SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

SWIFT 2000 1.G

SUZUKI

SUZUKI

https://www.carmanualsonline.info/img/20/7606/w960_7606-0.png

SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

Trending: key battery, OBD port, temperature indicator, Interior, bulb, seat memory, jacking

Page 311 of 698

5-38 BRAKES

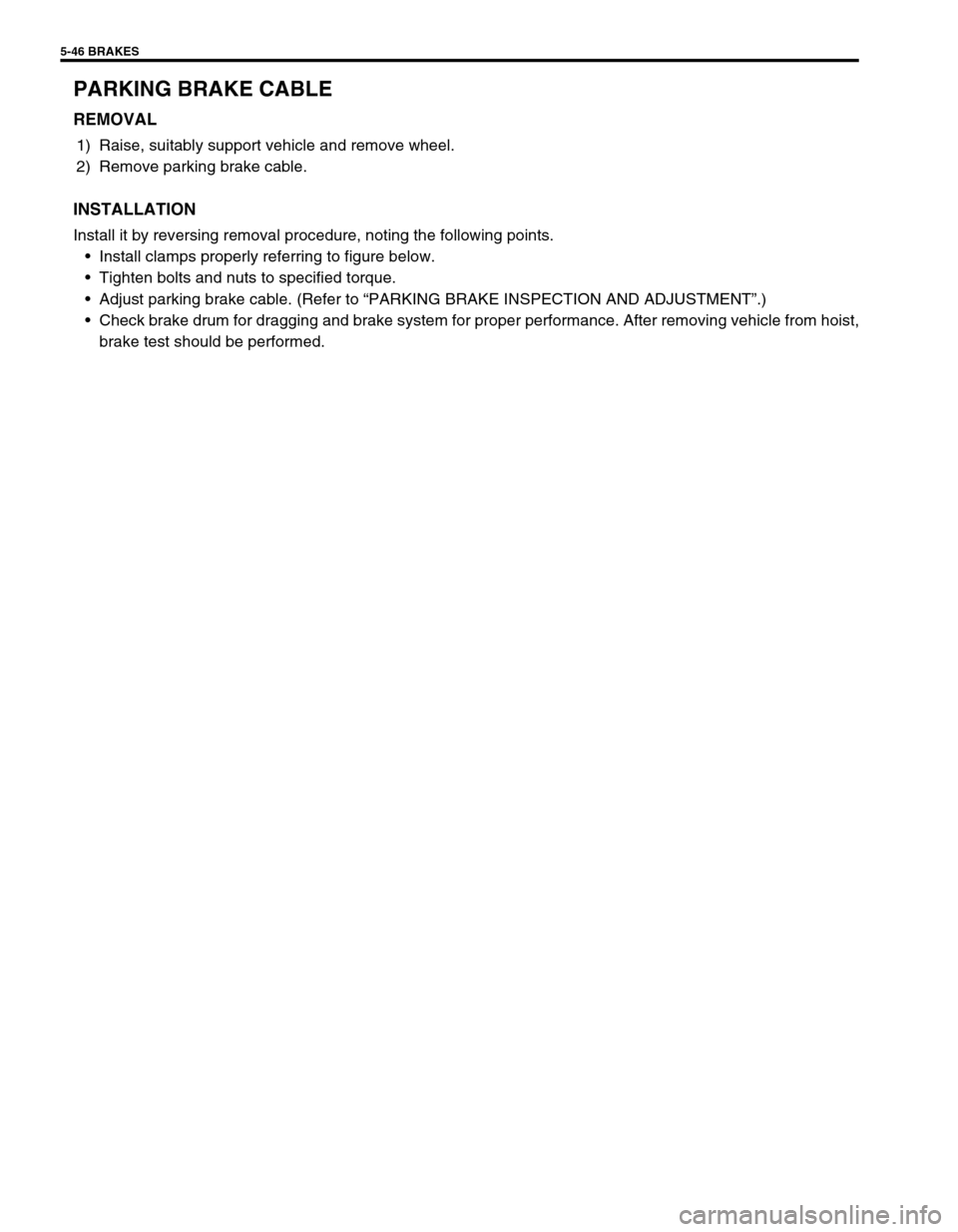

3) Set master cylinder (1) on vise (3) and adjust “A” to be the

following.

Cap adjustment position

“A” : 50 mm (1.97 in.)

4) Apply air with radiator cap tester, and confirm that 50 kPa

pressure is applied.

5) Perform same steps 1)-4) for port (2).

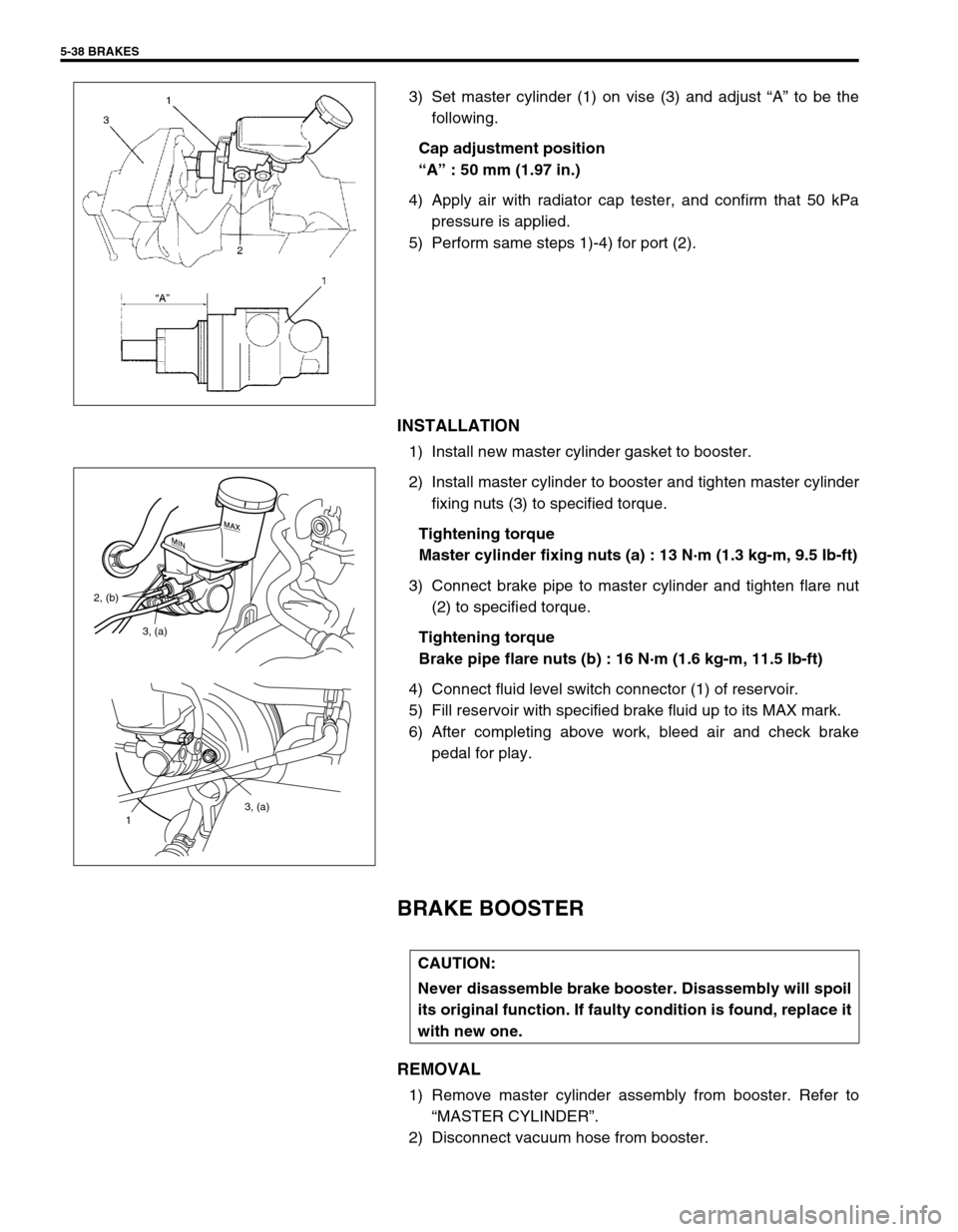

INSTALLATION

1) Install new master cylinder gasket to booster.

2) Install master cylinder to booster and tighten master cylinder

fixing nuts (3) to specified torque.

Tightening torque

Master cylinder fixing nuts (a) : 13 N·m (1.3 kg-m, 9.5 Ib-ft)

3) Connect brake pipe to master cylinder and tighten flare nut

(2) to specified torque.

Tightening torque

Brake pipe flare nuts (b) : 16 N·m (1.6 kg-m, 11.5 Ib-ft)

4) Connect fluid level switch connector (1) of reservoir.

5) Fill reservoir with specified brake fluid up to its MAX mark.

6) After completing above work, bleed air and check brake

pedal for play.

BRAKE BOOSTER

REMOVAL

1) Remove master cylinder assembly from booster. Refer to

“MASTER CYLINDER”.

2) Disconnect vacuum hose from booster.

3, (a)

1

3, (a) 2, (b)

CAUTION:

Never disassemble brake booster. Disassembly will spoil

its original function. If faulty condition is found, replace it

with new one.

Page 312 of 698

BRAKES 5-39

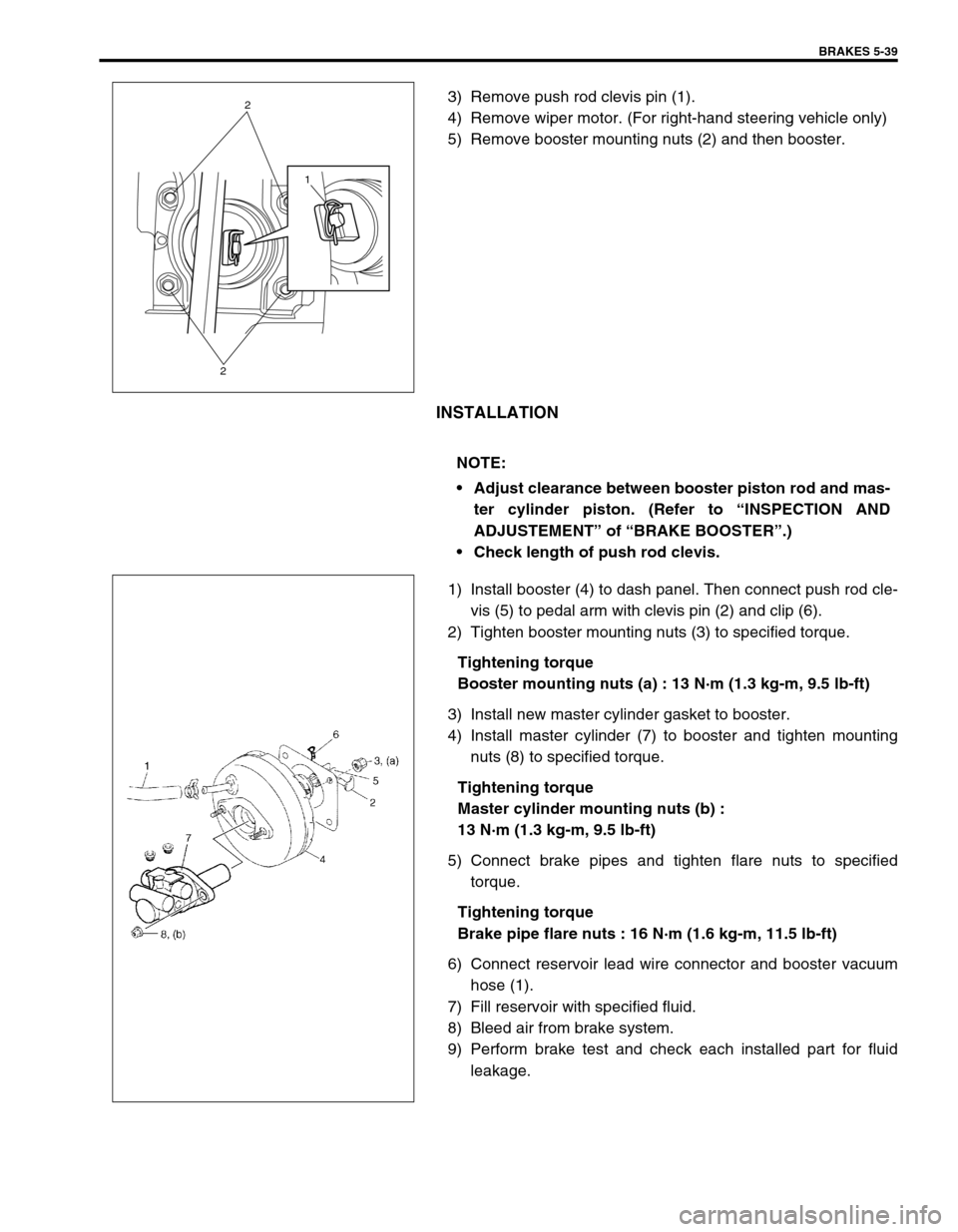

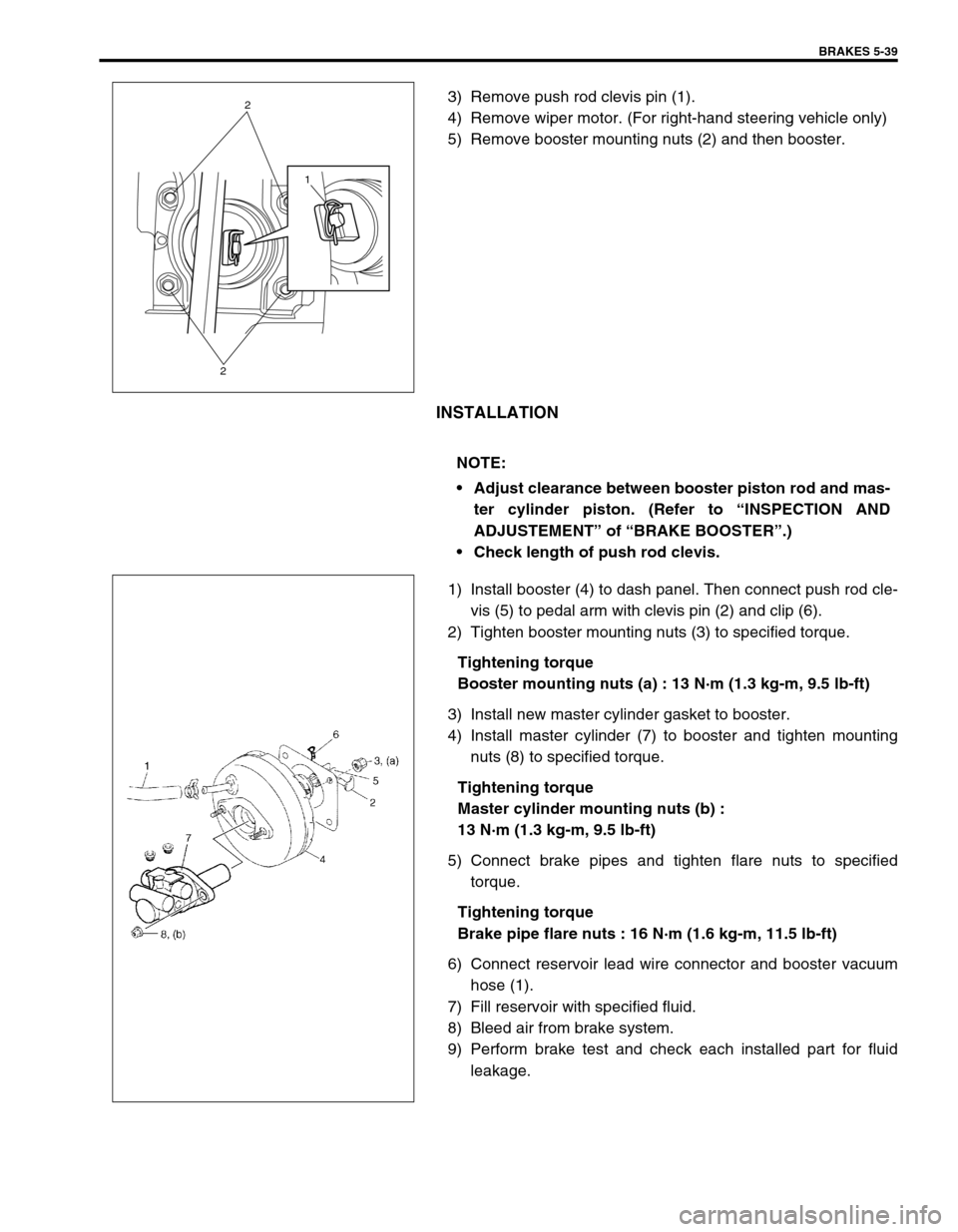

3) Remove push rod clevis pin (1).

4) Remove wiper motor. (For right-hand steering vehicle only)

5) Remove booster mounting nuts (2) and then booster.

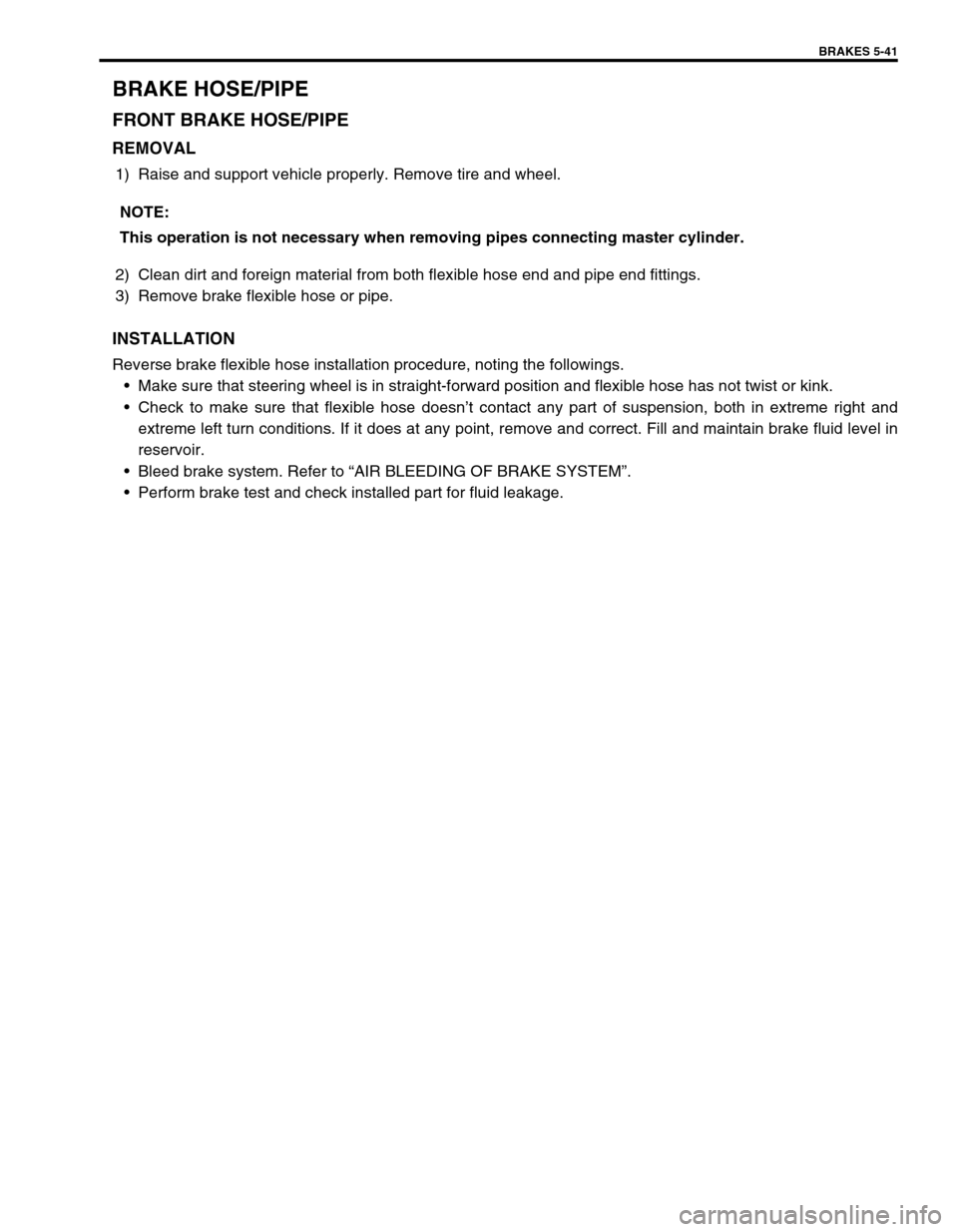

INSTALLATION

1) Install booster (4) to dash panel. Then connect push rod cle-

vis (5) to pedal arm with clevis pin (2) and clip (6).

2) Tighten booster mounting nuts (3) to specified torque.

Tightening torque

Booster mounting nuts (a) : 13 N·m (1.3 kg-m, 9.5 lb-ft)

3) Install new master cylinder gasket to booster.

4) Install master cylinder (7) to booster and tighten mounting

nuts (8) to specified torque.

Tightening torque

Master cylinder mounting nuts (b) :

13 N·m (1.3 kg-m, 9.5 lb-ft)

5) Connect brake pipes and tighten flare nuts to specified

torque.

Tightening torque

Brake pipe flare nuts : 16 N·m (1.6 kg-m, 11.5 lb-ft)

6) Connect reservoir lead wire connector and booster vacuum

hose (1).

7) Fill reservoir with specified fluid.

8) Bleed air from brake system.

9) Perform brake test and check each installed part for fluid

leakage.

1

2

2

NOTE:

Adjust clearance between booster piston rod and mas-

ter cylinder piston. (Refer to “INSPECTION AND

ADJUSTEMENT” of “BRAKE BOOSTER”.)

Check length of push rod clevis.

Page 313 of 698

5-40 BRAKES

INSPECTION AND ADJUSTMENT

Installation Position Of Push Rod

If push rod clevis (1) has been removed, adjust distance between

booster installation surface (without including packing) and the

center of clevis pin hole to standard value “a” and tighten nut (2)

to specified torque.

Distance “a” between center of booster clevis pin hole

and booster surface

Standard : 97 - 98 mm (3.82 - 3.86 in.)

Tightening torque

Clevis pin lock nut (a) : 19 N·m (1.9 kg-m, 14.0 lb-ft)

Clearance Between Booster Piston Rod And Master Cylin-

der Piston

The length of booster piston rod (1) is adjusted to provide speci-

fied clearance “a” between piston rod (1) end and master cylinder

piston (2).

Before measuring clearance, push piston rod several times

so as to make sure reaction disc is in place.

Keep inside of booster at atmospheric pressure for measure-

ment.

Measure length “a” of piston rod, i.e. distance between piston rod

and mating surface of booster-to-master cylinder.

Length “a” of piston rod

: 30.3 - 30.5 mm (1.193 - 1.200 in.)

If measurement is out of specification, adjust piston rod by turning

adjusting screw of piston rod.

Special tool

(B) : 09952-16020

NOTE:

Remove gasket from booster, if equipped.

Page 314 of 698

BRAKES 5-41

BRAKE HOSE/PIPE

FRONT BRAKE HOSE/PIPE

REMOVAL

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Remove brake flexible hose or pipe.

INSTALLATION

Reverse brake flexible hose installation procedure, noting the followings.

Make sure that steering wheel is in straight-forward position and flexible hose has not twist or kink.

Check to make sure that flexible hose doesn’t contact any part of suspension, both in extreme right and

extreme left turn conditions. If it does at any point, remove and correct. Fill and maintain brake fluid level in

reservoir.

Bleed brake system. Refer to “AIR BLEEDING OF BRAKE SYSTEM”.

Perform brake test and check installed part for fluid leakage. NOTE:

This operation is not necessary when removing pipes connecting master cylinder.

Page 315 of 698

5-42 BRAKES

For vehicle with ABS

T : Top side [A] : For left-hand steering vehicle 4. From ABS hydraulic unit to right front brake

F : Front side [B] : For right-hand steering vehicle 5. ABS hydraulic unit

R : Right side 1. From master cylinder primary to ABS hydraulic unit 6. Master cylinder

A : View A 2. From master cylinder secondary to ABS hydraulic unit 7. Front brake hose

a-f: Clamp 3. From ABS hydraulic unit to left front brake Tightening torque

Page 316 of 698

BRAKES 5-43

For vehicle without ABS

T : Top side 1. From master cylinder primary to left front brake [A] : For left-hand steering vehicle

F : Front side 2. From master cylinder secondary to right front brake [B] : For right-hand steering vehicle

R : Right side 3. Master cylinder a-g: Clamp

A : View A 4. Front brake hose Tightening torque

Page 317 of 698

5-44 BRAKES

REAR BRAKE HOSE/PIPE

REMOVAL

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Remove brake flexible hose or pipe.

INSTALLATION

Reverse brake flexible hose installation procedure, nothing the followings.

Fill and maintain brake fluid level in reservoir.

Bleed brake system. Refer to “AIR BLEEDING OF BRAKE SYSTEM”.

Perform brake test and check each installed part for fluid leakage.

Never reuse protector nut once removed. Be sure to use a new one.

Install clamps properly referring to figure below and tighten bolts.

When installing hose, make sure that it has no twist or kink.

Page 318 of 698

BRAKES 5-45

T : Top side 1. 4 way joint [A] : with ABS

F : Front side 2. LSPV assembly [B] : without ABS

R : Right side 3. P valve [C] : with LSPV

L : Left side 4. Rear brake hose Tightening torque

B : View B a-g: Clamp

Page 319 of 698

5-46 BRAKES

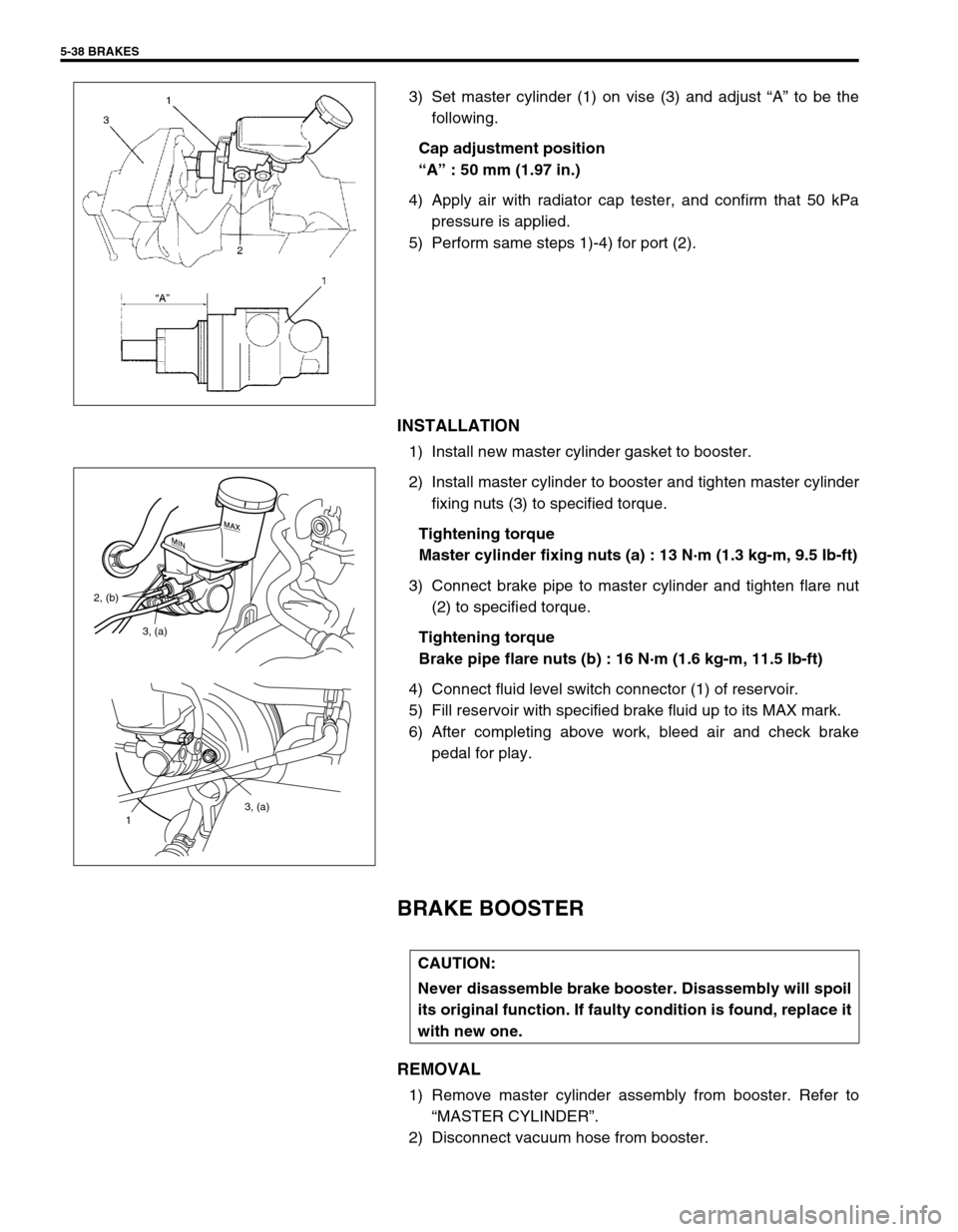

PARKING BRAKE CABLE

REMOVAL

1) Raise, suitably support vehicle and remove wheel.

2) Remove parking brake cable.

INSTALLATION

Install it by reversing removal procedure, noting the following points.

Install clamps properly referring to figure below.

Tighten bolts and nuts to specified torque.

Adjust parking brake cable. (Refer to “PARKING BRAKE INSPECTION AND ADJUSTMENT”.)

Check brake drum for dragging and brake system for proper performance. After removing vehicle from hoist,

brake test should be performed.

Page 320 of 698

BRAKES 5-47

T : Top side 3. Inner cable end a : View A f : View F

F : Front side 4. Spring b : View B Tightening torque

R : Rear side 5. Adjusting nut c : View C

1. Cable

: Apply water tight sealant (99000-31090)6. Clip d : View D

2. Parking brake shoe lever 7. Parking brake lever e : View E

Trending: wheel bolt torque, radio, weight, towing, ignition, compression ratio, wiring diagram

![SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual 5-42 BRAKES

For vehicle with ABS

T : Top side [A] : For left-hand steering vehicle 4. From ABS hydraulic unit to right front brake

F : Front side [B] : For right-hand steering vehicle 5. ABS hydrauli SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual 5-42 BRAKES

For vehicle with ABS

T : Top side [A] : For left-hand steering vehicle 4. From ABS hydraulic unit to right front brake

F : Front side [B] : For right-hand steering vehicle 5. ABS hydrauli](/img/20/7606/w960_7606-314.png)

![SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual BRAKES 5-43

For vehicle without ABS

T : Top side 1. From master cylinder primary to left front brake [A] : For left-hand steering vehicle

F : Front side 2. From master cylinder secondary to right fro SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual BRAKES 5-43

For vehicle without ABS

T : Top side 1. From master cylinder primary to left front brake [A] : For left-hand steering vehicle

F : Front side 2. From master cylinder secondary to right fro](/img/20/7606/w960_7606-315.png)

![SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual BRAKES 5-45

T : Top side 1. 4 way joint [A] : with ABS

F : Front side 2. LSPV assembly [B] : without ABS

R : Right side 3. P valve [C] : with LSPV

L : Left side 4. Rear brake hose Tightening torque SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual BRAKES 5-45

T : Top side 1. 4 way joint [A] : with ABS

F : Front side 2. LSPV assembly [B] : without ABS

R : Right side 3. P valve [C] : with LSPV

L : Left side 4. Rear brake hose Tightening torque](/img/20/7606/w960_7606-317.png)