sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1397 of 2453

EN(H6DO)(diag)-236

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

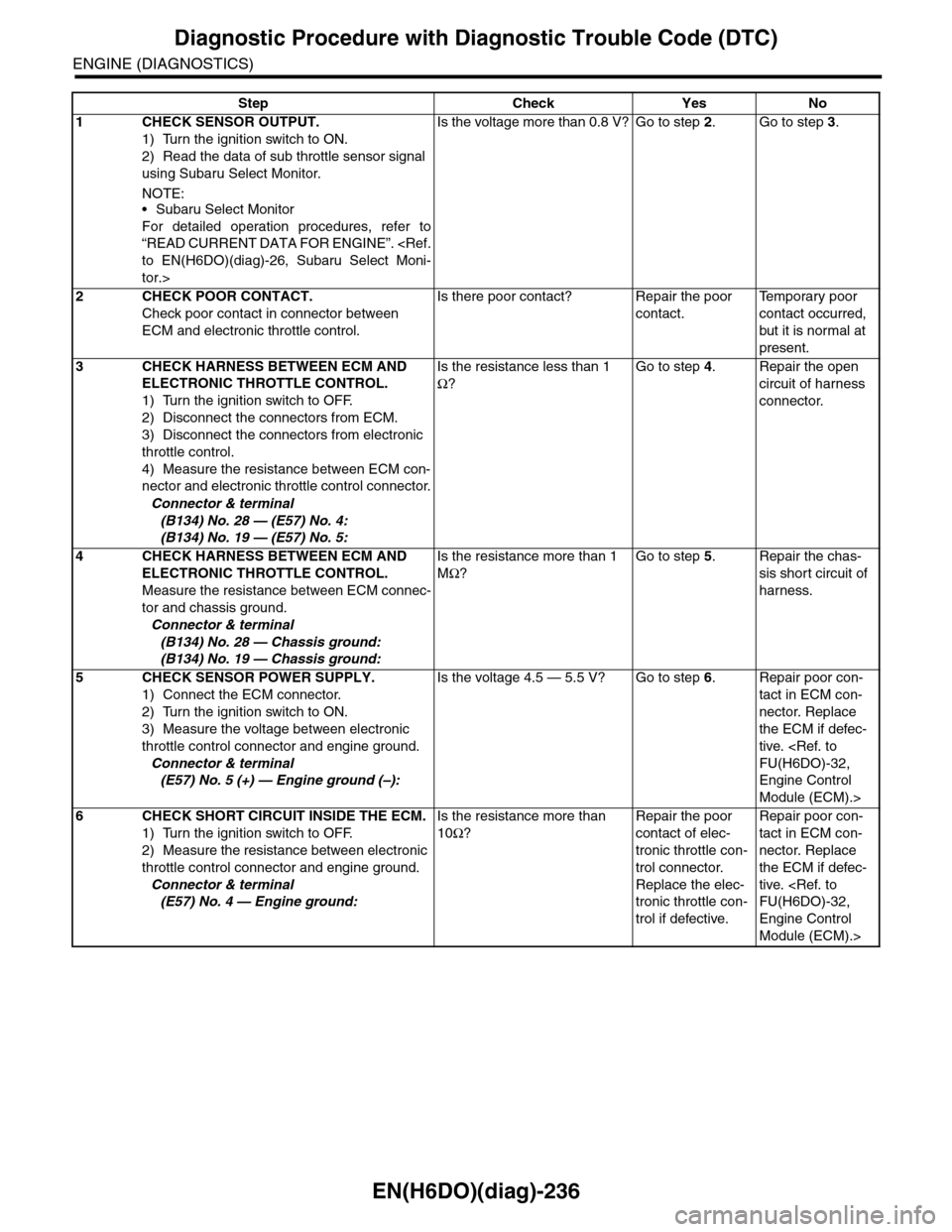

Step Check Yes No

1CHECK SENSOR OUTPUT.

1) Turn the ignition switch to ON.

2) Read the data of sub throttle sensor signal

using Subaru Select Monitor.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the voltage more than 0.8 V? Go to step 2.Go to step 3.

2CHECK POOR CONTACT.

Check poor contact in connector between

ECM and electronic throttle control.

Is there poor contact? Repair the poor

contact.

Te m p o r a r y p o o r

contact occurred,

but it is normal at

present.

3CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Disconnect the connectors from electronic

throttle control.

4) Measure the resistance between ECM con-

nector and electronic throttle control connector.

Connector & terminal

(B134) No. 28 — (E57) No. 4:

(B134) No. 19 — (E57) No. 5:

Is the resistance less than 1

Ω?

Go to step 4.Repair the open

circuit of harness

connector.

4CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

Measure the resistance between ECM connec-

tor and chassis ground.

Connector & terminal

(B134) No. 28 — Chassis ground:

(B134) No. 19 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 5.Repair the chas-

sis short circuit of

harness.

5CHECK SENSOR POWER SUPPLY.

1) Connect the ECM connector.

2) Turn the ignition switch to ON.

3) Measure the voltage between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 5 (+) — Engine ground (–):

Is the voltage 4.5 — 5.5 V? Go to step 6.Repair poor con-

tact in ECM con-

nector. Replace

the ECM if defec-

tive.

Engine Control

Module (ECM).>

6CHECK SHORT CIRCUIT INSIDE THE ECM.

1) Turn the ignition switch to OFF.

2) Measure the resistance between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 4 — Engine ground:

Is the resistance more than

10Ω?

Repair the poor

contact of elec-

tronic throttle con-

trol connector.

Replace the elec-

tronic throttle con-

trol if defective.

Repair poor con-

tact in ECM con-

nector. Replace

the ECM if defec-

tive.

Engine Control

Module (ECM).>

Page 1398 of 2453

EN(H6DO)(diag)-237

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

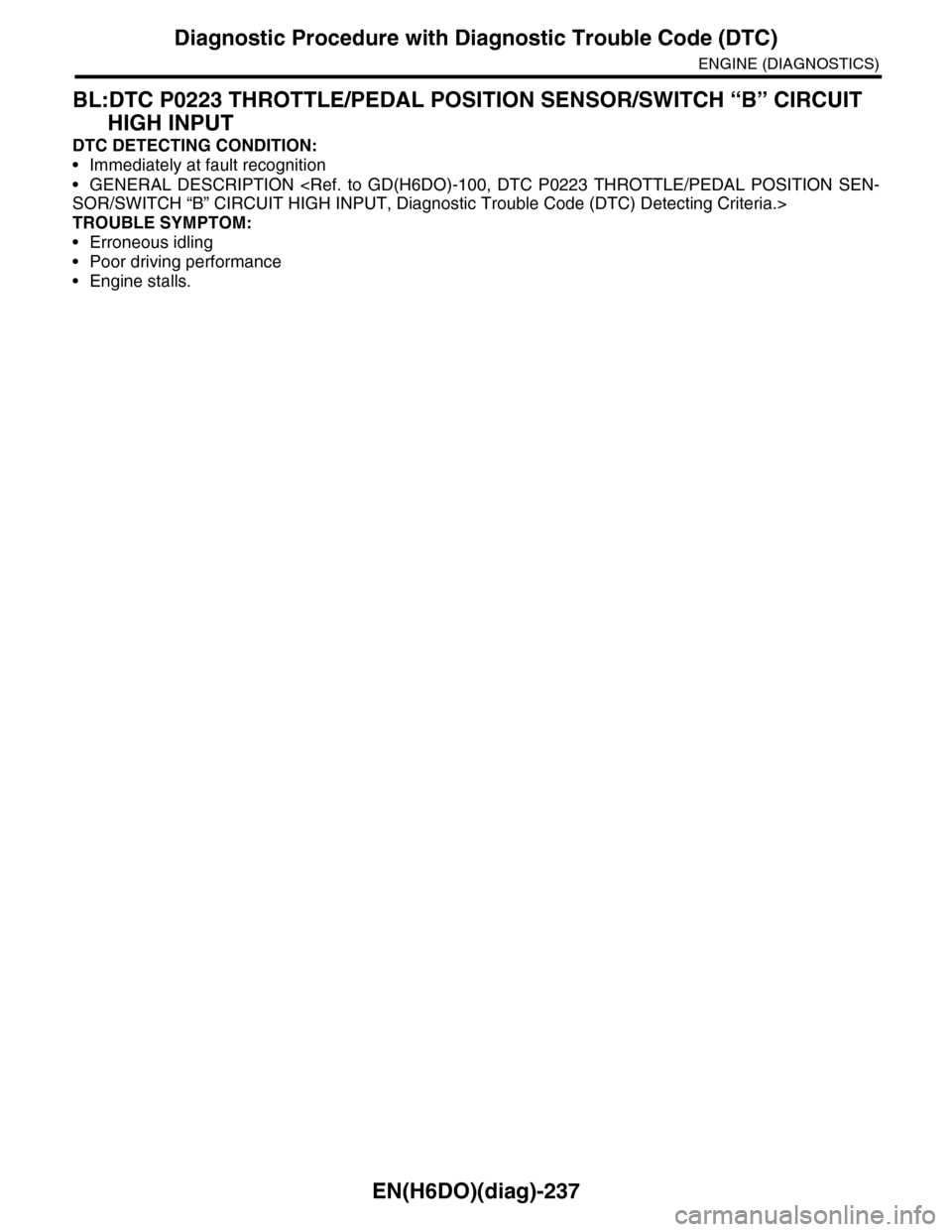

BL:DTC P0223 THROTTLE/PEDAL POSITION SENSOR/SWITCH “B” CIRCUIT

HIGH INPUT

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Erroneous idling

•Poor driving performance

•Engine stalls.

Page 1400 of 2453

EN(H6DO)(diag)-239

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK SENSOR OUTPUT.

1) Turn the ignition switch to ON.

2) Read the data of sub throttle sensor signal

using Subaru Select Monitor.

NOTE:•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the voltage less than 4.73

V?

Go to step 2.Go to step 3.

2CHECK POOR CONTACT.

Check poor contact in connector between

ECM and electronic throttle control.

Is there poor contact in con-

nector between ECM and elec-

tronic throttle control?

Repair the poor

contact.

Te m p o r a r y p o o r

contact occurred,

but it is normal at

present.

3CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Disconnect the connectors from electronic

throttle control.

4) Measure the resistance between ECM con-

nector and electronic throttle control connector.

Connector & terminal

(B134) No. 29 — (E57) No. 3:

(B134) No. 28 — (E57) No. 4:

Is the resistance less than 1

Ω?

Go to step 4.Repair the open

circuit of harness

connector.

4CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Connect the ECM connector.

2) Measure the resistance between electronic

throttle control connector and engine ground.

Connector & terminal

(E57) No. 3 — Engine ground:

Is the resistance less than 5

Ω?

Go to step 5.Repair poor con-

tact in ECM con-

nector. Replace

the ECM if defec-

tive.

Engine Control

Module (ECM).>

5CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

Measure the voltage between electronic throt-

tle control connector and engine ground.

Connector & terminal

(E57) No. 4 (+) — Engine ground (–):

Is the voltage less than 10 V? Go to step 6.Repair the battery

short circuit of har-

ness between

ECM connector

and electronic

throttle control

connector.

6CHECK HARNESS BETWEEN ECM AND

ELECTRONIC THROTTLE CONTROL.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance between connector

terminals.

Connector & terminal

(B134) No. 19 — (B134) No. 28:

Is the resistance more than 1

MΩ?

Repair the poor

contact. Replace

the electronic

throttle control.

Sensor power sup-

ply circuit may be

shorted.

Page 1407 of 2453

EN(H6DO)(diag)-246

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

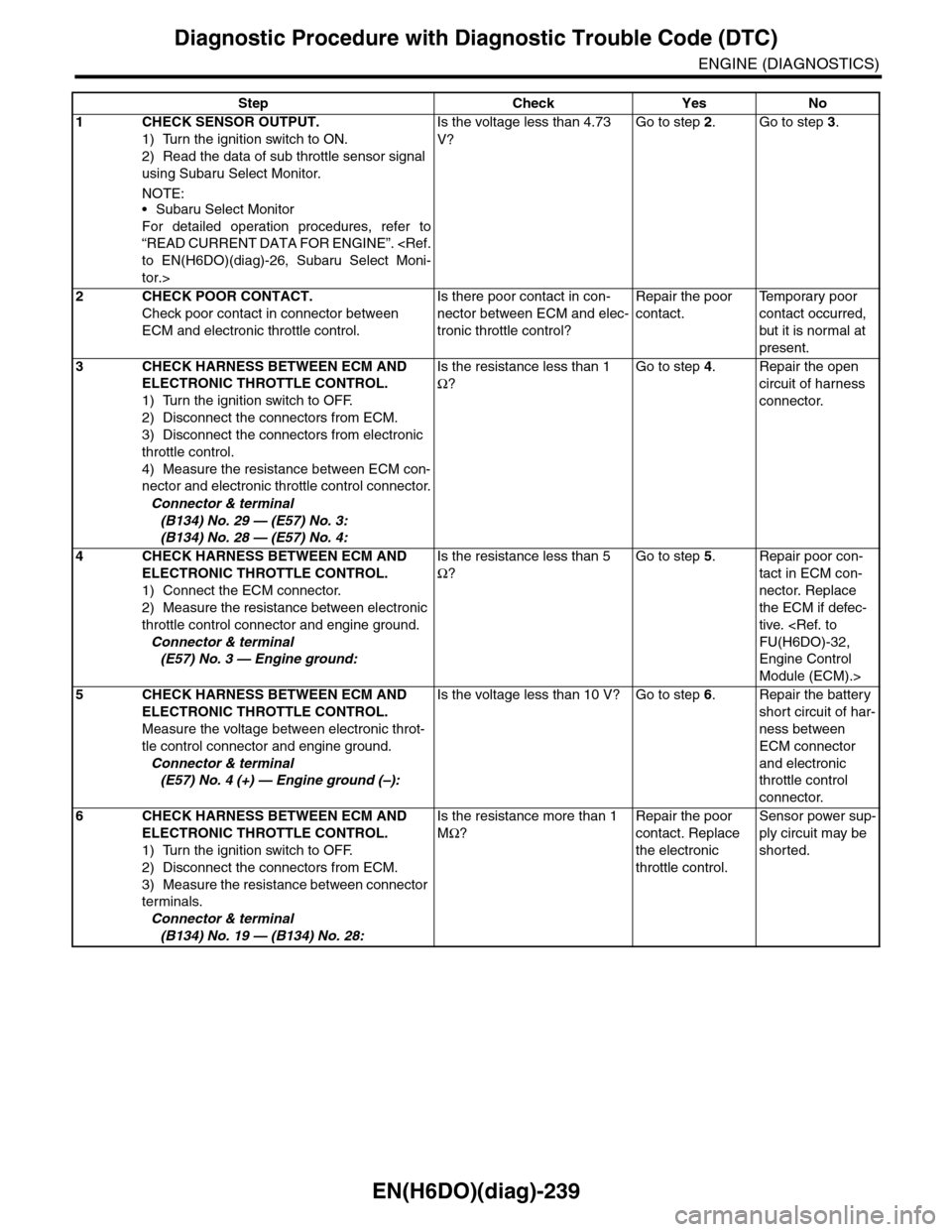

6CHECK POWER SUPPLY LINE.

1) Turn the ignition switch to ON.

2) Measure the voltage between fuel injector

and engine ground on faulty cylinders.

Connector & terminal

#1 (E5) No. 2 (+) — Engine ground (–):

#2 (E16) No. 2 (+) — Engine ground (–):

#3 (E6) No. 2 (+) — Engine ground (–):

#4 (E17) No. 2 (+) — Engine ground (–):

#5 (E43) No. 2 (+) — Engine ground (–):

#6 (E44) No. 2 (+) — Engine ground (–):

Is the voltage more than 10 V? Repair the poor

contact of all con-

nectors in fuel

injector circuit.

Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween main re-

lay and fuel

injector on

faulty cylinders

•Poor contact

of coupling con-

nector

•Poor contact

of main relay

connector

•Poor contact

of fuel injector

connector on

faulty cylinders

7CHECK HARNESS BETWEEN FUEL INJEC-

TOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel injector

on faulty cylinders.

3) Turn the ignition switch to ON.

4) Measure the voltage between ECM con-

nector and chassis ground on faulty cylinders.

Connector & terminal

#1 (B137) No. 8 (+) — Chassis ground (–):

#2 (B137) No. 9 (+) — Chassis ground (–):

#3 (B137) No. 10 (+) — Chassis ground (–):

#4 (B137) No. 11 (+) — Chassis ground (–):

#5 (B137) No. 12 (+) — Chassis ground (–):

#6 (B137) No. 13 (+) — Chassis ground (–):

Is the voltage more than 10 V? Repair the battery

short circuit of har-

ness between

ECM and fuel

injector. After

repair, replace the

ECM.

Engine Control

Module (ECM).>

Go to step 8.

8CHECK FUEL INJECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between fuel injec-

tor terminals on faulty cylinder.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance less than 1

Ω?

Replace the faulty

fuel injector

Fuel Injector.> and

ECM.

Engine Control

Module (ECM).>

Go to step 9.

9CHECK INSTALLATION OF CAMSHAFT PO-

SITION SENSOR/CRANKSHAFT POSITION

SENSOR.

Is the camshaft position sensor

or crankshaft position sensor

loosely installed?

Tighten the cam-

shaft position sen-

sor or crankshaft

position sensor.

Go to step 10.

10 CHECK CRANK PLATE.Is the crank sprocket rusted or

the teeth of crank plate bro-

ken?

Replace the crank

plate.

Cylinder Block.>

Go to step 11.

11 CHECK INSTALLATION CONDITION OF

TIMING CHAIN.

Tu r n t h e c r a n k s h a f t u s i n g S T, a n d a l i g n a l i g n -

ment mark on crank sprocket with alignment

mark on cylinder block.

ST 18252AA000 CRANKSHAFT

SOCKET

Is the timing chain dislocated

from its proper position?

Correct the instal-

lation condition of

timing chain.

Timing Chain

Assembly.>

Go to step 12.

Step Check Yes No

Page 1412 of 2453

EN(H6DO)(diag)-251

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

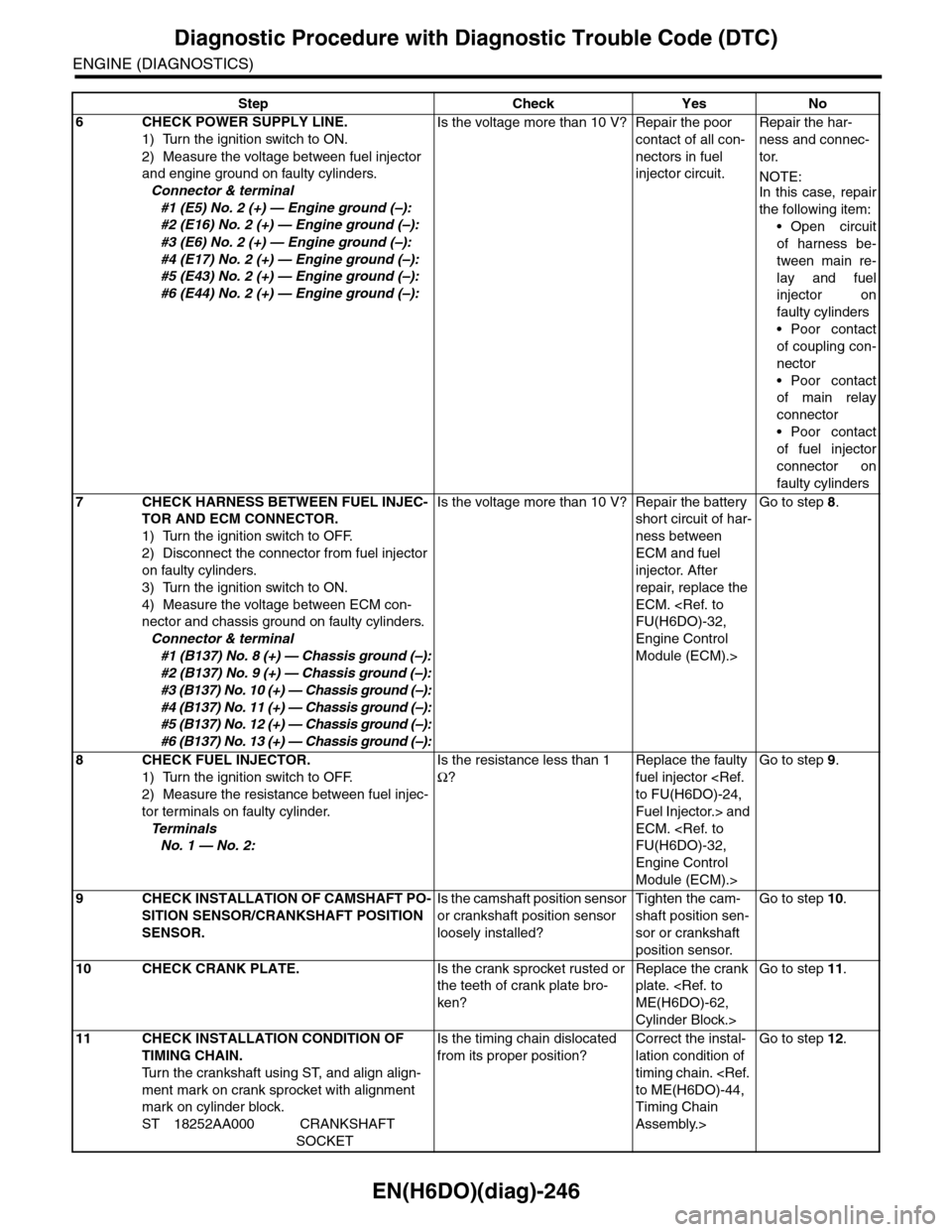

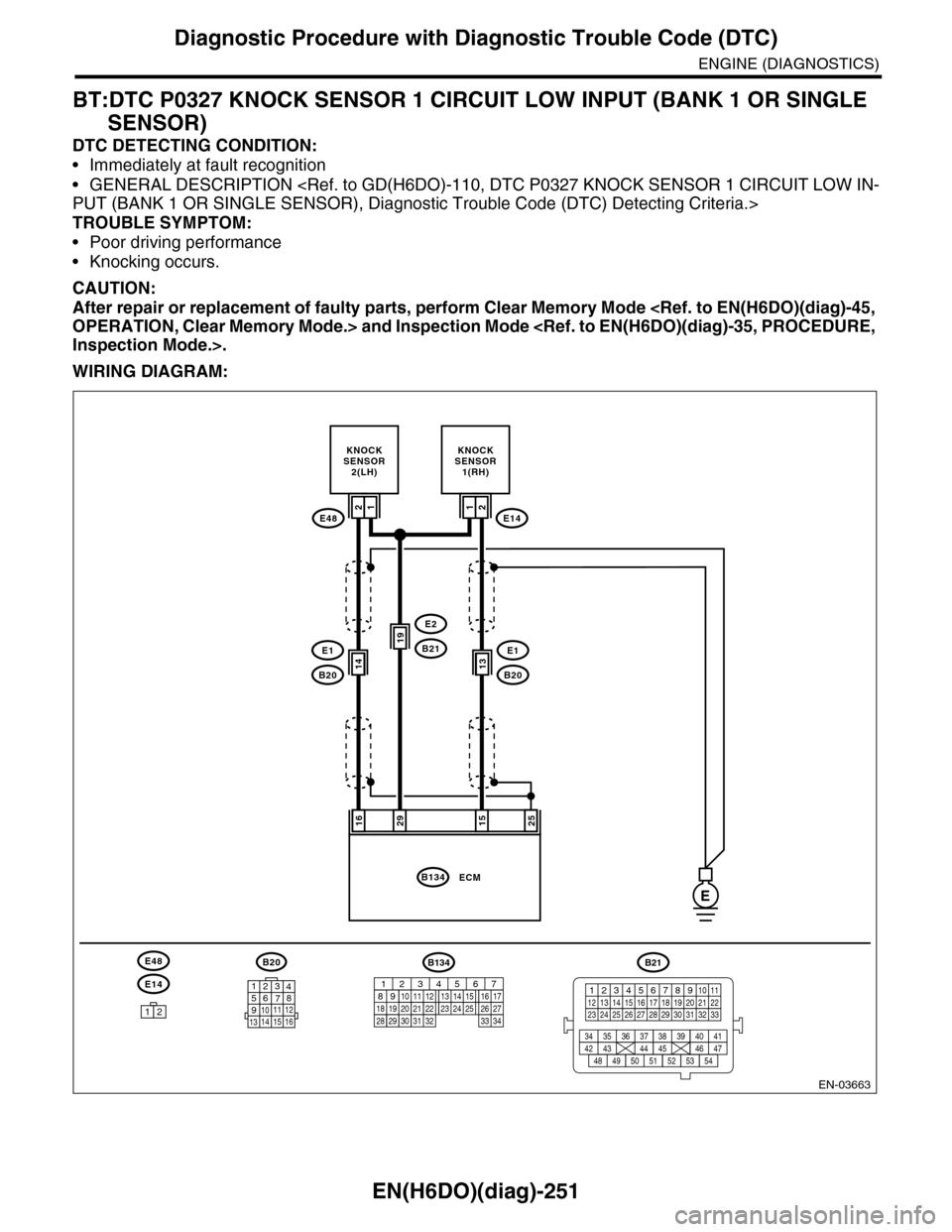

BT:DTC P0327 KNOCK SENSOR 1 CIRCUIT LOW INPUT (BANK 1 OR SINGLE

SENSOR)

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Poor driving performance

•Knocking occurs.

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03663

152925

KNOCKSENSOR1(RH)

13

21

ECMB134

B20

E1B21

E2

B20

E1

E14

12

16

KNOCKSENSOR2(LH)

1414

19

13

E48E14

E48B20

1234567891011 121314 15 16

E

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

B21

12345678910 1112 13 14 15 16 17 18 19 20 21 2223 24 25 26 27 28 29 30 31 32 33

34 3542 4336 3738 39

48 4950 5152 5354

40 41444546 47

21

Page 1413 of 2453

EN(H6DO)(diag)-252

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

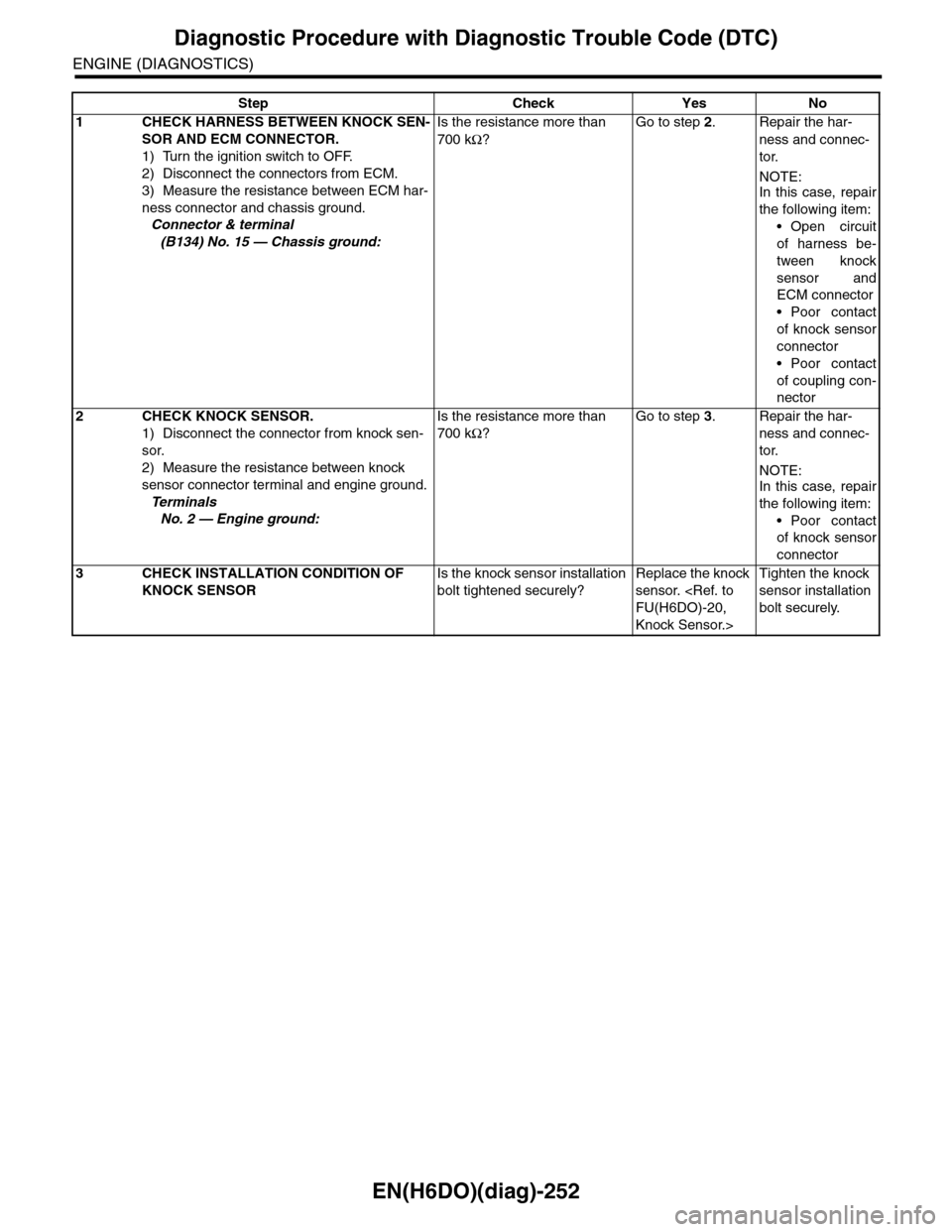

Step Check Yes No

1CHECK HARNESS BETWEEN KNOCK SEN-

SOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance between ECM har-

ness connector and chassis ground.

Connector & terminal

(B134) No. 15 — Chassis ground:

Is the resistance more than

700 kΩ?

Go to step 2.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween knock

sensor and

ECM connector

•Poor contact

of knock sensor

connector

•Poor contact

of coupling con-

nector

2CHECK KNOCK SENSOR.

1) Disconnect the connector from knock sen-

sor.

2) Measure the resistance between knock

sensor connector terminal and engine ground.

Te r m i n a l s

No. 2 — Engine ground:

Is the resistance more than

700 kΩ?

Go to step 3.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Poor contact

of knock sensor

connector

3CHECK INSTALLATION CONDITION OF

KNOCK SENSOR

Is the knock sensor installation

bolt tightened securely?

Replace the knock

sensor.

Knock Sensor.>

Tighten the knock

sensor installation

bolt securely.

Page 1414 of 2453

EN(H6DO)(diag)-253

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

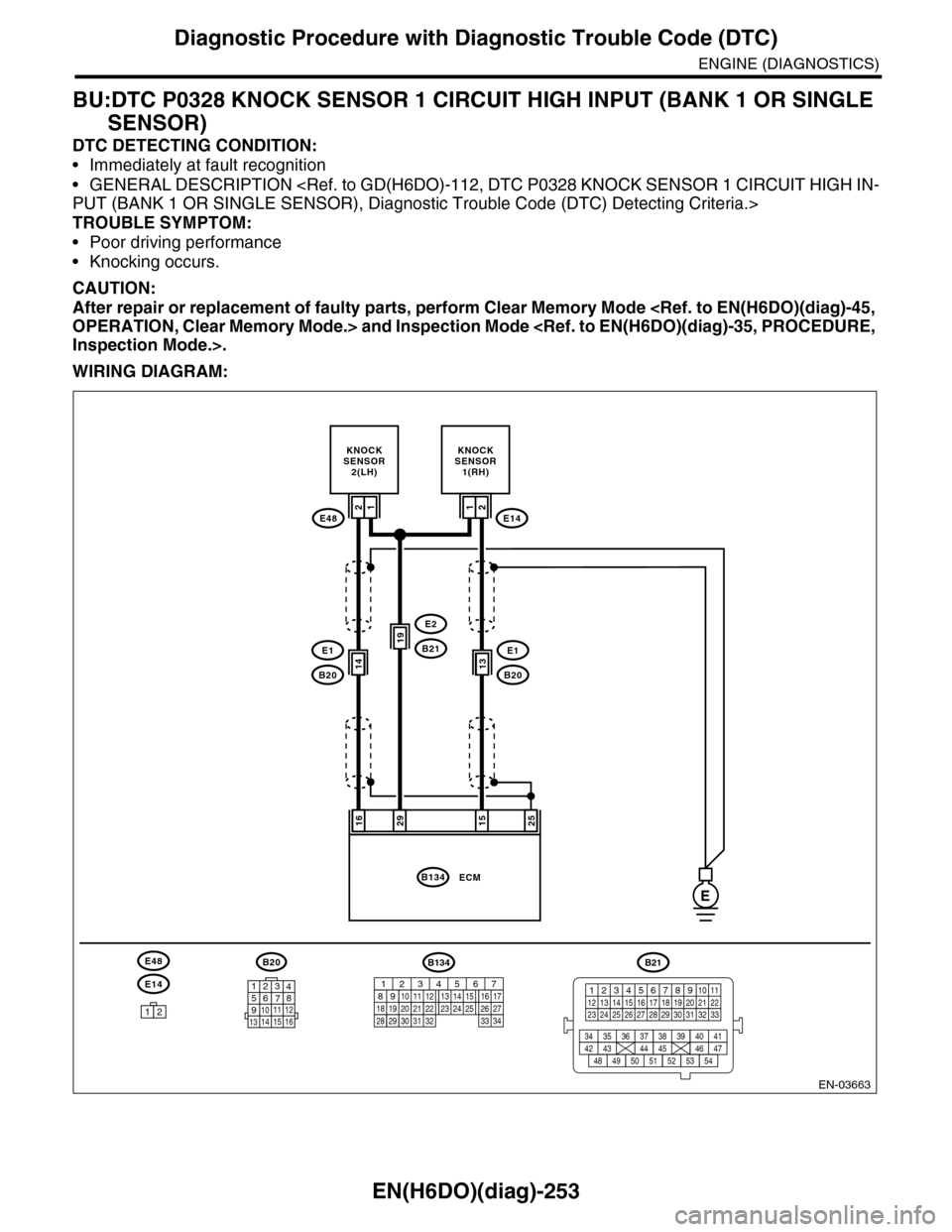

BU:DTC P0328 KNOCK SENSOR 1 CIRCUIT HIGH INPUT (BANK 1 OR SINGLE

SENSOR)

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Poor driving performance

•Knocking occurs.

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03663

152925

KNOCKSENSOR1(RH)

13

21

ECMB134

B20

E1B21

E2

B20

E1

E14

12

16

KNOCKSENSOR2(LH)

1414

19

13

E48E14

E48B20

1234567891011 121314 15 16

E

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

B21

12345678910 1112 13 14 15 16 17 18 19 20 21 2223 24 25 26 27 28 29 30 31 32 33

34 3542 4336 3738 39

48 4950 5152 5354

40 41444546 47

21

Page 1415 of 2453

EN(H6DO)(diag)-254

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

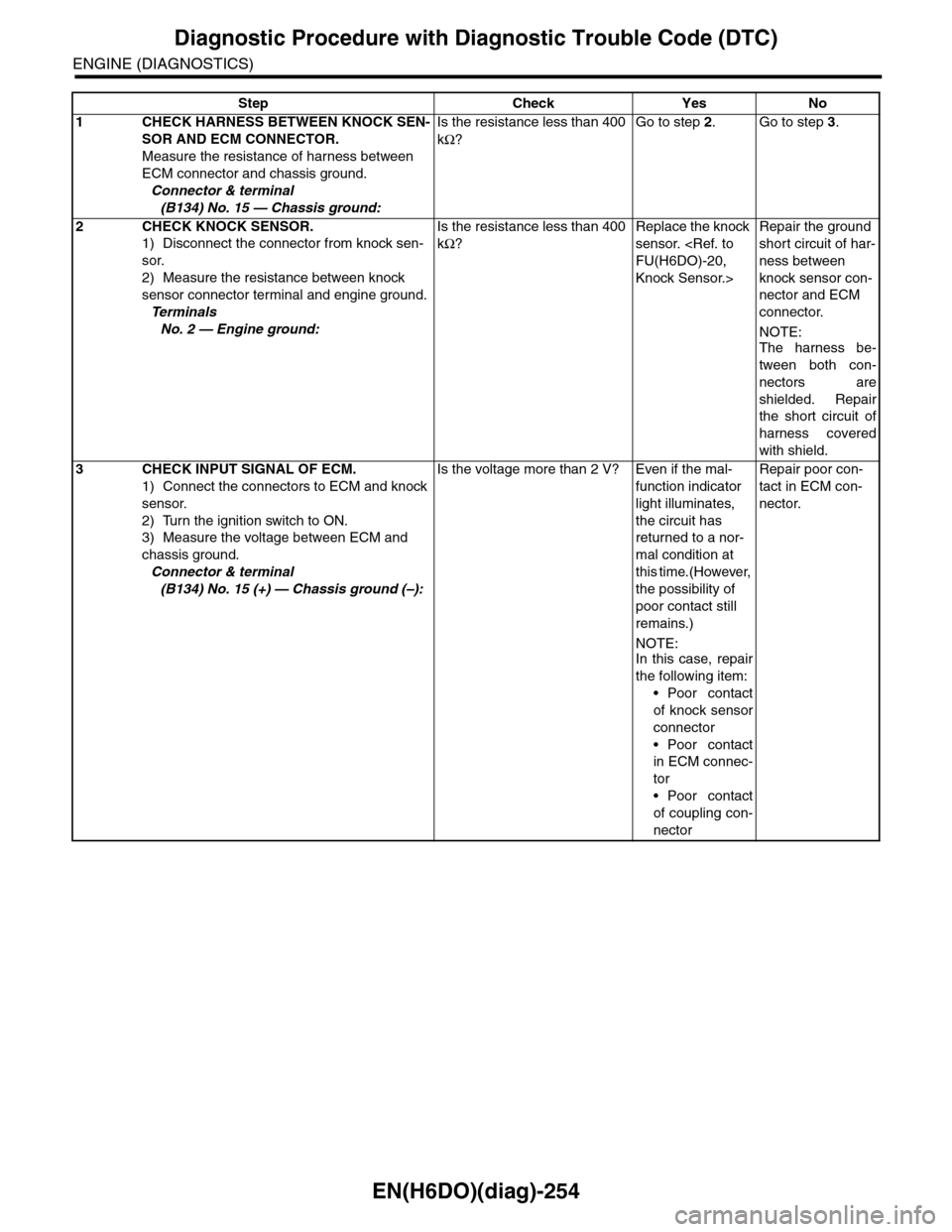

Step Check Yes No

1CHECK HARNESS BETWEEN KNOCK SEN-

SOR AND ECM CONNECTOR.

Measure the resistance of harness between

ECM connector and chassis ground.

Connector & terminal

(B134) No. 15 — Chassis ground:

Is the resistance less than 400

kΩ?

Go to step 2.Go to step 3.

2CHECK KNOCK SENSOR.

1) Disconnect the connector from knock sen-

sor.

2) Measure the resistance between knock

sensor connector terminal and engine ground.

Te r m i n a l s

No. 2 — Engine ground:

Is the resistance less than 400

kΩ?

Replace the knock

sensor.

Knock Sensor.>

Repair the ground

short circuit of har-

ness between

knock sensor con-

nector and ECM

connector.

NOTE:

The harness be-

tween both con-

nectors are

shielded. Repair

the short circuit of

harness covered

with shield.

3CHECK INPUT SIGNAL OF ECM.

1) Connect the connectors to ECM and knock

sensor.

2) Turn the ignition switch to ON.

3) Measure the voltage between ECM and

chassis ground.

Connector & terminal

(B134) No. 15 (+) — Chassis ground (–):

Is the voltage more than 2 V? Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.(However,

the possibility of

poor contact still

remains.)

NOTE:In this case, repair

the following item:

•Poor contact

of knock sensor

connector

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

Repair poor con-

tact in ECM con-

nector.

Page 1416 of 2453

EN(H6DO)(diag)-255

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

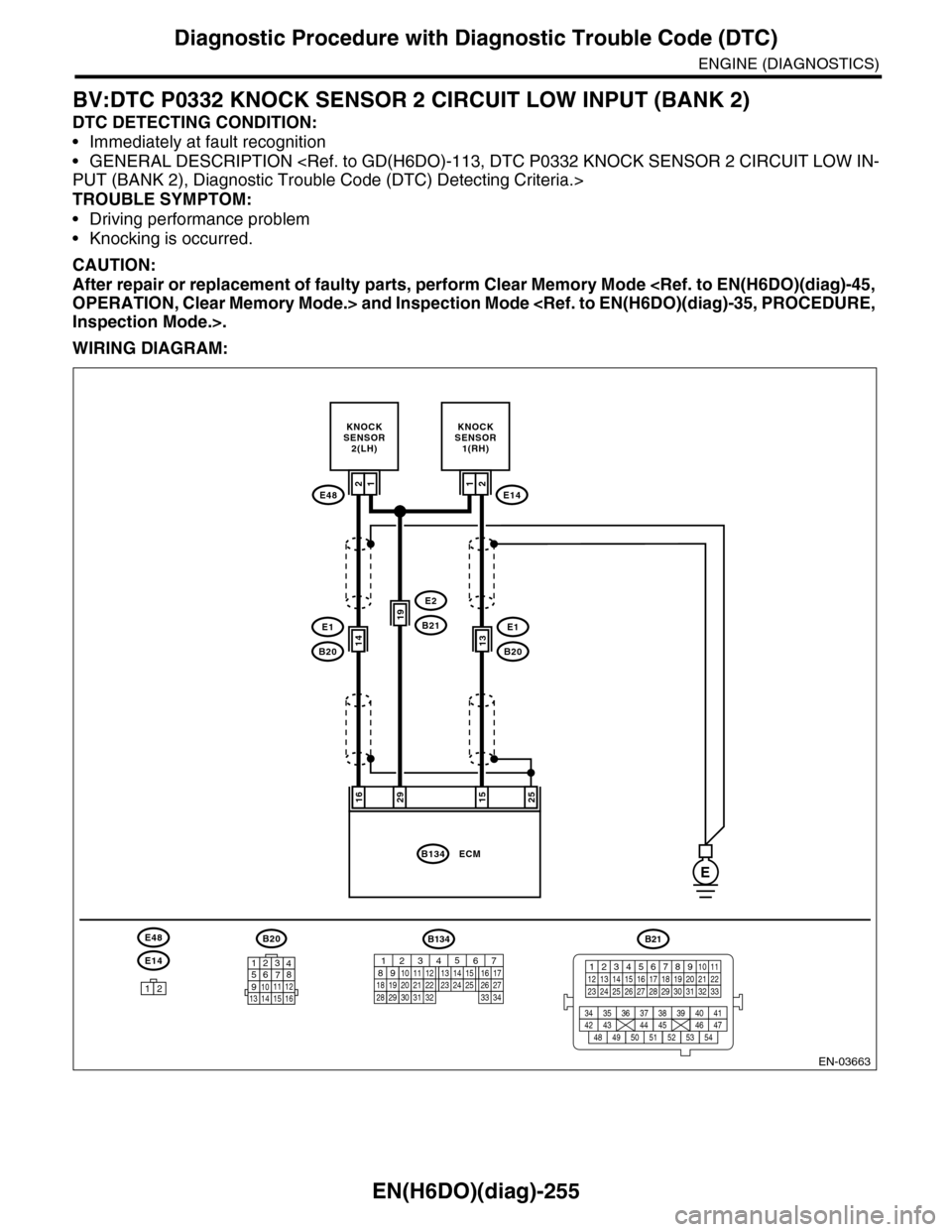

BV:DTC P0332 KNOCK SENSOR 2 CIRCUIT LOW INPUT (BANK 2)

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

•Driving performance problem

•Knocking is occurred.

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03663

152925

KNOCKSENSOR1(RH)

13

21

ECMB134

B20

E1B21

E2

B20

E1

E14

12

16

KNOCKSENSOR2(LH)

1414

19

13

E48E14

E48B20

1234567891011 121314 15 16

E

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

B21

12345678910 1112 13 14 15 16 17 18 19 20 21 2223 24 25 26 27 28 29 30 31 32 33

34 3542 4336 3738 39

48 4950 5152 5354

40 41444546 47

21

Page 1417 of 2453

EN(H6DO)(diag)-256

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

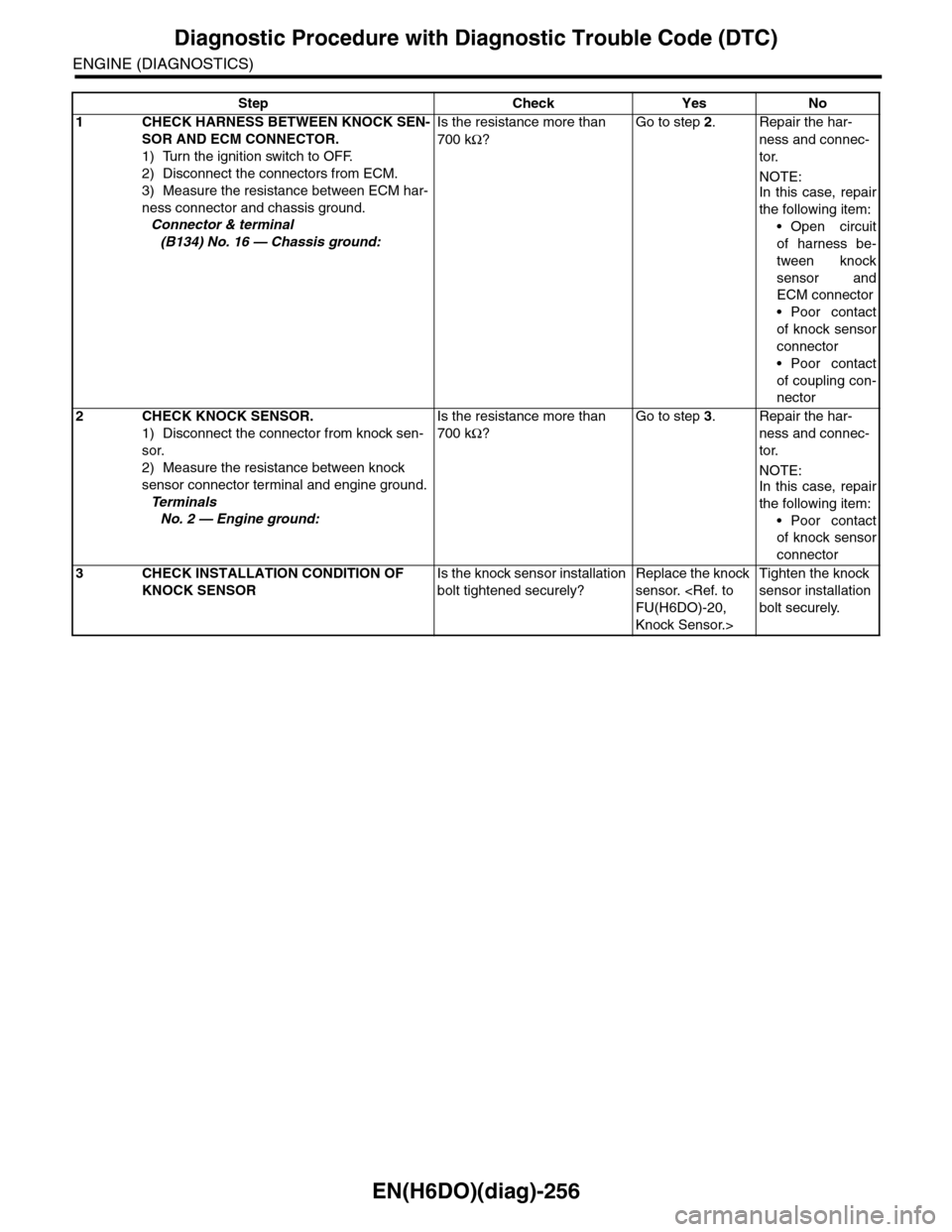

Step Check Yes No

1CHECK HARNESS BETWEEN KNOCK SEN-

SOR AND ECM CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance between ECM har-

ness connector and chassis ground.

Connector & terminal

(B134) No. 16 — Chassis ground:

Is the resistance more than

700 kΩ?

Go to step 2.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween knock

sensor and

ECM connector

•Poor contact

of knock sensor

connector

•Poor contact

of coupling con-

nector

2CHECK KNOCK SENSOR.

1) Disconnect the connector from knock sen-

sor.

2) Measure the resistance between knock

sensor connector terminal and engine ground.

Te r m i n a l s

No. 2 — Engine ground:

Is the resistance more than

700 kΩ?

Go to step 3.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Poor contact

of knock sensor

connector

3CHECK INSTALLATION CONDITION OF

KNOCK SENSOR

Is the knock sensor installation

bolt tightened securely?

Replace the knock

sensor.

Knock Sensor.>

Tighten the knock

sensor installation

bolt securely.