sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1272 of 2453

EN(H6DO)(diag)-111

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

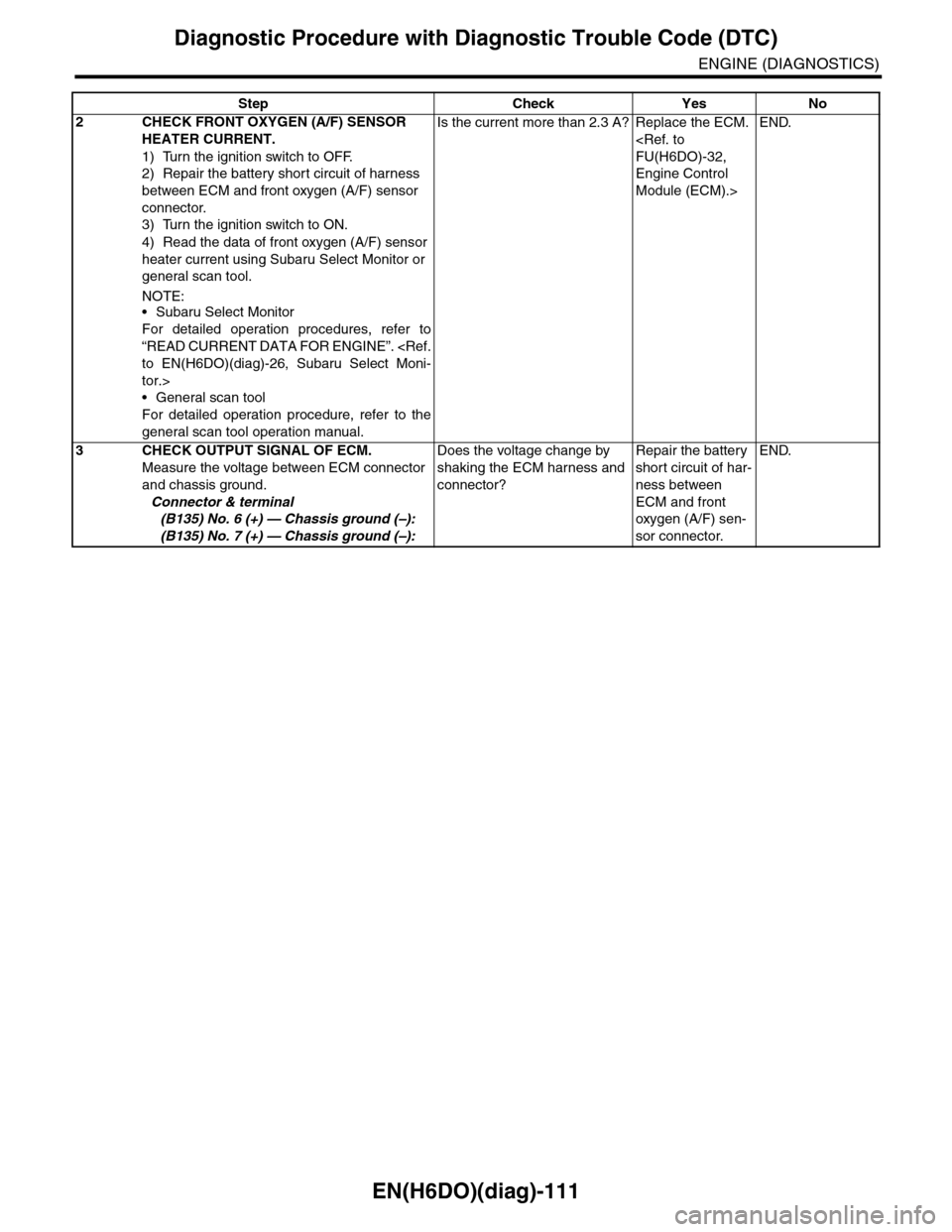

2CHECK FRONT OXYGEN (A/F) SENSOR

HEATER CURRENT.

1) Turn the ignition switch to OFF.

2) Repair the battery short circuit of harness

between ECM and front oxygen (A/F) sensor

connector.

3) Turn the ignition switch to ON.

4) Read the data of front oxygen (A/F) sensor

heater current using Subaru Select Monitor or

general scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the current more than 2.3 A? Replace the ECM.

Engine Control

Module (ECM).>

END.

3CHECK OUTPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B135) No. 6 (+) — Chassis ground (–):

(B135) No. 7 (+) — Chassis ground (–):

Does the voltage change by

shaking the ECM harness and

connector?

Repair the battery

short circuit of har-

ness between

ECM and front

oxygen (A/F) sen-

sor connector.

END.

Step Check Yes No

Page 1273 of 2453

EN(H6DO)(diag)-112

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

O: DTC P0057 HO2S HEATER CONTROL CIRCUIT LOW (BANK 2 SENSOR 2)

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Page 1274 of 2453

EN(H6DO)(diag)-113

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

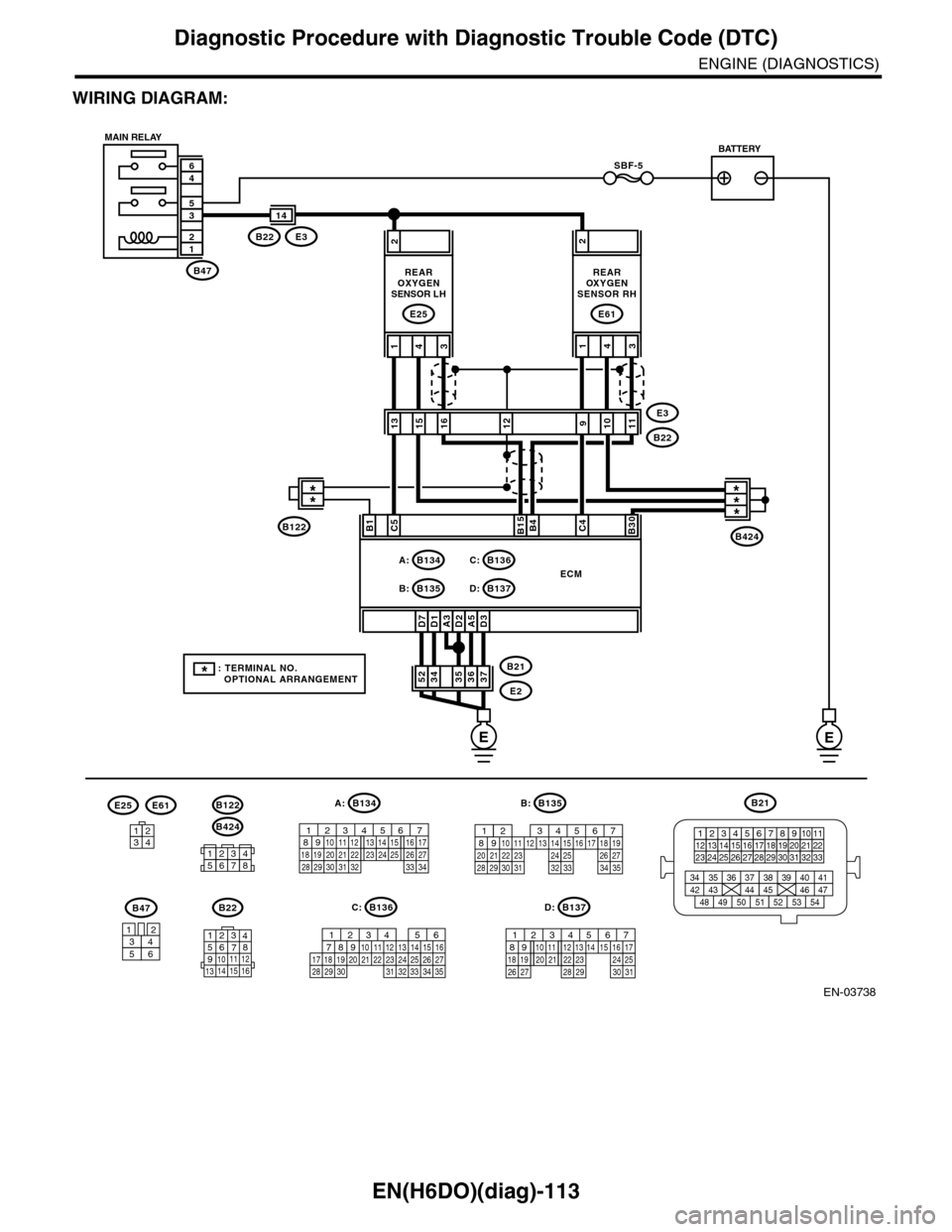

WIRING DIAGRAM:

EN-03738

SBF-5

B47

12

35

46

A3D7D1D2A5D3

2

373635363452B21

E2

ECM

C5B15B4C4B30

431

REAROXYGENSENSOR LH

E25

2

431

REAROXYGENSENSOR RH

E61

E3B22

14

1315E3

B221011129

B424

B47

3456

12

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

B135

567821943102422 23 2511 12 13 14 1526 2728

16 17 18 1920 2129 30 31 32 33 34 35

B:B134

56 7821943102422 23 2511 12 13 14 1526 2728

16 1718 19 20 2133 34293230 31

A:

16

B134A:

B135B:

B136C:

B137D:

B22

1234567891011 121314 15 16

B136

567821943102422 23 2511 12 13141526 2728

1617 18 19 20 2133 3429323031 35

C:B137

5678219431022 2311 12 13 14 1524 2526

16 1718 19 20 2127 28 29 30 31

D:

12345678

B424

B122

3412

E25E61

MAIN RELAYBATTERY

EE

* : TERMINAL NO. OPTIONAL ARRANGEMENT

***B1

**

B122

Page 1275 of 2453

EN(H6DO)(diag)-114

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

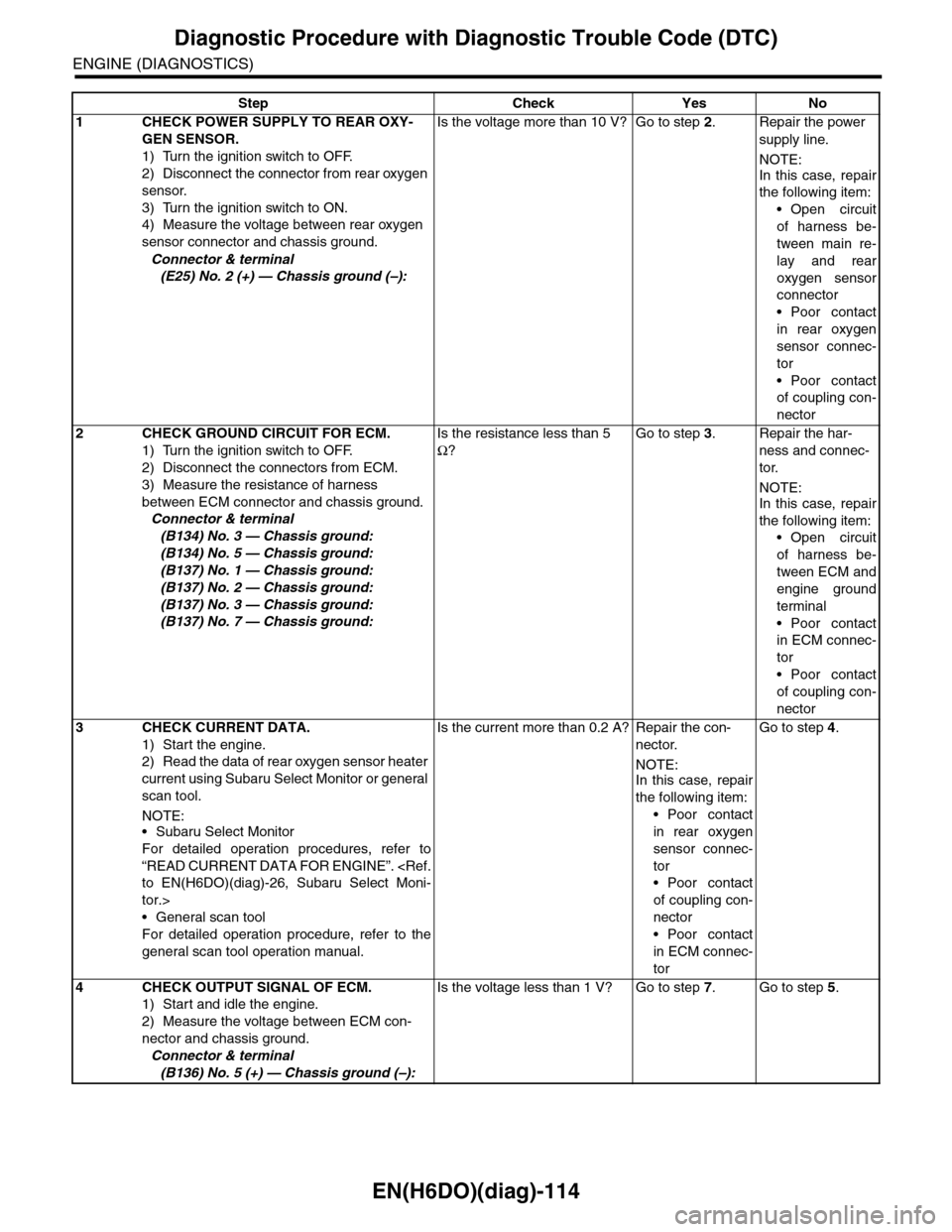

Step Check Yes No

1CHECK POWER SUPPLY TO REAR OXY-

GEN SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from rear oxygen

sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between rear oxygen

sensor connector and chassis ground.

Connector & terminal

(E25) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 2.Repair the power

supply line.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween main re-

lay and rear

oxygen sensor

connector

•Poor contact

in rear oxygen

sensor connec-

tor

•Poor contact

of coupling con-

nector

2CHECK GROUND CIRCUIT FOR ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between ECM connector and chassis ground.

Connector & terminal

(B134) No. 3 — Chassis ground:

(B134) No. 5 — Chassis ground:

(B137) No. 1 — Chassis ground:

(B137) No. 2 — Chassis ground:

(B137) No. 3 — Chassis ground:

(B137) No. 7 — Chassis ground:

Is the resistance less than 5

Ω?

Go to step 3.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

engine ground

terminal

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

3CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of rear oxygen sensor heater

current using Subaru Select Monitor or general

scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the current more than 0.2 A? Repair the con-

nector.

NOTE:In this case, repair

the following item:

•Poor contact

in rear oxygen

sensor connec-

tor

•Poor contact

of coupling con-

nector

•Poor contact

in ECM connec-

tor

Go to step 4.

4CHECK OUTPUT SIGNAL OF ECM.

1) Start and idle the engine.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 5 (+) — Chassis ground (–):

Is the voltage less than 1 V? Go to step 7.Go to step 5.

Page 1276 of 2453

EN(H6DO)(diag)-115

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

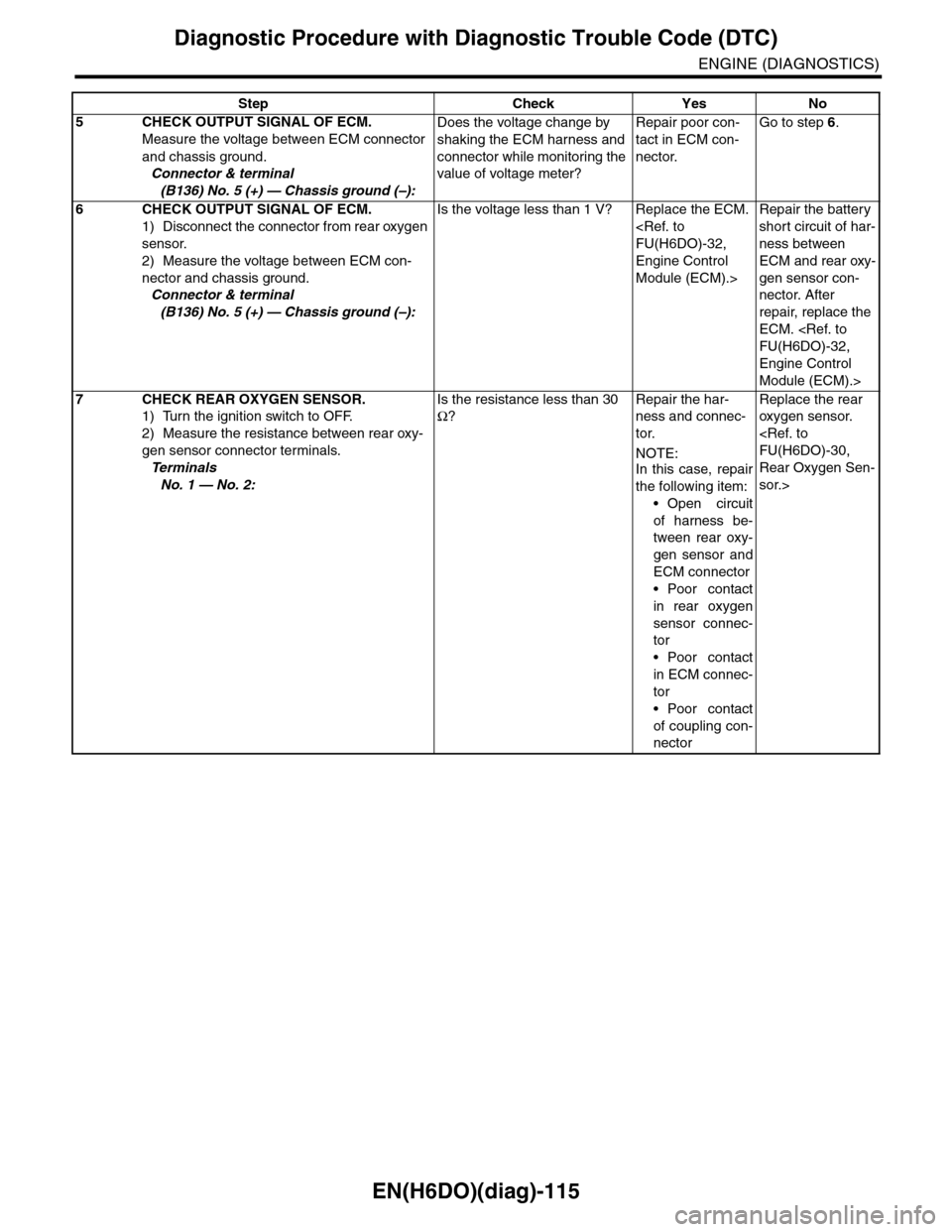

5CHECK OUTPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B136) No. 5 (+) — Chassis ground (–):

Does the voltage change by

shaking the ECM harness and

connector while monitoring the

value of voltage meter?

Repair poor con-

tact in ECM con-

nector.

Go to step 6.

6CHECK OUTPUT SIGNAL OF ECM.

1) Disconnect the connector from rear oxygen

sensor.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 5 (+) — Chassis ground (–):

Is the voltage less than 1 V? Replace the ECM.

Engine Control

Module (ECM).>

Repair the battery

short circuit of har-

ness between

ECM and rear oxy-

gen sensor con-

nector. After

repair, replace the

ECM.

Engine Control

Module (ECM).>

7CHECK REAR OXYGEN SENSOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between rear oxy-

gen sensor connector terminals.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance less than 30

Ω?

Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween rear oxy-

gen sensor and

ECM connector

•Poor contact

in rear oxygen

sensor connec-

tor

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

Replace the rear

oxygen sensor.

Rear Oxygen Sen-

sor.>

Step Check Yes No

Page 1277 of 2453

EN(H6DO)(diag)-116

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

P: DTC P0058 HO2S HEATER CONTROL CIRCUIT HIGH (BANK 2 SENSOR 2)

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Page 1278 of 2453

EN(H6DO)(diag)-117

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

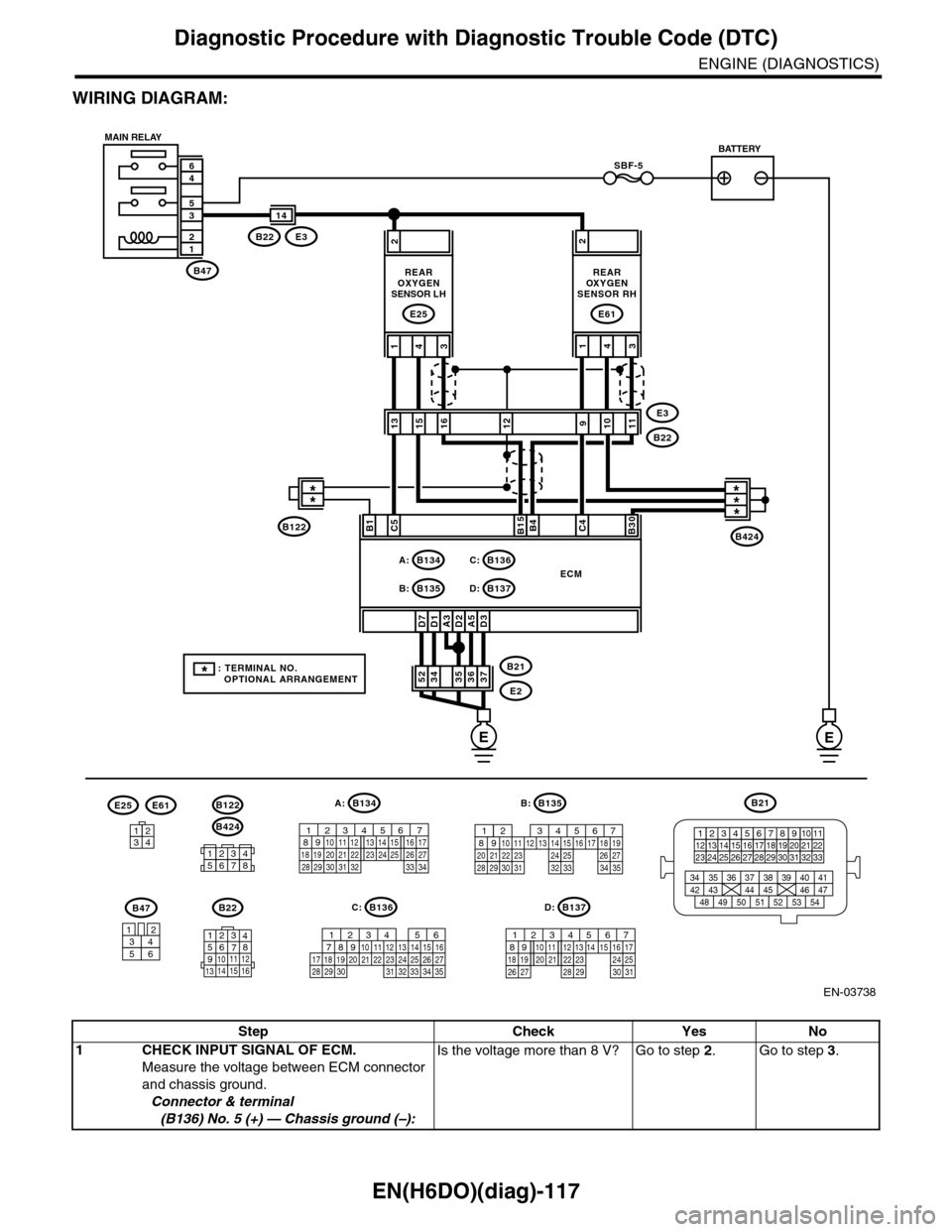

WIRING DIAGRAM:

EN-03738

SBF-5

B47

12

35

46

A3D7D1D2A5D3

2

373635363452B21

E2

ECM

C5B15B4C4B30

431

REAROXYGENSENSOR LH

E25

2

431

REAROXYGENSENSOR RH

E61

E3B22

14

1315E3

B221011129

B424

B47

3456

12

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

B135

567821943102422 23 2511 12 13 14 1526 2728

16 17 18 1920 2129 30 31 32 33 34 35

B:B134

56 7821943102422 23 2511 12 13 14 1526 2728

16 1718 19 20 2133 34293230 31

A:

16

B134A:

B135B:

B136C:

B137D:

B22

1234567891011 121314 15 16

B136

567821943102422 23 2511 12 13141526 2728

1617 18 19 20 2133 3429323031 35

C:B137

5678219431022 2311 12 13 14 1524 2526

16 1718 19 20 2127 28 29 30 31

D:

12345678

B424

B122

3412

E25E61

MAIN RELAYBATTERY

EE

* : TERMINAL NO. OPTIONAL ARRANGEMENT

***B1

**

B122

Step Check Yes No

1CHECK INPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B136) No. 5 (+) — Chassis ground (–):

Is the voltage more than 8 V? Go to step 2.Go to step 3.

Page 1279 of 2453

EN(H6DO)(diag)-118

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

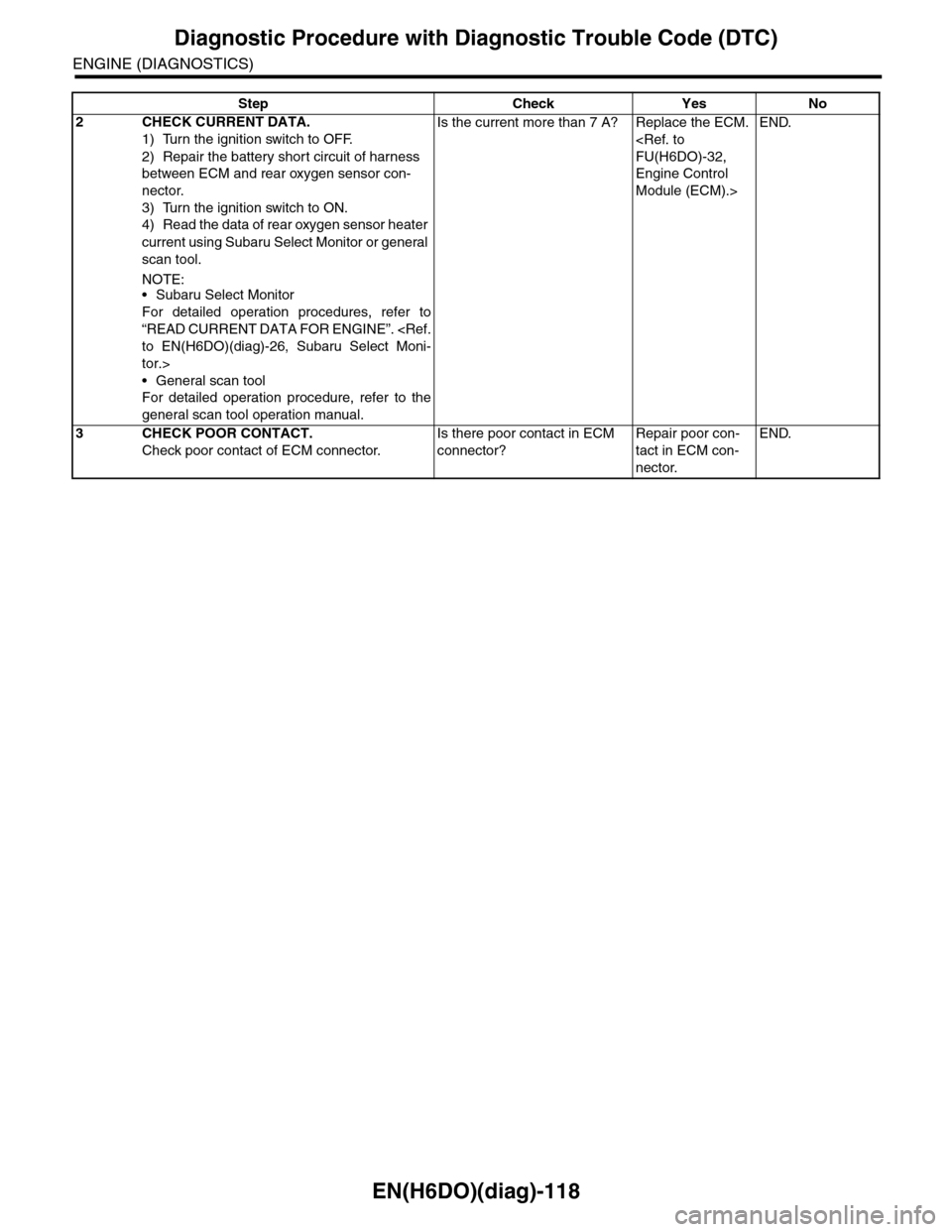

2CHECK CURRENT DATA.

1) Turn the ignition switch to OFF.

2) Repair the battery short circuit of harness

between ECM and rear oxygen sensor con-

nector.

3) Turn the ignition switch to ON.

4) Read the data of rear oxygen sensor heater

current using Subaru Select Monitor or general

scan tool.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the current more than 7 A? Replace the ECM.

Engine Control

Module (ECM).>

END.

3CHECK POOR CONTACT.

Check poor contact of ECM connector.

Is there poor contact in ECM

connector?

Repair poor con-

tact in ECM con-

nector.

END.

Step Check Yes No

Page 1280 of 2453

EN(H6DO)(diag)-119

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

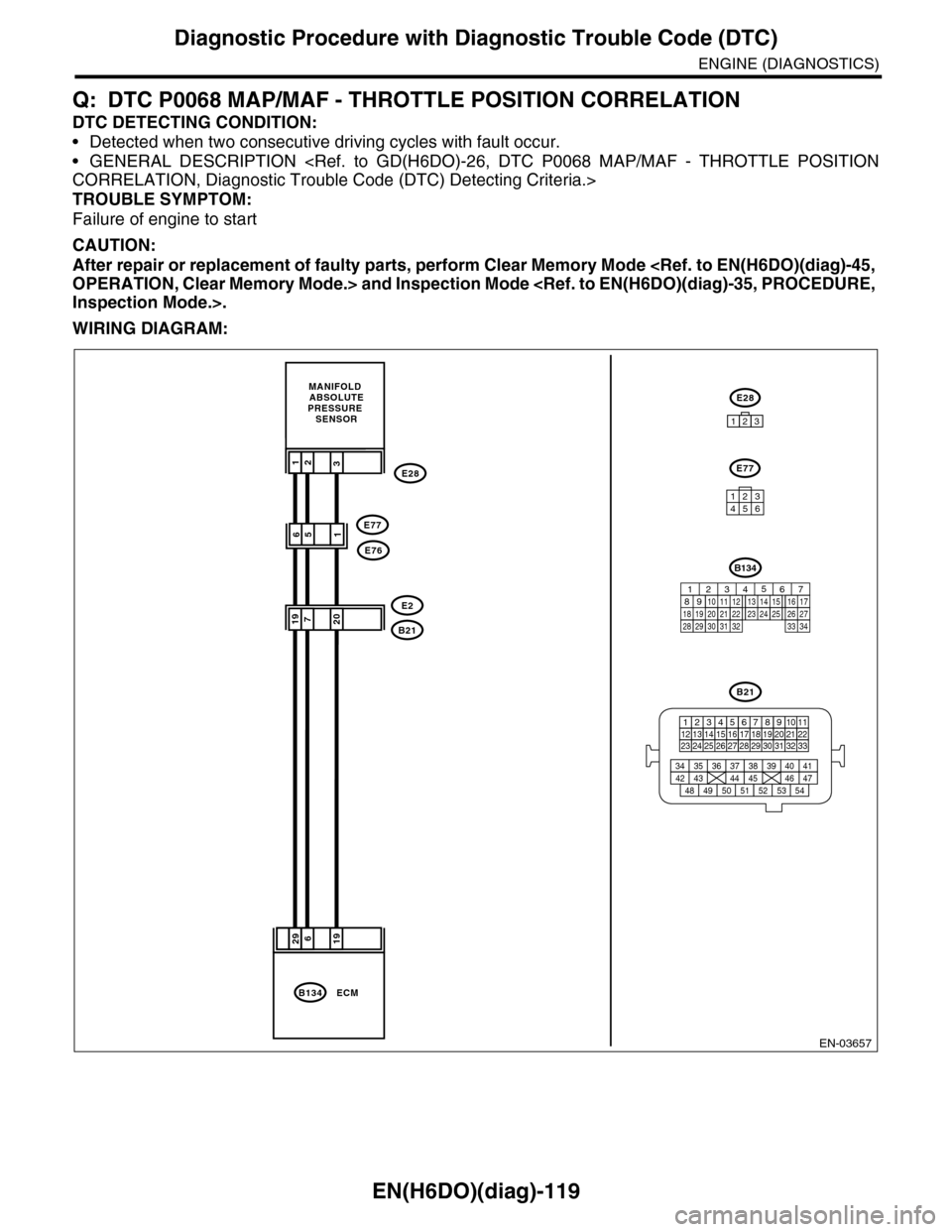

Q: DTC P0068 MAP/MAF - THROTTLE POSITION CORRELATION

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

Failure of engine to start

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03657

29619

MANIFOLD ABSOLUTEPRESSURE SENSOR

19207B21

E2

132E28

ECMB134

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

651E77

E76

E28

123

E77

134562

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 1281 of 2453

EN(H6DO)(diag)-120

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK IDLE SWITCH SIGNAL.

1) Turn the ignition switch to ON.

2) Operate the LED operation mode for

engine using Subaru Select Monitor.

NOTE:•Subaru Select Monitor

For detailed operation procedure, refer to the

“LED OPERATION MODE FOR ENGINE.”

Does the LED of {Idle Switch

Signal} come on?

Go to step 2.Check the throttle

position sensor cir-

cuit.

382, DTC P2135

THROTTLE/

PEDAL POSI-

TION SENSOR/

SWITCH “A”/“B”

VOLTAGE RATIO-

NALITY, Diagnos-

tic Procedure with

Diagnostic Trou-

ble Code (DTC).>

NOTE:

In this case, it is

not necessary to

inspect DTC

P0106.

2CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the relative

DTC.“List of Diag-

nostic Trouble

Code (DTC)”

EN(H6DO)(diag)-

69, List of Diag-

nostic Trouble

Code (DTC).>

NOTE:

In this case, it is

not necessary to

inspect DTC

P0106.

Go to step 3.

3CHECK CONDITION OF MANIFOLD ABSO-

LUTE PRESSURE SENSOR.

Is the manifold absolute pres-

sure sensor installation bolt

tightened securely?

Go to step 4.Securely tighten

the manifold abso-

lute pressure sen-

sor installation

bolt.

4CHECK CONDITION OF THROTTLE BODY.Is the throttle body installation

bolt tightened securely?

Replace the mani-

fold absolute pres-

sure sensor.

Manifold Absolute

Pressure Sensor.>

Tighten the throttle

body installation

bolt securely.