sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1290 of 2453

EN(H6DO)(diag)-129

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

V: DTC P0101 MASS OR VOLUME AIR FLOW CIRCUIT RANGE/PERFOR-

MANCE

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Erroneous idling

•Engine stalls.

•Poor driving performance

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

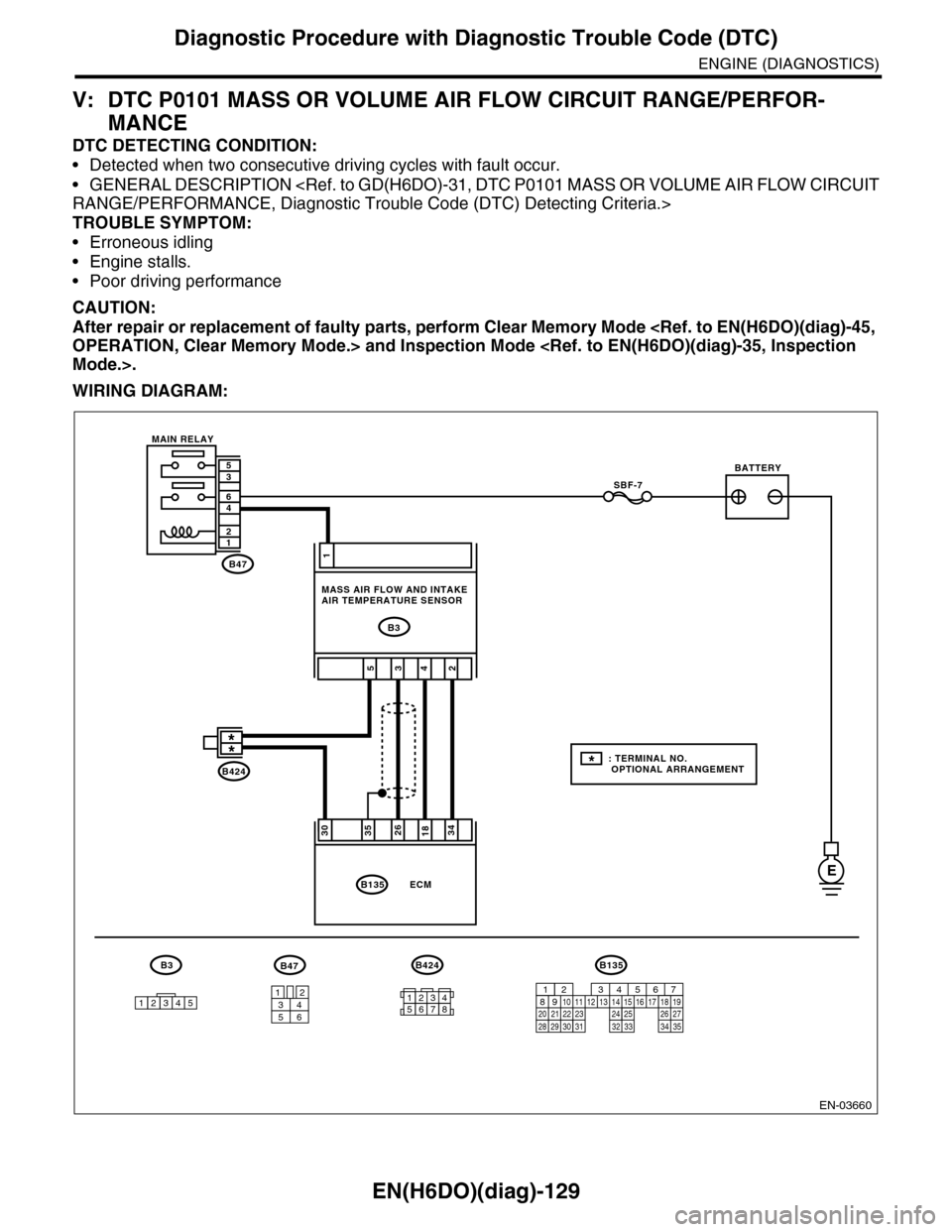

WIRING DIAGRAM:

EN-03660

B3

BATTERY

E

B424

1

B3

MASS AIR FLOW AND INTAKEAIR TEMPERATURE SENSOR

ECMB135

SBF-7

123453412

56

B47

**

2435

3418263035

MAIN RELAY

B47

12

46

35

B424

12345678

* : TERMINAL NO. OPTIONAL ARRANGEMENT

B135

567821943102422 23 2511 12 13 14 1526 2728

16 17 18 1920 2129 30 31 32 33 34 35

Page 1291 of 2453

EN(H6DO)(diag)-130

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

NOTE:In this case, it is

not necessary to

inspect DTC

P0101.

Replace the mass

air flow and intake

air temperature

sensor.

Mass Air Flow and

Intake Air Temper-

ature Sensor.>

Page 1292 of 2453

EN(H6DO)(diag)-131

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

W: DTC P0102 MASS OR VOLUME AIR FLOW CIRCUIT LOW INPUT

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Erroneous idling

•Engine stalls.

•Poor driving performance

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

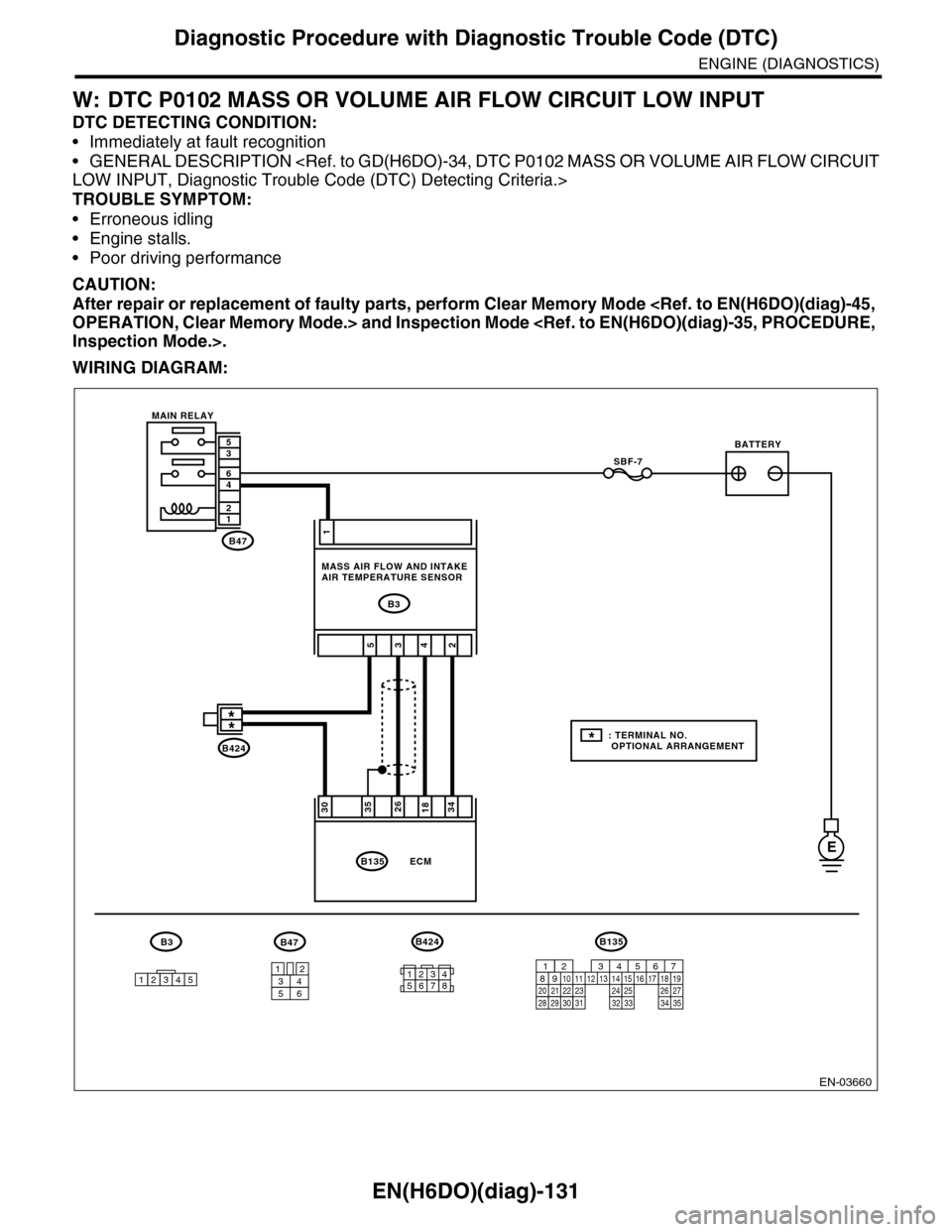

WIRING DIAGRAM:

EN-03660

B3

BATTERY

E

B424

1

B3

MASS AIR FLOW AND INTAKEAIR TEMPERATURE SENSOR

ECMB135

SBF-7

123453412

56

B47

**

2435

3418263035

MAIN RELAY

B47

12

46

35

B424

12345678

* : TERMINAL NO. OPTIONAL ARRANGEMENT

B135

567821943102422 23 2511 12 13 14 1526 2728

16 17 18 1920 2129 30 31 32 33 34 35

Page 1293 of 2453

EN(H6DO)(diag)-132

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

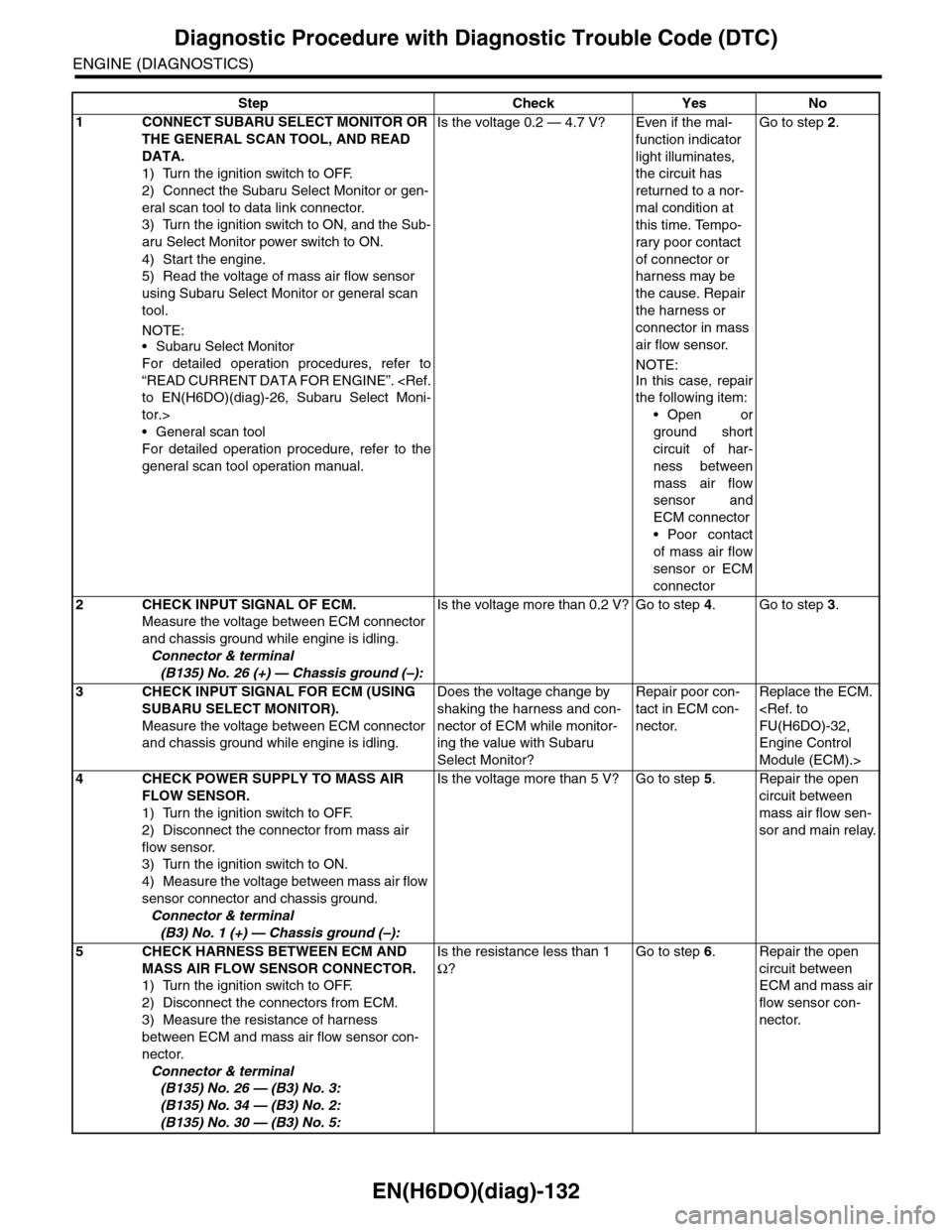

Step Check Yes No

1CONNECT SUBARU SELECT MONITOR OR

THE GENERAL SCAN TOOL, AND READ

DATA.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor or gen-

eral scan tool to data link connector.

3) Turn the ignition switch to ON, and the Sub-

aru Select Monitor power switch to ON.

4) Start the engine.

5) Read the voltage of mass air flow sensor

using Subaru Select Monitor or general scan

tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the voltage 0.2 — 4.7 V? Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time. Tempo-

rary poor contact

of connector or

harness may be

the cause. Repair

the harness or

connector in mass

air flow sensor.

NOTE:

In this case, repair

the following item:

•Open or

ground short

circuit of har-

ness between

mass air flow

sensor and

ECM connector

•Poor contact

of mass air flow

sensor or ECM

connector

Go to step 2.

2CHECK INPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground while engine is idling.

Connector & terminal

(B135) No. 26 (+) — Chassis ground (–):

Is the voltage more than 0.2 V? Go to step 4.Go to step 3.

3CHECK INPUT SIGNAL FOR ECM (USING

SUBARU SELECT MONITOR).

Measure the voltage between ECM connector

and chassis ground while engine is idling.

Does the voltage change by

shaking the harness and con-

nector of ECM while monitor-

ing the value with Subaru

Select Monitor?

Repair poor con-

tact in ECM con-

nector.

Replace the ECM.

Engine Control

Module (ECM).>

4CHECK POWER SUPPLY TO MASS AIR

FLOW SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from mass air

flow sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between mass air flow

sensor connector and chassis ground.

Connector & terminal

(B3) No. 1 (+) — Chassis ground (–):

Is the voltage more than 5 V? Go to step 5.Repair the open

circuit between

mass air flow sen-

sor and main relay.

5CHECK HARNESS BETWEEN ECM AND

MASS AIR FLOW SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between ECM and mass air flow sensor con-

nector.

Connector & terminal

(B135) No. 26 — (B3) No. 3:

(B135) No. 34 — (B3) No. 2:

(B135) No. 30 — (B3) No. 5:

Is the resistance less than 1

Ω?

Go to step 6.Repair the open

circuit between

ECM and mass air

flow sensor con-

nector.

Page 1294 of 2453

EN(H6DO)(diag)-133

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

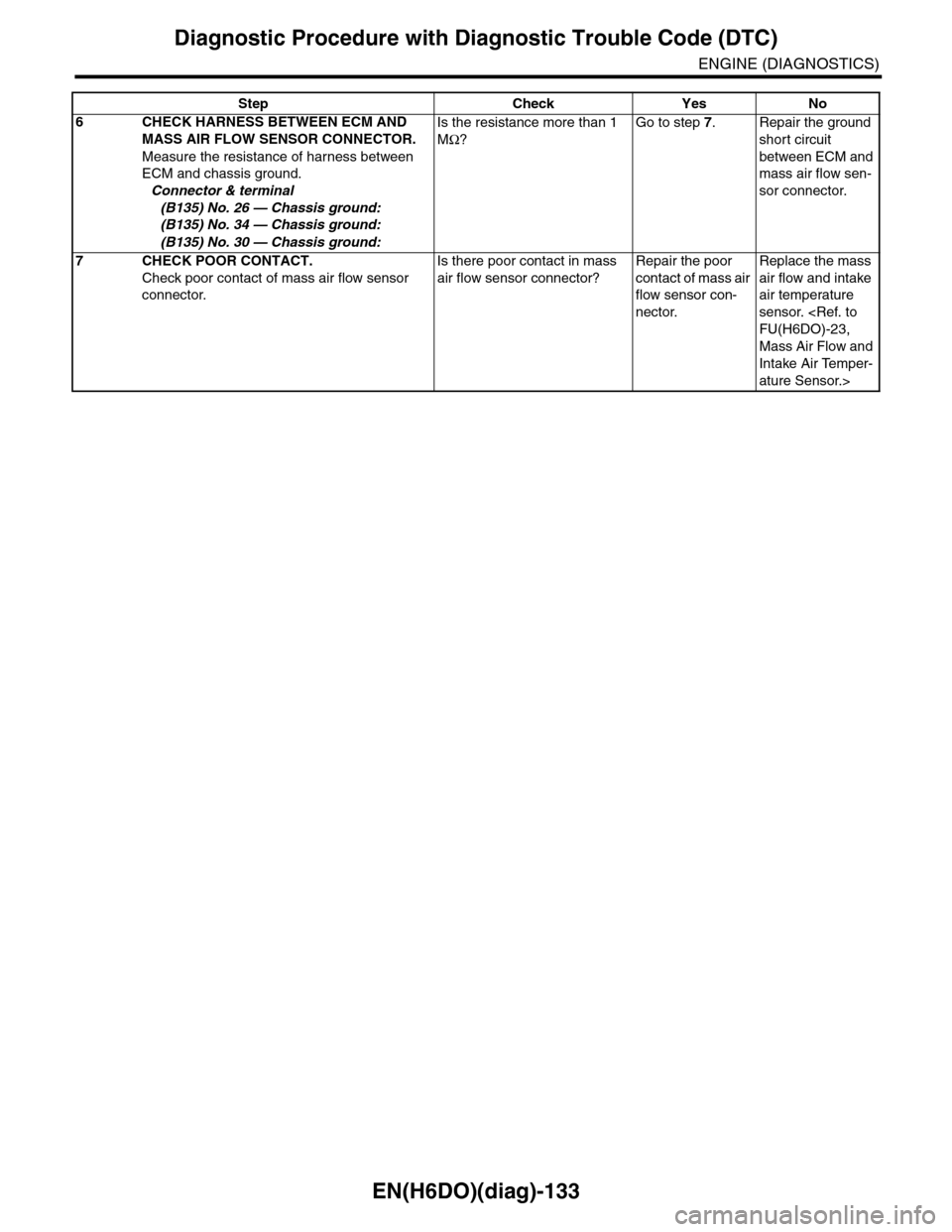

6CHECK HARNESS BETWEEN ECM AND

MASS AIR FLOW SENSOR CONNECTOR.

Measure the resistance of harness between

ECM and chassis ground.

Connector & terminal

(B135) No. 26 — Chassis ground:

(B135) No. 34 — Chassis ground:

(B135) No. 30 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 7.Repair the ground

short circuit

between ECM and

mass air flow sen-

sor connector.

7CHECK POOR CONTACT.

Check poor contact of mass air flow sensor

connector.

Is there poor contact in mass

air flow sensor connector?

Repair the poor

contact of mass air

flow sensor con-

nector.

Replace the mass

air flow and intake

air temperature

sensor.

Mass Air Flow and

Intake Air Temper-

ature Sensor.>

Step Check Yes No

Page 1295 of 2453

EN(H6DO)(diag)-134

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

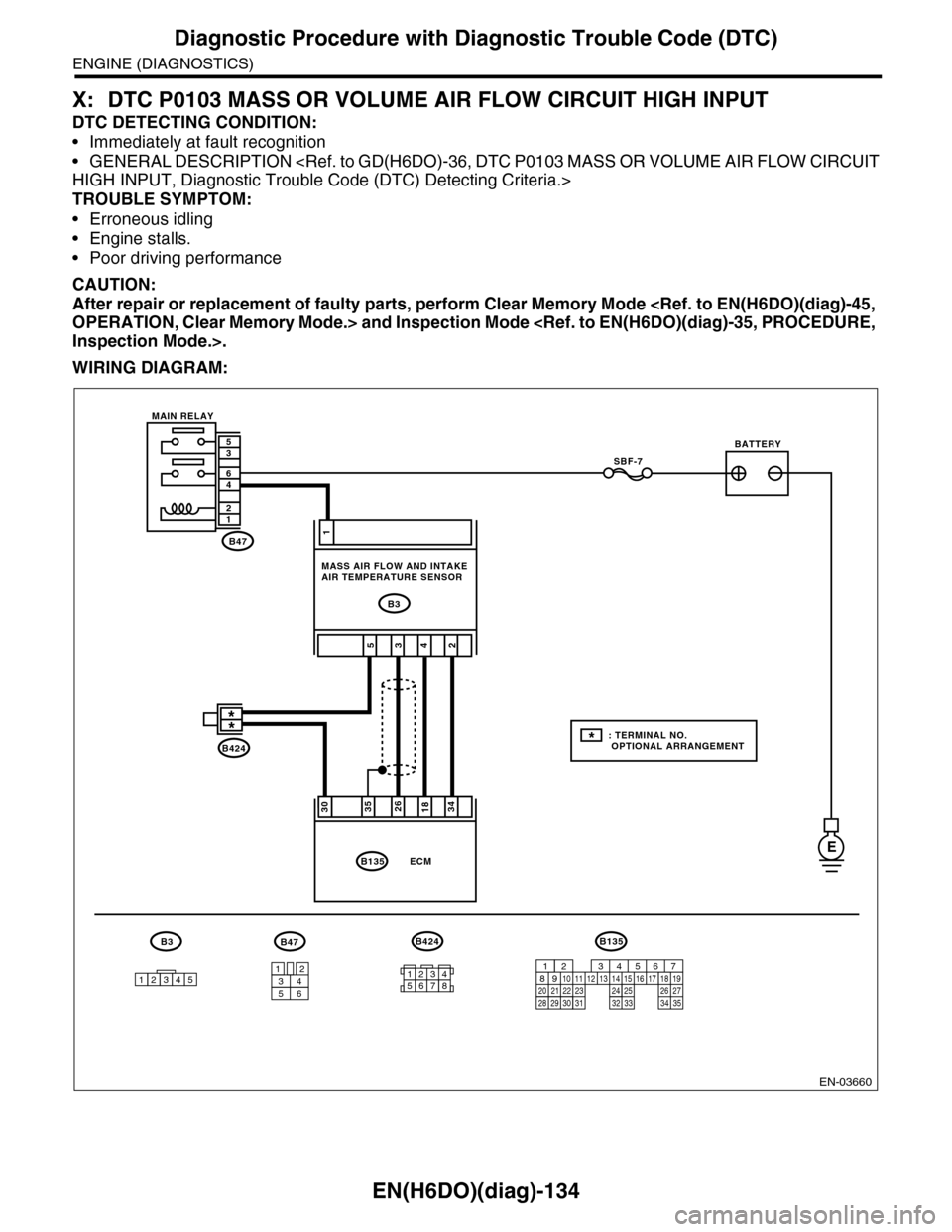

X: DTC P0103 MASS OR VOLUME AIR FLOW CIRCUIT HIGH INPUT

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Erroneous idling

•Engine stalls.

•Poor driving performance

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03660

B3

BATTERY

E

B424

1

B3

MASS AIR FLOW AND INTAKEAIR TEMPERATURE SENSOR

ECMB135

SBF-7

123453412

56

B47

**

2435

3418263035

MAIN RELAY

B47

12

46

35

B424

12345678

* : TERMINAL NO. OPTIONAL ARRANGEMENT

B135

567821943102422 23 2511 12 13 14 1526 2728

16 17 18 1920 2129 30 31 32 33 34 35

Page 1296 of 2453

EN(H6DO)(diag)-135

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

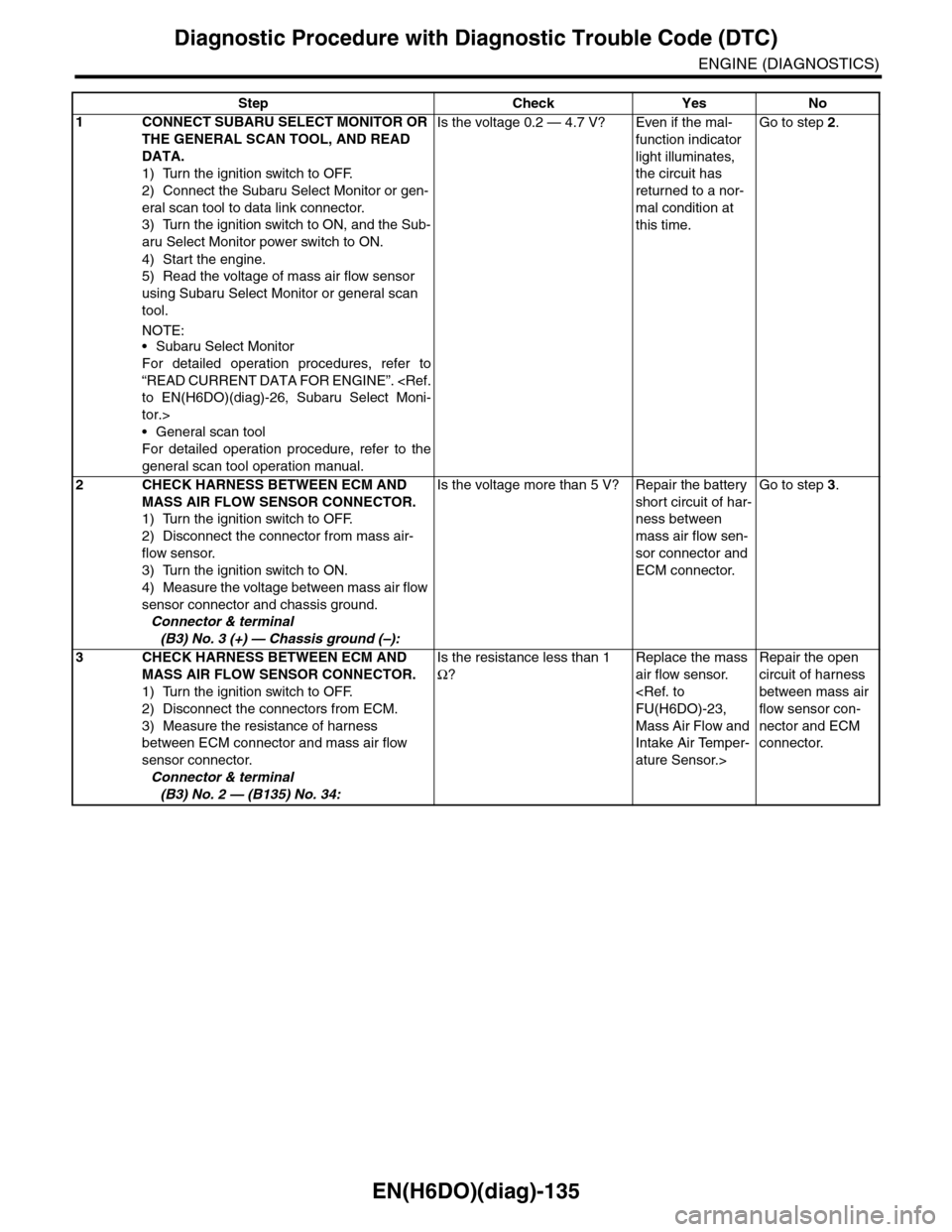

1CONNECT SUBARU SELECT MONITOR OR

THE GENERAL SCAN TOOL, AND READ

DATA.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor or gen-

eral scan tool to data link connector.

3) Turn the ignition switch to ON, and the Sub-

aru Select Monitor power switch to ON.

4) Start the engine.

5) Read the voltage of mass air flow sensor

using Subaru Select Monitor or general scan

tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the voltage 0.2 — 4.7 V? Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.

Go to step 2.

2CHECK HARNESS BETWEEN ECM AND

MASS AIR FLOW SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from mass air-

flow sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between mass air flow

sensor connector and chassis ground.

Connector & terminal

(B3) No. 3 (+) — Chassis ground (–):

Is the voltage more than 5 V? Repair the battery

short circuit of har-

ness between

mass air flow sen-

sor connector and

ECM connector.

Go to step 3.

3CHECK HARNESS BETWEEN ECM AND

MASS AIR FLOW SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between ECM connector and mass air flow

sensor connector.

Connector & terminal

(B3) No. 2 — (B135) No. 34:

Is the resistance less than 1

Ω?

Replace the mass

air flow sensor.

Mass Air Flow and

Intake Air Temper-

ature Sensor.>

Repair the open

circuit of harness

between mass air

flow sensor con-

nector and ECM

connector.

Page 1297 of 2453

EN(H6DO)(diag)-136

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

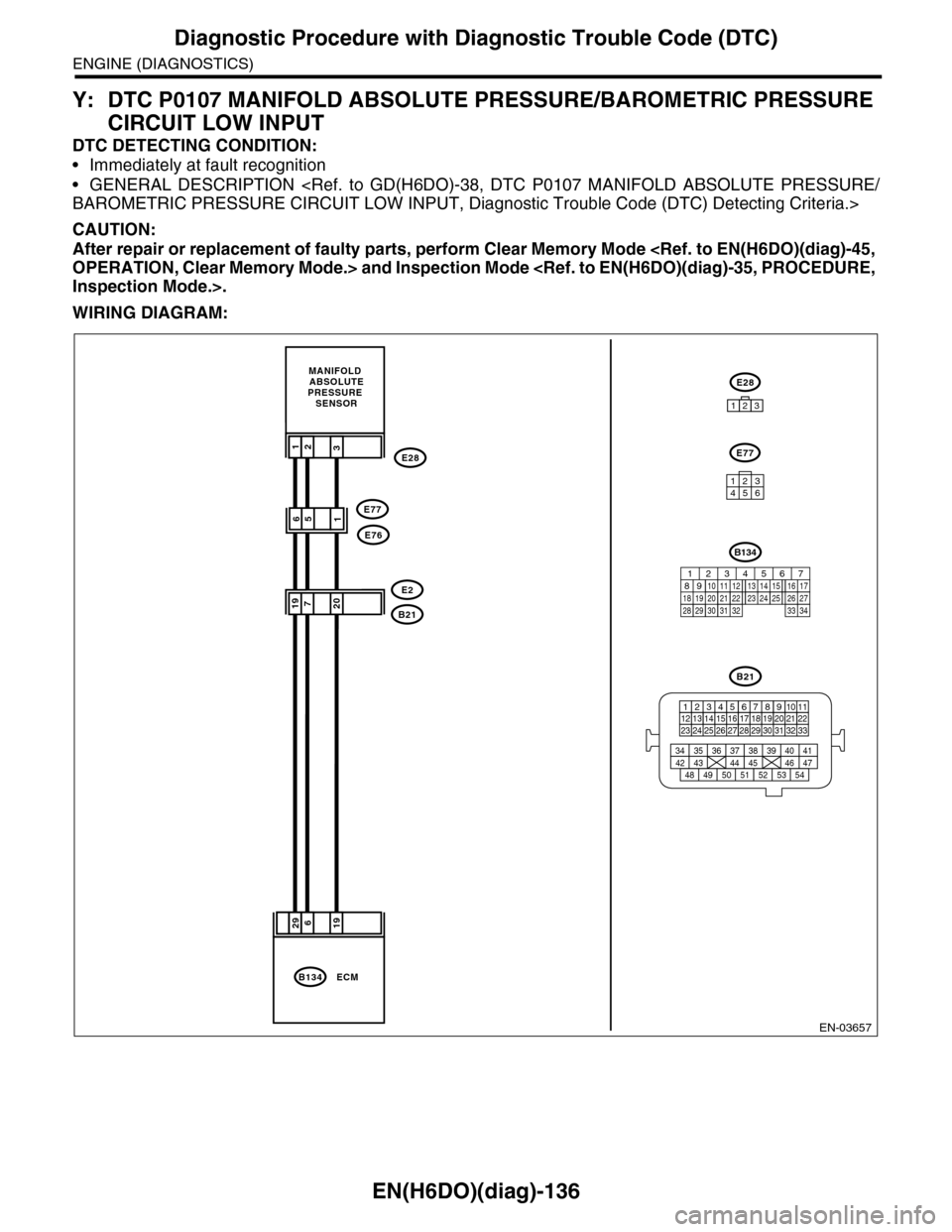

Y: DTC P0107 MANIFOLD ABSOLUTE PRESSURE/BAROMETRIC PRESSURE

CIRCUIT LOW INPUT

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03657

29619

MANIFOLD ABSOLUTEPRESSURE SENSOR

19207B21

E2

132E28

ECMB134

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

651E77

E76

E28

123

E77

134562

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 1298 of 2453

EN(H6DO)(diag)-137

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

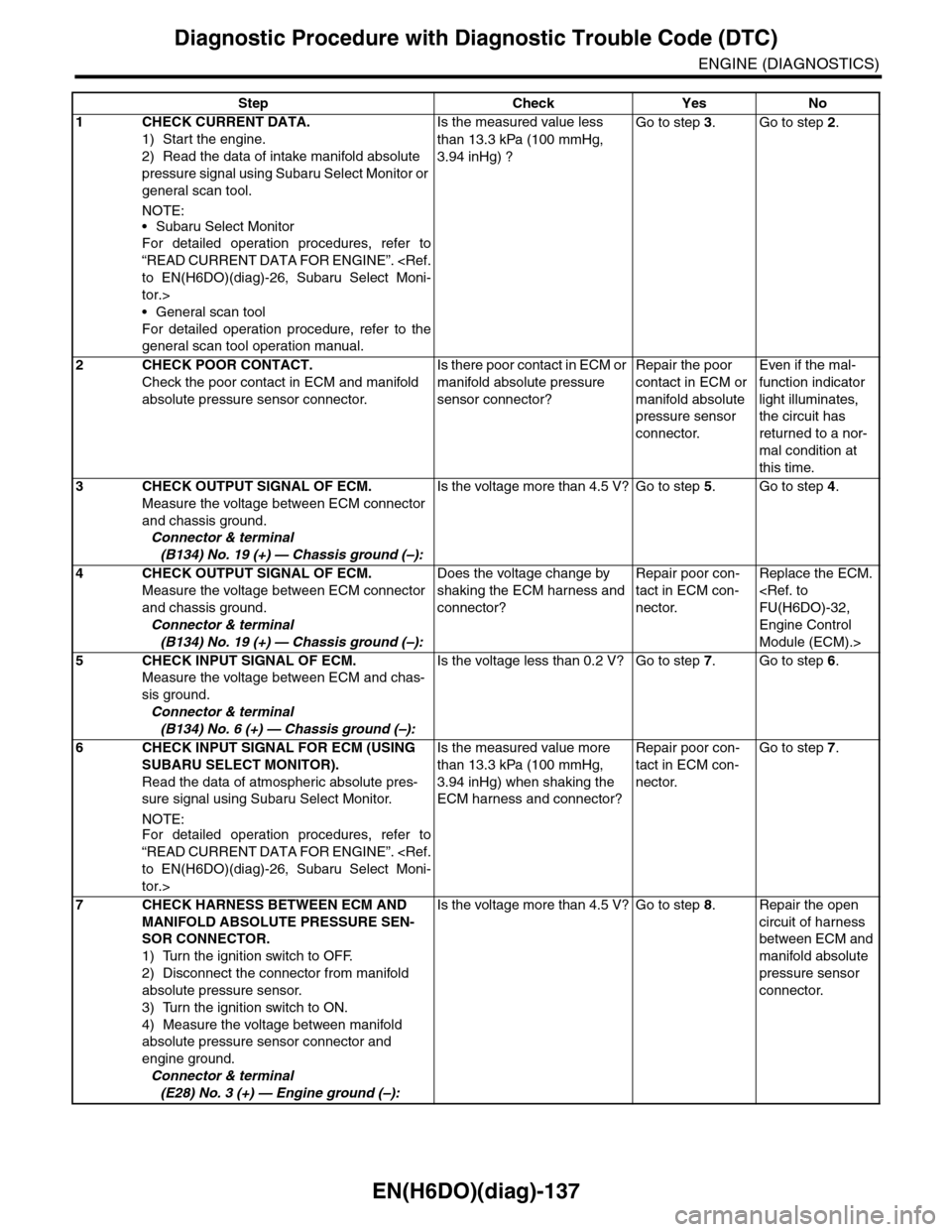

1CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of intake manifold absolute

pressure signal using Subaru Select Monitor or

general scan tool.

NOTE:

•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the measured value less

than 13.3 kPa (100 mmHg,

3.94 inHg) ?

Go to step 3.Go to step 2.

2CHECK POOR CONTACT.

Check the poor contact in ECM and manifold

absolute pressure sensor connector.

Is there poor contact in ECM or

manifold absolute pressure

sensor connector?

Repair the poor

contact in ECM or

manifold absolute

pressure sensor

connector.

Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.

3CHECK OUTPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B134) No. 19 (+) — Chassis ground (–):

Is the voltage more than 4.5 V? Go to step 5.Go to step 4.

4CHECK OUTPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B134) No. 19 (+) — Chassis ground (–):

Does the voltage change by

shaking the ECM harness and

connector?

Repair poor con-

tact in ECM con-

nector.

Replace the ECM.

Engine Control

Module (ECM).>

5CHECK INPUT SIGNAL OF ECM.

Measure the voltage between ECM and chas-

sis ground.

Connector & terminal

(B134) No. 6 (+) — Chassis ground (–):

Is the voltage less than 0.2 V? Go to step 7.Go to step 6.

6CHECK INPUT SIGNAL FOR ECM (USING

SUBARU SELECT MONITOR).

Read the data of atmospheric absolute pres-

sure signal using Subaru Select Monitor.

NOTE:For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the measured value more

than 13.3 kPa (100 mmHg,

3.94 inHg) when shaking the

ECM harness and connector?

Repair poor con-

tact in ECM con-

nector.

Go to step 7.

7CHECK HARNESS BETWEEN ECM AND

MANIFOLD ABSOLUTE PRESSURE SEN-

SOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from manifold

absolute pressure sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between manifold

absolute pressure sensor connector and

engine ground.

Connector & terminal

(E28) No. 3 (+) — Engine ground (–):

Is the voltage more than 4.5 V? Go to step 8.Repair the open

circuit of harness

between ECM and

manifold absolute

pressure sensor

connector.

Page 1299 of 2453

EN(H6DO)(diag)-138

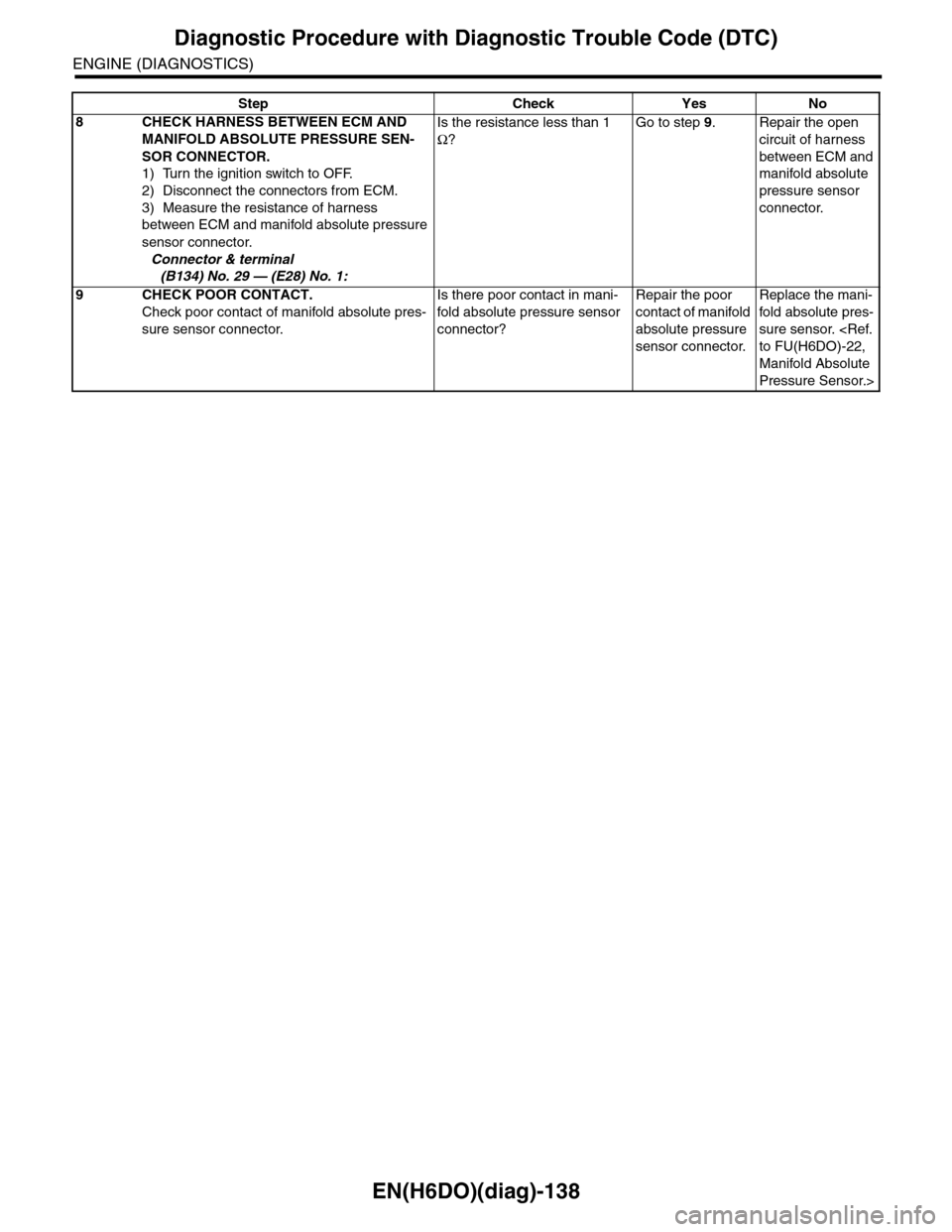

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

8CHECK HARNESS BETWEEN ECM AND

MANIFOLD ABSOLUTE PRESSURE SEN-

SOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between ECM and manifold absolute pressure

sensor connector.

Connector & terminal

(B134) No. 29 — (E28) No. 1:

Is the resistance less than 1

Ω?

Go to step 9.Repair the open

circuit of harness

between ECM and

manifold absolute

pressure sensor

connector.

9CHECK POOR CONTACT.

Check poor contact of manifold absolute pres-

sure sensor connector.

Is there poor contact in mani-

fold absolute pressure sensor

connector?

Repair the poor

contact of manifold

absolute pressure

sensor connector.

Replace the mani-

fold absolute pres-

sure sensor.

Manifold Absolute

Pressure Sensor.>

Step Check Yes No