ac 25 procedure SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 182 of 2453

CC(ETC)(diag)-15

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

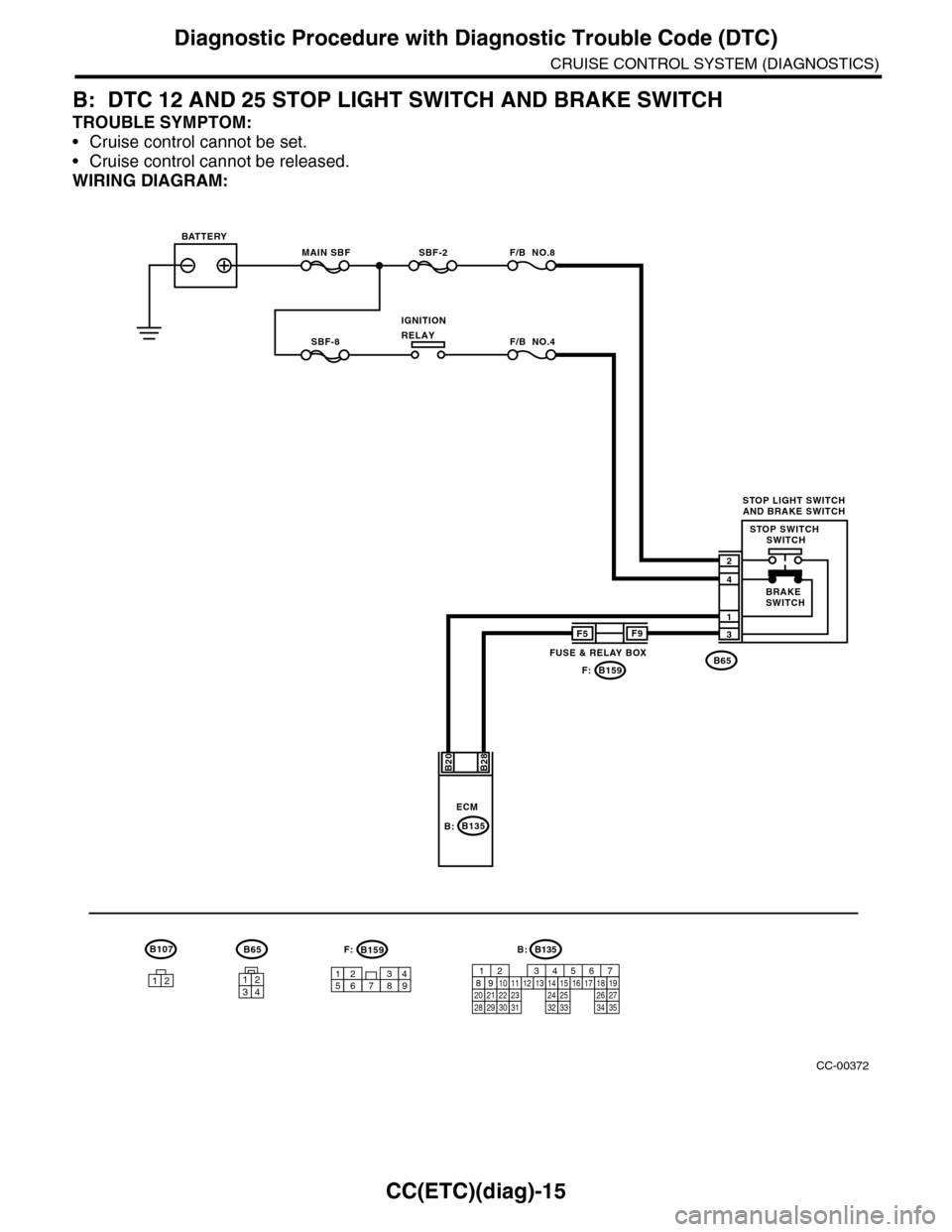

B: DTC 12 AND 25 STOP LIGHT SWITCH AND BRAKE SWITCH

TROUBLE SYMPTOM:

•Cruise control cannot be set.

•Cruise control cannot be released.

WIRING DIAGRAM:

CC-00372

B65

MAIN SBFSBF-2 F/B NO.8

B65

4

3

1

2

B28B20

1234

SBF-8 F/B NO.4

F5

B159

F9

F:

947621538

B159F:

ECM

BATTERY

STOP LIGHT SWITCHAND BRAKE SWITCH

BRAKESWITCH

STOP SWITCH SWITCH

IGNITIONRELAY

FUSE & RELAY BOX

12

B107

B135B:

B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

B:

Page 183 of 2453

CC(ETC)(diag)-16

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

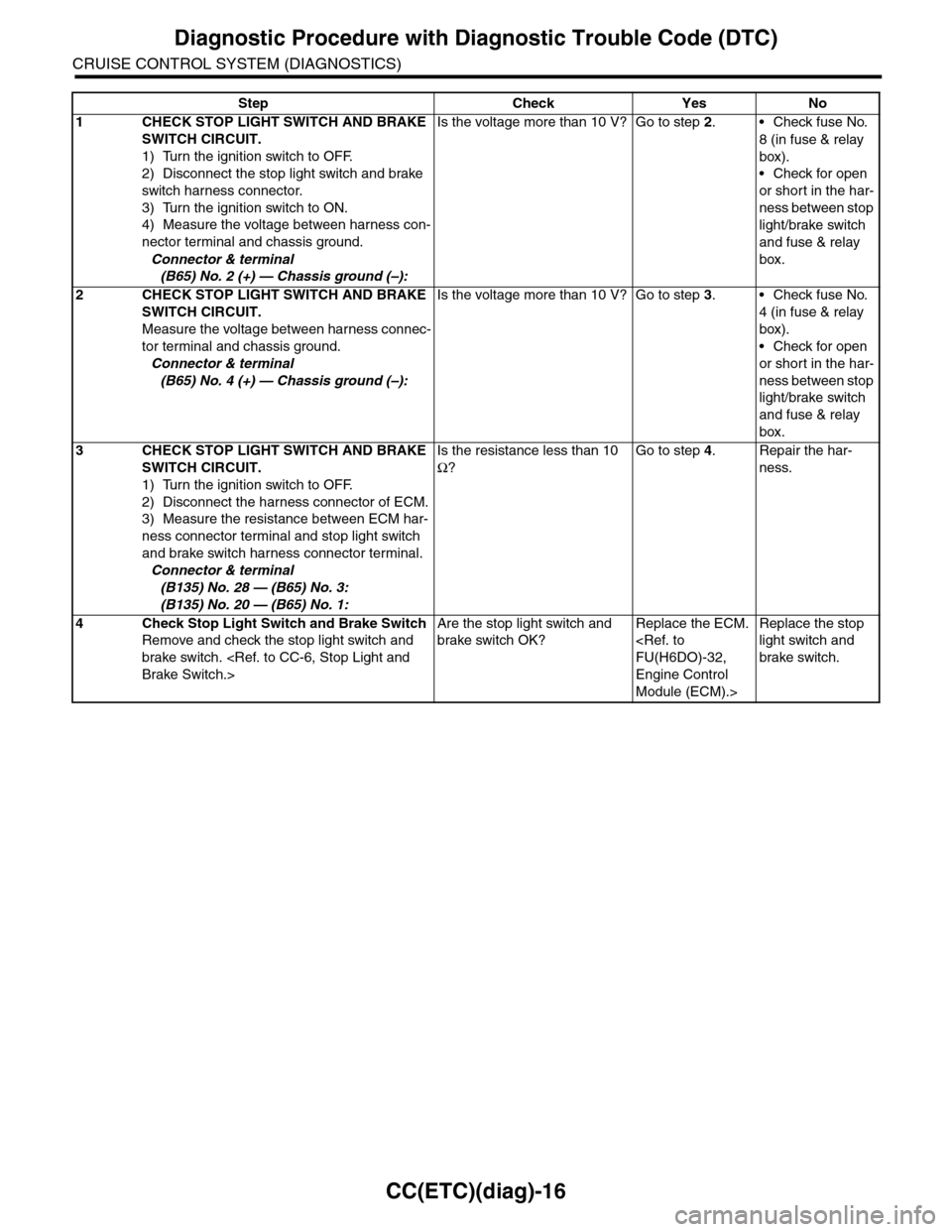

Step Check Yes No

1CHECK STOP LIGHT SWITCH AND BRAKE

SWITCH CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the stop light switch and brake

switch harness connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between harness con-

nector terminal and chassis ground.

Connector & terminal

(B65) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.•Check fuse No.

8 (in fuse & relay

box).

•Check for open

or short in the har-

ness between stop

light/brake switch

and fuse & relay

box.

2CHECK STOP LIGHT SWITCH AND BRAKE

SWITCH CIRCUIT.

Measure the voltage between harness connec-

tor terminal and chassis ground.

Connector & terminal

(B65) No. 4 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 3.•Check fuse No.

4 (in fuse & relay

box).

•Check for open

or short in the har-

ness between stop

light/brake switch

and fuse & relay

box.

3CHECK STOP LIGHT SWITCH AND BRAKE

SWITCH CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector of ECM.

3) Measure the resistance between ECM har-

ness connector terminal and stop light switch

and brake switch harness connector terminal.

Connector & terminal

(B135) No. 28 — (B65) No. 3:

(B135) No. 20 — (B65) No. 1:

Is the resistance less than 10

Ω?

Go to step 4.Repair the har-

ness.

4Check Stop Light Switch and Brake Switch

Remove and check the stop light switch and

brake switch.

Are the stop light switch and

brake switch OK?

Replace the ECM.

Engine Control

Module (ECM).>

Replace the stop

light switch and

brake switch.

Page 184 of 2453

CC(ETC)(diag)-17

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

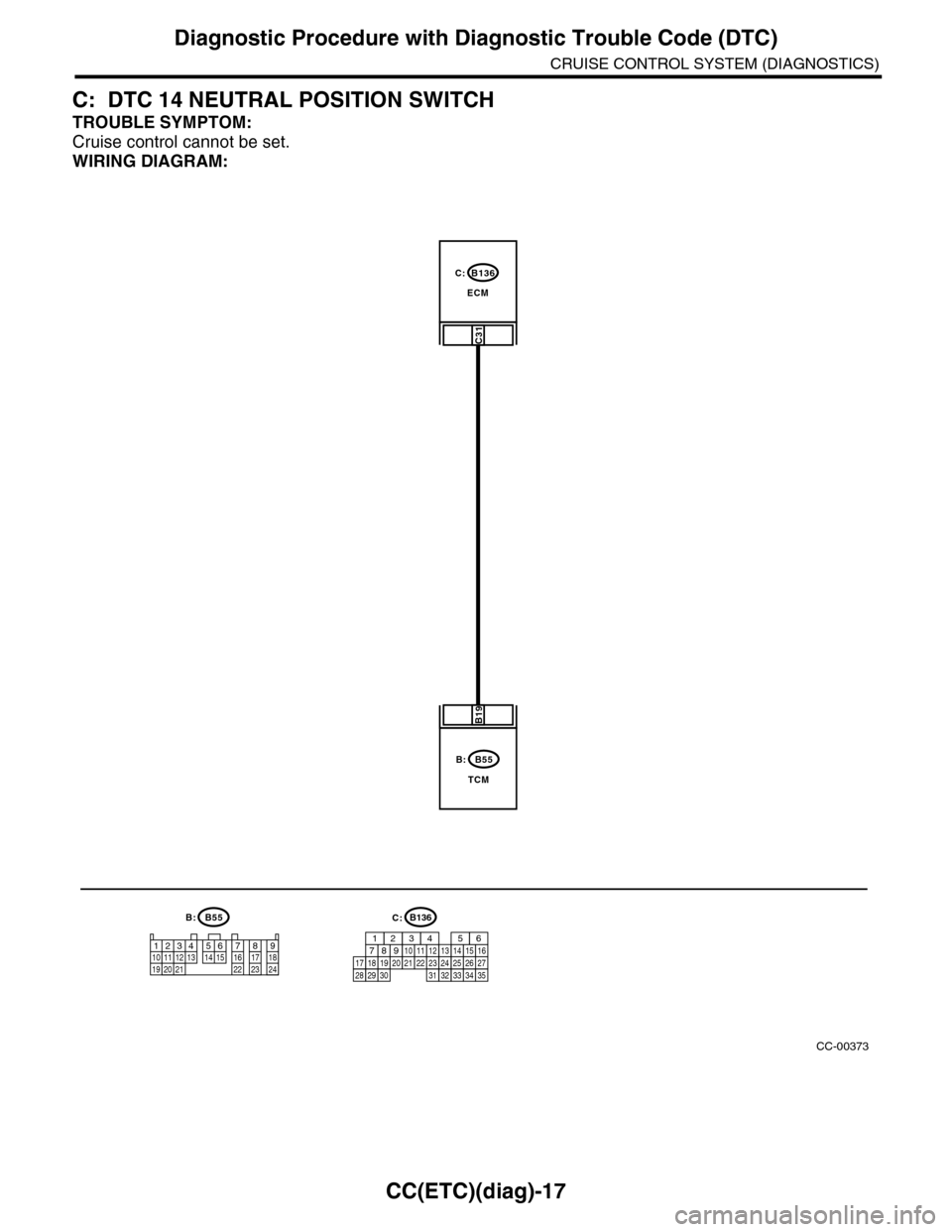

C: DTC 14 NEUTRAL POSITION SWITCH

TROUBLE SYMPTOM:

Cruise control cannot be set.

WIRING DIAGRAM:

CC-00373

B136

ECM

C31

C:

B19

B55

TCM

B:

12341011 1219 20 21135614 1578916 17 1822 23 24

B55B:C:B136

16101112131415252430

9871718192028212223293231

123456

2726333435

Page 185 of 2453

CC(ETC)(diag)-18

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

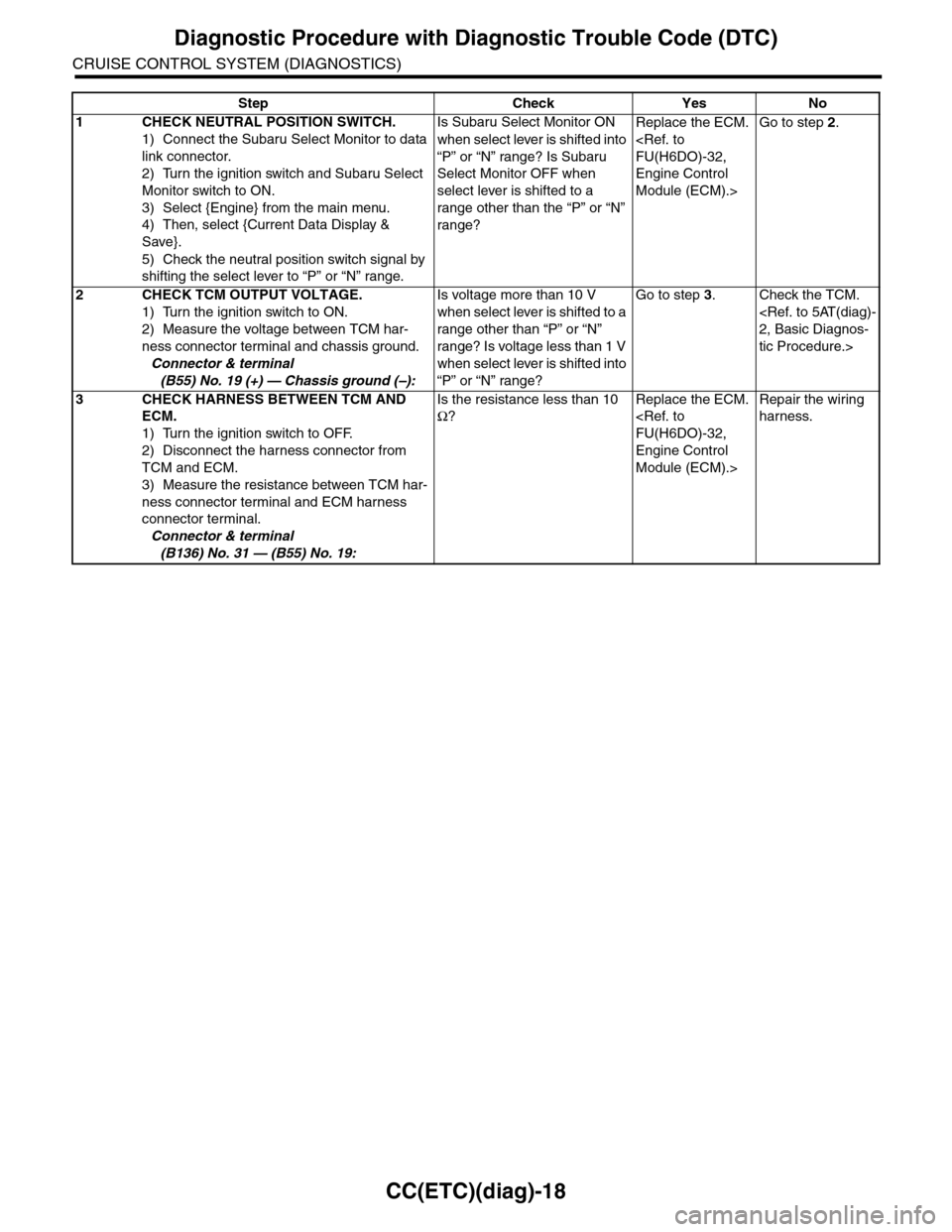

Step Check Yes No

1CHECK NEUTRAL POSITION SWITCH.

1) Connect the Subaru Select Monitor to data

link connector.

2) Turn the ignition switch and Subaru Select

Monitor switch to ON.

3) Select {Engine} from the main menu.

4) Then, select {Current Data Display &

Save}.

5) Check the neutral position switch signal by

shifting the select lever to “P” or “N” range.

Is Subaru Select Monitor ON

when select lever is shifted into

“P” or “N” range? Is Subaru

Select Monitor OFF when

select lever is shifted to a

range other than the “P” or “N”

range?

Replace the ECM.

Engine Control

Module (ECM).>

Go to step 2.

2CHECK TCM OUTPUT VOLTAGE.

1) Turn the ignition switch to ON.

2) Measure the voltage between TCM har-

ness connector terminal and chassis ground.

Connector & terminal

(B55) No. 19 (+) — Chassis ground (–):

Is voltage more than 10 V

when select lever is shifted to a

range other than “P” or “N”

range? Is voltage less than 1 V

when select lever is shifted into

“P” or “N” range?

Go to step 3.Check the TCM.

tic Procedure.>

3CHECK HARNESS BETWEEN TCM AND

ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector from

TCM and ECM.

3) Measure the resistance between TCM har-

ness connector terminal and ECM harness

connector terminal.

Connector & terminal

(B136) No. 31 — (B55) No. 19:

Is the resistance less than 10

Ω?

Replace the ECM.

Engine Control

Module (ECM).>

Repair the wiring

harness.

Page 186 of 2453

CC(ETC)(diag)-19

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

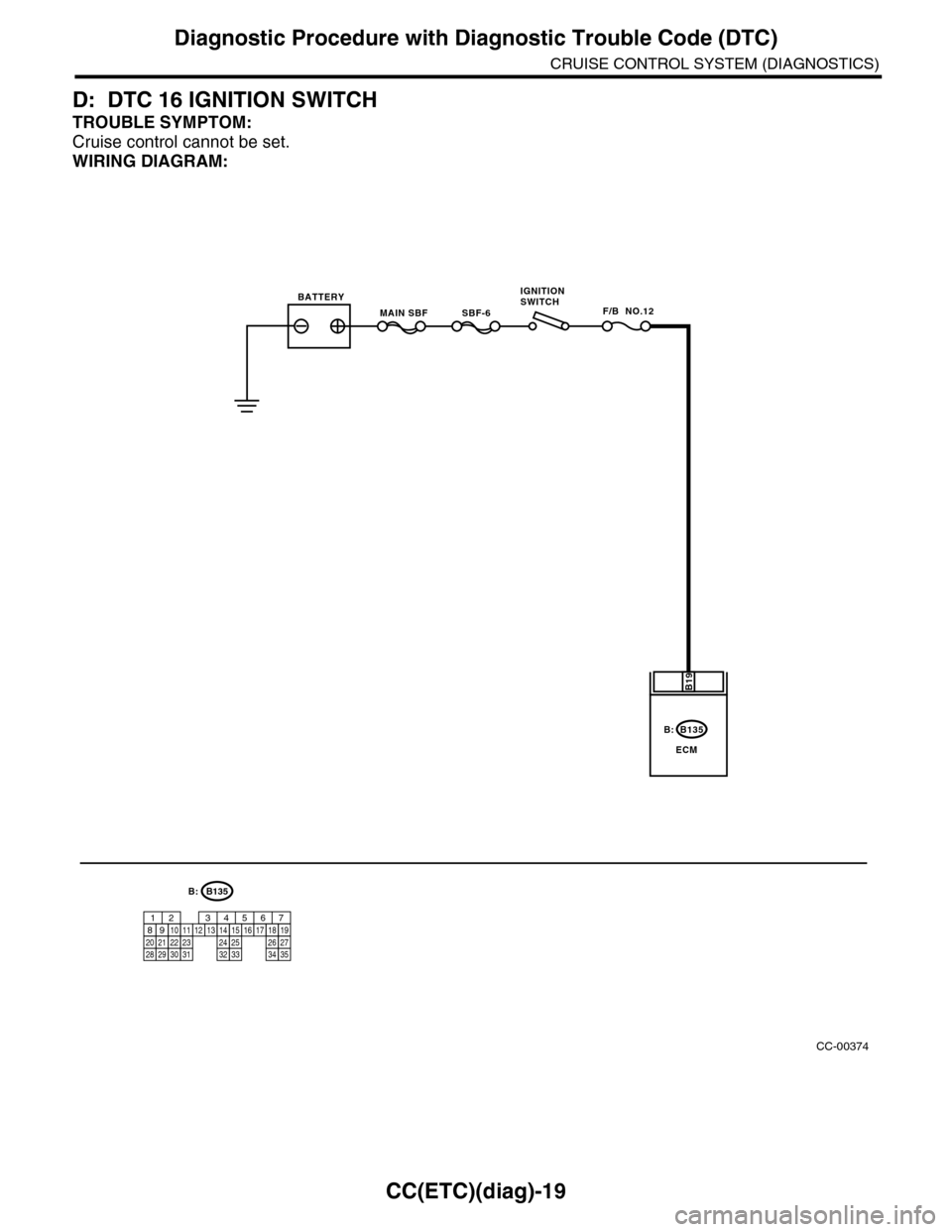

D: DTC 16 IGNITION SWITCH

TROUBLE SYMPTOM:

Cruise control cannot be set.

WIRING DIAGRAM:

CC-00374

B135

ECM

B19

B:

MAIN SBFF/B NO.12SBF-6

BATTERYIGNITIONSWITCH

B:B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

Page 187 of 2453

CC(ETC)(diag)-20

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

CRUISE CONTROL SYSTEM (DIAGNOSTICS)

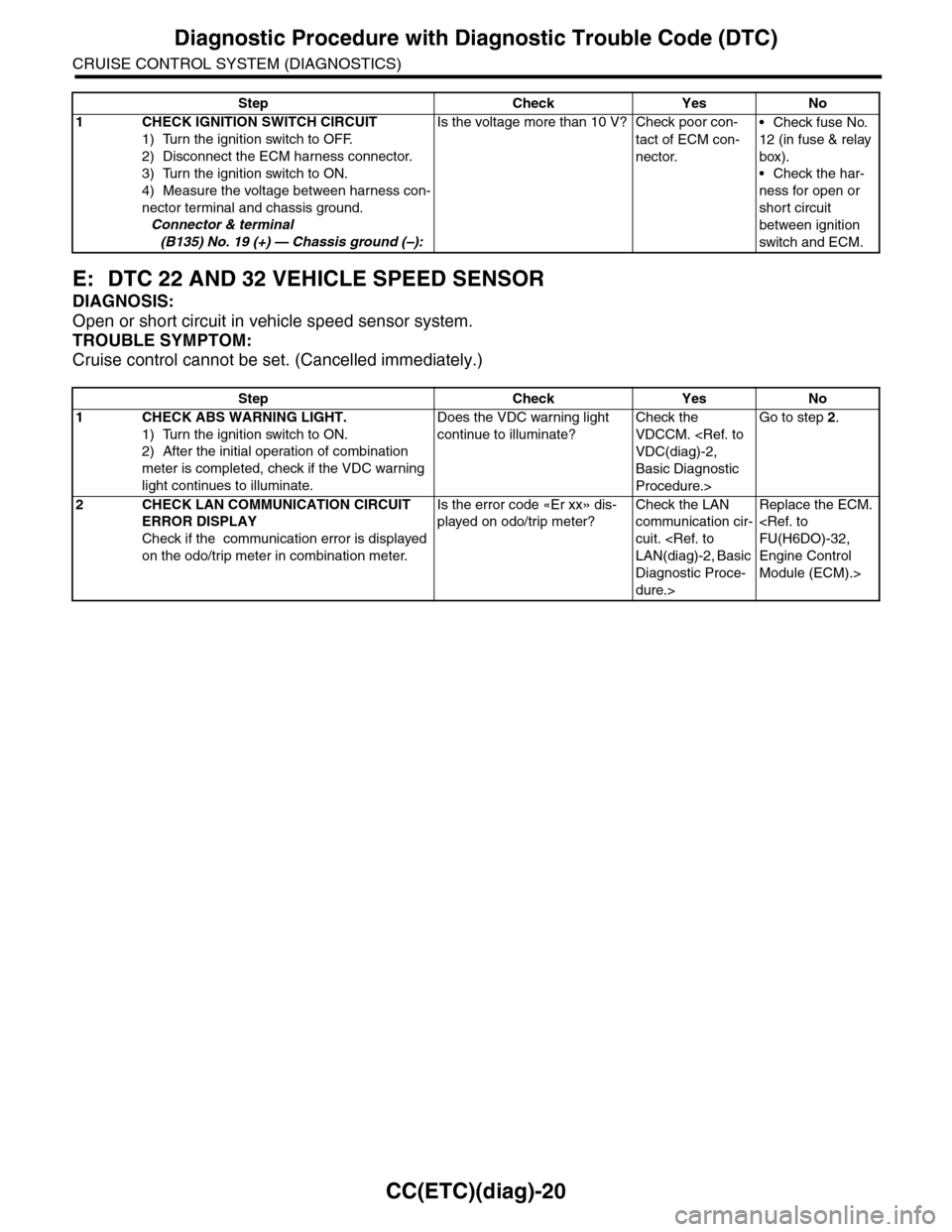

E: DTC 22 AND 32 VEHICLE SPEED SENSOR

DIAGNOSIS:

Open or short circuit in vehicle speed sensor system.

TROUBLE SYMPTOM:

Cruise control cannot be set. (Cancelled immediately.)

Step Check Yes No

1 CHECK IGNITION SWITCH CIRCUIT

1) Turn the ignition switch to OFF.

2) Disconnect the ECM harness connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between harness con-

nector terminal and chassis ground.

Connector & terminal

(B135) No. 19 (+) — Chassis ground (–):

Is the voltage more than 10 V? Check poor con-

tact of ECM con-

nector.

•Check fuse No.

12 (in fuse & relay

box).

•Check the har-

ness for open or

short circuit

between ignition

switch and ECM.

Step Check Yes No

1CHECK ABS WARNING LIGHT.

1) Turn the ignition switch to ON.

2) After the initial operation of combination

meter is completed, check if the VDC warning

light continues to illuminate.

Does the VDC warning light

continue to illuminate?

Check the

VDCCM.

Basic Diagnostic

Procedure.>

Go to step 2.

2CHECK LAN COMMUNICATION CIRCUIT

ERROR DISPLAY

Check if the communication error is displayed

on the odo/trip meter in combination meter.

Is the error code «Er xx» dis-

played on odo/trip meter?

Check the LAN

communication cir-

cuit.

Diagnostic Proce-

dure.>

Replace the ECM.

Engine Control

Module (ECM).>

Page 188 of 2453

ET-2

General Description

ENTERTAINMENT

1. General Description

A: CAUTION

•Before disassembling or reassembling parts, al-

ways disconnect the battery ground cable from bat-

tery.

•When replacing the audio, control module and

other parts provided with memory functions, record

the memory contents before disconnecting the bat-

tery ground cable. Otherwise, the memory is

cleared.

•Reassemble the parts in the reverse order of dis-

assembly procedure unless otherwise indicated.

•Adjust parts to the given specifications.

•Connect the connectors securely during reas-

sembly.

•After reassembly, make sure functional parts op-

erate smoothly.

B: PREPARATION TOOL

1. GENERAL TOOL

TOOL NAME REMARKS

Circuit Tester Used for measuring resis-

tance and voltage.

Conductive silver composition

(DUPONT No. 4817 or equiv-

alent)

Used for repairing antenna

wire.

Page 233 of 2453

EB-14

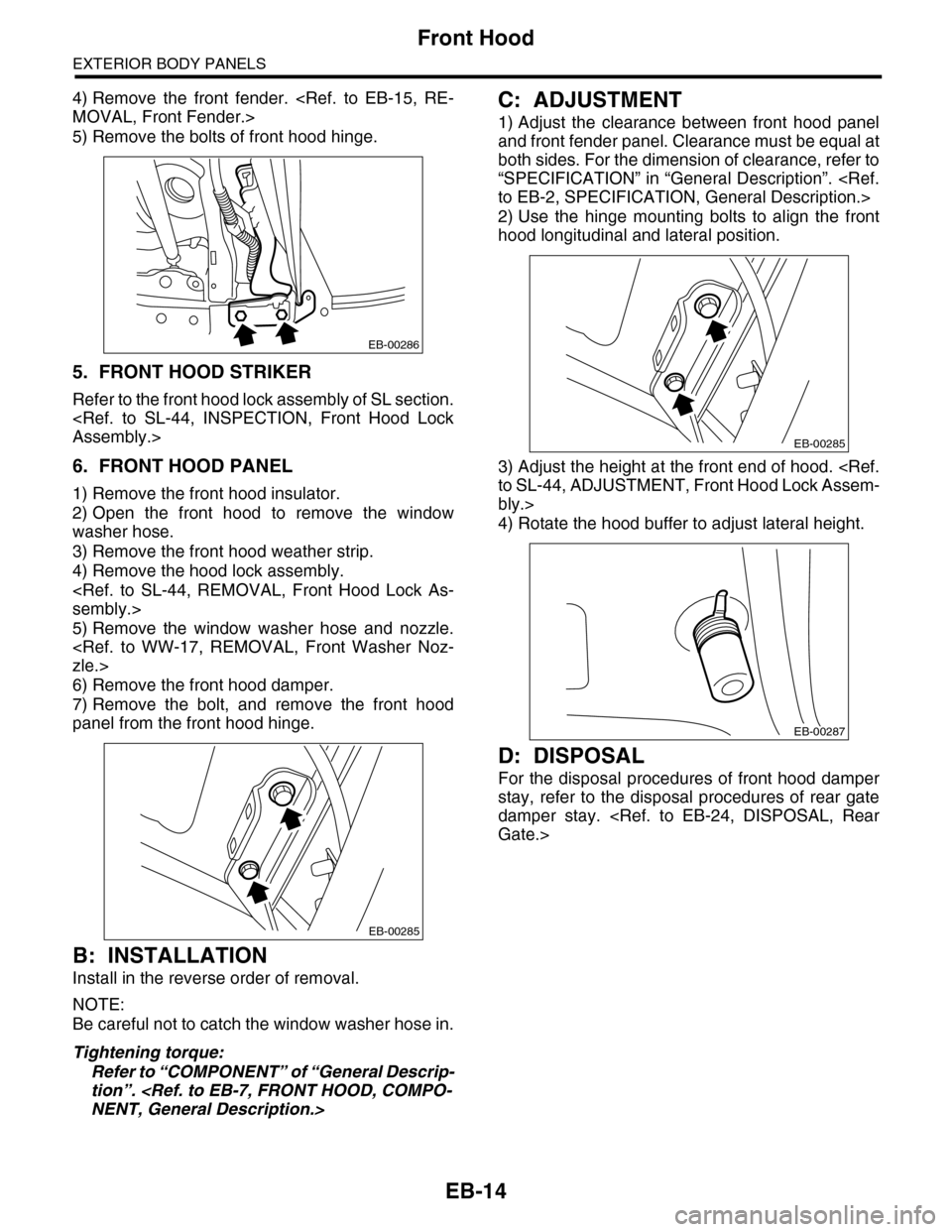

Front Hood

EXTERIOR BODY PANELS

4) Remove the front fender.

5) Remove the bolts of front hood hinge.

5. FRONT HOOD STRIKER

Refer to the front hood lock assembly of SL section.

6. FRONT HOOD PANEL

1) Remove the front hood insulator.

2) Open the front hood to remove the window

washer hose.

3) Remove the front hood weather strip.

4) Remove the hood lock assembly.

5) Remove the window washer hose and nozzle.

6) Remove the front hood damper.

7) Remove the bolt, and remove the front hood

panel from the front hood hinge.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Be careful not to catch the window washer hose in.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion”.

C: ADJUSTMENT

1) Adjust the clearance between front hood panel

and front fender panel. Clearance must be equal at

both sides. For the dimension of clearance, refer to

“SPECIFICATION” in “General Description”.

2) Use the hinge mounting bolts to align the front

hood longitudinal and lateral position.

3) Adjust the height at the front end of hood.

bly.>

4) Rotate the hood buffer to adjust lateral height.

D: DISPOSAL

For the disposal procedures of front hood damper

stay, refer to the disposal procedures of rear gate

damper stay.

EB-00286

EB-00285

EB-00285

EB-00287

Page 265 of 2453

EI-23

Front Bumper

EXTERIOR/INTERIOR TRIM

C: REPAIR

1. COATING METHOD FOR PP BUMPER

Process

No.Process name Job contents

1Bumper installation

Place the bumper on a paint worktable as

required. Use the paint worktable conforming

to inner shape of bumper if possible.

(1) Bumper

(2) Set bumper section

2MaskingMask specified part (black base) with masking tape. Use masking tape for PP (example,

Nichiban No. 533, etc. ).

3Degreasing/cleaningClean all parts to be painted with white gasoline, normal alcohol, etc. to remove dirt, oil, fat, etc.

4Primer paint Apply primer to all parts to be painted, using spray gun. Use primer (clear).

5Drying

Dry at normal temperature [10 — 15 min. at 20°C (68°F)].

In half-dried condition, PP primer paint is dissolved by solvent, e.g. thinner, etc.

Therefore, if dust or dirt must be removed, use ordinary alcohol etc.

6Top coat paint (I)

Non-colored Metallic paint

Use section (block) paint for top coat.

•Paint to be used (for each color):

Solid paint

Hardener PB

Thinner T-301

•Mixture ratio:

Main agent vs. hardener = 4:1

• Viscosity: 10 — 13 sec./20°C (68°F)

•Film thickness: 35 — 45 µ

•Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

Use section (block) paint for top coat.

•Paint to be used (for each color):

Metallic paint

Hardener PB

Thinner T-306

•Mixture ratio:

Main agent vs. hardener = 10:1

•Viscosity: 10 — 13 sec./20°C (68°F)

•Film thickness: 15 — 20 µ

•Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

7Drying Not required.

Dry at normal temperature [at least 10 min. at

20°C (68°F)].

In half-dried condition, avoid dust, dirt.

8Top coat paint (II)Not required.

Apply a clear coat to parts with top coat paint

(I), three times at 5 — 7 minutes intervals.

•Paint to be used:

Metallic paint

Hardener PB

Thinner T-301

•Mixture ratio:

Clear coat vs. hardener = 6:1

•Viscosity: 14 — 16 sec./20°C (68°F)

•Film thickness: 25 — 30 µ

•Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

9Drying

60°C (140°F), 60 min. or 80°C (176°F), 30 min.

If higher than 80°C (176°F), PP may become be deformed. Keep maximum temperature below

80°C (176°F).

10 Inspection Check paint.

11 Removal of masking Remove the masking tape applied in procedure 2.

EI-00234(2)

(1)

Page 267 of 2453

EI-25

Front Bumper

EXTERIOR/INTERIOR TRIM

3) Deep damage such as a break or hole that requires filling

Much of the peripheral grained surface must be sacrificed for repair. The degree of restoration is not really

worth the expense. (The surface, however, will become almost flush with adjacent areas. )

Recommended repair kit: PP Part Repair Kit (NRM)

Process

No.Process name Job contents

1Bumper removalRemove the bumper as required.

2Removal of partsRemove the parts built into bumper as required.

3Bumper placement

Place the bumper on a paint worktable as

required.

It is recommended to use the paint worktable

conforming to internal shape of bumper.

(1) Bumper

(2) Set bumper section

4Surface prepara-

tion

Remove dust, oil, etc. from areas to be repaired and surrounding areas, using a suitable solvent

(NRM No. 900 Precleno, white gasoline, or alcohol, etc.).

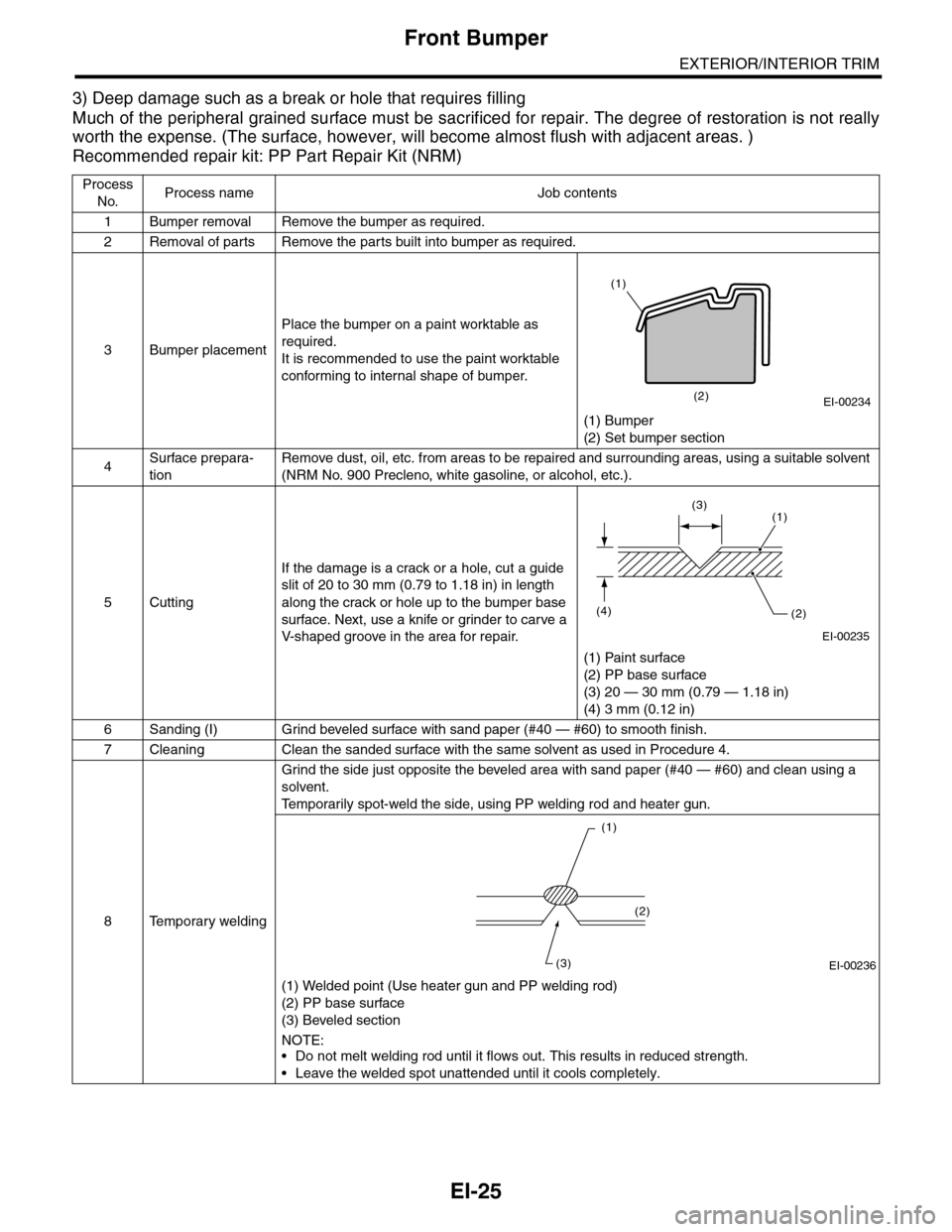

5Cutting

If the damage is a crack or a hole, cut a guide

slit of 20 to 30 mm (0.79 to 1.18 in) in length

along the crack or hole up to the bumper base

surface. Next, use a knife or grinder to carve a

V- s h a p e d g r o o ve i n t h e a r e a f o r r e p a i r.

(1) Paint surface

(2) PP base surface

(3) 20 — 30 mm (0.79 — 1.18 in)

(4) 3 mm (0.12 in)

6Sanding (I) Grind beveled surface with sand paper (#40 — #60) to smooth finish.

7Cleaning Clean the sanded surface with the same solvent as used in Procedure 4.

8Temporary welding

Grind the side just opposite the beveled area with sand paper (#40 — #60) and clean using a

solvent.

Te m p o r a r i l y s p o t - w e l d t h e s i d e , u s i n g P P w e l d i n g r o d a n d h e a t e r g u n .

(1) Welded point (Use heater gun and PP welding rod)

(2) PP base surface

(3) Beveled section

NOTE:•Do not melt welding rod until it flows out. This results in reduced strength.

•Leave the welded spot unattended until it cools completely.

EI-00234(2)

(1)

EI-00235

(4)(2)

(1)(3)

EI-00236

(1)

(2)

(3)