SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2071 of 2453

5AT-55

ATF Filter

AUTOMATIC TRANSMISSION

18.ATF Filter

A: REMOVAL

1) Remove the front bumper.

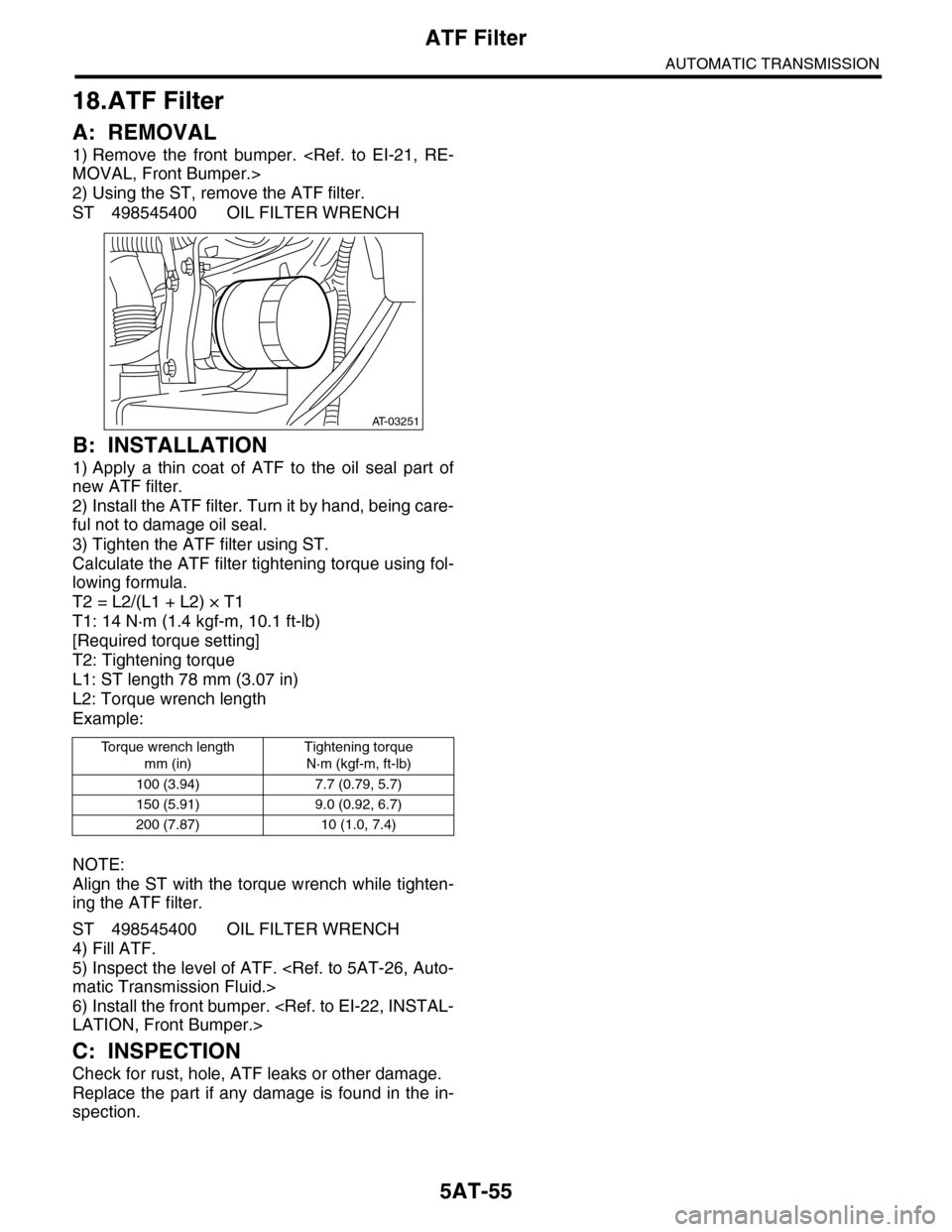

2) Using the ST, remove the ATF filter.

ST 498545400 OIL FILTER WRENCH

B: INSTALLATION

1) Apply a thin coat of ATF to the oil seal part of

new ATF filter.

2) Install the ATF filter. Turn it by hand, being care-

ful not to damage oil seal.

3) Tighten the ATF filter using ST.

Calculate the ATF filter tightening torque using fol-

lowing formula.

T2 = L2/(L1 + L2) × T1

T1: 14 N·m (1.4 kgf-m, 10.1 ft-lb)

[Required torque setting]

T2: Tightening torque

L1: ST length 78 mm (3.07 in)

L2: Torque wrench length

Example:

NOTE:

Align the ST with the torque wrench while tighten-

ing the ATF filter.

ST 498545400 OIL FILTER WRENCH

4) Fill ATF.

5) Inspect the level of ATF.

6) Install the front bumper.

C: INSPECTION

Check for rust, hole, ATF leaks or other damage.

Replace the part if any damage is found in the in-

spection.

To r q u e w r e n c h l e n g t h

mm (in)

Tightening torque

N·m (kgf-m, ft-lb)

100 (3.94) 7.7 (0.79, 5.7)

150 (5.91) 9.0 (0.92, 6.7)

200 (7.87) 10 (1.0, 7.4)

AT-03251

Page 2072 of 2453

5AT-56

Transmission Control Module (TCM)

AUTOMATIC TRANSMISSION

19.Transmission Control Mod-

ule (TCM)

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the lower cover and then disconnect

the connector.

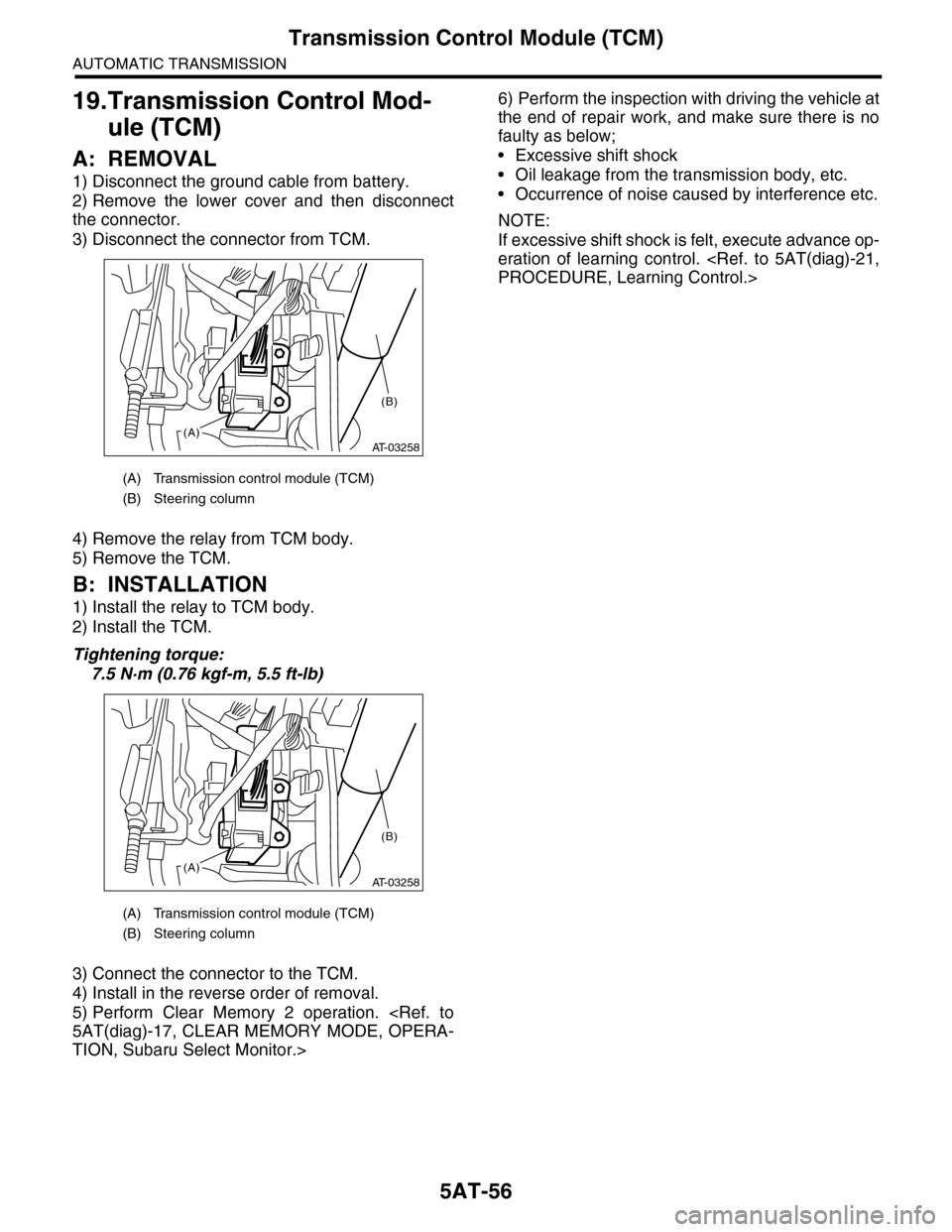

3) Disconnect the connector from TCM.

4) Remove the relay from TCM body.

5) Remove the TCM.

B: INSTALLATION

1) Install the relay to TCM body.

2) Install the TCM.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

3) Connect the connector to the TCM.

4) Install in the reverse order of removal.

5) Perform Clear Memory 2 operation.

TION, Subaru Select Monitor.>

6) Perform the inspection with driving the vehicle at

the end of repair work, and make sure there is no

faulty as below;

•Excessive shift shock

•Oil leakage from the transmission body, etc.

•Occurrence of noise caused by interference etc.

NOTE:

If excessive shift shock is felt, execute advance op-

eration of learning control.

(A) Transmission control module (TCM)

(B) Steering column

(A) Transmission control module (TCM)

(B) Steering column

AT-03258(A)

(B)

AT-03258(A)

(B)

Page 2073 of 2453

5AT-57

ATF Cooler Pipe & Hose

AUTOMATIC TRANSMISSION

20.ATF Cooler Pipe & Hose

A: REMOVAL

1) Set the vehicle on a lift.

2) Lift-up the vehicle.

3) Remove the under cover.

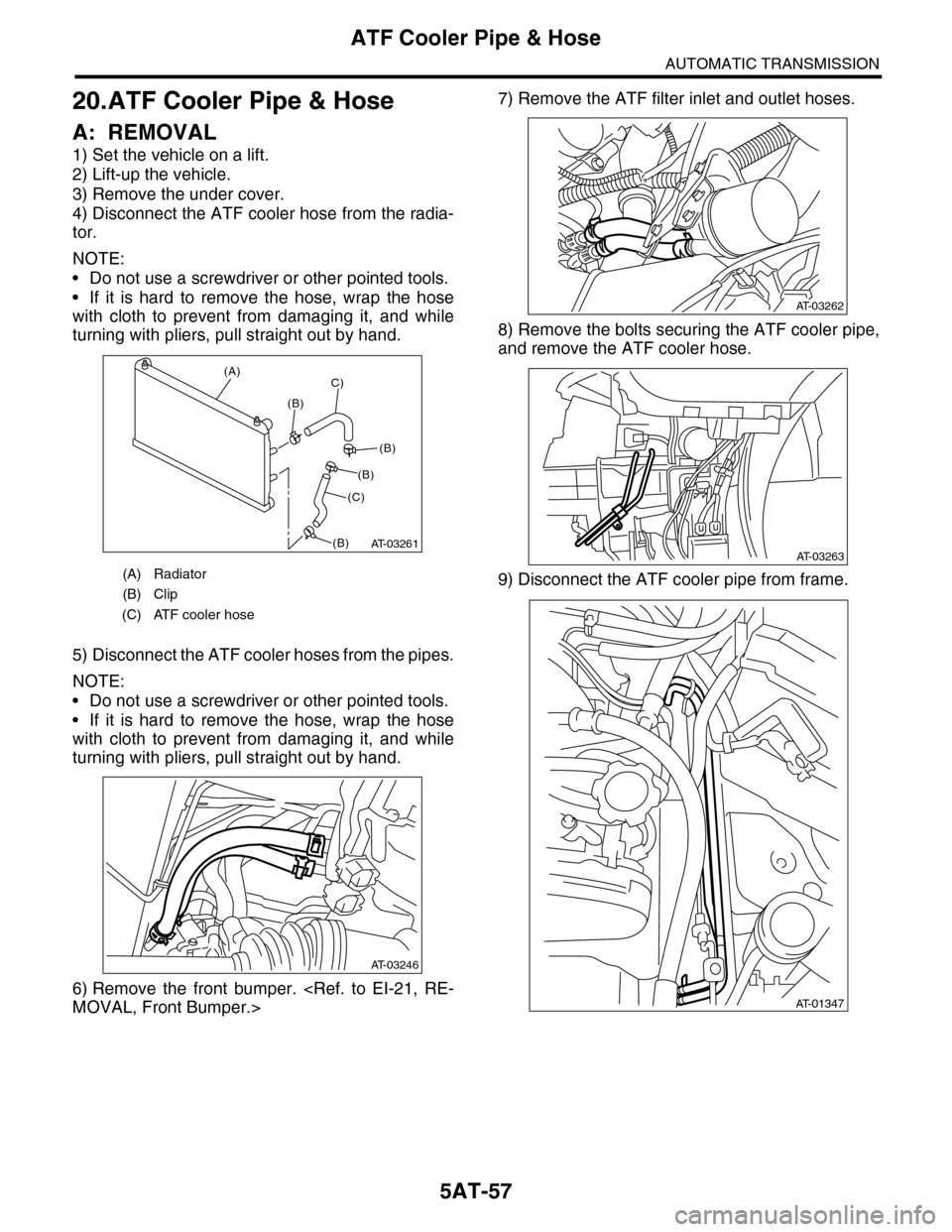

4) Disconnect the ATF cooler hose from the radia-

tor.

NOTE:

•Do not use a screwdriver or other pointed tools.

•If it is hard to remove the hose, wrap the hose

with cloth to prevent from damaging it, and while

turning with pliers, pull straight out by hand.

5) Disconnect the ATF cooler hoses from the pipes.

NOTE:

•Do not use a screwdriver or other pointed tools.

•If it is hard to remove the hose, wrap the hose

with cloth to prevent from damaging it, and while

turning with pliers, pull straight out by hand.

6) Remove the front bumper.

7) Remove the ATF filter inlet and outlet hoses.

8) Remove the bolts securing the ATF cooler pipe,

and remove the ATF cooler hose.

9) Disconnect the ATF cooler pipe from frame.(A) Radiator

(B) Clip

(C) ATF cooler hose

AT-03261

(A)

(B)

C)

(C)

(B)

(B)

(B)

AT-03246

AT-03262

AT-03263

AT-01347

Page 2074 of 2453

5AT-58

ATF Cooler Pipe & Hose

AUTOMATIC TRANSMISSION

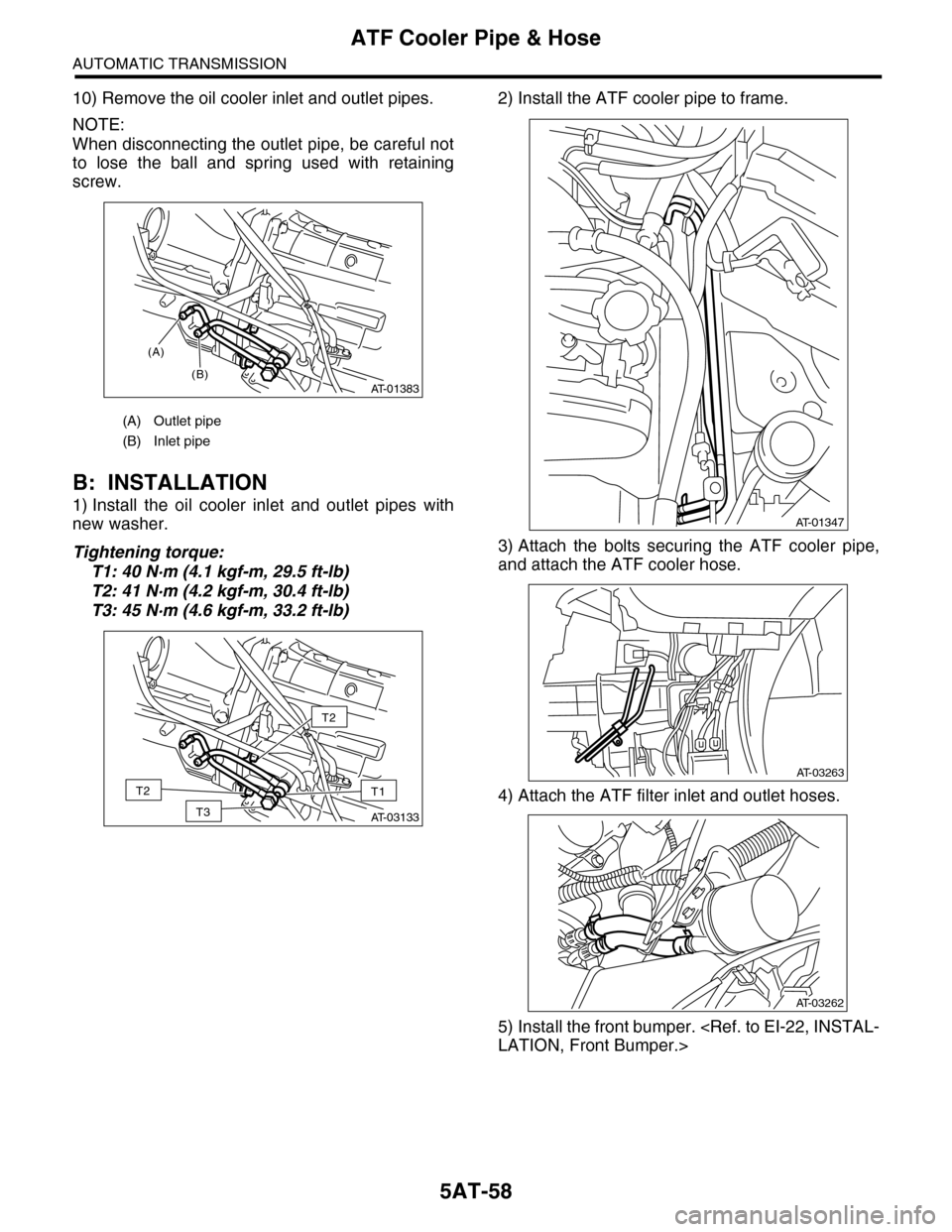

10) Remove the oil cooler inlet and outlet pipes.

NOTE:

When disconnecting the outlet pipe, be careful not

to lose the ball and spring used with retaining

screw.

B: INSTALLATION

1) Install the oil cooler inlet and outlet pipes with

new washer.

Tightening torque:

T1: 40 N·m (4.1 kgf-m, 29.5 ft-lb)

T2: 41 N·m (4.2 kgf-m, 30.4 ft-lb)

T3: 45 N·m (4.6 kgf-m, 33.2 ft-lb)

2) Install the ATF cooler pipe to frame.

3) Attach the bolts securing the ATF cooler pipe,

and attach the ATF cooler hose.

4) Attach the ATF filter inlet and outlet hoses.

5) Install the front bumper.

(A) Outlet pipe

(B) Inlet pipe

AT-01383

(A)

(B)

AT-03133

T2

T1 T2

T3

AT-01347

AT-03263

AT-03262

Page 2075 of 2453

5AT-59

ATF Cooler Pipe & Hose

AUTOMATIC TRANSMISSION

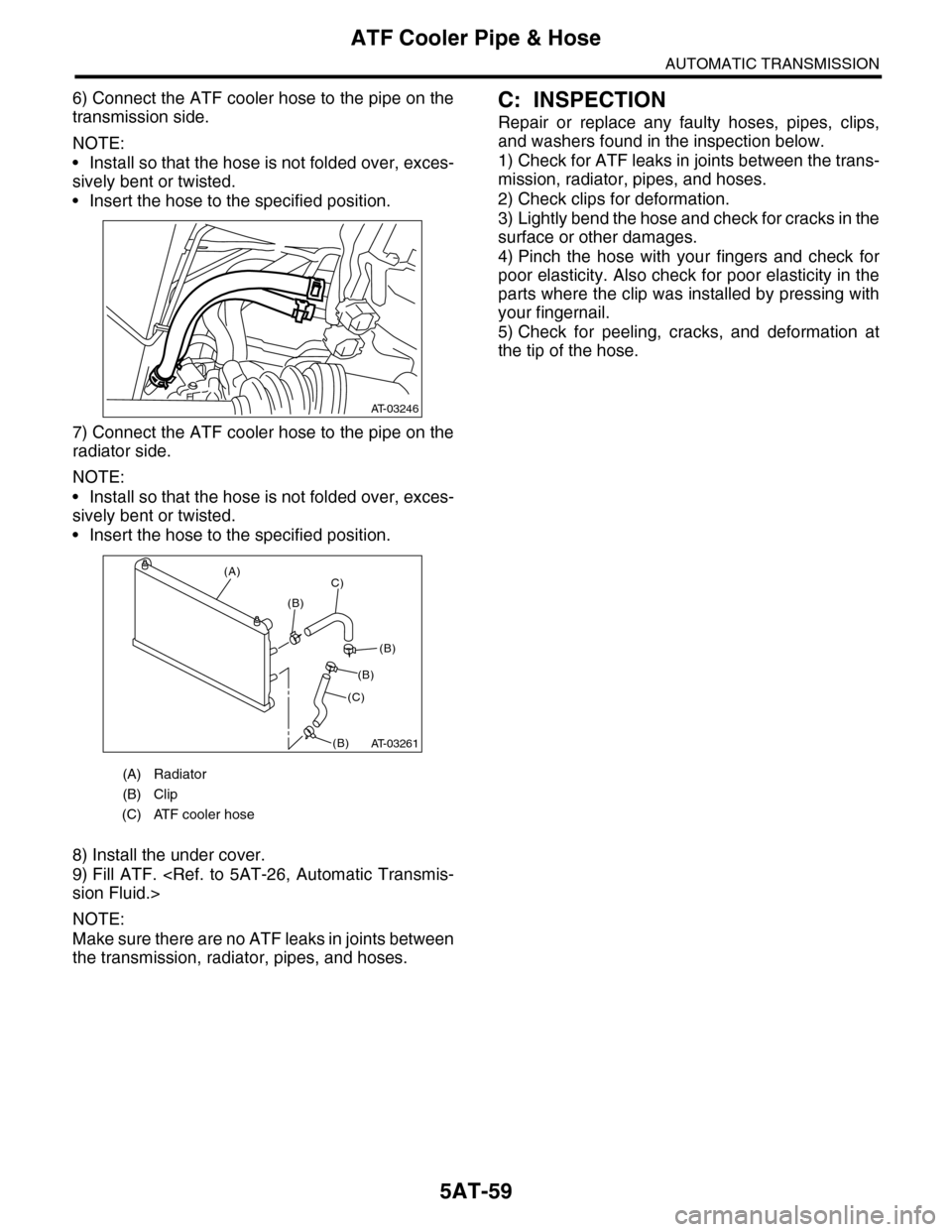

6) Connect the ATF cooler hose to the pipe on the

transmission side.

NOTE:

•Install so that the hose is not folded over, exces-

sively bent or twisted.

•Insert the hose to the specified position.

7) Connect the ATF cooler hose to the pipe on the

radiator side.

NOTE:

•Install so that the hose is not folded over, exces-

sively bent or twisted.

•Insert the hose to the specified position.

8) Install the under cover.

9) Fill ATF.

NOTE:

Make sure there are no ATF leaks in joints between

the transmission, radiator, pipes, and hoses.

C: INSPECTION

Repair or replace any faulty hoses, pipes, clips,

and washers found in the inspection below.

1) Check for ATF leaks in joints between the trans-

mission, radiator, pipes, and hoses.

2) Check clips for deformation.

3) Lightly bend the hose and check for cracks in the

surface or other damages.

4) Pinch the hose with your fingers and check for

poor elasticity. Also check for poor elasticity in the

parts where the clip was installed by pressing with

your fingernail.

5) Check for peeling, cracks, and deformation at

the tip of the hose.

(A) Radiator

(B) Clip

(C) ATF cooler hose

AT-03246

AT-03261

(A)

(B)

C)

(C)

(B)

(B)

(B)

Page 2076 of 2453

5AT-60

Air Breather Hose

AUTOMATIC TRANSMISSION

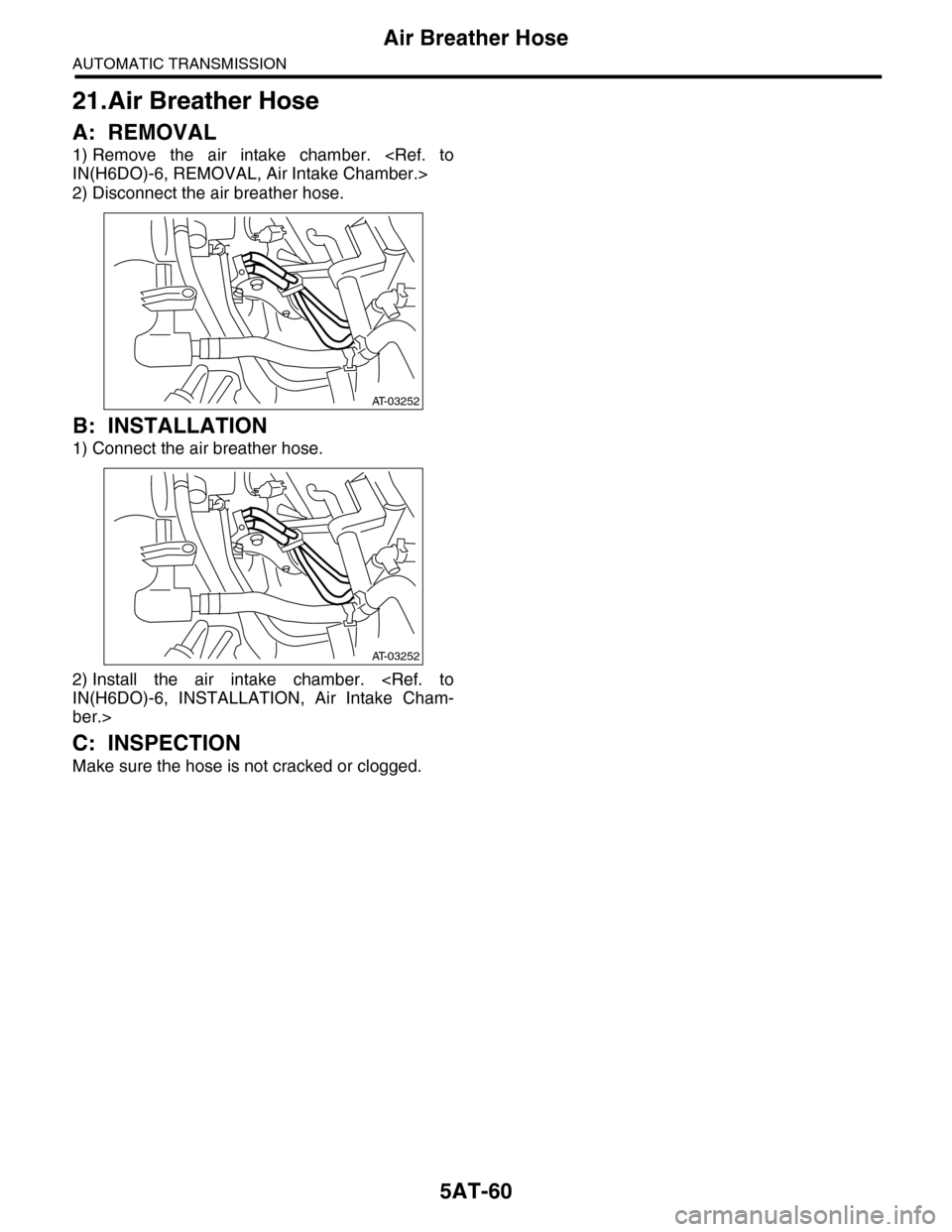

21.Air Breather Hose

A: REMOVAL

1) Remove the air intake chamber.

2) Disconnect the air breather hose.

B: INSTALLATION

1) Connect the air breather hose.

2) Install the air intake chamber.

ber.>

C: INSPECTION

Make sure the hose is not cracked or clogged.

AT-03252

AT-03252

Page 2077 of 2453

5AT-61

Oil Charge Pipe

AUTOMATIC TRANSMISSION

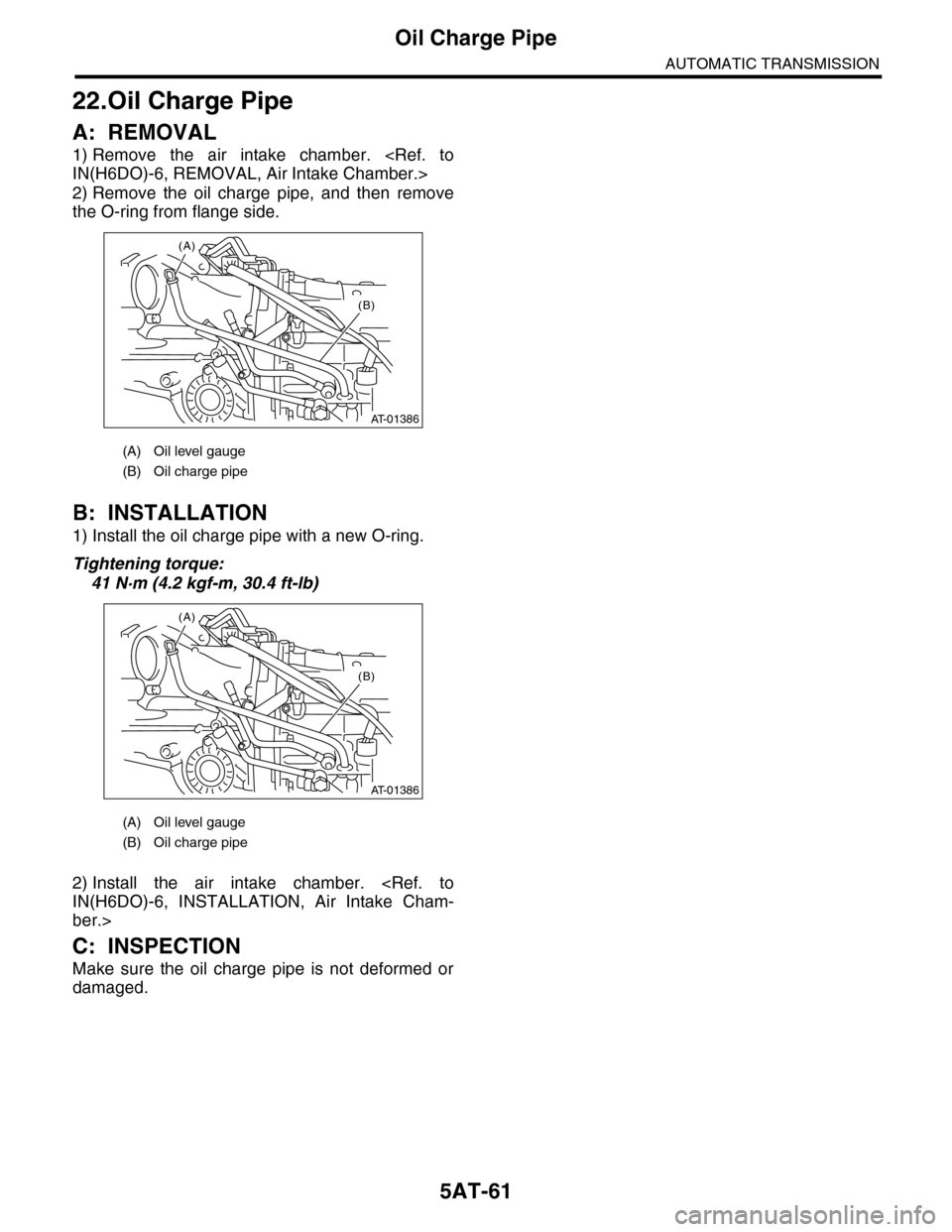

22.Oil Charge Pipe

A: REMOVAL

1) Remove the air intake chamber.

2) Remove the oil charge pipe, and then remove

the O-ring from flange side.

B: INSTALLATION

1) Install the oil charge pipe with a new O-ring.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

2) Install the air intake chamber.

ber.>

C: INSPECTION

Make sure the oil charge pipe is not deformed or

damaged.

(A) Oil level gauge

(B) Oil charge pipe

(A) Oil level gauge

(B) Oil charge pipe

AT-01386

(B)

(A)

AT-01386

(B)

(A)

Page 2078 of 2453

5AT-62

Torque Converter Assembly

AUTOMATIC TRANSMISSION

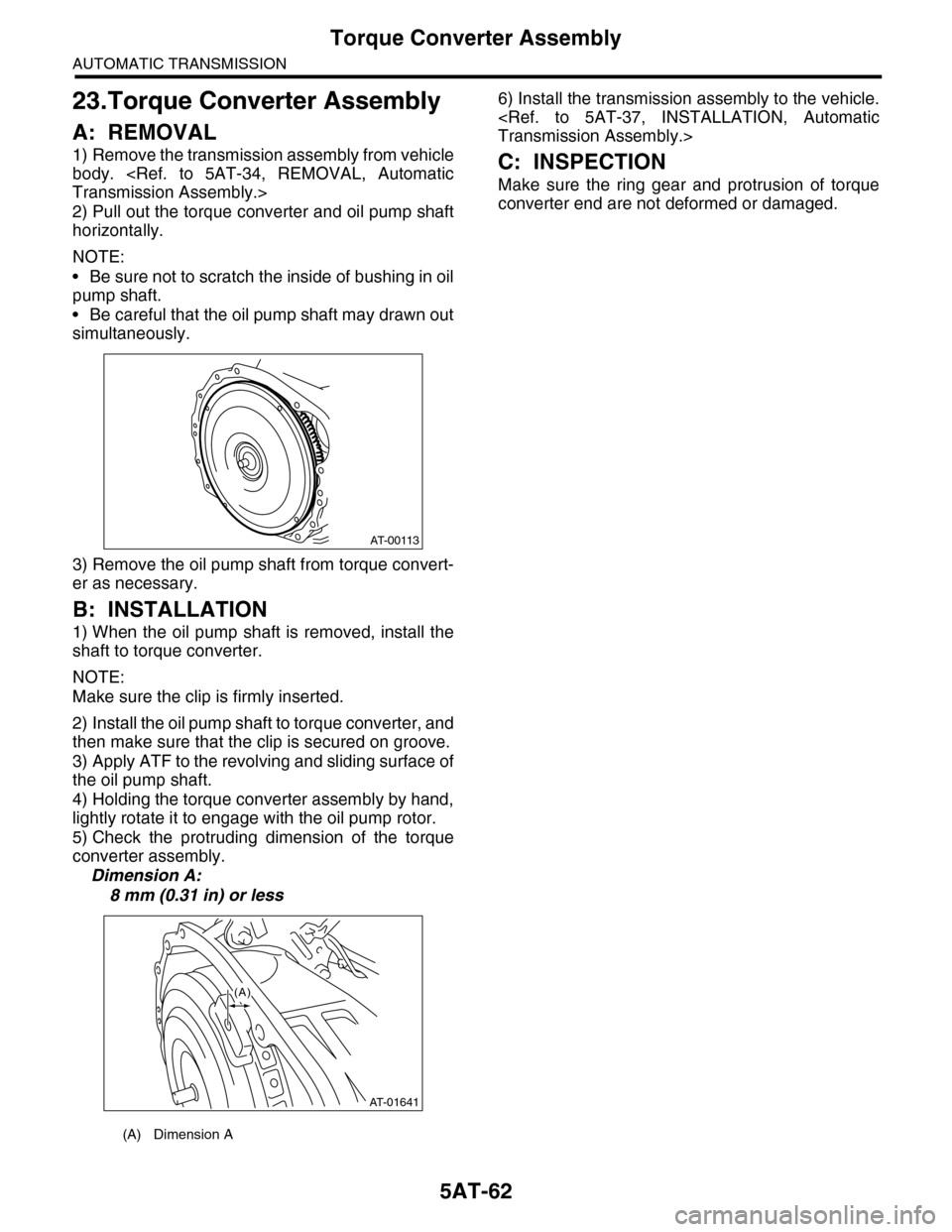

23.Torque Converter Assembly

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter and oil pump shaft

horizontally.

NOTE:

•Be sure not to scratch the inside of bushing in oil

pump shaft.

•Be careful that the oil pump shaft may drawn out

simultaneously.

3) Remove the oil pump shaft from torque convert-

er as necessary.

B: INSTALLATION

1) When the oil pump shaft is removed, install the

shaft to torque converter.

NOTE:

Make sure the clip is firmly inserted.

2) Install the oil pump shaft to torque converter, and

then make sure that the clip is secured on groove.

3) Apply ATF to the revolving and sliding surface of

the oil pump shaft.

4) Holding the torque converter assembly by hand,

lightly rotate it to engage with the oil pump rotor.

5) Check the protruding dimension of the torque

converter assembly.

Dimension A:

8 mm (0.31 in) or less

6) Install the transmission assembly to the vehicle.

C: INSPECTION

Make sure the ring gear and protrusion of torque

converter end are not deformed or damaged.

(A) Dimension A

AT-00113

AT-01641

(A)

Page 2079 of 2453

5AT-63

Extension Case

AUTOMATIC TRANSMISSION

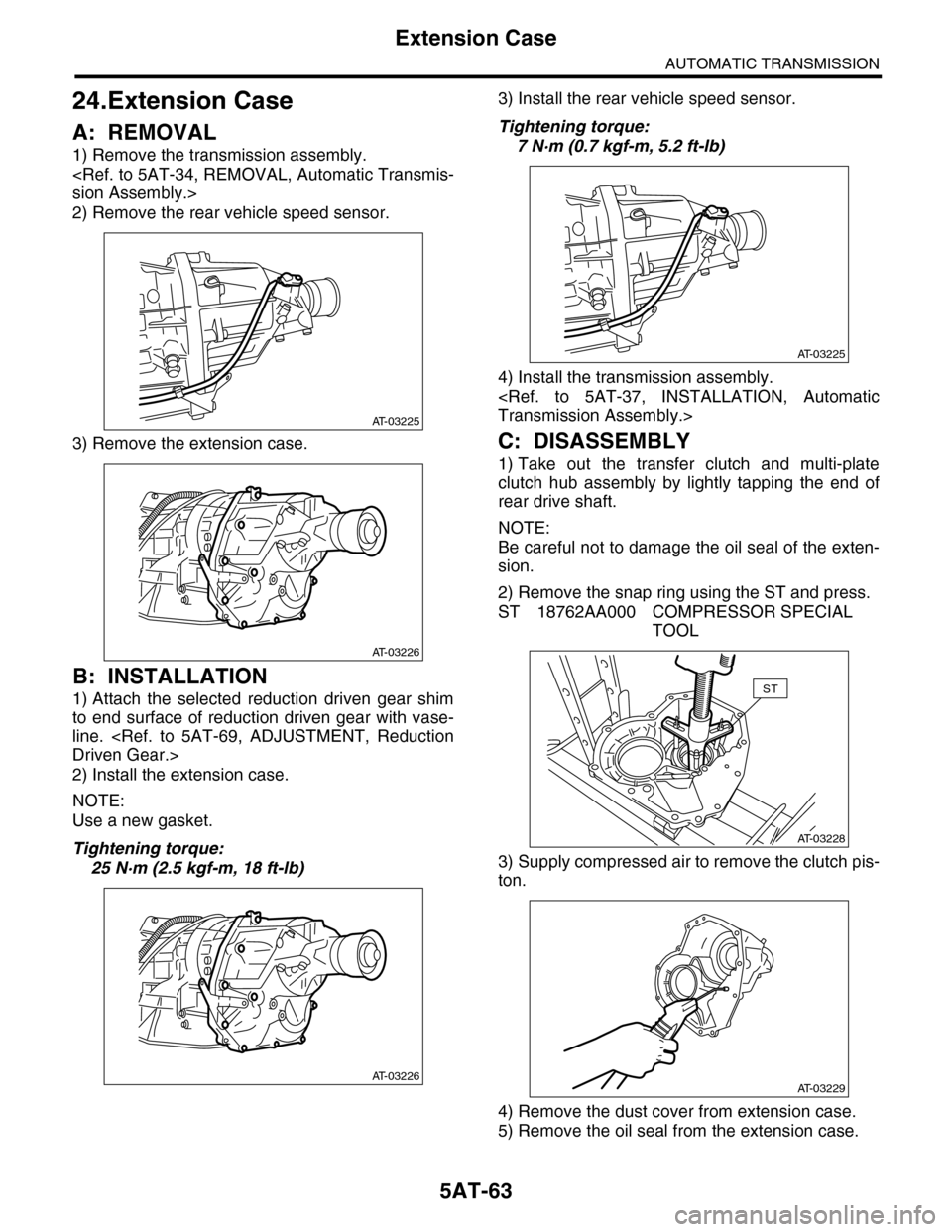

24.Extension Case

A: REMOVAL

1) Remove the transmission assembly.

2) Remove the rear vehicle speed sensor.

3) Remove the extension case.

B: INSTALLATION

1) Attach the selected reduction driven gear shim

to end surface of reduction driven gear with vase-

line.

2) Install the extension case.

NOTE:

Use a new gasket.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

3) Install the rear vehicle speed sensor.

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

4) Install the transmission assembly.

C: DISASSEMBLY

1) Take out the transfer clutch and multi-plate

clutch hub assembly by lightly tapping the end of

rear drive shaft.

NOTE:

Be careful not to damage the oil seal of the exten-

sion.

2) Remove the snap ring using the ST and press.

ST 18762AA000 COMPRESSOR SPECIAL

TOOL

3) Supply compressed air to remove the clutch pis-

ton.

4) Remove the dust cover from extension case.

5) Remove the oil seal from the extension case.

AT-03225

AT-03226

AT-03226

AT-03225

AT-03228

ST

AT-03229

Page 2080 of 2453

5AT-64

Extension Case

AUTOMATIC TRANSMISSION

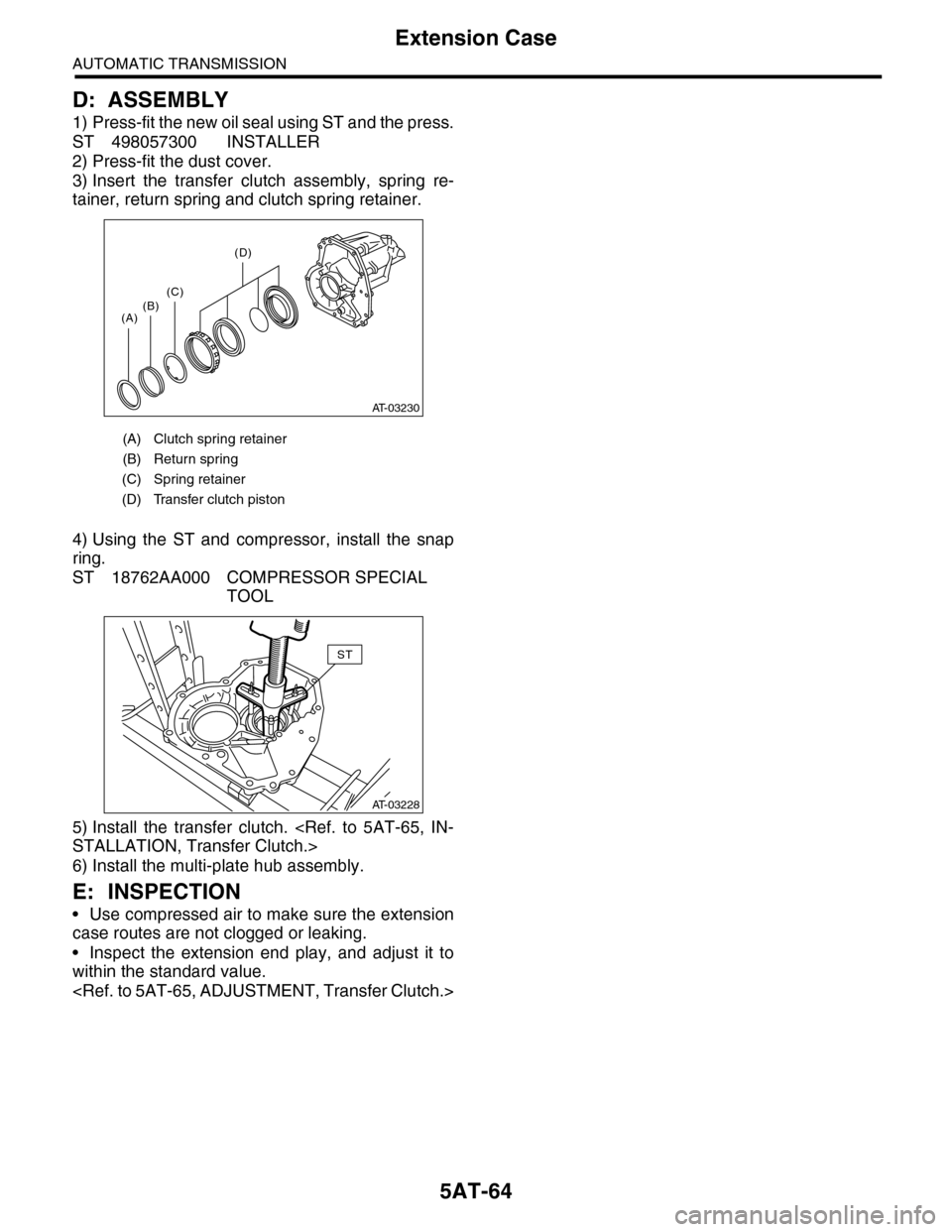

D: ASSEMBLY

1) Press-fit the new oil seal using ST and the press.

ST 498057300 INSTALLER

2) Press-fit the dust cover.

3) Insert the transfer clutch assembly, spring re-

tainer, return spring and clutch spring retainer.

4) Using the ST and compressor, install the snap

ring.

ST 18762AA000 COMPRESSOR SPECIAL

TOOL

5) Install the transfer clutch.

6) Install the multi-plate hub assembly.

E: INSPECTION

•Use compressed air to make sure the extension

case routes are not clogged or leaking.

•Inspect the extension end play, and adjust it to

within the standard value.

(A) Clutch spring retainer

(B) Return spring

(C) Spring retainer

(D) Transfer clutch piston

AT-03230

(A)(B)(C)

(D)

AT-03228

ST