ECU SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2078 of 2453

5AT-62

Torque Converter Assembly

AUTOMATIC TRANSMISSION

23.Torque Converter Assembly

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter and oil pump shaft

horizontally.

NOTE:

•Be sure not to scratch the inside of bushing in oil

pump shaft.

•Be careful that the oil pump shaft may drawn out

simultaneously.

3) Remove the oil pump shaft from torque convert-

er as necessary.

B: INSTALLATION

1) When the oil pump shaft is removed, install the

shaft to torque converter.

NOTE:

Make sure the clip is firmly inserted.

2) Install the oil pump shaft to torque converter, and

then make sure that the clip is secured on groove.

3) Apply ATF to the revolving and sliding surface of

the oil pump shaft.

4) Holding the torque converter assembly by hand,

lightly rotate it to engage with the oil pump rotor.

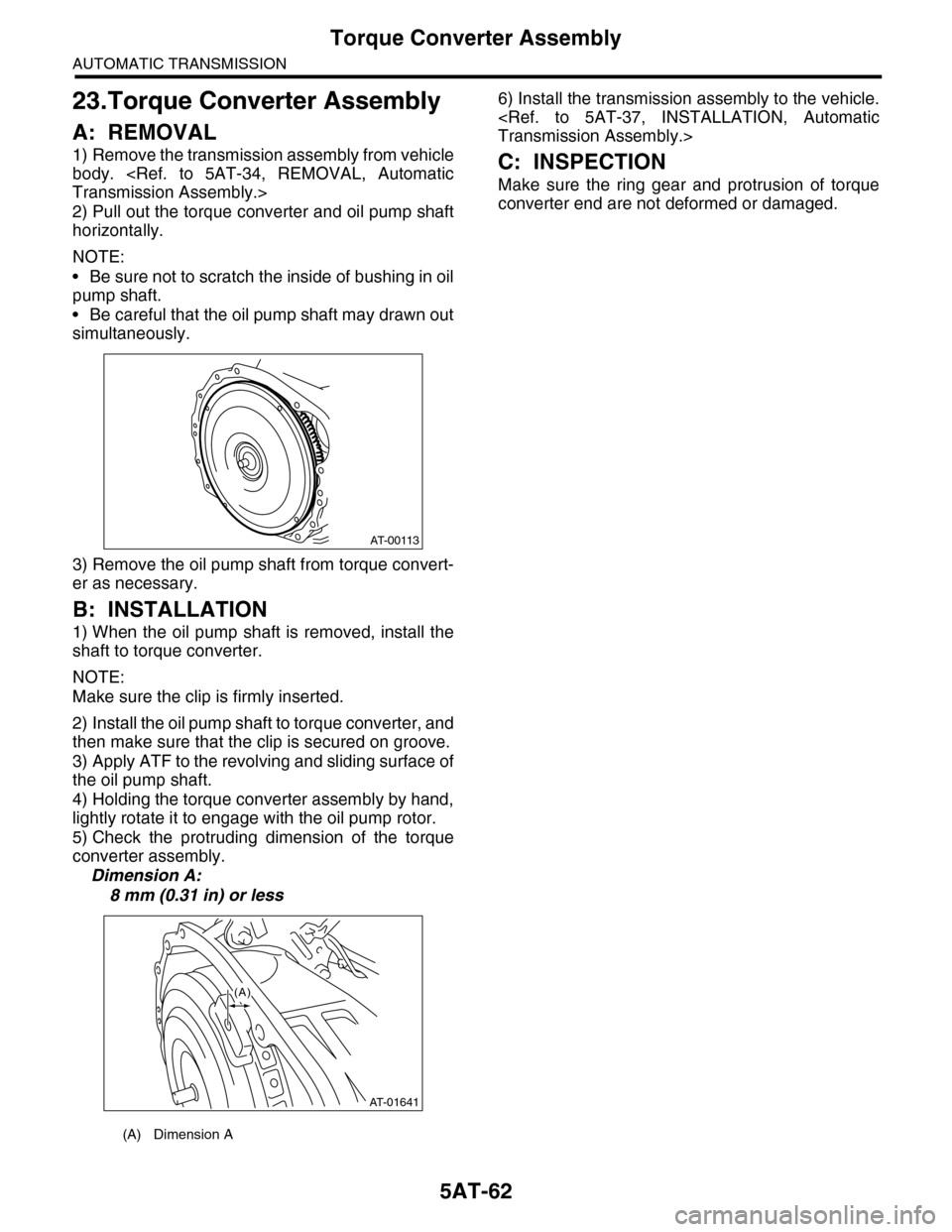

5) Check the protruding dimension of the torque

converter assembly.

Dimension A:

8 mm (0.31 in) or less

6) Install the transmission assembly to the vehicle.

C: INSPECTION

Make sure the ring gear and protrusion of torque

converter end are not deformed or damaged.

(A) Dimension A

AT-00113

AT-01641

(A)

Page 2093 of 2453

5AT-77

Oil Pump Cover

AUTOMATIC TRANSMISSION

31.Oil Pump Cover

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter assembly.

3) Remove the transmission harness connector

from stay.

4) Remove the oil charge pipe.

5) Remove the ATF filter inlet and outlet pipes.

6) Separate the converter case and transmission

case.

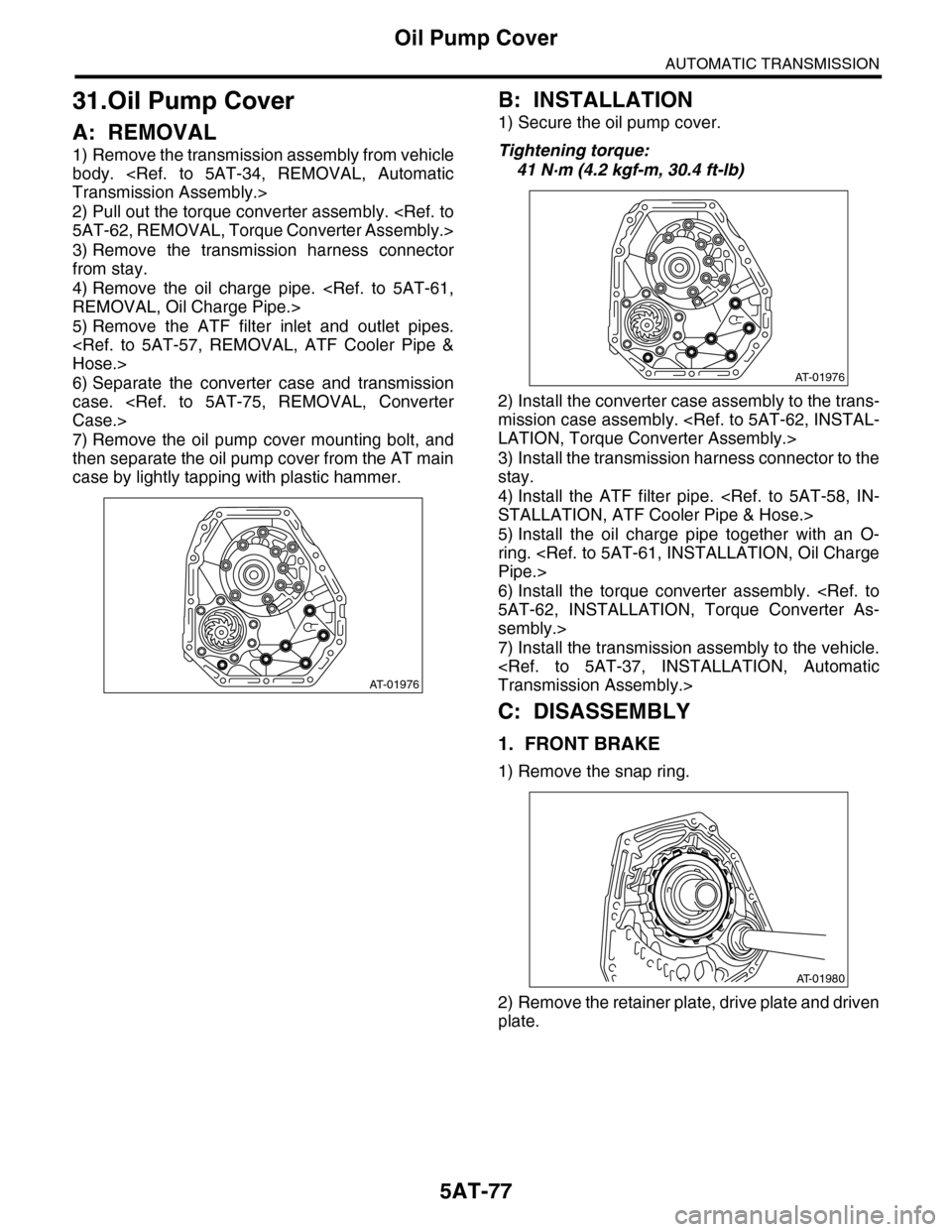

7) Remove the oil pump cover mounting bolt, and

then separate the oil pump cover from the AT main

case by lightly tapping with plastic hammer.

B: INSTALLATION

1) Secure the oil pump cover.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

2) Install the converter case assembly to the trans-

mission case assembly.

3) Install the transmission harness connector to the

stay.

4) Install the ATF filter pipe.

5) Install the oil charge pipe together with an O-

ring.

6) Install the torque converter assembly.

sembly.>

7) Install the transmission assembly to the vehicle.

C: DISASSEMBLY

1. FRONT BRAKE

1) Remove the snap ring.

2) Remove the retainer plate, drive plate and driven

plate.

AT-01976

AT-01976

AT-01980

Page 2099 of 2453

5AT-83

Drive Pinion Shaft Assembly

AUTOMATIC TRANSMISSION

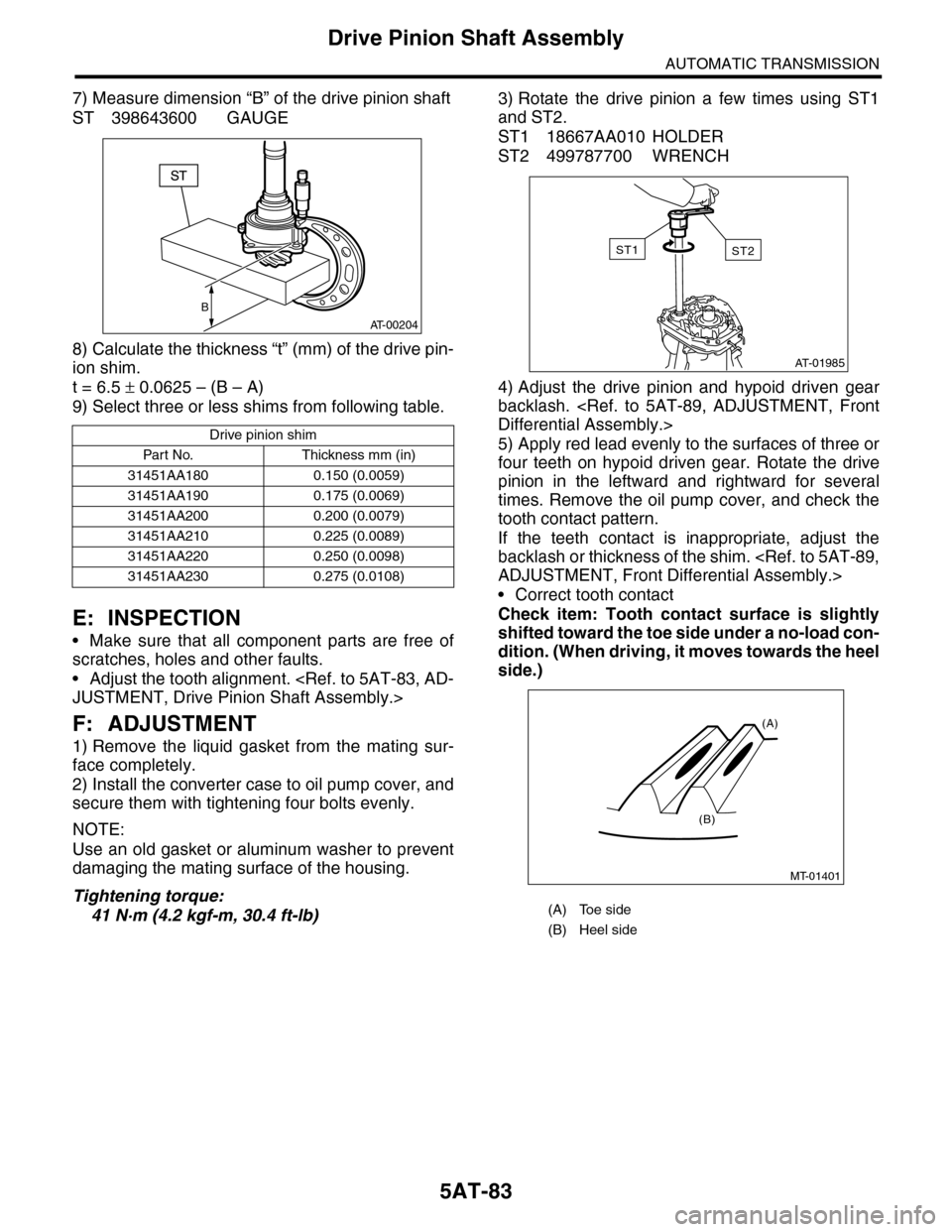

7) Measure dimension “B” of the drive pinion shaft

ST 398643600 GAUGE

8) Calculate the thickness “t” (mm) of the drive pin-

ion shim.

t = 6.5 ± 0.0625 – (B – A)

9) Select three or less shims from following table.

E: INSPECTION

•Make sure that all component parts are free of

scratches, holes and other faults.

•Adjust the tooth alignment.

F: ADJUSTMENT

1) Remove the liquid gasket from the mating sur-

face completely.

2) Install the converter case to oil pump cover, and

secure them with tightening four bolts evenly.

NOTE:

Use an old gasket or aluminum washer to prevent

damaging the mating surface of the housing.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

3) Rotate the drive pinion a few times using ST1

and ST2.

ST1 18667AA010 HOLDER

ST2 499787700 WRENCH

4) Adjust the drive pinion and hypoid driven gear

backlash.

5) Apply red lead evenly to the surfaces of three or

four teeth on hypoid driven gear. Rotate the drive

pinion in the leftward and rightward for several

times. Remove the oil pump cover, and check the

tooth contact pattern.

If the teeth contact is inappropriate, adjust the

backlash or thickness of the shim.

•Correct tooth contact

Check item: Tooth contact surface is slightly

shifted toward the toe side under a no-load con-

dition. (When driving, it moves towards the heel

side.)

Drive pinion shim

Par t No. Thickness mm (in)

31451AA180 0.150 (0.0059)

31451AA190 0.175 (0.0069)

31451AA200 0.200 (0.0079)

31451AA210 0.225 (0.0089)

31451AA220 0.250 (0.0098)

31451AA230 0.275 (0.0108)

B

AT-00204

(A) Toe side

(B) Heel side

AT-01985

ST2ST1

MT-01401

(A)

(B)

Page 2103 of 2453

5AT-87

Front Differential Assembly

AUTOMATIC TRANSMISSION

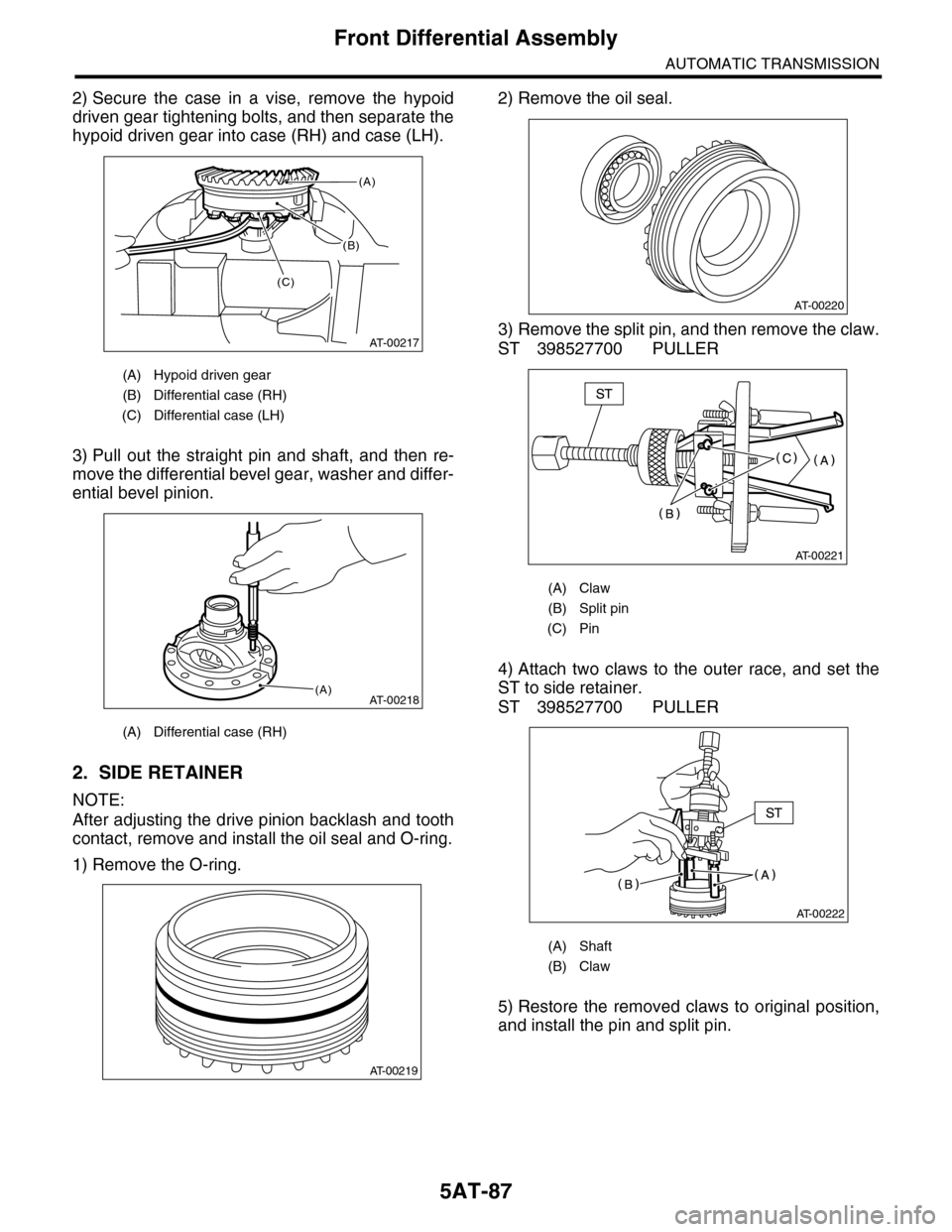

2) Secure the case in a vise, remove the hypoid

driven gear tightening bolts, and then separate the

hypoid driven gear into case (RH) and case (LH).

3) Pull out the straight pin and shaft, and then re-

move the differential bevel gear, washer and differ-

ential bevel pinion.

2. SIDE RETAINER

NOTE:

After adjusting the drive pinion backlash and tooth

contact, remove and install the oil seal and O-ring.

1) Remove the O-ring.

2) Remove the oil seal.

3) Remove the split pin, and then remove the claw.

ST 398527700 PULLER

4) Attach two claws to the outer race, and set the

ST to side retainer.

ST 398527700 PULLER

5) Restore the removed claws to original position,

and install the pin and split pin.

(A) Hypoid driven gear

(B) Differential case (RH)

(C) Differential case (LH)

(A) Differential case (RH)

(B)

AT-00217

(A)

(C)

AT-00218(A)

AT-00219

(A) Claw

(B) Split pin

(C) Pin

(A) Shaft

(B) Claw

AT-00220

AT-00221

AT-00222

Page 2104 of 2453

5AT-88

Front Differential Assembly

AUTOMATIC TRANSMISSION

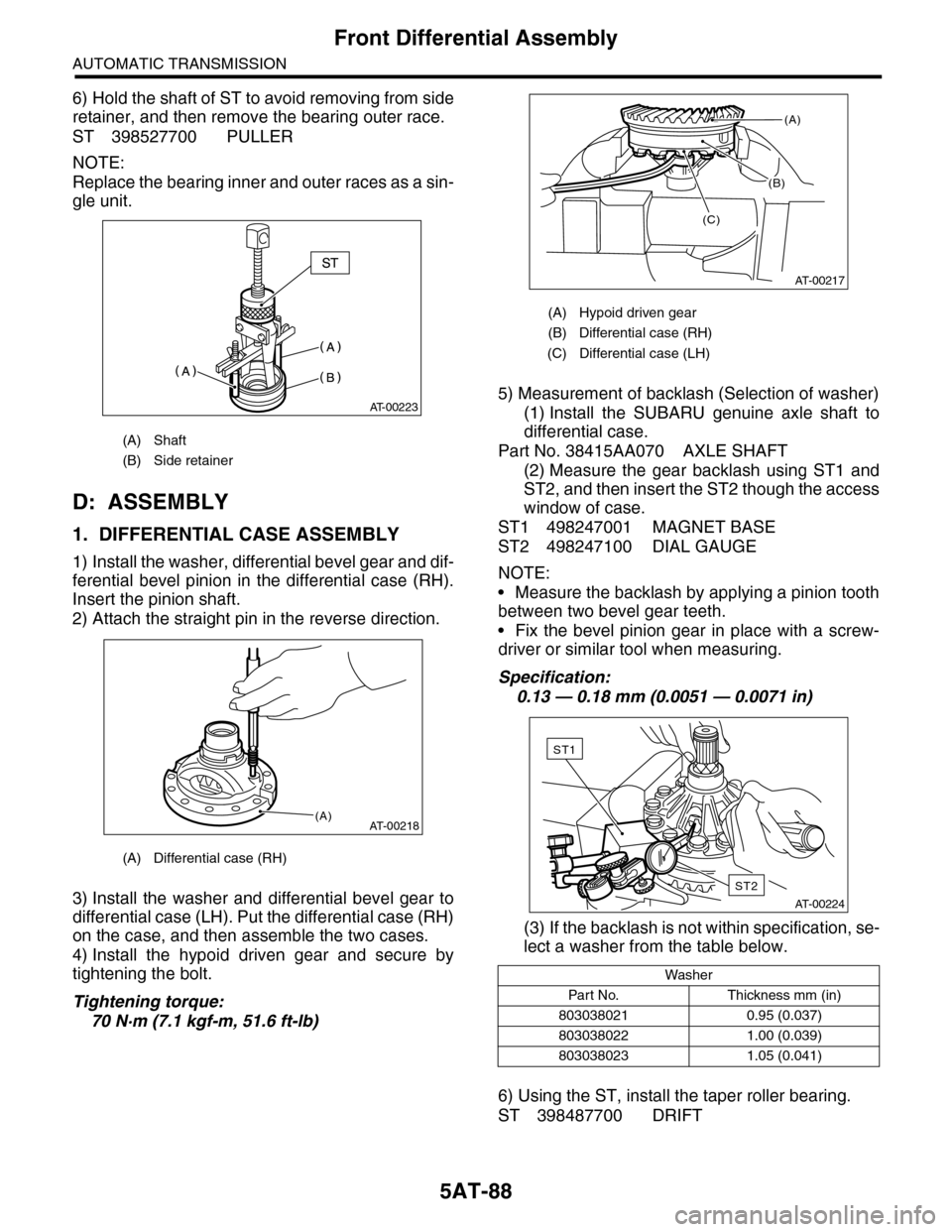

6) Hold the shaft of ST to avoid removing from side

retainer, and then remove the bearing outer race.

ST 398527700 PULLER

NOTE:

Replace the bearing inner and outer races as a sin-

gle unit.

D: ASSEMBLY

1. DIFFERENTIAL CASE ASSEMBLY

1) Install the washer, differential bevel gear and dif-

ferential bevel pinion in the differential case (RH).

Insert the pinion shaft.

2) Attach the straight pin in the reverse direction.

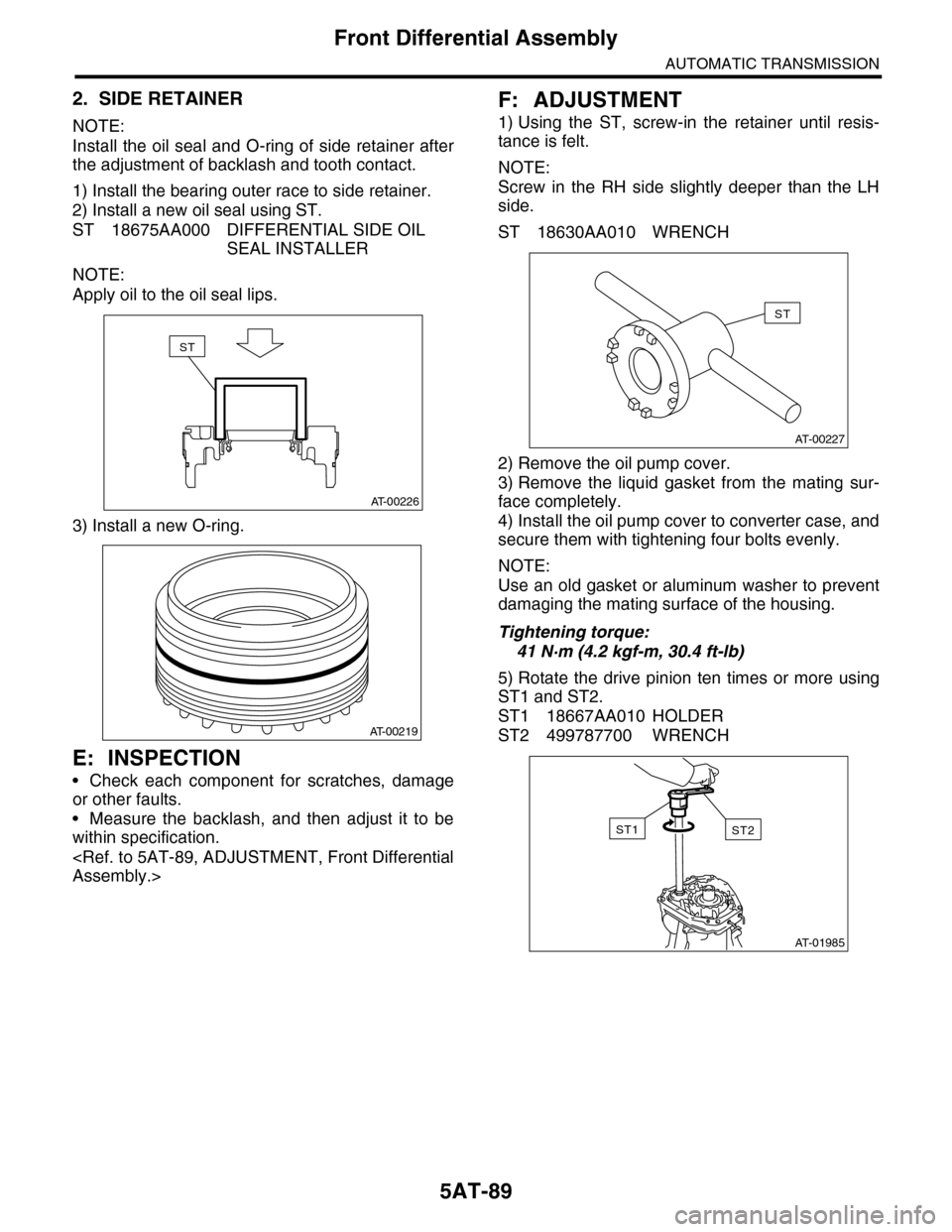

3) Install the washer and differential bevel gear to

differential case (LH). Put the differential case (RH)

on the case, and then assemble the two cases.

4) Install the hypoid driven gear and secure by

tightening the bolt.

Tightening torque:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

5) Measurement of backlash (Selection of washer)

(1) Install the SUBARU genuine axle shaft to

differential case.

Part No. 38415AA070 AXLE SHAFT

(2) Measure the gear backlash using ST1 and

ST2, and then insert the ST2 though the access

window of case.

ST1 498247001 MAGNET BASE

ST2 498247100 DIAL GAUGE

NOTE:

•Measure the backlash by applying a pinion tooth

between two bevel gear teeth.

•Fix the bevel pinion gear in place with a screw-

driver or similar tool when measuring.

Specification:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

(3) If the backlash is not within specification, se-

lect a washer from the table below.

6) Using the ST, install the taper roller bearing.

ST 398487700 DRIFT

(A) Shaft

(B) Side retainer

(A) Differential case (RH)

AT-00223

AT-00218(A)

(A) Hypoid driven gear

(B) Differential case (RH)

(C) Differential case (LH)

Washer

Par t N o. Thickness mm (in)

803038021 0.95 (0.037)

803038022 1.00 (0.039)

803038023 1.05 (0.041)

(B)

AT-00217

(A)

(C)

AT-00224

ST2

ST1

Page 2105 of 2453

5AT-89

Front Differential Assembly

AUTOMATIC TRANSMISSION

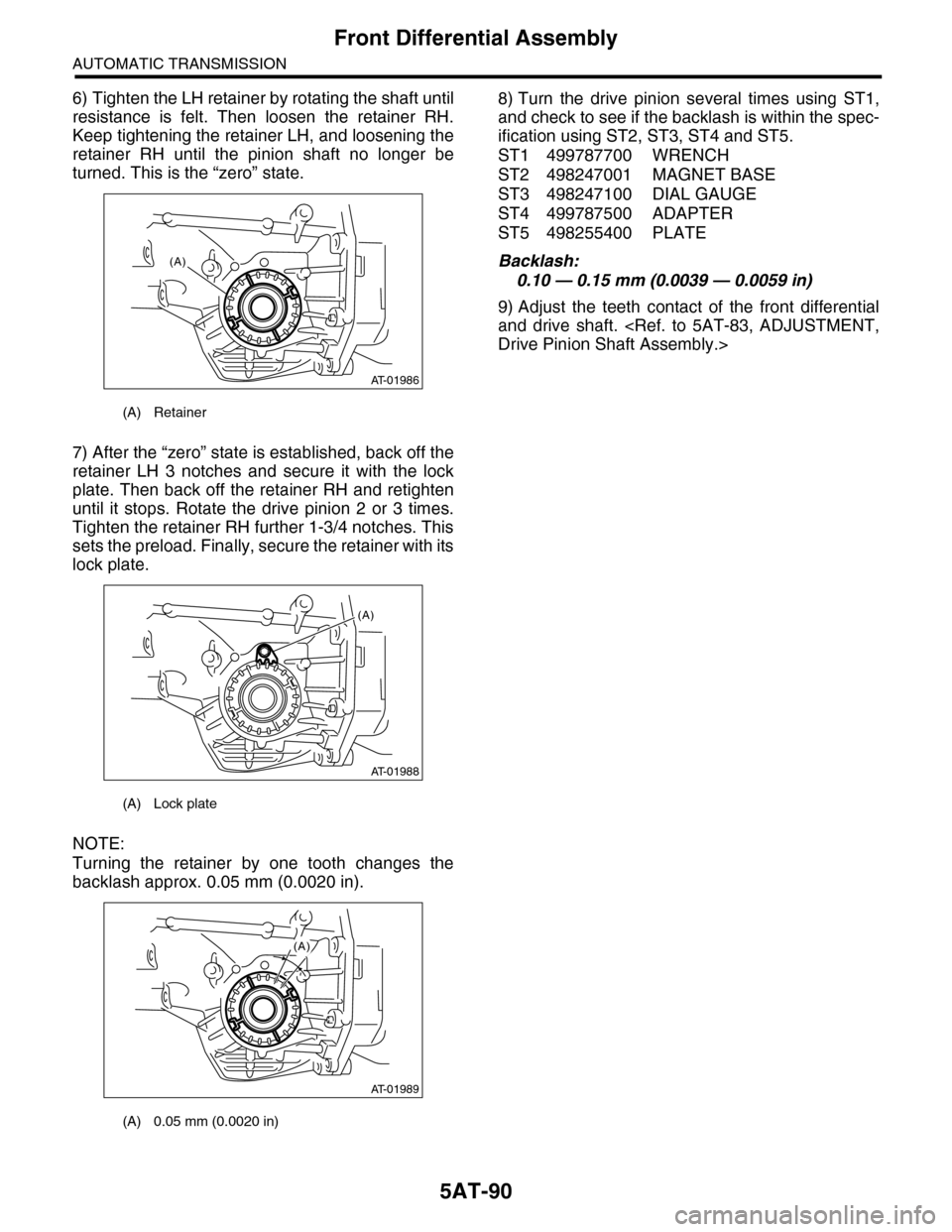

2. SIDE RETAINER

NOTE:

Install the oil seal and O-ring of side retainer after

the adjustment of backlash and tooth contact.

1) Install the bearing outer race to side retainer.

2) Install a new oil seal using ST.

ST 18675AA000 DIFFERENTIAL SIDE OIL

SEAL INSTALLER

NOTE:

Apply oil to the oil seal lips.

3) Install a new O-ring.

E: INSPECTION

•Check each component for scratches, damage

or other faults.

•Measure the backlash, and then adjust it to be

within specification.

F: ADJUSTMENT

1) Using the ST, screw-in the retainer until resis-

tance is felt.

NOTE:

Screw in the RH side slightly deeper than the LH

side.

ST 18630AA010 WRENCH

2) Remove the oil pump cover.

3) Remove the liquid gasket from the mating sur-

face completely.

4) Install the oil pump cover to converter case, and

secure them with tightening four bolts evenly.

NOTE:

Use an old gasket or aluminum washer to prevent

damaging the mating surface of the housing.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

5) Rotate the drive pinion ten times or more using

ST1 and ST2.

ST1 18667AA010 HOLDER

ST2 499787700 WRENCH

AT-00226

ST

AT-00219

AT-00227

ST

AT-01985

ST2ST1

Page 2106 of 2453

5AT-90

Front Differential Assembly

AUTOMATIC TRANSMISSION

6) Tighten the LH retainer by rotating the shaft until

resistance is felt. Then loosen the retainer RH.

Keep tightening the retainer LH, and loosening the

retainer RH until the pinion shaft no longer be

turned. This is the “zero” state.

7) After the “zero” state is established, back off the

retainer LH 3 notches and secure it with the lock

plate. Then back off the retainer RH and retighten

until it stops. Rotate the drive pinion 2 or 3 times.

Tighten the retainer RH further 1-3/4 notches. This

sets the preload. Finally, secure the retainer with its

lock plate.

NOTE:

Turning the retainer by one tooth changes the

backlash approx. 0.05 mm (0.0020 in).

8) Turn the drive pinion several times using ST1,

and check to see if the backlash is within the spec-

ification using ST2, ST3, ST4 and ST5.

ST1 499787700 WRENCH

ST2 498247001 MAGNET BASE

ST3 498247100 DIAL GAUGE

ST4 499787500 ADAPTER

ST5 498255400 PLATE

Backlash:

0.10 — 0.15 mm (0.0039 — 0.0059 in)

9) Adjust the teeth contact of the front differential

and drive shaft.

(A) Retainer

(A) Lock plate

(A) 0.05 mm (0.0020 in)

AT-01986

(A)

AT-01988

(A)

AT-01989

(A)

Page 2113 of 2453

5AT-97

AT Main Case

AUTOMATIC TRANSMISSION

24) Install the extension case.

25) Install the control valve body.

26) Install the converter case assembly to the

transmission case assembly.

27) Install the air breather hose.

28) Install the ATF filter pipe.

29) Install the oil charge pipe together with an O-

ring.

30) Install the torque converter assembly.

sembly.>

31) Install the transmission assembly to the vehi-

cle.

32) Perform Clear Memory 2 operation.

TION, Subaru Select Monitor.>

33) Perform the inspection with driving the vehicle

at the end of repair work, and make sure there is no

faulty as below;

•Excessive shift shock

•Oil leakage from the transmission body, etc.

•Occurrence of noise caused by interference etc.

NOTE:

If excessive shift shock is felt, execute advance op-

eration of learning control.

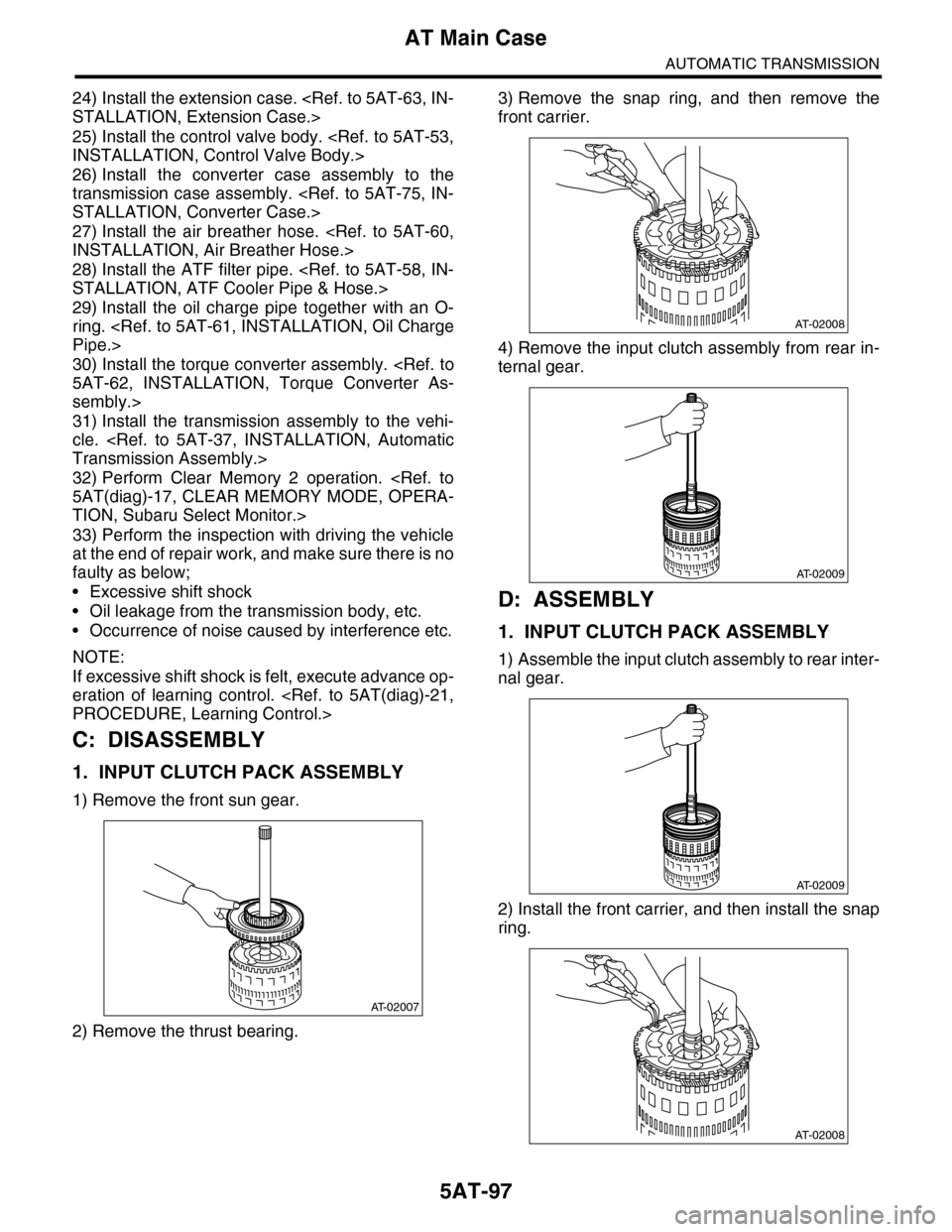

C: DISASSEMBLY

1. INPUT CLUTCH PACK ASSEMBLY

1) Remove the front sun gear.

2) Remove the thrust bearing.

3) Remove the snap ring, and then remove the

front carrier.

4) Remove the input clutch assembly from rear in-

ternal gear.

D: ASSEMBLY

1. INPUT CLUTCH PACK ASSEMBLY

1) Assemble the input clutch assembly to rear inter-

nal gear.

2) Install the front carrier, and then install the snap

ring.

AT-02007

AT-02008

AT-02009

AT-02009

AT-02008

Page 2116 of 2453

5AT-100

Transmission Control Device

AUTOMATIC TRANSMISSION

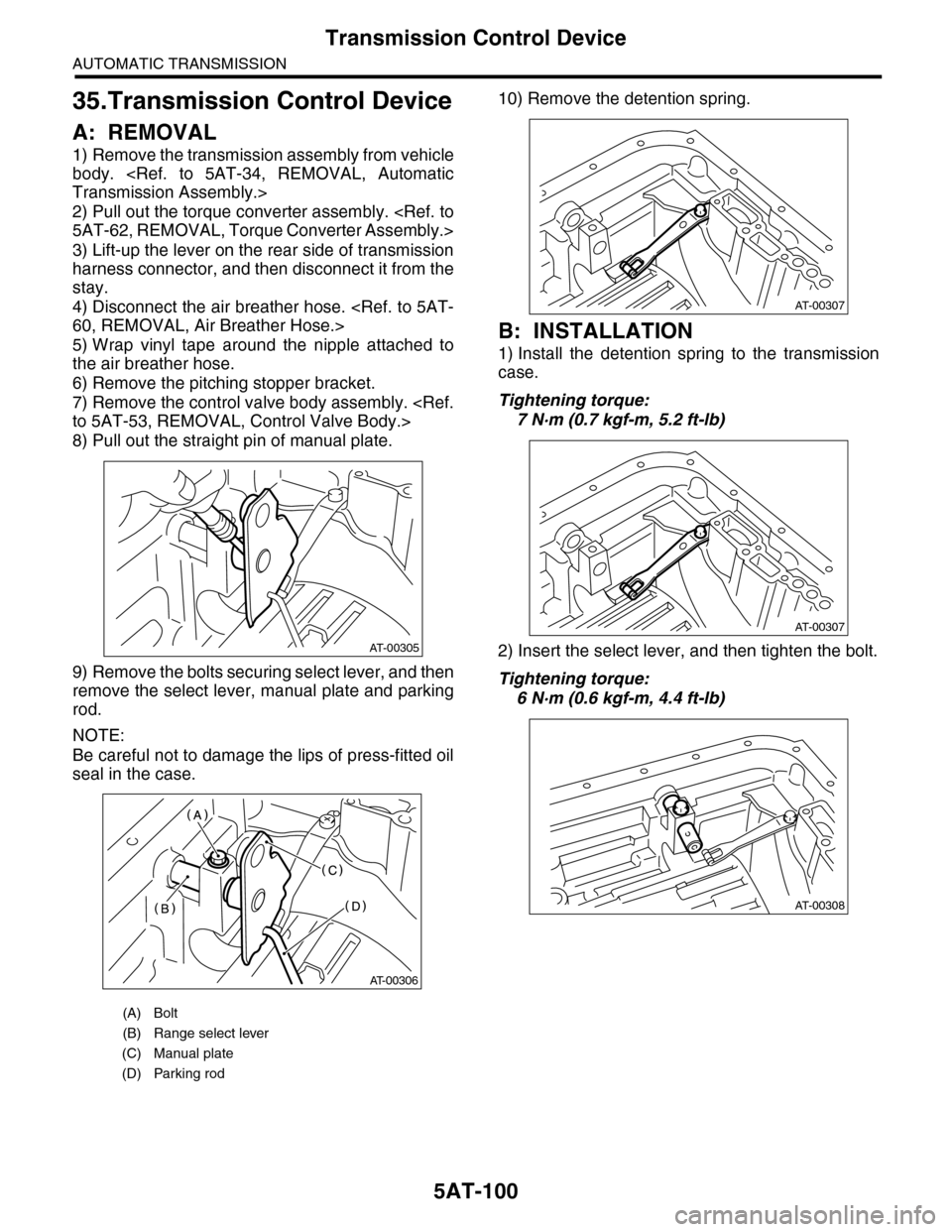

35.Transmission Control Device

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter assembly.

3) Lift-up the lever on the rear side of transmission

harness connector, and then disconnect it from the

stay.

4) Disconnect the air breather hose.

5) Wrap vinyl tape around the nipple attached to

the air breather hose.

6) Remove the pitching stopper bracket.

7) Remove the control valve body assembly.

8) Pull out the straight pin of manual plate.

9) Remove the bolts securing select lever, and then

remove the select lever, manual plate and parking

rod.

NOTE:

Be careful not to damage the lips of press-fitted oil

seal in the case.

10) Remove the detention spring.

B: INSTALLATION

1) Install the detention spring to the transmission

case.

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

2) Insert the select lever, and then tighten the bolt.

Tightening torque:

6 N·m (0.6 kgf-m, 4.4 ft-lb)

(A) Bolt

(B) Range select lever

(C) Manual plate

(D) Parking rod

AT-00305

AT-00306

AT-00307

AT-00307

AT-00308

Page 2119 of 2453

5AT(diag)-2

Basic Diagnostic Procedure

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

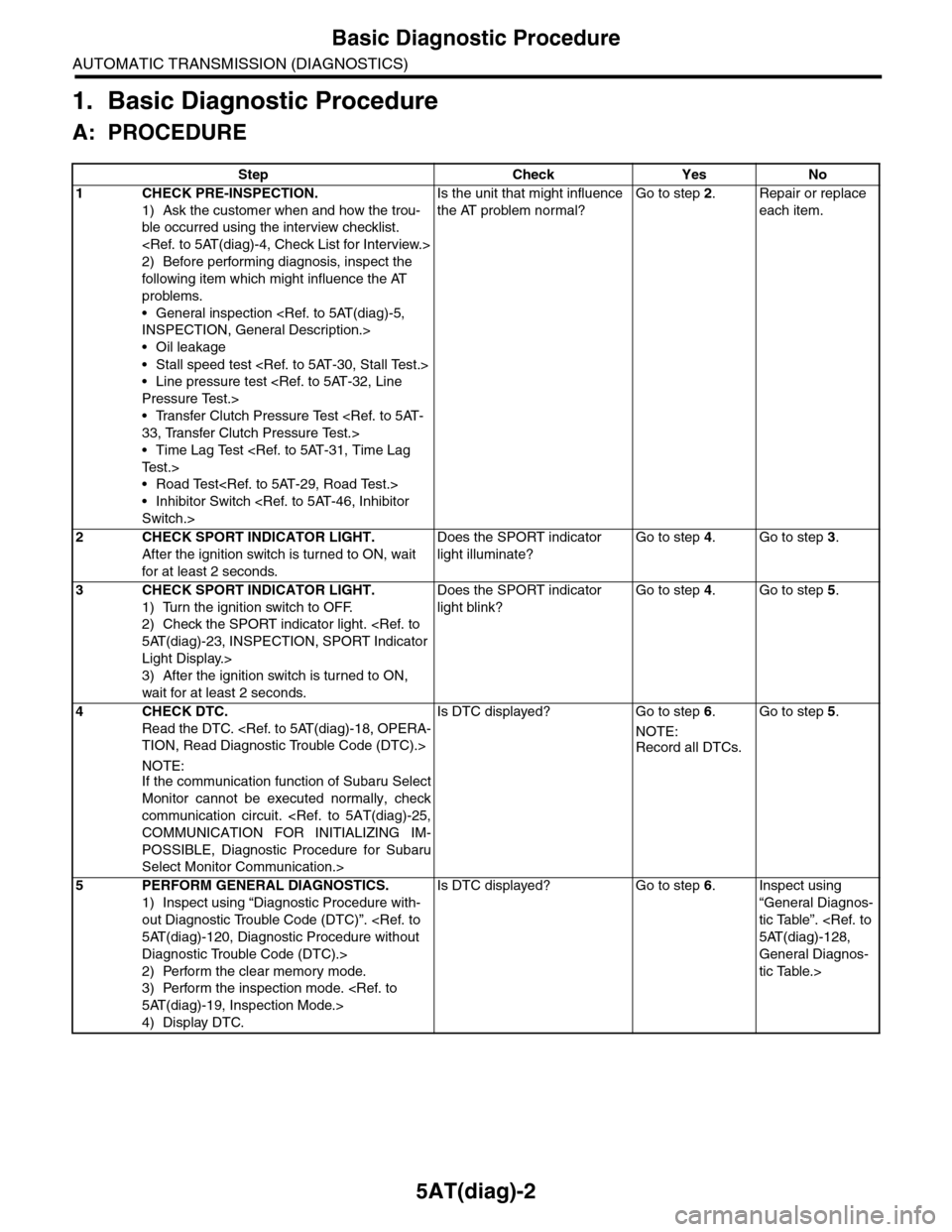

1. Basic Diagnostic Procedure

A: PROCEDURE

Step Check Yes No

1CHECK PRE-INSPECTION.

1) Ask the customer when and how the trou-

ble occurred using the interview checklist.

2) Before performing diagnosis, inspect the

following item which might influence the AT

problems.

•General inspection

•Oil leakage

•Stall speed test

•Line pressure test

•Transfer Clutch Pressure Test

•Time Lag Test

•Road Test

•Inhibitor Switch

Is the unit that might influence

the AT problem normal?

Go to step 2.Repair or replace

each item.

2CHECK SPORT INDICATOR LIGHT.

After the ignition switch is turned to ON, wait

for at least 2 seconds.

Does the SPORT indicator

light illuminate?

Go to step 4.Go to step 3.

3CHECK SPORT INDICATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Check the SPORT indicator light.

Light Display.>

3) After the ignition switch is turned to ON,

wait for at least 2 seconds.

Does the SPORT indicator

light blink?

Go to step 4.Go to step 5.

4CHECK DTC.

Read the DTC.

NOTE:If the communication function of Subaru Select

Monitor cannot be executed normally, check

communication circuit.

POSSIBLE, Diagnostic Procedure for Subaru

Select Monitor Communication.>

Is DTC displayed? Go to step 6.

NOTE:

Record all DTCs.

Go to step 5.

5PERFORM GENERAL DIAGNOSTICS.

1) Inspect using “Diagnostic Procedure with-

out Diagnostic Trouble Code (DTC)”.

Diagnostic Trouble Code (DTC).>

2) Perform the clear memory mode.

3) Perform the inspection mode.

4) Display DTC.

Is DTC displayed? Go to step 6.Inspect using

“General Diagnos-

tic Table”.

General Diagnos-

tic Table.>