sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1385 of 2453

EN(H6DO)(diag)-224

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

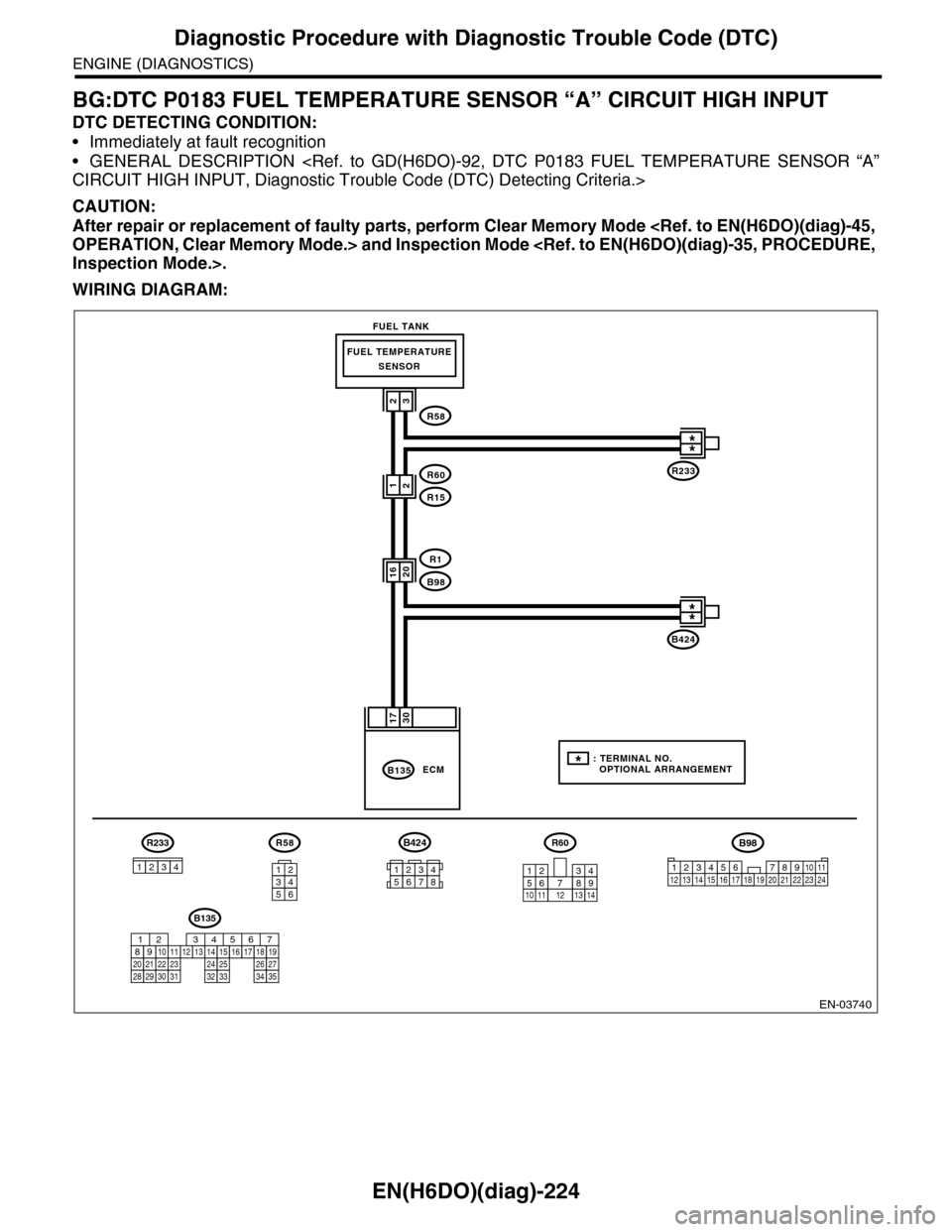

BG:DTC P0183 FUEL TEMPERATURE SENSOR “A” CIRCUIT HIGH INPUT

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03740

B424

3017

ECMB135

R58

R60

R15

R1

B98

23

FUEL TEMPERATURESENSOR

FUEL TANK

R58

123456

B424

34561278

: TERMINAL NO. OPTIONAL ARRANGEMENT*

**

R233

**

12

1620

R60

12

10115634897131412

1234

R233B98

3412 8910 1112 13 14 15 16 17 18 19 20 21 22 23 2456 7

B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

Page 1386 of 2453

EN(H6DO)(diag)-225

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

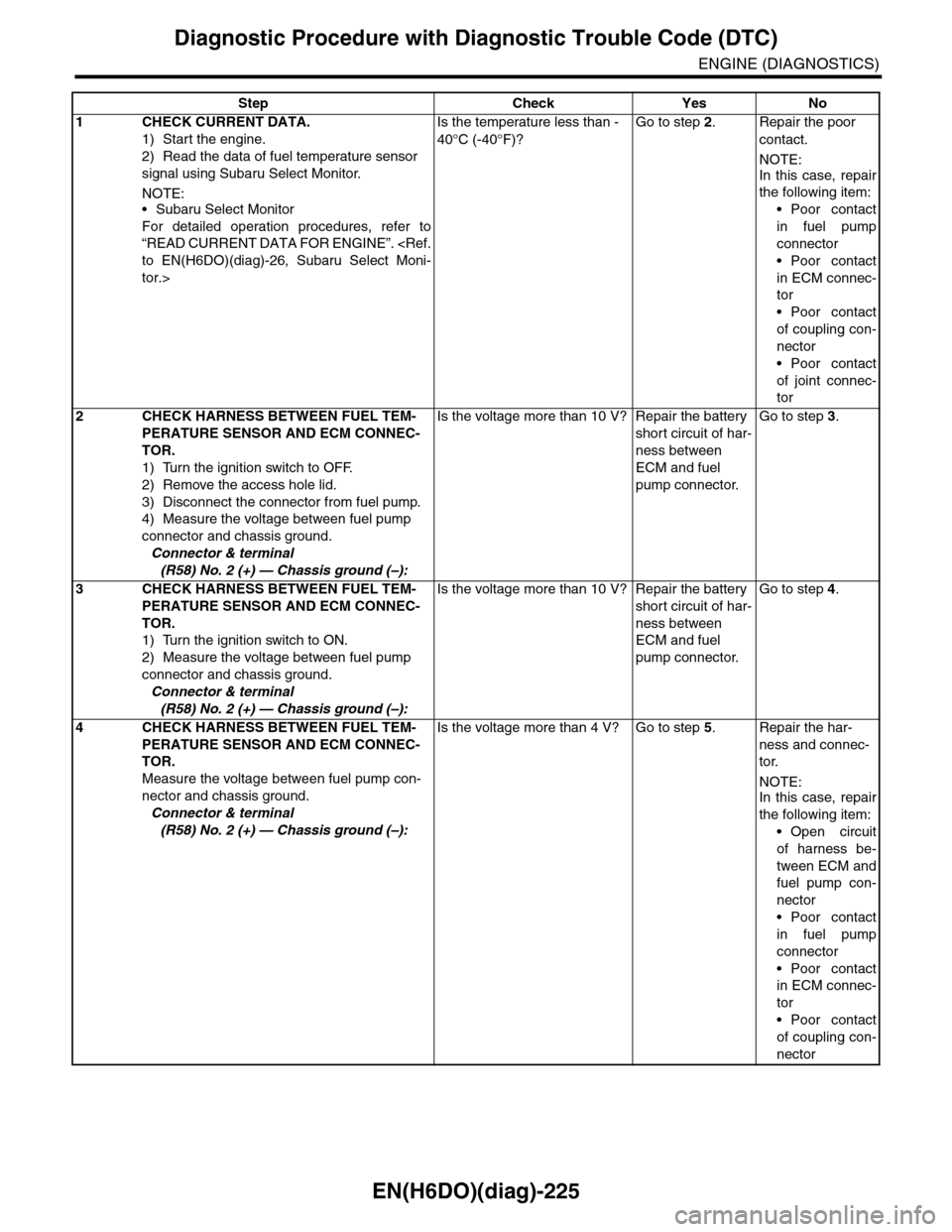

Step Check Yes No

1CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of fuel temperature sensor

signal using Subaru Select Monitor.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the temperature less than -

40°C (-40°F)?

Go to step 2.Repair the poor

contact.

NOTE:

In this case, repair

the following item:

•Poor contact

in fuel pump

connector

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

•Poor contact

of joint connec-

tor

2 CHECK HARNESS BETWEEN FUEL TEM-

PERATURE SENSOR AND ECM CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Remove the access hole lid.

3) Disconnect the connector from fuel pump.

4) Measure the voltage between fuel pump

connector and chassis ground.

Connector & terminal

(R58) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Repair the battery

short circuit of har-

ness between

ECM and fuel

pump connector.

Go to step 3.

3 CHECK HARNESS BETWEEN FUEL TEM-

PERATURE SENSOR AND ECM CONNEC-

TOR.

1) Turn the ignition switch to ON.

2) Measure the voltage between fuel pump

connector and chassis ground.

Connector & terminal

(R58) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Repair the battery

short circuit of har-

ness between

ECM and fuel

pump connector.

Go to step 4.

4 CHECK HARNESS BETWEEN FUEL TEM-

PERATURE SENSOR AND ECM CONNEC-

TOR.

Measure the voltage between fuel pump con-

nector and chassis ground.

Connector & terminal

(R58) No. 2 (+) — Chassis ground (–):

Is the voltage more than 4 V? Go to step 5.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

fuel pump con-

nector

•Poor contact

in fuel pump

connector

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

Page 1387 of 2453

EN(H6DO)(diag)-226

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

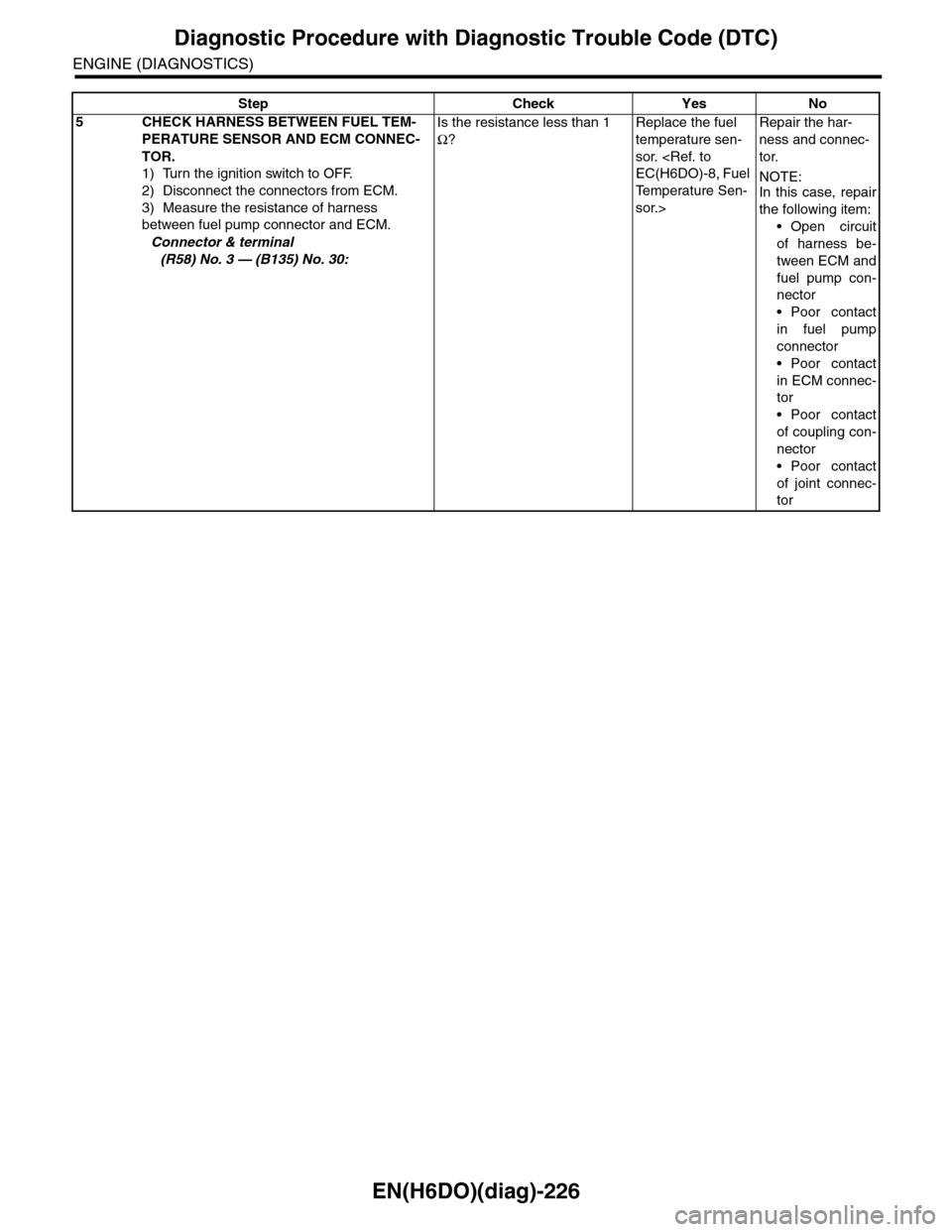

5 CHECK HARNESS BETWEEN FUEL TEM-

PERATURE SENSOR AND ECM CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between fuel pump connector and ECM.

Connector & terminal

(R58) No. 3 — (B135) No. 30:

Is the resistance less than 1

Ω?

Replace the fuel

temperature sen-

sor.

Te m p e r a t u r e S e n -

sor.>

Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

fuel pump con-

nector

•Poor contact

in fuel pump

connector

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

•Poor contact

of joint connec-

tor

Step Check Yes No

Page 1388 of 2453

EN(H6DO)(diag)-227

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

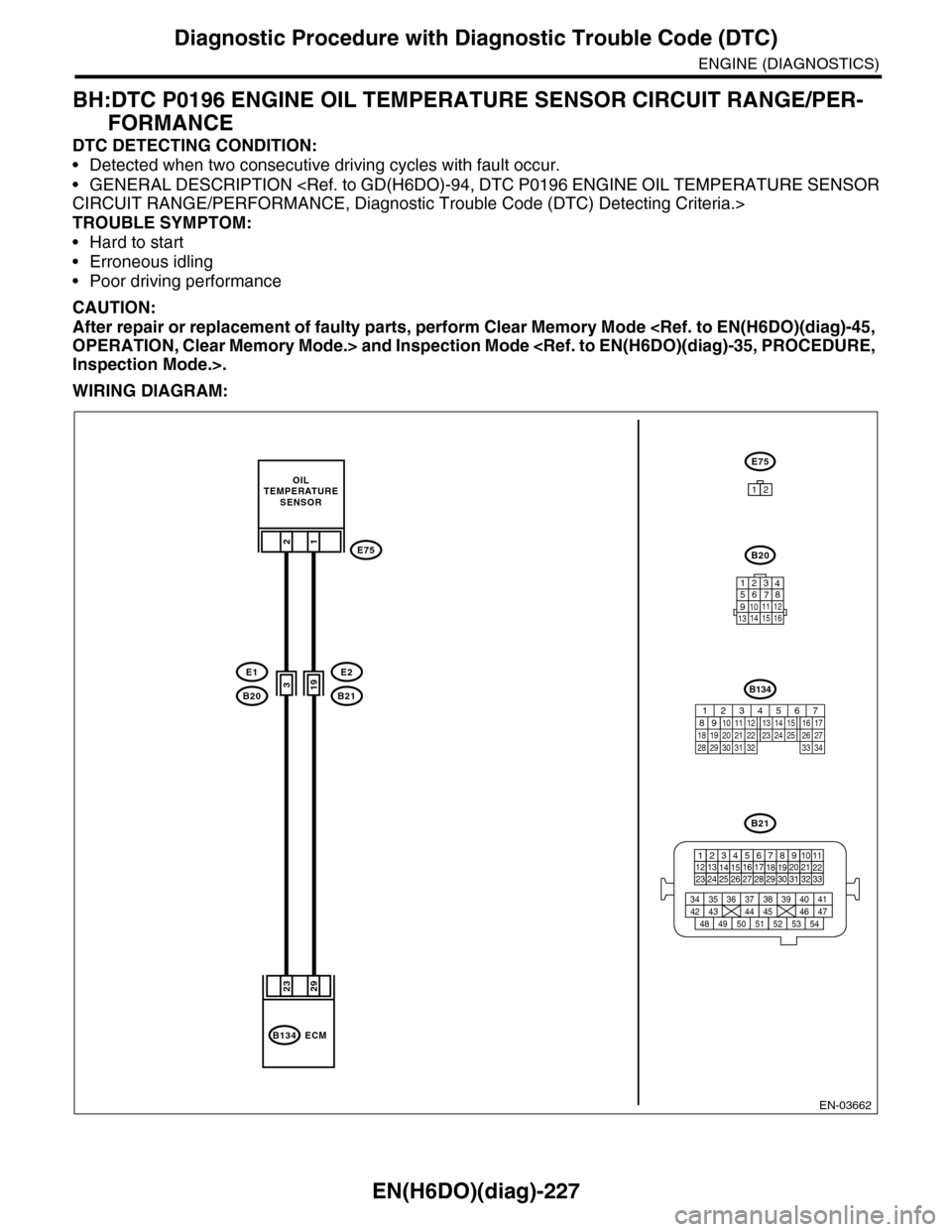

BH:DTC P0196 ENGINE OIL TEMPERATURE SENSOR CIRCUIT RANGE/PER-

FORMANCE

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Hard to start

•Erroneous idling

•Poor driving performance

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03662

E75

E2

B21

B134 ECM

1

19

29

E1

B20

2

3

23

E75

12

B20

1234567891011 121314 15 16

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

OILTEMPERATURESENSOR

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 1390 of 2453

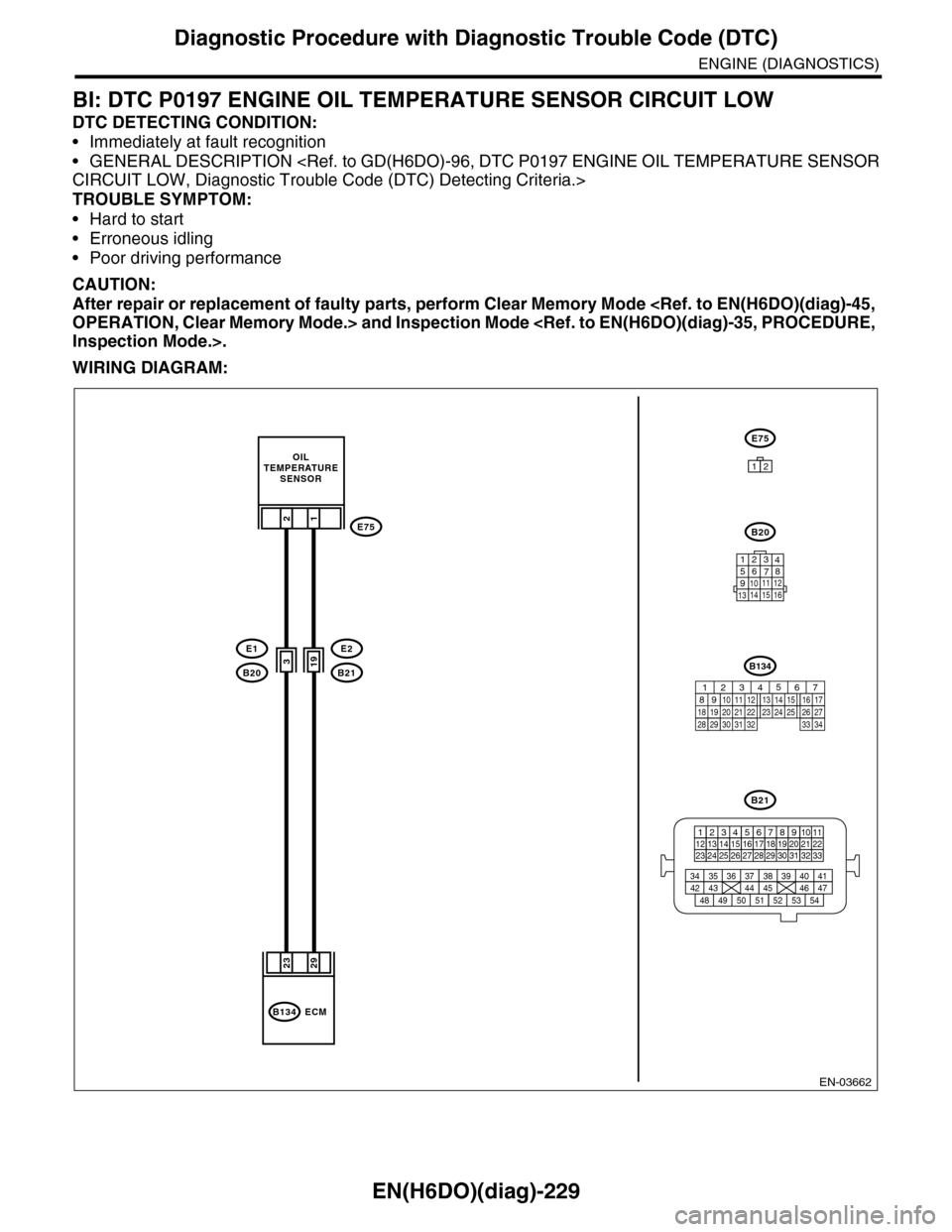

EN(H6DO)(diag)-229

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

BI: DTC P0197 ENGINE OIL TEMPERATURE SENSOR CIRCUIT LOW

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Hard to start

•Erroneous idling

•Poor driving performance

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03662

E75

E2

B21

B134 ECM

1

19

29

E1

B20

2

3

23

E75

12

B20

1234567891011 121314 15 16

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

OILTEMPERATURESENSOR

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 1391 of 2453

EN(H6DO)(diag)-230

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

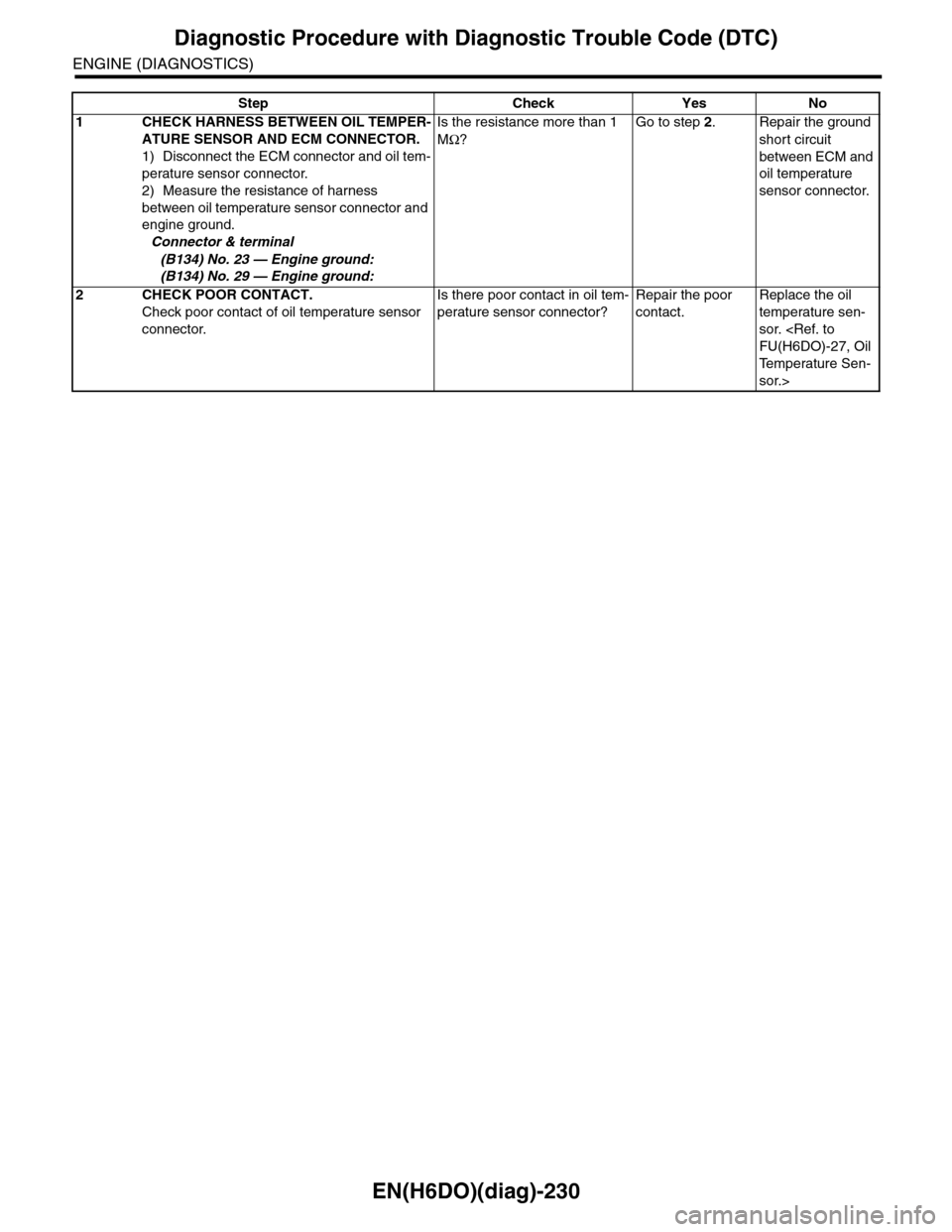

Step Check Yes No

1CHECK HARNESS BETWEEN OIL TEMPER-

ATURE SENSOR AND ECM CONNECTOR.

1) Disconnect the ECM connector and oil tem-

perature sensor connector.

2) Measure the resistance of harness

between oil temperature sensor connector and

engine ground.

Connector & terminal

(B134) No. 23 — Engine ground:

(B134) No. 29 — Engine ground:

Is the resistance more than 1

MΩ?

Go to step 2.Repair the ground

short circuit

between ECM and

oil temperature

sensor connector.

2CHECK POOR CONTACT.

Check poor contact of oil temperature sensor

connector.

Is there poor contact in oil tem-

perature sensor connector?

Repair the poor

contact.

Replace the oil

temperature sen-

sor.

Te m p e r a t u r e S e n -

sor.>

Page 1392 of 2453

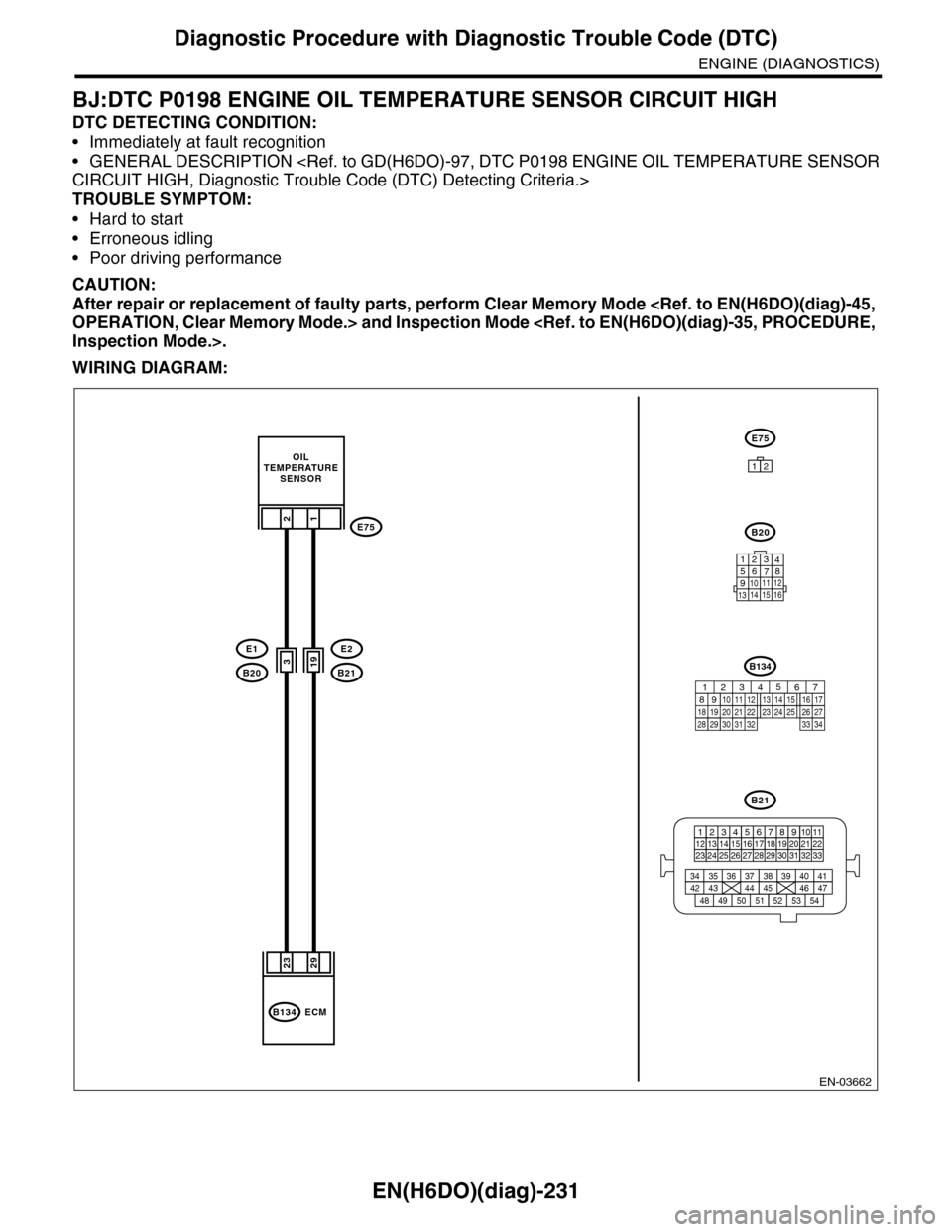

EN(H6DO)(diag)-231

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

BJ:DTC P0198 ENGINE OIL TEMPERATURE SENSOR CIRCUIT HIGH

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Hard to start

•Erroneous idling

•Poor driving performance

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03662

E75

E2

B21

B134 ECM

1

19

29

E1

B20

2

3

23

E75

12

B20

1234567891011 121314 15 16

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

OILTEMPERATURESENSOR

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 1393 of 2453

EN(H6DO)(diag)-232

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

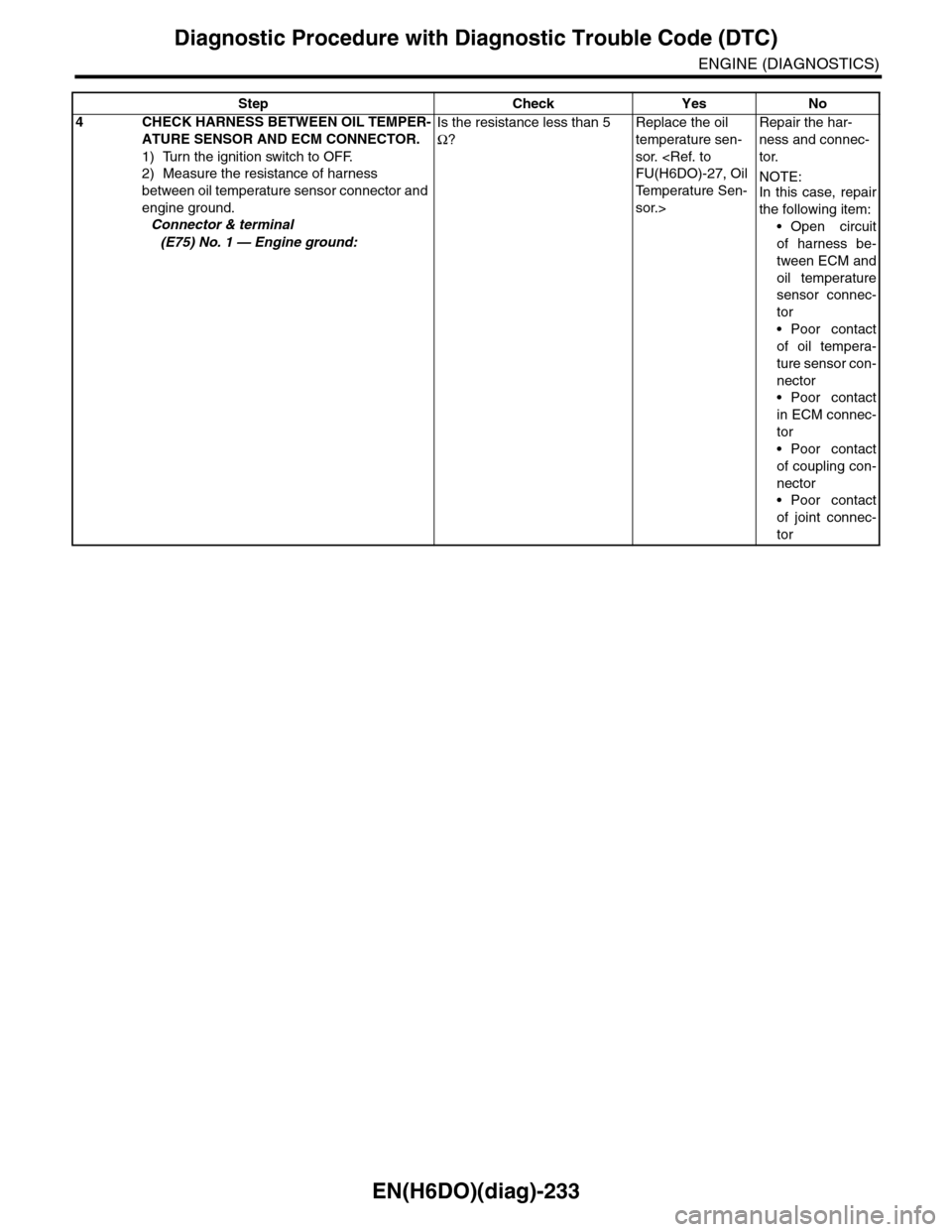

Step Check Yes No

1CHECK HARNESS BETWEEN OIL TEMPER-

ATURE SENSOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from oil tempera-

ture sensor.

3) Measure the voltage between oil tempera-

ture sensor connector and engine ground.

Connector & terminal

(E75) No. 2 (+) — Engine ground (–):

Is the voltage more than 10 V? Repair the battery

short circuit of har-

ness between

ECM and oil tem-

perature sensor

connector.

Go to step 2.

2CHECK HARNESS BETWEEN OIL TEMPER-

ATURE SENSOR AND ECM CONNECTOR.

1) Turn the ignition switch to ON.

2) Measure the voltage between oil tempera-

ture sensor connector and engine ground.

Connector & terminal

(E75) No. 2 (+) — Engine ground (–):

Is the voltage more than 10 V? Repair the battery

short circuit of har-

ness between

ECM and oil tem-

perature sensor

connector.

Go to step 3.

3CHECK HARNESS BETWEEN OIL TEMPER-

ATURE SENSOR AND ECM CONNECTOR.

Measure the voltage between oil temperature

sensor connector and engine ground.

Connector & terminal

(E75) No. 2 (+) — Engine ground (–):

Is the voltage more than 4 V? Go to step 4.Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

oil temperature

sensor connec-

tor

•Poor contact

of oil tempera-

ture sensor con-

nector

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

Page 1394 of 2453

EN(H6DO)(diag)-233

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

4CHECK HARNESS BETWEEN OIL TEMPER-

ATURE SENSOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between oil temperature sensor connector and

engine ground.

Connector & terminal

(E75) No. 1 — Engine ground:

Is the resistance less than 5

Ω?

Replace the oil

temperature sen-

sor.

Te m p e r a t u r e S e n -

sor.>

Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

oil temperature

sensor connec-

tor

•Poor contact

of oil tempera-

ture sensor con-

nector

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

•Poor contact

of joint connec-

tor

Step Check Yes No

Page 1395 of 2453

EN(H6DO)(diag)-234

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

BK:DTC P0222 THROTTLE/PEDAL POSITION SENSOR/SWITCH “B” CIRCUIT

LOW INPUT

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Erroneous idling

•Poor driving performance

•Engine stalls.