SUZUKI GRAND VITARA 1987 Service Service Manual

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 41 of 962

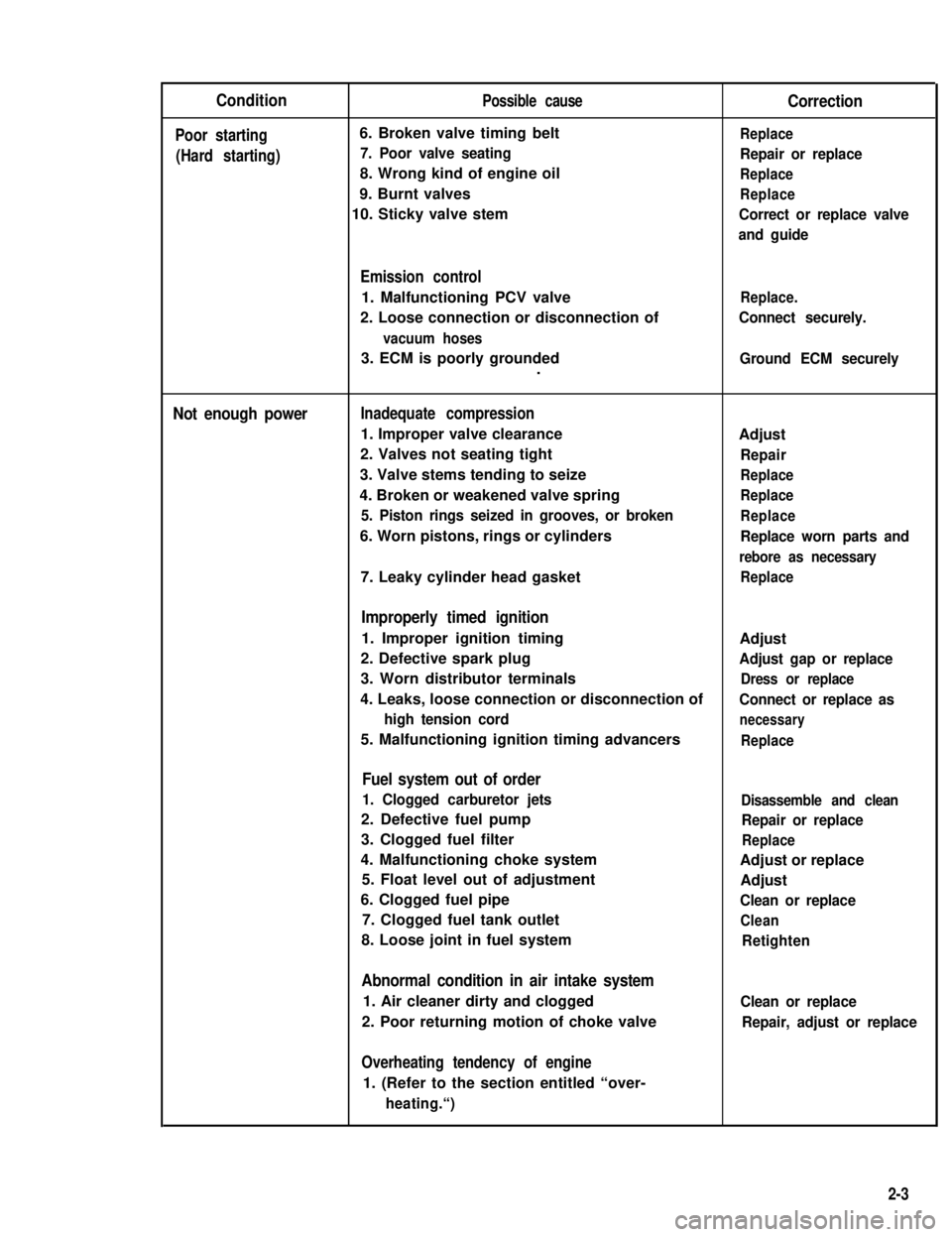

Condition

Poor starting

(Hard starting)

Possible cause

6. Broken valve timing belt

7. Poor valve seating

8. Wrong kind of engine oil

9. Burnt valves

10. Sticky valve stem

Correction

Replace

Repair or replace

Replace

Replace

Correct or replace valve

and guide

Emission control

1. Malfunctioning PCV valve

2. Loose connection or disconnection of

vacuum hoses

Replace.

Connect securely.

3. ECM is poorly grounded.Ground ECM securely

Not enough powerInadequate compression

1. Improper valve clearance

2. Valves not seating tight

3. Valve stems tending to seize

4. Broken or weakened valve spring

5. Piston rings seized in grooves, or broken

6. Worn pistons, rings or cylinders

Adjust

Repair

Replace

Replace

Replace

Replace worn parts and

rebore as necessary

7. Leaky cylinder head gasketReplace

Improperly timed ignition

1. Improper ignition timing

2. Defective spark plug

3. Worn distributor terminals

4. Leaks, loose connection or disconnection of

high tension cord

5. Malfunctioning ignition timing advancers

Adjust

Adjust gap or replace

Dress or replace

Connect or replace as

necessary

Replace

Fuel system out of order

1. Clogged carburetor jets

2. Defective fuel pump

3. Clogged fuel filter

4. Malfunctioning choke system

5. Float level out of adjustment

6. Clogged fuel pipe

7. Clogged fuel tank outlet

8. Loose joint in fuel system

Disassemble and clean

Repair or replace

Replace

Adjust or replace

Adjust

Clean or replace

Clean

Retighten

Abnormal condition in air intake system

1. Air cleaner dirty and clogged

2. Poor returning motion of choke valve

Clean or replace

Repair, adjust or replace

Overheating tendency of engine

1. (Refer to the section entitled “over-

heating.“)

2-3

Page 42 of 962

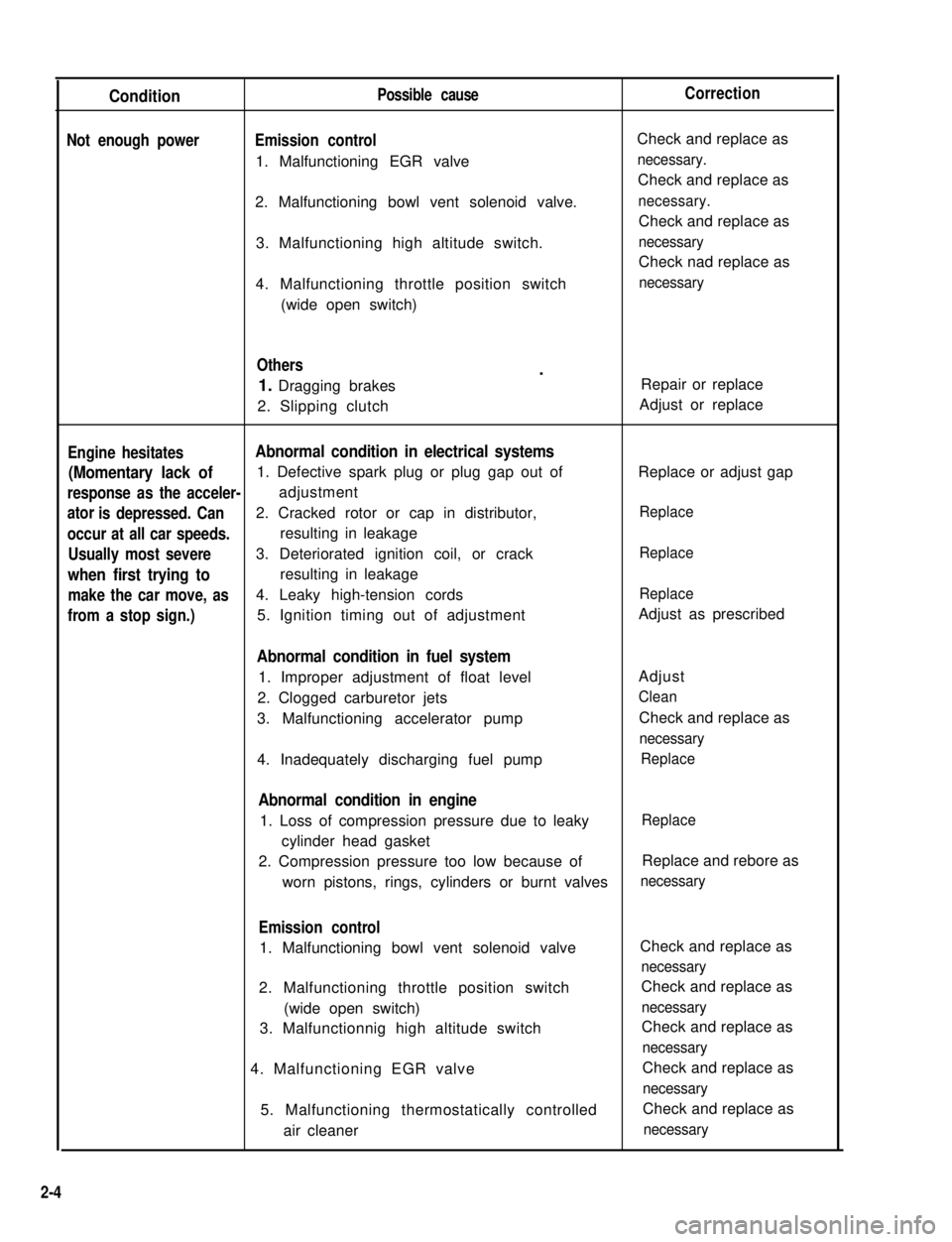

ConditionPossible causeCorrection

Not enough powerEmission control

1. Malfunctioning EGR valve

Check and replace as

necessary.

Check and replace as

2. Malfunctioning bowl vent solenoid valve.necessary.

Check and replace as

3. Malfunctioning high altitude switch.necessary

Check nad replace as

4. Malfunctioning throttle position switch

(wide open switch)

necessary

Others

1. Dragging brakes

2. Slipping clutch

.Repair or replace

Adjust or replace

Engine hesitatesAbnormal condition in electrical systems

(Momentary lack of1. Defective spark plug or plug gap out ofReplace or adjust gap

response as the acceler-

ator

adjustment

is depressed. Can2. Cracked rotor or cap in distributor,Replace

occur at all car speeds.resulting in leakage

Usually most severe3. Deteriorated ignition coil, or crackReplace

when first trying toresulting in leakage

make the car move, as4. Leaky high-tension cordsReplace

from a stop sign.)5. Ignition timing out of adjustmentAdjust as prescribed

Abnormal condition in fuel system

1. Improper adjustment of float level

2. Clogged carburetor jets

3. Malfunctioning accelerator pump

Adjust

Clean

Check and replace as

necessary

4. Inadequately discharging fuel pumpReplace

Abnormal condition in engine

1. Loss of compression pressure due to leaky

cylinder head gasket

Replace

2. Compression pressure too low because ofReplace and rebore as

worn pistons, rings, cylinders or burnt valvesnecessary

Emission control

1. Malfunctioning bowl vent solenoid valveCheck and replace as

necessary

2. Malfunctioning throttle position switch

(wide open switch)

3. Malfunctionnig high altitude switch

4. Malfunctioning EGR valve

Check and replace as

necessary

Check and replace as

necessary

Check and replace as

necessary

5. Malfunctioning thermostatically controlled

air cleaner

Check and replace as

necessary

2-4

Page 43 of 962

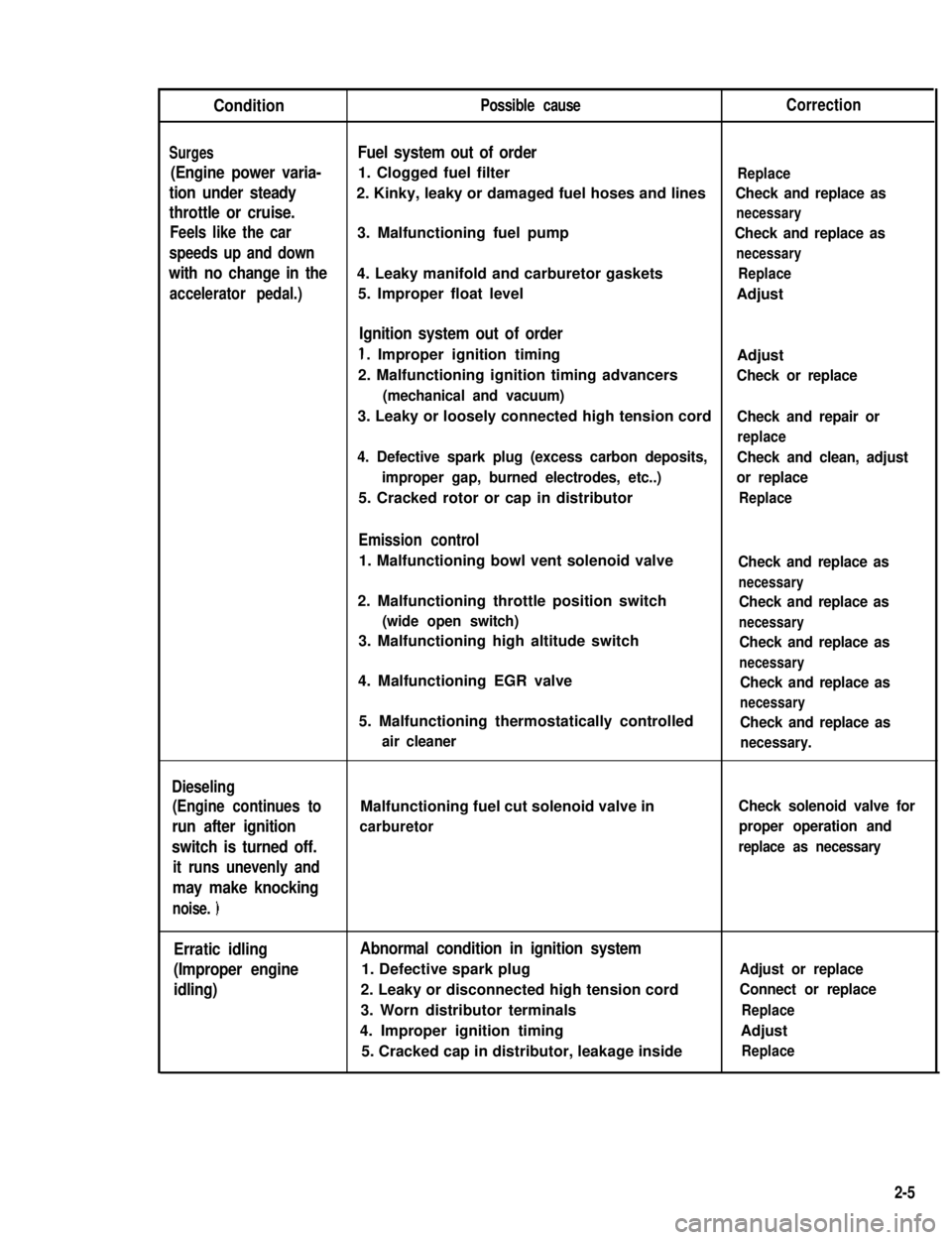

ConditionPossible causeCorrection

SurgesFuel system out of order

(Engine power varia- 1. Clogged fuel filterReplace

tion under steady2. Kinky, leaky or damaged fuel hoses and linesCheck and replace as

throttle or cruise.necessary

Feels like the car3. Malfunctioning fuel pumpCheck and replace as

speeds up and downnecessary

with no change in the4. Leaky manifold and carburetor gasketsReplace

accelerator pedal.)5. Improper float levelAdjust

Ignition system out of order

1. Improper ignition timing

2. Malfunctioning ignition timing advancers

(mechanical and vacuum)

Adjust

Check or replace

3. Leaky or loosely connected high tension cordCheck and repair or

replace

4. Defective spark plug (excess carbon deposits,Check and clean, adjust

improper gap, burned electrodes, etc..)or replace

5. Cracked rotor or cap in distributorReplace

Emission control

1. Malfunctioning bowl vent solenoid valve

2. Malfunctioning throttle position switch

(wide open switch)

3. Malfunctioning high altitude switch

4. Malfunctioning EGR valve

5. Malfunctioning thermostatically controlled

air cleaner

Check and replace as

necessary

Check and replace as

necessary

Check and replace as

necessary

Check and replace as

necessary

Check and replace as

necessary.

Dieseling

(Engine continues to

run after ignition

switch is turned off.

it runs unevenly and

may make knocking

noise. )

Malfunctioning fuel cut solenoid valve in

carburetor

Check solenoid valve for

proper operation and

replace as necessary

Erratic idling

(Improper engine

idling)

Abnormal condition in ignition system

1. Defective spark plug

2. Leaky or disconnected high tension cord

3. Worn distributor terminals

4. Improper ignition timing

5. Cracked cap in distributor, leakage inside

Adjust or replace

Connect or replace

Replace

Adjust

Replace

2-5

Page 44 of 962

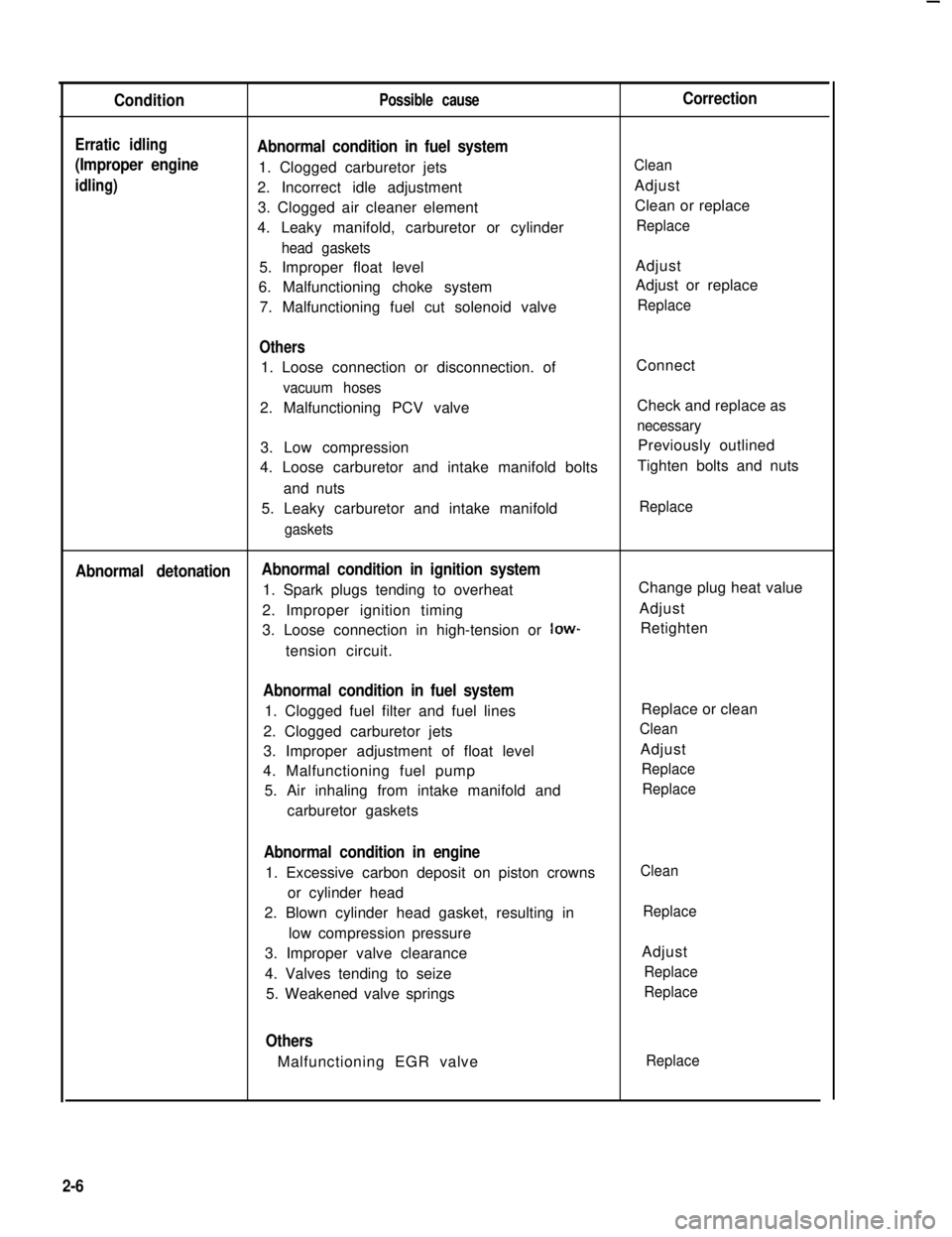

ConditionPossible causeCorrection

Erratic idling

(Improper engine

idling)

Abnormal condition in fuel system

1. Clogged carburetor jets

2. Incorrect idle adjustment

3. Clogged air cleaner element

4. Leaky manifold, carburetor or cylinder

head gaskets

5. Improper float level

6. Malfunctioning choke system

7. Malfunctioning fuel cut solenoid valve

Clean

Adjust

Clean or replace

Replace

Adjust

Adjust or replace

Replace

Others

1. Loose connection or disconnection. of

vacuum hoses

Connect

2. Malfunctioning PCV valve

3. Low compression

4. Loose carburetor and intake manifold bolts

and nuts

Check and replace as

necessary

Previously outlined

Tighten bolts and nuts

5. Leaky carburetor and intake manifold

gaskets

Replace

Abnormal detonationAbnormal condition in ignition system

1. Spark plugs tending to overheatChange plug heat value

2. Improper ignition timingAdjust

3. Loose connection in high-tension or low-Retighten

tension circuit.

Abnormal condition in fuel system

1. Clogged fuel filter and fuel lines

2. Clogged carburetor jets

3. Improper adjustment of float level

4. Malfunctioning fuel pump

5. Air inhaling from intake manifold and

carburetor gaskets

Replace or clean

Clean

Adjust

Replace

Replace

Abnormal condition in engine

1. Excessive carbon deposit on piston crowns

or cylinder head

Clean

2. Blown cylinder head gasket, resulting in

low compression pressure

3. Improper valve clearance

4. Valves tending to seize

5. Weakened valve springs

Replace

Adjust

Replace

Replace

Others

Malfunctioning EGR valveReplace

2-6

Page 45 of 962

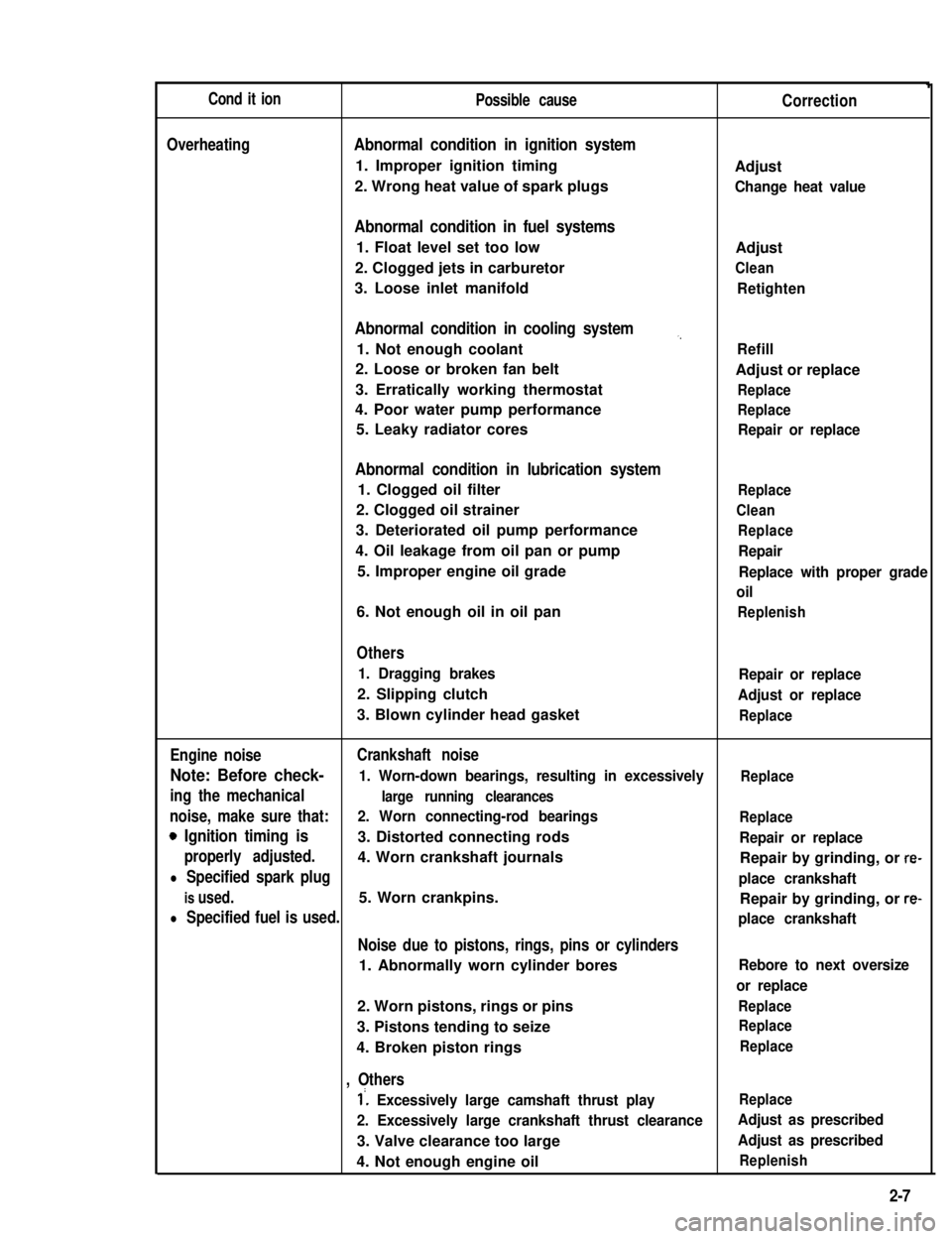

9

Cond it ionPossible causeCorrection

OverheatingAbnormal condition in ignition system

1. Improper ignition timingAdjust

2. Wrong heat value of spark plugsChange heat value

Abnormal condition in fuel systems

1. Float level set too lowAdjust

2. Clogged jets in carburetorClean

3. Loose inlet manifoldRetighten

Abnormal condition in cooling system,,

1. Not enough coolantRefill

2. Loose or broken fan beltAdjust or replace

3. Erratically working thermostatReplace

4. Poor water pump performanceReplace

5. Leaky radiator coresRepair or replace

Abnormal condition in lubrication system

1. Clogged oil filterReplace

2. Clogged oil strainerClean

3. Deteriorated oil pump performanceReplace

4. Oil leakage from oil pan or pumpRepair

5. Improper engine oil gradeReplace with proper grade

oil

6. Not enough oil in oil panReplenish

Others

1. Dragging brakesRepair or replace

2. Slipping clutchAdjust or replace

3. Blown cylinder head gasketReplace

Engine noiseCrankshaft noise

Note: Before check- 1. Worn-down bearings, resulting in excessivelyReplace

ing the mechanicallarge running clearances

noise, make sure that:2. Worn connecting-rod bearingsReplace

0 Ignition timing is3. Distorted connecting rodsRepair or replace

properly adjusted.4. Worn crankshaft journalsRepair by grinding, or re-

l Specified spark plugplace crankshaft

is used.5. Worn crankpins.Repair by grinding, or re-

l Specified fuel is used.place crankshaft

Noise due to pistons, rings, pins or cylinders

1. Abnormally worn cylinder boresRebore to next oversize

or replace

2. Worn pistons, rings or pinsReplace

3. Pistons tending to seizeReplace

4. Broken piston ringsReplace

, Others

1’. Excessively large camshaft thrust playReplace

2. Excessively large crankshaft thrust clearanceAdjust as prescribed

3. Valve clearance too largeAdjust as prescribed

4. Not enough engine oilReplenish

2-7

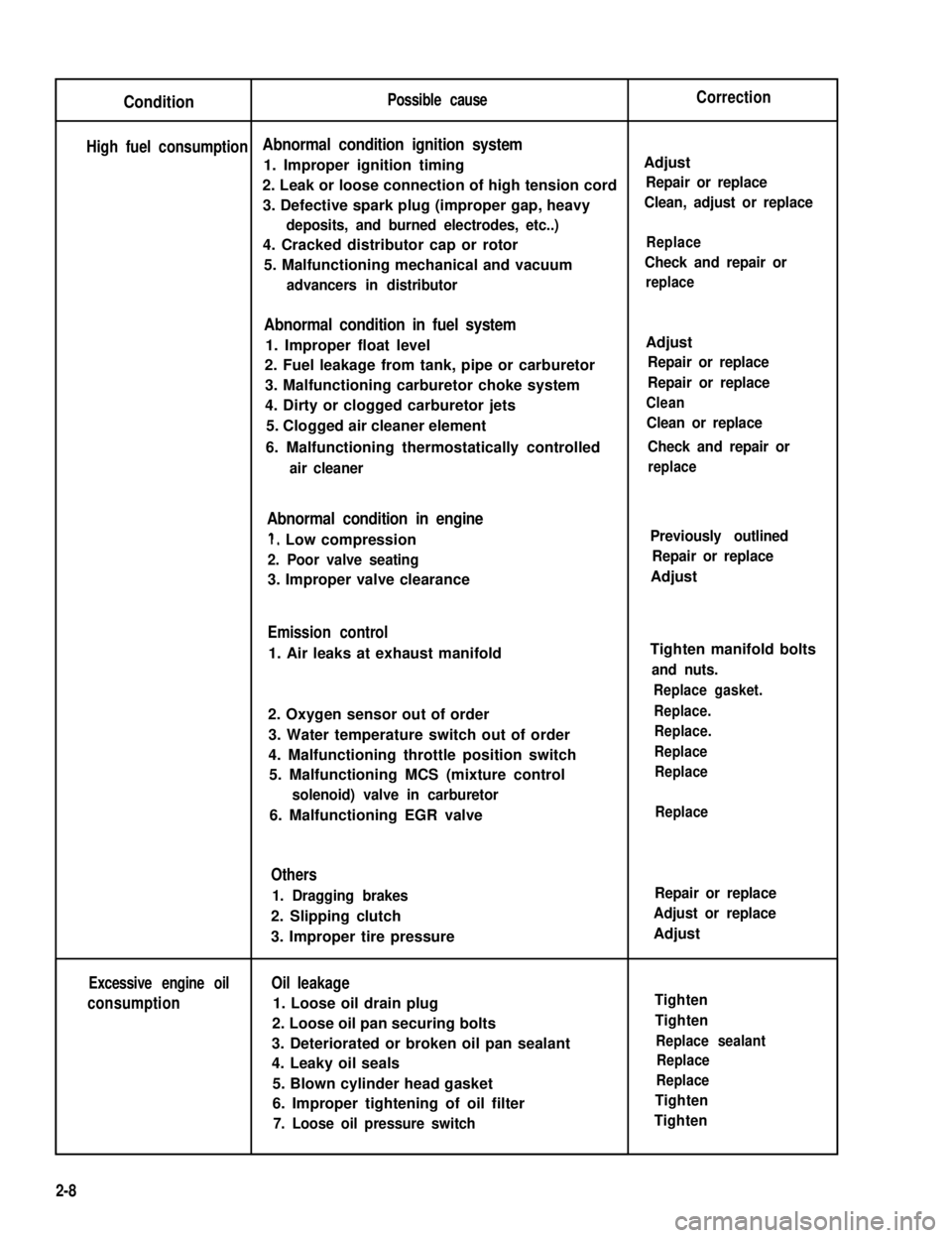

Page 46 of 962

ConditionPossible causeCorrection

High fuel consumptionAbnormal condition ignition system

1. Improper ignition timingAdjust

2. Leak or loose connection of high tension cordRepair or replace

3. Defective spark plug (improper gap, heavyClean, adjust or replace

deposits, and burned electrodes, etc..)

4. Cracked distributor cap or rotorReplace

5. Malfunctioning mechanical and vacuumCheck and repair or

advancers in distributorreplace

Abnormal condition in fuel system

1. Improper float levelAdjust

2. Fuel leakage from tank, pipe or carburetorRepair or replace

3. Malfunctioning carburetor choke systemRepair or replace

4. Dirty or clogged carburetor jetsClean

5. Clogged air cleaner elementClean or replace

6. Malfunctioning thermostatically controlledCheck and repair or

air cleanerreplace

Abnormal condition in engine

1. Low compressionPreviously outlined

2. Poor valve seatingRepair or replace

3. Improper valve clearanceAdjust

Emission control

1. Air leaks at exhaust manifoldTighten manifold bolts

and nuts.

Replace gasket.

2. Oxygen sensor out of orderReplace.

3. Water temperature switch out of orderReplace.

4. Malfunctioning throttle position switchReplace

5. Malfunctioning MCS (mixture controlReplace

solenoid) valve in carburetor

6. Malfunctioning EGR valveReplace

Others

1. Dragging brakesRepair or replace

2. Slipping clutchAdjust or replace

3. Improper tire pressureAdjust

Excessive engine oilOil leakage

consumption1. Loose oil drain plugTighten

2. Loose oil pan securing boltsTighten

3. Deteriorated or broken oil pan sealantReplace sealant

4. Leaky oil sealsReplace

5. Blown cylinder head gasketReplace

6. Improper tightening of oil filterTighten

7. Loose oil pressure switchTighten

2-8

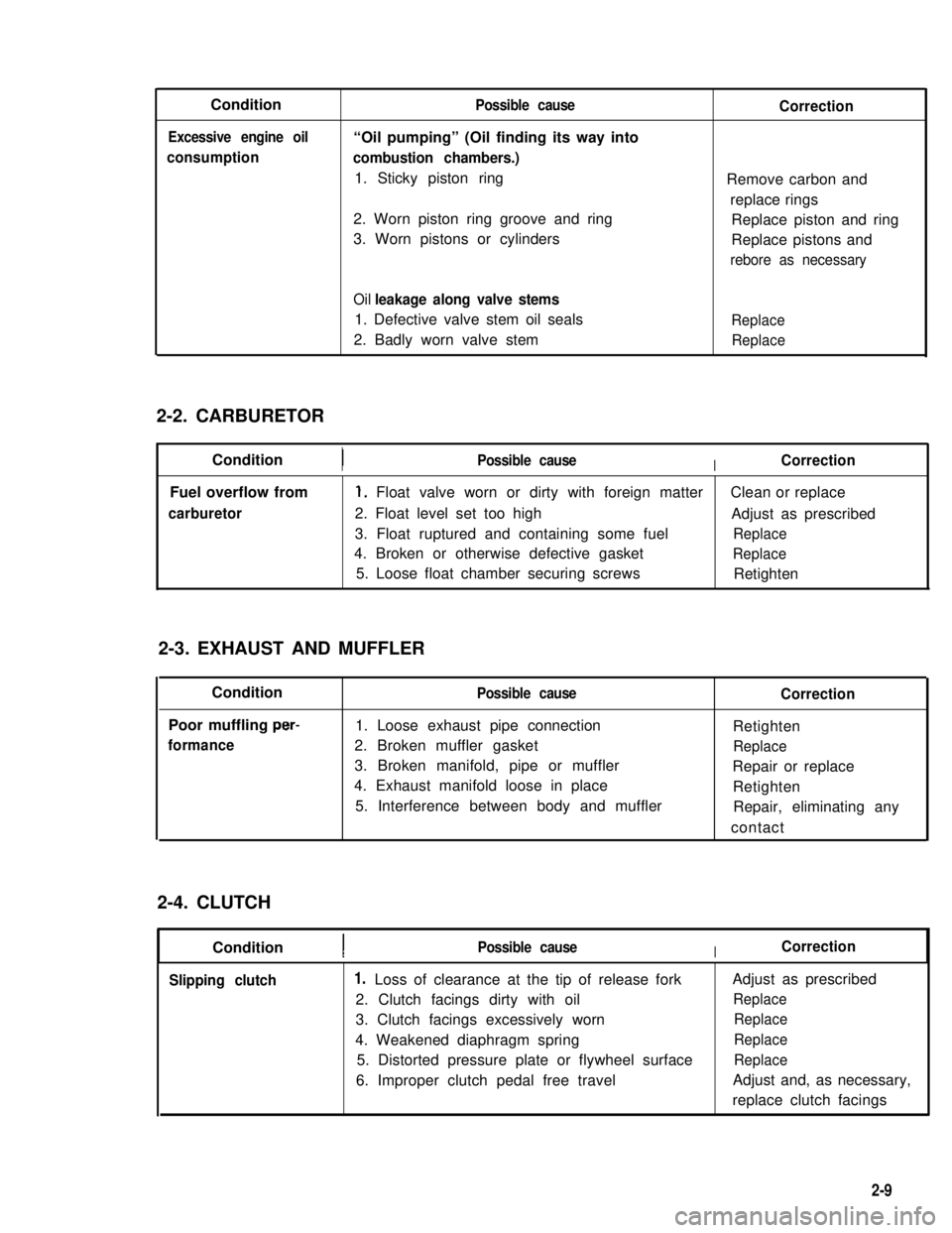

Page 47 of 962

Condition

Excessive engine oil

consumption

Possible cause

“Oil pumping” (Oil finding its way into

combustion chambers.)

1. Sticky piston ring

2. Worn piston ring groove and ring

3. Worn pistons or cylinders

Correction

Remove carbon and

replace rings

Replace piston and ring

Replace pistons and

rebore as necessary

Oil leakage along valve stems

1. Defective valve stem oil sealsReplace

2. Badly worn valve stemReplace

2-2. CARBURETOR

ConditionPossible causeICorrection

Fuel overflow from

carburetor

1, Float valve worn or dirty with foreign matterClean or replace

2. Float level set too highAdjust as prescribed

3. Float ruptured and containing some fuelReplace

4. Broken or otherwise defective gasketReplace

5. Loose float chamber securing screwsRetighten

2-3. EXHAUST AND MUFFLER

Condition

Poor muffling per-

formance

Possible cause

1. Loose exhaust pipe connection

2. Broken muffler gasket

3. Broken manifold, pipe or muffler

4. Exhaust manifold loose in place

5. Interference between body and muffler

Correction

Retighten

Replace

Repair or replace

Retighten

Repair, eliminating any

contact

2-4. CLUTCH

ConditionPossible causeICorrection

Slipping clutch Loss of clearance at the tip of release fork

2. Clutch facings dirty with oil

3. Clutch facings excessively worn

4. Weakened diaphragm spring

5. Distorted pressure plate or flywheel surface

6. Improper clutch pedal free travel

Adjust as prescribed

Replace

Replace

Replace

Replace

Adjust and, as necessary,

replace clutch facings

2-9

1.

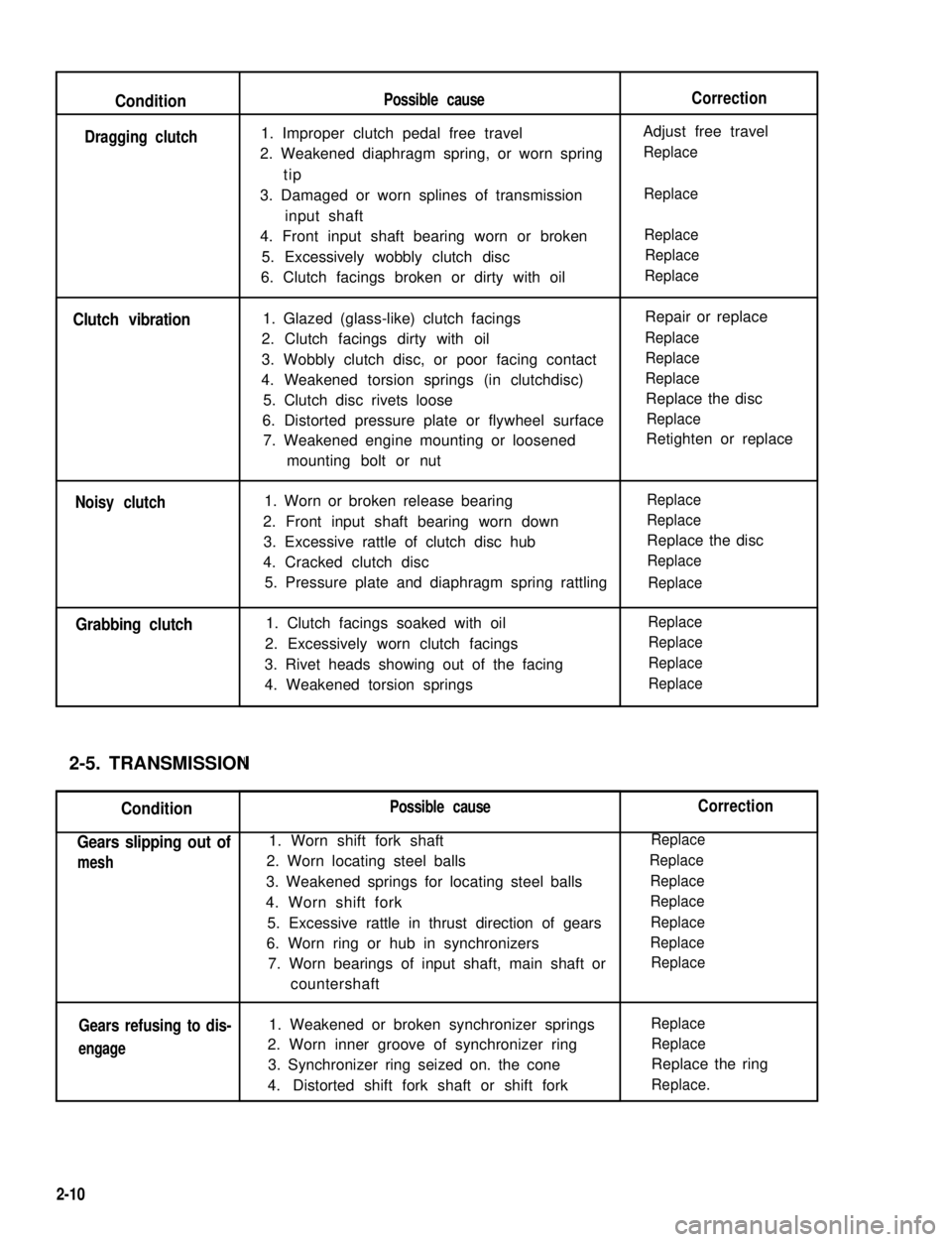

Page 48 of 962

Condition

Clutch vibration

Noisy clutch

Grabbing clutch

2-5. TRANSMISSION

Condition

Gears slipping out of

mesh

Gears refusing to dis-

engage

Possible cause

1. Improper clutch pedal free travel

2. Weakened diaphragm spring, or worn spring

tip

3. Damaged or worn splines of transmission

input shaft

4. Front input shaft bearing worn or broken

5. Excessively wobbly clutch disc

6. Clutch facings broken or dirty with oil

1. Glazed (glass-like) clutch facings

2. Clutch facings dirty with oil

3. Wobbly clutch disc, or poor facing contact

4. Weakened torsion springs (in clutchdisc)

5. Clutch disc rivets loose

6. Distorted pressure plate or flywheel surface

7. Weakened engine mounting or loosened

mounting bolt or nut

1. Worn or broken release bearing

2. Front input shaft bearing worn down

3. Excessive rattle of clutch disc hub

4. Cracked clutch disc

5. Pressure plate and diaphragm spring rattling

1. Clutch facings soaked with oil

2. Excessively worn clutch facings

3. Rivet heads showing out of the facing

4. Weakened torsion springs

Possible cause

1. Worn shift fork shaft

2. Worn locating steel balls

3. Weakened springs for locating steel balls

4. Worn shift fork

5. Excessive rattle in thrust direction of gears

6. Worn ring or hub in synchronizers

7. Worn bearings of input shaft, main shaft or

countershaft

1. Weakened or broken synchronizer springs

2. Worn inner groove of synchronizer ring

3. Synchronizer ring seized on. the cone

4.Distorted shift fork shaft or shift fork

Correction

Adjust free travel

Replace

Replace

Replace

Replace

Replace

Repair or replace

Replace

Replace

Replace

Replace the disc

Replace

Retighten or replace

Replace

Replace

Replace the disc

Replace

Replace

Replace

Replace

Replace

Replace

Correction

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace the ring

Replace.

Dragging clutch

2-10

Page 49 of 962

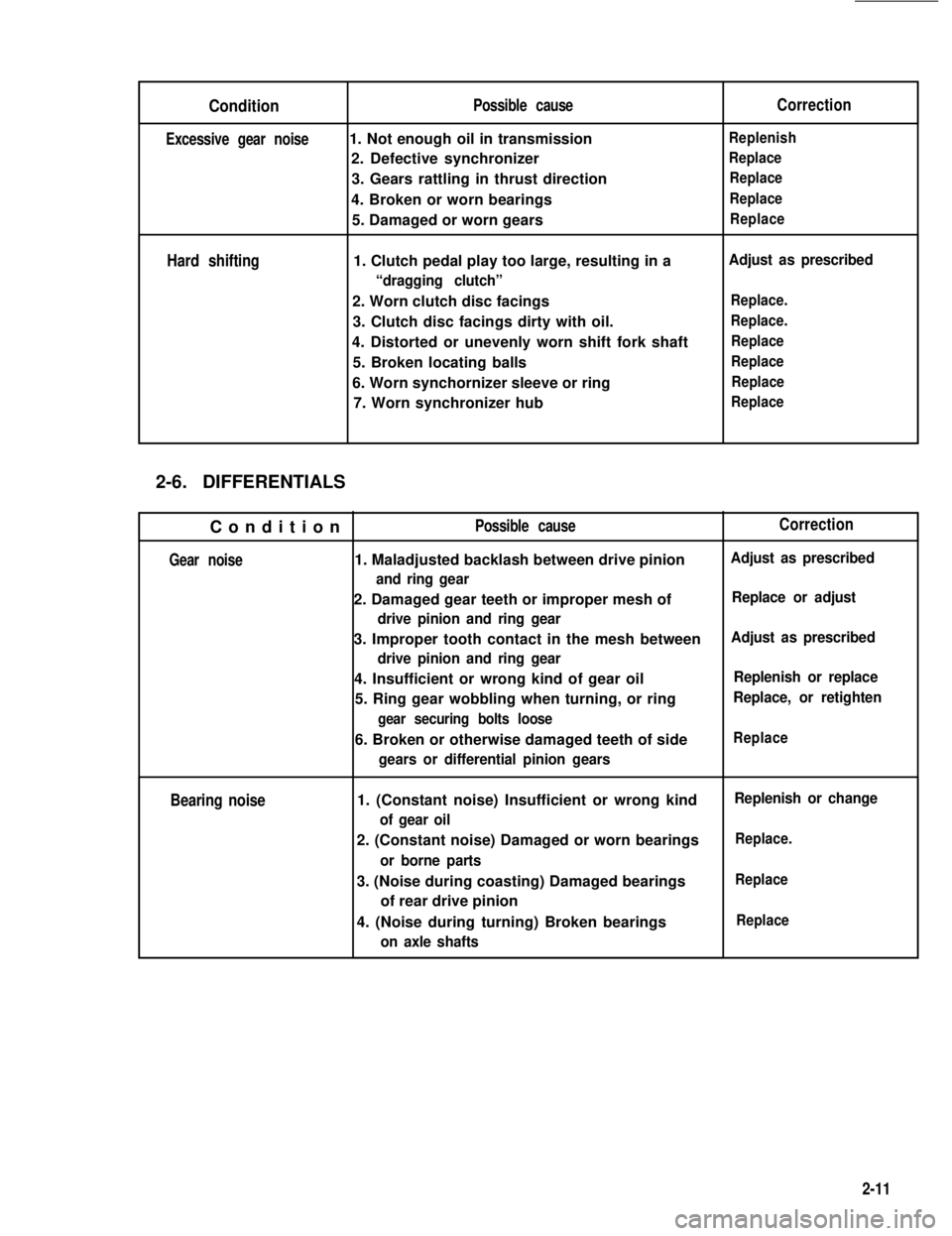

Condition

Excessive gear noise

Hard shifting

2-6. DIFFERENTIALS

Possible cause

1. Not enough oil in transmission

2. Defective synchronizer

3. Gears rattling in thrust direction

4. Broken or worn bearings

5. Damaged or worn gears

1. Clutch pedal play too large, resulting in a

“dragging clutch”

2. Worn clutch disc facings

3. Clutch disc facings dirty with oil.

4. Distorted or unevenly worn shift fork shaft

5. Broken locating balls

6. Worn synchornizer sleeve or ring

7. Worn synchronizer hub

Condition

Gear noise

Bearing noise

Possible cause

1. Maladjusted backlash between drive pinion

and ring gear

2. Damaged gear teeth or improper mesh of

drive pinion and ring gear

3. Improper tooth contact in the mesh between

drive pinion and ring gear

4. Insufficient or wrong kind of gear oil

5. Ring gear wobbling when turning, or ring

gear securing bolts loose

6. Broken or otherwise damaged teeth of side

gears or differential pinion gears

1. (Constant noise) Insufficient or wrong kind

of gear oil

2. (Constant noise) Damaged or worn bearings

or borne parts

3. (Noise during coasting) Damaged bearings

of rear drive pinion

4. (Noise during turning) Broken bearings

on axle shafts

Correction

Replenish

Replace

Replace

Replace

Replace

Adjust as prescribed

Replace.

Replace.

Replace

Replace

Replace

Replace

Correction

Adjust as prescribed

Replace or adjust

Adjust as prescribed

Replenish or replace

Replace, or retighten

Replace

Replenish or change

Replace.

Replace

Replace

2-11

Page 50 of 962

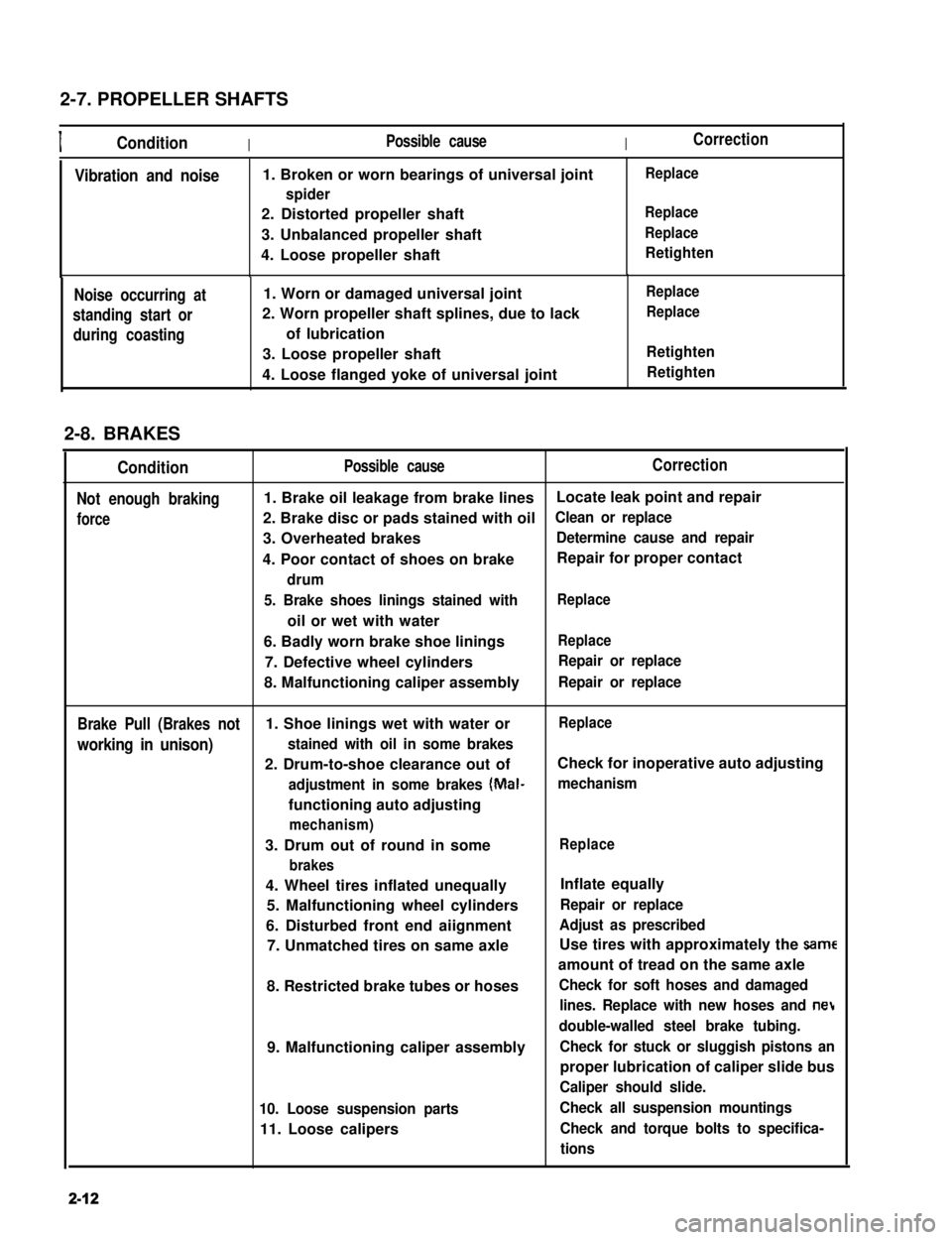

2-7. PROPELLER SHAFTS

IConditionIPossible causeICorrection

Vibration and noise1. Broken or worn bearings of universal joint

spider

2. Distorted propeller shaft

3. Unbalanced propeller shaft

4. Loose propeller shaft

Replace

Replace

Replace

Retighten

Noise occurring at

standing start or

during coasting

1. Worn or damaged universal joint

2. Worn propeller shaft splines, due to lack

of lubrication

3. Loose propeller shaft

4. Loose flanged yoke of universal joint

Replace

Replace

Retighten

Retighten

2-8. BRAKES

Condition

Not enough braking

force

Possible causeCorrection

1. Brake oil leakage from brake linesLocate leak point and repair

2. Brake disc or pads stained with oilClean or replace

3. Overheated brakesDetermine cause and repair

4. Poor contact of shoes on brakeRepair for proper contact

drum

5. Brake shoes linings stained with

oil or wet with water

Replace

6. Badly worn brake shoe liningsReplace

7. Defective wheel cylindersRepair or replace

8. Malfunctioning caliper assemblyRepair or replace

Brake Pull (Brakes not1. Shoe linings wet with water orReplace

working in unison)stained with oil in some brakes

2. Drum-to-shoe clearance out ofCheck for inoperative auto adjusting

adjustment in some brakes (Mal-mechanism

functioning auto adjusting

mechanism)

3. Drum out of round in some

brakes

Replace

4. Wheel tires inflated unequally

5. Malfunctioning wheel cylinders

6. Disturbed front end aiignment

7. Unmatched tires on same axle

8. Restricted brake tubes or hoses

9. Malfunctioning caliper assembly

10. Loose suspension parts

11. Loose calipers

Inflate equally

Repair or replace

Adjust as prescribed

Use tires with approximately the same

amount of tread on the same axle

Check for soft hoses and damaged

lines. Replace with new hoses and net

double-walled steel brake tubing.

Check for stuck or sluggish pistons an

proper lubrication of caliper slide bus

Caliper should slide.

Check all suspension mountings

Check and torque bolts to specifica-

tions

2-12