SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 321 of 698

5-48 BRAKES

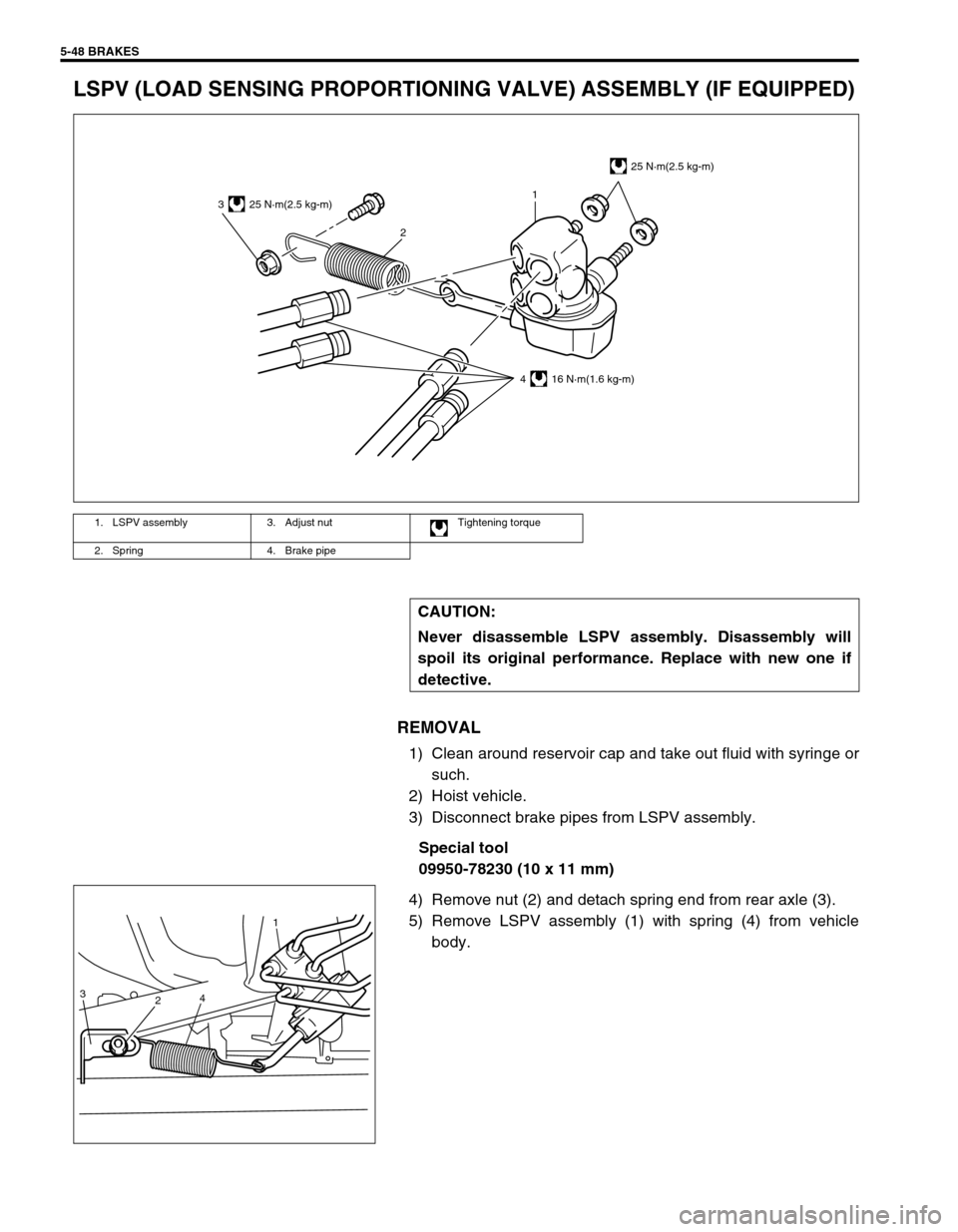

LSPV (LOAD SENSING PROPORTIONING VALVE) ASSEMBLY (IF EQUIPPED)

REMOVAL

1) Clean around reservoir cap and take out fluid with syringe or

such.

2) Hoist vehicle.

3) Disconnect brake pipes from LSPV assembly.

Special tool

09950-78230 (10 x 11 mm)

4) Remove nut (2) and detach spring end from rear axle (3).

5) Remove LSPV assembly (1) with spring (4) from vehicle

body.

1. LSPV assembly 3. Adjust nut Tightening torque

2. Spring 4. Brake pipe

CAUTION:

Never disassemble LSPV assembly. Disassembly will

spoil its original performance. Replace with new one if

detective.

3

21

25 N·m(2.5 kg-m)

4 16 N·m(1.6 kg-m)

25 N·m(2.5 kg-m)

3

24

1

Page 322 of 698

BRAKES 5-49

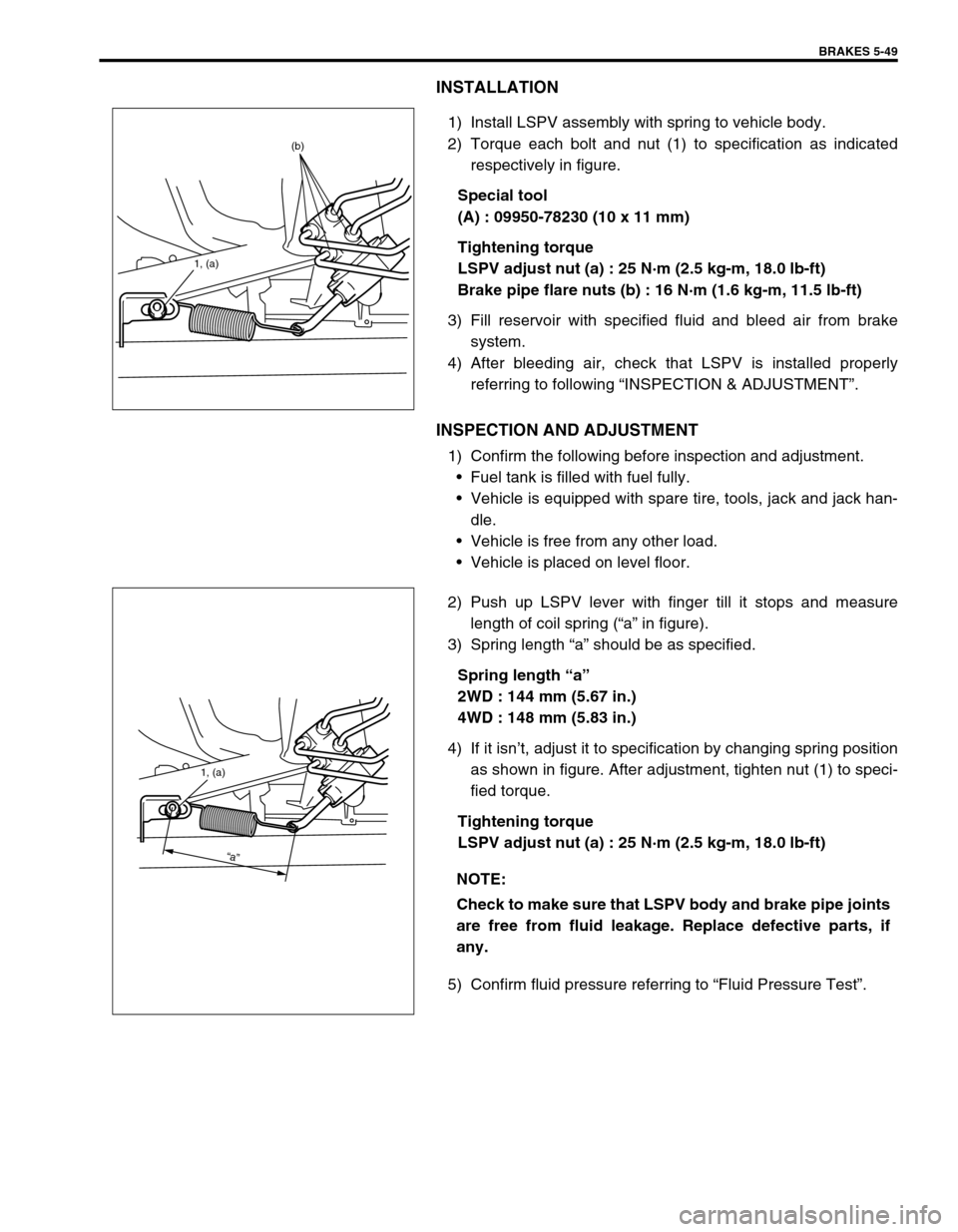

INSTALLATION

1) Install LSPV assembly with spring to vehicle body.

2) Torque each bolt and nut (1) to specification as indicated

respectively in figure.

Special tool

(A) : 09950-78230 (10 x 11 mm)

Tightening torque

LSPV adjust nut (a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

Brake pipe flare nuts (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

3) Fill reservoir with specified fluid and bleed air from brake

system.

4) After bleeding air, check that LSPV is installed properly

referring to following “INSPECTION & ADJUSTMENT”.

INSPECTION AND ADJUSTMENT

1) Confirm the following before inspection and adjustment.

Fuel tank is filled with fuel fully.

Vehicle is equipped with spare tire, tools, jack and jack han-

dle.

Vehicle is free from any other load.

Vehicle is placed on level floor.

2) Push up LSPV lever with finger till it stops and measure

length of coil spring (“a” in figure).

3) Spring length “a” should be as specified.

Spring length “a”

2WD : 144 mm (5.67 in.)

4WD : 148 mm (5.83 in.)

4) If it isn’t, adjust it to specification by changing spring position

as shown in figure. After adjustment, tighten nut (1) to speci-

fied torque.

Tightening torque

LSPV adjust nut (a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

5) Confirm fluid pressure referring to “Fluid Pressure Test”.

1, (a)

(b)

NOTE:

Check to make sure that LSPV body and brake pipe joints

are free from fluid leakage. Replace defective parts, if

any.

1, (a)

“a”

Page 323 of 698

5-50 BRAKES

REQUIRED SERVICE MATERIAL

SPECIAL TOOL

MaterialRecommended SUZUKI product

(Part Number)Use

Brake fluid DOT 3 or SAE J1703To fill master cylinder reservoir.

To clean and apply to inner parts of master

cylinder caliper and wheel cylinder when they

are disassembled.

Water tight sealant SEALING COMPOUND 366E

(99000-31090)To apply to mating surfaces of brake back

plate and rear axle (2WD vehicle) or rear

axle housing (4WD vehicle).

To apply to mating surfaces of brake back

plate and parking brake cable.

Lithium grease SUZUKI SUPER GREASE A

(99000-25010)To apply to slide pin of brake caliper carrier.

09900-06106 09900-20606 09900-20701 09942-15510

Snap ring remover Dial gauge Dial gauge chuck Sliding hammer

09943-17912 09951-18220 09952-16020 09952-46010

Brake drum remover

(Front wheel hub

remover)Secondary cup installer

setBooster piston rod

adjusterMaster cylinder attach-

ment

Page 324 of 698

BRAKES 5-51

09950-96010 09956-02310 09950-78230 09952-48320

Booster piston rod gauge Fluid pressure gauge Flare nut wrench

(10 x 11 mm)Pressure gauge attach-

ment

09952-26020

Master cylinder plug

Page 325 of 698

5-52 BRAKES

Page 326 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

5E

9

10

10A

10B

SECTION 5E

ANTILOCK BRAKE SYSTEM (ABS)

CONTENTS

GENERAL DESCRIPTION .............................. 5E-2

COMPONENTS/PARTS LOCATION AND

BRAKE HOSE/PIPE ROUTING ................... 5E-2

SYSTEM SCHEMATIC ................................ 5E-4

ABS HYDRAULIC UNIT/CONTROL

MODULE ASSEMBLY ................................. 5E-5

SELF-DIAGNOSIS FUNCTION................ 5E-5

FAIL-SAFE FUNCTION............................ 5E-5

SYSTEM CIRCUIT ....................................... 5E-6

DIAGNOSIS ..................................................... 5E-8

PRECAUTION IN DIAGNOSING

TROUBLES .................................................. 5E-8

ABS DIAGNOSTIC FLOW TABLE ............... 5E-9

ABS WARNING LAMP CHECK ................. 5E-12

EBD WARNING LAMP (BRAKE

WARNING LAMP) CHECK ........................ 5E-12

TABLE – A ABS WARNING LAMP

CIRCUIT CHECK – LAMP DOES NOT

COME “ON” AT IGNITION SWITCH ON.... 5E-13

TABLE – B ABS WARNING LAMP

CIRCUIT CHECK – LAMP COMES

“ON” STEADY ............................................ 5E-14TABLE – C ABS WARNING LAMP

CIRCUIT CHECK – THE LAMP FLASHES

CONTINUOUSLY WHILE IGNITION

SWITCH IS ON .......................................... 5E-15

TABLE – D CODE (DTC) IS NOT

OUTPUTTED EVEN WITH DIAGNOSIS

SWITCH TERMINAL CONNECTED TO

GROUND ................................................... 5E-16

TABLE – E EBD WARNING LAMP

(BRAKE WARNING LAMP) CHECK

– LAMP COMES “ON” STEADY ................ 5E-17

DIAGNOSTIC TROUBLE CODE

(DTC) CHECK (USING ABS WARNING

LAMP) ........................................................ 5E-18

DIAGNOSTIC TROUBLE CODE (DTC)

CHECK (USING SUZUKI SCAN TOOL).... 5E-19

DIAGNOSTIC TROUBLE CODE

(DTC) CLEARANCE .................................. 5E-19

DIAGNOSTIC TROUBLE CODE (DTC)

TABLE........................................................ 5E-20

DTC C1013 (DTC 13) – SYSTEM

SPECIFICATIONS DIFFERENT FROM ABS

CONTROL MODULE SPECIFICATIONS .. 5E-22 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

All brake fasteners are important attaching parts in that they could affect the performance of vital

parts and systems, and/or could result in major repair expense. They must be replaced with one of

same part number or with an equivalent part if replacement becomes necessary. Do not use a replace-

ment part of lesser quality or substitute design. Torque values must be used as specified during reas-

sembly to assure proper retention of all parts. There is to be no welding as it may result in extensive

damage and weakening of the metal.

Page 327 of 698

5E-2 ANTILOCK BRAKE SYSTEM (ABS)

DTC C1015 (DTC 15) – G SENSOR

CIRCUIT .................................................... 5E-22

DTC C1021 (DTC 21), DTC C1022

(DTC 22) – RIGHT-FRONT WHEEL

SPEED SENSOR CIRCUIT OR SENSOR

RING .......................................................... 5E-24

DTC C1025 (DTC 25), DTC C1026

(DTC 26) – LEFT-FRONT WHEEL

SPEED SENSOR CIRCUIT OR SENSOR

RING .......................................................... 5E-24

DTC C1031 (DTC 31), DTC C1032

(DTC 32) – RIGHT-REAR WHEEL

SPEED SENSOR CIRCUIT OR SENSOR

RING .......................................................... 5E-24

DTC C1035 (DTC 35), DTC C1036

(DTC 36) – LEFT-REAR WHEEL SPEED

SENSOR CIRCUIT OR SENSOR RING.... 5E-24

DTC C1041 (DTC 41) – RIGHT-FRONT

INLET SOLENOID CIRCUIT...................... 5E-26

DTC C1045 (DTC 45) – LEFT-FRONT

INLET SOLENOID CIRCUIT...................... 5E-26

DTC C1051 (DTC 51) – RIGHT-REAR

INLET SOLENOID CIRCUIT...................... 5E-26

DTC C1055 (DTC 55) – LEFT-REAR

INLET SOLENOID CIRCUIT...................... 5E-26

DTC C1042 (DTC 42) – RIGHT-FRONT

OUTLET SOLENOID CIRCUIT.................. 5E-26

DTC C1046 (DTC 46) – LEFT-FRONT

OUTLET SOLENOID CIRCUIT.................. 5E-26

DTC C1052 (DTC 52) – RIGHT-REAR

OUTLET SOLENOID CIRCUIT.................. 5E-26DTC C1056 (DTC 56) – LEFT-REAR

OUTLET SOLENOID CIRCUIT ................. 5E-26

DTC C1057 (DTC 57) – POWER

SOURCE CIRCUIT .................................... 5E-27

DTC C1061 (DTC 61) – ABS PUMP

MOTOR CIRCUIT ...................................... 5E-28

DTC C1063 (DTC 63) – ABS FAIL-SAFE

RELAY CIRCUIT ....................................... 5E-29

DTC C1071 (DTC 71) – ABS CONTROL

MODULE ................................................... 5E-30

ON-VEHICLE SERVICE................................ 5E-31

PRECAUTIONS ......................................... 5E-31

ABS HYDRAULIC UNIT OPERATION

CHECK (USING SUZUKI SCAN TOOL) ... 5E-31

ABS HYDRAULIC UNIT OPERATION

CHECK (NOT USING SUZUKI SCAN

TOOL) ........................................................ 5E-31

ABS HYDRAULIC UNIT/CONTROL

MODULE ASSEMBLY ............................... 5E-33

FRONT WHEEL SPEED SENSOR ........... 5E-35

FRONT WHEEL SPEED SENSOR

RING .......................................................... 5E-37

REAR WHEEL SPEED SENSOR.............. 5E-38

REAR WHEEL SPEED SENSOR

RING (FOR 2WD VEHICLE) ..................... 5E-41

REAR WHEEL SPEED SENSOR

RING(FOR 4WD VEHICLE) ...................... 5E-42

G SENSOR (FOR 4WD VEHICLE

ONLY) ........................................................ 5E-43

SPECIAL TOOL ............................................ 5E-44

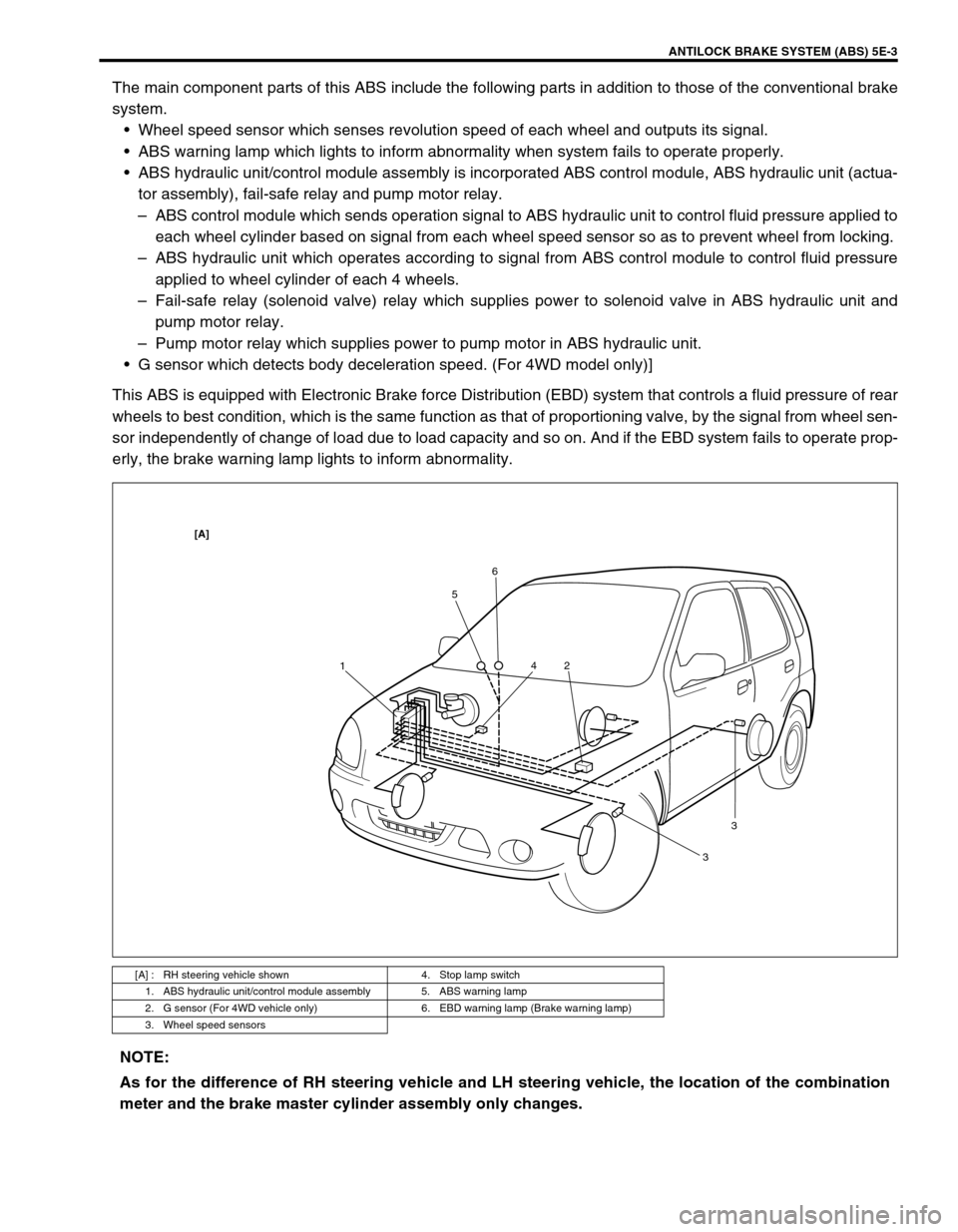

GENERAL DESCRIPTION

COMPONENTS/PARTS LOCATION AND BRAKE HOSE/PIPE ROUTING

The ABS (Antilock Brake System) controls the fluid pressure applied to the Wheel cylinder of each brake from

the master cylinder so that each wheel is not locked even when hard braking is applied.

This ABS has also the following function.

While braking is applied, but before ABS control becomes effective, braking force is distributed between the front

and rear so as to prevent the rear wheels from being locked too early for better stability of the vehicle.

Page 328 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-3

The main component parts of this ABS include the following parts in addition to those of the conventional brake

system.

Wheel speed sensor which senses revolution speed of each wheel and outputs its signal.

ABS warning lamp which lights to inform abnormality when system fails to operate properly.

ABS hydraulic unit/control module assembly is incorporated ABS control module, ABS hydraulic unit (actua-

tor assembly), fail-safe relay and pump motor relay.

–ABS control module which sends operation signal to ABS hydraulic unit to control fluid pressure applied to

each wheel cylinder based on signal from each wheel speed sensor so as to prevent wheel from locking.

–ABS hydraulic unit which operates according to signal from ABS control module to control fluid pressure

applied to wheel cylinder of each 4 wheels.

–Fail-safe relay (solenoid valve) relay which supplies power to solenoid valve in ABS hydraulic unit and

pump motor relay.

–Pump motor relay which supplies power to pump motor in ABS hydraulic unit.

G sensor which detects body deceleration speed. (For 4WD model only)]

This ABS is equipped with Electronic Brake force Distribution (EBD) system that controls a fluid pressure of rear

wheels to best condition, which is the same function as that of proportioning valve, by the signal from wheel sen-

sor independently of change of load due to load capacity and so on. And if the EBD system fails to operate prop-

erly, the brake warning lamp lights to inform abnormality.

[A] : RH steering vehicle shown 4. Stop lamp switch

1. ABS hydraulic unit/control module assembly 5. ABS warning lamp

2. G sensor (For 4WD vehicle only) 6. EBD warning lamp (Brake warning lamp)

3. Wheel speed sensors

156

2 4

33

[A]

NOTE:

As for the difference of RH steering vehicle and LH steering vehicle, the location of the combination

meter and the brake master cylinder assembly only changes.

Page 329 of 698

5E-4 ANTILOCK BRAKE SYSTEM (ABS)

SYSTEM SCHEMATIC

1. ABS hydraulic unit/control module assembly 7.“ABS” warning lamp 13. Wheel speed sensor (Right-front)

2. ABS control module 8.“EBD” warning lamp (Brake warning lamp) 14. Wheel speed sensor (Left-front)

3. ABS hydraulic unit 9. Lamp driver module 15. Wheel speed sensor (Right-rear)

4. Fail safe relay 10. ECM 16. Wheel speed sensor (Left-rear)

5. Pump motor relay 11. Data link connector 17. G sensor (For 4WD vehicle only)

6. Stop lamp switch 12. Monitor coupler

INPUT OUTPUT

ABS control

module Wheel speed sensor (LF)

Wheel speed sensor (LR)

Wheel speed sensor (RF)

Wheel speed sensor (RR)

Stop lamp switch

Diag. switch terminal

Battery Voltage

G sensor (for 4WD vehicle only)

Pump motor

relay

Fail-safe

relay

Hydraulic unit

Pump motor

LF inlet solenoid

LF outlet solenoid

LR inlet solenoid

LR outlet solenoid

RF inlet solenoid

RF outlet solenoid

RR inlet solenoid

RR outlet solenoid

“ABS” warning lamp

ECM

EBD warning lamp

(Brake warning lamp)

Data link connector

ABS hydraulic unit/control

module assembly

Page 330 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-5

ABS HYDRAULIC UNIT/CONTROL MODULE

ASSEMBLY

ABS control module is a component of ABS hydraulic unit/control

module assembly and has the following functions.

SELF-DIAGNOSIS FUNCTION

ABS control module diagnoses conditions of the system compo-

nent parts (whether or not there is any abnormality) all the time

and indicates the results (warning of abnormality occurrence and

DTC) through the ABS warning lamp as described below.

1) When ignition switch is turned ON, ABS warning lamp lights

for 2 seconds to check its bulb and circuit.

2) When no abnormality has been detected (the system is in

good condition), ABS warning lamp turns OFF after 2 sec-

onds.

3) When an abnormality in the system is detected, ABS warn-

ing lamp lights and the area where that abnormality lies is

stored in the memory of EEPROM in ABS control module.

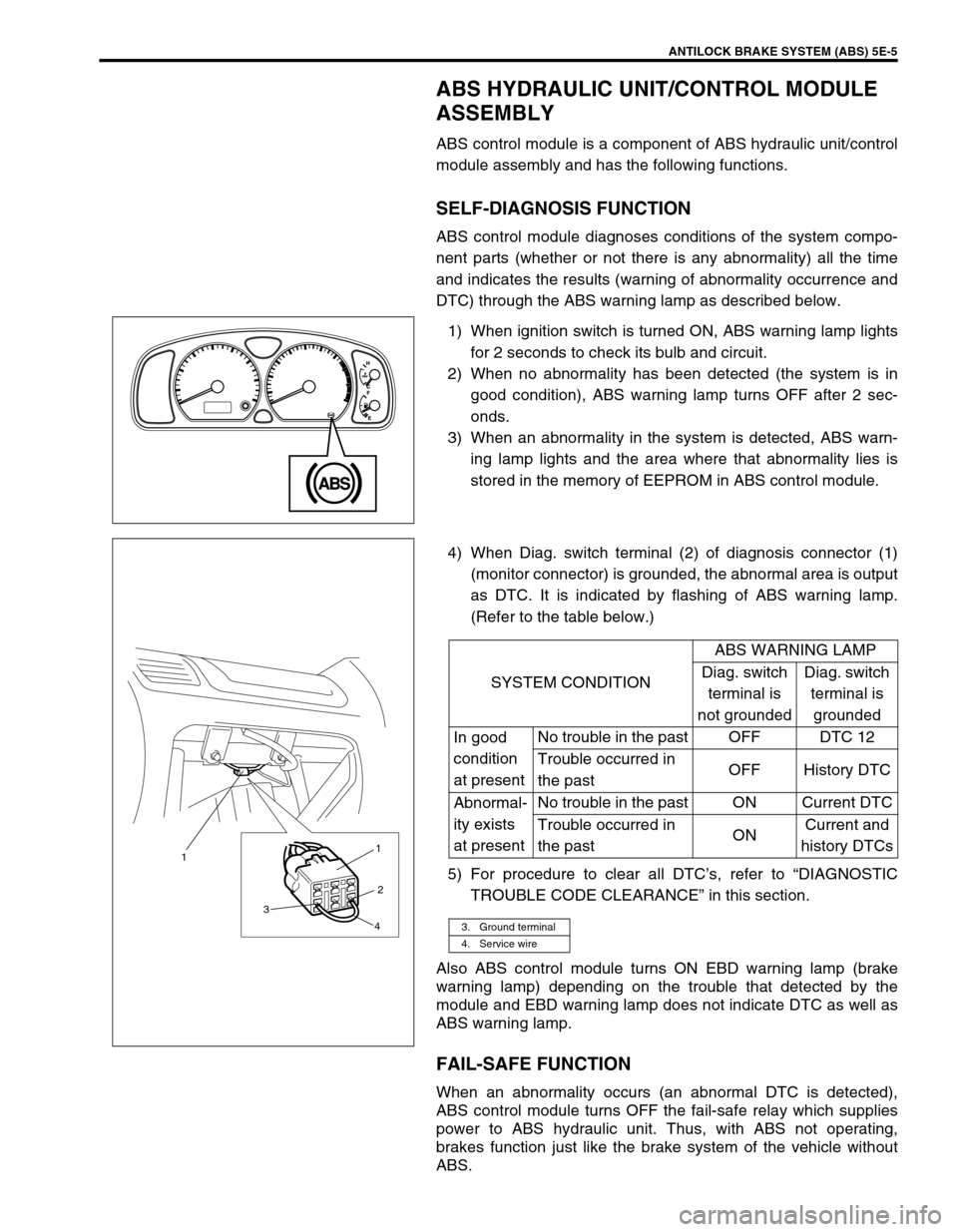

4) When Diag. switch terminal (2) of diagnosis connector (1)

(monitor connector) is grounded, the abnormal area is output

as DTC. It is indicated by flashing of ABS warning lamp.

(Refer to the table below.)

5) For procedure to clear all DTC’s, refer to “DIAGNOSTIC

TROUBLE CODE CLEARANCE” in this section.

Also ABS control module turns ON EBD warning lamp (brake

warning lamp) depending on the trouble that detected by the

module and EBD warning lamp does not indicate DTC as well as

ABS warning lamp.

FAIL-SAFE FUNCTION

When an abnormality occurs (an abnormal DTC is detected),

ABS control module turns OFF the fail-safe relay which supplies

power to ABS hydraulic unit. Thus, with ABS not operating,

brakes function just like the brake system of the vehicle without

ABS.

SYSTEM CONDITIONABS WARNING LAMP

Diag. switch

terminal is

not groundedDiag. switch

terminal is

grounded

In good

condition

at presentNo trouble in the past OFF DTC 12

Trouble occurred in

the pastOFF History DTC

Abnormal-

ity exists

at presentNo trouble in the past ON Current DTC

Trouble occurred in

the pastONCurrent and

history DTCs

3. Ground terminal

4. Service wire

3 11

2

4