SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 421 of 698

6-52 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0105 (DTC NO.11) MANIFOLD ABSOLUTE PRESSURE (MAP) CIRCUIT

MALFUNCTION

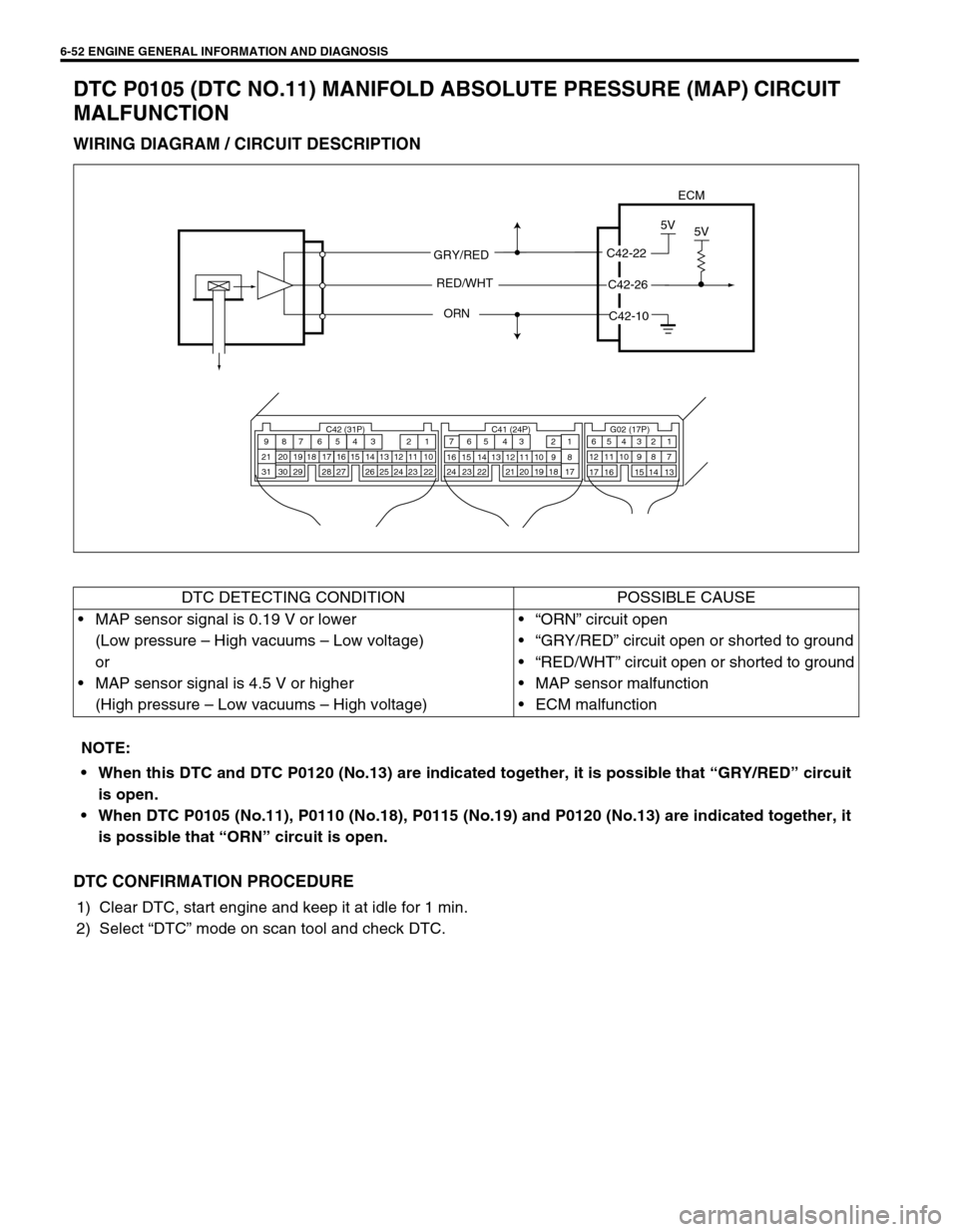

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC.

ECM

GRY/RED

ORN

C42-22

5V

AMPC42-26

5V

RED/WHT

C42-10

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

MAP sensor signal is 0.19 V or lower

(Low pressure – High vacuums – Low voltage)

or

MAP sensor signal is 4.5 V or higher

(High pressure – Low vacuums – High voltage)“ORN” circuit open

“GRY/RED” circuit open or shorted to ground

“RED/WHT” circuit open or shorted to ground

MAP sensor malfunction

ECM malfunction

NOTE:

When this DTC and DTC P0120 (No.13) are indicated together, it is possible that “GRY/RED” circuit

is open.

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” circuit is open.

Page 422 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-53

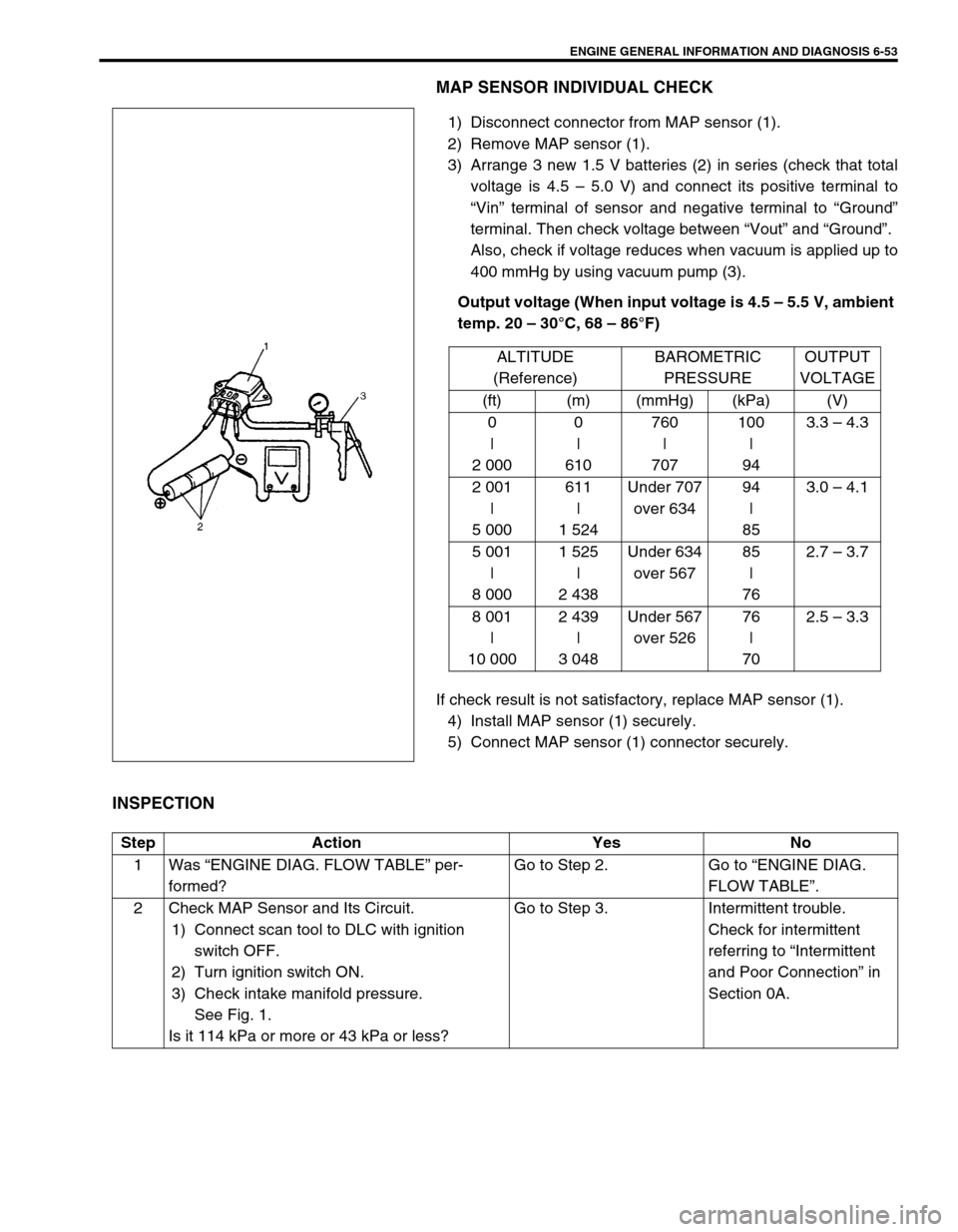

MAP SENSOR INDIVIDUAL CHECK

1) Disconnect connector from MAP sensor (1).

2) Remove MAP sensor (1).

3) Arrange 3 new 1.5 V batteries (2) in series (check that total

voltage is 4.5 – 5.0 V) and connect its positive terminal to

“Vin” terminal of sensor and negative terminal to “Ground”

terminal. Then check voltage between “Vout” and “Ground”.

Also, check if voltage reduces when vacuum is applied up to

400 mmHg by using vacuum pump (3).

Output voltage (When input voltage is 4.5 – 5.5 V, ambient

temp. 20 – 30°C, 68 – 86°F)

If check result is not satisfactory, replace MAP sensor (1).

4) Install MAP sensor (1) securely.

5) Connect MAP sensor (1) connector securely.

INSPECTION

ALTITUDE

(Reference)BAROMETRIC

PRESSUREOUTPUT

VOLTAGE

(ft) (m) (mmHg) (kPa) (V)

0

|

2 0000

|

610760

|

707100

|

943.3 – 4.3

2 001

|

5 000611

|

1 524Under 707

over 63494

|

853.0 – 4.1

5 001

|

8 0001 525

|

2 438Under 634

over 56785

|

762.7 – 3.7

8 001

|

10 0002 439

|

3 048Under 567

over 52676

|

702.5 – 3.3

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check MAP Sensor and Its Circuit.

1) Connect scan tool to DLC with ignition

switch OFF.

2) Turn ignition switch ON.

3) Check intake manifold pressure.

See Fig. 1.

Is it 114 kPa or more or 43 kPa or less?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.

Page 423 of 698

6-54 ENGINE GENERAL INFORMATION AND DIAGNOSIS

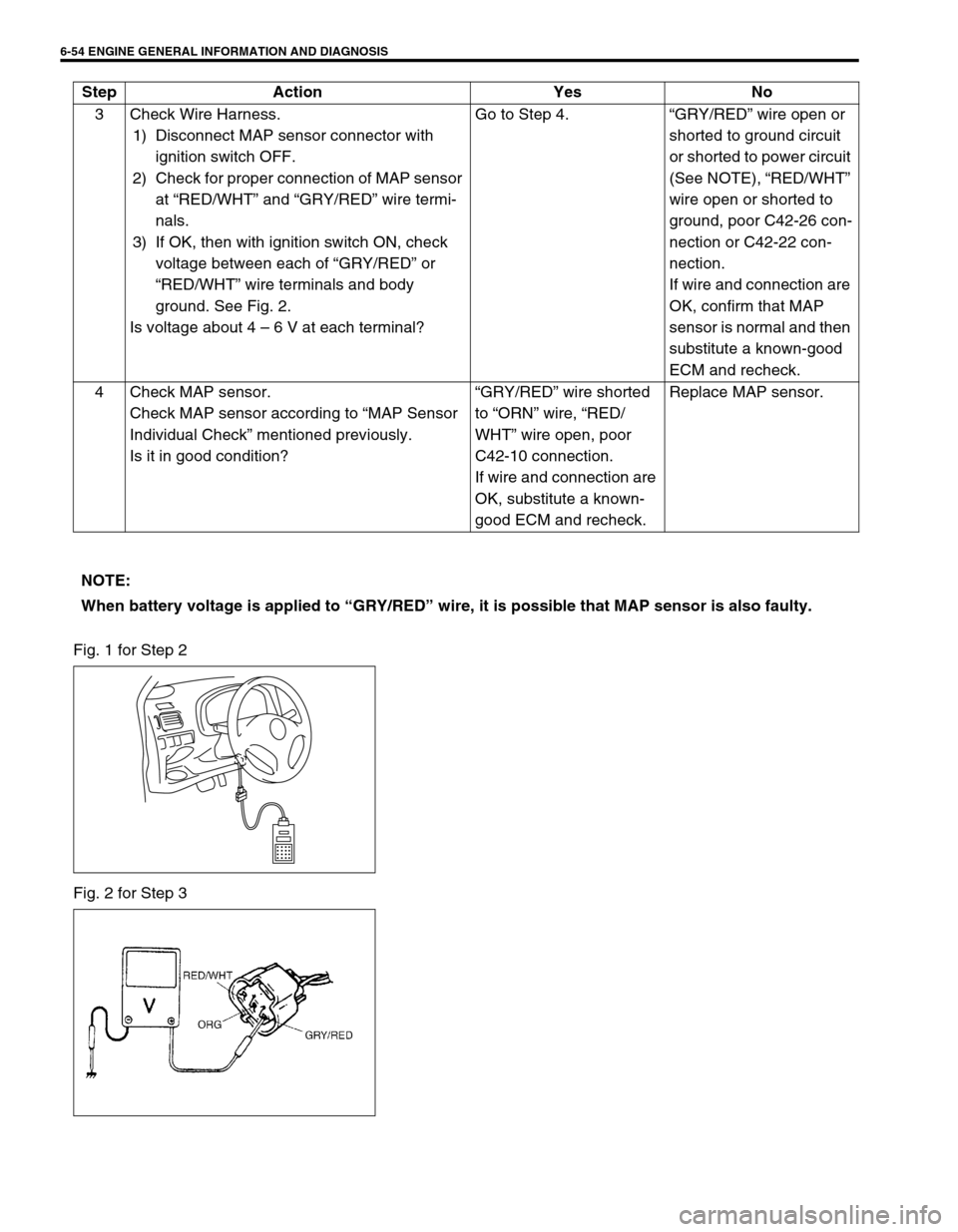

Fig. 1 for Step 2

Fig. 2 for Step 33 Check Wire Harness.

1) Disconnect MAP sensor connector with

ignition switch OFF.

2) Check for proper connection of MAP sensor

at “RED/WHT” and “GRY/RED” wire termi-

nals.

3) If OK, then with ignition switch ON, check

voltage between each of “GRY/RED” or

“RED/WHT” wire terminals and body

ground. See Fig. 2.

Is voltage about 4 – 6 V at each terminal?Go to Step 4.“GRY/RED” wire open or

shorted to ground circuit

or shorted to power circuit

(See NOTE), “RED/WHT”

wire open or shorted to

ground, poor C42-26 con-

nection or C42-22 con-

nection.

If wire and connection are

OK, confirm that MAP

sensor is normal and then

substitute a known-good

ECM and recheck.

4 Check MAP sensor.

Check MAP sensor according to “MAP Sensor

Individual Check” mentioned previously.

Is it in good condition?“GRY/RED” wire shorted

to “ORN” wire, “RED/

WHT” wire open, poor

C42-10 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.Replace MAP sensor. Step Action Yes No

NOTE:

When battery voltage is applied to “GRY/RED” wire, it is possible that MAP sensor is also faulty.

Page 424 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-55

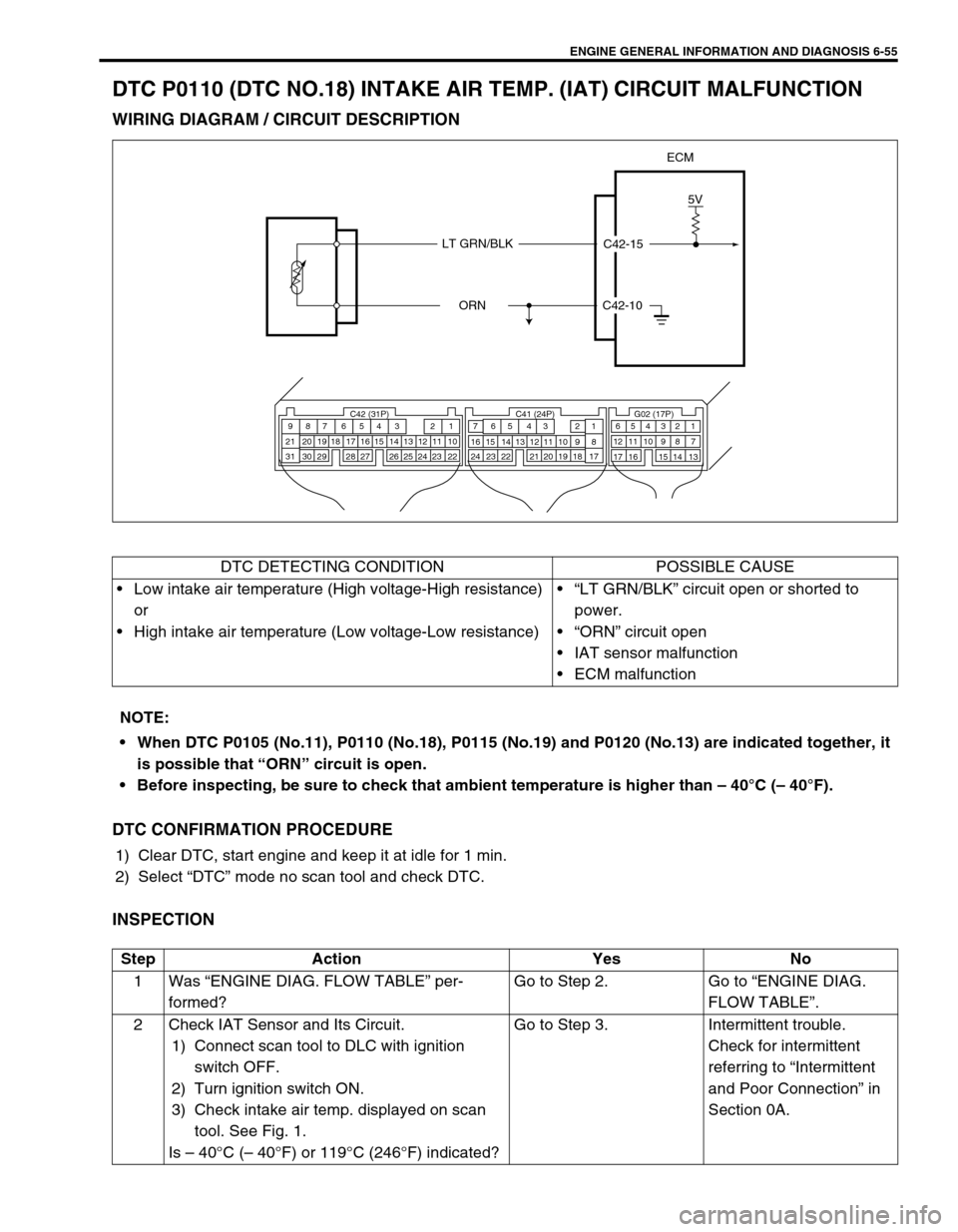

DTC P0110 (DTC NO.18) INTAKE AIR TEMP. (IAT) CIRCUIT MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode no scan tool and check DTC.

INSPECTION

C42-10

C42-15

5V

ECM

LT GRN/BLK

ORN

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

Low intake air temperature (High voltage-High resistance)

or

High intake air temperature (Low voltage-Low resistance)“LT GRN/BLK” circuit open or shorted to

power.

“ORN” circuit open

IAT sensor malfunction

ECM malfunction

NOTE:

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” circuit is open.

Before inspecting, be sure to check that ambient temperature is higher than – 40°C (– 40°F).

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check IAT Sensor and Its Circuit.

1) Connect scan tool to DLC with ignition

switch OFF.

2) Turn ignition switch ON.

3) Check intake air temp. displayed on scan

tool. See Fig. 1.

Is – 40°C (– 40°F) or 119°C (246°F) indicated?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.

Page 425 of 698

6-56 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Fig. 1 for Step 2

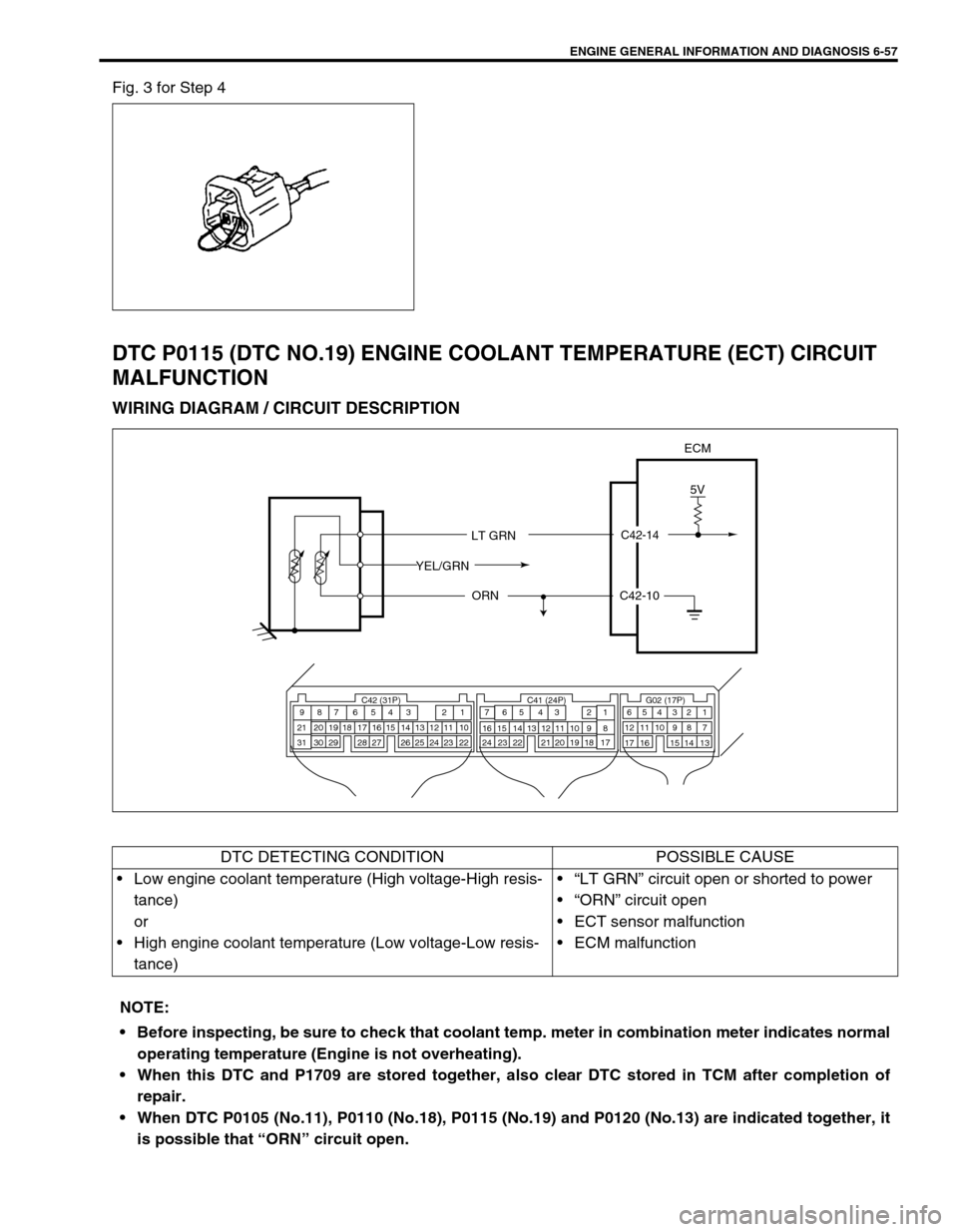

Fig. 2 for Step 33 Check Wire Harness.

1) Disconnect IAT sensor connector with igni-

tion switch OFF.

2) Check for proper connection to IAT sensor

at “LT GRN/BLK” and “ORN” wire terminals.

3) If OK, then with ignition switch ON, is volt-

age applied to “LT GRN/BLK” wire terminal

about 4 – 6 V? See Fig. 2.Go to Step 5.“LT GRN/BLK” wire open

or shorted to power, or

poor C42-15 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.

4 Does scan tool indicate – 40°C (– 40°F) at Step

2.Go to Step 6. Go to Step 5.

5 Check Wire Harness

1) Check intake air temp. displayed on scan

tool with ignition switch ON.

Is – 40°C (– 40°F) indicated?Replace IAT sensor.“LT GRN/BLK” wire

shorted to ground.

If wire is OK, substitute a

known-good ECM and

recheck.

6 Check Wire Harness.

1) Using service wire, connect IAT sensor con-

nector terminals.

2) Check intake air temp. displayed on scan

tool with ignition switch ON. See Fig. 3.

Is 119°C (246°F) indicated?Replace IAT sensor.“LT GRN/BLK” wire open

or poor C42-10 connec-

tion.

If wire and connection are

OK, substitute a known-

good ECM and recheck. Step Action Yes No

Page 426 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-57

Fig. 3 for Step 4

DTC P0115 (DTC NO.19) ENGINE COOLANT TEMPERATURE (ECT) CIRCUIT

MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

C42-14

5V

ECM

LT GRN

ORN

YEL/GRN

C42-10

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

Low engine coolant temperature (High voltage-High resis-

tance)

or

High engine coolant temperature (Low voltage-Low resis-

tance)“LT GRN” circuit open or shorted to power

“ORN” circuit open

ECT sensor malfunction

ECM malfunction

NOTE:

Before inspecting, be sure to check that coolant temp. meter in combination meter indicates normal

operating temperature (Engine is not overheating).

When this DTC and P1709 are stored together, also clear DTC stored in TCM after completion of

repair.

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” circuit open.

Page 427 of 698

6-58 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode no scan tool and check DTC.

INSPECTION

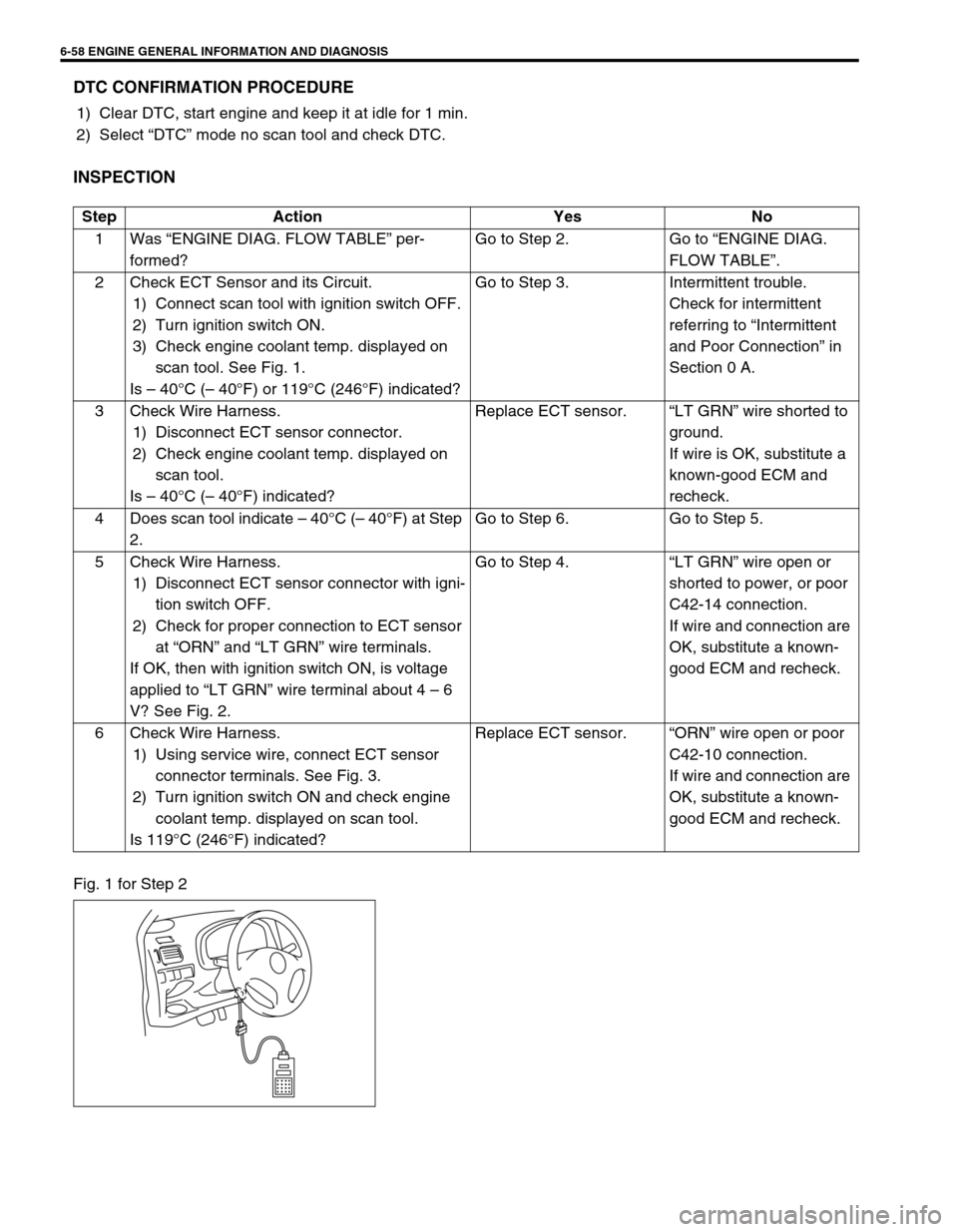

Fig. 1 for Step 2Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check ECT Sensor and its Circuit.

1) Connect scan tool with ignition switch OFF.

2) Turn ignition switch ON.

3) Check engine coolant temp. displayed on

scan tool. See Fig. 1.

Is – 40°C (– 40°F) or 119°C (246°F) indicated?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0 A.

3 Check Wire Harness.

1) Disconnect ECT sensor connector.

2) Check engine coolant temp. displayed on

scan tool.

Is – 40°C (– 40°F) indicated?Replace ECT sensor.“LT GRN” wire shorted to

ground.

If wire is OK, substitute a

known-good ECM and

recheck.

4 Does scan tool indicate – 40°C (– 40°F) at Step

2.Go to Step 6. Go to Step 5.

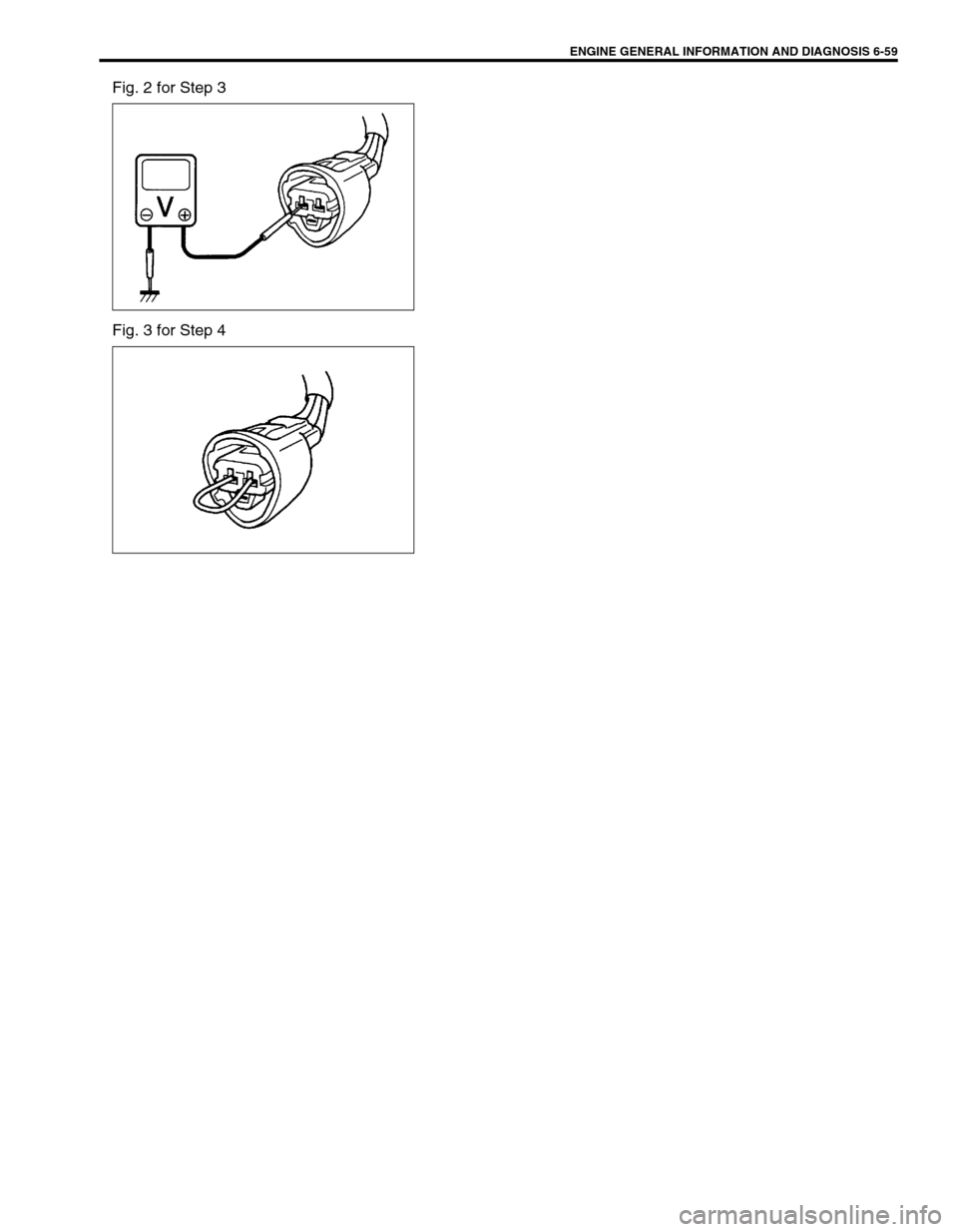

5 Check Wire Harness.

1) Disconnect ECT sensor connector with igni-

tion switch OFF.

2) Check for proper connection to ECT sensor

at “ORN” and “LT GRN” wire terminals.

If OK, then with ignition switch ON, is voltage

applied to “LT GRN” wire terminal about 4 – 6

V? See Fig. 2.Go to Step 4.“LT GRN” wire open or

shorted to power, or poor

C42-14 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.

6 Check Wire Harness.

1) Using service wire, connect ECT sensor

connector terminals. See Fig. 3.

2) Turn ignition switch ON and check engine

coolant temp. displayed on scan tool.

Is 119°C (246°F) indicated?Replace ECT sensor.“ORN” wire open or poor

C42-10 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.

Page 428 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-59

Fig. 2 for Step 3

Fig. 3 for Step 4

Page 429 of 698

6-60 ENGINE GENERAL INFORMATION AND DIAGNOSIS

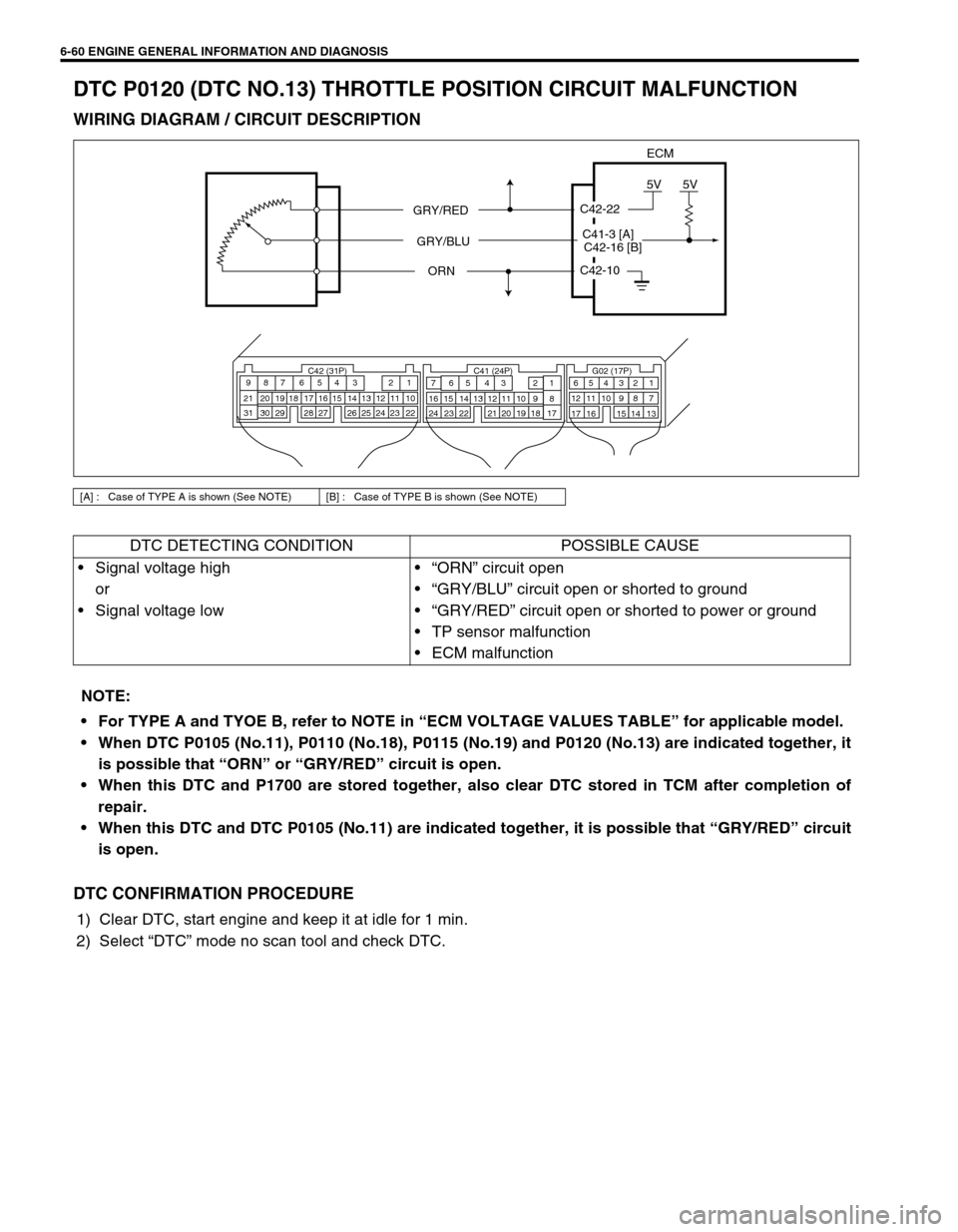

DTC P0120 (DTC NO.13) THROTTLE POSITION CIRCUIT MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode no scan tool and check DTC.

[A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

DTC DETECTING CONDITION POSSIBLE CAUSE

Signal voltage high

or

Signal voltage low“ORN” circuit open

“GRY/BLU” circuit open or shorted to ground

“GRY/RED” circuit open or shorted to power or ground

TP sensor malfunction

ECM malfunction

C42-10

C42-22

5V5V

ECM

GRY/RED

GRY/BLU

ORN

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

C42-16 [B] C41-3 [A]

NOTE:

For TYPE A and TYOE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” or “GRY/RED” circuit is open.

When this DTC and P1700 are stored together, also clear DTC stored in TCM after completion of

repair.

When this DTC and DTC P0105 (No.11) are indicated together, it is possible that “GRY/RED” circuit

is open.

Page 430 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-61

INSPECTION

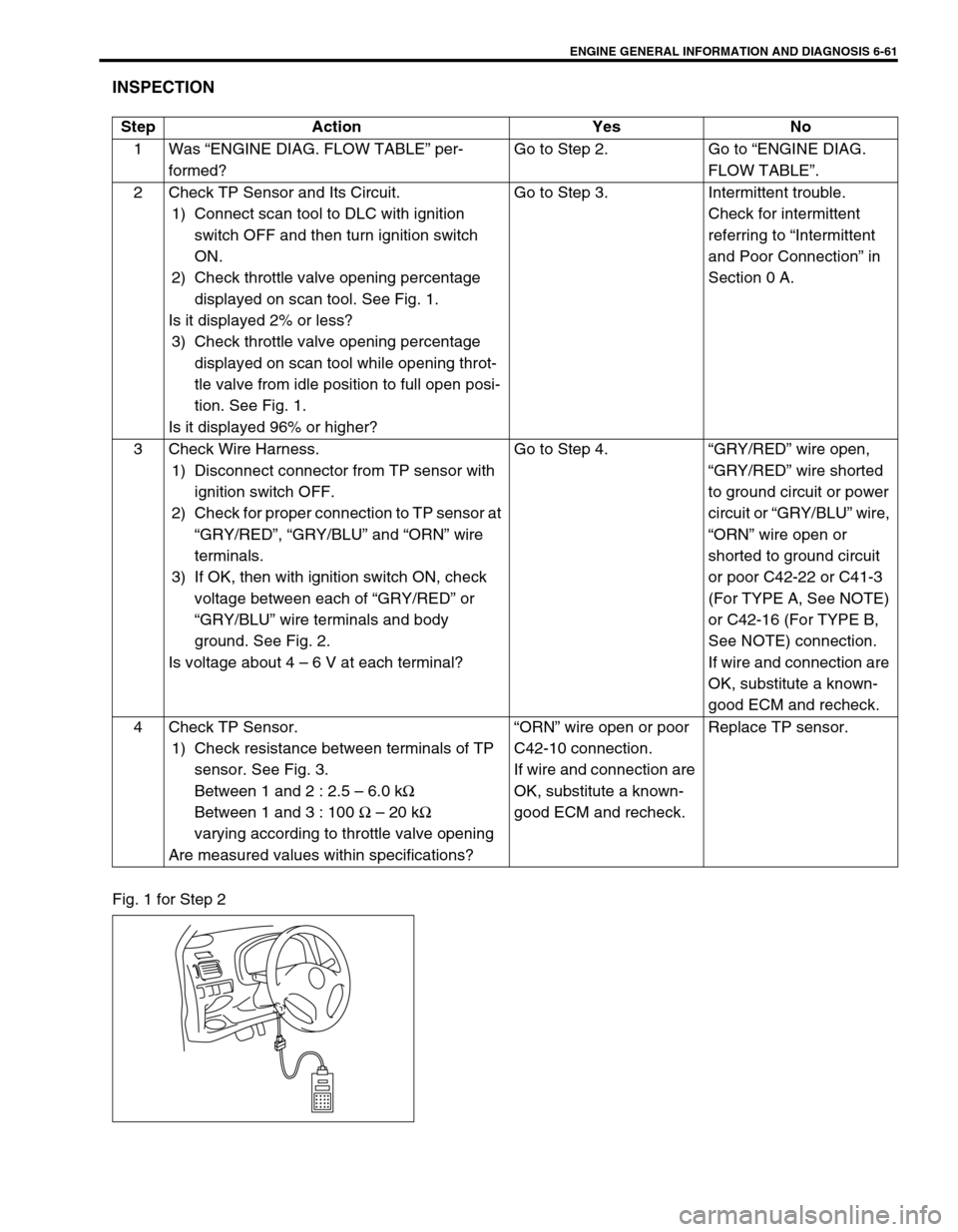

Fig. 1 for Step 2Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check TP Sensor and Its Circuit.

1) Connect scan tool to DLC with ignition

switch OFF and then turn ignition switch

ON.

2) Check throttle valve opening percentage

displayed on scan tool. See Fig. 1.

Is it displayed 2% or less?

3) Check throttle valve opening percentage

displayed on scan tool while opening throt-

tle valve from idle position to full open posi-

tion. See Fig. 1.

Is it displayed 96% or higher?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0 A.

3 Check Wire Harness.

1) Disconnect connector from TP sensor with

ignition switch OFF.

2) Check for proper connection to TP sensor at

“GRY/RED”, “GRY/BLU” and “ORN” wire

terminals.

3) If OK, then with ignition switch ON, check

voltage between each of “GRY/RED” or

“GRY/BLU” wire terminals and body

ground. See Fig. 2.

Is voltage about 4 – 6 V at each terminal?Go to Step 4.“GRY/RED” wire open,

“GRY/RED” wire shorted

to ground circuit or power

circuit or “GRY/BLU” wire,

“ORN” wire open or

shorted to ground circuit

or poor C42-22 or C41-3

(For TYPE A, See NOTE)

or C42-16 (For TYPE B,

See NOTE) connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.

4 Check TP Sensor.

1) Check resistance between terminals of TP

sensor. See Fig. 3.

Between 1 and 2 : 2.5 – 6.0 kΩ

Between 1 and 3 : 100 Ω – 20 kΩ

varying according to throttle valve opening

Are measured values within specifications?“ORN” wire open or poor

C42-10 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.Replace TP sensor.