEY SWITCH.

Remove the key from ignition switch.

Does the security indicator

light blink within 1 second after

removing the key?

Go to step 3.Check the key

switch circuit.

SWITCH CIR-

CUIT, INSPEC-

TION, Diagnostics

Chart for Security

Indicator Light.>

3CHECK SECURITY INDICATOR LIGHT.

Tu r n t h e i g n i t i o n s w i t c h t o O N .

Does the security indicator

light go off?

Go to step 5.Go to step 4.

4CHECK ENGINE START.

Tu r n t h e i g n i t i o n s w i t c h t o S TA R T.

Does the starter operate? Check the LAN

communication cir-

cuit.

Diagnostic Proce-

dure.>

Check the DTC

display (body inte-

grated unit). Go to

step 7.

5CHECK ENGINE START.

Tu r n t h e i g n i t i o n s w i t c h t o S TA R T.

Does the starter operate? Go to step 6.Check the LAN

communication cir-

cuit.

Diagnostic Proce-

dure.>

6CHECK ENGINE START.

Tu r n t h e i g n i t i o n s w i t c h t o S TA R T.

Does the engine start? Immobilizer sys-

tem is OK.

Check the DTC

display (ECM). Go

to step 7.

7CHECK ANY OTHER DTC ON DISPLAY.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch and Subaru Select

Monitor switch to ON.

4) Read DTC on display.

Is the DTC displayed on

screen?

Go to step 8.Repair the related

parts.

8PERFORM THE DIAGNOSIS.

1) Inspect using the “Diagnostic Procedure

with Diagnostic Trouble Code (DTC).”

nostic Trouble Code (DTC).>

2) Repair the trouble cause.

3) Perform the clear memory mode.

4) Read DTC again.

Is the DTC displayed on

screen?

Inspect using the

“Diagnostic Proce-

dure with Diagnos-

tic Trouble Code

(DTC).”

nostic Procedure

with Diagnostic

Tr o u b l e C o d e

(DTC).>

Finish the diagno-

sis.

Page 419 of 2453

IM (diag)-3

General Description

IMMOBILIZER (DIAGNOSTICS)

2. General Description

A: CAUTION

CAUTION:

•The airbag system wiring harnesses and con-

nectors are yellow. Do not use electrical test

equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness.

•While diagnostic items are being checked, do

not operate radios, portable telephones, etc.

which emit electromagnetic waves near or in-

side the vehicle.

•When turning the ignition switch to ON or

OFF while diagnostic items are being checked,

do not allow keys with different ID codes close

to the ignition switch. If the ignition key is in a

key holder, remove it from the holder before

carrying out diagnosis.

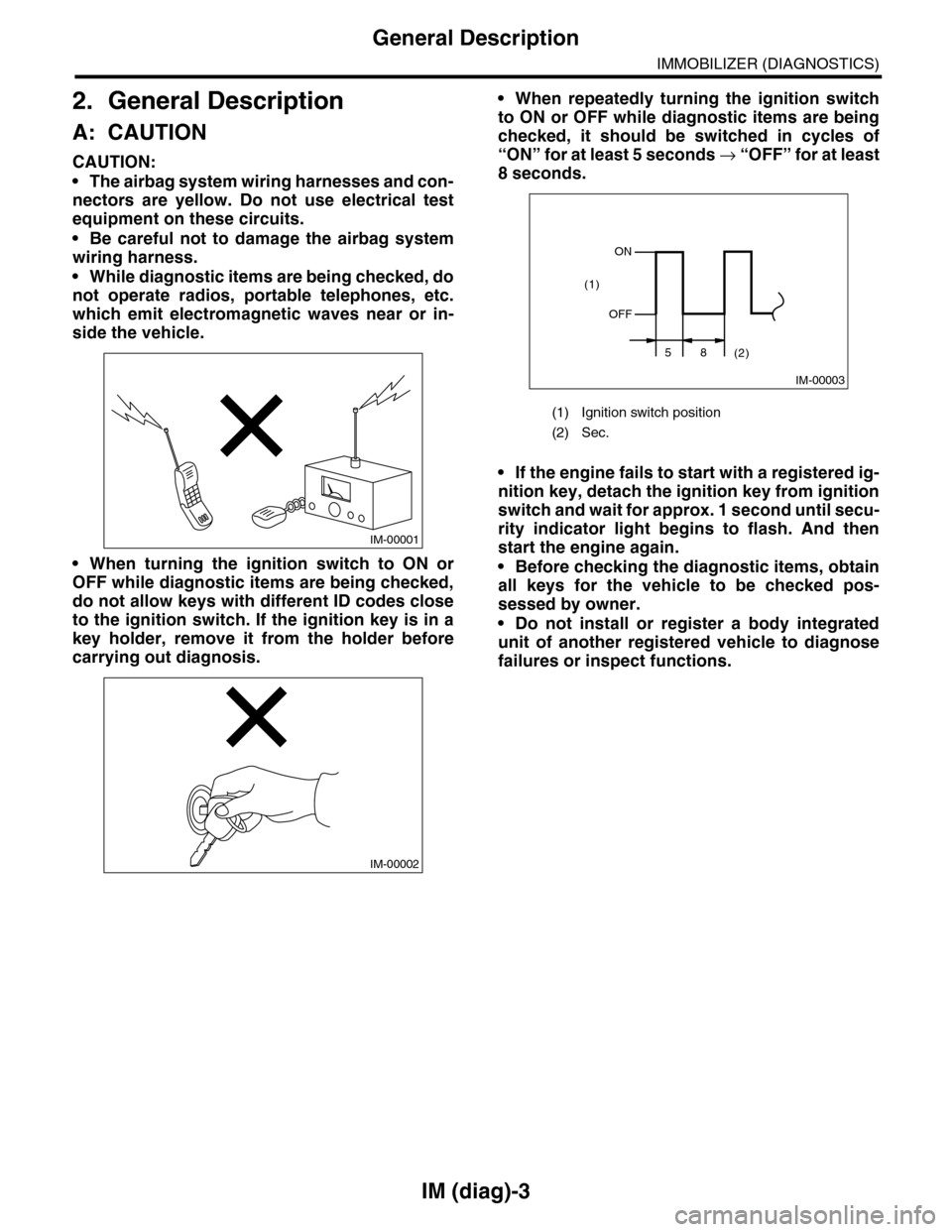

•When repeatedly turning the ignition switch

to ON or OFF while diagnostic items are being

checked, it should be switched in cycles of

“ON” for at least 5 seconds → “O F F ” fo r a t le a s t

8 seconds.

•If the engine fails to start with a registered ig-

nition key, detach the ignition key from ignition

switch and wait for approx. 1 second until secu-

rity indicator light begins to flash. And then

start the engine again.

•Before checking the diagnostic items, obtain

all keys for the vehicle to be checked pos-

sessed by owner.

•Do not install or register a body integrated

unit of another registered vehicle to diagnose

failures or inspect functions.

IM-00001

IM-00002

(1) Ignition switch position

(2) Sec.

IM-00003

ON

OFF

58(2)

(1)

Page 427 of 2453

IM (diag)-11

Diagnostics Chart for Security Indicator Light

IMMOBILIZER (DIAGNOSTICS)

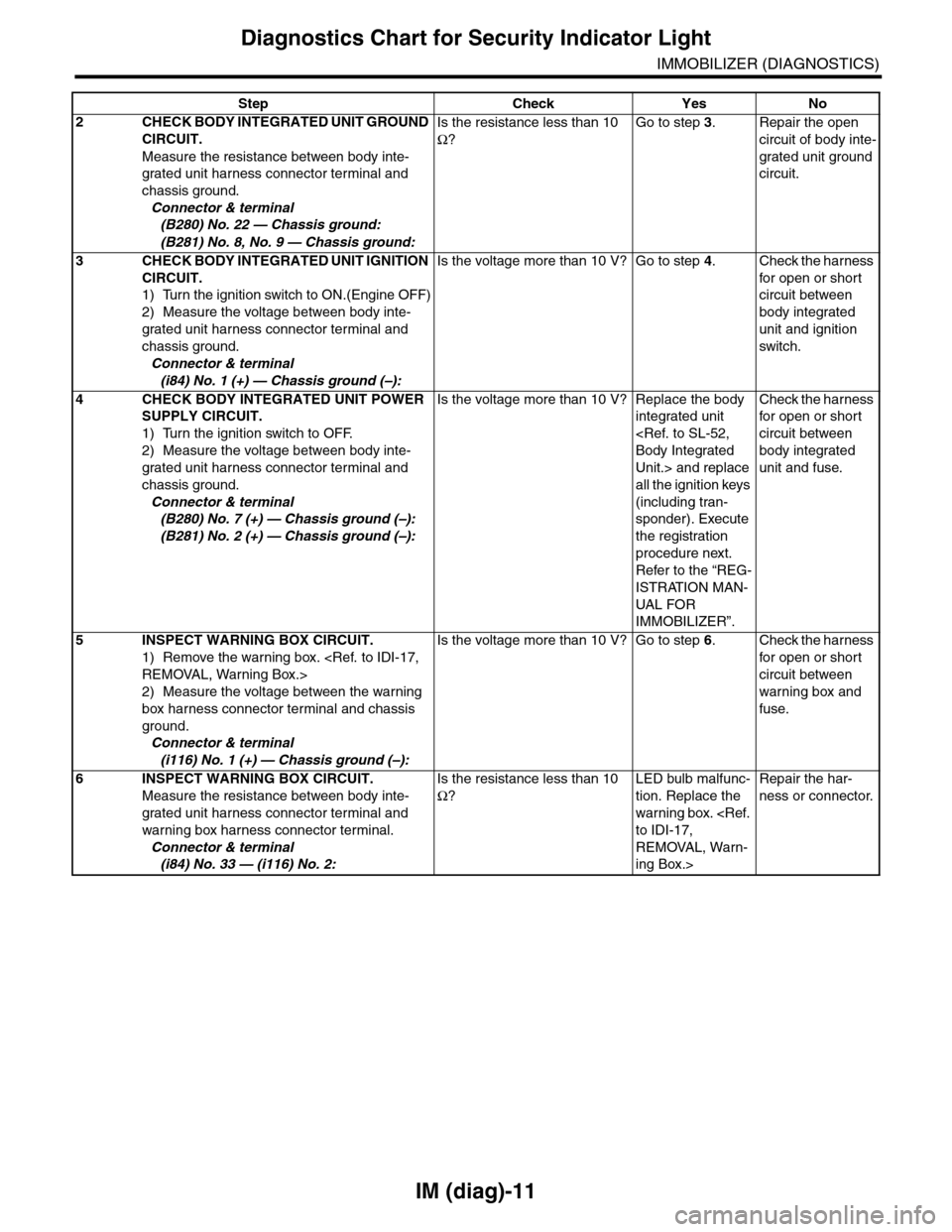

2CHECK BODY INTEGRATED UNIT GROUND

CIRCUIT.

Measure the resistance between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 22 — Chassis ground:

(B281) No. 8, No. 9 — Chassis ground:

Is the resistance less than 10

Ω?

Go to step 3.Repair the open

circuit of body inte-

grated unit ground

circuit.

3CHECK BODY INTEGRATED UNIT IGNITION

CIRCUIT.

1) Turn the ignition switch to ON.(Engine OFF)

2) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(i84) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 4.Check the harness

for open or shor t

circuit between

body integrated

unit and ignition

switch.

4CHECK BODY INTEGRATED UNIT POWER

SUPPLY CIRCUIT.

1) Turn the ignition switch to OFF.

2) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 7 (+) — Chassis ground (–):

(B281) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Replace the body

integrated unit

Unit.> and replace

all the ignition keys

(including tran-

sponder). Execute

the registration

procedure next.

Refer to the “REG-

ISTRATION MAN-

UAL FO R

IMMOBILIZER”.

Check the harness

for open or shor t

circuit between

body integrated

unit and fuse.

5INSPECT WARNING BOX CIRCUIT.

1) Remove the warning box.

2) Measure the voltage between the warning

box harness connector terminal and chassis

ground.

Connector & terminal

(i116) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 6.Check the harness

for open or shor t

circuit between

warning box and

fuse.

6INSPECT WARNING BOX CIRCUIT.

Measure the resistance between body inte-

grated unit harness connector terminal and

warning box harness connector terminal.

Connector & terminal

(i84) No. 33 — (i116) No. 2:

Is the resistance less than 10

Ω?

LED bulb malfunc-

tion. Replace the

warning box.

REMOVAL, Warn-

ing Box.>

Repair the har-

ness or connector.

Step Check Yes No

Page 443 of 2453

IDI-4

Combination Meter System

INSTRUMENTATION/DRIVER INFO

2. Combination Meter System

A: WIRING DIAGRAM

1. COMBINATION METER

B: INSPECTION

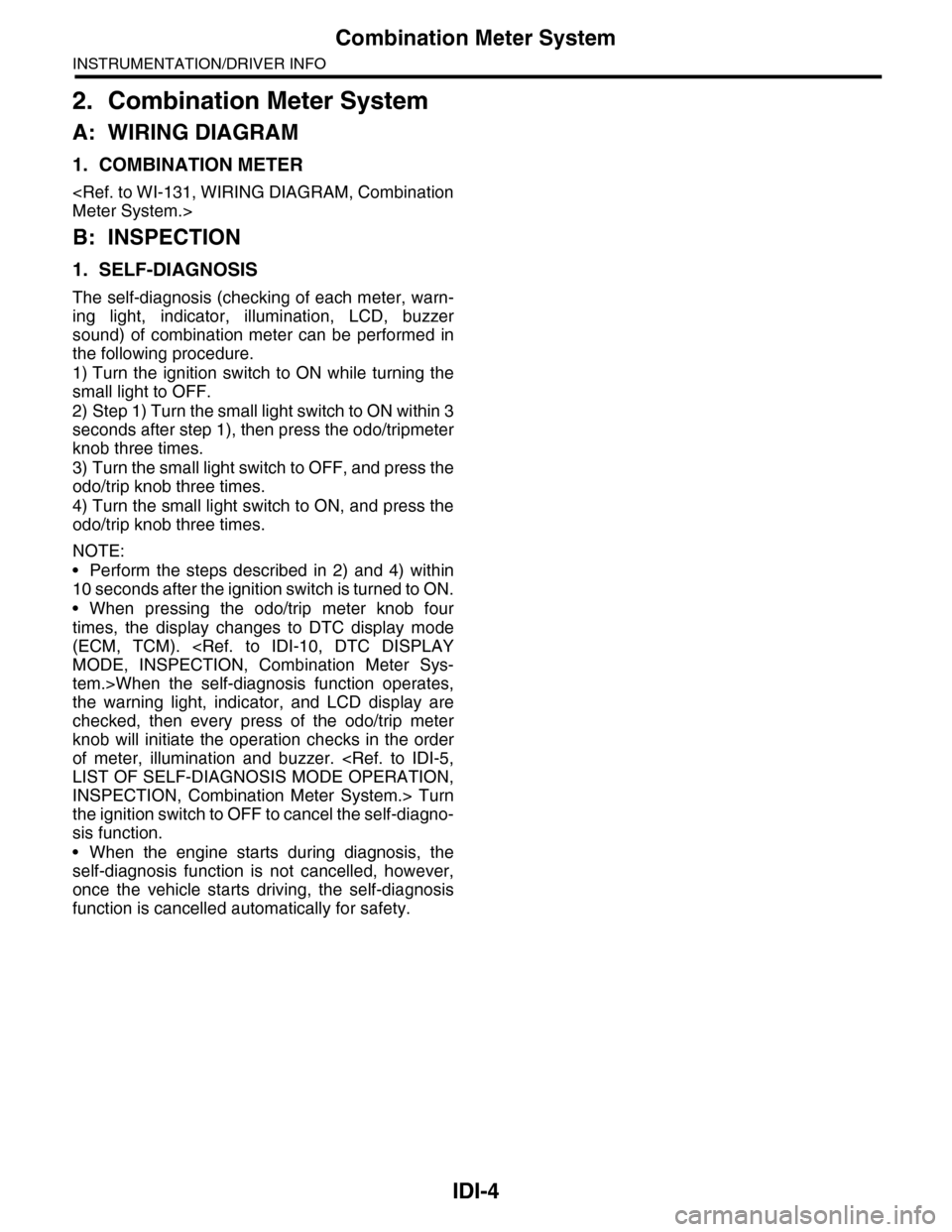

1. SELF-DIAGNOSIS

The self-diagnosis (checking of each meter, warn-

ing light, indicator, illumination, LCD, buzzer

sound) of combination meter can be performed in

the following procedure.

1) Turn the ignition switch to ON while turning the

small light to OFF.

2) Step 1) Turn the small light switch to ON within 3

seconds after step 1), then press the odo/tripmeter

knob three times.

3) Turn the small light switch to OFF, and press the

odo/trip knob three times.

4) Turn the small light switch to ON, and press the

odo/trip knob three times.

NOTE:

•Perform the steps described in 2) and 4) within

10 seconds after the ignition switch is turned to ON.

•When pressing the odo/trip meter knob four

times, the display changes to DTC display mode

(ECM, TCM).

tem.>When the self-diagnosis function operates,

the warning light, indicator, and LCD display are

checked, then every press of the odo/trip meter

knob will initiate the operation checks in the order

of meter, illumination and buzzer.

INSPECTION, Combination Meter System.> Turn

the ignition switch to OFF to cancel the self-diagno-

sis function.

•When the engine starts during diagnosis, the

self-diagnosis function is not cancelled, however,

once the vehicle starts driving, the self-diagnosis

function is cancelled automatically for safety.

Page 444 of 2453

IDI-5

Combination Meter System

INSTRUMENTATION/DRIVER INFO

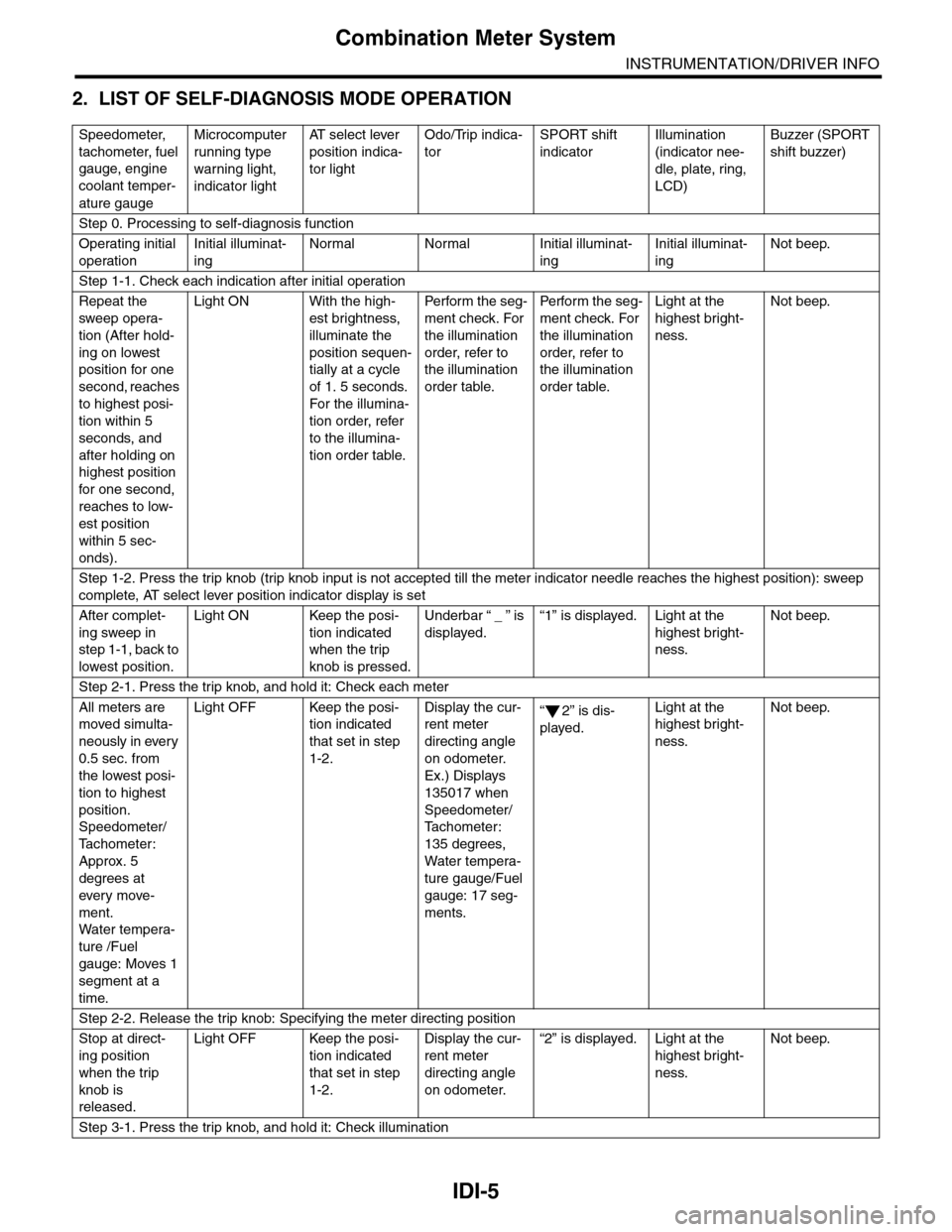

2. LIST OF SELF-DIAGNOSIS MODE OPERATION

Speedometer,

tachometer, fuel

gauge, engine

coolant temper-

ature gauge

Microcomputer

running type

warning light,

indicator light

AT s e l e c t l e v e r

position indica-

tor light

Odo/Trip indica-

tor

SPORT shift

indicator

Illumination

(indicator nee-

dle, plate, ring,

LCD)

Buzzer (SPORT

shift buzzer)

Step 0. Processing to self-diagnosis function

Operating initial

operation

Initial illuminat-

ing

Normal Normal Initial illuminat-

ing

Initial illuminat-

ing

Not beep.

Step 1-1. Check each indication after initial operation

Repeat the

sweep opera-

tion (After hold-

ing on lowest

position for one

second, reaches

to highest posi-

tion within 5

seconds, and

after holding on

highest position

for one second,

reaches to low-

est position

within 5 sec-

onds).

Light ON With the high-

est brightness,

illuminate the

position sequen-

tially at a cycle

of 1. 5 seconds.

For the illumina-

tion order, refer

to the illumina-

tion order table.

Pe r for m t he s eg -

ment check. For

the illumination

order, refer to

the illumination

order table.

Pe rfo r m t h e se g -

ment check. For

the illumination

order, refer to

the illumination

order table.

Light at the

highest bright-

ness.

Not beep.

Step 1-2. Press the trip knob (trip knob input is not accepted till the meter indicator needle reaches the highest position): sweep

complete, AT select lever position indicator display is set

After complet-

ing sweep in

step 1-1, back to

lowest position.

Light ON Keep the posi-

tion indicated

when the trip

knob is pressed.

Underbar “ _ ” is

displayed.

“1” is displayed. Light at the

highest bright-

ness.

Not beep.

Step 2-1. Press the trip knob, and hold it: Check each meter

All meters are

moved simulta-

neously in every

0.5 sec. from

the lowest posi-

tion to highest

position.

Speedometer/

Ta c h o m e t e r :

Approx. 5

degrees at

ever y move-

ment.

Wa t er t e mp er a-

ture /Fuel

gauge: Moves 1

segment at a

time.

Light OFF Keep the posi-

tion indicated

that set in step

1-2.

Display the cur-

rent meter

directing angle

on odometer.

Ex.) Displays

135017 when

Speedometer/

Ta c h o m e t e r :

135 degrees,

Water tempera-

ture gauge/Fuel

gauge: 17 seg-

ments.

“2” is dis-

played.

Light at the

highest bright-

ness.

Not beep.

Step 2-2. Release the trip knob: Specifying the meter directing position

Stop at direct-

ing position

when the trip

knob is

released.

Light OFF Keep the posi-

tion indicated

that set in step

1-2.

Display the cur-

rent meter

directing angle

on odometer.

“2” is displayed. Light at the

highest bright-

ness.

Not beep.

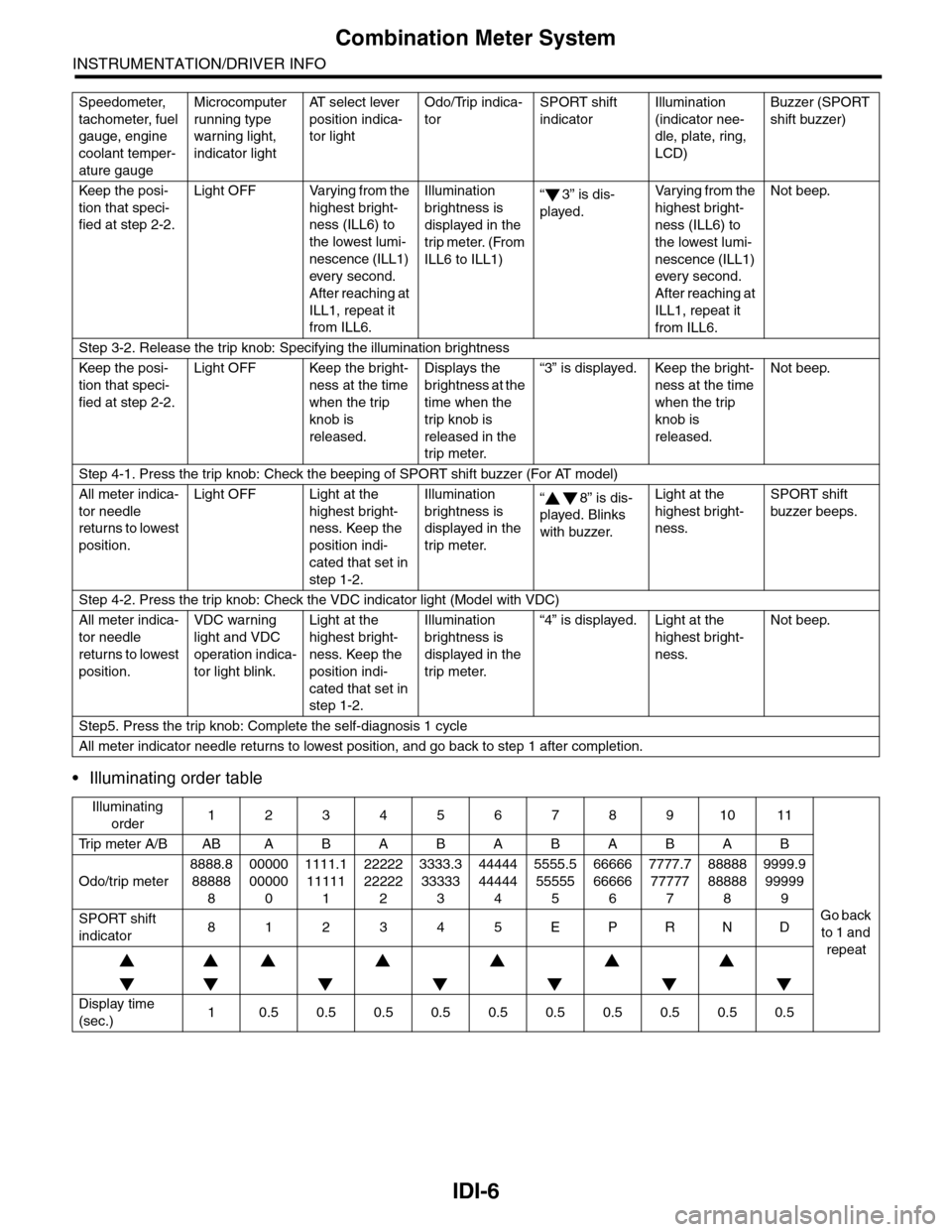

Step 3-1. Press the trip knob, and hold it: Check illumination

Page 445 of 2453

IDI-6

Combination Meter System

INSTRUMENTATION/DRIVER INFO

•Illuminating order table

Keep the posi-

tion that speci-

fied at step 2-2.

Light OFF Varying from the

highest bright-

ness (ILL6) to

the lowest lumi-

nescence (ILL1)

ever y second.

After reaching at

ILL1, repeat it

from ILL6.

Illumination

brightness is

displayed in the

trip meter. (From

ILL6 to ILL1)

“3” is dis-

played.

Va r y i n g f r o m t h e

highest bright-

ness (ILL6) to

the lowest lumi-

nescence (ILL1)

every second.

After reaching at

ILL1, repeat it

from ILL6.

Not beep.

Step 3-2. Release the trip knob: Specifying the illumination brightness

Keep the posi-

tion that speci-

fied at step 2-2.

Light OFF Keep the bright-

ness at the time

when the trip

knob is

released.

Displays the

brightness at the

time when the

trip knob is

released in the

trip meter.

“3” is displayed. Keep the bright-

ness at the time

when the trip

knob is

released.

Not beep.

Step 4-1. Press the trip knob: Check the beeping of SPORT shift buzzer (For AT model)

All meter indica-

tor needle

returns to lowest

position.

Light OFF Light at the

highest bright-

ness. Keep the

position indi-

cated that set in

step 1-2.

Illumination

brightness is

displayed in the

trip meter.

“8” is dis-

played. Blinks

with buzzer.

Light at the

highest bright-

ness.

SPORT shift

buzzer beeps.

Step 4-2. Press the trip knob: Check the VDC indicator light (Model with VDC)

All meter indica-

tor needle

returns to lowest

position.

VDC warning

light and VDC

operation indica-

tor light blink.

Light at the

highest bright-

ness. Keep the

position indi-

cated that set in

step 1-2.

Illumination

brightness is

displayed in the

trip meter.

“4” is displayed. Light at the

highest bright-

ness.

Not beep.

Step5. Press the trip knob: Complete the self-diagnosis 1 cycle

All meter indicator needle returns to lowest position, and go back to step 1 after completion.

Illuminating

order1234567891011

Tr i p m e t e r A / B A B A B A B A B A B A B

Go back

to 1 and

repeat

Odo/trip meter

8888.8

88888

8

00000

00000

0

1111.1

11111

1

22222

22222

2

3333.3

33333

3

44444

44444

4

5555.5

55555

5

66666

66666

6

7777.7

77777

7

88888

88888

8

9999.9

99999

9

SPORT shift

indicator812345EPRND

Display time

(sec.)10.50.50.50.50.50.50.50.50.50.5

Speedometer,

tachometer, fuel

gauge, engine

coolant temper-

ature gauge

Microcomputer

running type

warning light,

indicator light

AT s e l e c t l e v e r

position indica-

tor light

Odo/Trip indica-

tor

SPORT shift

indicator

Illumination

(indicator nee-

dle, plate, ring,

LCD)

Buzzer (SPORT

shift buzzer)

Page 459 of 2453

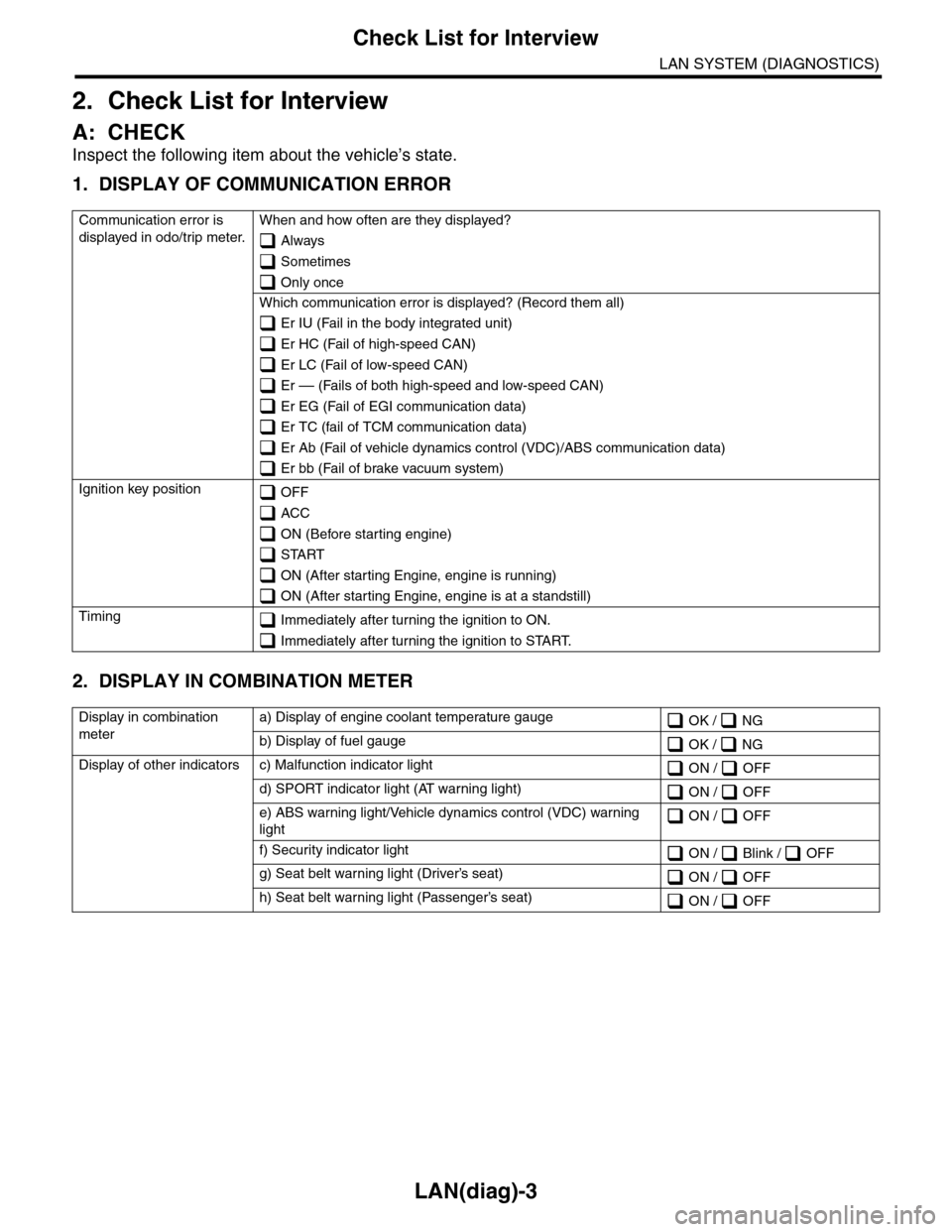

LAN(diag)-3

Check List for Interview

LAN SYSTEM (DIAGNOSTICS)

2. Check List for Interview

A: CHECK

Inspect the following item about the vehicle’s state.

1. DISPLAY OF COMMUNICATION ERROR

2. DISPLAY IN COMBINATION METER

Communication error is

displayed in odo/trip meter.

When and how often are they displayed?

Always

Sometimes

Only once

Which communication error is displayed? (Record them all)

Er IU (Fail in the body integrated unit)

Er HC (Fail of high-speed CAN)

Er LC (Fail of low-speed CAN)

Er –– (Fails of both high-speed and low-speed CAN)

Er EG (Fail of EGI communication data)

Er TC (fail of TCM communication data)

Er Ab (Fail of vehicle dynamics control (VDC)/ABS communication data)

Er bb (Fail of brake vacuum system)

Ignition key position OFF

ACC

ON (Before starting engine)

START

ON (After starting Engine, engine is running)

ON (After starting Engine, engine is at a standstill)

Timing Immediately after turning the ignition to ON.

Immediately after turning the ignition to START.

Display in combination

meter

a) Display of engine coolant temperature gauge OK / NG

b) Display of fuel gauge OK / NG

Display of other indicators c) Malfunction indicator light ON / OFF

d) SPORT indicator light (AT warning light) ON / OFF

e) ABS warning light/Vehicle dynamics control (VDC) warning

light ON / OFF

f) Security indicator light ON / Blink / OFF

g) Seat belt warning light (Driver’s seat) ON / OFF

h) Seat belt warning light (Passenger’s seat) ON / OFF

Page 467 of 2453

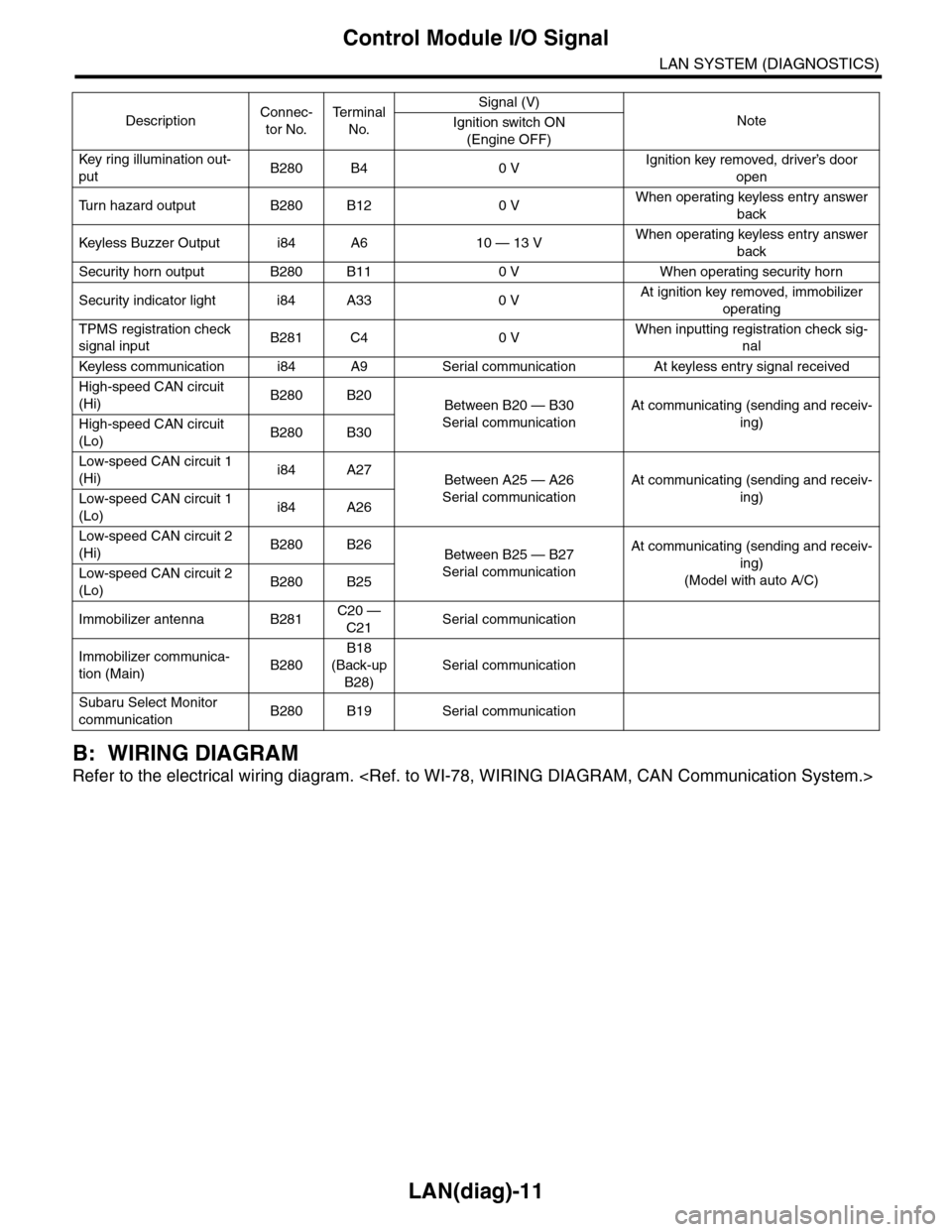

LAN(diag)-11

Control Module I/O Signal

LAN SYSTEM (DIAGNOSTICS)

B: WIRING DIAGRAM

Refer to the electrical wiring diagram.

Key r ing illumination out-

putB280 B4 0 VIgnition key removed, driver’s door

open

Tu r n h a z a r d o u t p u t B 2 8 0 B 1 2 0 VWhen operating keyless entry answer

back

Keyless Buzzer Output i84 A6 10 — 13 VWhen operating keyless entry answer

back

Security horn output B280 B11 0 V When operating security horn

Security indicator light i84 A33 0 VAt ignition key removed, immobilizer

operating

TPMS registration check

signal inputB281 C4 0 VWhen inputting registration check sig-

nal

Keyless communication i84 A9 Ser ial communication At keyless entr y signal received

High-speed CAN circuit

(Hi)B280 B20Between B20 — B30

Serial communication

At communicating (sending and receiv-

ing)High-speed CAN circuit

(Lo)B280 B30

Low-speed CAN circuit 1

(Hi)i84 A27Between A25 — A26

Serial communication

At communicating (sending and receiv-

ing)Low-speed CAN circuit 1

(Lo)i84 A26

Low-speed CAN circuit 2

(Hi)B280 B26Between B25 — B27

Serial communication

At communicating (sending and receiv-

ing)

(Model with auto A/C)Low-speed CAN circuit 2

(Lo)B280 B25

Immobilizer antenna B281C20 —

C21Serial communication

Immobilizer communica-

tion (Main)B280

B18

(Back-up

B28)

Serial communication

Subaru Select Monitor

communicationB280 B19 Serial communication

DescriptionConnec-

tor No.

Te r m i n a l

No.

Signal (V)

NoteIgnition switch ON

(Engine OFF)

Page 544 of 2453

LI-11

Headlight Assembly

LIGHTING SYSTEM

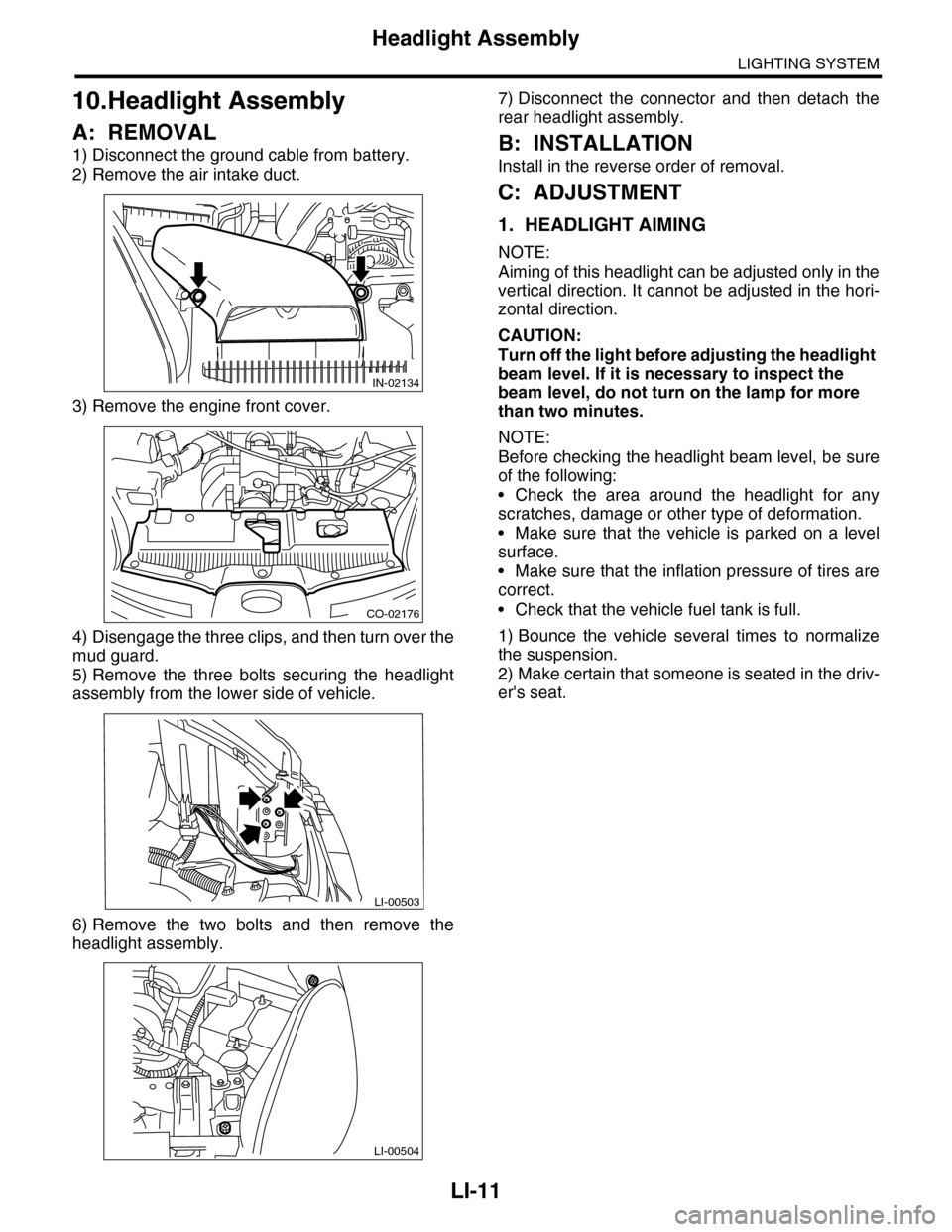

10.Headlight Assembly

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air intake duct.

3) Remove the engine front cover.

4) Disengage the three clips, and then turn over the

mud guard.

5) Remove the three bolts securing the headlight

assembly from the lower side of vehicle.

6) Remove the two bolts and then remove the

headlight assembly.

7) Disconnect the connector and then detach the

rear headlight assembly.

B: INSTALLATION

Install in the reverse order of removal.

C: ADJUSTMENT

1. HEADLIGHT AIMING

NOTE:

Aiming of this headlight can be adjusted only in the

vertical direction. It cannot be adjusted in the hori-

zontal direction.

CAUTION:

Turn off the light before adjusting the headlight

beam level. If it is necessary to inspect the

beam level, do not turn on the lamp for more

than two minutes.

NOTE:

Before checking the headlight beam level, be sure

of the following:

•Check the area around the headlight for any

scratches, damage or other type of deformation.

•Make sure that the vehicle is parked on a level

surface.

•Make sure that the inflation pressure of tires are

correct.

•Check that the vehicle fuel tank is full.

1) Bounce the vehicle several times to normalize

the suspension.

2) Make certain that someone is seated in the driv-

er's seat.

IN-02134

CO-02176

LI-00503

LI-00504

Page 605 of 2453

SB-8

Seat Belt Warning System

SEAT BELT SYSTEM

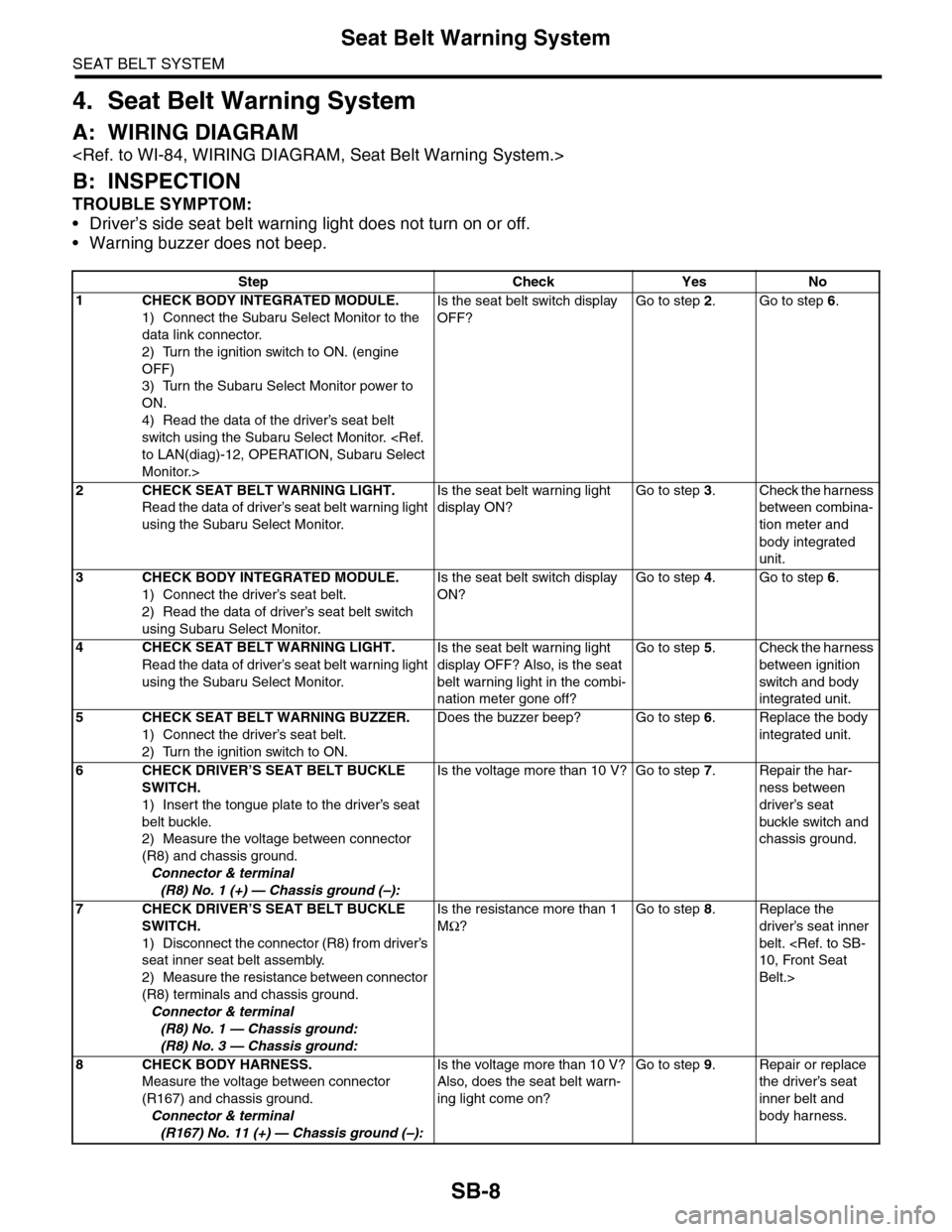

4. Seat Belt Warning System

A: WIRING DIAGRAM

B: INSPECTION

TROUBLE SYMPTOM:

•Driver’s side seat belt warning light does not turn on or off.

•Warning buzzer does not beep.

Step Check Yes No

1CHECK BODY INTEGRATED MODULE.

1) Connect the Subaru Select Monitor to the

data link connector.

2) Turn the ignition switch to ON. (engine

OFF)

3) Turn the Subaru Select Monitor power to

ON.

4) Read the data of the driver’s seat belt

switch using the Subaru Select Monitor.

Monitor.>

Is the seat belt switch display

OFF?

Go to step 2.Go to step 6.

2CHECK SEAT BELT WARNING LIGHT.

Read the data of driver’s seat belt warning light

using the Subaru Select Monitor.

Is the seat belt warning light

display ON?

Go to step 3.Check the harness

between combina-

tion meter and

body integrated

unit.

3CHECK BODY INTEGRATED MODULE.

1) Connect the driver’s seat belt.

2) Read the data of driver’s seat belt switch

using Subaru Select Monitor.

Is the seat belt switch display

ON?

Go to step 4.Go to step 6.

4CHECK SEAT BELT WARNING LIGHT.

Read the data of driver’s seat belt warning light

using the Subaru Select Monitor.

Is the seat belt warning light

display OFF? Also, is the seat

belt warning light in the combi-

nation meter gone off?

Go to step 5.Check the harness

between ignition

switch and body

integrated unit.

5CHECK SEAT BELT WARNING BUZZER.

1) Connect the driver’s seat belt.

2) Turn the ignition switch to ON.

Does the buzzer beep? Go to step 6.Replace the body

integrated unit.

6CHECK DRIVER’S SEAT BELT BUCKLE

SWITCH.

1) Insert the tongue plate to the driver’s seat

belt buckle.

2) Measure the voltage between connector

(R8) and chassis ground.

Connector & terminal

(R8) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 7.Repair the har-

ness between

driver’s seat

buckle switch and

chassis ground.

7CHECK DRIVER’S SEAT BELT BUCKLE

SWITCH.

1) Disconnect the connector (R8) from driver’s

seat inner seat belt assembly.

2) Measure the resistance between connector

(R8) terminals and chassis ground.

Connector & terminal

(R8) No. 1 — Chassis ground:

(R8) No. 3 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 8.Replace the

driver’s seat inner

belt.

Belt.>

8CHECK BODY HARNESS.

Measure the voltage between connector

(R167) and chassis ground.

Connector & terminal

(R167) No. 11 (+) — Chassis ground (–):

Is the voltage more than 10 V?

Also, does the seat belt warn-

ing light come on?

Go to step 9.Repair or replace

the driver’s seat

inner belt and

body harness.