wheel torque SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 14 of 2453

AB-15

Driver’s Airbag Module

AIRBAG SYSTEM

4. Driver’s Airbag Module

A: REMOVAL

CAUTION:

Refer to “CAUTION” of “General Description”

before handling the airbag module.

1) Position the front wheels straight ahead. (After

moving a vehicle more than 5 m (16 ft) with front

wheels positioned straight ahead, make sure that

the vehicle moves straight ahead).

2) Turn the ignition switch to OFF.

3) Disconnect the ground cable from battery and

wait for at least 20 seconds before starting work.

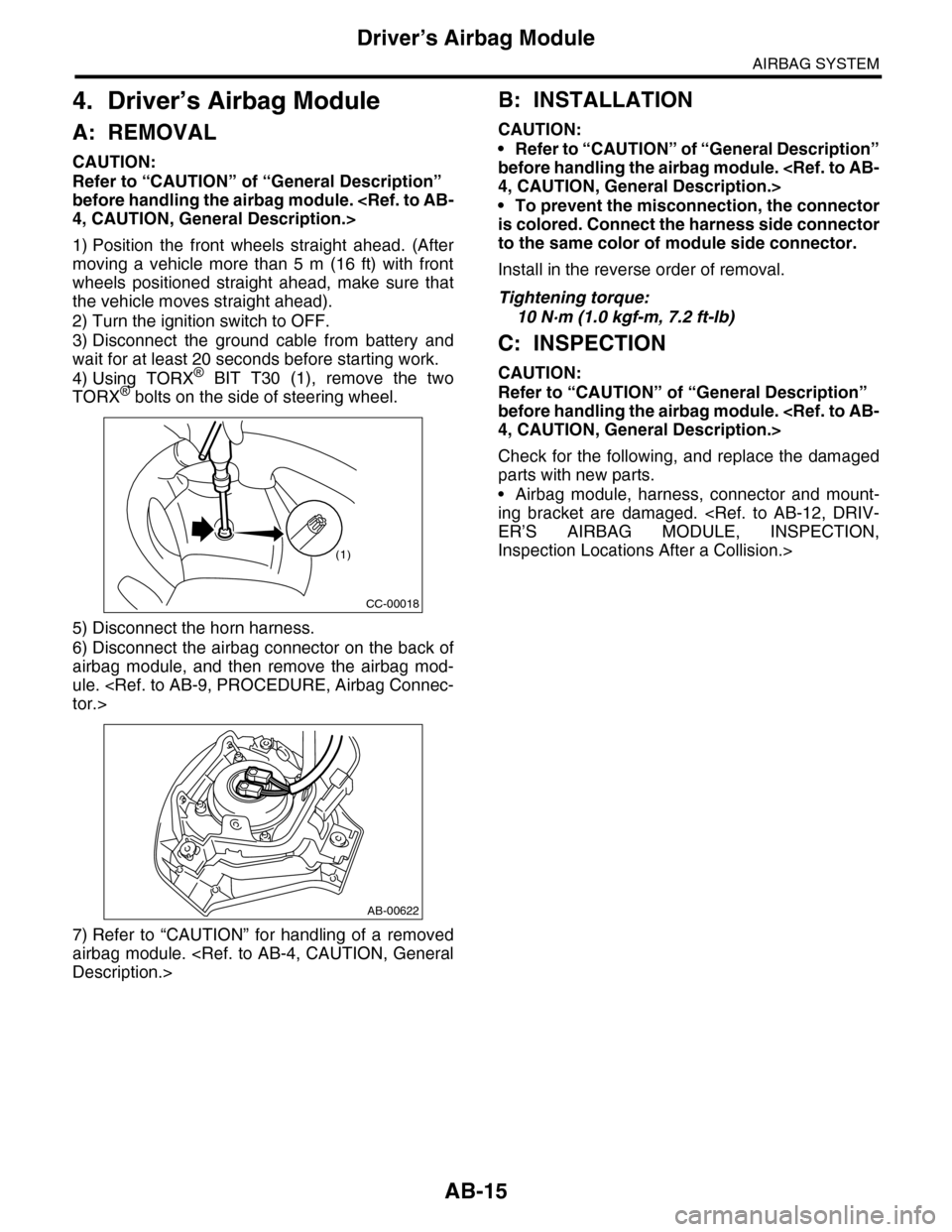

4) Using TORX® BIT T30 (1), remove the two

TORX® bolts on the side of steering wheel.

5) Disconnect the horn harness.

6) Disconnect the airbag connector on the back of

airbag module, and then remove the airbag mod-

ule.

7) Refer to “CAUTION” for handling of a removed

airbag module.

B: INSTALLATION

CAUTION:

•Refer to “CAUTION” of “General Description”

before handling the airbag module.

•To prevent the misconnection, the connector

is colored. Connect the harness side connector

to the same color of module side connector.

Install in the reverse order of removal.

Tightening torque:

10 N·m (1.0 kgf-m, 7.2 ft-lb)

C: INSPECTION

CAUTION:

Refer to “CAUTION” of “General Description”

before handling the airbag module.

Check for the following, and replace the damaged

parts with new parts.

•Airbag module, harness, connector and mount-

ing bracket are damaged.

Inspection Locations After a Collision.>

CC-00018

(1)

AB-00622

Page 728 of 2453

BR-14

Front Disc Rotor

BRAKE

3. Front Disc Rotor

A: REMOVAL

1) Lift-up the vehicle, and remove the front wheels.

2) Remove the caliper body and the support from

housing, and suspend it from the strut using a wire.

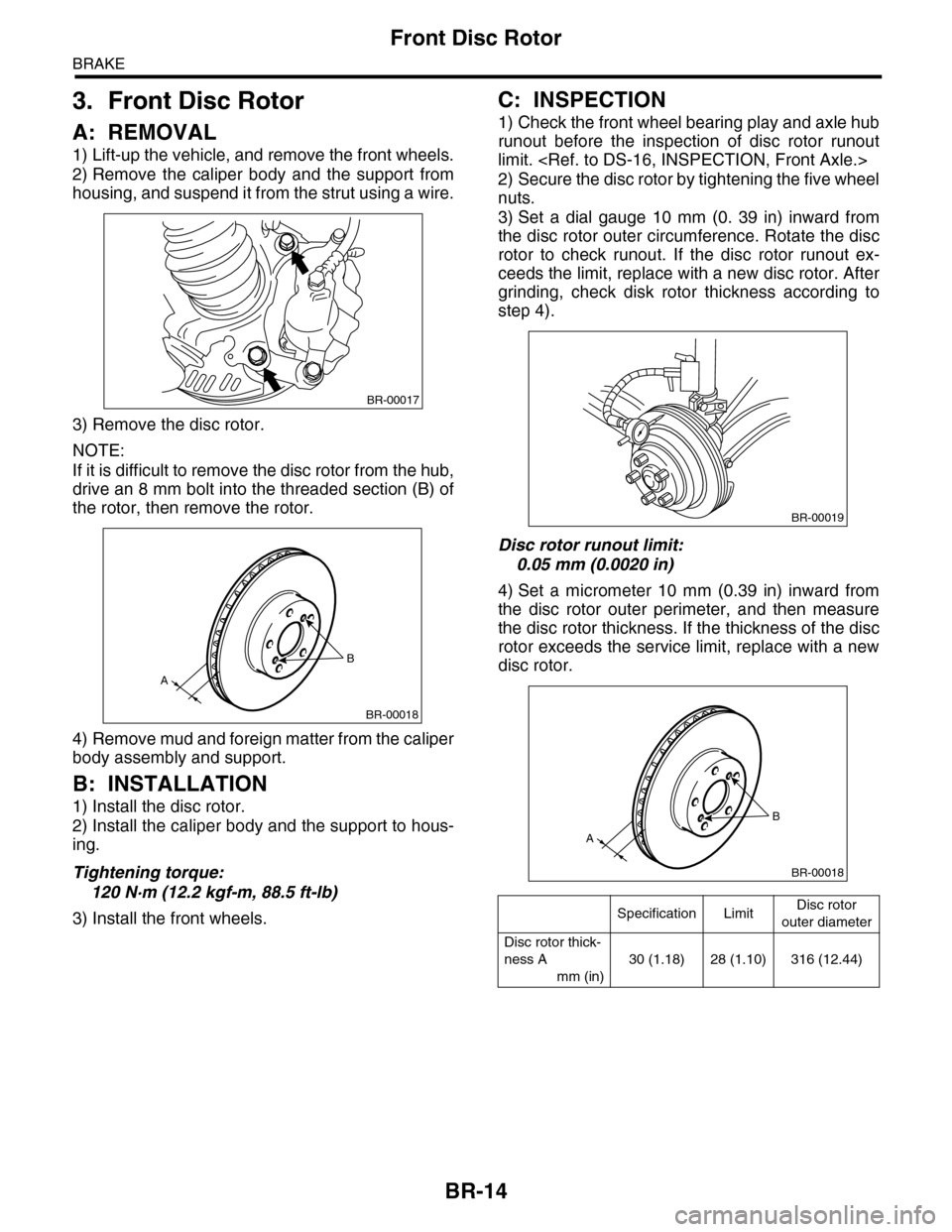

3) Remove the disc rotor.

NOTE:

If it is difficult to remove the disc rotor from the hub,

drive an 8 mm bolt into the threaded section (B) of

the rotor, then remove the rotor.

4) Remove mud and foreign matter from the caliper

body assembly and support.

B: INSTALLATION

1) Install the disc rotor.

2) Install the caliper body and the support to hous-

ing.

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

3) Install the front wheels.

C: INSPECTION

1) Check the front wheel bearing play and axle hub

runout before the inspection of disc rotor runout

limit.

2) Secure the disc rotor by tightening the five wheel

nuts.

3) Set a dial gauge 10 mm (0. 39 in) inward from

the disc rotor outer circumference. Rotate the disc

rotor to check runout. If the disc rotor runout ex-

ceeds the limit, replace with a new disc rotor. After

grinding, check disk rotor thickness according to

step 4).

Disc rotor runout limit:

0.05 mm (0.0020 in)

4) Set a micrometer 10 mm (0.39 in) inward from

the disc rotor outer perimeter, and then measure

the disc rotor thickness. If the thickness of the disc

rotor exceeds the service limit, replace with a new

disc rotor.

BR-00017

B

A

BR-00018

Specification LimitDisc rotor

outer diameter

Disc rotor thick-

ness A

mm (in)

30 (1.18) 28 (1.10) 316 (12.44)

BR-00019

B

A

BR-00018

Page 729 of 2453

BR-15

Front Disc Brake Assembly

BRAKE

4. Front Disc Brake Assembly

A: REMOVAL

CAUTION:

Do not allow brake fluid to come in contact with

vehicle body. If it does, wash off with water and

wipe away completely.

1) Lift-up the vehicle, and remove the front wheels.

2) Remove the union bolt, and disconnect the

brake hose from the caliper body assembly.

3) Remove the bolt securing the lock pin to caliper

body.

4) Raise the caliper body, and then move it toward

vehicle center to separate it from the support.

5) Remove the support from housing.

NOTE:

Remove the support only when replacing the rotor

or support. It need not be removed when servicing

the caliper body assembly.

6) Remove mud and foreign matter from the caliper

body assembly and support.

B: INSTALLATION

1) Install the support to the housing.

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

2) Apply a thin coat of Molykote M7439 to the pad

clip.

3) Apply a thin coat of Molykote AS880N (Part No.

K0777YA010) to the contact surface between pad

and inner shim.

4) Apply a thin coat of Molykote AS880N (Part No.

K0779YA010) to the three contact surfaces be-

tween inner shim and outer shim of outer pads.

BR-00021

BR-00022

BR-00023

BR-00340

BR-00238

BR-00341

Page 733 of 2453

BR-19

Rear Brake Pad

BRAKE

5. Rear Brake Pad

A: REMOVAL

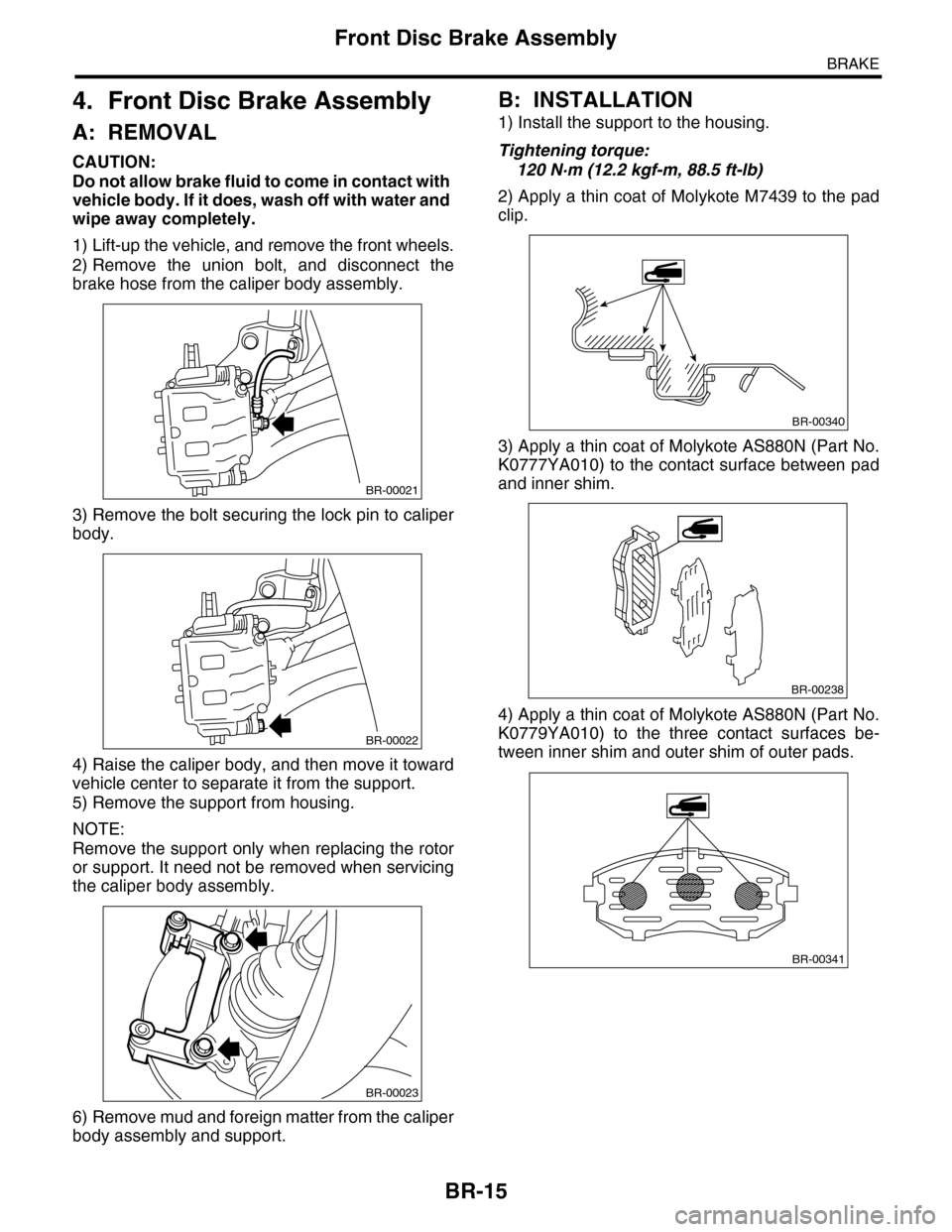

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Remove the brake hose bracket.

3) Remove the caliper bolt.

4) Raise the caliper body and support it.

NOTE:

Do not disconnect the brake hose from the caliper

body.

5) Remove the pad.

B: INSTALLATION

1) Apply a thin coat of Molykote M7439 to the pad

clip.

2) Apply a thin coat of Molykote AS880N (Part No.

K0777YA010) to the contact surface between the

pad and shim.

3) Install the pad to support.

4) Install the caliper body to the support.

Tightening torque:

27 N·m (2.8 kgf-m, 19.9 ft-lb)

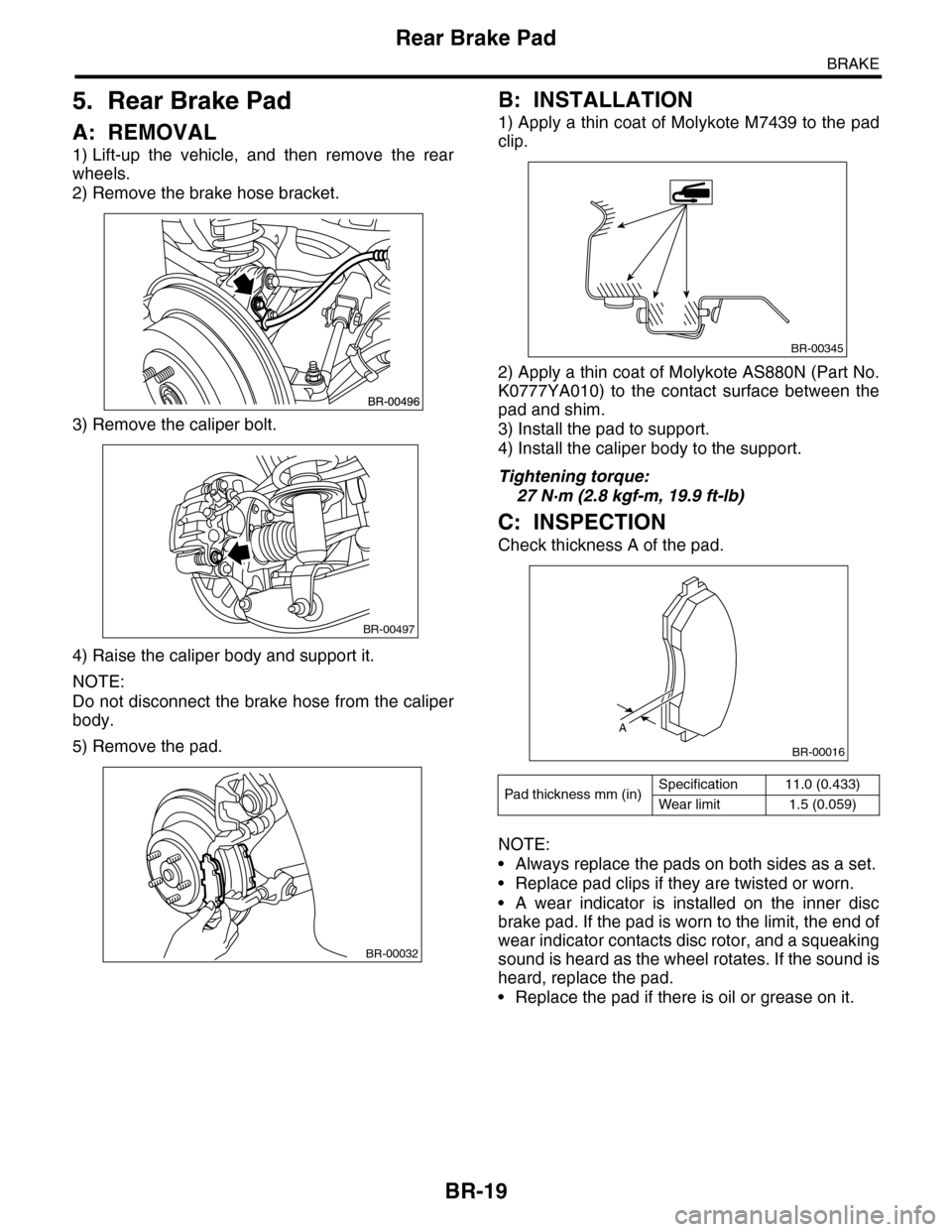

C: INSPECTION

Check thickness A of the pad.

NOTE:

•Always replace the pads on both sides as a set.

•Replace pad clips if they are twisted or worn.

•A wear indicator is installed on the inner disc

brake pad. If the pad is worn to the limit, the end of

wear indicator contacts disc rotor, and a squeaking

sound is heard as the wheel rotates. If the sound is

heard, replace the pad.

•Replace the pad if there is oil or grease on it.

BR-00497

BR-00032

Pad thickness mm (in)Specification 11.0 (0.433)

Wear limit 1.5 (0.059)

BR-00345

A

BR-00016

Page 734 of 2453

BR-20

Rear Disc Rotor

BRAKE

6. Rear Disc Rotor

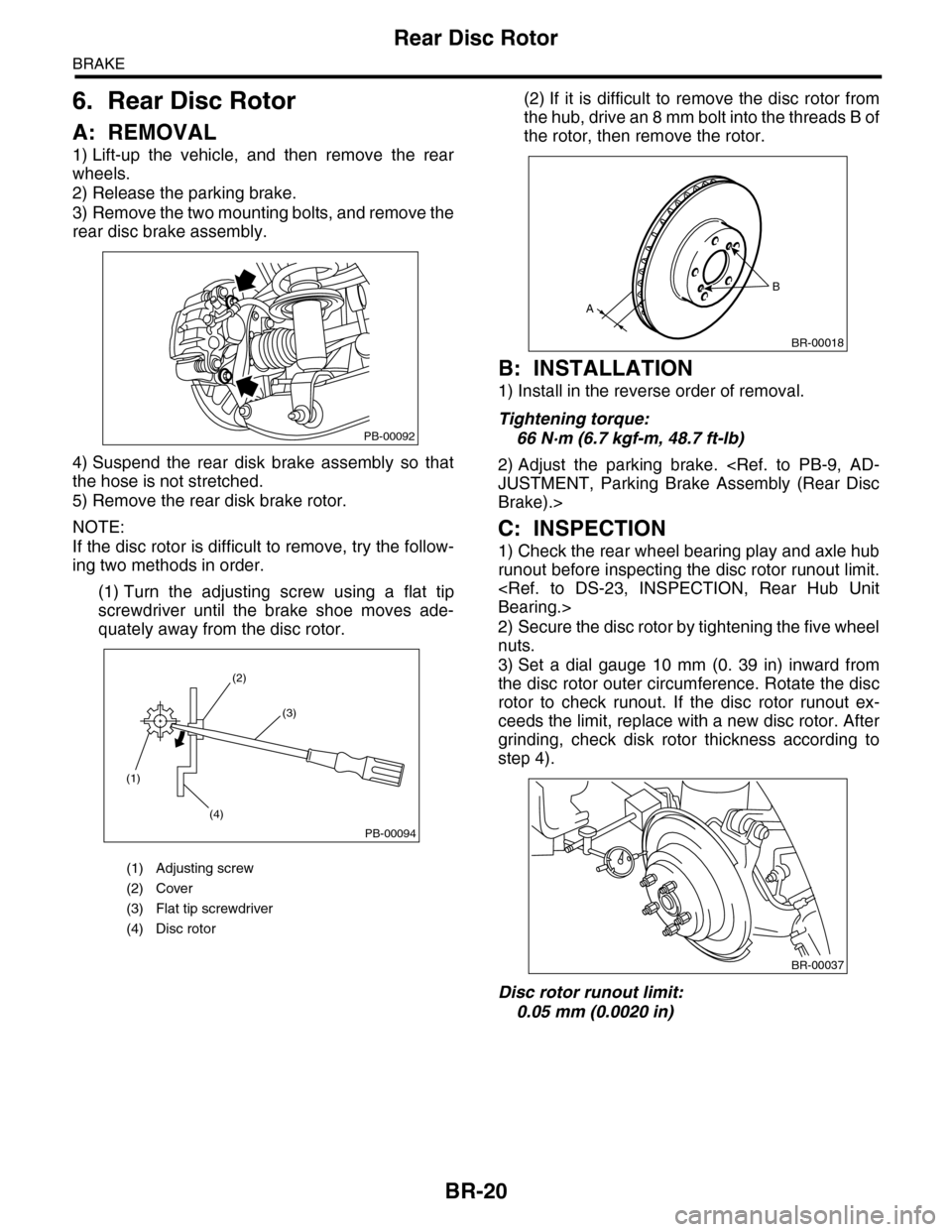

A: REMOVAL

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Release the parking brake.

3) Remove the two mounting bolts, and remove the

rear disc brake assembly.

4) Suspend the rear disk brake assembly so that

the hose is not stretched.

5) Remove the rear disk brake rotor.

NOTE:

If the disc rotor is difficult to remove, try the follow-

ing two methods in order.

(1) Turn the adjusting screw using a flat tip

screwdriver until the brake shoe moves ade-

quately away from the disc rotor.

(2) If it is difficult to remove the disc rotor from

the hub, drive an 8 mm bolt into the threads B of

the rotor, then remove the rotor.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

66 N·m (6.7 kgf-m, 48.7 ft-lb)

2) Adjust the parking brake.

Brake).>

C: INSPECTION

1) Check the rear wheel bearing play and axle hub

runout before inspecting the disc rotor runout limit.

2) Secure the disc rotor by tightening the five wheel

nuts.

3) Set a dial gauge 10 mm (0. 39 in) inward from

the disc rotor outer circumference. Rotate the disc

rotor to check runout. If the disc rotor runout ex-

ceeds the limit, replace with a new disc rotor. After

grinding, check disk rotor thickness according to

step 4).

Disc rotor runout limit:

0.05 mm (0.0020 in)

(1) Adjusting screw

(2) Cover

(3) Flat tip screwdriver

(4) Disc rotor

PB-00092

(1)

(4)

(2)

(3)

PB-00094

B

A

BR-00018

BR-00037

Page 736 of 2453

BR-22

Rear Disc Brake Assembly

BRAKE

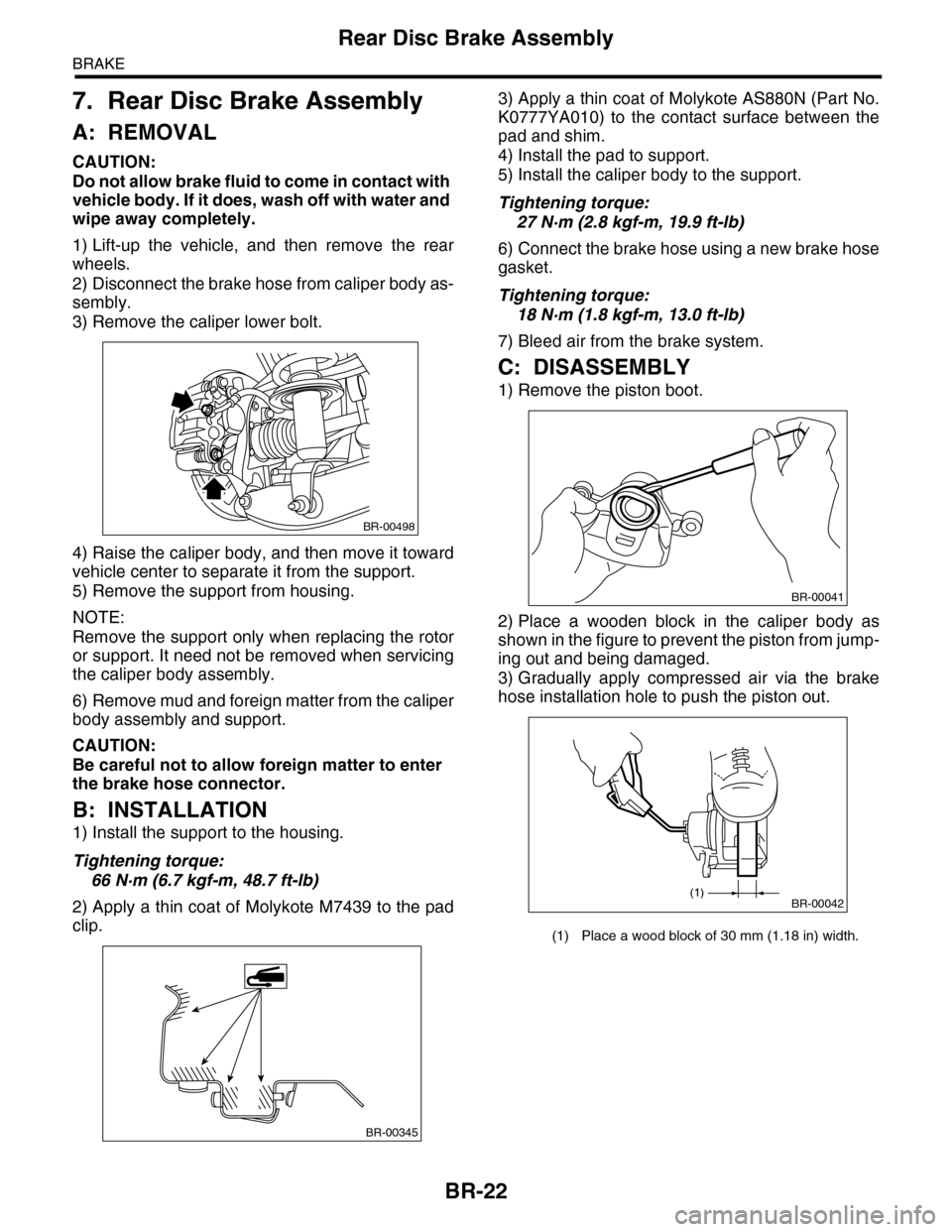

7. Rear Disc Brake Assembly

A: REMOVAL

CAUTION:

Do not allow brake fluid to come in contact with

vehicle body. If it does, wash off with water and

wipe away completely.

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Disconnect the brake hose from caliper body as-

sembly.

3) Remove the caliper lower bolt.

4) Raise the caliper body, and then move it toward

vehicle center to separate it from the support.

5) Remove the support from housing.

NOTE:

Remove the support only when replacing the rotor

or support. It need not be removed when servicing

the caliper body assembly.

6) Remove mud and foreign matter from the caliper

body assembly and support.

CAUTION:

Be careful not to allow foreign matter to enter

the brake hose connector.

B: INSTALLATION

1) Install the support to the housing.

Tightening torque:

66 N·m (6.7 kgf-m, 48.7 ft-lb)

2) Apply a thin coat of Molykote M7439 to the pad

clip.

3) Apply a thin coat of Molykote AS880N (Part No.

K0777YA010) to the contact surface between the

pad and shim.

4) Install the pad to support.

5) Install the caliper body to the support.

Tightening torque:

27 N·m (2.8 kgf-m, 19.9 ft-lb)

6) Connect the brake hose using a new brake hose

gasket.

Tightening torque:

18 N·m (1.8 kgf-m, 13.0 ft-lb)

7) Bleed air from the brake system.

C: DISASSEMBLY

1) Remove the piston boot.

2) Place a wooden block in the caliper body as

shown in the figure to prevent the piston from jump-

ing out and being damaged.

3) Gradually apply compressed air via the brake

hose installation hole to push the piston out.

BR-00498

BR-00345

(1) Place a wood block of 30 mm (1.18 in) width.

BR-00041

(1)BR-00042

Page 745 of 2453

BR-31

Air Bleeding

BRAKE

11.Air Bleeding

A: PROCEDURE

CAUTION:

•Do not let brake fluid come into contact with

the painted surface of the vehicle body. Wash

away with water immediately and wipe off if it is

spilled by accident.

•Avoid mixing brake fluids of different brands

to prevent fluid performance from degrading.

•Be careful not to allow dirt or dust to enter the

reservoir tank.

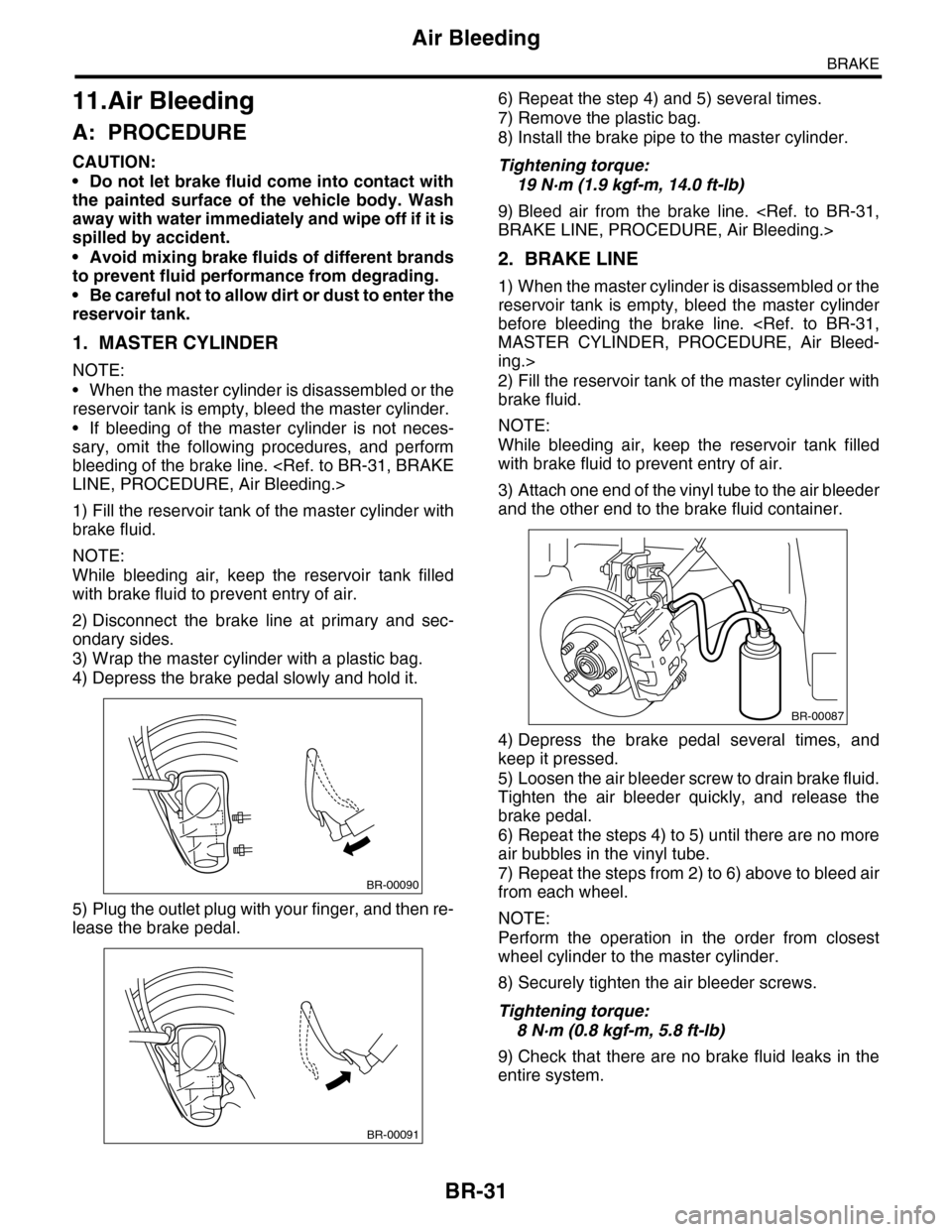

1. MASTER CYLINDER

NOTE:

•When the master cylinder is disassembled or the

reservoir tank is empty, bleed the master cylinder.

•If bleeding of the master cylinder is not neces-

sary, omit the following procedures, and perform

bleeding of the brake line.

1) Fill the reservoir tank of the master cylinder with

brake fluid.

NOTE:

While bleeding air, keep the reservoir tank filled

with brake fluid to prevent entry of air.

2) Disconnect the brake line at primary and sec-

ondary sides.

3) Wrap the master cylinder with a plastic bag.

4) Depress the brake pedal slowly and hold it.

5) Plug the outlet plug with your finger, and then re-

lease the brake pedal.

6) Repeat the step 4) and 5) several times.

7) Remove the plastic bag.

8) Install the brake pipe to the master cylinder.

Tightening torque:

19 N·m (1.9 kgf-m, 14.0 ft-lb)

9) Bleed air from the brake line.

2. BRAKE LINE

1) When the master cylinder is disassembled or the

reservoir tank is empty, bleed the master cylinder

before bleeding the brake line.

ing.>

2) Fill the reservoir tank of the master cylinder with

brake fluid.

NOTE:

While bleeding air, keep the reservoir tank filled

with brake fluid to prevent entry of air.

3) Attach one end of the vinyl tube to the air bleeder

and the other end to the brake fluid container.

4) Depress the brake pedal several times, and

keep it pressed.

5) Loosen the air bleeder screw to drain brake fluid.

Tighten the air bleeder quickly, and release the

brake pedal.

6) Repeat the steps 4) to 5) until there are no more

air bubbles in the vinyl tube.

7) Repeat the steps from 2) to 6) above to bleed air

from each wheel.

NOTE:

Perform the operation in the order from closest

wheel cylinder to the master cylinder.

8) Securely tighten the air bleeder screws.

Tightening torque:

8 N·m (0.8 kgf-m, 5.8 ft-lb)

9) Check that there are no brake fluid leaks in the

entire system.

BR-00090

BR-00091

BR-00087

Page 748 of 2453

BR-34

Brake Hose

BRAKE

B: INSTALLATION

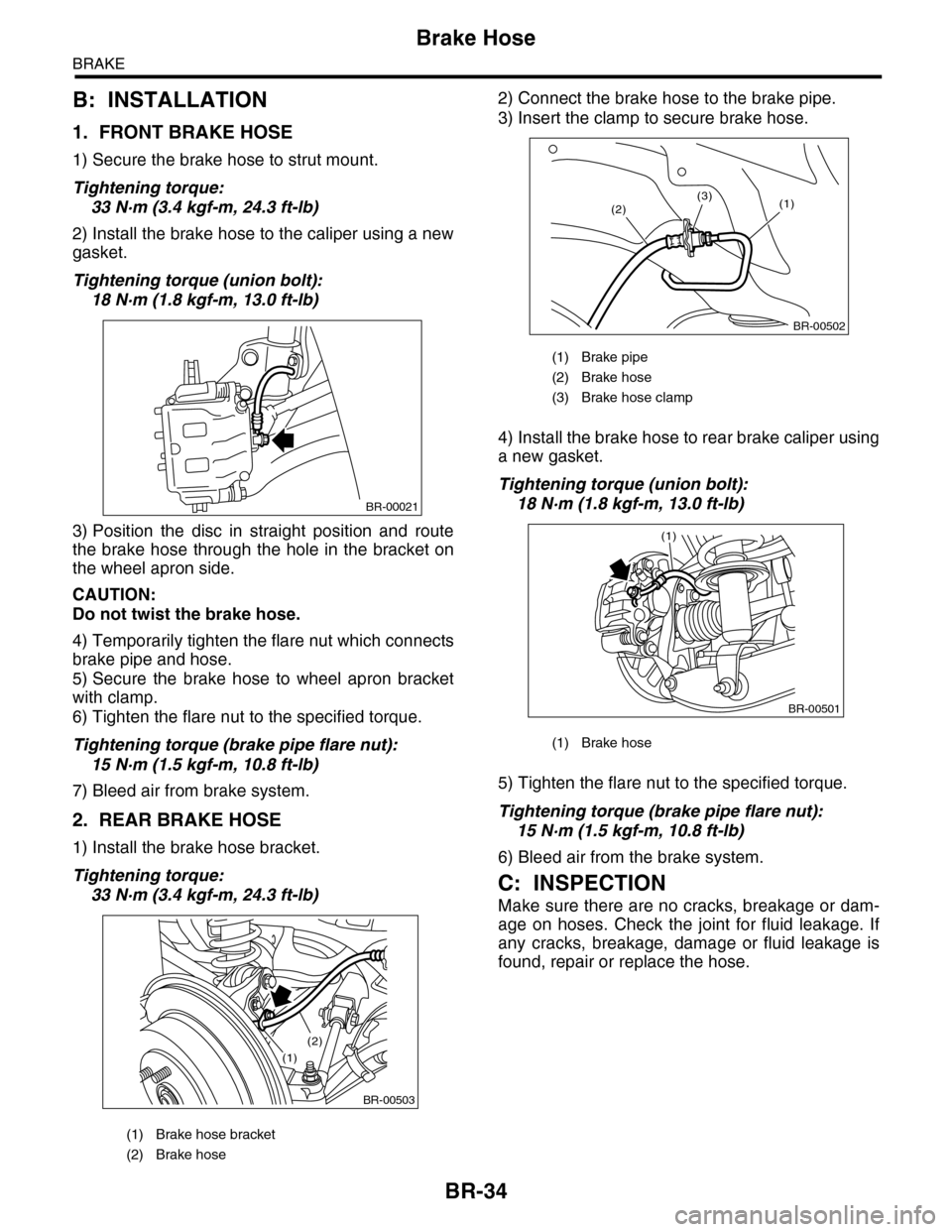

1. FRONT BRAKE HOSE

1) Secure the brake hose to strut mount.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

2) Install the brake hose to the caliper using a new

gasket.

Tightening torque (union bolt):

18 N·m (1.8 kgf-m, 13.0 ft-lb)

3) Position the disc in straight position and route

the brake hose through the hole in the bracket on

the wheel apron side.

CAUTION:

Do not twist the brake hose.

4) Temporarily tighten the flare nut which connects

brake pipe and hose.

5) Secure the brake hose to wheel apron bracket

with clamp.

6) Tighten the flare nut to the specified torque.

Tightening torque (brake pipe flare nut):

15 N·m (1.5 kgf-m, 10.8 ft-lb)

7) Bleed air from brake system.

2. REAR BRAKE HOSE

1) Install the brake hose bracket.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

2) Connect the brake hose to the brake pipe.

3) Insert the clamp to secure brake hose.

4) Install the brake hose to rear brake caliper using

a new gasket.

Tightening torque (union bolt):

18 N·m (1.8 kgf-m, 13.0 ft-lb)

5) Tighten the flare nut to the specified torque.

Tightening torque (brake pipe flare nut):

15 N·m (1.5 kgf-m, 10.8 ft-lb)

6) Bleed air from the brake system.

C: INSPECTION

Make sure there are no cracks, breakage or dam-

age on hoses. Check the joint for fluid leakage. If

any cracks, breakage, damage or fluid leakage is

found, repair or replace the hose.

(1) Brake hose bracket

(2) Brake hose

BR-00021

BR-00503

(1)

(2)

(1) Brake pipe

(2) Brake hose

(3) Brake hose clamp

(1) Brake hose

BR-00502

(1)(2)(3)

BR-00501

(1)

Page 755 of 2453

BR-41

General Diagnostic Table

BRAKE

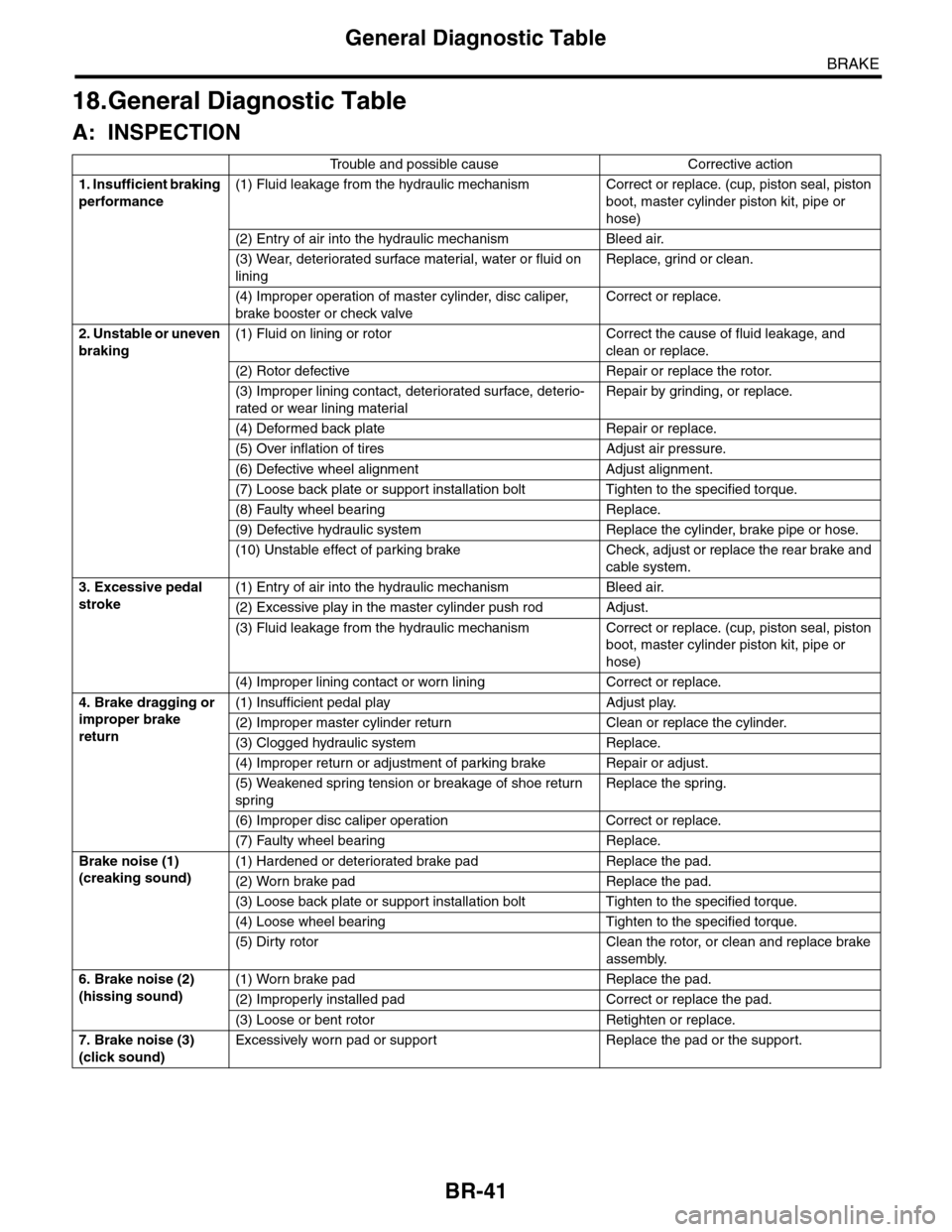

18.General Diagnostic Table

A: INSPECTION

Trouble and possible causeCorrective action

1. Insufficient braking

performance

(1) Fluid leakage from the hydraulic mechanism Correct or replace. (cup, piston seal, piston

boot, master cylinder piston kit, pipe or

hose)

(2) Entry of air into the hydraulic mechanism Bleed air.

(3) Wear, deteriorated surface material, water or fluid on

lining

Replace, grind or clean.

(4) Improper operation of master cylinder, disc caliper,

brake booster or check valve

Correct or replace.

2. Unstable or uneven

braking

(1) Fluid on lining or rotor Correct the cause of fluid leakage, and

clean or replace.

(2) Rotor defective Repair or replace the rotor.

(3) Improper lining contact, deteriorated surface, deterio-

rated or wear lining material

Repair by grinding, or replace.

(4) Deformed back plate Repair or replace.

(5) Over inflation of tires Adjust air pressure.

(6) Defective wheel alignment Adjust alignment.

(7) Loose back plate or suppor t installation bolt Tighten to the specified torque.

(8) Faulty wheel bearing Replace.

(9) Defective hydraulic system Replace the cylinder, brake pipe or hose.

(10) Unstable effect of parking brake Check, adjust or replace the rear brake and

cable system.

3. Excessive pedal

stroke

(1) Entry of air into the hydraulic mechanism Bleed air.

(2) Excessive play in the master cylinder push rod Adjust.

(3) Fluid leakage from the hydraulic mechanism Correct or replace. (cup, piston seal, piston

boot, master cylinder piston kit, pipe or

hose)

(4) Improper lining contact or worn lining Correct or replace.

4. Brake dragging or

improper brake

return

(1) Insufficient pedal play Adjust play.

(2) Improper master cylinder return Clean or replace the cylinder.

(3) Clogged hydraulic system Replace.

(4) Improper return or adjustment of parking brake Repair or adjust.

(5) Weakened spring tension or breakage of shoe return

spring

Replace the spring.

(6) Improper disc caliper operation Correct or replace.

(7) Faulty wheel bearing Replace.

Brake noise (1)

(creaking sound)

(1) Hardened or deteriorated brake pad Replace the pad.

(2) Worn brake pad Replace the pad.

(3) Loose back plate or suppor t installation bolt Tighten to the specified torque.

(4) Loose wheel bearing Tighten to the specified torque.

(5) Dir ty rotor Clean the rotor, or clean and replace brake

assembly.

6. Brake noise (2)

(hissing sound)

(1) Worn brake pad Replace the pad.

(2) Improperly installed pad Correct or replace the pad.

(3) Loose or bent rotor Retighten or replace.

7. Brake noise (3)

(click sound)

Excessively worn pad or suppor t Replace the pad or the suppor t.

Page 814 of 2453

DI-30

Rear Differential Front Oil Seal

DIFFERENTIALS

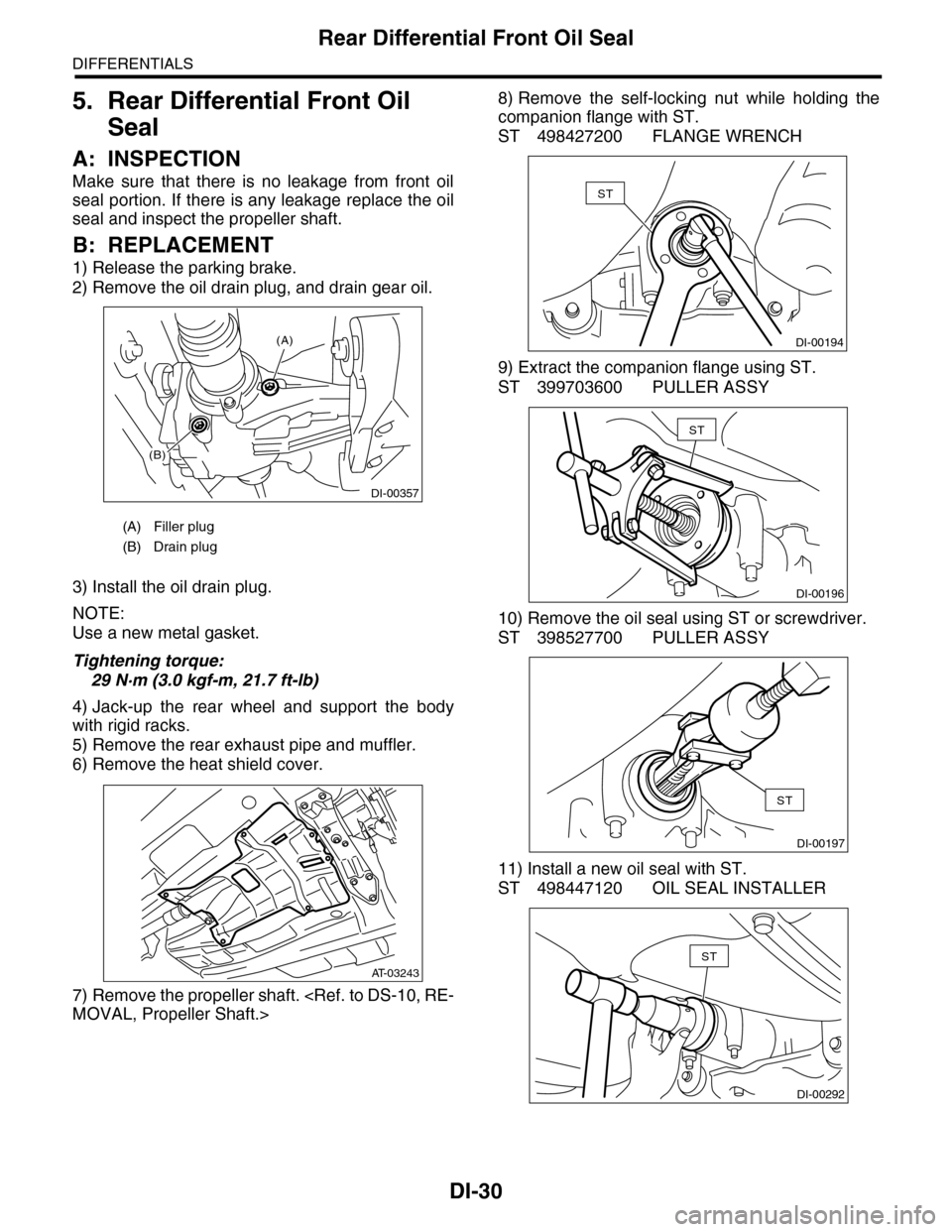

5. Rear Differential Front Oil

Seal

A: INSPECTION

Make sure that there is no leakage from front oil

seal portion. If there is any leakage replace the oil

seal and inspect the propeller shaft.

B: REPLACEMENT

1) Release the parking brake.

2) Remove the oil drain plug, and drain gear oil.

3) Install the oil drain plug.

NOTE:

Use a new metal gasket.

Tightening torque:

29 N·m (3.0 kgf-m, 21.7 ft-lb)

4) Jack-up the rear wheel and support the body

with rigid racks.

5) Remove the rear exhaust pipe and muffler.

6) Remove the heat shield cover.

7) Remove the propeller shaft.

8) Remove the self-locking nut while holding the

companion flange with ST.

ST 498427200 FLANGE WRENCH

9) Extract the companion flange using ST.

ST 399703600 PULLER ASSY

10) Remove the oil seal using ST or screwdriver.

ST 398527700 PULLER ASSY

11) Install a new oil seal with ST.

ST 498447120 OIL SEAL INSTALLER

(A) Filler plug

(B) Drain plug

(A)

DI-00357

(B)

AT-03243

DI-00194

ST

DI-00196

ST

DI-00197

ST

DI-00292

ST