ECU SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1551 of 2453

EN(H6DO)(diag)-390

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

EE:DTC P2227 BAROMETRIC PRESSURE CIRCUIT RANGE/PERFORMANCE

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

EF:DTC P2228 BAROMETRIC PRESSURE CIRCUIT LOW INPUT

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Replace the ECM.

Engine Control

Module (ECM).>

NOTE:

The barometric

pressure sensor is

built into the ECM.

It is not necessary

to inspect DTC

P0129.

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is DTC P1110 displayed on the

Subaru Select Monitor or gen-

eral scan tool?

Replace the ECM.

Engine Control

Module (ECM).>

NOTE:The barometric

pressure sensor is

built into the ECM.

Te m p o r a r y p o o r

contact occurs.

Page 1554 of 2453

EN(H6DO)(diag)-393

General Diagnostic Table

ENGINE (DIAGNOSTICS)

*1: Check ignition coil & ignitor assembly and spark plug.

*2: Indicate the symptom occurring only in cold temperatures.

*3: Make sure the secure installation.

*4: Check the fuel injector and fuel pressure regulator.

*5: Inspect air leak in air intake system.

6. Surging

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Fuel injection parts (*4)

7) Electronic throttle control

8) Fuel pump and fuel pump relay

7. Spark knock

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor

4) Knock sensor

5) Fuel injection parts (*4)

6) Fuel pump and fuel pump relay

8. After burning in exhaust system

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor (*2)

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay

Symptom Problem parts

Page 1572 of 2453

FU(H6DO)-11

Throttle Body

FUEL INJECTION (FUEL SYSTEMS)

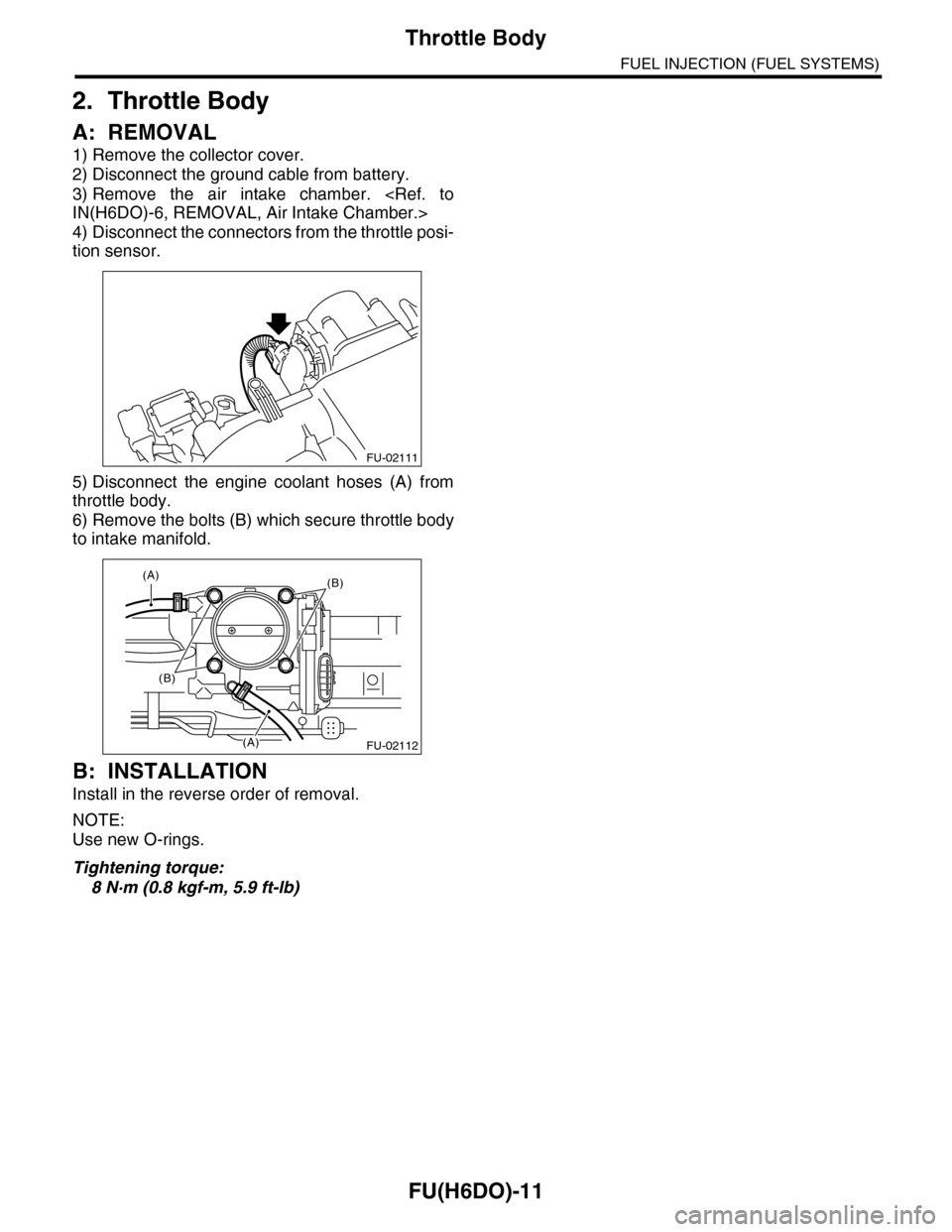

2. Throttle Body

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

4) Disconnect the connectors from the throttle posi-

tion sensor.

5) Disconnect the engine coolant hoses (A) from

throttle body.

6) Remove the bolts (B) which secure throttle body

to intake manifold.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Use new O-rings.

Tightening torque:

8 N·m (0.8 kgf-m, 5.9 ft-lb)

FU-02111

FU-02112

(A)(B)

(B)

(A)

Page 1602 of 2453

FU(H6DO)-41

Fuel Filler Pipe

FUEL INJECTION (FUEL SYSTEMS)

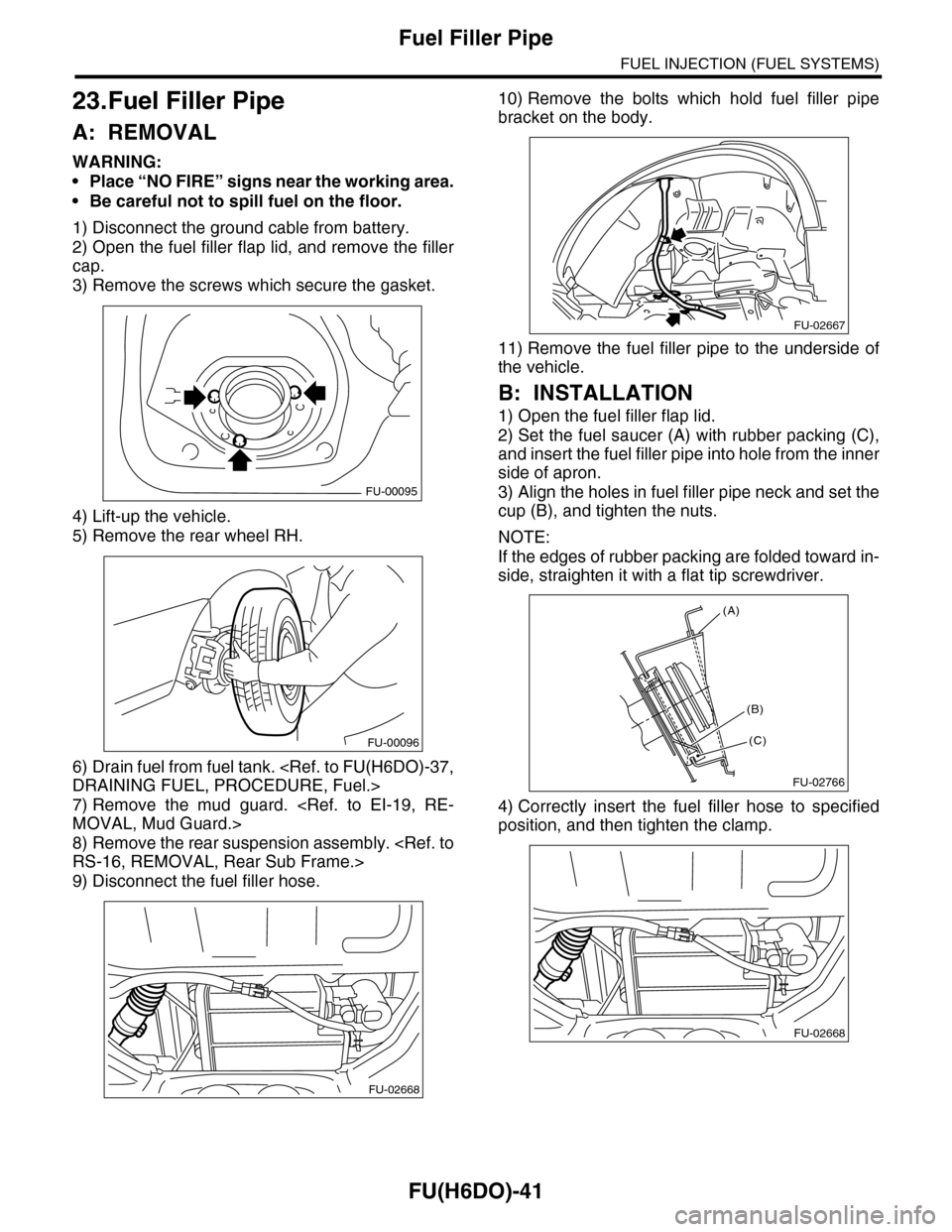

23.Fuel Filler Pipe

A: REMOVAL

WARNING:

•Place “NO FIRE” signs near the working area.

•Be careful not to spill fuel on the floor.

1) Disconnect the ground cable from battery.

2) Open the fuel filler flap lid, and remove the filler

cap.

3) Remove the screws which secure the gasket.

4) Lift-up the vehicle.

5) Remove the rear wheel RH.

6) Drain fuel from fuel tank.

7) Remove the mud guard.

8) Remove the rear suspension assembly.

9) Disconnect the fuel filler hose.

10) Remove the bolts which hold fuel filler pipe

bracket on the body.

11) Remove the fuel filler pipe to the underside of

the vehicle.

B: INSTALLATION

1) Open the fuel filler flap lid.

2) Set the fuel saucer (A) with rubber packing (C),

and insert the fuel filler pipe into hole from the inner

side of apron.

3) Align the holes in fuel filler pipe neck and set the

cup (B), and tighten the nuts.

NOTE:

If the edges of rubber packing are folded toward in-

side, straighten it with a flat tip screwdriver.

4) Correctly insert the fuel filler hose to specified

position, and then tighten the clamp.

FU-00095

FU-00096

FU-02668

FU-02667

FU-02766

(A)

(C)

(B)

FU-02668

Page 1611 of 2453

FU(H6DO)-50

Fuel Delivery, Return and Evaporation Lines

FUEL INJECTION (FUEL SYSTEMS)

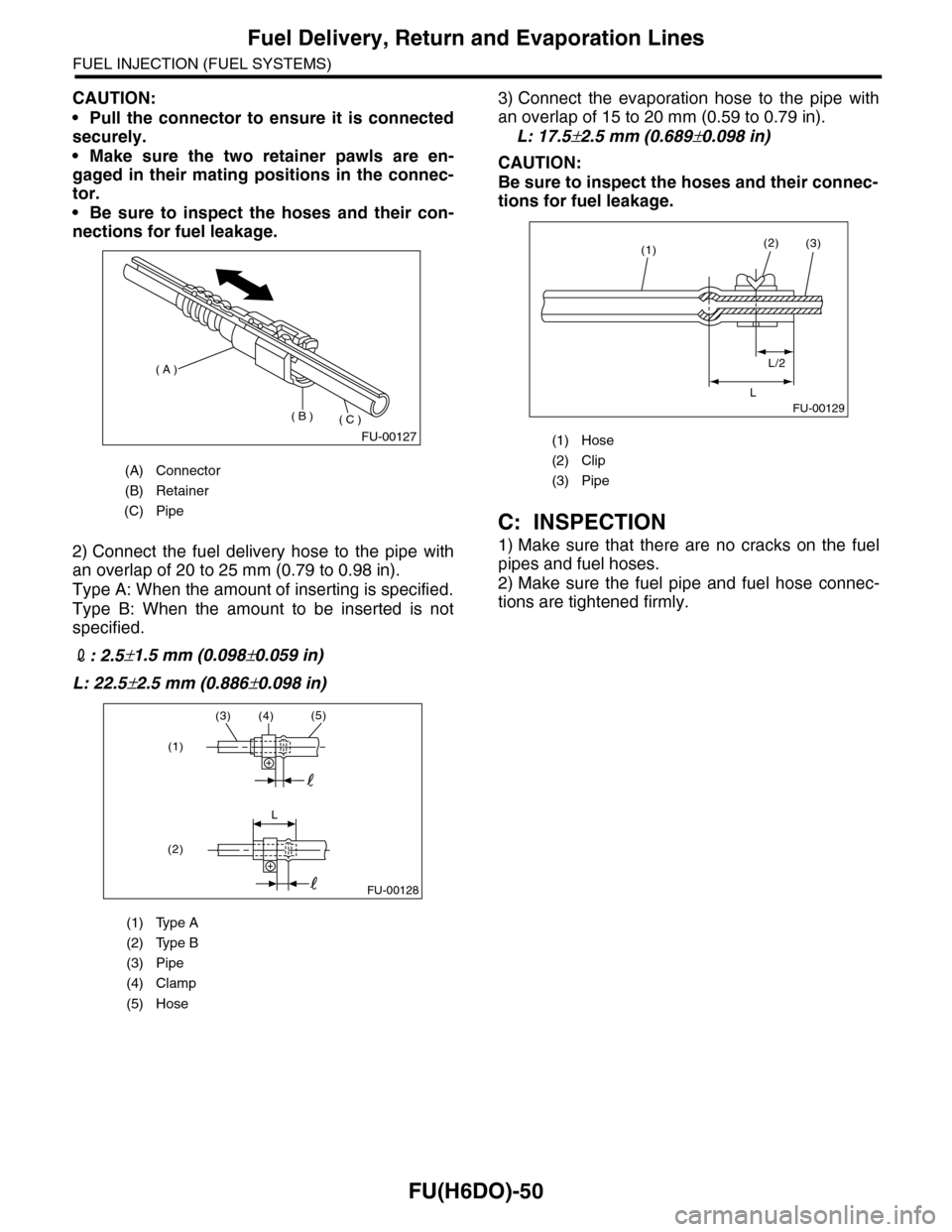

CAUTION:

•Pull the connector to ensure it is connected

securely.

•Make sure the two retainer pawls are en-

gaged in their mating positions in the connec-

tor.

•Be sure to inspect the hoses and their con-

nections for fuel leakage.

2) Connect the fuel delivery hose to the pipe with

an overlap of 20 to 25 mm (0.79 to 0.98 in).

Type A: When the amount of inserting is specified.

Type B: When the amount to be inserted is not

specified.

2: 2.5±1.5 mm (0.098±0.059 in)

L: 22.5±2.5 mm (0.886±0.098 in)

3) Connect the evaporation hose to the pipe with

an overlap of 15 to 20 mm (0.59 to 0.79 in).

L: 17.5±2.5 mm (0.689±0.098 in)

CAUTION:

Be sure to inspect the hoses and their connec-

tions for fuel leakage.

C: INSPECTION

1) Make sure that there are no cracks on the fuel

pipes and fuel hoses.

2) Make sure the fuel pipe and fuel hose connec-

tions are tightened firmly.

(A) Connector

(B) Retainer

(C) Pipe

(1) Type A

(2) Type B

(3) Pipe

(4) Clamp

(5) Hose

FU-00127

( A )

( B )( C )

(3)(4)(5)

L

(1)

(2)

FU-00128

(1) Hose

(2) Clip

(3) Pipe

FU-00129

(1)(2)

L/2

L

(3)

Page 1612 of 2453

FU(H6DO)-51

Fuel System Trouble in General

FUEL INJECTION (FUEL SYSTEMS)

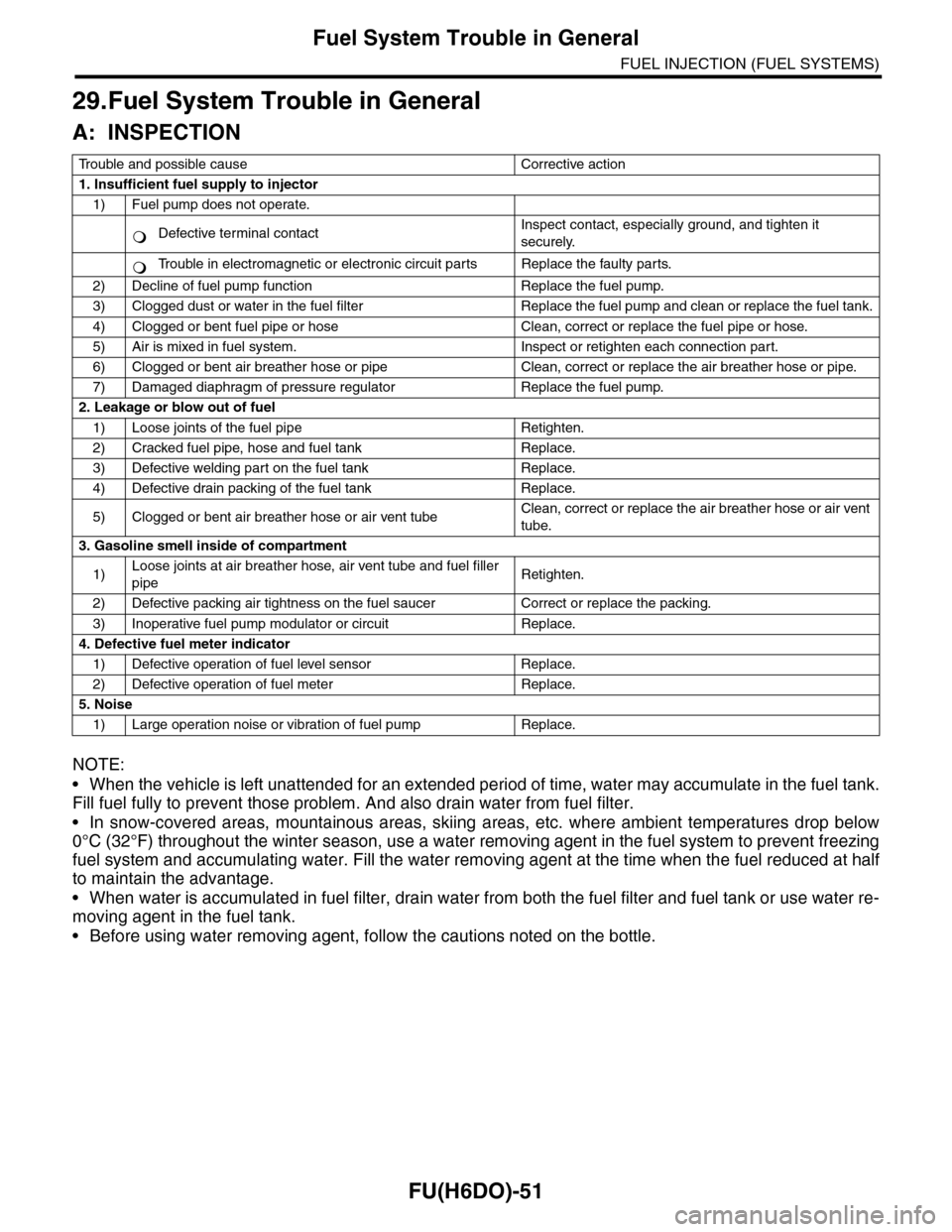

29.Fuel System Trouble in General

A: INSPECTION

NOTE:

•When the vehicle is left unattended for an extended period of time, water may accumulate in the fuel tank.

Fill fuel fully to prevent those problem. And also drain water from fuel filter.

•In snow-covered areas, mountainous areas, skiing areas, etc. where ambient temperatures drop below

0°C (32°F) throughout the winter season, use a water removing agent in the fuel system to prevent freezing

fuel system and accumulating water. Fill the water removing agent at the time when the fuel reduced at half

to maintain the advantage.

•When water is accumulated in fuel filter, drain water from both the fuel filter and fuel tank or use water re-

moving agent in the fuel tank.

•Before using water removing agent, follow the cautions noted on the bottle.

Tr o u b l e a n d p o s s i b l e c a u s e C o r r e c t i v e a c t i o n

1. Insufficient fuel supply to injector

1) Fuel pump does not operate.

Defective terminal contactInspect contact, especially ground, and tighten it

securely.

Tr o u b l e i n e l e c t r o m a g n e t i c o r e l e c t r o n i c c i r c u i t p a r t s R e p l a c e t h e f a u l t y p a r t s .

2) Decline of fuel pump function Replace the fuel pump.

3) Clogged dust or water in the fuel filter Replace the fuel pump and clean or replace the fuel tank.

4) Clogged or bent fuel pipe or hose Clean, correct or replace the fuel pipe or hose.

5) Air is mixed in fuel system. Inspect or retighten each connection part.

6) Clogged or bent air breather hose or pipe Clean, correct or replace the air breather hose or pipe.

7) Damaged diaphragm of pressure regulator Replace the fuel pump.

2. Leakage or blow out of fuel

1) Loose joints of the fuel pipe Retighten.

2) Cracked fuel pipe, hose and fuel tank Replace.

3) Defective welding part on the fuel tank Replace.

4) Defective drain packing of the fuel tank Replace.

5) Clogged or bent air breather hose or air vent tubeClean, correct or replace the air breather hose or air vent

tube.

3. Gasoline smell inside of compartment

1)Loose joints at air breather hose, air vent tube and fuel filler

pipeRetighten.

2) Defective packing air tightness on the fuel saucer Correct or replace the packing.

3) Inoperative fuel pump modulator or circuit Replace.

4. Defective fuel meter indicator

1) Defective operation of fuel level sensor Replace.

2) Defective operation of fuel meter Replace.

5. Noise

1) Large operation noise or vibration of fuel pump Replace.

�

Page 1621 of 2453

GD(H6DO)-9

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

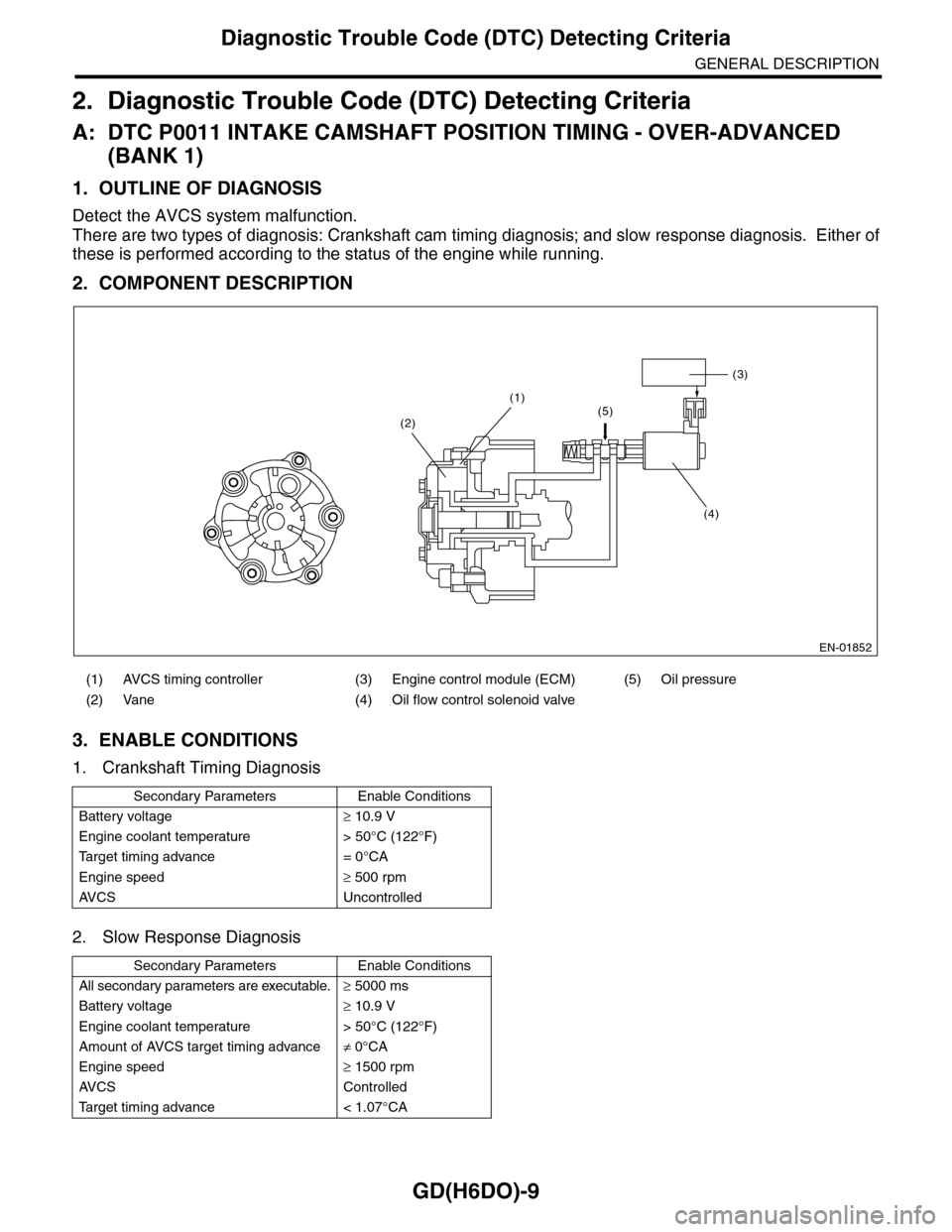

2. Diagnostic Trouble Code (DTC) Detecting Criteria

A: DTC P0011 INTAKE CAMSHAFT POSITION TIMING - OVER-ADVANCED

(BANK 1)

1. OUTLINE OF DIAGNOSIS

Detect the AVCS system malfunction.

There are two types of diagnosis: Crankshaft cam timing diagnosis; and slow response diagnosis. Either of

these is performed according to the status of the engine while running.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

1. Crankshaft Timing Diagnosis

2. Slow Response Diagnosis

(1) AVCS timing controller (3) Engine control module (ECM) (5) Oil pressure

(2) Vane (4) Oil flow control solenoid valve

Secondary Parameters Enable Conditions

Battery voltage≥ 10.9 V

Engine coolant temperature > 50°C (122°F)

Ta r g e t t i m i n g a d v a n c e = 0 ° C A

Engine speed≥ 500 rpm

AV C S U n c o n t r o l l e d

Secondary Parameters Enable Conditions

All secondary parameters are executable.≥ 5000 ms

Battery voltage≥ 10.9 V

Engine coolant temperature > 50°C (122°F)

Amount of AVCS target timing advance≠ 0°CA

Engine speed≥ 1500 rpm

AV C S C o n t r o l l e d

Ta r g e t t i m i n g a d v a n c e < 1 . 0 7 ° C A

EN-01852

(3)

(4)

(1)(5)(2)

Page 1688 of 2453

GD(H6DO)-76

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

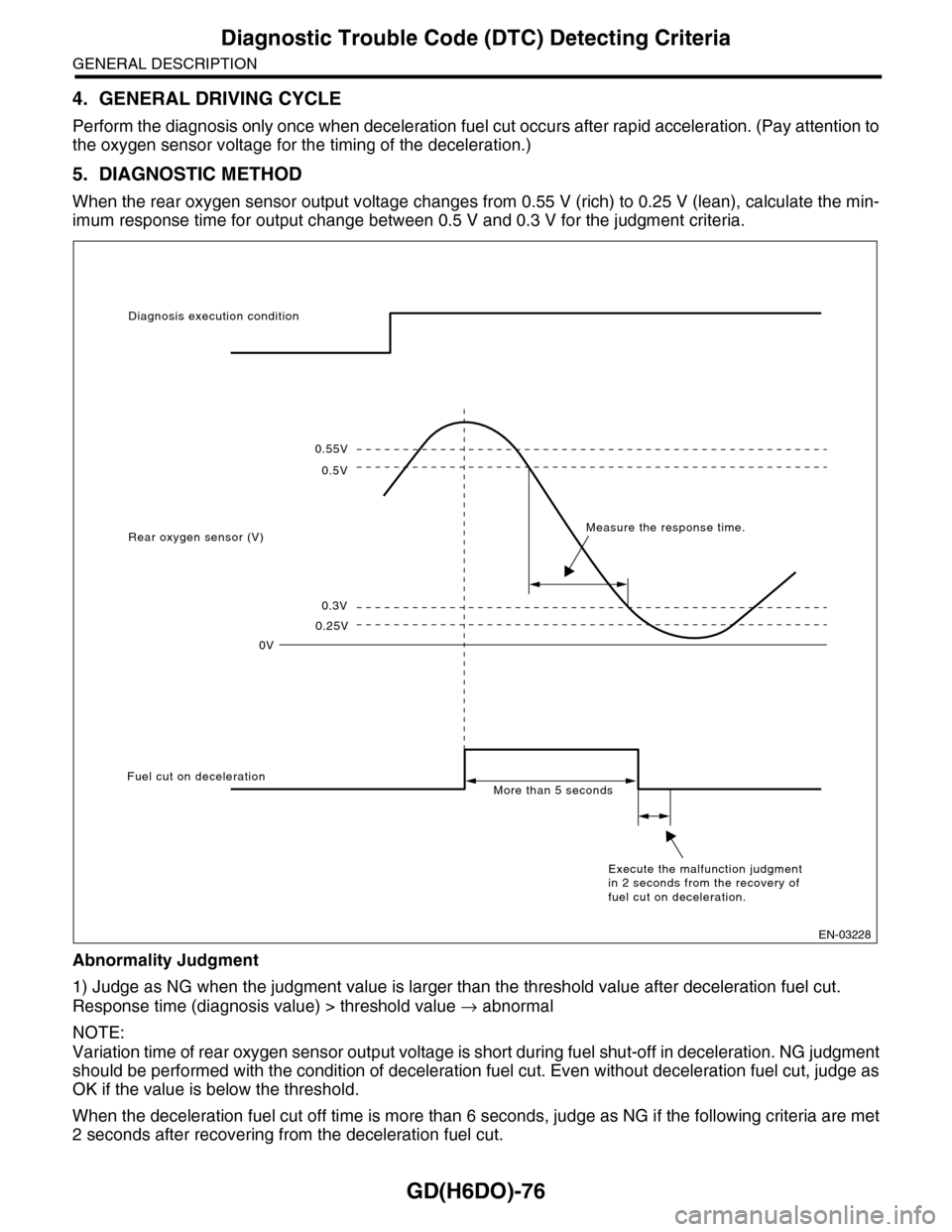

4. GENERAL DRIVING CYCLE

Perform the diagnosis only once when deceleration fuel cut occurs after rapid acceleration. (Pay attention to

the oxygen sensor voltage for the timing of the deceleration.)

5. DIAGNOSTIC METHOD

When the rear oxygen sensor output voltage changes from 0.55 V (rich) to 0.25 V (lean), calculate the min-

imum response time for output change between 0.5 V and 0.3 V for the judgment criteria.

Abnormality Judgment

1) Judge as NG when the judgment value is larger than the threshold value after deceleration fuel cut.

Response time (diagnosis value) > threshold value → abnormal

NOTE:

Variation time of rear oxygen sensor output voltage is short during fuel shut-off in deceleration. NG judgment

should be performed with the condition of deceleration fuel cut. Even without deceleration fuel cut, judge as

OK if the value is below the threshold.

When the deceleration fuel cut off time is more than 6 seconds, judge as NG if the following criteria are met

2 seconds after recovering from the deceleration fuel cut.

0.55V

0.5V

0.3V

0.25V

0V

Diagnosis execution condition

Rear oxygen sensor (V)Measure the response time.

Fuel cut on decelerationMore than 5 seconds

Execute the malfunction judgment in 2 seconds from the recovery of fuel cut on deceleration.

EN-03228

Page 1690 of 2453

GD(H6DO)-78

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

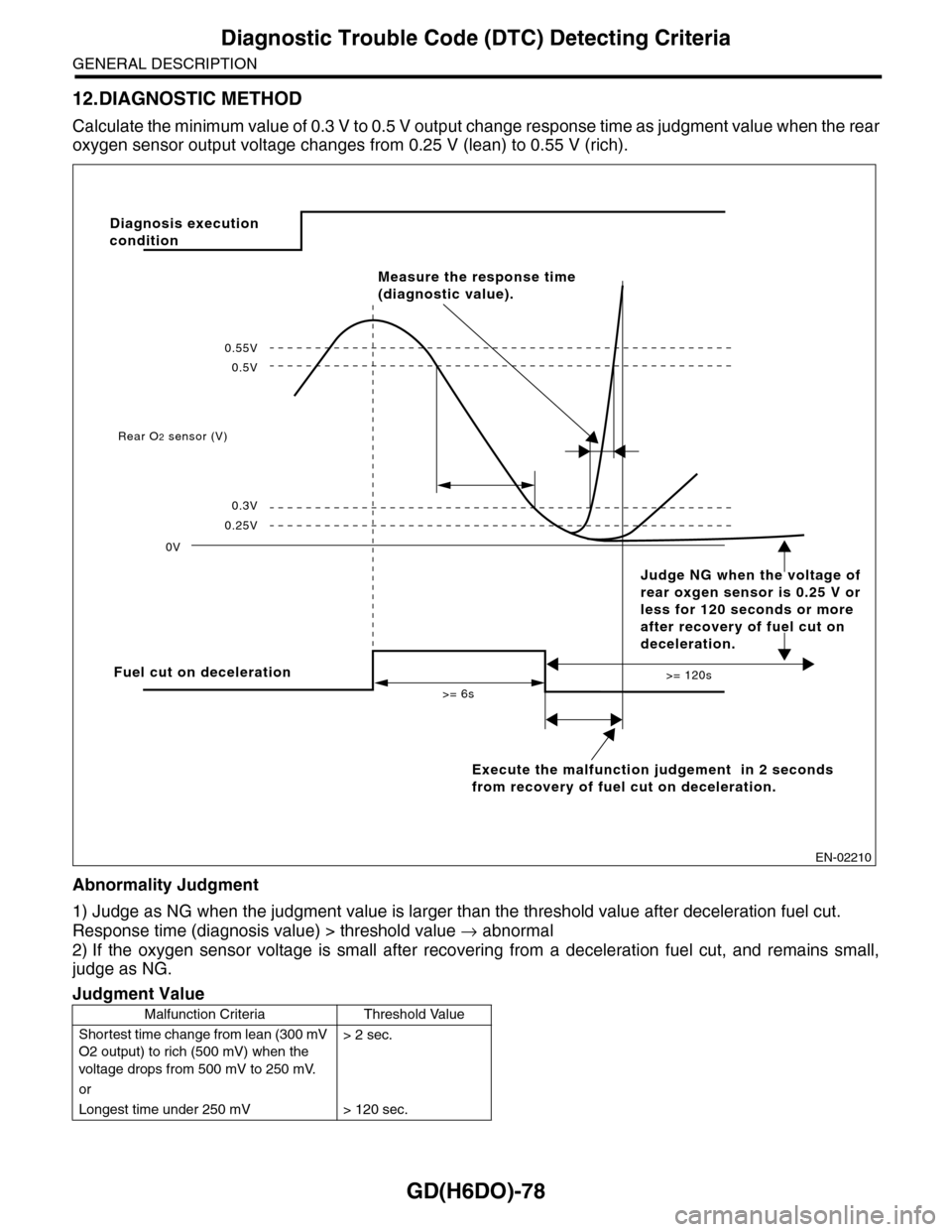

12.DIAGNOSTIC METHOD

Calculate the minimum value of 0.3 V to 0.5 V output ch a n g e r e s p on s e t im e a s ju d g m e n t v a lu e w h en th e re a r

oxygen sensor output voltage changes from 0.25 V (lean) to 0.55 V (rich).

Abnormality Judgment

1) Judge as NG when the judgment value is larger than the threshold value after deceleration fuel cut.

Response time (diagnosis value) > threshold value → abnormal

2) If the oxygen sensor voltage is small after recovering from a deceleration fuel cut, and remains small,

judge as NG.

Judgment Value

Malfunction Criteria Threshold Value

Shortest time change from lean (300 mV

O2 output) to rich (500 mV) when the

voltage drops from 500 mV to 250 mV.

> 2 sec.

or

Longest time under 250 mV > 120 sec.

EN-02210

Fuel cut on deceleration

Execute the malfunction judgement in 2 seconds

from recovery of fuel cut on deceleration.

Rear O2 sensor (V)

0V

>= 6s

>= 120s

0.25V

0.3V

0.5V

0.55V

Measure the response time

(diagnostic value).

Diagnosis execution

condition

Judge NG when the voltage of

rear oxgen sensor is 0.25 V or

less for 120 seconds or more

after recovery of fuel cut on

deceleration.

Page 1734 of 2453

GD(H6DO)-122

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

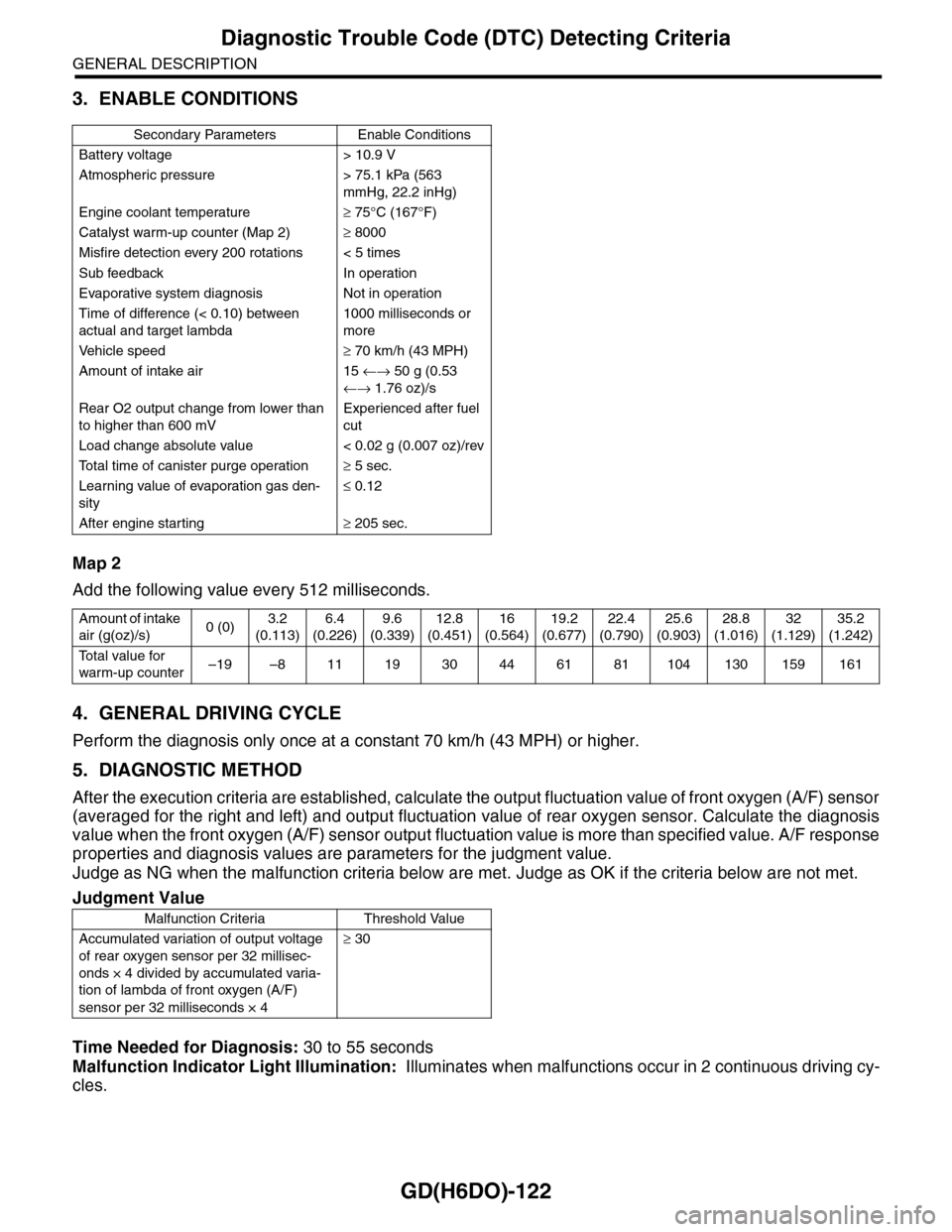

3. ENABLE CONDITIONS

Map 2

Add the following value every 512 milliseconds.

4. GENERAL DRIVING CYCLE

Perform the diagnosis only once at a constant 70 km/h (43 MPH) or higher.

5. DIAGNOSTIC METHOD

After the execution criteria are established, calculate the output fluctuation value of front oxygen (A/F) sensor

(averaged for the right and left) and output fluctuation value of rear oxygen sensor. Calculate the diagnosis

value when the front oxygen (A/F) sensor output fluctuation value is more than specified value. A/F response

properties and diagnosis values are parameters for the judgment value.

Judge as NG when the malfunction criteria below are met. Judge as OK if the criteria below are not met.

Time Needed for Diagnosis: 30 to 55 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Secondary Parameters Enable Conditions

Battery voltage > 10.9 V

Atmospheric pressure > 75.1 kPa (563

mmHg, 22.2 inHg)

Engine coolant temperature≥ 75°C (167°F)

Catalyst warm-up counter (Map 2)≥ 8000

Misfire detection every 200 rotations < 5 times

Sub feedback In operation

Evaporative system diagnosis Not in operation

Time of difference (< 0.10) between

actual and target lambda

1000 milliseconds or

more

Ve h i c l e s p e e d≥ 70 km/h (43 MPH)

Amount of intake air 15 ←→ 50 g (0.53

←→ 1.76 oz)/s

Rear O2 output change from lower than

to higher than 600 mV

Experienced after fuel

cut

Load change absolute value < 0.02 g (0.007 oz)/rev

To t a l t i m e o f c a n i s t e r p u r g e o p e r a t i o n≥ 5 sec.

Learning value of evaporation gas den-

sity

≤ 0.12

After engine starting≥ 205 sec.

Amount of intake

air (g(oz)/s)0 (0)3.2

(0.113)

6.4

(0.226)

9.6

(0.339)

12.8

(0.451)

16

(0.564)

19.2

(0.677)

22.4

(0.790)

25.6

(0.903)

28.8

(1.016)

32

(1.129)

35.2

(1.242)

To t a l v a l u e f o r

warm-up counter–19 –8 11 19 30 44 61 81 104 130 159 161

Judgment Value

Malfunction Criteria Threshold Value

Accumulated variation of output voltage

of rear oxygen sensor per 32 millisec-

onds × 4 divided by accumulated varia-

tion of lambda of front oxygen (A/F)

sensor per 32 milliseconds × 4

≥ 30