SUZUKI GRAND VITARA 1987 Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 51 of 962

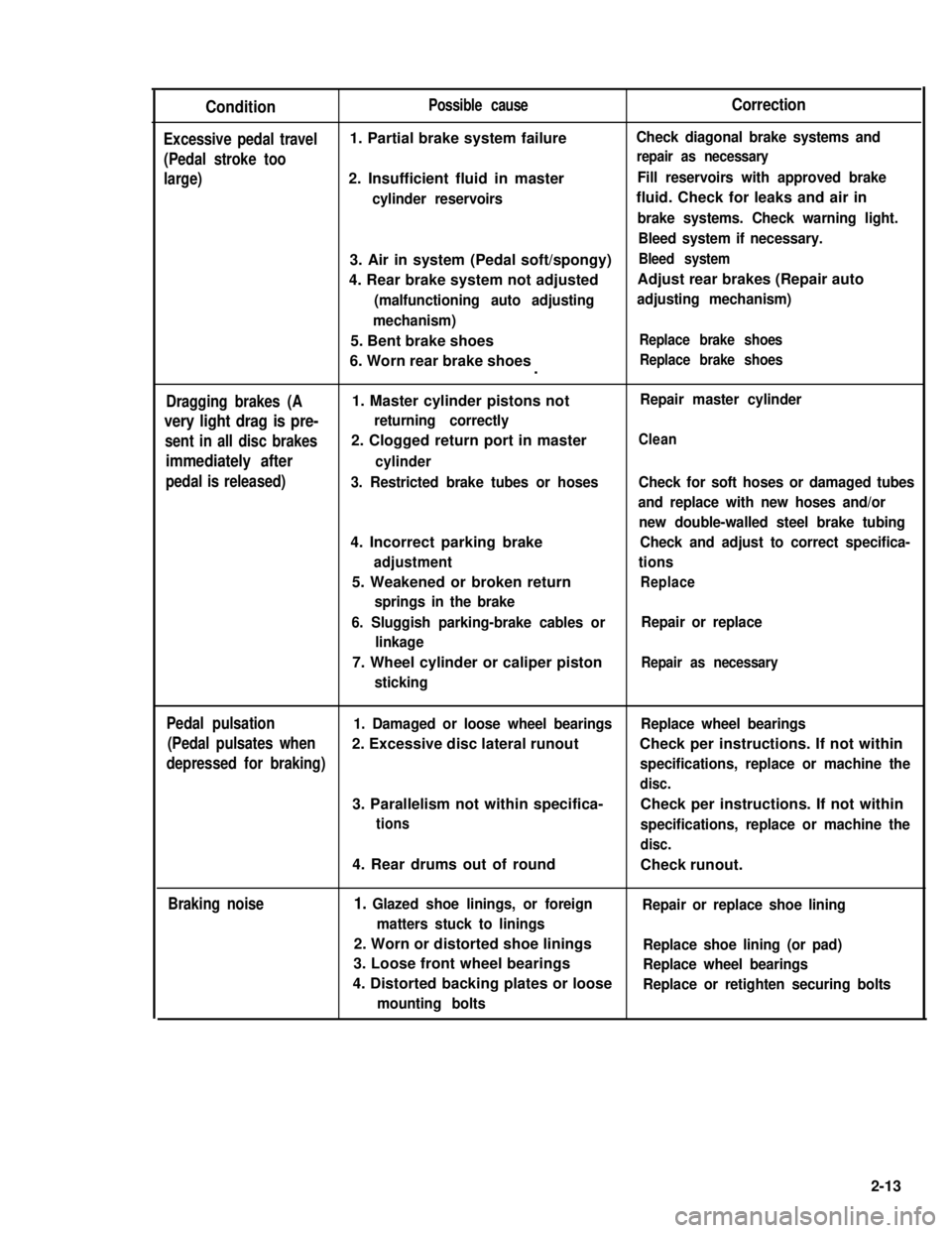

Condition

Excessive pedal travel

(Pedal stroke too

large)

Possible cause

1. Partial brake system failure

2. Insufficient fluid in master

cylinder reservoirs

Correction

Check diagonal brake systems and

repair as necessary

Fill reservoirs with approved brake

fluid. Check for leaks and air in

brake systems. Check warning light.

Bleed system if necessary.

3. Air in system (Pedal soft/spongy)Bleed system

4. Rear brake system not adjustedAdjust rear brakes (Repair auto

(malfunctioning auto adjustingadjusting mechanism)

mechanism)

5. Bent brake shoesReplace brake shoes

6. Worn rear brake shoesReplace brake shoes.

Dragging brakes (A

very light drag is pre-

sent in all disc brakes

immediately after

pedal is released)

1. Master cylinder pistons not

returning correctly

2. Clogged return port in master

cylinder

3. Restricted brake tubes or hoses

4. Incorrect parking brake

adjustment

5. Weakened or broken return

springs in the brake

Repair master cylinder

Clean

Check for soft hoses or damaged tubes

and replace with new hoses and/or

new double-walled steel brake tubing

Check and adjust to correct specifica-

tions

Replace

6. Sluggish parking-brake cables or

linkage

Repair or replace

7. Wheel cylinder or caliper piston

sticking

Repair as necessary

Pedal pulsation1. Damaged or loose wheel bearingsReplace wheel bearings

(Pedal pulsates when2. Excessive disc lateral runout Check per instructions. If not within

depressed for braking)specifications, replace or machine the

disc.

3. Parallelism not within specifica-Check per instructions. If not within

tionsspecifications, replace or machine the

disc.

4. Rear drums out of roundCheck runout.

Braking noise1. Glazed shoe linings, or foreignRepair or replace shoe lining

matters stuck to linings

2. Worn or distorted shoe liningsReplace shoe lining (or pad)

3. Loose front wheel bearingsReplace wheel bearings

4. Distorted backing plates or looseReplace or retighten securing bolts

mounting bolts

2-13

Page 52 of 962

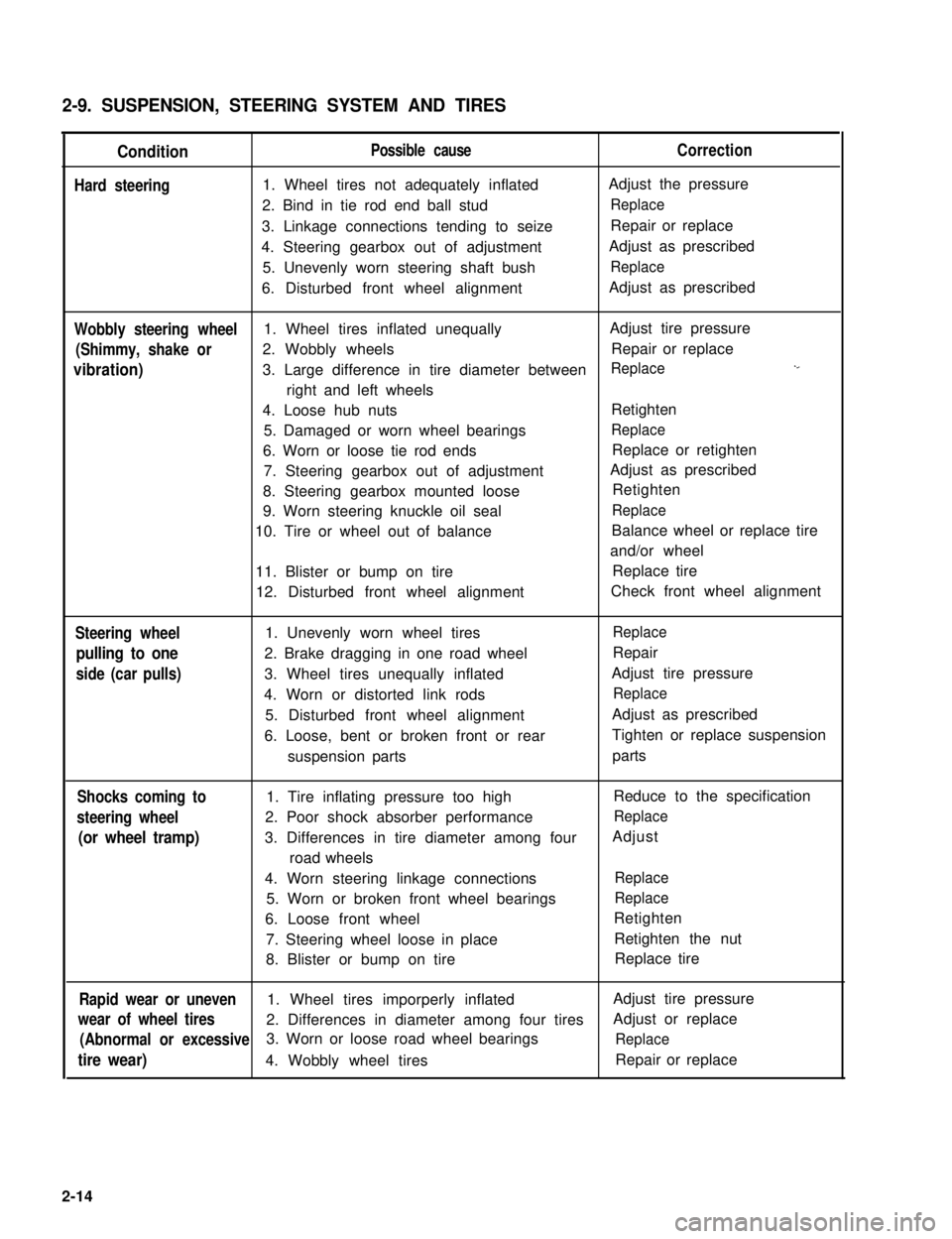

2-9. SUSPENSION, STEERING SYSTEM AND TIRES

Condition

Hard steering

Possible causeCorrection

1. Wheel tires not adequately inflatedAdjust the pressure

2. Bind in tie rod end ball studReplace

3. Linkage connections tending to seizeRepair or replace

4. Steering gearbox out of adjustmentAdjust as prescribed

5. Unevenly worn steering shaft bushReplace

6. Disturbed front wheel alignmentAdjust as prescribed

Wobbly steering wheel1. Wheel tires inflated unequallyAdjust tire pressure

(Shimmy, shake or2. Wobbly wheelsRepair or replace

vibration)3. Large difference in tire diameter betweenReplace._

right and left wheels

4. Loose hub nutsRetighten

5. Damaged or worn wheel bearingsReplace

6. Worn or loose tie rod endsReplace or retighten

7. Steering gearbox out of adjustmentAdjust as prescribed

8. Steering gearbox mounted looseRetighten

9. Worn steering knuckle oil sealReplace

10. Tire or wheel out of balanceBalance wheel or replace tire

and/or wheel

11. Blister or bump on tireReplace tire

12. Disturbed front wheel alignmentCheck front wheel alignment

Steering wheel

pulling to one

side (car pulls)

1. Unevenly worn wheel tires

2. Brake dragging in one road wheel

3. Wheel tires unequally inflated

4. Worn or distorted link rods

5. Disturbed front wheel alignment

6. Loose, bent or broken front or rear

suspension parts

Replace

Repair

Adjust tire pressure

Replace

Adjust as prescribed

Tighten or replace suspension

parts

Shocks coming to1. Tire inflating pressure too highReduce to the specification

steering wheel2. Poor shock absorber performanceReplace

(or wheel tramp)3. Differences in tire diameter among fourAdjust

road wheels

4. Worn steering linkage connectionsReplace

5. Worn or broken front wheel bearingsReplace

6. Loose front wheelRetighten

7. Steering wheel loose in placeRetighten the nut

8. Blister or bump on tireReplace tire

Rapid wear or uneven1. Wheel tires imporperly inflatedAdjust tire pressure

wear of wheel tires2. Differences in diameter among four tiresAdjust or replace

(Abnormal or excessive3. Worn or loose road wheel bearingsReplace

tire wear)4. Wobbly wheel tiresRepair or replace

2-14

Page 53 of 962

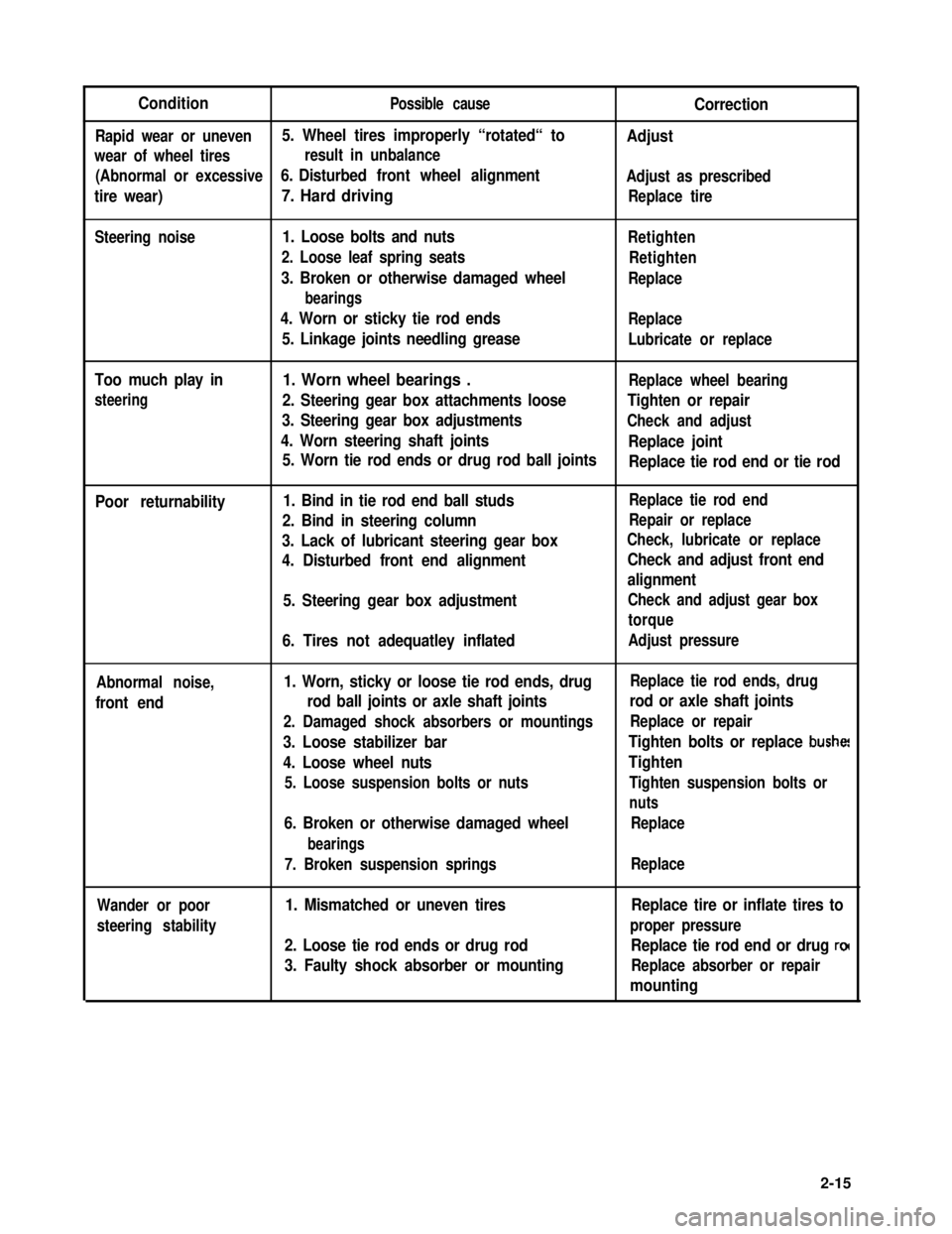

ConditionPossible causeCorrection

Rapid wear or uneven5. Wheel tires improperly “rotated“ toAdjust

wear of wheel tiresresult in unbalance

(Abnormal or excessive6. Disturbed front wheel alignmentAdjust as prescribed

tire wear)7. Hard drivingReplace tire

Steering noise1. Loose bolts and nuts

2. Loose leaf spring seats

3. Broken or otherwise damaged wheel

bearings

4. Worn or sticky tie rod ends

5. Linkage joints needling grease

Retighten

Retighten

Replace

Replace

Lubricate or replace

Too much play in

steering

1. Worn wheel bearings .Replace wheel bearing

2. Steering gear box attachments looseTighten or repair

3. Steering gear box adjustmentsCheck and adjust

4. Worn steering shaft jointsReplace joint

5. Worn tie rod ends or drug rod ball jointsReplace tie rod end or tie rod

Poor returnability1. Bind in tie rod end ball studs

2. Bind in steering column

3. Lack of lubricant steering gear box

4. Disturbed front end alignment

5. Steering gear box adjustment

6. Tires not adequatley inflated

Replace tie rod end

Repair or replace

Check, lubricate or replace

Check and adjust front end

alignment

Check and adjust gear box

torque

Adjust pressure

Abnormal noise,

front end

1. Worn, sticky or loose tie rod ends, drug

rod ball joints or axle shaft joints

2. Damaged shock absorbers or mountings

3. Loose stabilizer bar

4. Loose wheel nuts

5. Loose suspension bolts or nuts

6. Broken or otherwise damaged wheel

bearings

7. Broken suspension springs

Replace tie rod ends, drug

rod or axle shaft joints

Replace or repair

Tighten bolts or replace bushe!

Tighten

Tighten suspension bolts or

nuts

Replace

Replace

Wander or poor

steering stability

1. Mismatched or uneven tires

2. Loose tie rod ends or drug rod

3. Faulty shock absorber or mounting

Replace tire or inflate tires to

proper pressure

Replace tie rod end or drug ro(

Replace absorber or repair

mounting

2-15

Page 54 of 962

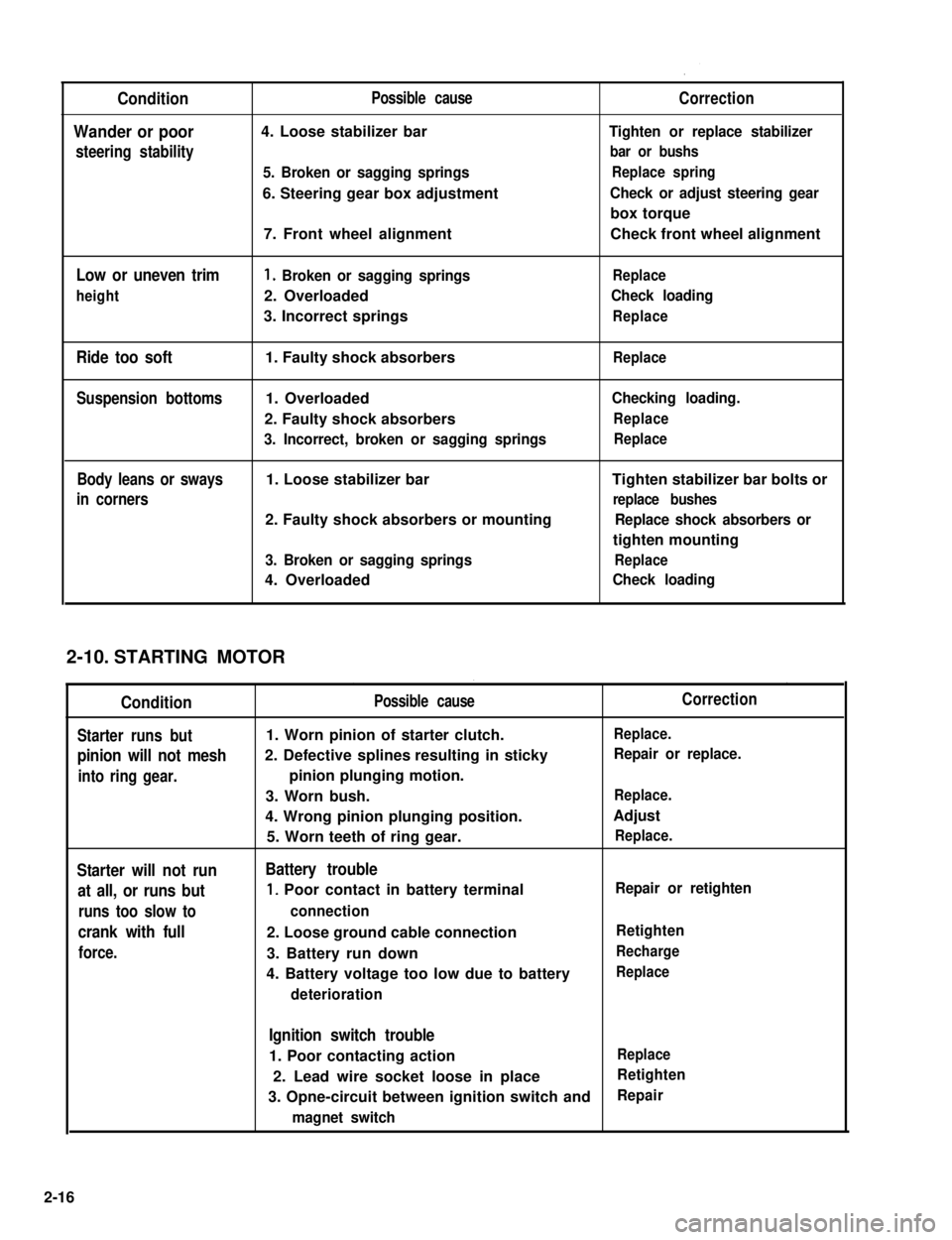

Condition

Wander or poor

steering stability

Low or uneven trim

height

Ride too soft

Suspension bottoms

Body leans or sways

in corners

Possible cause

4. Loose stabilizer bar

5. Broken or sagging springs

6. Steering gear box adjustment

7. Front wheel alignment

1. Broken or sagging springs

2. Overloaded

3. Incorrect springs

1. Faulty shock absorbers

1. Overloaded

2. Faulty shock absorbers

3. Incorrect, broken or sagging springs

1. Loose stabilizer bar

2. Faulty shock absorbers or mounting

3. Broken or sagging springs

4. Overloaded

Correction

Tighten or replace stabilizer

bar or bushs

Replace spring

Check or adjust steering gear

box torque

Check front wheel alignment

Replace

Check loading

Replace

Replace

Checking loading.

Replace

Replace

Tighten stabilizer bar bolts or

replace bushes

Replace shock absorbers or

tighten mounting

Replace

Check loading

STARTING MOTOR

Condition

Starter runs but

pinion will not mesh

into ring gear.

Starter will not run

at all, or runs but

runs too slow to

crank with full

force.

Possible cause

1. Worn pinion of starter clutch.

2. Defective splines resulting in sticky

pinion plunging motion.

3. Worn bush.

4. Wrong pinion plunging position.

5. Worn teeth of ring gear.

Battery trouble

1, Poor contact in battery terminal

connection

2. Loose ground cable connection

3. Battery run down

4. Battery voltage too low due to battery

deterioration

Correction

Replace.

Repair or replace.

Replace.

Adjust

Replace.

Repair or retighten

Retighten

Recharge

Replace

Ignition switch trouble

1. Poor contacting actionReplace

2. Lead wire socket loose in placeRetighten

3. Opne-circuit between ignition switch andRepair

magnet switch

2-10.

2-16

Page 55 of 962

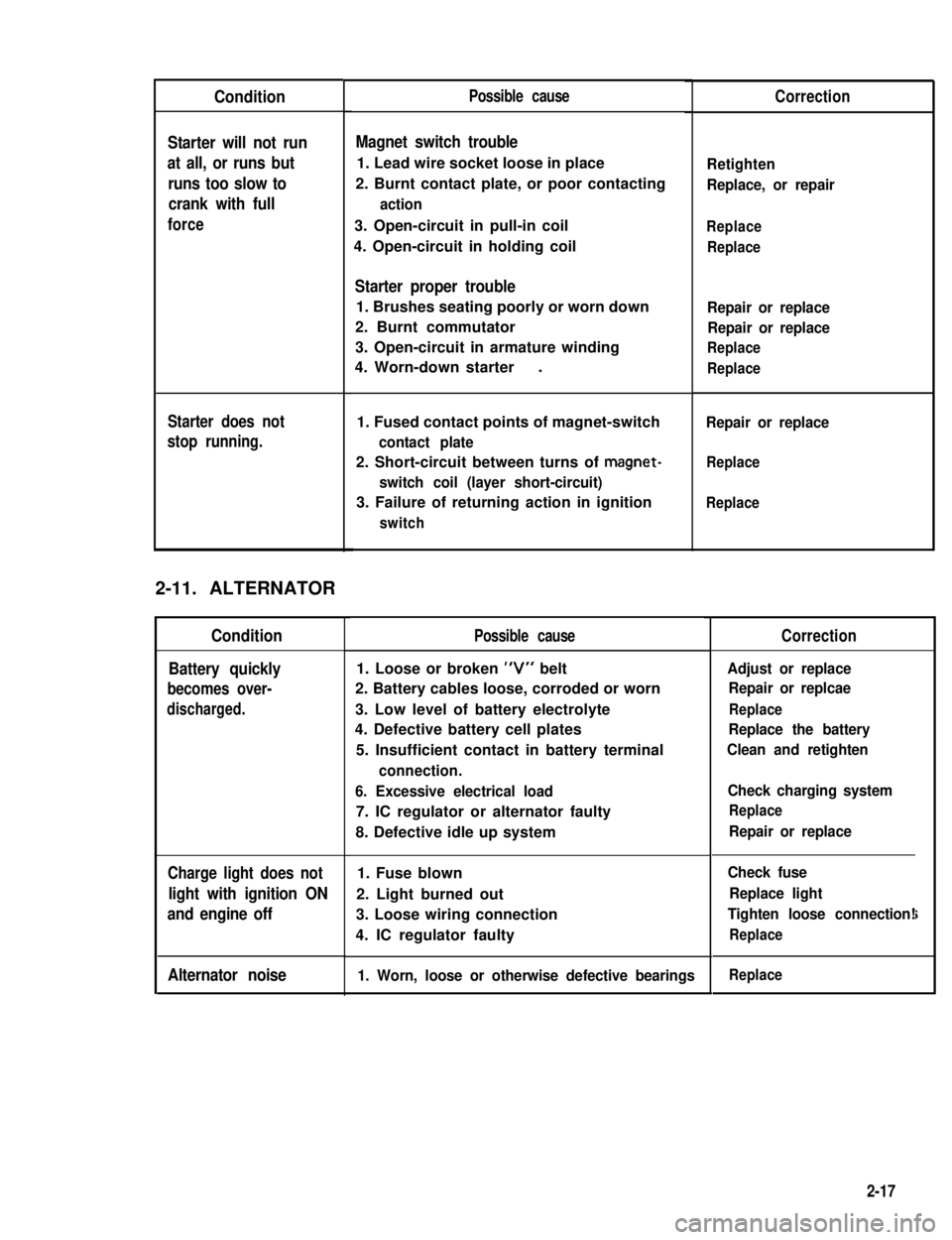

Condition

Starter will not run

at all, or runs but

runs too slow to

crank with full

force

Starter does not

stop running.

2-11. ALTERNATOR

Condition

Battery quickly

becomes over-

discharged.

Charge light does not

light with ignition ON

and engine off

Alternator noise

Possible cause

Magnet switch trouble

1. Lead wire socket loose in place

2. Burnt contact plate, or poor contacting

action

3. Open-circuit in pull-in coil

4. Open-circuit in holding coil

Starter proper trouble

1. Brushes seating poorly or worn down

2. Burnt commutator

3. Open-circuit in armature winding

4. Worn-down starter.

1. Fused contact points of magnet-switch

contact plate

2. Short-circuit between turns of magnet-

switch coil (layer short-circuit)

3. Failure of returning action in ignition

switch

Possible cause

1. Loose or broken “V” belt

2. Battery cables loose, corroded or worn

3. Low level of battery electrolyte

4. Defective battery cell plates

5. Insufficient contact in battery terminal

connection.

6. Excessive electrical load

7. IC regulator or alternator faulty

8. Defective idle up system

1. Fuse blown

2. Light burned out

3. Loose wiring connection

4. IC regulator faulty

1. Worn, loose or otherwise defective bearings

Correction

Retighten

Replace, or repair

Replace

Replace

Repair or replace

Repair or replace

Replace

Replace

Repair or replace

Replace

Replace

Correction

Adjust or replace

Repair or replcae

Replace

Replace the battery

Clean and retighten

Check charging system

Replace

Repair or replace

Check fuse

Replace light

Tighten loose connection!

Replace

i

Replace

2-17

Page 56 of 962

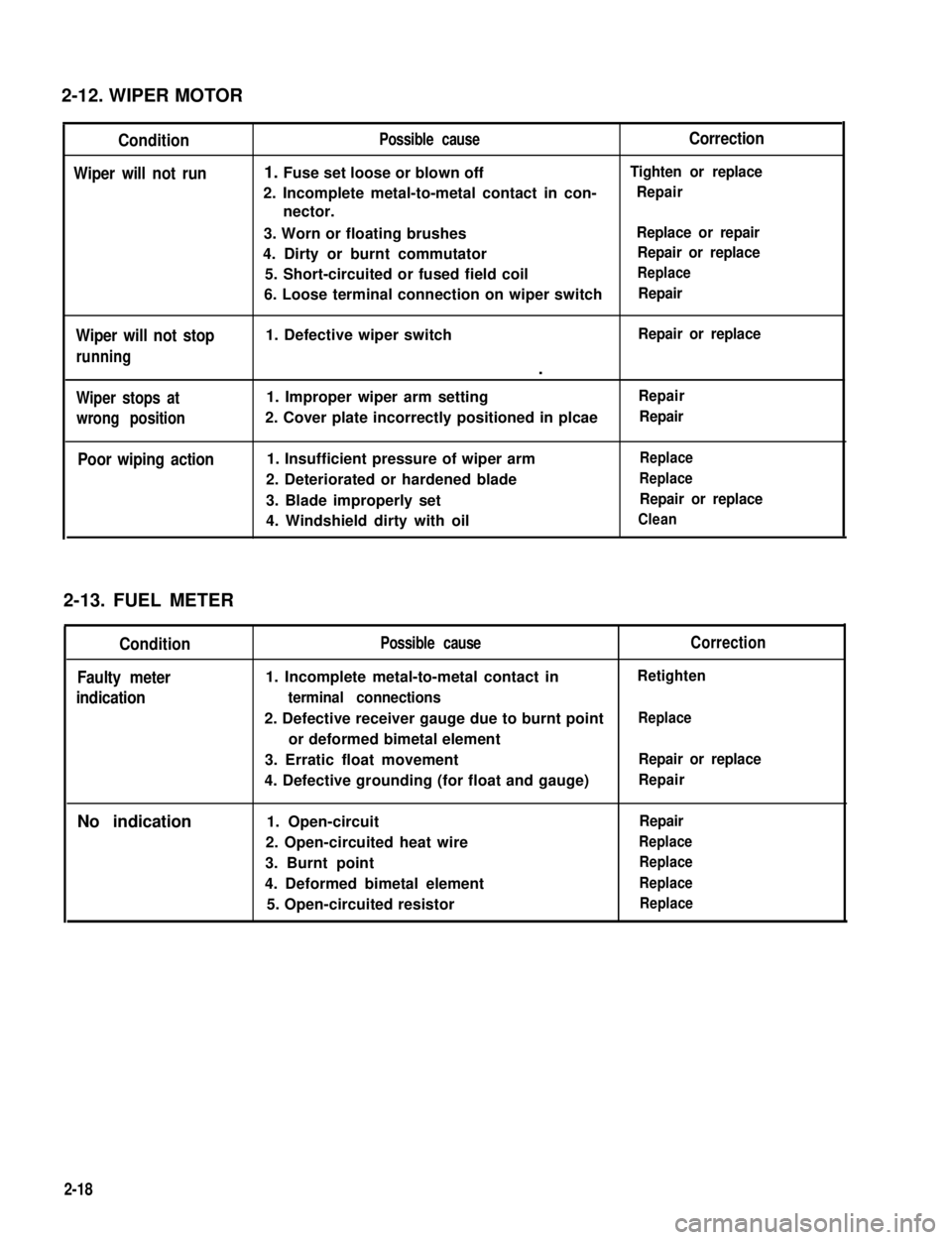

2-12. WIPER MOTOR

Condition

Wiper will not run

Wiper will not stop

running

Wiper stops at

wrong position

Poor wiping action

Possible causeCorrection

1. Fuse set loose or blown offTighten or replace

2. Incomplete metal-to-metal contact in con-

nector.

Repair

3. Worn or floating brushesReplace or repair

4. Dirty or burnt commutatorRepair or replace

5. Short-circuited or fused field coilReplace

6. Loose terminal connection on wiper switchRepair

1. Defective wiper switchRepair or replace

.

1. Improper wiper arm settingRepair

2. Cover plate incorrectly positioned in plcaeRepair

1. Insufficient pressure of wiper armReplace

2. Deteriorated or hardened bladeReplace

3. Blade improperly setRepair or replace

4. Windshield dirty with oilClean

2-13. FUEL METER

Condition

Faulty meter

indication

No indication

Possible cause

1. Incomplete metal-to-metal contact in

terminal connections

2. Defective receiver gauge due to burnt point

or deformed bimetal element

3. Erratic float movement

4. Defective grounding (for float and gauge)

1. Open-circuit

2. Open-circuited heat wire

3. Burnt point

4. Deformed bimetal element

5. Open-circuited resistor

Correction

Retighten

Replace

Repair or replace

Repair

Repair

Replace

Replace

Replace

Replace

2-18

Page 57 of 962

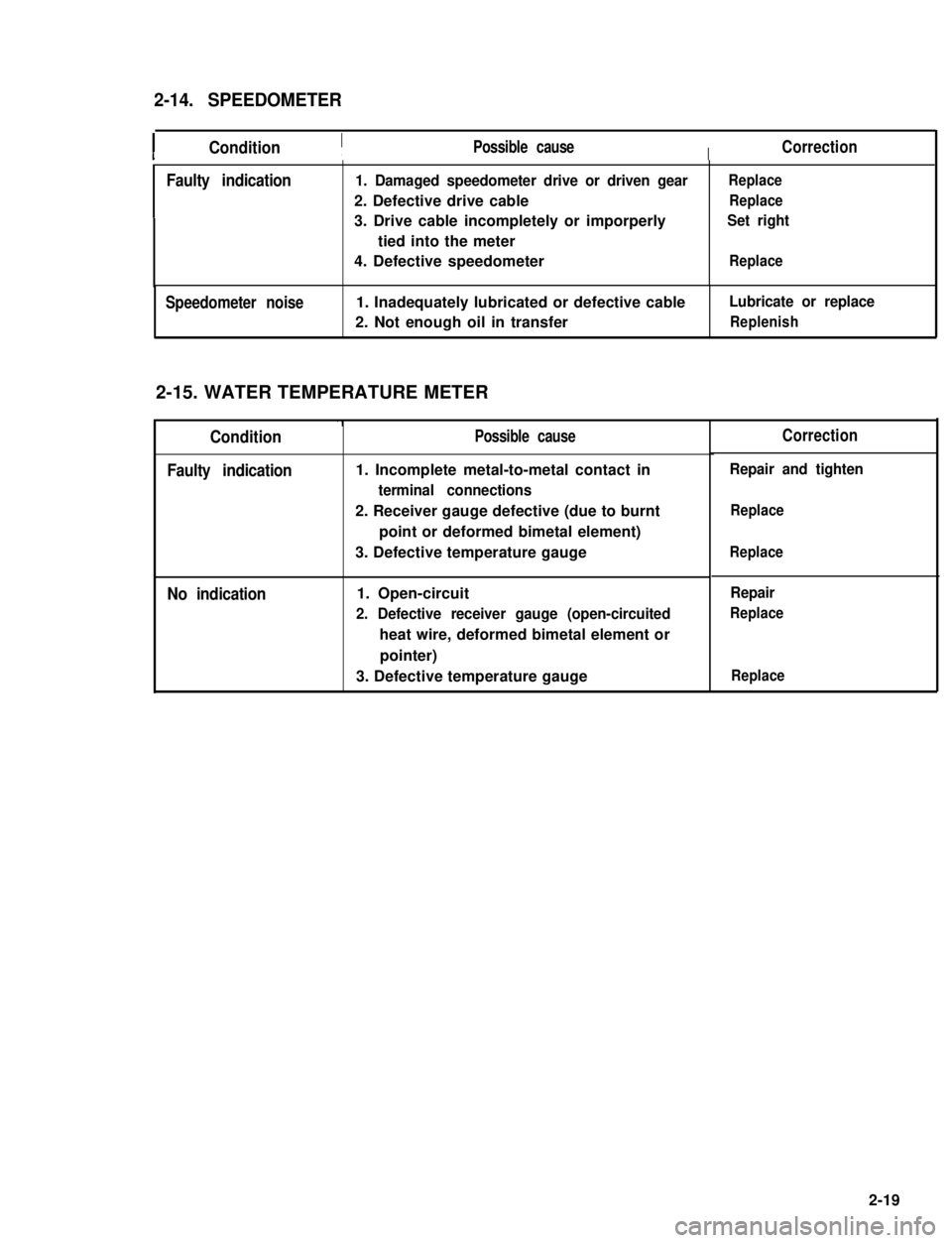

2-14. SPEEDOMETER

IConditionIPossible causeICorrection

Faulty indication1. Damaged speedometer drive or driven gear

2. Defective drive cable

3. Drive cable incompletely or imporperly

tied into the meter

4. Defective speedometer

Replace

Replace

Set right

Replace

Speedometer noise1. Inadequately lubricated or defective cable

2. Not enough oil in transfer

Lubricate or replace

Replenish

2-15. WATER TEMPERATURE METER

Condition

Faulty indication

No indication

Possible cause

1. Incomplete metal-to-metal contact in

terminal connections

2. Receiver gauge defective (due to burnt

point or deformed bimetal element)

3. Defective temperature gauge

1. Open-circuit

2. Defective receiver gauge (open-circuited

heat wire, deformed bimetal element or

pointer)

Repair

Replace

3. Defective temperature gaugeReplace

Correction

Repair and tighten

Replace

Replace

2-19

Page 58 of 962

3-1.

3-2.

3-3.

3-5.

3-6.

3-7.

3-8.

3-9.

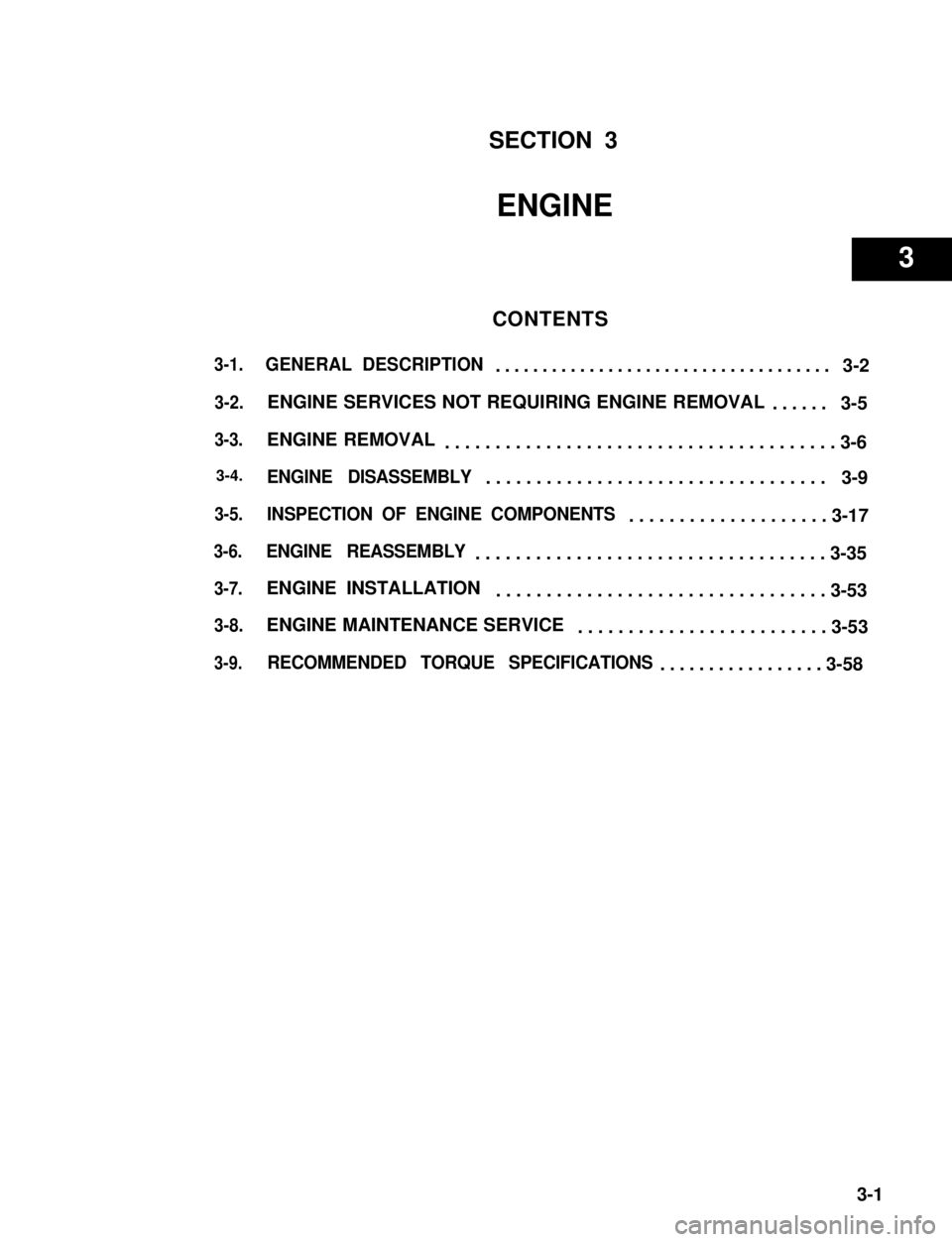

SECTION 3

ENGINE

CONTENTS

GENERAL DESCRIPTION.................................... 3-2

ENGINE SERVICES NOT REQUIRING ENGINE REMOVAL...... 3-5

ENGINE REMOVAL.......................................3-6

ENGINE DISASSEMBLY.................................. 3-9

INSPECTION OF ENGINE COMPONENTS....................3-17

ENGINE REASSEMBLY...................................3-35

ENGINE INSTALLATION.................................3-53

ENGINE MAINTENANCE SERVICE.........................3-53

RECOMMENDED TORQUE SPECIFICATIONS.................3-58

3-4.

3-1

3

Page 59 of 962

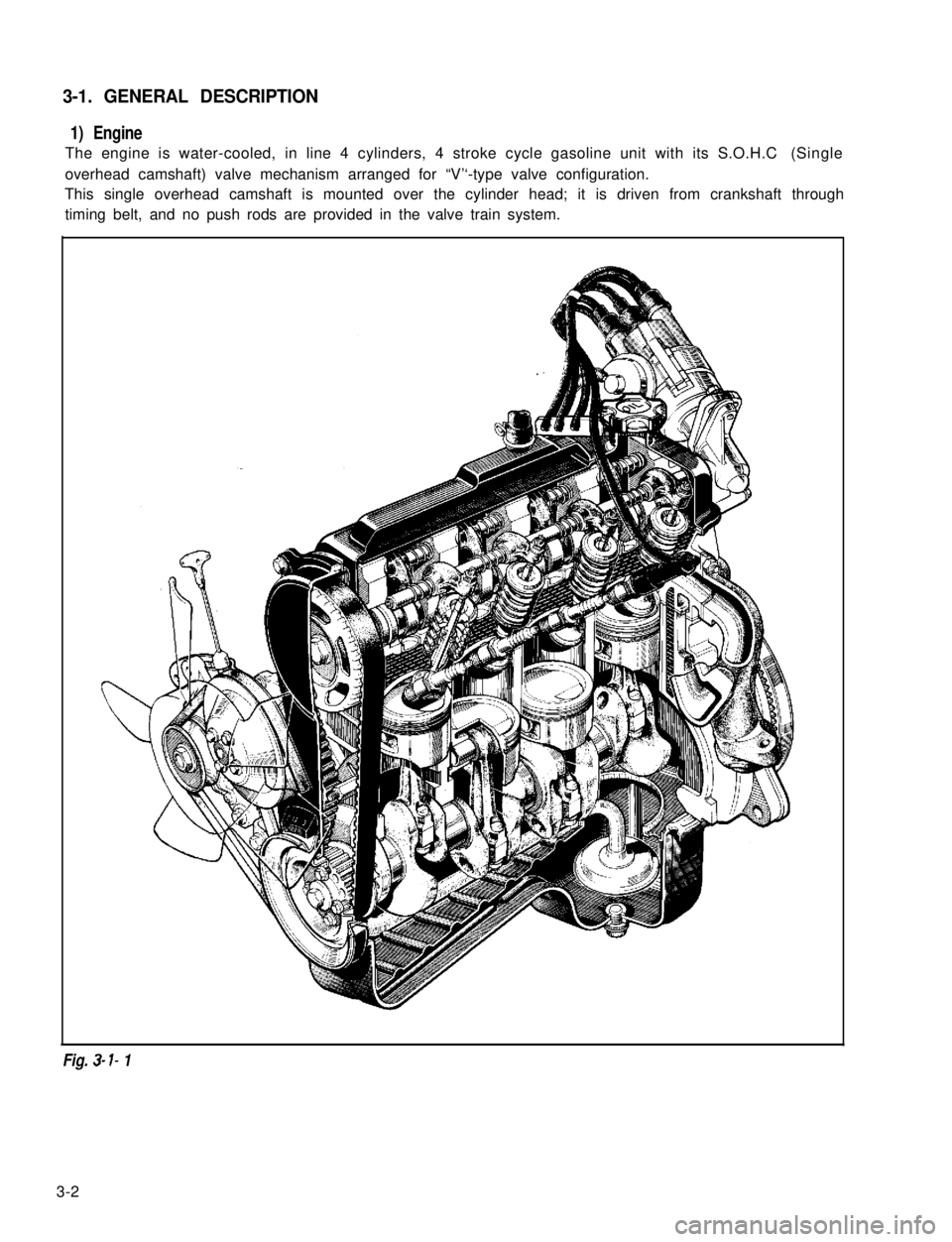

3-1. GENERAL DESCRIPTION

1) Engine

The engine is water-cooled, in line 4 cylinders, 4 stroke cycle gasoline unit with its S.O.H.C (Single

overhead camshaft) valve mechanism arranged for “V’‘-type valve configuration.

This single overhead camshaft is mounted over the cylinder head; it is driven from crankshaft through

timing belt, and no push rods are provided in the valve train system.

Fig. 3- I- 1

3-2

Page 60 of 962

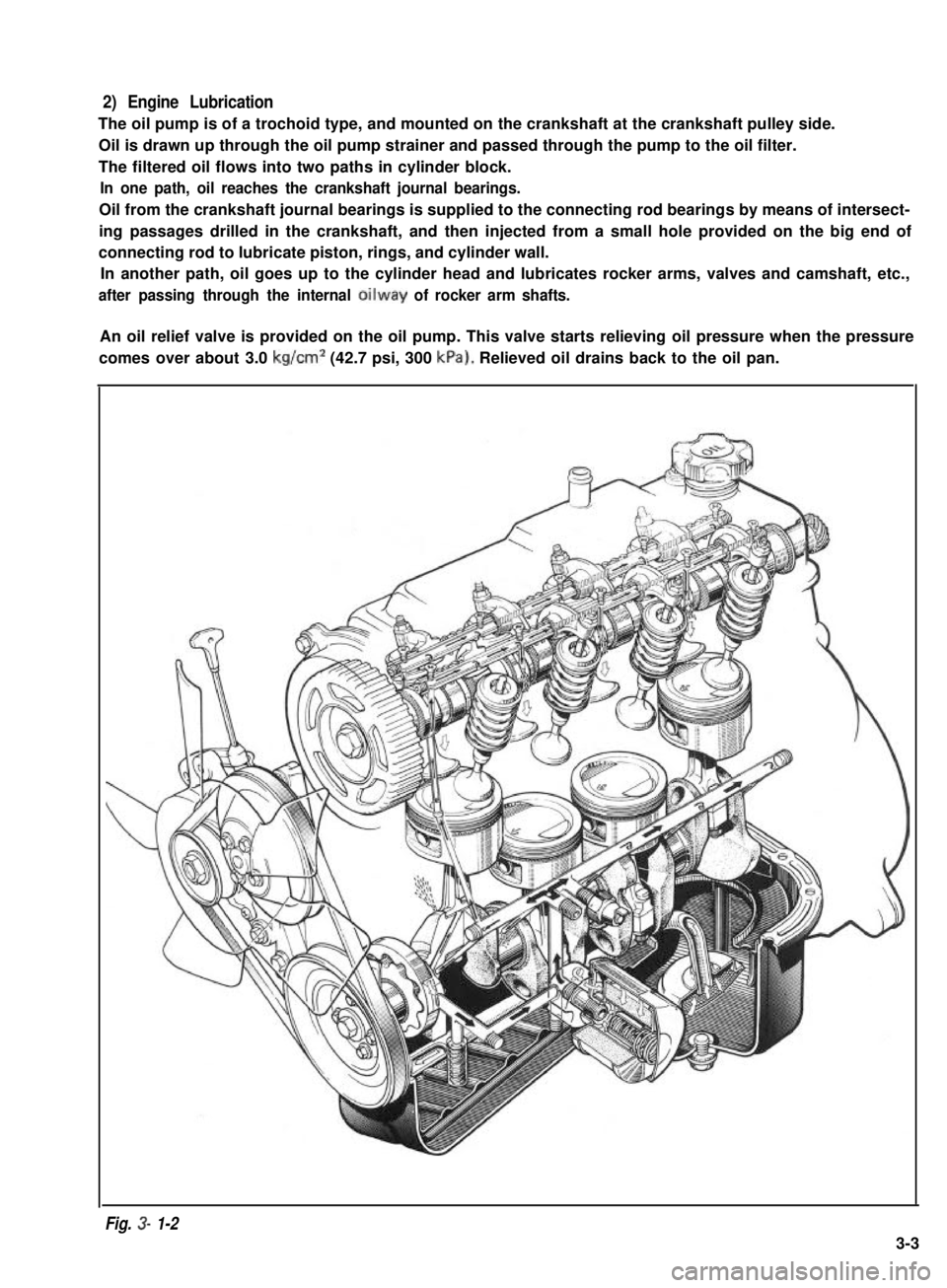

2) Engine Lubrication

The oil pump is of a trochoid type, and mounted on the crankshaft at the crankshaft pulley side.

Oil is drawn up through the oil pump strainer and passed through the pump to the oil filter.

The filtered oil flows into two paths in cylinder block.

In one path, oil reaches the crankshaft journal bearings.

Oil from the crankshaft journal bearings is supplied to the connecting rod bearings by means of intersect-

ing passages drilled in the crankshaft, and then injected from a small hole provided on the big end of

connecting rod to lubricate piston, rings, and cylinder wall.

In another path, oil goes up to the cylinder head and lubricates rocker arms, valves and camshaft, etc.,

after passing through the internal oilway of rocker arm shafts.

An oil relief valve is provided on the oil pump. This valve starts relieving oil pressure when the pressure

comes over about 3.0 kg/cm2 (42.7 psi, 300 kPa). Relieved oil drains back to the oil pan.

Fig. 3- 1-2

3-3