SUZUKI GRAND VITARA 1987 Service Owner's Guide

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 31 of 962

1) Replace fuel hoses (pipe to fuel pump, pipe to

fuel filter and breather hose) in fuel feed and

return lines with new ones.

2) Remove fuel tank.

3) Replace return hose (tank to return pipe)

with new one.

4) Clamp hoses securely.

5) Install fuel tank referring to p. 4-35.

6) After installation, start engine and check it

for leaks.

27. IDLE SPEED INSPECTION

NOTE:

Before starting engine, place transmission gear

shift lever in “Neutral”, and set parking brake

and block drive wheels.

1) Warm up engine to normal operating tempe-

rature.

2) Check to ensure that idle speed is within

750 - 850 r/min (rpm).

3) If idle speed is not within specified range,

adjust idle speed. Refer to MAINTENANCE

SERVICE (p. 4-26) for procedures to check

and adjust idle speed.

28. IDLE MIXTURE INSPECTION

1) Warm up engine to normal operating tem-

perature.

2) Remove seal rubber of duty check coupler

and connect positive terminal of duty meter

to “Blue/Red” wire and negative terminal to

“Black/Green” wire.

1

1. Duty check coupler

2. Air intake case

3) Set tachometer.

4) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

5) Check duty at specified idle speed. If it is out

of specification,adjust it to specification

according to following adjustment procedure.

Specified Duty10-50

at 750 - 850 r/min.I

After inspection, install seal rubber to duty

check coupler.

Idle mixture adjustment procedure is as follows:

1) Remove carburetor from intake manifold

following normal service procedure to gain

access to mixture adjusting screw pin covering

mixture adjusting screw.

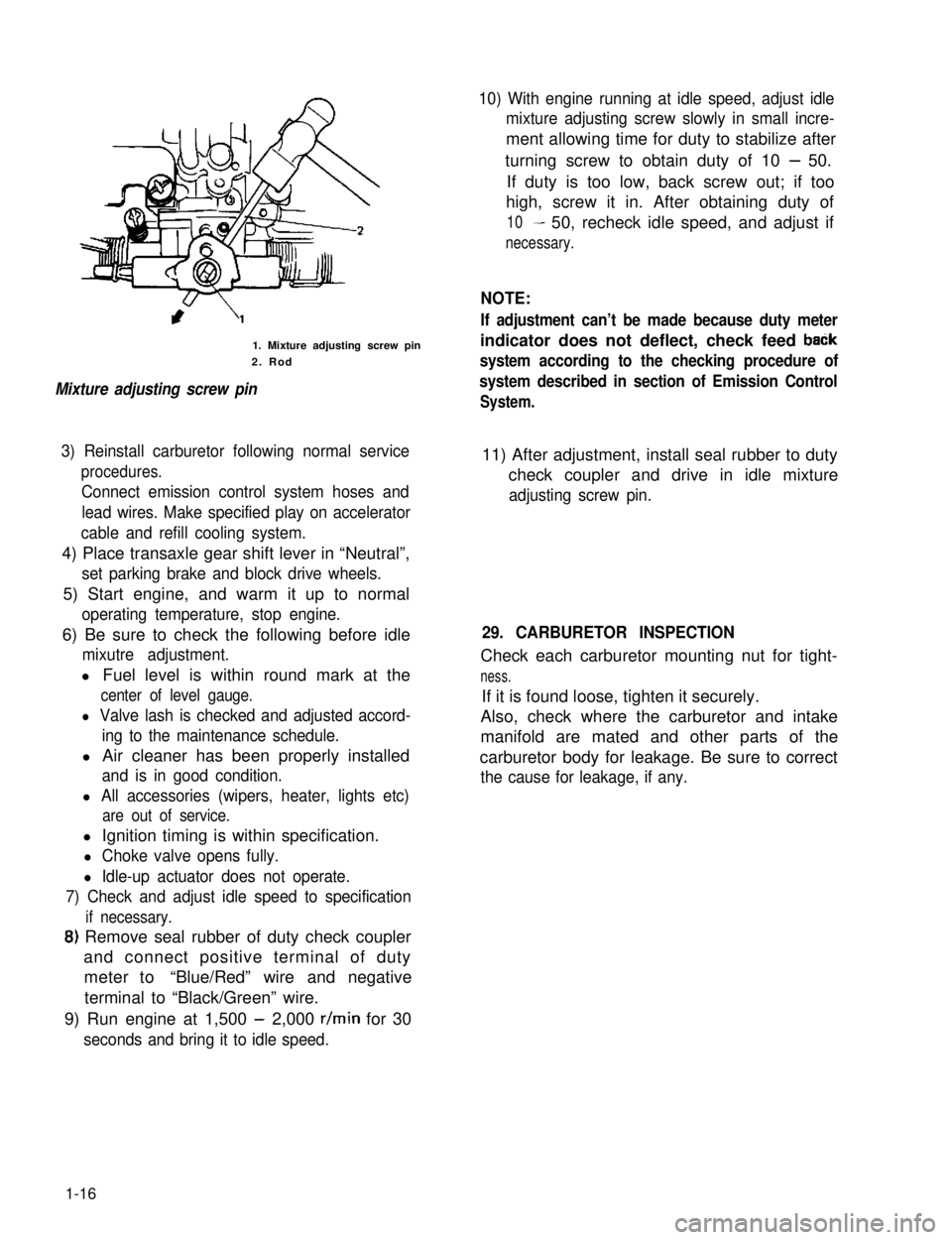

2) Drive out mixture adjusting screw pin using

about 4.5 mm (0.18 in) thick iron rod as

shown below.

1-15

Page 32 of 962

1. Mixture adjusting screw pin

2. Rod

Mixture adjusting screw pin

10) With engine running at idle speed, adjust idle

mixture adjusting screw slowly in small incre-

ment allowing time for duty to stabilize after

turning screw to obtain duty of 10 - 50.

If duty is too low, back screw out; if too

high, screw it in. After obtaining duty of

10- 50, recheck idle speed, and adjust if

necessary.

NOTE:

If adjustment can’t be made because duty meter

indicator does not deflect, check feed baCk

system according to the checking procedure of

system described in section of Emission Control

System.

3) Reinstall carburetor following normal service

procedures.

Connect emission control system hoses and

lead wires. Make specified play on accelerator

cable and refill cooling system.

11) After adjustment, install seal rubber to duty

check coupler and drive in idle mixture

adjusting screw pin.

4) Place transaxle gear shift lever in “Neutral”,

set parking brake and block drive wheels.

5) Start engine, and warm it up to normal

operating temperature, stop engine.

6) Be sure to check the following before idle

mixutre adjustment.

l Fuel level is within round mark at the

center of level gauge.

l Valve lash is checked and adjusted accord-

ing to the maintenance schedule.

l Air cleaner has been properly installed

and is in good condition.

l All accessories (wipers, heater, lights etc)

are out of service.

29. CARBURETOR INSPECTION

Check each carburetor mounting nut for tight-

ness.

If it is found loose, tighten it securely.

Also, check where the carburetor and intake

manifold are mated and other parts of the

carburetor body for leakage. Be sure to correct

the cause for leakage, if any.

l Ignition timing is within specification.

l Choke valve opens fully.

l Idle-up actuator does not operate.

7) Check and adjust idle speed to specification

if necessary.

8) Remove seal rubber of duty check coupler

and connect positive terminal of duty

meter to“Blue/Red” wire and negative

terminal to “Black/Green” wire.

9) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

1-16

Page 33 of 962

1-3. CHASSIS AND BODY

30. CLUTCH PEDAL INSPECTION

1) Check clutch pedal height. It should be the

same as brake pedal height.

2) Check clutch pedal free travel.

Clutch pedal free travel20 - 30 mm

(0.8 - 1.1 in.)

For the details of the above steps 1) and 2),

refer to MAINTENANCE SERVICE (p. 11-8) of

SECTION 11.

31. BRAKE DISCS, PADS, BRAKE DRUMS

AND SHOES INSPECTION

Brake Discs and Pads

I) Remove wheel and caliper but don’t discon-

nect brake hose from caliper.

2) Check front disc brake pads and discs for

excessivewear,damageand deflection.

Replace parts as necessary. For the details,

refer to p. 19-I 6 and 19-I 7 of SECT ION 19.

Be sure to torque caliper guide pins to specifi-

cation for reinstallation.

Brake Drums and Shoes

I) Remove wheel and brake drum.

2) Check rear brake drums and brake linings for

excessive wear and damage, while wheels and

drums are removed. Also check wheel cylin-

ders for leaks, at the same time. Replace

these parts as necessary.

For the details, refer to p. 19-21 and p. 19-

22 of SECTION 19.

32. BRAKE HOSES AND PIPES INSPECTION

Check brake hoses and pipes for proper hook-

up, leaks, cracks, chafing and other damage.

Replace any of these parts as necessary.

CAUTION:

After replacing any brake pipe or hose, be

sure to carry out air purge operation.

33. BRAKE FLUID INSPECTION AND

CHANGE

[INSPECTION]

1) Check around master cylinder and reservoir

for fluid leakage.

If found leaky, correct.

2) Check fluid level

If fluid level is lower than the minimum level

of reservoir, refilling is necessary. Fill reservoir

with specified brake fluids.

Brake fluid Speifi;t3ons

For the details, refer to MAINTENANCE

SERVICE (p. 19-42) of SECTION 19.

CAUTION:

Since the brake system of this car is factory-

filled with glycol-base brake fluid, do not

use or mix different type of fluid when

refilling the system; otherwise serious

damage will occur. Do not use old or used

brake fluid, or one taken from unsealed

container.

[CHANGE]

1) Change brake fluid. As fluid change procedure,

drain existing fluid from brake system com-

pletely, fill the system with above recom-

mended fluid and carry out air purge opera-

tion.

For description of air purge, refer to p. 19-46

and 19-47 of SECTION 19.

34. BRAKE PEDAL INSPECTION

Check brake pedal travel.

For -checking procedure, refer to PEDAL TRA-

VEL CHECK (p. 19-43) of SECTION 19.

35. BRAKE LEVER AND CABLE

INSPECTION

Parking Brake Lever

I) Check tooth tip of each notch for damage or

wear. If any damage or wear is found, replace

parking lever.

2) Check parking brake lever for proper opera-

tion and stroke, and adjust it if necessary.

For checking and adjusting procedures,

refer to PARKING BRAKE INSPECTION

AND ADJUSTMENT (p. 19-44) of SECTION

19.

1-17

Page 34 of 962

Parking Brake Cable

Inspect brake cable for damage and smooth

movement. Replace cable if it is in deteriorat-

ed condition.

36. TIRE INSPECTION AND ROTATION

1) Check tires for uneven or excessive wear, or

damage. If defective, replace.

2) Check inflating pressure of each tire and

adjust pressure to specification as necessary.

NOTE:

l Tire inflation pressure should be checked

when tires are cool.

l Specified tire inflation pressure should be

found on tire placard or in owners’ manual

which came with the car.

3) Rotate tires.

For the details of above steps 1) to 3), refer

to MAINTENANCE SERVICE (p. 18-19 and

18-20) of SECTION 18.

37. WHEEL DISCS AND FREE WHEELING

HUBS (if equipped) INSPECTION

Wheel Discs

Inspect each wheel disc for dents, distortion and

cracks. A disc in badly damaged condition must

be replaced.

Free Wheeling Hub

This is applicable to the car equipped with

free wheeling hubs.

Check free wheeling hub for proper operation

by moving free wheeling hub knob to LOCK

and FREE positions. (The same check on both

right and left wheels)

For checking procedure, refer to MAINTE-

NANCE SERVICE (p. 17-29) of SECTION 17.

38. STEERING KNUCKLE OIL SEAL

REPLACEMENT

For replacement procedure, refer to MAIN-

TENANCE SERVICE (p. 17-23) of SECTION

17.

39. WHEEL BEARING INSPECTION

[Inspection of wheel bearing]

1) Check front wheel bearing for wear, damage,

abnormal noise or rattles. For the details,

refer to MAINTENANCE (p. 17-20 and

17-21) of SECTION 17.

2) Check rear wheel bearing for wear, damage

abnormal noise or rattles. For the details,

refer to MAINTENANCE SERVICE (p. 17-24)

of SECTION 17.

[Inspection of front wheel bearing grease]

1) Remove wheel hub and spindle referring to

FRONT WHEEL HUB REMOVAL of SEC-

TION 17.

2) Check grease around front wheel bearing

rollars and between front axle shaft surface

and wheel spindle bush for deterioration and

capacity.

If grease is deteriorated, remove grease tho-

roughly and apply enough amount of new

SUZUKI SUPER GREASE A or wheel bearing

grease. If grease is found insufficient, add some

more.

1-18

Page 35 of 962

3) Install spindle, bearings, wheel hub, bearing

nut and brake disc referring to INSTALLA-

TION (p. 17-12) of SECTION 17.

4) Adjust bearing preload and then tighten

bearing lock nut to specification. Refer to

MAINTENANCE (p. 17-21) of SECTION 17.

5) Install drive flange or free wheeling hub (if

equipped), brake caliper with mounting and

wheel referring to INSTALLATION (p. 17-

12) of SECTION 17.

For tightening torque of each bolt and nut,

refer to torque table (p. 17-26) of SECTION

17.

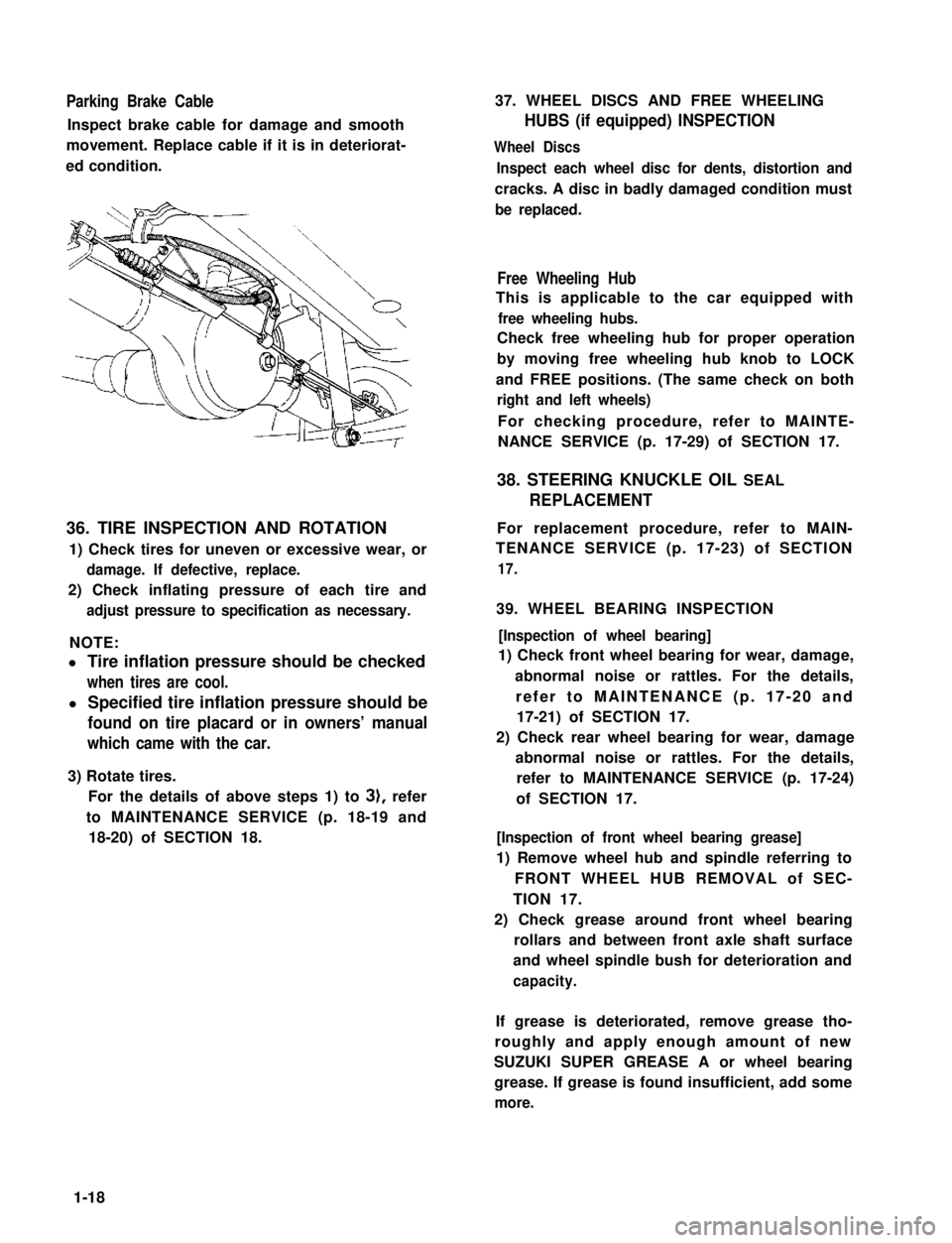

40. SHOCK ABSORBERS INSPECTION

1) Inspect absorbers for evidence of oil leakage,

dents or any other damage on sleeves; and

inspect anchor ends for deterioration.

2) Depending on the results of the above inspec-

tion, replace absorbers.

2

1. Shock absorber

2. Leaf spring

WARNING:

When handling rear shock absorber in

which high-pressure gas is sealed, make

sure to observe the following precautions.

1. Don’t disassemble it.

2. Don’t put it into fire.

3. Don’t store it where it gets hot

4. Before disposing it, be sure to drill a

hole in it where shown in the illustration

below and let gas and oil out. Lay it

down sideways for this work.

Drill hole with approx-imately 3 mm (0.12 in.)diameter.

Cover with a vinyl envelope asshown so that drill dust willnot scatter around.

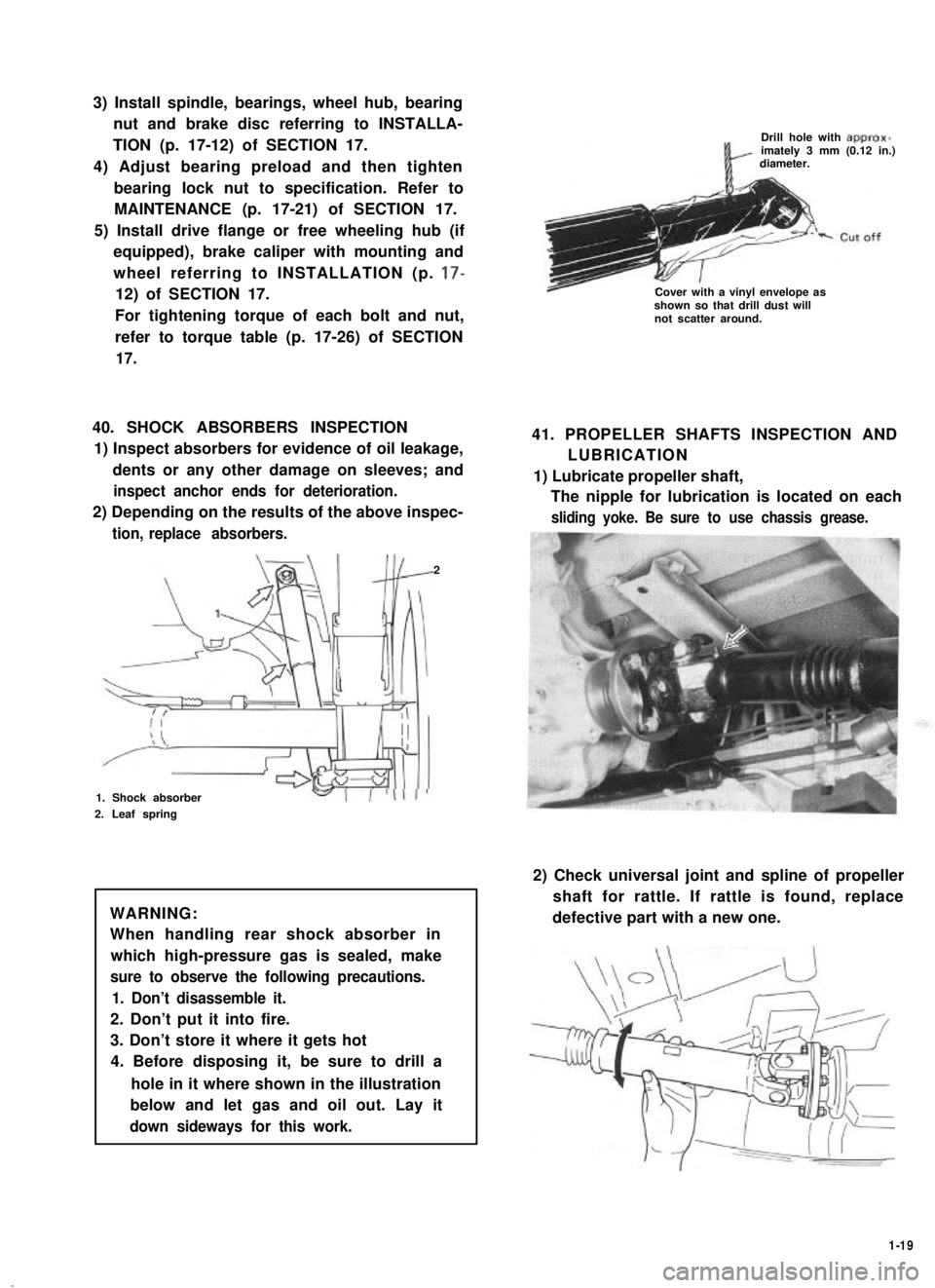

41. PROPELLER SHAFTS INSPECTION AND

LUBRICATION

1) Lubricate propeller shaft,

The nipple for lubrication is located on each

sliding yoke. Be sure to use chassis grease.

2) Check universal joint and spline of propeller

shaft for rattle. If rattle is found, replace

defective part with a new one.

1-19

Page 36 of 962

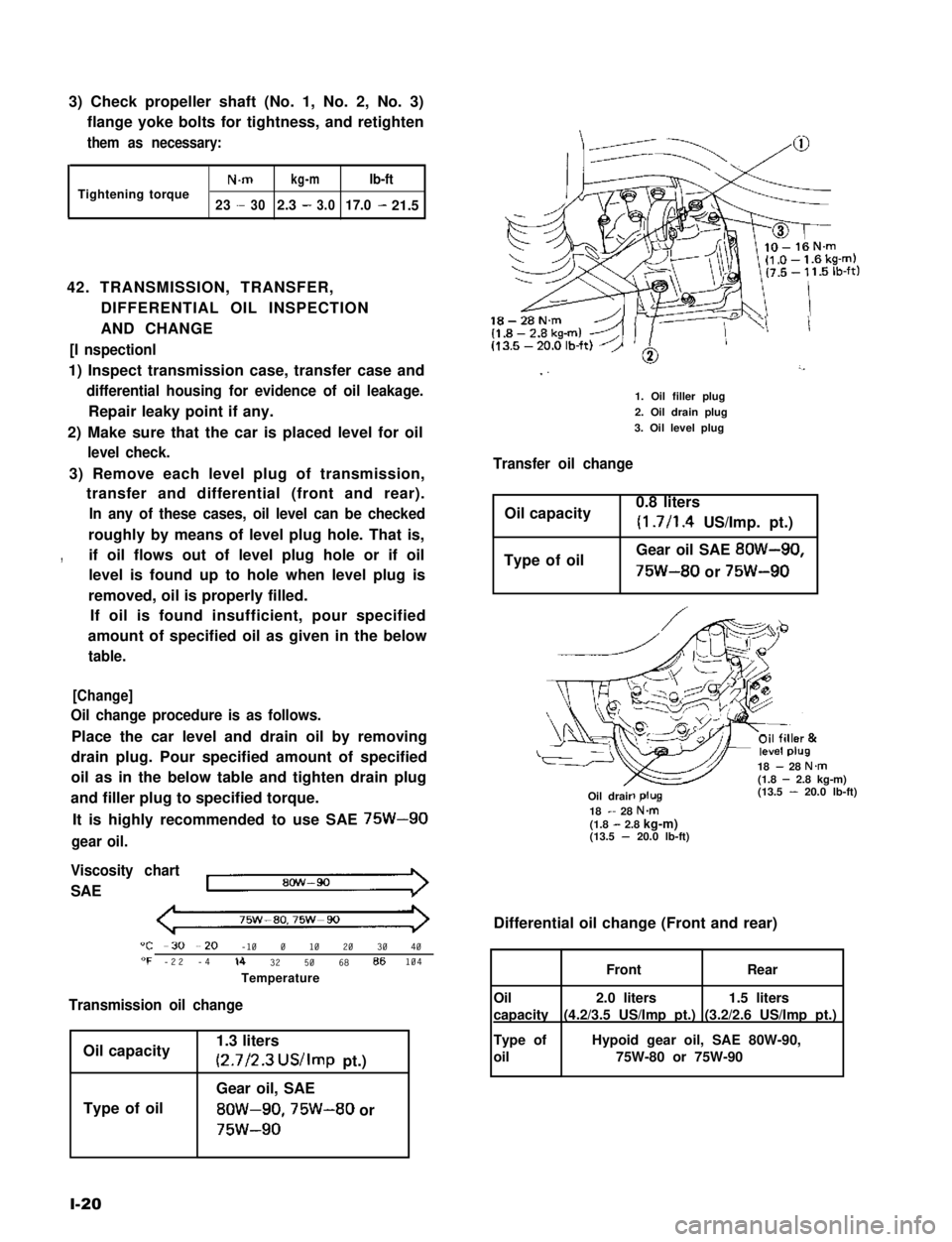

3) Check propeller shaft (No. 1, No. 2, No. 3)

flange yoke bolts for tightness, and retighten

them as necessary:

N.mkg-mlb-ftTighteningtorque23-302.3-3.017.0-21.5

42. TRANSMISSION, TRANSFER,

DIFFERENTIAL OIL INSPECTION

AND CHANGE

[I nspectionl

1) Inspect transmission case, transfer case and

differential housing for evidence of oil leakage.

Repair leaky point if any.

2) Make sure that the car is placed level for oil

level check.

3) Remove each level plug of transmission,

transfer and differential (front and rear).

In any of these cases, oil level can be checked

roughly by means of level plug hole. That is,

,if oil flows out of level plug hole or if oil

level is found up to hole when level plug is

removed, oil is properly filled.

If oil is found insufficient, pour specified

amount of specified oil as given in the below

table.

[Change]

Oil change procedure is as follows.

Place the car level and drain oil by removing

drain plug. Pour specified amount of specified

oil as in the below table and tighten drain plug

and filler plug to specified torque.

It is highly recommended to use SAE 75W-90

gear oil.

Viscosity chart

SAE

75w-ao,75w-90

"C -30 --20 -10 0 10 20 30 40"F -22 -4lb 32 50 68 86104

Temperature

Transmission oil change

Oil capacity

Type of oil

1.3 liters

(2.7/2.3 US/Imp pt.)

Gear oil, SAE

8OW-90,75W-80 or

75w-90

l-20

18-28N.m

I ”’

1. Oil filler plug

2. Oil drain plug

3. Oil level plug

Transfer oil change

Oil capacity0.8 liters

(1.7/l .4 US/Imp. pt.)

Type of oilGear oil SAE 8OW-90,

75W-80 or 75W-90

18 - 28 N.m(1.8 - 2.8 kg-m)(13.5 - 20.0 lb-ft)-R-Oil drair18 - 28 N&(1.8 - 2.8 kg-m)(13.5 - 20.0 lb-ft)

Differential oil change (Front and rear)

1.5 liters

(3.2/2.6 US/Imp pt.)

2.0 liters

(4.2/3.5 US/Imp pt.)

FrontRear

Oil

capacity

Type of

oil

Hypoid gear oil, SAE 80W-90,

75W-80 or 75W-90

Page 37 of 962

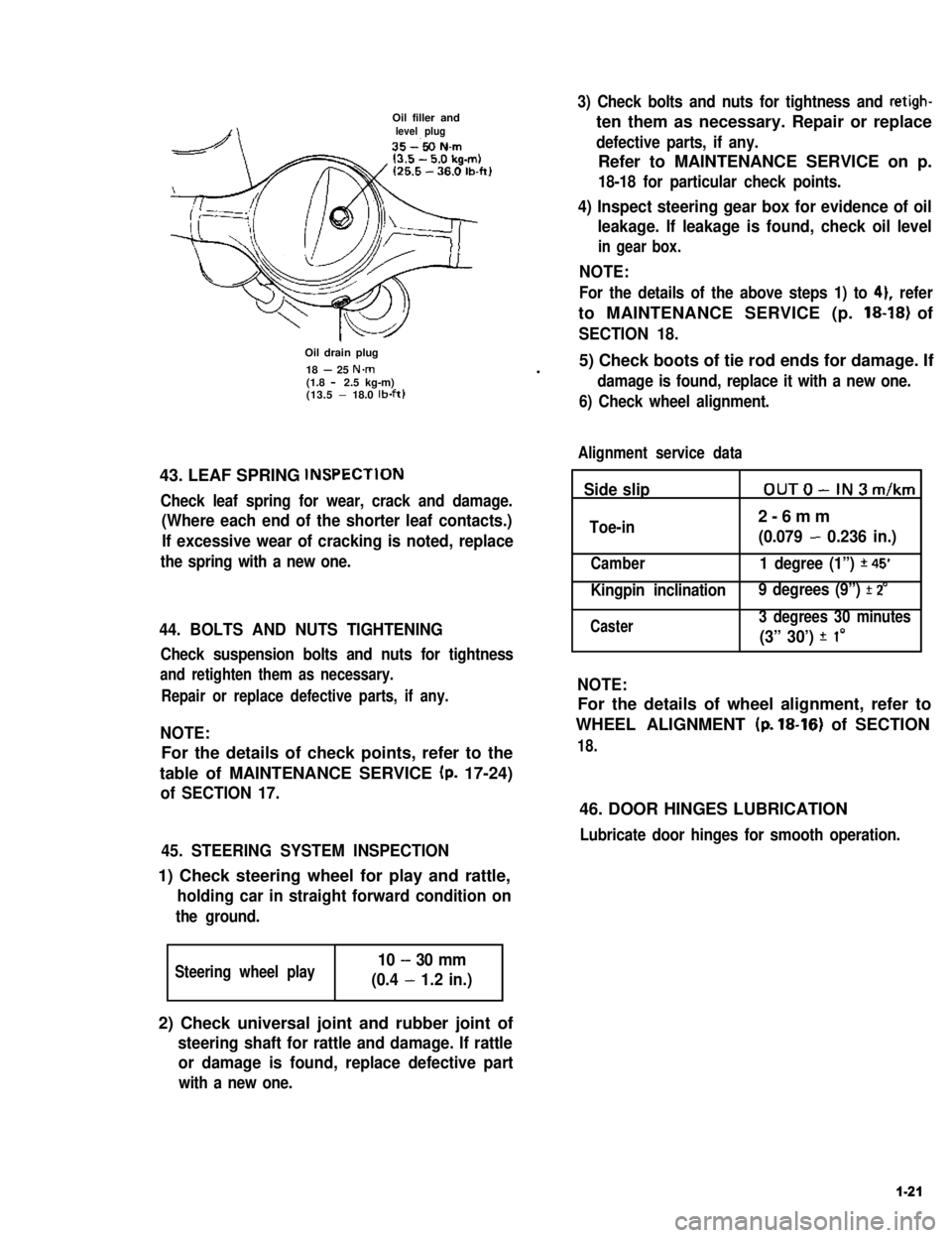

Oil filler andlevel plug

Oil drain plug

18 - 25 N.m(1.8 - 2.5 kg-m)(13.5 - 18.0 lb-ft)

43. LEAF SPRING lNSPECTlON

Check leaf spring for wear, crack and damage.

(Where each end of the shorter leaf contacts.)

If excessive wear of cracking is noted, replace

the spring with a new one.

44. BOLTS AND NUTS TIGHTENING

Check suspension bolts and nuts for tightness

and retighten them as necessary.

Repair or replace defective parts, if any.

NOTE:

For the details of check points, refer to the

table of MAINTENANCE SERVICE (p. 17-24)

of SECTION 17.

45. STEERING SYSTEM INSPECTION

1) Check steering wheel for play and rattle,

holding car in straight forward condition on

the ground.

Steering wheel play10 - 30 mm

(0.4 - 1.2 in.)

3) Check bolts and nuts for tightness and retigh-

ten them as necessary. Repair or replace

defective parts, if any.

Refer to MAINTENANCE SERVICE on p.

18-18 for particular check points.

4) Inspect steering gear box for evidence of oil

leakage. If leakage is found, check oil level

in gear box.

NOTE:

For the details of the above steps 1) to 41, refer

to MAINTENANCE SERVICE (p. 18-18) of

SECTION 18.

.5) Check boots of tie rod ends for damage. If

damage is found, replace it with a new one.

6) Check wheel alignment.

Alignment service data

Side slipOUTO-IN3m/km

Toe-in2-6mm

(0.079 - 0.236 in.)

Camber1 degree (1”) *45’

Kingpin inclination 9 degrees (9”) f 2’

Caster3 degrees 30 minutes

(3” 30’) f I0

NOTE:

For the details of wheel alignment, refer to

WHEEL ALIGNMENT (p. 18-16) of SECTION

18.

46. DOOR HINGES LUBRICATION

Lubricate door hinges for smooth operation.

2) Check universal joint and rubber joint of

steering shaft for rattle and damage. If rattle

or damage is found, replace defective part

with a new one.

1-21

Page 38 of 962

FINAL INSPECTION

Carry out road test in safe place.

WARNING:

When carrying out the following road

tests, select a safe place where no man or

no running car is seen so as to prevent any

accident.

1) Engine start

Check engine start for readiness.

2) Clutch

Check the following:

l that clutch is completely released when

depressing clutch pedal,

l that no slipping clutch occurs when releas-

ing pedal and accelerating,

l and that clutch itself is free from any

abnormal condition.

3) Gearshift Lever (Transmission and Transfer)

Check gearshift lever for smooth shifting

to all positions and for good performance of

transmission and transfer in any position.

4) Brake

[Foot brake]

Check the following when depressing brake

pedal while driving;

l that brake works properly,

l that it is free from noise,

l and that braking force applies equally on

all wheels.

[Parking brake]

Check to ensure that parking brake is fully

effective when the car is stopped on the slop

and brake lever is pulled all the way.

5) Steering

Check to ensure that steering wheel is free

from instability, or abnormally heavy feeling

while driving.

1-22

Page 39 of 962

2-1.

2-2.

2-3.

2-4.

2-5.

2-6.

2-7.

2-6.

2-9.

SECTION 2

TROUBLE SHOOTING

CONTENTS

ENGINE...................................................2-2

CARBURETOR...........................................

EXHAUST AND MUFFLER.................................

CLUTCH.................................................2-9

TRANSMISSION..........................................

DIFFERENTIALS.........................................2-11

PROPELLER SHAFTS.....................................2-12

BRAKES.............................................. 2-12

SUSPENSION, STEERING SYSTEM AND TIRES................

STARTING MOTOR.....................................

2-11. ALTERNATOR...........................................

FUEL METER............................................ 2-19

2-14. SPEEDOMETER..........................................2-19

2-15. WATER TEMPERATURE METER.............................2-19

2-9

2-9

2-10

2-14

2-16

2-17

2-18WIPER MOTOR.......................................

2-10.

2-12.

2-13.

2-1

2

Page 40 of 962

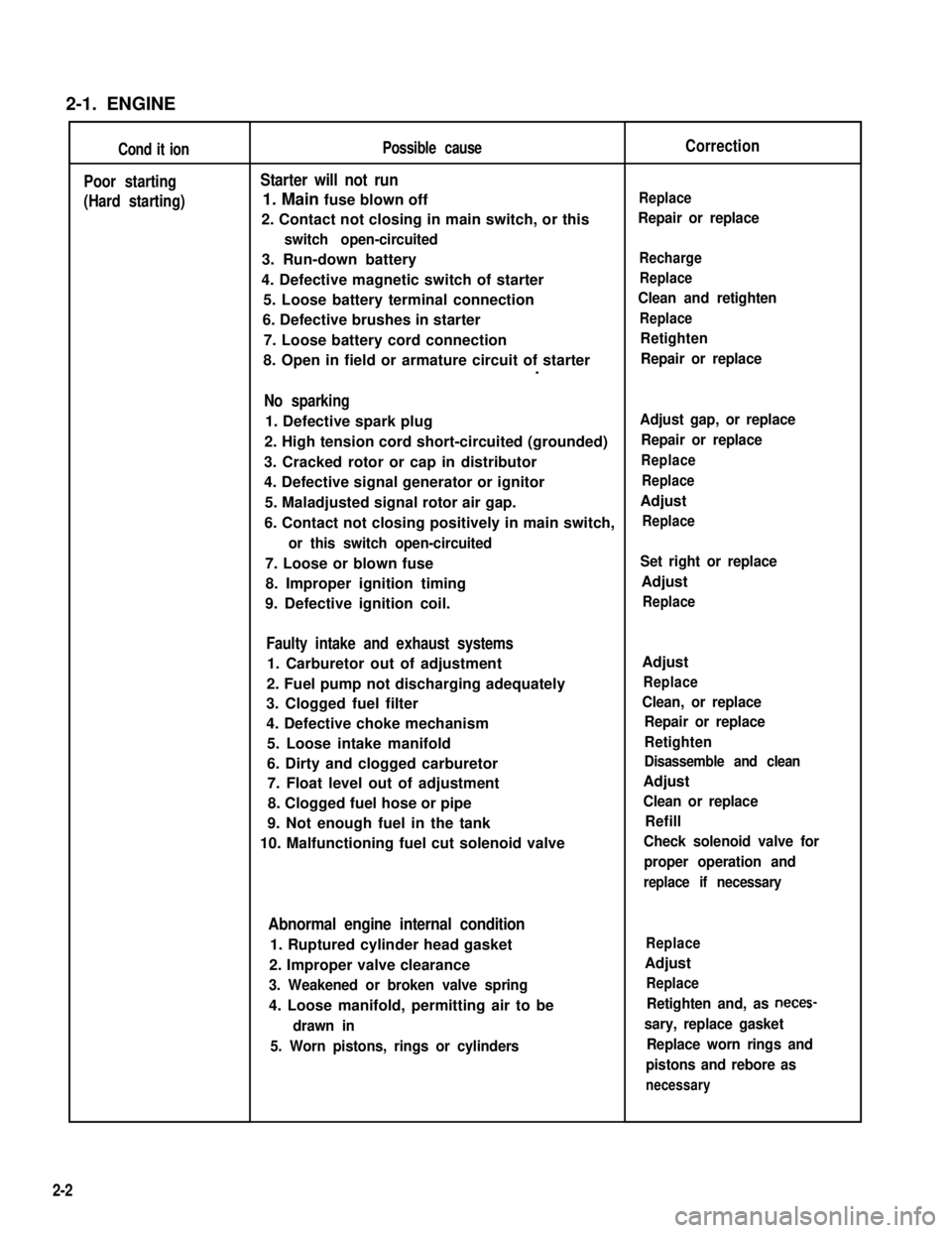

2-1. ENGINE

Cond it ion

Poor starting

(Hard starting)

Possible cause

Starter will not run

1. Main fuse blown off

2. Contact not closing in main switch, or this

switch open-circuited

3. Run-down battery

4. Defective magnetic switch of starter

5. Loose battery terminal connection

6. Defective brushes in starter

7. Loose battery cord connection

8. Open in field or armature circuit of starter.

Correction

Replace

Repair or replace

Recharge

Replace

Clean and retighten

Replace

Retighten

Repair or replace

No sparking

1. Defective spark plugAdjust gap, or replace

2. High tension cord short-circuited (grounded)Repair or replace

3. Cracked rotor or cap in distributorReplace

4. Defective signal generator or ignitorReplace

5. Maladjusted signal rotor air gap.Adjust

6. Contact not closing positively in main switch,Replace

or this switch open-circuited

7. Loose or blown fuseSet right or replace

8. Improper ignition timingAdjust

9. Defective ignition coil.Replace

Faulty intake and exhaust systems

1. Carburetor out of adjustment

2. Fuel pump not discharging adequately

3. Clogged fuel filter

4. Defective choke mechanism

5. Loose intake manifold

6. Dirty and clogged carburetor

7. Float level out of adjustment

8. Clogged fuel hose or pipe

9. Not enough fuel in the tank

10. Malfunctioning fuel cut solenoid valve

Adjust

Replace

Clean, or replace

Repair or replace

Retighten

Disassemble and clean

Adjust

Clean or replace

Refill

Check solenoid valve for

proper operation and

replace if necessary

Abnormal engine internal condition

1. Ruptured cylinder head gasket

2. Improper valve clearance

3. Weakened or broken valve spring

4. Loose manifold, permitting air to be

drawn in

5. Worn pistons, rings or cylinders

Replace

Adjust

Replace

Retighten and, as neces-

sary, replace gasket

Replace worn rings and

pistons and rebore as

necessary

2-2