sensor SUZUKI SWIFT 2000 1.G RG413 Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 328 of 698

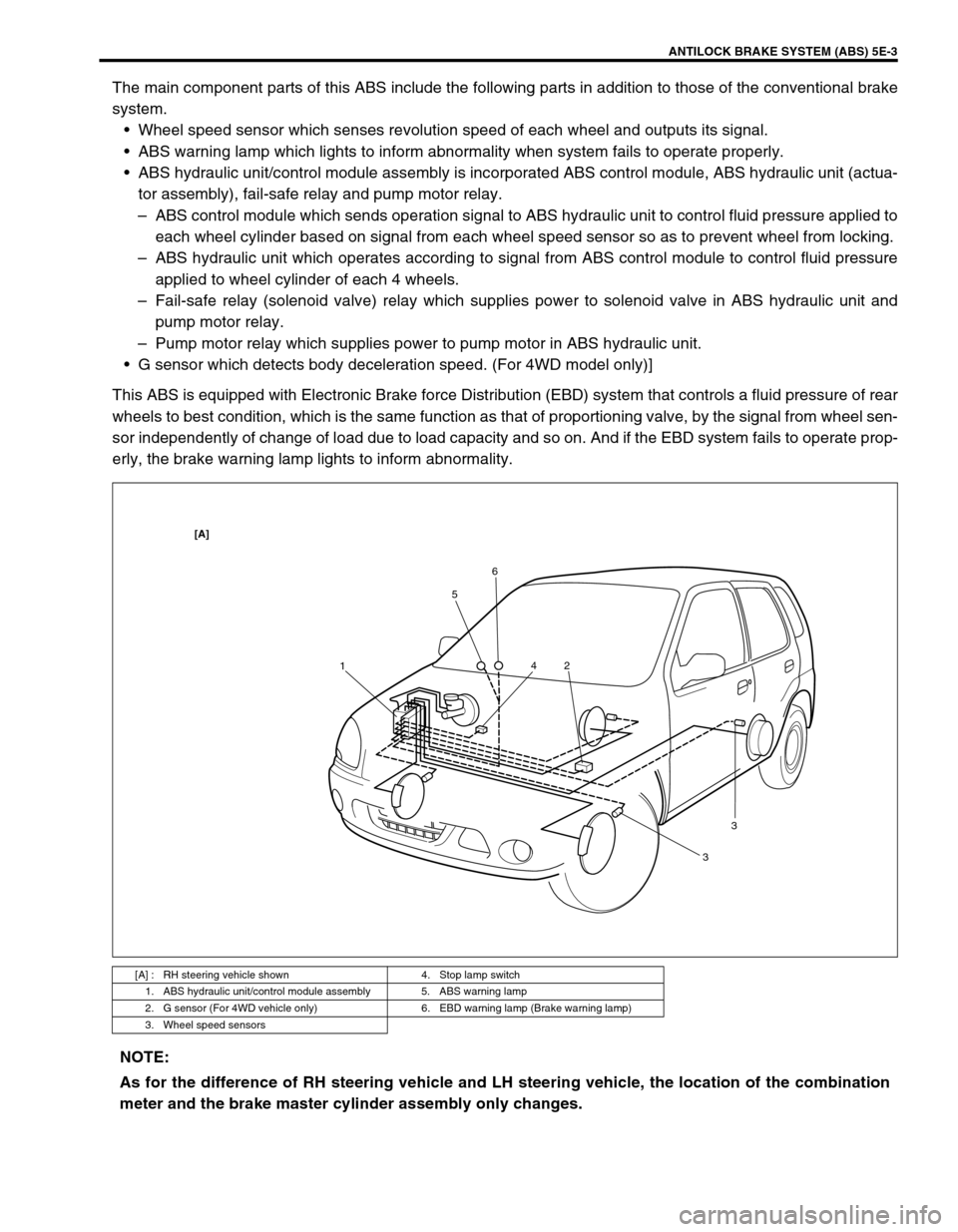

ANTILOCK BRAKE SYSTEM (ABS) 5E-3

The main component parts of this ABS include the following parts in addition to those of the conventional brake

system.

Wheel speed sensor which senses revolution speed of each wheel and outputs its signal.

ABS warning lamp which lights to inform abnormality when system fails to operate properly.

ABS hydraulic unit/control module assembly is incorporated ABS control module, ABS hydraulic unit (actua-

tor assembly), fail-safe relay and pump motor relay.

–ABS control module which sends operation signal to ABS hydraulic unit to control fluid pressure applied to

each wheel cylinder based on signal from each wheel speed sensor so as to prevent wheel from locking.

–ABS hydraulic unit which operates according to signal from ABS control module to control fluid pressure

applied to wheel cylinder of each 4 wheels.

–Fail-safe relay (solenoid valve) relay which supplies power to solenoid valve in ABS hydraulic unit and

pump motor relay.

–Pump motor relay which supplies power to pump motor in ABS hydraulic unit.

G sensor which detects body deceleration speed. (For 4WD model only)]

This ABS is equipped with Electronic Brake force Distribution (EBD) system that controls a fluid pressure of rear

wheels to best condition, which is the same function as that of proportioning valve, by the signal from wheel sen-

sor independently of change of load due to load capacity and so on. And if the EBD system fails to operate prop-

erly, the brake warning lamp lights to inform abnormality.

[A] : RH steering vehicle shown 4. Stop lamp switch

1. ABS hydraulic unit/control module assembly 5. ABS warning lamp

2. G sensor (For 4WD vehicle only) 6. EBD warning lamp (Brake warning lamp)

3. Wheel speed sensors

156

2 4

33

[A]

NOTE:

As for the difference of RH steering vehicle and LH steering vehicle, the location of the combination

meter and the brake master cylinder assembly only changes.

Page 329 of 698

5E-4 ANTILOCK BRAKE SYSTEM (ABS)

SYSTEM SCHEMATIC

1. ABS hydraulic unit/control module assembly 7.“ABS” warning lamp 13. Wheel speed sensor (Right-front)

2. ABS control module 8.“EBD” warning lamp (Brake warning lamp) 14. Wheel speed sensor (Left-front)

3. ABS hydraulic unit 9. Lamp driver module 15. Wheel speed sensor (Right-rear)

4. Fail safe relay 10. ECM 16. Wheel speed sensor (Left-rear)

5. Pump motor relay 11. Data link connector 17. G sensor (For 4WD vehicle only)

6. Stop lamp switch 12. Monitor coupler

INPUT OUTPUT

ABS control

module Wheel speed sensor (LF)

Wheel speed sensor (LR)

Wheel speed sensor (RF)

Wheel speed sensor (RR)

Stop lamp switch

Diag. switch terminal

Battery Voltage

G sensor (for 4WD vehicle only)

Pump motor

relay

Fail-safe

relay

Hydraulic unit

Pump motor

LF inlet solenoid

LF outlet solenoid

LR inlet solenoid

LR outlet solenoid

RF inlet solenoid

RF outlet solenoid

RR inlet solenoid

RR outlet solenoid

“ABS” warning lamp

ECM

EBD warning lamp

(Brake warning lamp)

Data link connector

ABS hydraulic unit/control

module assembly

Page 332 of 698

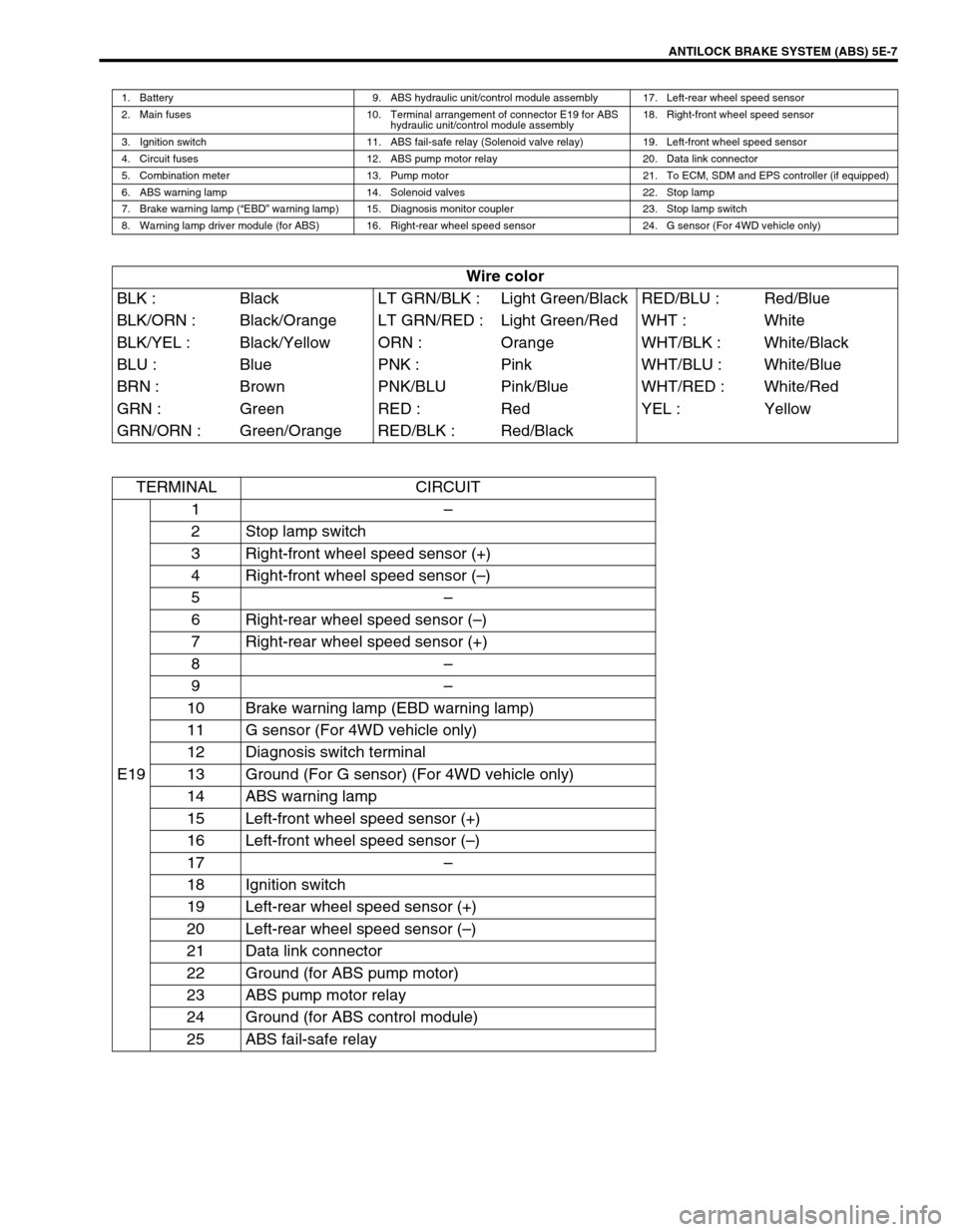

ANTILOCK BRAKE SYSTEM (ABS) 5E-7

1. Battery 9. ABS hydraulic unit/control module assembly 17. Left-rear wheel speed sensor

2. Main fuses 10. Terminal arrangement of connector E19 for ABS

hydraulic unit/control module assembly18. Right-front wheel speed sensor

3. Ignition switch 11. ABS fail-safe relay (Solenoid valve relay) 19. Left-front wheel speed sensor

4. Circuit fuses 12. ABS pump motor relay 20. Data link connector

5. Combination meter 13. Pump motor 21. To ECM, SDM and EPS controller (if equipped)

6. ABS warning lamp 14. Solenoid valves 22. Stop lamp

7. Brake warning lamp (“EBD” warning lamp) 15. Diagnosis monitor coupler 23. Stop lamp switch

8. Warning lamp driver module (for ABS) 16. Right-rear wheel speed sensor 24. G sensor (For 4WD vehicle only)

Wire color

BLK : Black LT GRN/BLK : Light Green/Black RED/BLU : Red/Blue

BLK/ORN : Black/Orange LT GRN/RED : Light Green/Red WHT : White

BLK/YEL : Black/Yellow ORN : Orange WHT/BLK : White/Black

BLU : Blue PNK : Pink WHT/BLU : White/Blue

BRN : Brown PNK/BLU Pink/Blue WHT/RED : White/Red

GRN : Green RED : Red YEL : Yellow

GRN/ORN : Green/Orange RED/BLK : Red/Black

TERMINAL CIRCUIT

E191–

2 Stop lamp switch

3 Right-front wheel speed sensor (+)

4 Right-front wheel speed sensor (–)

5–

6 Right-rear wheel speed sensor (–)

7 Right-rear wheel speed sensor (+)

8–

9–

10 Brake warning lamp (EBD warning lamp)

11 G sensor (For 4WD vehicle only)

12 Diagnosis switch terminal

13 Ground (For G sensor) (For 4WD vehicle only)

14 ABS warning lamp

15 Left-front wheel speed sensor (+)

16 Left-front wheel speed sensor (–)

17–

18 Ignition switch

19 Left-rear wheel speed sensor (+)

20 Left-rear wheel speed sensor (–)

21 Data link connector

22 Ground (for ABS pump motor)

23 ABS pump motor relay

24 Ground (for ABS control module)

25 ABS fail-safe relay

Page 336 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-11

c) Diagnostic Trouble Code (DTC) Check, Record and Clearance

Perform “DIAGNOSTIC TROUBLE CODE CHECK” procedure in this section, record it and then clear it

referring to “DIAGNOSTIC TROUBLE CODE CLEARANCE” in this section.

If the malfunction DTC which was once displayed and then cleared cannot be detected (indicated) again

when the ignition switch is turned ON, attempt to diagnose the trouble based on the DTC recorded in this

step may mislead the diagnosis or make diagnosing difficult. Proceed to Step 2) to check control module

for proper self-diagnosis function.

If the malfunction DTC which was once displayed and then cleared can be detected (indicated) again when

ignition switch is turned ON, proceed to Step 3).

2) DRIVING TEST

Test drive the vehicle at 40 km/h for more than a minute and check if any trouble symptom (such as abnor-

mal lighting of ABS warning light) exists.

If the malfunction DTC is confirmed again at ignition switch ON, driving test as described in above is not nec-

essary. Proceed to Step 3).

3) DIAGNOSTIC TROUBLE CODE CHECK

Recheck diagnostic trouble code referring to “DTC CHECK” as shown in the following page.

4) DIAGNOSTIC TROUBLE CODE FLOW TABLE

According to Diagnostic flow table for the diagnostic trouble code confirmation in Step 3), locate the cause of

the trouble, namely in a sensor, switch, wire harness, connector, actuator assembly or other part and repair

or replace faulty parts.

5)“DIAGNOSIS” IN “BRAKES” SECTION

Check the parts or system suspected as a possible cause referring to “DIAGNOSIS” in “BRAKES” section

and based on symptoms appearing on the vehicle (symptom obtained through Steps 1)-a, 1)-b and 2) and

repair or replace faulty parts, if any).

6) CHECK FOR INTERMITTENT PROBLEM

Check parts where an intermittent trouble is easy to occur (e.g., wire harness, connector, etc.), referring to

“INTERMITTENT TROUBLE” in “GENERAL INFORMATION” section and related circuit of trouble code

recorded in Step 1)-c.

7) FINAL CONFIRMATION TEST

Confirm that the problem symptom has gone and the ABS is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear the DTC once and perform test driving and confirm

that no DTC is indicated.

Page 343 of 698

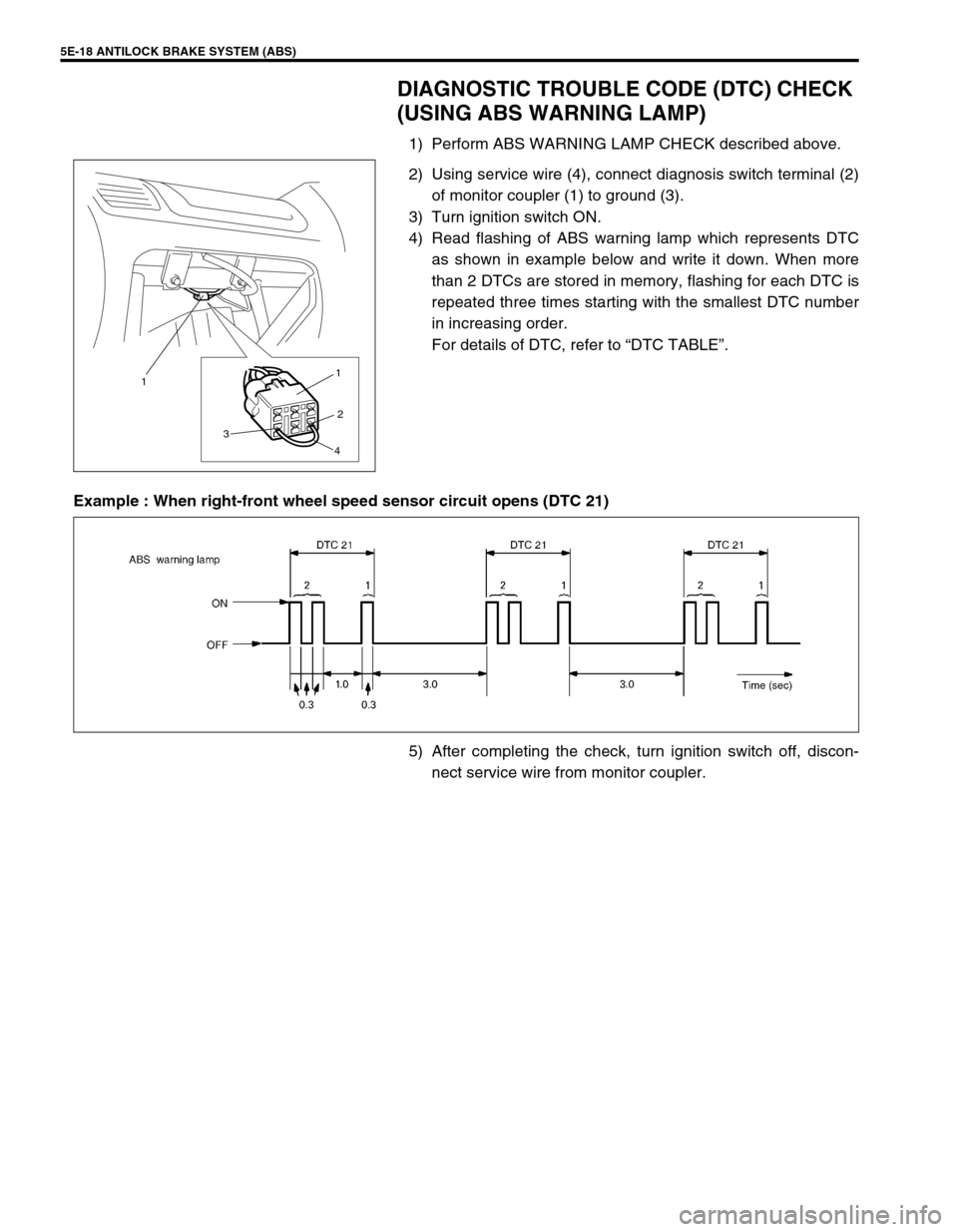

5E-18 ANTILOCK BRAKE SYSTEM (ABS)

DIAGNOSTIC TROUBLE CODE (DTC) CHECK

(USING ABS WARNING LAMP)

1) Perform ABS WARNING LAMP CHECK described above.

2) Using service wire (4), connect diagnosis switch terminal (2)

of monitor coupler (1) to ground (3).

3) Turn ignition switch ON.

4) Read flashing of ABS warning lamp which represents DTC

as shown in example below and write it down. When more

than 2 DTCs are stored in memory, flashing for each DTC is

repeated three times starting with the smallest DTC number

in increasing order.

For details of DTC, refer to “DTC TABLE”.

Example : When right-front wheel speed sensor circuit opens (DTC 21)

5) After completing the check, turn ignition switch off, discon-

nect service wire from monitor coupler.

3 11

2

4

Page 345 of 698

5E-20 ANTILOCK BRAKE SYSTEM (ABS)

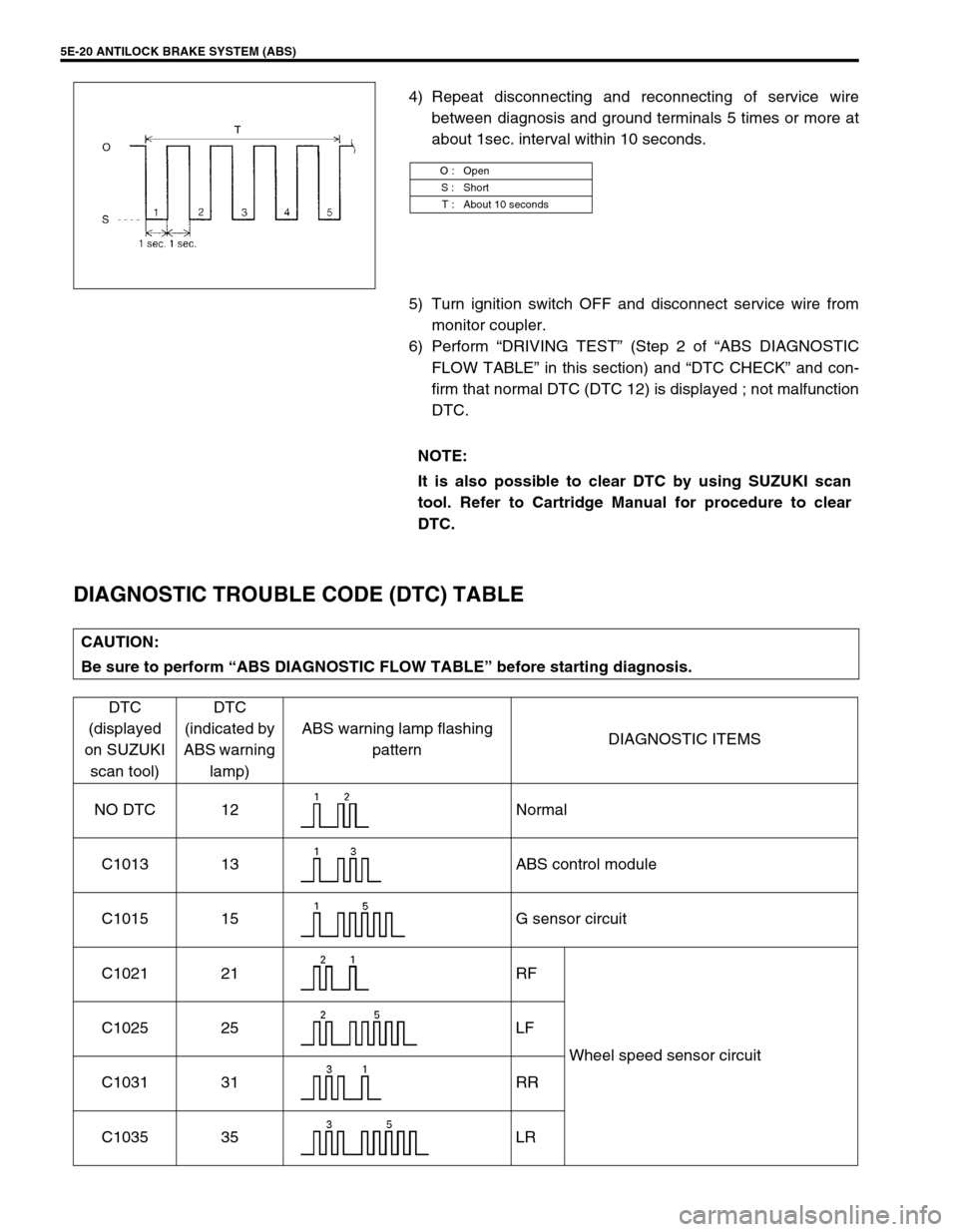

4) Repeat disconnecting and reconnecting of service wire

between diagnosis and ground terminals 5 times or more at

about 1sec. interval within 10 seconds.

5) Turn ignition switch OFF and disconnect service wire from

monitor coupler.

6) Perform “DRIVING TEST” (Step 2 of “ABS DIAGNOSTIC

FLOW TABLE” in this section) and “DTC CHECK” and con-

firm that normal DTC (DTC 12) is displayed ; not malfunction

DTC.

DIAGNOSTIC TROUBLE CODE (DTC) TABLE

O : Open

S : Short

T : About 10 seconds

NOTE:

It is also possible to clear DTC by using SUZUKI scan

tool. Refer to Cartridge Manual for procedure to clear

DTC.

CAUTION:

Be sure to perform “ABS DIAGNOSTIC FLOW TABLE” before starting diagnosis.

DTC

(displayed

on SUZUKI

scan tool)DTC

(indicated by

ABS warning

lamp)ABS warning lamp flashing

patternDIAGNOSTIC ITEMS

NO DTC 12 Normal

C1013 13 ABS control module

C1015 15 G sensor circuit

C1021 21 RF

Wheel speed sensor circuit C1025 25 LF

C1031 31 RR

C1035 35 LR

Page 346 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-21

C1022 22 RF

Wheel speed sensor circuit

or sensor ring C1026 26 LF

C1032 32 RR

C1036 36 LR

C1041 41

RFInlet solenoid valve circuit

C1042 42 Outlet solenoid valve circuit

C1045 45

LFInlet solenoid valve circuit

C1046 46 Outlet solenoid valve circuit

C1051 51

RRInlet solenoid valve circuit

C1052 52 Outlet solenoid valve circuit

C1055 55

LRInlet solenoid valve circuit

C1056 56 Outlet solenoid valve circuit

C1057 57 Power source

C1061 61 ABS pump motor and/or motor relay circuit

C1063 63 Fail safe-relay

C1071 71 ABS control moduleDTC

(displayed

on SUZUKI

scan tool)DTC

(indicated by

ABS warning

lamp)ABS warning lamp flashing

patternDIAGNOSTIC ITEMS

Page 347 of 698

5E-22 ANTILOCK BRAKE SYSTEM (ABS)

DTC C1013 (DTC 13) – SYSTEM SPECIFICATIONS DIFFERENT FROM ABS

CONTROL MODULE SPECIFICATIONS

DESCRIPTION

When abnormal signal is inputted to a no-used terminal of control module white running or wrong ABS hydraulic

unit/control module assembly is installed, this DTC will be set.

INSPECTION

1) Ignition switch OFF.

2) Check for proper connection from harness to control module.

3) If OK, substitute a known-good and correct specifications ABS hydraulic unit/control module assembly.

4) Recheck system.

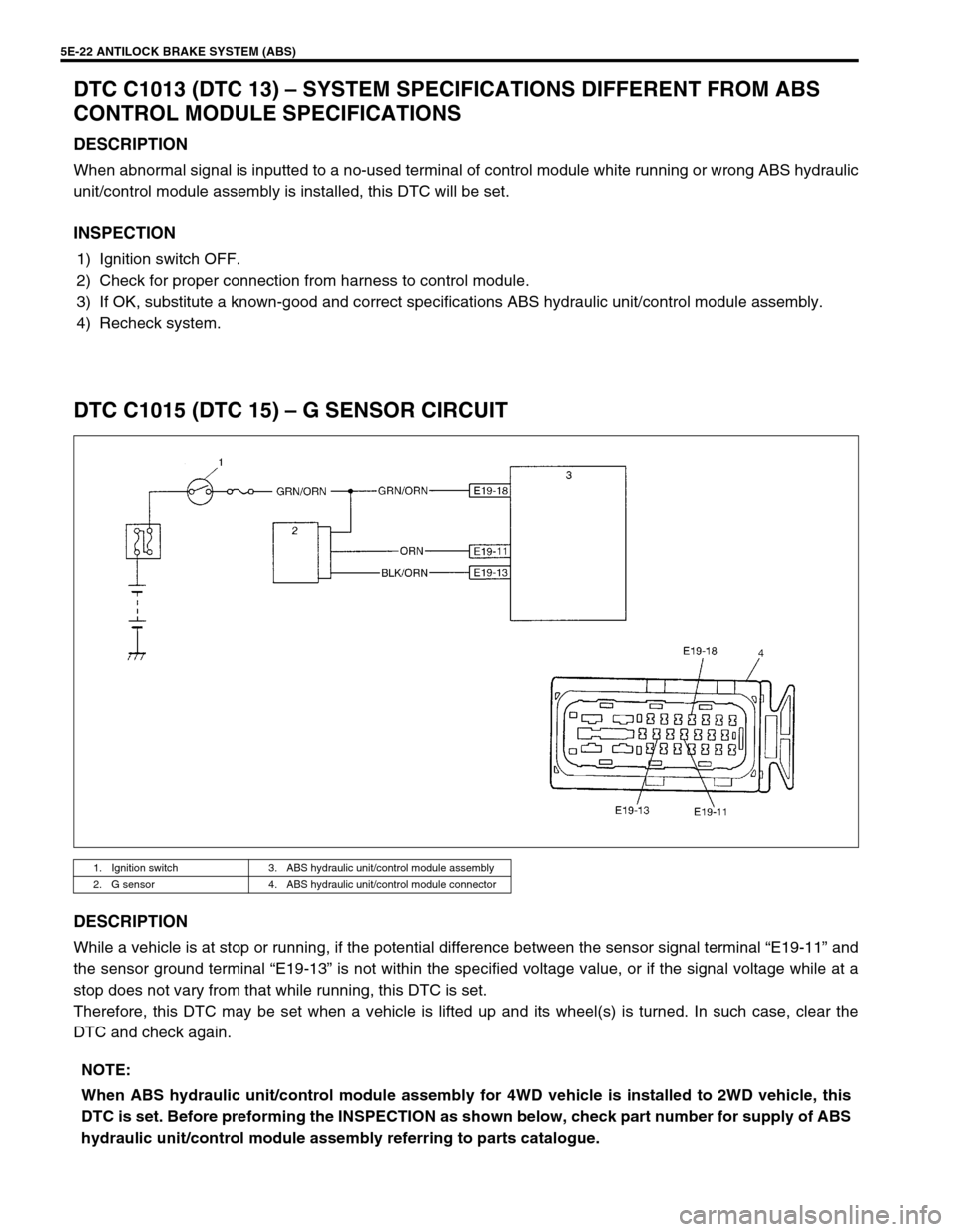

DTC C1015 (DTC 15) – G SENSOR CIRCUIT

DESCRIPTION

While a vehicle is at stop or running, if the potential difference between the sensor signal terminal “E19-11” and

the sensor ground terminal “E19-13” is not within the specified voltage value, or if the signal voltage while at a

stop does not vary from that while running, this DTC is set.

Therefore, this DTC may be set when a vehicle is lifted up and its wheel(s) is turned. In such case, clear the

DTC and check again.

1. Ignition switch 3. ABS hydraulic unit/control module assembly

2. G sensor 4. ABS hydraulic unit/control module connector

NOTE:

When ABS hydraulic unit/control module assembly for 4WD vehicle is installed to 2WD vehicle, this

DTC is set. Before preforming the INSPECTION as shown below, check part number for supply of ABS

hydraulic unit/control module assembly referring to parts catalogue.

Page 348 of 698

ANTILOCK BRAKE SYSTEM (ABS) 5E-23

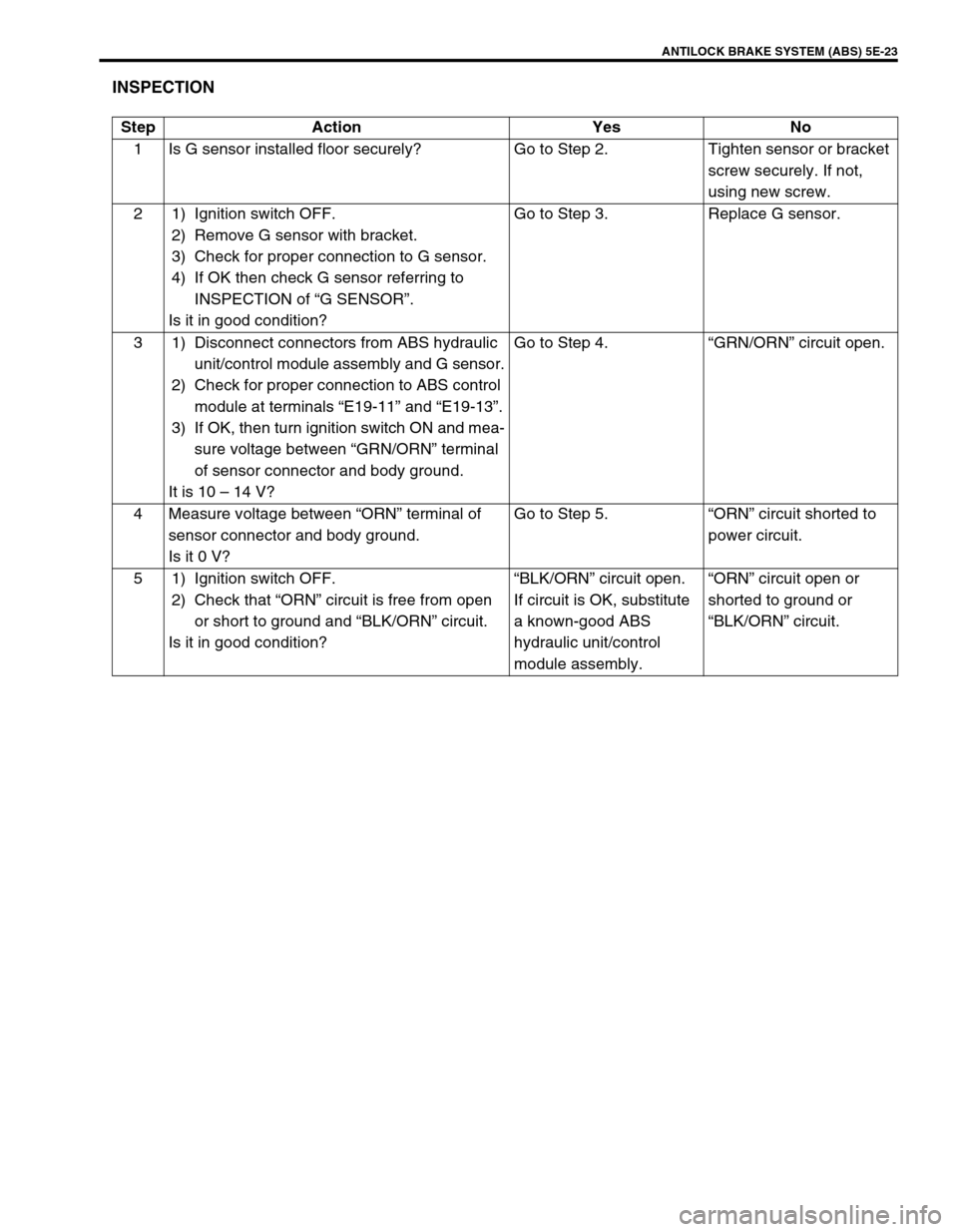

INSPECTION

Step Action Yes No

1 Is G sensor installed floor securely? Go to Step 2. Tighten sensor or bracket

screw securely. If not,

using new screw.

2 1) Ignition switch OFF.

2) Remove G sensor with bracket.

3) Check for proper connection to G sensor.

4) If OK then check G sensor referring to

INSPECTION of “G SENSOR”.

Is it in good condition?Go to Step 3. Replace G sensor.

3 1) Disconnect connectors from ABS hydraulic

unit/control module assembly and G sensor.

2) Check for proper connection to ABS control

module at terminals “E19-11” and “E19-13”.

3) If OK, then turn ignition switch ON and mea-

sure voltage between “GRN/ORN” terminal

of sensor connector and body ground.

It is 10 – 14 V?Go to Step 4.“GRN/ORN” circuit open.

4 Measure voltage between “ORN” terminal of

sensor connector and body ground.

Is it 0 V?Go to Step 5.“ORN” circuit shorted to

power circuit.

5 1) Ignition switch OFF.

2) Check that “ORN” circuit is free from open

or short to ground and “BLK/ORN” circuit.

Is it in good condition?“BLK/ORN” circuit open.

If circuit is OK, substitute

a known-good ABS

hydraulic unit/control

module assembly.“ORN” circuit open or

shorted to ground or

“BLK/ORN” circuit.

Page 349 of 698

5E-24 ANTILOCK BRAKE SYSTEM (ABS)

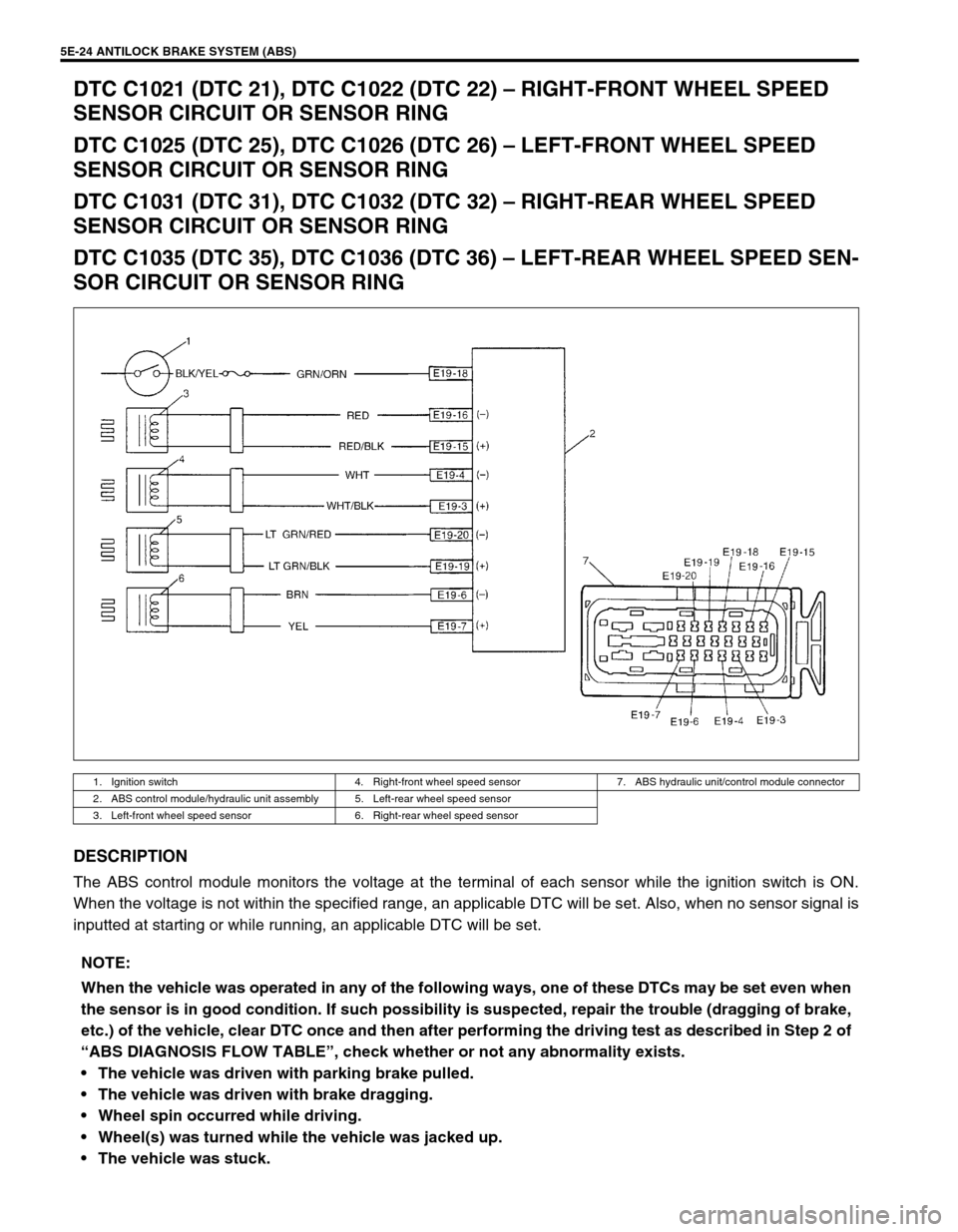

DTC C1021 (DTC 21), DTC C1022 (DTC 22) – RIGHT-FRONT WHEEL SPEED

SENSOR CIRCUIT OR SENSOR RING

DTC C1025 (DTC 25), DTC C1026 (DTC 26) – LEFT-FRONT WHEEL SPEED

SENSOR CIRCUIT OR SENSOR RING

DTC C1031 (DTC 31), DTC C1032 (DTC 32) – RIGHT-REAR WHEEL SPEED

SENSOR CIRCUIT OR SENSOR RING

DTC C1035 (DTC 35), DTC C1036 (DTC 36) – LEFT-REAR WHEEL SPEED SEN-

SOR CIRCUIT OR SENSOR RING

DESCRIPTION

The ABS control module monitors the voltage at the terminal of each sensor while the ignition switch is ON.

When the voltage is not within the specified range, an applicable DTC will be set. Also, when no sensor signal is

inputted at starting or while running, an applicable DTC will be set.

1. Ignition switch 4. Right-front wheel speed sensor 7. ABS hydraulic unit/control module connector

2. ABS control module/hydraulic unit assembly 5. Left-rear wheel speed sensor

3. Left-front wheel speed sensor 6. Right-rear wheel speed sensor

NOTE:

When the vehicle was operated in any of the following ways, one of these DTCs may be set even when

the sensor is in good condition. If such possibility is suspected, repair the trouble (dragging of brake,

etc.) of the vehicle, clear DTC once and then after performing the driving test as described in Step 2 of

“ABS DIAGNOSIS FLOW TABLE”, check whether or not any abnormality exists.

The vehicle was driven with parking brake pulled.

The vehicle was driven with brake dragging.

Wheel spin occurred while driving.

Wheel(s) was turned while the vehicle was jacked up.

The vehicle was stuck.