SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 351 of 698

5E-26 ANTILOCK BRAKE SYSTEM (ABS)

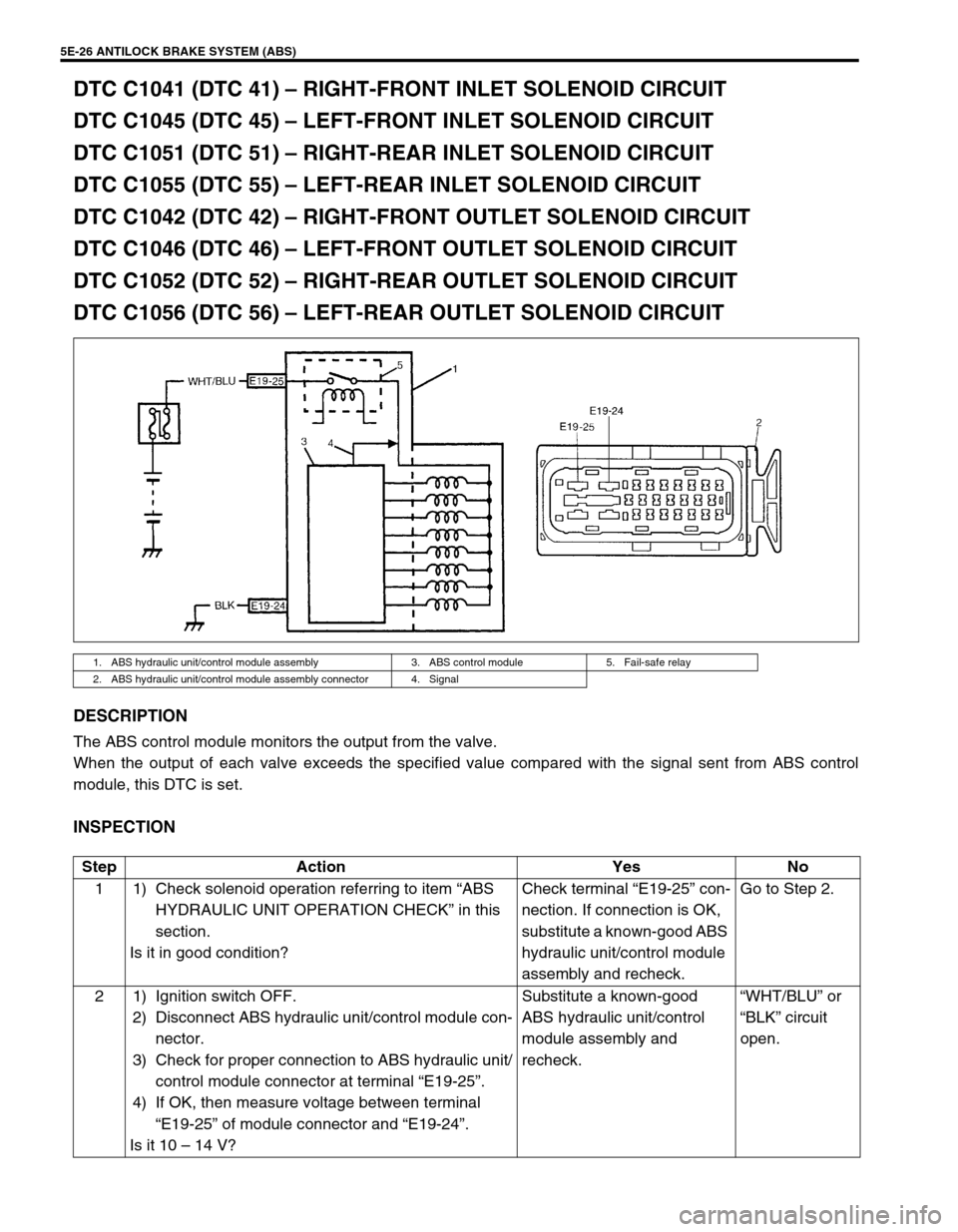

DTC C1041 (DTC 41) – RIGHT-FRONT INLET SOLENOID CIRCUIT

DTC C1045 (DTC 45) – LEFT-FRONT INLET SOLENOID CIRCUIT

DTC C1051 (DTC 51) – RIGHT-REAR INLET SOLENOID CIRCUIT

DTC C1055 (DTC 55) – LEFT-REAR INLET SOLENOID CIRCUIT

DTC C1042 (DTC 42) – RIGHT-FRONT OUTLET SOLENOID CIRCUIT

DTC C1046 (DTC 46) – LEFT-FRONT OUTLET SOLENOID CIRCUIT

DTC C1052 (DTC 52) – RIGHT-REAR OUTLET SOLENOID CIRCUIT

DTC C1056 (DTC 56) – LEFT-REAR OUTLET SOLENOID CIRCUIT

DESCRIPTION

The ABS control module monitors the output from the valve.

When the output of each valve exceeds the specified value compared with the signal sent from ABS control

module, this DTC is set.

INSPECTION

1. ABS hydraulic unit/control module assembly 3. ABS control module 5. Fail-safe relay

2. ABS hydraulic unit/control module assembly connector 4. Signal

Step Action Yes No

1 1) Check solenoid operation referring to item “ABS

HYDRAULIC UNIT OPERATION CHECK” in this

section.

Is it in good condition?Check terminal “E19-25” con-

nection. If connection is OK,

substitute a known-good ABS

hydraulic unit/control module

assembly and recheck.Go to Step 2.

2 1) Ignition switch OFF.

2) Disconnect ABS hydraulic unit/control module con-

nector.

3) Check for proper connection to ABS hydraulic unit/

control module connector at terminal “E19-25”.

4) If OK, then measure voltage between terminal

“E19-25” of module connector and “E19-24”.

Is it 10 – 14 V?Substitute a known-good

ABS hydraulic unit/control

module assembly and

recheck.“WHT/BLU” or

“BLK” circuit

open.

Page 352 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-27

DTC C1057 (DTC 57) – POWER SOURCE CIRCUIT

DESCRIPTION

The ABS control module monitors the power source voltage at terminal “E19-18”. When the power source volt-

age becomes extremely high or low, this DTC will be set. As soon as the voltage rises or lowers to the specified

level, the set DTC will be cleared.

INSPECTION

1. Ignition switch 3. ABS hydraulic unit/control module assembly

2. Main fuse 4. ABS hydraulic unit/control module connector

Step Action Yes No

1 1) Connect a voltmeter between battery posi-

tive (+) terminal and body ground.

2) Start the engine and measure the maximum

voltage when racing the engine.

Is it over 18V?Check charging system

referring to “CHARGING

SYSTEM” section.Go to Step 2.

2 1) Disconnect ABS hydraulic unit/control mod-

ule connector.

2) Keep the engine idling, measure the voltage

between terminal “E19-18” of ABS control

module and body ground.

Is it always under 9V?Check charging system

referring to “CHARGING

SYSTEM” section.

Imperfect short between

wire “GRN/ORN” and

ground.Poor connection of termi-

nal “E19-18” or “E19-24”

of the ABS control mod-

ule.

If the above are in good

condition, substitute a

known-good ABS hydrau-

lic unit/control module and

recheck.

Page 353 of 698

5E-28 ANTILOCK BRAKE SYSTEM (ABS)

DTC C1061 (DTC 61) – ABS PUMP MOTOR CIRCUIT

DESCRIPTION

The ABS control module monitors the voltage at monitor terminal of pump motor circuit constantly with the igni-

tion switch turned ON. It sets this DTC when the voltage at the monitor terminal does not become high/low

according to ON/OFF commands to the motor relay of the module (does not follow these commands).

INSPECTION

1. ABS hydraulic unit/control module assembly 3. ABS pump motor 5. ABS hydraulic unit/control module connector

2. ABS pump motor relay 4. ABS fail safe relay

Step Action Yes No

1 1) Check pump motor referring to “ABS

HYDRAULIC UNIT OPERATION CHECK”

in this section.

Is it in good condition?Check terminals “E19-25”

and “E19-23” connection.

If connections OK, substi-

tute a known-good ABS

hydraulic unit/control

module assembly and

recheck.Go to Step 2.

2 1) Ignition switch OFF.

2) Disconnect ABS hydraulic unit/control mod-

ule connector.

3) Check for proper connection to ABS

hydraulic unit/control module connector at

terminal “E19-23”.

4) If OK, then measure voltage between termi-

nal “E19-23” of module connector and body

ground.

Is it 10 – 14 V?Go to Step 3.“WHT/BLU” circuit open.

3 Measure resistance between terminal “E19-22”

of ABS hydraulic unit/control module connector

and body ground.

Is it infinite (∞)?“BLK” circuit open. Substitute a known-good

ABS hydraulic unit/con-

trol module assembly and

recheck.

Page 354 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-29

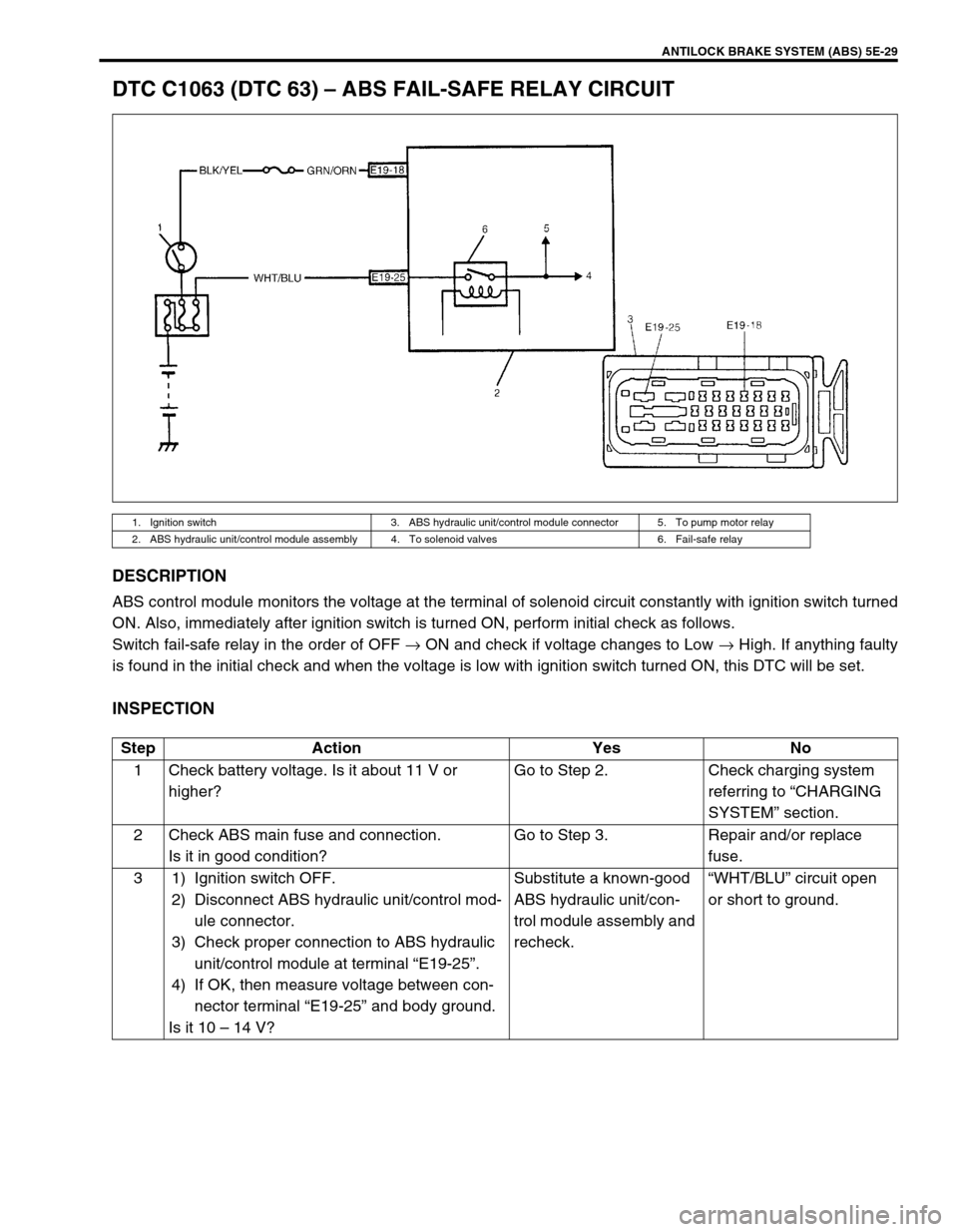

DTC C1063 (DTC 63) – ABS FAIL-SAFE RELAY CIRCUIT

DESCRIPTION

ABS control module monitors the voltage at the terminal of solenoid circuit constantly with ignition switch turned

ON. Also, immediately after ignition switch is turned ON, perform initial check as follows.

Switch fail-safe relay in the order of OFF → ON and check if voltage changes to Low → High. If anything faulty

is found in the initial check and when the voltage is low with ignition switch turned ON, this DTC will be set.

INSPECTION

1. Ignition switch 3. ABS hydraulic unit/control module connector 5. To pump motor relay

2. ABS hydraulic unit/control module assembly 4. To solenoid valves 6. Fail-safe relay

Step Action Yes No

1 Check battery voltage. Is it about 11 V or

higher?Go to Step 2. Check charging system

referring to “CHARGING

SYSTEM” section.

2 Check ABS main fuse and connection.

Is it in good condition?Go to Step 3. Repair and/or replace

fuse.

3 1) Ignition switch OFF.

2) Disconnect ABS hydraulic unit/control mod-

ule connector.

3) Check proper connection to ABS hydraulic

unit/control module at terminal “E19-25”.

4) If OK, then measure voltage between con-

nector terminal “E19-25” and body ground.

Is it 10 – 14 V?Substitute a known-good

ABS hydraulic unit/con-

trol module assembly and

recheck.“WHT/BLU” circuit open

or short to ground.

Page 355 of 698

5E-30 ANTILOCK BRAKE SYSTEM (ABS)

DTC C1071 (DTC 71) – ABS CONTROL MODULE

DESCRIPTION

This DTC will be set when an internal malfunction is detected in the ABS control module.

INSPECTION

1. ABS hydraulic unit/control module assembly 3. ABS pump motor 5. ABS hydraulic unit/control module connector

2. ABS pump motor relay 4. ABS fail safe relay

Step Action Yes No

1 Clear all DTCs and check DTC.

Is it DTC 71?Go to Step 2. Could be a temporary

malfunction of the ABS

control module.

2 1) Check proper connection of ABS hydraulic

unit/control module connector.

2) If OK, disconnect ABS hydraulic unit/control

module connector and check the followings.

Voltage “E19-25” terminal : 10 – 14 V

Resistance between “E19-22” and body

ground : Continuity

Are the check result as specified above?Replace ABS hydraulic

unit/control module

assembly.Repair and recheck.

Page 356 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-31

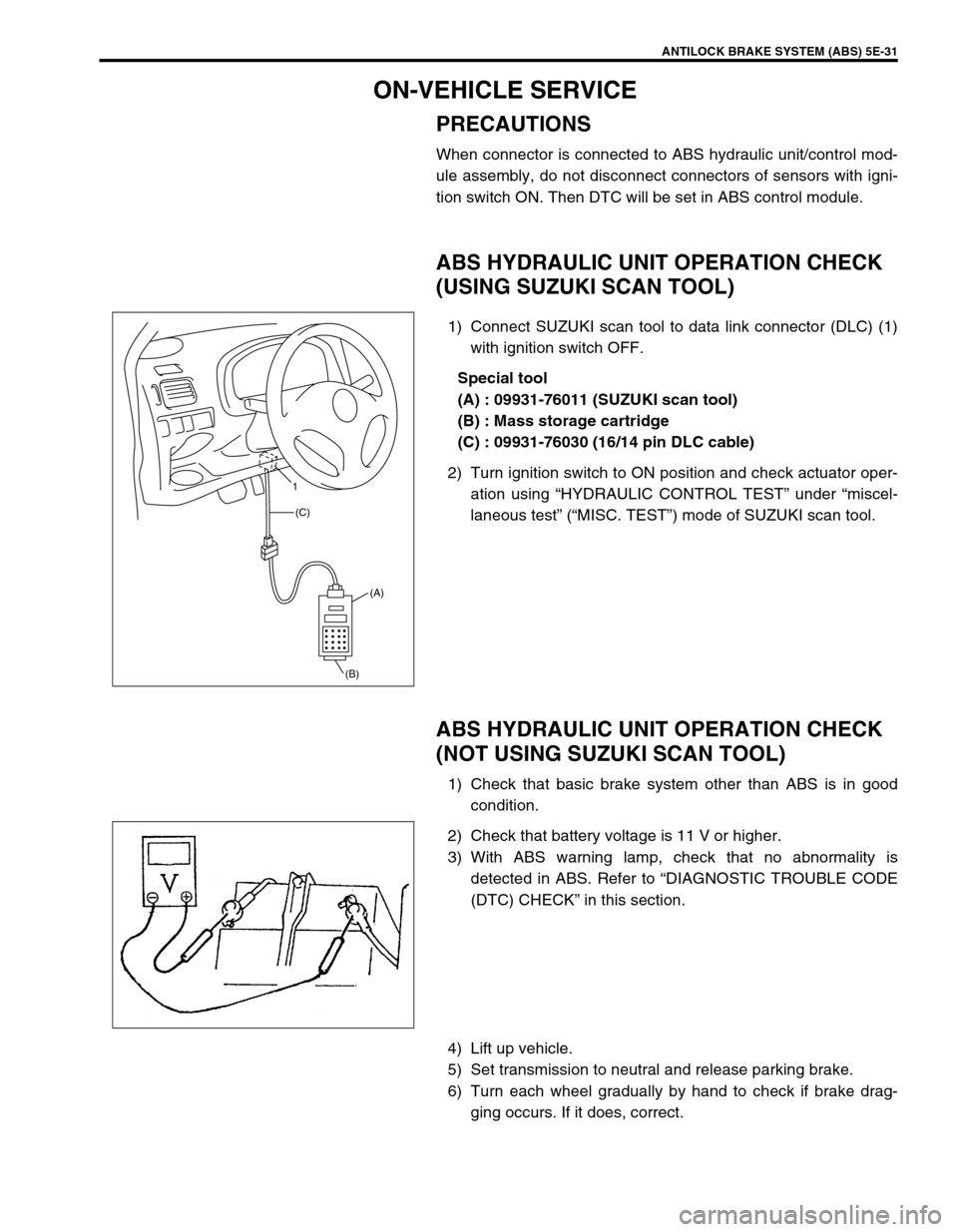

ON-VEHICLE SERVICE

PRECAUTIONS

When connector is connected to ABS hydraulic unit/control mod-

ule assembly, do not disconnect connectors of sensors with igni-

tion switch ON. Then DTC will be set in ABS control module.

ABS HYDRAULIC UNIT OPERATION CHECK

(USING SUZUKI SCAN TOOL)

1) Connect SUZUKI scan tool to data link connector (DLC) (1)

with ignition switch OFF.

Special tool

(A) : 09931-76011 (SUZUKI scan tool)

(B) : Mass storage cartridge

(C) : 09931-76030 (16/14 pin DLC cable)

2) Turn ignition switch to ON position and check actuator oper-

ation using “HYDRAULIC CONTROL TEST” under “miscel-

laneous test” (“MISC. TEST”) mode of SUZUKI scan tool.

ABS HYDRAULIC UNIT OPERATION CHECK

(NOT USING SUZUKI SCAN TOOL)

1) Check that basic brake system other than ABS is in good

condition.

2) Check that battery voltage is 11 V or higher.

3) With ABS warning lamp, check that no abnormality is

detected in ABS. Refer to “DIAGNOSTIC TROUBLE CODE

(DTC) CHECK” in this section.

4) Lift up vehicle.

5) Set transmission to neutral and release parking brake.

6) Turn each wheel gradually by hand to check if brake drag-

ging occurs. If it does, correct.

(A)

(B) (C) 1

Page 357 of 698

5E-32 ANTILOCK BRAKE SYSTEM (ABS)

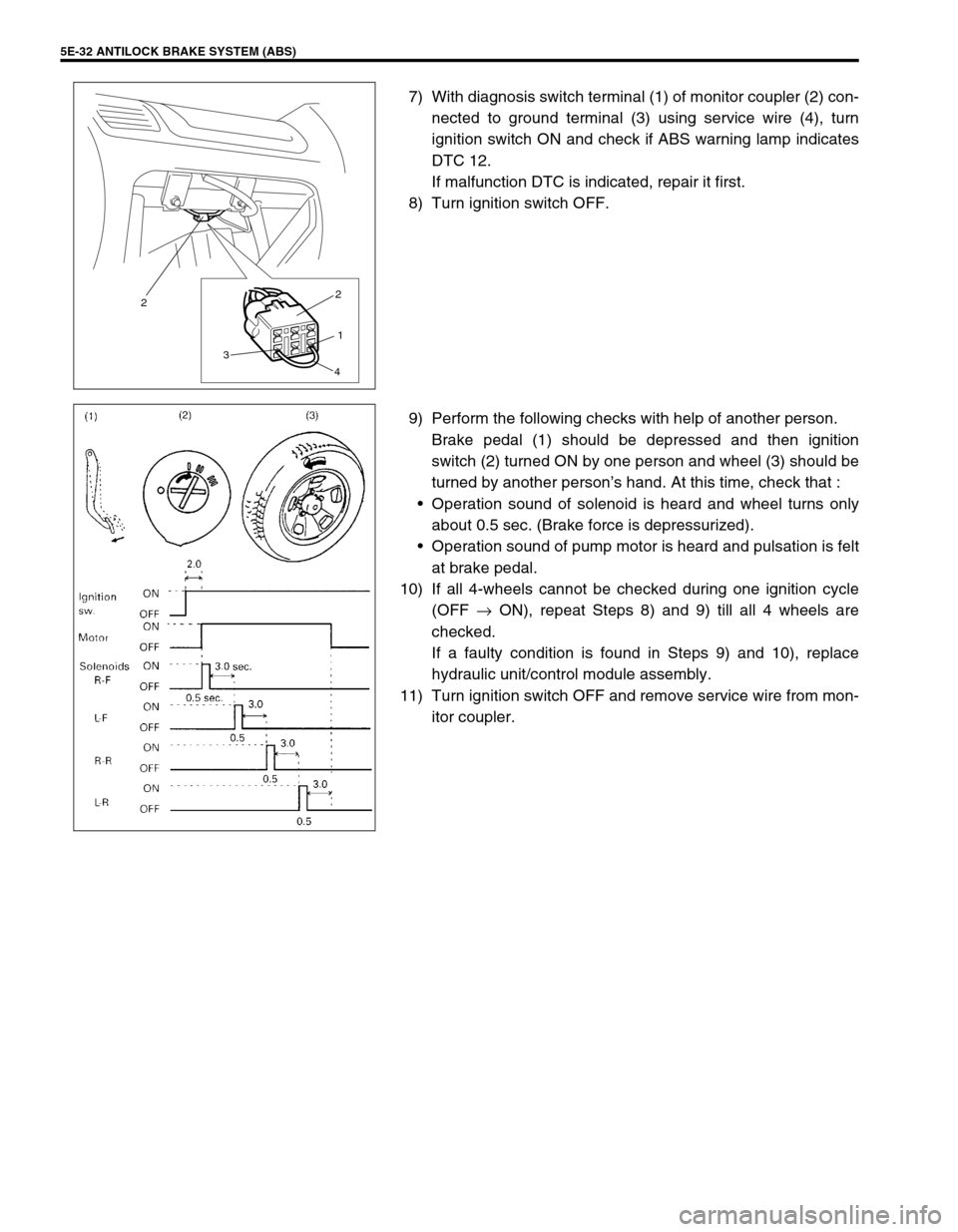

7) With diagnosis switch terminal (1) of monitor coupler (2) con-

nected to ground terminal (3) using service wire (4), turn

ignition switch ON and check if ABS warning lamp indicates

DTC 12.

If malfunction DTC is indicated, repair it first.

8) Turn ignition switch OFF.

9) Perform the following checks with help of another person.

Brake pedal (1) should be depressed and then ignition

switch (2) turned ON by one person and wheel (3) should be

turned by another person’s hand. At this time, check that :

Operation sound of solenoid is heard and wheel turns only

about 0.5 sec. (Brake force is depressurized).

Operation sound of pump motor is heard and pulsation is felt

at brake pedal.

10) If all 4-wheels cannot be checked during one ignition cycle

(OFF → ON), repeat Steps 8) and 9) till all 4 wheels are

checked.

If a faulty condition is found in Steps 9) and 10), replace

hydraulic unit/control module assembly.

11) Turn ignition switch OFF and remove service wire from mon-

itor coupler.

3 22

1

4

Page 358 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-33

ABS HYDRAULIC UNIT/CONTROL MODULE ASSEMBLY

HYDRAULIC UNIT INSPECTION

Check hydraulic unit for fluid leakage.

If any, repair or replace.

REMOVAL

1) Disconnect negative cable from battery.

2) Disconnect ABS hydraulic unit/control module assembly

connector (1) by pulling up lock (2). CAUTION:

Never disassemble ABS hydraulic unit/control module assembly, loosen blind plug or remove motor.

Performing any of these prohibited services will affect original performance of ABS hydraulic unit/

control module assembly.

1. Brake pipe 3. Bracket

2. ABS hydraulic unit/control module assembly 4. Connector

9 N·m (0.9 kg-m)

9 N·m (0.9 kg-m)

26 N·m (2.6 kg-m)

16 N·m (1.6 kg-m)

16 N·m (1.6 kg-m)

4 2

3

11

1

Page 359 of 698

5E-34 ANTILOCK BRAKE SYSTEM (ABS)

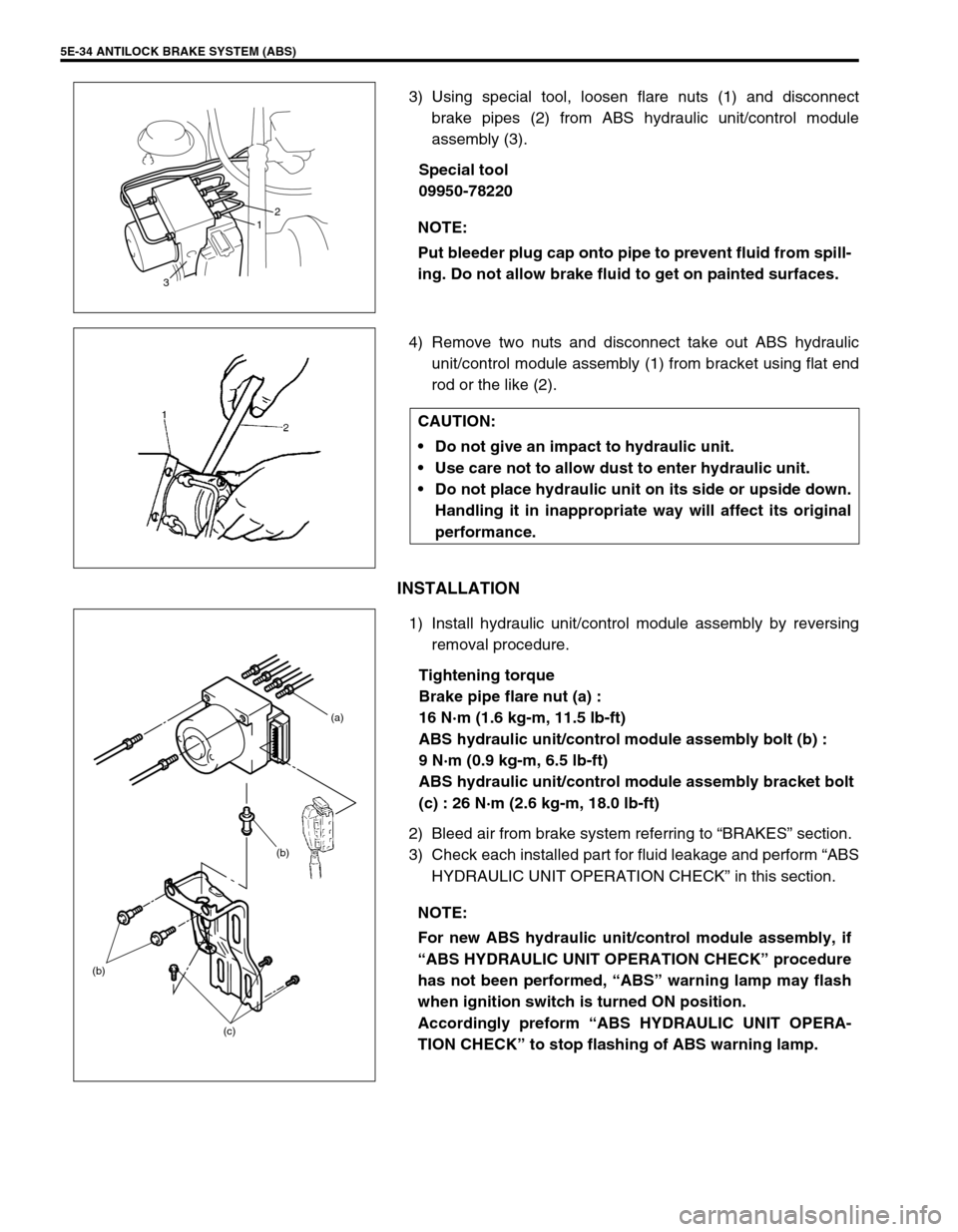

3) Using special tool, loosen flare nuts (1) and disconnect

brake pipes (2) from ABS hydraulic unit/control module

assembly (3).

Special tool

09950-78220

4) Remove two nuts and disconnect take out ABS hydraulic

unit/control module assembly (1) from bracket using flat end

rod or the like (2).

INSTALLATION

1) Install hydraulic unit/control module assembly by reversing

removal procedure.

Tightening torque

Brake pipe flare nut (a) :

16 N·m (1.6 kg-m, 11.5 lb-ft)

ABS hydraulic unit/control module assembly bolt (b) :

9 N·m (0.9 kg-m, 6.5 lb-ft)

ABS hydraulic unit/control module assembly bracket bolt

(c) : 26 N·m (2.6 kg-m, 18.0 lb-ft)

2) Bleed air from brake system referring to “BRAKES” section.

3) Check each installed part for fluid leakage and perform “ABS

HYDRAULIC UNIT OPERATION CHECK” in this section. NOTE:

Put bleeder plug cap onto pipe to prevent fluid from spill-

ing. Do not allow brake fluid to get on painted surfaces.

312

CAUTION:

Do not give an impact to hydraulic unit.

Use care not to allow dust to enter hydraulic unit.

Do not place hydraulic unit on its side or upside down.

Handling it in inappropriate way will affect its original

performance.

NOTE:

For new ABS hydraulic unit/control module assembly, if

“ABS HYDRAULIC UNIT OPERATION CHECK” procedure

has not been performed, “ABS” warning lamp may flash

when ignition switch is turned ON position.

Accordingly preform “ABS HYDRAULIC UNIT OPERA-

TION CHECK” to stop flashing of ABS warning lamp.

(b)

(c) (b)(a)

Page 360 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-35

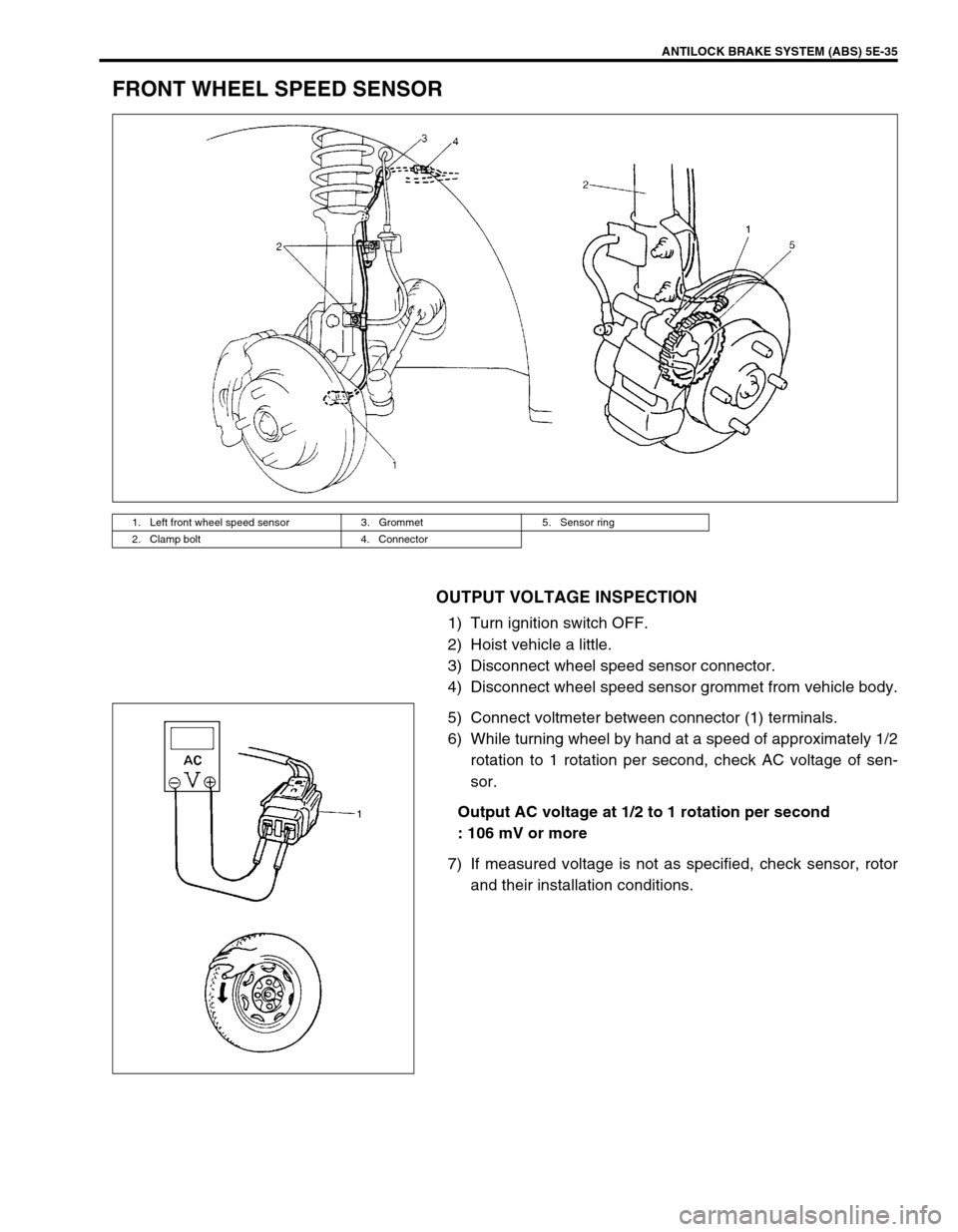

FRONT WHEEL SPEED SENSOR

OUTPUT VOLTAGE INSPECTION

1) Turn ignition switch OFF.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Disconnect wheel speed sensor grommet from vehicle body.

5) Connect voltmeter between connector (1) terminals.

6) While turning wheel by hand at a speed of approximately 1/2

rotation to 1 rotation per second, check AC voltage of sen-

sor.

Output AC voltage at 1/2 to 1 rotation per second

: 106 mV or more

7) If measured voltage is not as specified, check sensor, rotor

and their installation conditions.

1. Left front wheel speed sensor 3. Grommet 5. Sensor ring

2. Clamp bolt 4. Connector