SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 301 of 698

5-28 BRAKES

INSTALLATION

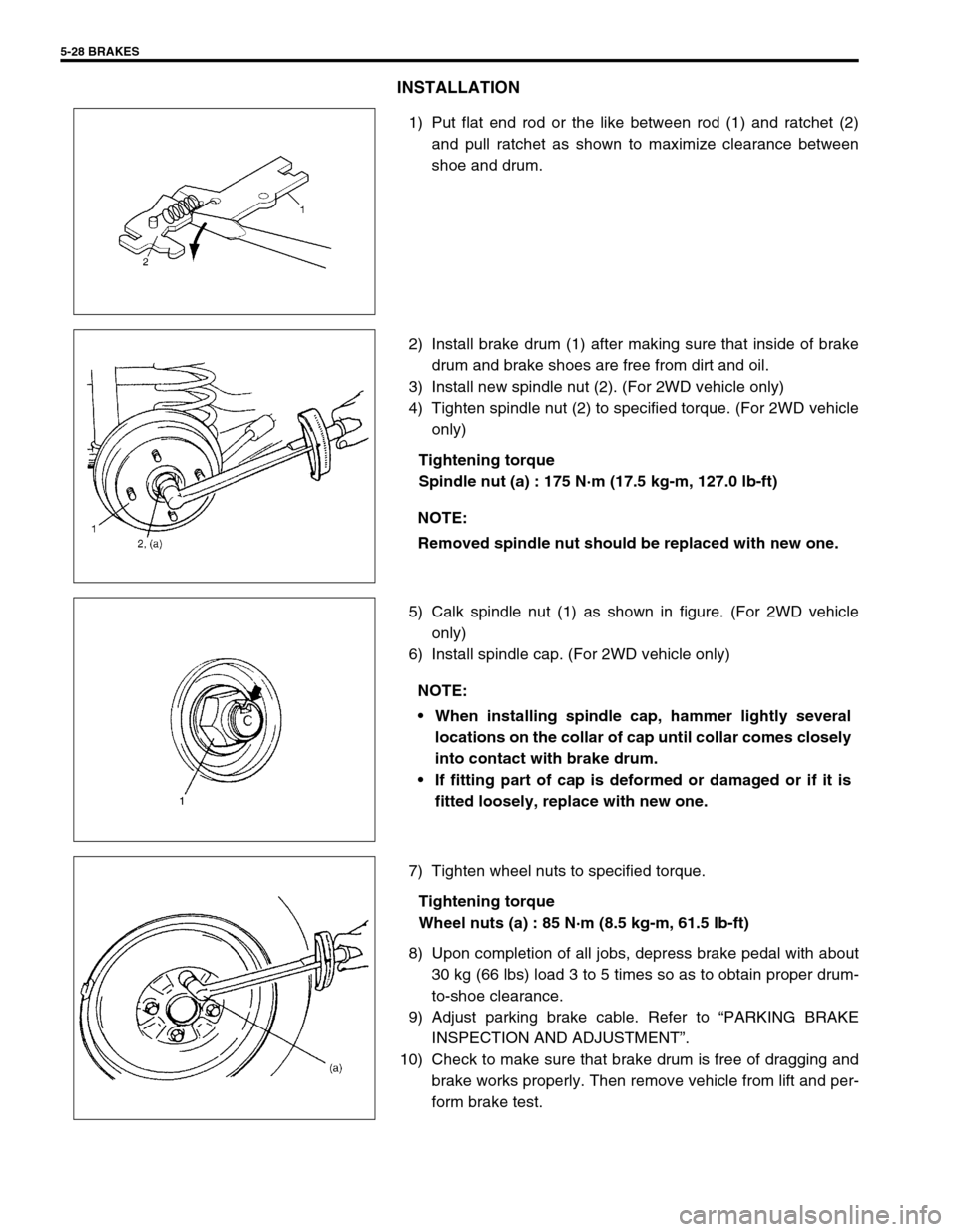

1) Put flat end rod or the like between rod (1) and ratchet (2)

and pull ratchet as shown to maximize clearance between

shoe and drum.

2) Install brake drum (1) after making sure that inside of brake

drum and brake shoes are free from dirt and oil.

3) Install new spindle nut (2). (For 2WD vehicle only)

4) Tighten spindle nut (2) to specified torque. (For 2WD vehicle

only)

Tightening torque

Spindle nut (a) : 175 N·m (17.5 kg-m, 127.0 lb-ft)

5) Calk spindle nut (1) as shown in figure. (For 2WD vehicle

only)

6) Install spindle cap. (For 2WD vehicle only)

7) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts (a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

8) Upon completion of all jobs, depress brake pedal with about

30 kg (66 lbs) load 3 to 5 times so as to obtain proper drum-

to-shoe clearance.

9) Adjust parking brake cable. Refer to “PARKING BRAKE

INSPECTION AND ADJUSTMENT”.

10) Check to make sure that brake drum is free of dragging and

brake works properly. Then remove vehicle from lift and per-

form brake test.

NOTE:

Removed spindle nut should be replaced with new one.

NOTE:

When installing spindle cap, hammer lightly several

locations on the collar of cap until collar comes closely

into contact with brake drum.

If fitting part of cap is deformed or damaged or if it is

fitted loosely, replace with new one.

Page 302 of 698

BRAKES 5-29

BRAKE SHOE

REMOVAL

1) Remove brake drum referring to “BRAKE DRUM”.

2) Remove shoe hold down springs (1) by turning shoe hold

down pins (2).

3) Remove return springs, brake shoes and strut.

4) Disconnect parking brake shoe lever (1) from parking brake

cable (2).

5) Remove push nut (1).

6) Remove parking brake shoe lever (2) from shoe rim (3).

INSPECTION

Check ratchet of brake strut (1) assembly for wear or dam-

age.

Check shoe return spring, strut shoe return spring and shoe

hold down spring for damage, corrosion and weakening.

Check for smooth movement of brake shoe lever (2) along

shoe rim.

CAUTION:

Use a new push nut.

Page 303 of 698

5-30 BRAKES

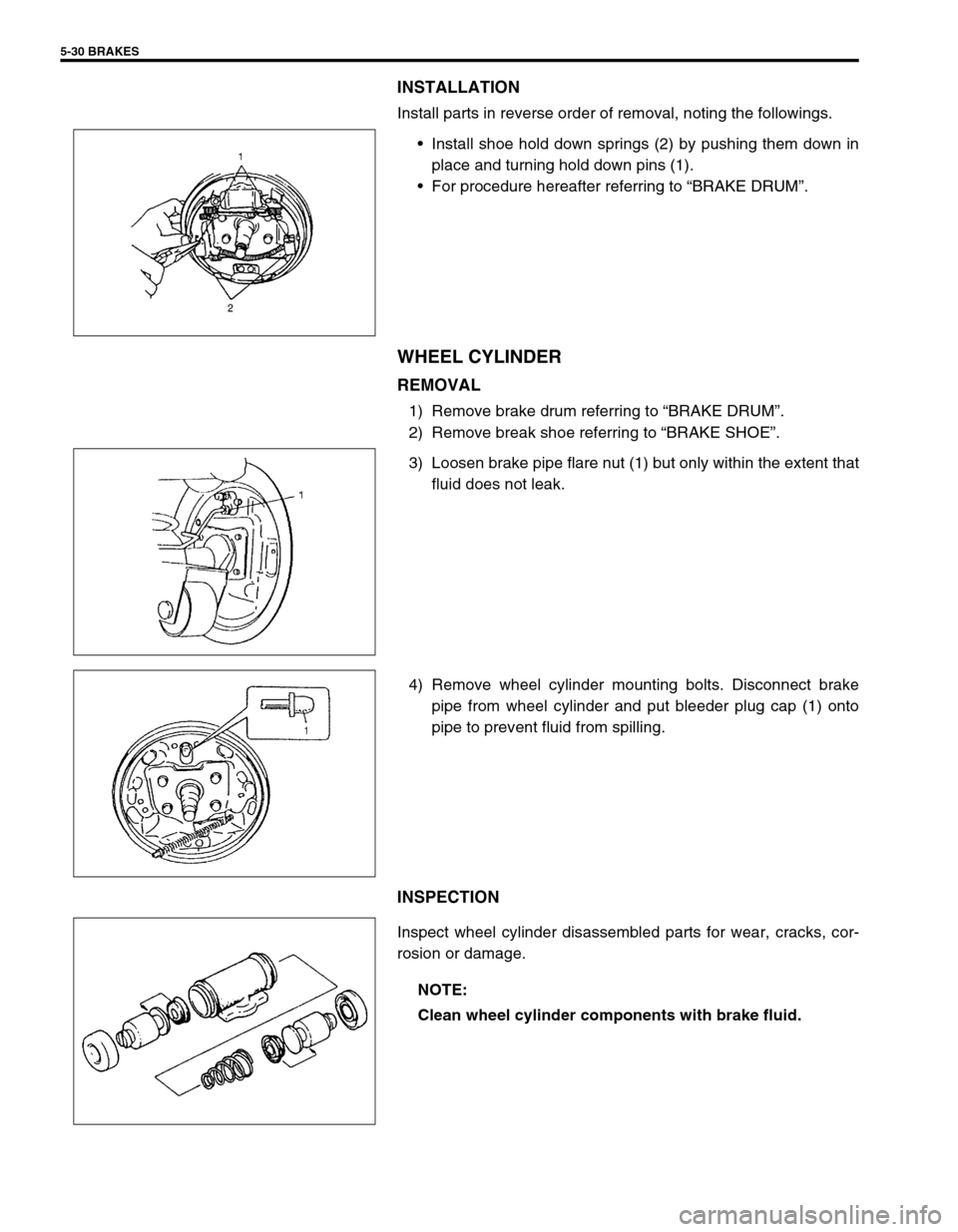

INSTALLATION

Install parts in reverse order of removal, noting the followings.

Install shoe hold down springs (2) by pushing them down in

place and turning hold down pins (1).

For procedure hereafter referring to “BRAKE DRUM”.

WHEEL CYLINDER

REMOVAL

1) Remove brake drum referring to “BRAKE DRUM”.

2) Remove break shoe referring to “BRAKE SHOE”.

3) Loosen brake pipe flare nut (1) but only within the extent that

fluid does not leak.

4) Remove wheel cylinder mounting bolts. Disconnect brake

pipe from wheel cylinder and put bleeder plug cap (1) onto

pipe to prevent fluid from spilling.

INSPECTION

Inspect wheel cylinder disassembled parts for wear, cracks, cor-

rosion or damage.

NOTE:

Clean wheel cylinder components with brake fluid.

Page 304 of 698

BRAKES 5-31

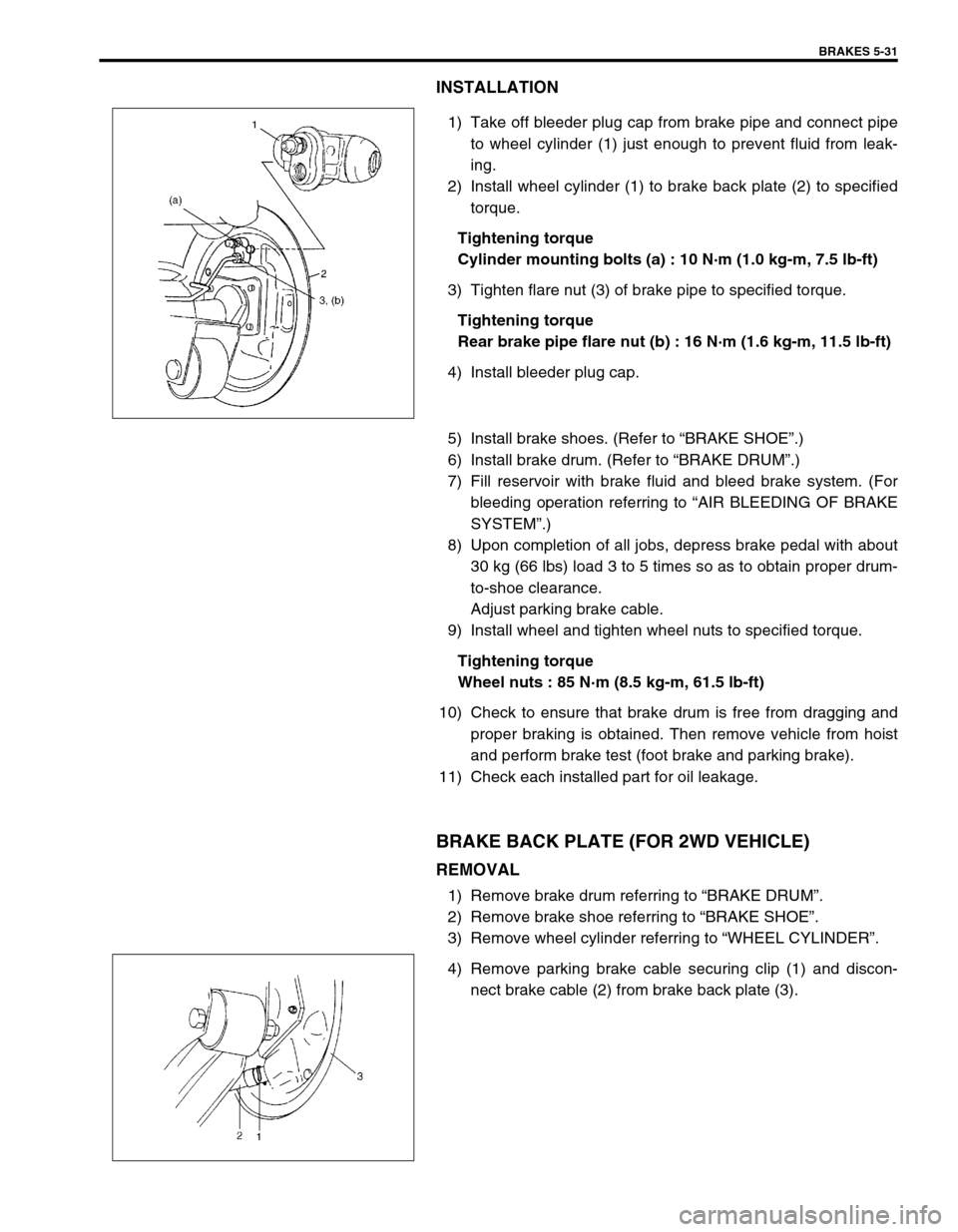

INSTALLATION

1) Take off bleeder plug cap from brake pipe and connect pipe

to wheel cylinder (1) just enough to prevent fluid from leak-

ing.

2) Install wheel cylinder (1) to brake back plate (2) to specified

torque.

Tightening torque

Cylinder mounting bolts (a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

3) Tighten flare nut (3) of brake pipe to specified torque.

Tightening torque

Rear brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

4) Install bleeder plug cap.

5) Install brake shoes. (Refer to “BRAKE SHOE”.)

6) Install brake drum. (Refer to “BRAKE DRUM”.)

7) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation referring to “AIR BLEEDING OF BRAKE

SYSTEM”.)

8) Upon completion of all jobs, depress brake pedal with about

30 kg (66 lbs) load 3 to 5 times so as to obtain proper drum-

to-shoe clearance.

Adjust parking brake cable.

9) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts : 85 N·m (8.5 kg-m, 61.5 lb-ft)

10) Check to ensure that brake drum is free from dragging and

proper braking is obtained. Then remove vehicle from hoist

and perform brake test (foot brake and parking brake).

11) Check each installed part for oil leakage.

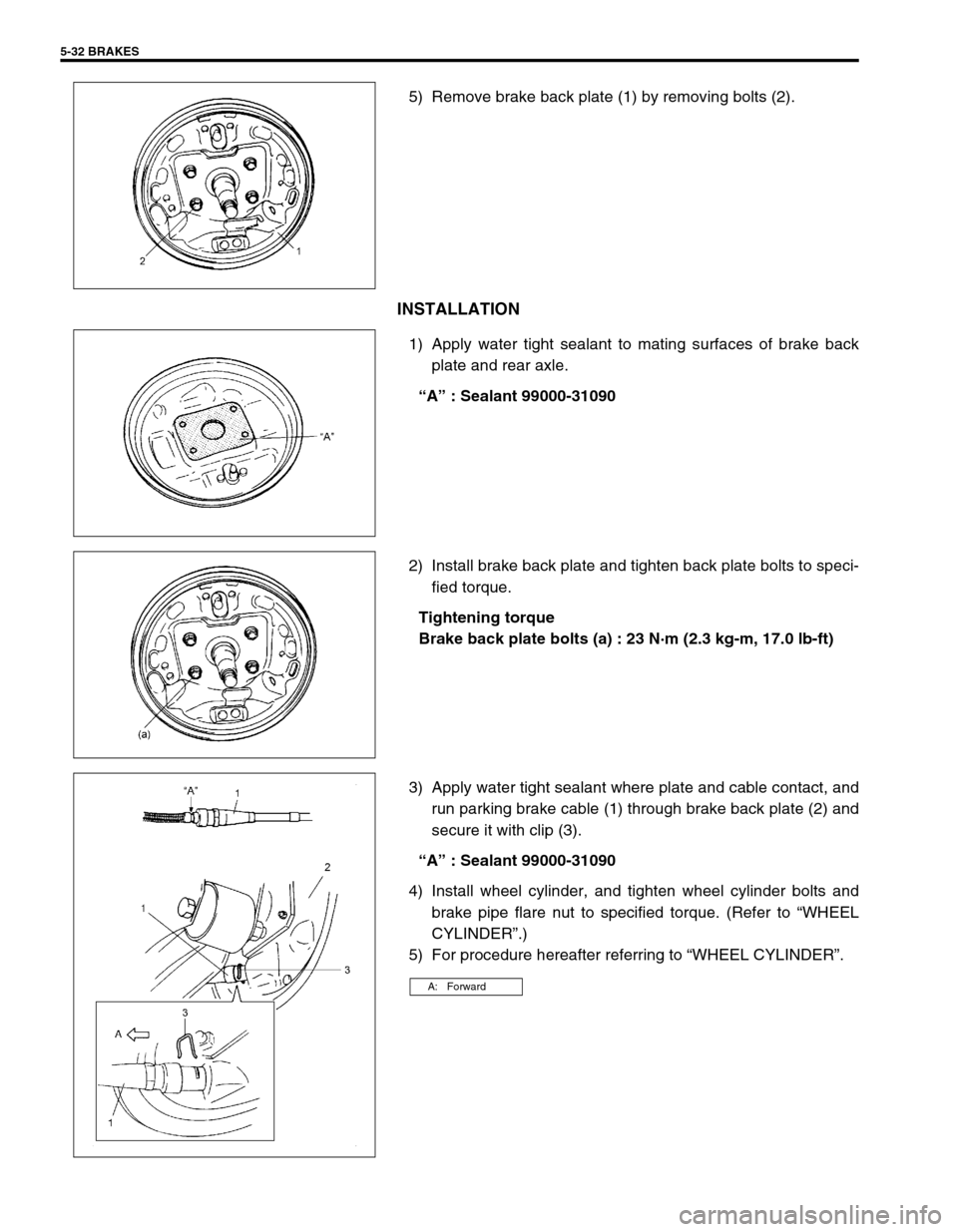

BRAKE BACK PLATE (FOR 2WD VEHICLE)

REMOVAL

1) Remove brake drum referring to “BRAKE DRUM”.

2) Remove brake shoe referring to “BRAKE SHOE”.

3) Remove wheel cylinder referring to “WHEEL CYLINDER”.

4) Remove parking brake cable securing clip (1) and discon-

nect brake cable (2) from brake back plate (3).

Page 305 of 698

5-32 BRAKES

5) Remove brake back plate (1) by removing bolts (2).

INSTALLATION

1) Apply water tight sealant to mating surfaces of brake back

plate and rear axle.

“A” : Sealant 99000-31090

2) Install brake back plate and tighten back plate bolts to speci-

fied torque.

Tightening torque

Brake back plate bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

3) Apply water tight sealant where plate and cable contact, and

run parking brake cable (1) through brake back plate (2) and

secure it with clip (3).

“A” : Sealant 99000-31090

4) Install wheel cylinder, and tighten wheel cylinder bolts and

brake pipe flare nut to specified torque. (Refer to “WHEEL

CYLINDER”.)

5) For procedure hereafter referring to “WHEEL CYLINDER”.

A: Forward

Page 306 of 698

BRAKES 5-33

BRAKE BACK PLATE (FOR 4WD VEHICLE)

REMOVAL AND INSTALLATION

Refer to “REAR AXLE SHAFT AND WHEEL BEARING (4WD VEHICLE)” in Section 3E.

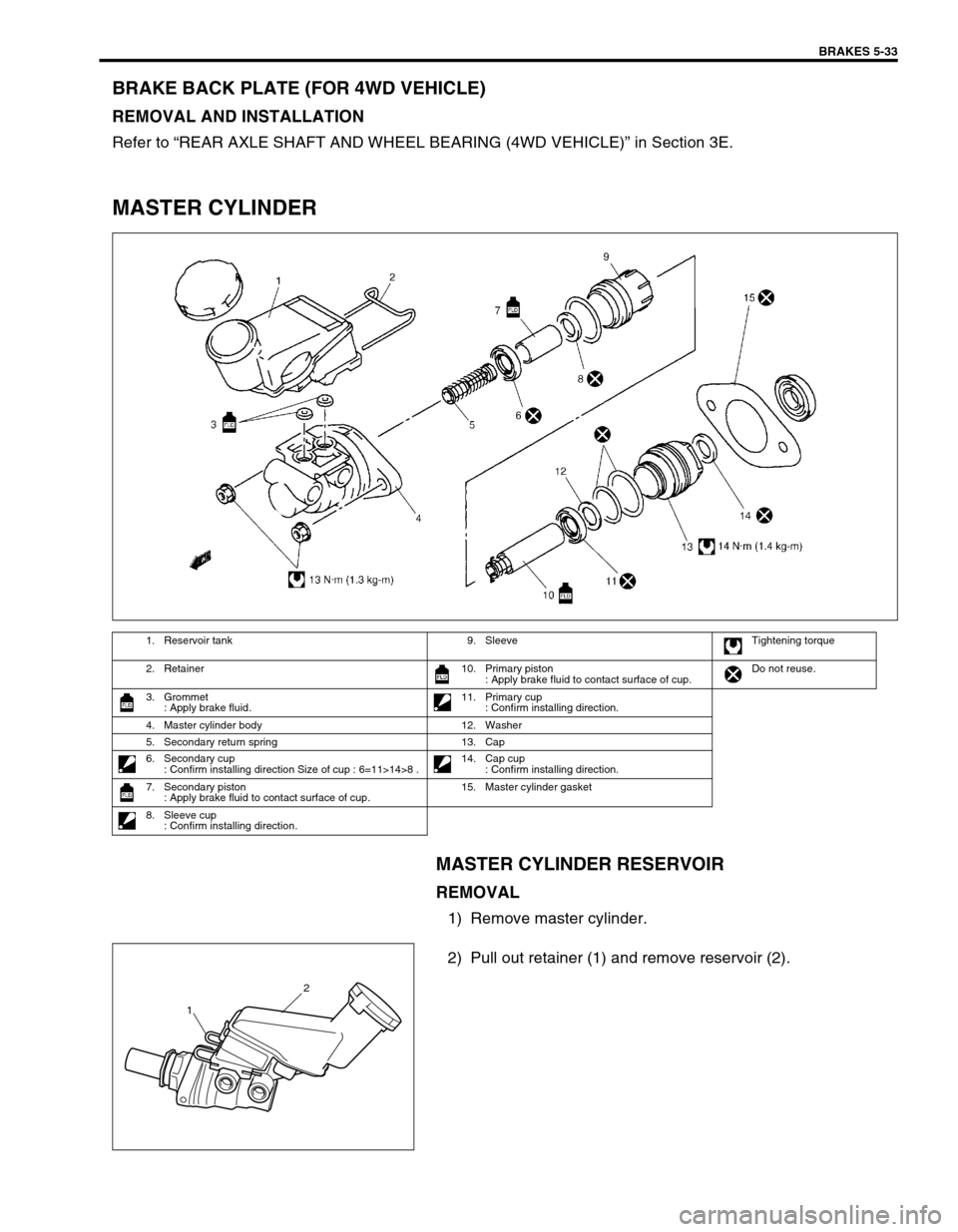

MASTER CYLINDER

MASTER CYLINDER RESERVOIR

REMOVAL

1) Remove master cylinder.

2) Pull out retainer (1) and remove reservoir (2).

1. Reservoir tank 9. Sleeve Tightening torque

2. Retainer 10. Primary piston

: Apply brake fluid to contact surface of cup.Do not reuse.

3. Grommet

: Apply brake fluid.11. Primary cup

: Confirm installing direction.

4. Master cylinder body 12. Washer

5. Secondary return spring 13. Cap

6. Secondary cup

: Confirm installing direction Size of cup : 6=11>14>8 .14. Cap cup

: Confirm installing direction.

7. Secondary piston

: Apply brake fluid to contact surface of cup.15. Master cylinder gasket

8. Sleeve cup

: Confirm installing direction.

2

1

Page 307 of 698

5-34 BRAKES

INSTALLATION

1) Apply brake fluid to new grommets and attach grommets (2)

to master cylinder (1).

2) Install reservoir (2) to master cylinder and insert retainer (1).

3) Install master cylinder.

4) Fill reservoir with specified brake fluid up to MAX mark on it.

5) After installation, purge air and check for brake fluid leakage.

MASTER CYLINDER ASSEMBLY

REMOVAL

1) Clean outside of master cylinder.

2) Drain brake fluid in reservoir.

3) Disconnect fluid level switch coupler (1) on reservoir.

4) Disconnect brake pipes (2) connected to master cylinder.

5) Remove master cylinder fixing nuts (3).

6) Remove master cylinder and master cylinder gasket.NOTE:

Be sure to use new grommets.

1 2

2

1

CAUTION:

Do not allow brake fluid to get on painted surface.

Painted surface will be damaged by brake fluid, flush it

with water immediately if any fluid is spilled.

13

MAX

MIN

2

3

Page 308 of 698

BRAKES 5-35

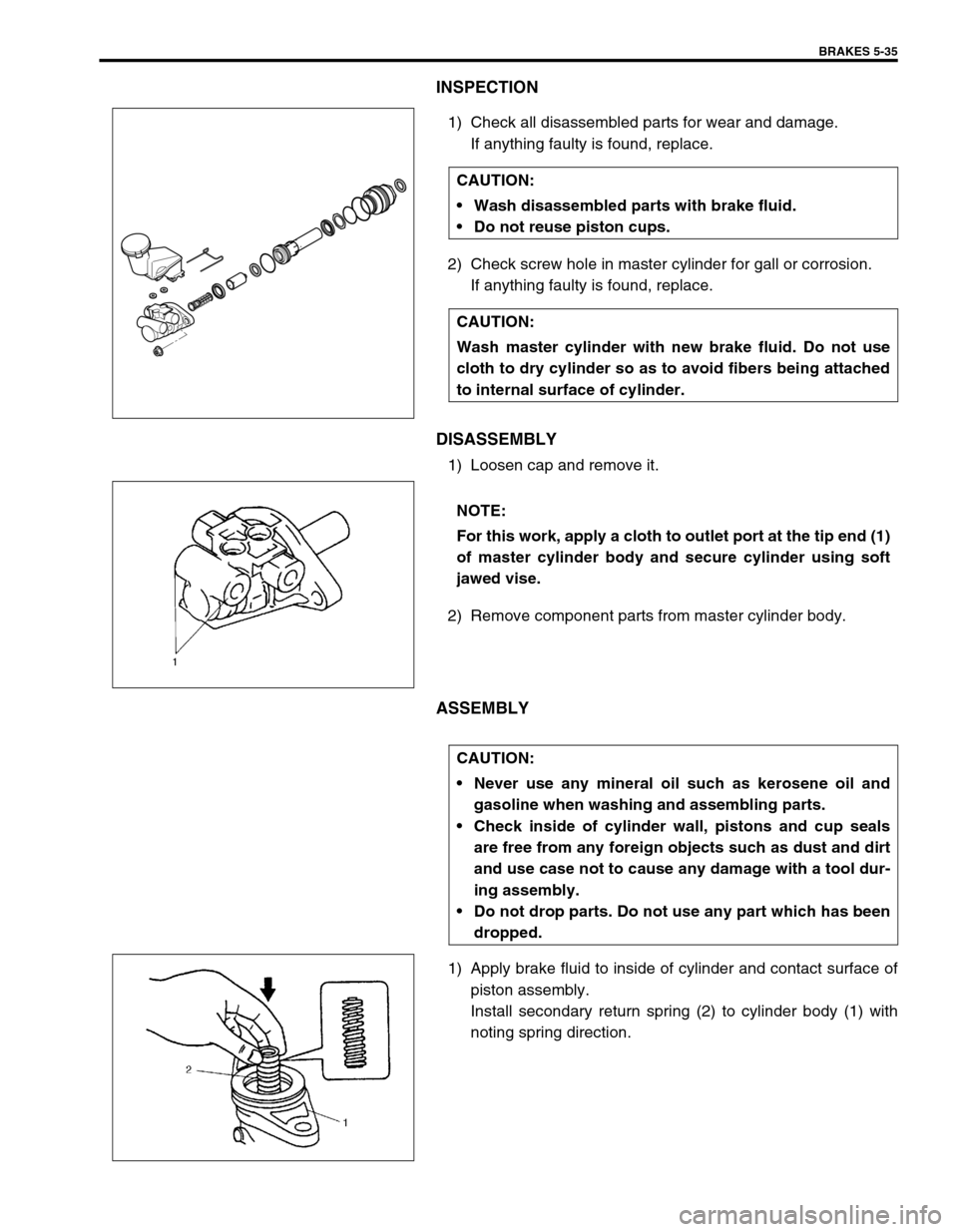

INSPECTION

1) Check all disassembled parts for wear and damage.

If anything faulty is found, replace.

2) Check screw hole in master cylinder for gall or corrosion.

If anything faulty is found, replace.

DISASSEMBLY

1) Loosen cap and remove it.

2) Remove component parts from master cylinder body.

ASSEMBLY

1) Apply brake fluid to inside of cylinder and contact surface of

piston assembly.

Install secondary return spring (2) to cylinder body (1) with

noting spring direction. CAUTION:

Wash disassembled parts with brake fluid.

Do not reuse piston cups.

CAUTION:

Wash master cylinder with new brake fluid. Do not use

cloth to dry cylinder so as to avoid fibers being attached

to internal surface of cylinder.

NOTE:

For this work, apply a cloth to outlet port at the tip end (1)

of master cylinder body and secure cylinder using soft

jawed vise.

CAUTION:

Never use any mineral oil such as kerosene oil and

gasoline when washing and assembling parts.

Check inside of cylinder wall, pistons and cup seals

are free from any foreign objects such as dust and dirt

and use case not to cause any damage with a tool dur-

ing assembly.

Do not drop parts. Do not use any part which has been

dropped.

Page 309 of 698

5-36 BRAKES

2) Attach secondary cup (1) to secondary piston (2), they install

it to cylinder body such a direction as shown.

3) Push secondary cup to the bottom by using special tool.

Special tool

(A) : 09951-18220

4) Remove O-ring (1) from sleeve (2).

Special tool

(A) : 09900-06106

5) Install sleeve cup (3) and O-ring (2) to sleeve (1) such a

direction as shown.

6) Install sleeve assembly with aligning protrusion (1) of sleeve

and dent (2) of cylinder body. NOTE:

Secondary cup is the same as primary cup.

Diameter of secondary cup is the largest compared

with sleeve cup and cap cup.

(A)

CAUTION:

Do not cause any damage to inside of sleeve.

If caused, replace primary piston assembly.

NOTE:

Diameter of sleeve cup and O-ring are smaller than

those of cap.

O-ring is the same as that of smaller one of cap O-ring.

Page 310 of 698

BRAKES 5-37

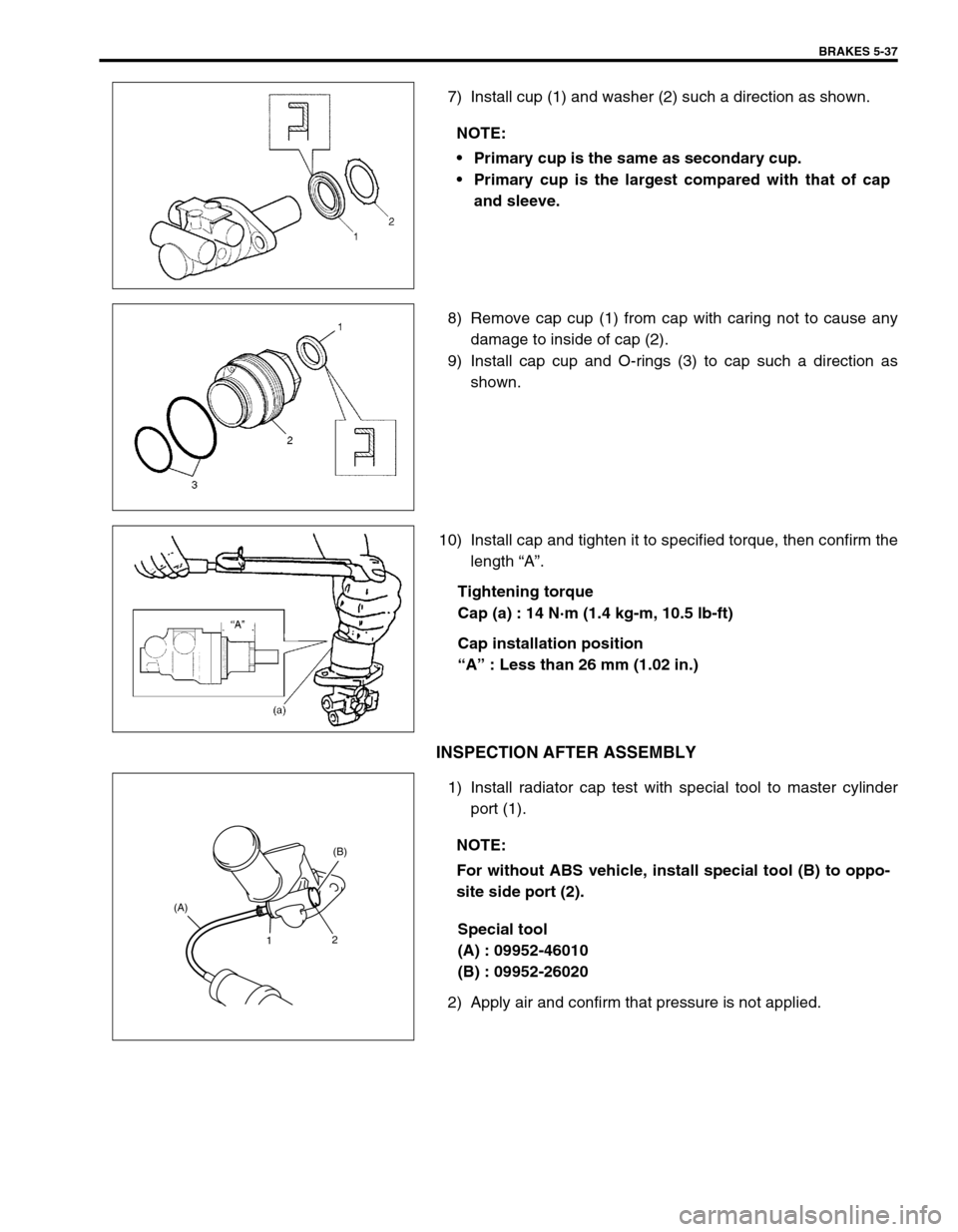

7) Install cup (1) and washer (2) such a direction as shown.

8) Remove cap cup (1) from cap with caring not to cause any

damage to inside of cap (2).

9) Install cap cup and O-rings (3) to cap such a direction as

shown.

10) Install cap and tighten it to specified torque, then confirm the

length “A”.

Tightening torque

Cap (a) : 14 N·m (1.4 kg-m, 10.5 lb-ft)

Cap installation position

“A” : Less than 26 mm (1.02 in.)

INSPECTION AFTER ASSEMBLY

1) Install radiator cap test with special tool to master cylinder

port (1).

Special tool

(A) : 09952-46010

(B) : 09952-26020

2) Apply air and confirm that pressure is not applied.NOTE:

Primary cup is the same as secondary cup.

Primary cup is the largest compared with that of cap

and sleeve.

NOTE:

For without ABS vehicle, install special tool (B) to oppo-

site side port (2).

1(B)

2 (A)