SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 111 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-69

TRANSMISSION CONTROL MODULE (TCM)

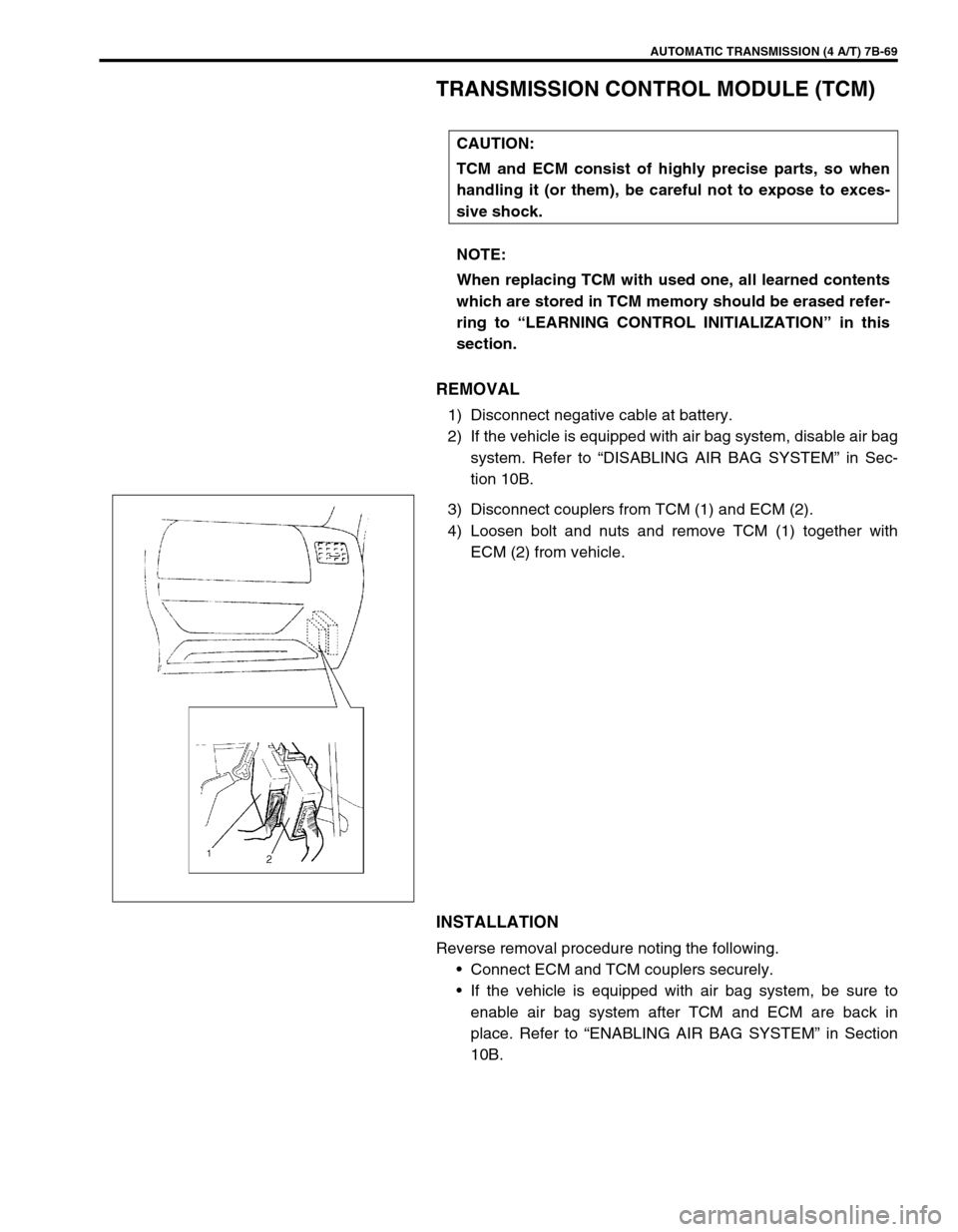

REMOVAL

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system, disable air bag

system. Refer to “DISABLING AIR BAG SYSTEM” in Sec-

tion 10B.

3) Disconnect couplers from TCM (1) and ECM (2).

4) Loosen bolt and nuts and remove TCM (1) together with

ECM (2) from vehicle.

INSTALLATION

Reverse removal procedure noting the following.

Connect ECM and TCM couplers securely.

If the vehicle is equipped with air bag system, be sure to

enable air bag system after TCM and ECM are back in

place. Refer to “ENABLING AIR BAG SYSTEM” in Section

10B. CAUTION:

TCM and ECM consist of highly precise parts, so when

handling it (or them), be careful not to expose to exces-

sive shock.

NOTE:

When replacing TCM with used one, all learned contents

which are stored in TCM memory should be erased refer-

ring to “LEARNING CONTROL INITIALIZATION” in this

section.

Page 112 of 447

7B-70 AUTOMATIC TRANSMISSION (4 A/T)

LEARNING CONTROL INITIALIZATION

When one or more operations such as shown below are per-

formed, all learned contents which are stored in TCM memory

should be erased after the operations.

Replacing transmission with new or used one.

Repairing transmission partially by replacing any brake com-

ponent parts with new and/or used brake disc(s), plate(s)

and/or flange.

Repairing transmission partially by replacing any clutch com-

ponent parts with new and/or used clutch disc(s), plate(s)

and/or flange.

Replacing TCM with used one.

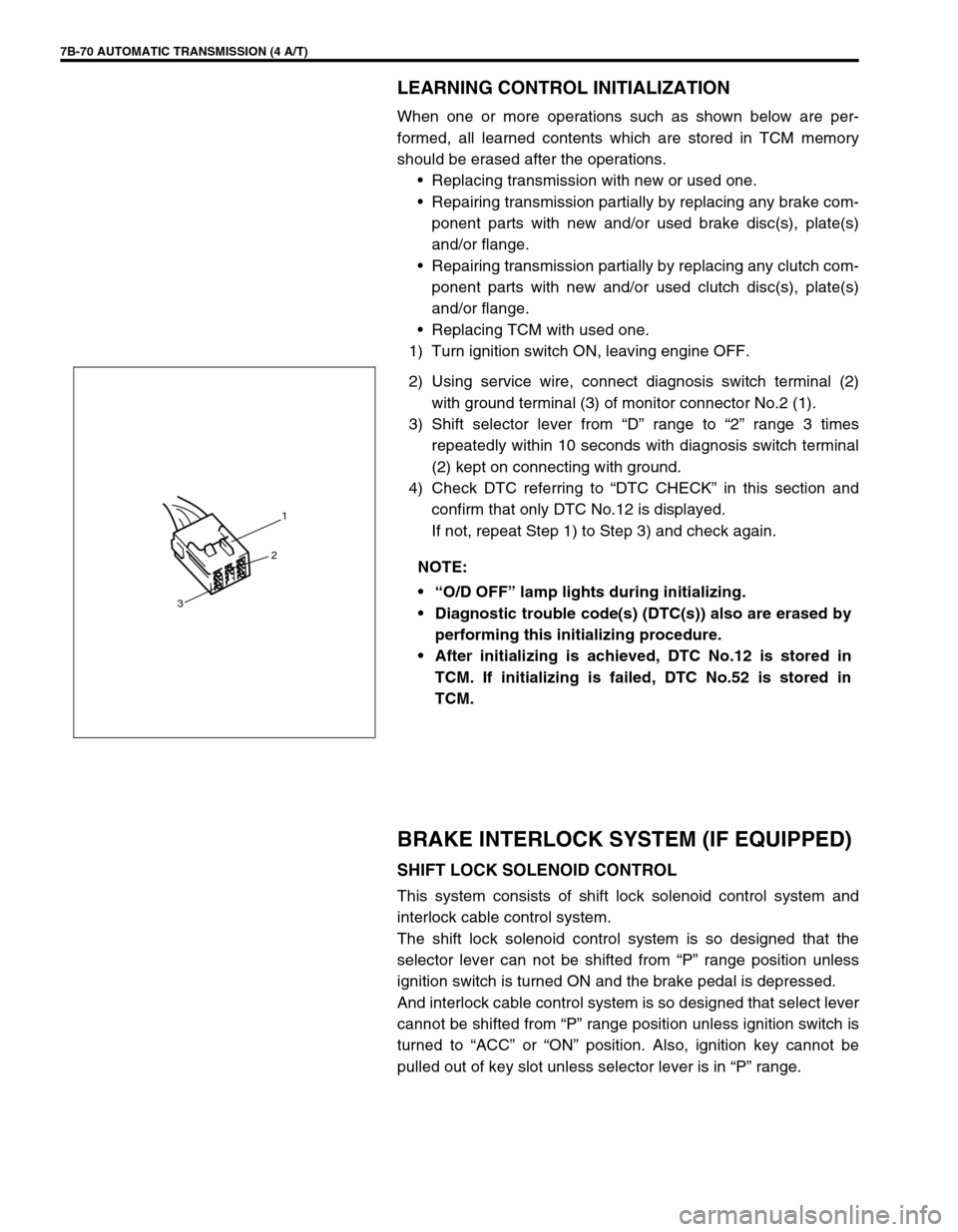

1) Turn ignition switch ON, leaving engine OFF.

2) Using service wire, connect diagnosis switch terminal (2)

with ground terminal (3) of monitor connector No.2 (1).

3) Shift selector lever from “D” range to “2” range 3 times

repeatedly within 10 seconds with diagnosis switch terminal

(2) kept on connecting with ground.

4) Check DTC referring to “DTC CHECK” in this section and

confirm that only DTC No.12 is displayed.

If not, repeat Step 1) to Step 3) and check again.

BRAKE INTERLOCK SYSTEM (IF EQUIPPED)

SHIFT LOCK SOLENOID CONTROL

This system consists of shift lock solenoid control system and

interlock cable control system.

The shift lock solenoid control system is so designed that the

selector lever can not be shifted from “P” range position unless

ignition switch is turned ON and the brake pedal is depressed.

And interlock cable control system is so designed that select lever

cannot be shifted from “P” range position unless ignition switch is

turned to “ACC” or “ON” position. Also, ignition key cannot be

pulled out of key slot unless selector lever is in “P” range. NOTE:

“O/D OFF” lamp lights during initializing.

Diagnostic trouble code(s) (DTC(s)) also are erased by

performing this initializing procedure.

After initializing is achieved, DTC No.12 is stored in

TCM. If initializing is failed, DTC No.52 is stored in

TCM.

1

2

3

Page 113 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-71

SHIFT LOCK SOLENOID MANUAL RLEASE

Without using brake pedal, shift lock can be moved by pushing

shift lock solenoid cam (1) with screw driver or like through hole

(2). (To shift selector lever from “P” range to any other position,

turn ignition switch to “ACC” or “ON” position.)

INSPECTION

1) Check to make sure that selector lever cannot be moved to

any other range from “P” range position when ignition switch

key is at “ACC” position, at “LOCK” position (or it is removed

from keyhole of ignition switch) or brake pedal is not

depressed.

2) Shift selector lever to “P” range position, release knob button

and check for the following.

Ignition key can be turned between “LOCK” and “ACC” posi-

tions back and forth and also it can be removed from ignition

switch.

With shift lock solenoid cam (1) moved in arrow direction and

ignition key turned to “ACC” position, selector lever can be

shifted from “P” range position to any other range.

With shift lock solenoid cam moved in arrow direction and

ignition key turned to “LOCK” position, selector lever can not

be shifted from “P” range position to any other range.

1

2

1

Page 114 of 447

7B-72 AUTOMATIC TRANSMISSION (4 A/T)

When ignition switch is turned “ON” and brake pedal is

depressed, selector lever can be shifted from “P” range posi-

tion to any other range.

3) With ignition lever shifted to any position other than “P”

range, check that ignition key cannot be turned “LOCK” posi-

tion and it cannot be removed from ignition switch unless it is

at “LOCK” position.

KEY INTERLOCK CABLE (IF EQUIPPED)

1. selector lever 3. key inter lock cable

2. knob button 4. key cylinder

NOTE:

Don’t bend interlock cable excessively when removing and installing it, or system will not operate

correctly.

Page 115 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-73

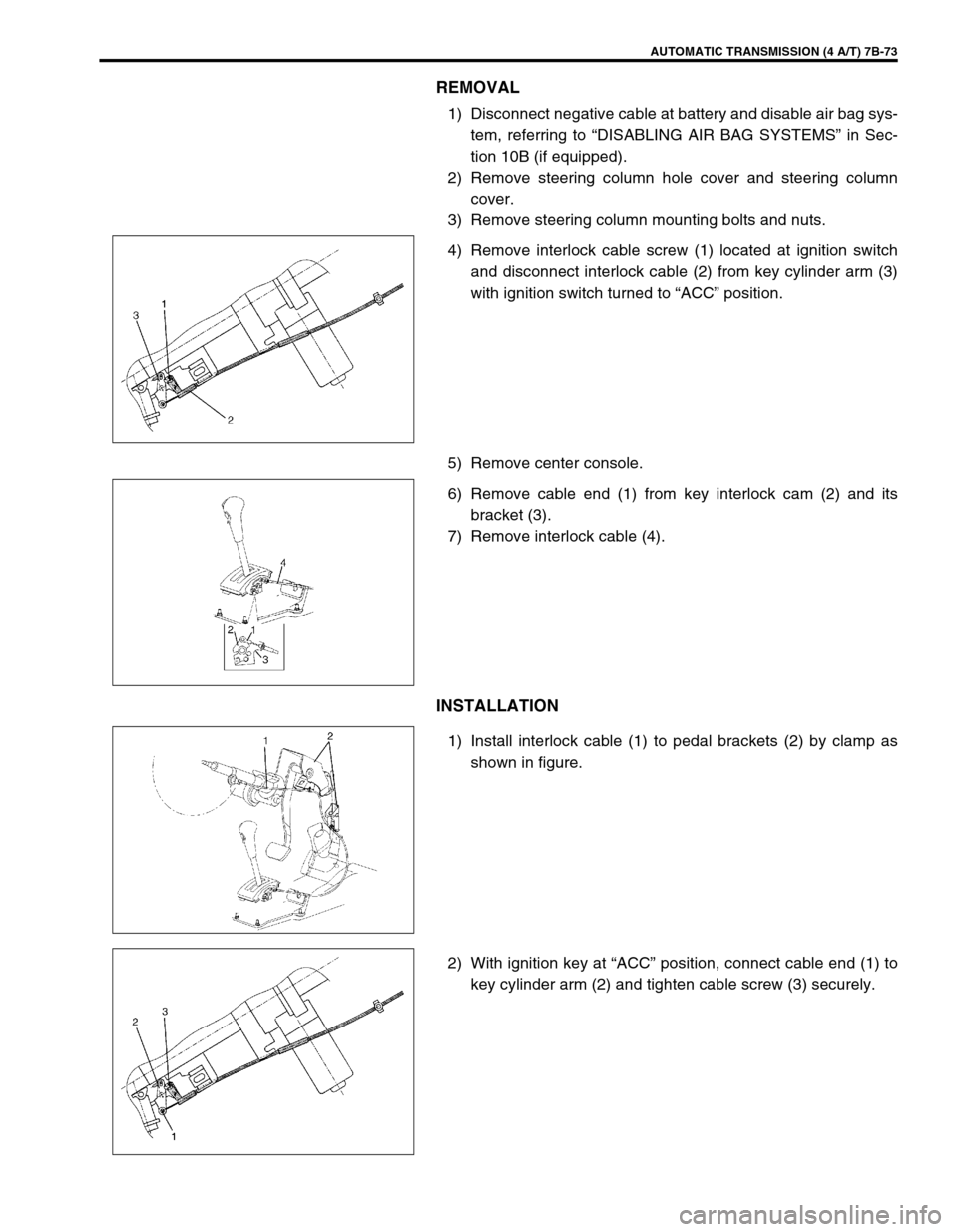

REMOVAL

1) Disconnect negative cable at battery and disable air bag sys-

tem, referring to “DISABLING AIR BAG SYSTEMS” in Sec-

tion 10B (if equipped).

2) Remove steering column hole cover and steering column

cover.

3) Remove steering column mounting bolts and nuts.

4) Remove interlock cable screw (1) located at ignition switch

and disconnect interlock cable (2) from key cylinder arm (3)

with ignition switch turned to “ACC” position.

5) Remove center console.

6) Remove cable end (1) from key interlock cam (2) and its

bracket (3).

7) Remove interlock cable (4).

INSTALLATION

1) Install interlock cable (1) to pedal brackets (2) by clamp as

shown in figure.

2) With ignition key at “ACC” position, connect cable end (1) to

key cylinder arm (2) and tighten cable screw (3) securely.

Page 116 of 447

7B-74 AUTOMATIC TRANSMISSION (4 A/T)

3) If selector lever is in “P” range, shift selector lever to other

than “P” range with releasing shift lock referring to “SHIFT

LOCK SOLENOID MANUAL RELEASE” in this section.

4) Install cable end (1) and cable casing cap (2) to key interlock

cam (3) and its bracket (4), then install cable (5) to selector

pad (6).

5) With selector lever set at “P” position, turn ignition key to

“ACC” position and then check for following conditions.

With knob button released, ignition key can be turned from

“ACC” position to “LOCK” position.

With knob button pressed, ignition key cannot be turned from

“ACC” position to “LOCK” position.

6) Install steering column referring to Section 3C.

7) Install steering column hole cover.

8) Install center console.

9) Connect negative cable at battery and enable air bag sys-

tem, referring to “ENABLING AIR BAG SYSTEM” in Section

10B (if equipped).

Page 117 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-75

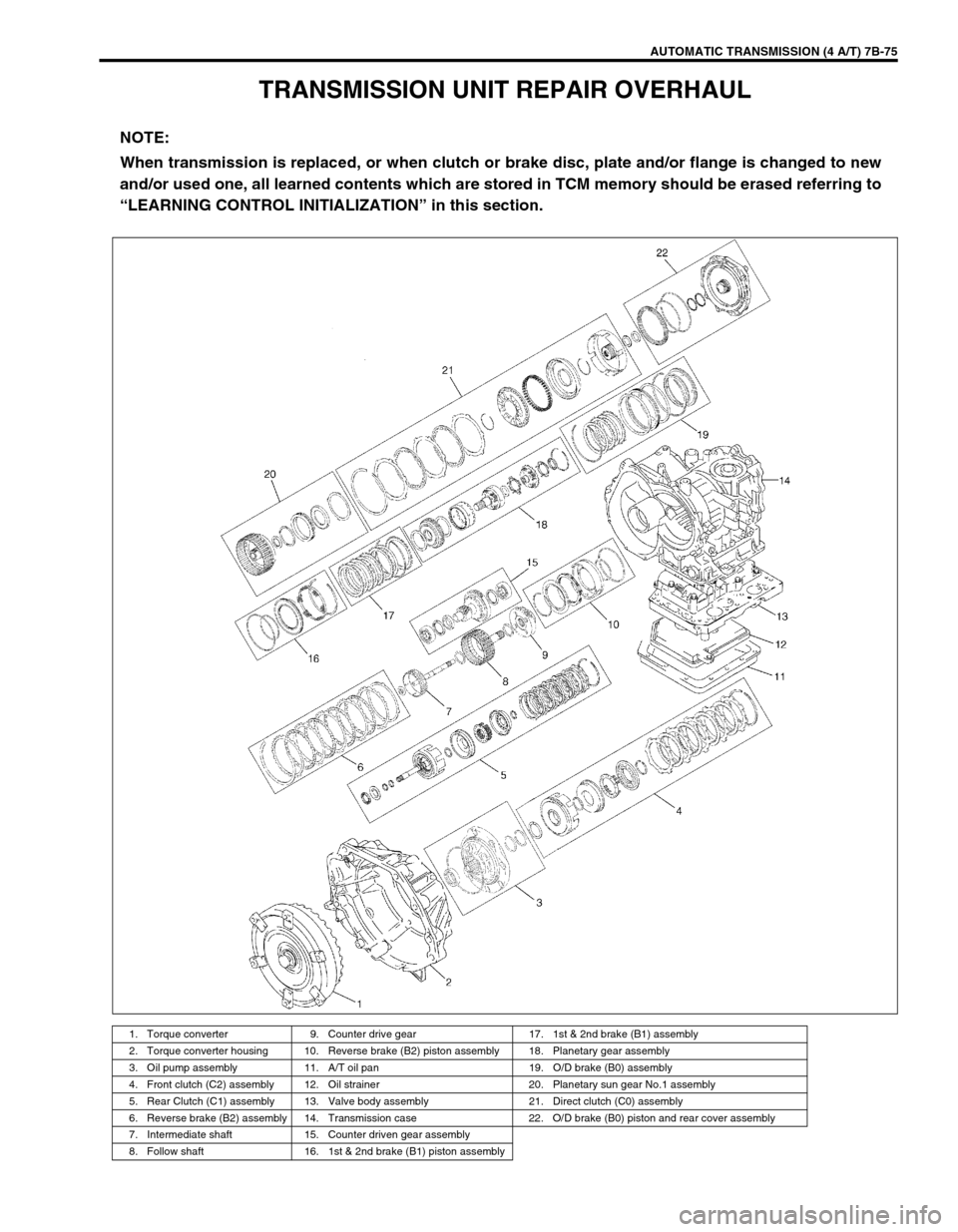

TRANSMISSION UNIT REPAIR OVERHAUL

NOTE:

When transmission is replaced, or when clutch or brake disc, plate and/or flange is changed to new

and/or used one, all learned contents which are stored in TCM memory should be erased referring to

“LEARNING CONTROL INITIALIZATION” in this section.

1. Torque converter 9. Counter drive gear 17. 1st & 2nd brake (B1) assembly

2. Torque converter housing 10. Reverse brake (B2) piston assembly 18. Planetary gear assembly

3. Oil pump assembly 11. A/T oil pan 19. O/D brake (B0) assembly

4. Front clutch (C2) assembly 12. Oil strainer 20. Planetary sun gear No.1 assembly

5. Rear Clutch (C1) assembly 13. Valve body assembly 21. Direct clutch (C0) assembly

6. Reverse brake (B2) assembly 14. Transmission case 22. O/D brake (B0) piston and rear cover assembly

7. Intermediate shaft 15. Counter driven gear assembly

8. Follow shaft 16. 1st & 2nd brake (B1) piston assembly

Page 118 of 447

7B-76 AUTOMATIC TRANSMISSION (4 A/T)

DISMOUNTING

1) Take down transmission with engine. For its procedure, refer

to Section 6A1.

2) For 4WD vehicle, remove transfer referring to Section 7D

For 2WD vehicle, remove engine rear mounting No.1

bracket and engine rear mounting No.2 bracket with stiff-

ener.

3) Remove torque converter housing lower plate (1).

4) Remove drive plate bolts.

To lock drive plate (1), engage a flat head rod or the like (2)

with drive plate gear.

5) Remove starting motor.

6) Remove bolts and nut fastening engine and transmission,

then detach transmission from engine.

NOTE:

When detaching transmission from engine, move it in

parallel with crankshaft and use care so as not to apply

excessive force to drive plate and torque converter.

WARNING:

Be sure to keep transmission with torque converter hori-

zontal or facing up throughout the work. Should it be

tilted with torque converter down, converter may fall off

and cause personal injury.

Page 119 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-77

REMOUNTING

1) Make sure that torque converter is installed correctly to

transmission.

Refer to “UNIT ASSEMBLY” in this section.

2) Attach transmission to engine.

Tightening torque

Transmission to engine bolts and nut

(a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

3) Tighten drive plate-torque converter bolts.

Align drive plate bolt hole and torque converter through

starter motor mounting opening then tighten bolts through

torque converter housing lower plate opening.

Lock drive plate (1) by engaging a flat head rod or the like (2)

with drive plate gear.

Tightening torque

Drive plate to torque converter bolts

(a) : 20 N·m (2.0 kg-m, 14.5 lb-ft)

4) Install torque converter housing lower plate (1).

5) Install starter motor.

Tightening Torque

Starter motor bolts : 23 N·m (2.3 kg-m, 16.5 lb-ft)

6) For 4WD vehicle, install transfer referring to Section 7D.

For 2WD vehicle, install engine rear mounting brackets and

stiffener.

7) Remount engine with transmission assembly to vehicle.

Refer to Section 6A1 for its procedure. WARNING:

Be sure to keep transmission with torque converter hori-

zontal or facing up throughout the work. Should it be

tilted with torque converter down, converter may fall off

and cause personal injury.

3. Wrench

4. Engine oil pan

Page 120 of 447

7B-78 AUTOMATIC TRANSMISSION (4 A/T)

UNIT DISASSEMBLY

1) Remove torque converter (1).

2) Remove engine mounting LH bracket.

3) Remove oil cooler (1) and battery ground cable (2) (if still

attached). CAUTION:

Thoroughly clean transmission exterior before over-

hauling it.

Keep working table, tools and hands clean while over-

hauling.

Use special care to handle aluminum parts so as not to

damage them.

Do not expose removed parts to dust. Keep them

always clean.