SUZUKI SWIFT 2000 1.G Transmission Service Manual Online

Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 81 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-39

Figure for Step 1, 2

Figure for Step 2, 33 1) Turn ignition switch OFF and disconnect

output shaft speed sensor – input shaft

speed sensor coupler. (See figure.)

2) Measure resistance between terminal “3”

(of disconnected sensor side coupler) and

body ground then terminal “4” (of discon-

nected sensor side coupler) and body

ground.

Is it about 0 Ω

?

(See figure.)Replace output shaft

speed sensor.Go to Step 4.

4 1) Turn ignition switch OFF and connect out-

put shaft speed sensor coupler then discon-

nect TCM couplers.

2) Measure resistance between terminal “C43-

6” (of disconnected harness side coupler)

and body ground then terminal “C43-14” (of

disconnected harness side coupler) and

body ground.

Is it about 0 Ω

?

(See figure.)“WHT” or “BLK” wire

shorted to ground.Go to Step 5.

5 Measure resistance between terminal “C43-6”

and “C43-13” (of disconnected harness side

coupler) then terminal “C43-14” and “C43-13”

(of disconnected harness side coupler).

Is it about 0 Ω

?

(See figure.)“WHT” wire or “BLK” wire

shorted to shield portion.Poor connection of termi-

nal “C43-6” or “C43-14” of

the TCM.

If all the above are in

good condition, substitute

a known-good TCM and

recheck. Step Action Yes No

1. Output shaft speed sensor

2. Input shaft speed sensor coupler

1. Terminal “3”

2. Terminal “4”

Page 82 of 447

7B-40 AUTOMATIC TRANSMISSION (4 A/T)

Figure for Step 2, 5

Figure for Step 4

1.“C43-14” terminal

2.“C43-6” terminal

3.“C43-13” terminal

4. TCM coupler

1.“C43-14” terminal

2.“C43-6” terminal

3. TCM coupler

Page 83 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-41

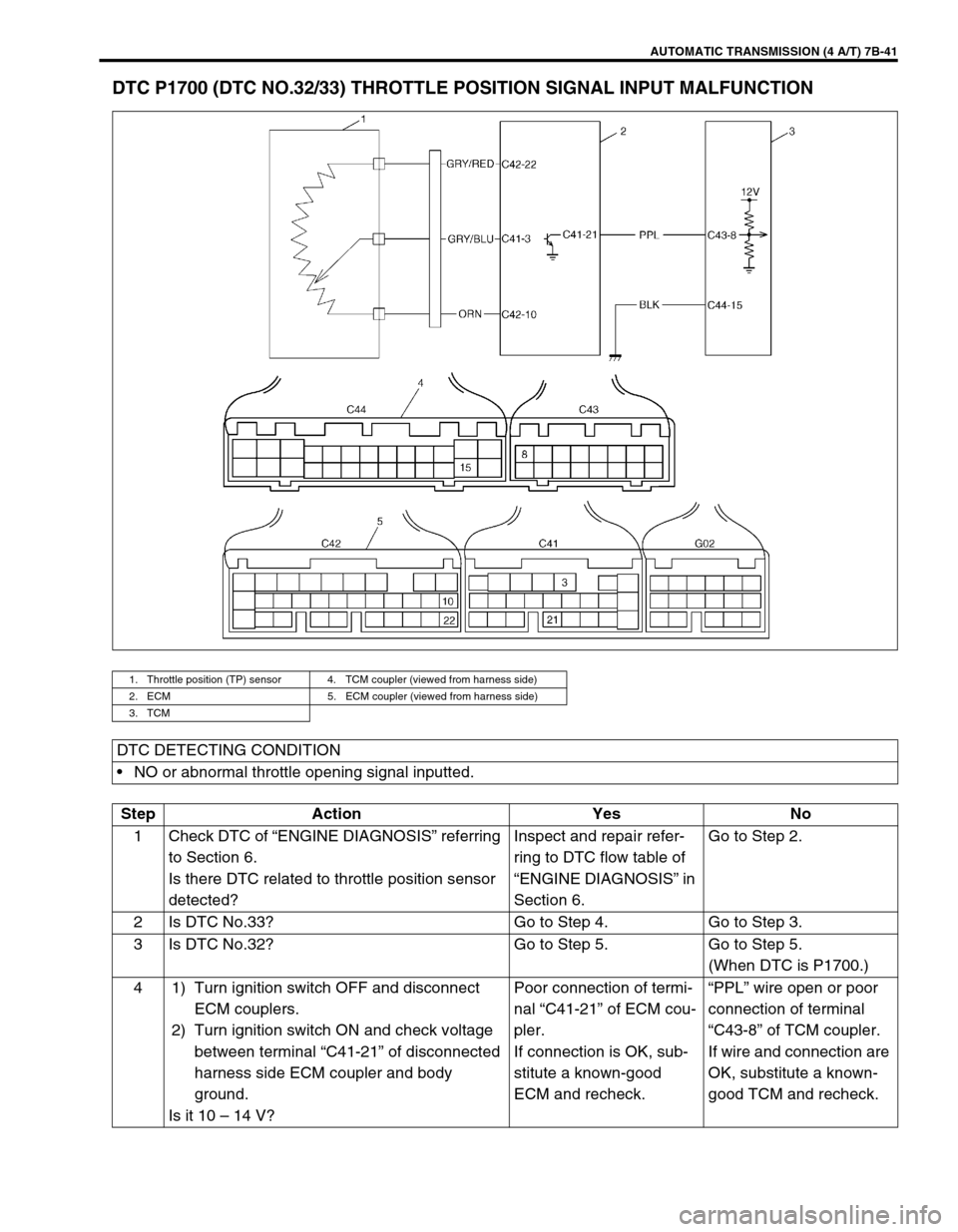

DTC P1700 (DTC NO.32/33) THROTTLE POSITION SIGNAL INPUT MALFUNCTION

1. Throttle position (TP) sensor 4. TCM coupler (viewed from harness side)

2. ECM 5. ECM coupler (viewed from harness side)

3. TCM

DTC DETECTING CONDITION

NO or abnormal throttle opening signal inputted.

Step Action Yes No

1 Check DTC of “ENGINE DIAGNOSIS” referring

to Section 6.

Is there DTC related to throttle position sensor

detected?Inspect and repair refer-

ring to DTC flow table of

“ENGINE DIAGNOSIS” in

Section 6.Go to Step 2.

2 Is DTC No.33? Go to Step 4. Go to Step 3.

3 Is DTC No.32? Go to Step 5. Go to Step 5.

(When DTC is P1700.)

4 1) Turn ignition switch OFF and disconnect

ECM couplers.

2) Turn ignition switch ON and check voltage

between terminal “C41-21” of disconnected

harness side ECM coupler and body

ground.

Is it 10 – 14 V?Poor connection of termi-

nal “C41-21” of ECM cou-

pler.

If connection is OK, sub-

stitute a known-good

ECM and recheck.“PPL” wire open or poor

connection of terminal

“C43-8” of TCM coupler.

If wire and connection are

OK, substitute a known-

good TCM and recheck.

Page 84 of 447

7B-42 AUTOMATIC TRANSMISSION (4 A/T)

5 1) Turn ignition switch OFF and disconnect

ECM couplers.

2) Turn ignition switch ON and check voltage

between terminal “C41-21” of disconnected

harness side ECM coupler and body

ground.

Is it 10 – 14 V?Go to Step 7. Substitute a known-good

TCM and recheck.

6 1) Check for proper connection of terminal

“C41-21” of ECM coupler.

2) If OK, turn ignition switch OFF and discon-

nect ECM couplers.

3) Turn ignition switch ON and check voltage

between terminal “C41-21” of disconnected

harness side ECM coupler and body

ground.

Is it 10 – 14 V?Go to Step 7.“PPL” wire open or poor

connection of terminal

“C43-8” of TCM coupler.

If wire and connection are

OK, substitute a known-

good TCM and recheck.

7 1) Turn ignition switch OFF and disconnect

TCM couplers.

2) Check resistance between terminal “C43-8”

of disconnected harness side TCM coupler

and body ground.

Is it infinity?Intermittent trouble or

faulty ECM.

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.

If no trouble found, substi-

tute a known-good ECM

and recheck.“PPL” wire shorted to

ground. Step Action Yes No

Page 85 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-43

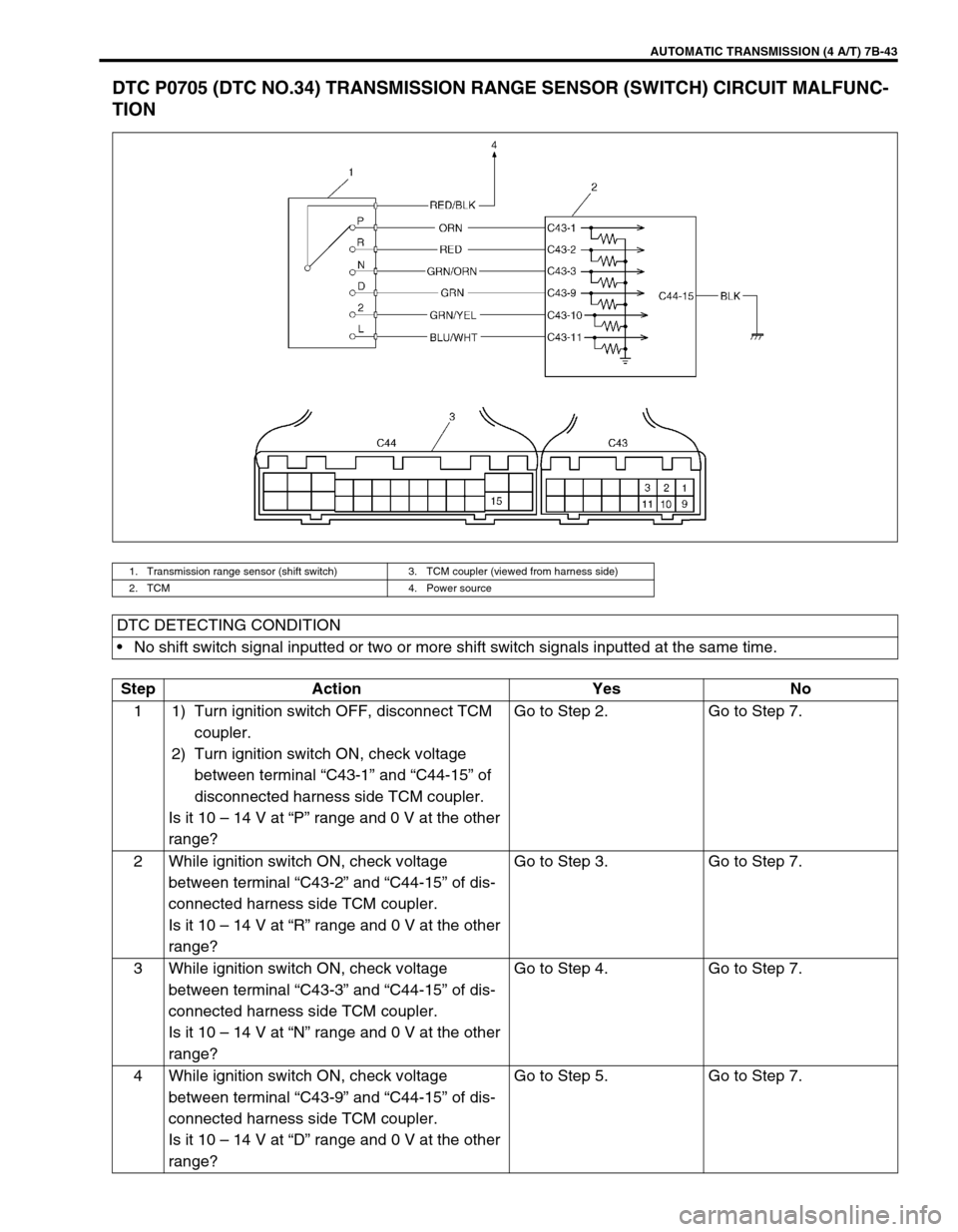

DTC P0705 (DTC NO.34) TRANSMISSION RANGE SENSOR (SWITCH) CIRCUIT MALFUNC-

TION

1. Transmission range sensor (shift switch) 3. TCM coupler (viewed from harness side)

2. TCM 4. Power source

DTC DETECTING CONDITION

No shift switch signal inputted or two or more shift switch signals inputted at the same time.

Step Action Yes No

1 1) Turn ignition switch OFF, disconnect TCM

coupler.

2) Turn ignition switch ON, check voltage

between terminal “C43-1” and “C44-15” of

disconnected harness side TCM coupler.

Is it 10 – 14 V at “P” range and 0 V at the other

range?Go to Step 2. Go to Step 7.

2 While ignition switch ON, check voltage

between terminal “C43-2” and “C44-15” of dis-

connected harness side TCM coupler.

Is it 10 – 14 V at “R” range and 0 V at the other

range?Go to Step 3. Go to Step 7.

3 While ignition switch ON, check voltage

between terminal “C43-3” and “C44-15” of dis-

connected harness side TCM coupler.

Is it 10 – 14 V at “N” range and 0 V at the other

range?Go to Step 4. Go to Step 7.

4 While ignition switch ON, check voltage

between terminal “C43-9” and “C44-15” of dis-

connected harness side TCM coupler.

Is it 10 – 14 V at “D” range and 0 V at the other

range?Go to Step 5. Go to Step 7.

Page 86 of 447

7B-44 AUTOMATIC TRANSMISSION (4 A/T)

5 While ignition switch ON, check voltage

between terminal “C43-10” and “C44-15” of dis-

connected harness side TCM coupler.

Is it 10 – 14 V at “2” range and 0 V at the other

range?Go to Step 6. Go to Step 7.

6 While ignition switch ON, check voltage

between terminal “C43-11” and “C44-15” of dis-

connected harness side TCM coupler.

Is it 10 – 14 V at “L” range and 0 V at the other

range?Intermittent trouble or

faulty TCM.

Check for intermittent

trouble referring to

“INTERMITTENT AND

POOR CONNECTION”

in Section 0B.Go to Step 7.

7 Check transmission range sensor referring in

this section.

Is it OK?Transmission range sen-

sor wire shorted.

If wire harnesses are OK,

substitute a known-good

TCM and recheck.Replace transmission

range sensor. Step Action Yes No

Page 87 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-45

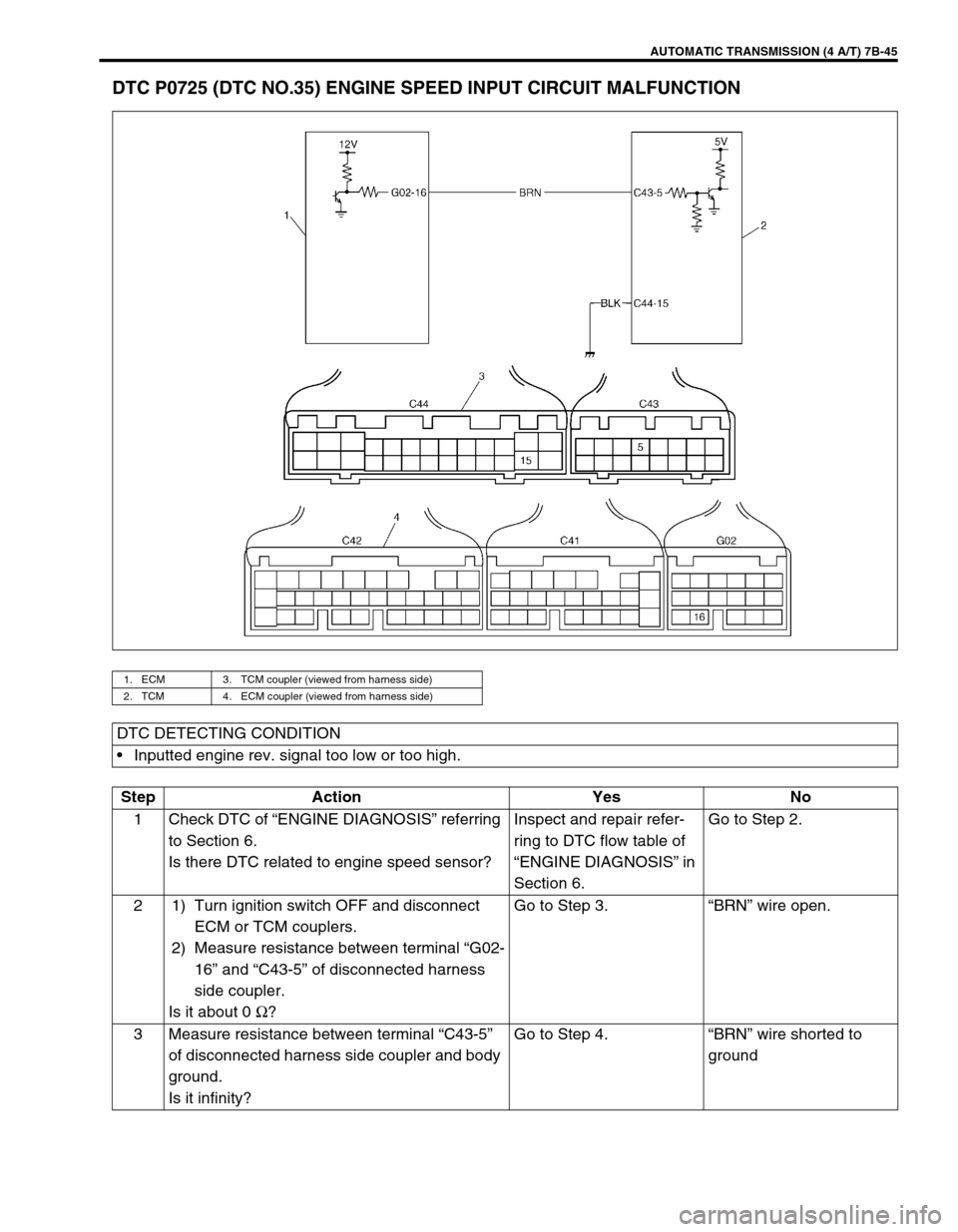

DTC P0725 (DTC NO.35) ENGINE SPEED INPUT CIRCUIT MALFUNCTION

1. ECM 3. TCM coupler (viewed from harness side)

2. TCM 4. ECM coupler (viewed from harness side)

DTC DETECTING CONDITION

Inputted engine rev. signal too low or too high.

Step Action Yes No

1 Check DTC of “ENGINE DIAGNOSIS” referring

to Section 6.

Is there DTC related to engine speed sensor?Inspect and repair refer-

ring to DTC flow table of

“ENGINE DIAGNOSIS” in

Section 6.Go to Step 2.

2 1) Turn ignition switch OFF and disconnect

ECM or TCM couplers.

2) Measure resistance between terminal “G02-

16” and “C43-5” of disconnected harness

side coupler.

Is it about 0 Ω

?Go to Step 3.“BRN” wire open.

3 Measure resistance between terminal “C43-5”

of disconnected harness side coupler and body

ground.

Is it infinity?Go to Step 4.“BRN” wire shorted to

ground

Page 88 of 447

7B-46 AUTOMATIC TRANSMISSION (4 A/T)

4 1) Turn ignition switch OFF and connect ECM

couplers.

2) Turn ignition switch ON and measure volt-

age between terminal “C43-5” of discon-

nected harness side TCM coupler and body

ground.

Is it 10 – 14 V?Intermittent trouble or

faulty ECM or TCM.

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.

If no trouble found, substi-

tute a known-good ECM

or TCM and recheck.“BRN” wire is shorted to

power circuit or faulty

ECM.

If “BRN” wire is OK, sub-

stitute a known-good

ECM and recheck. Step Action Yes No

Page 89 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-47

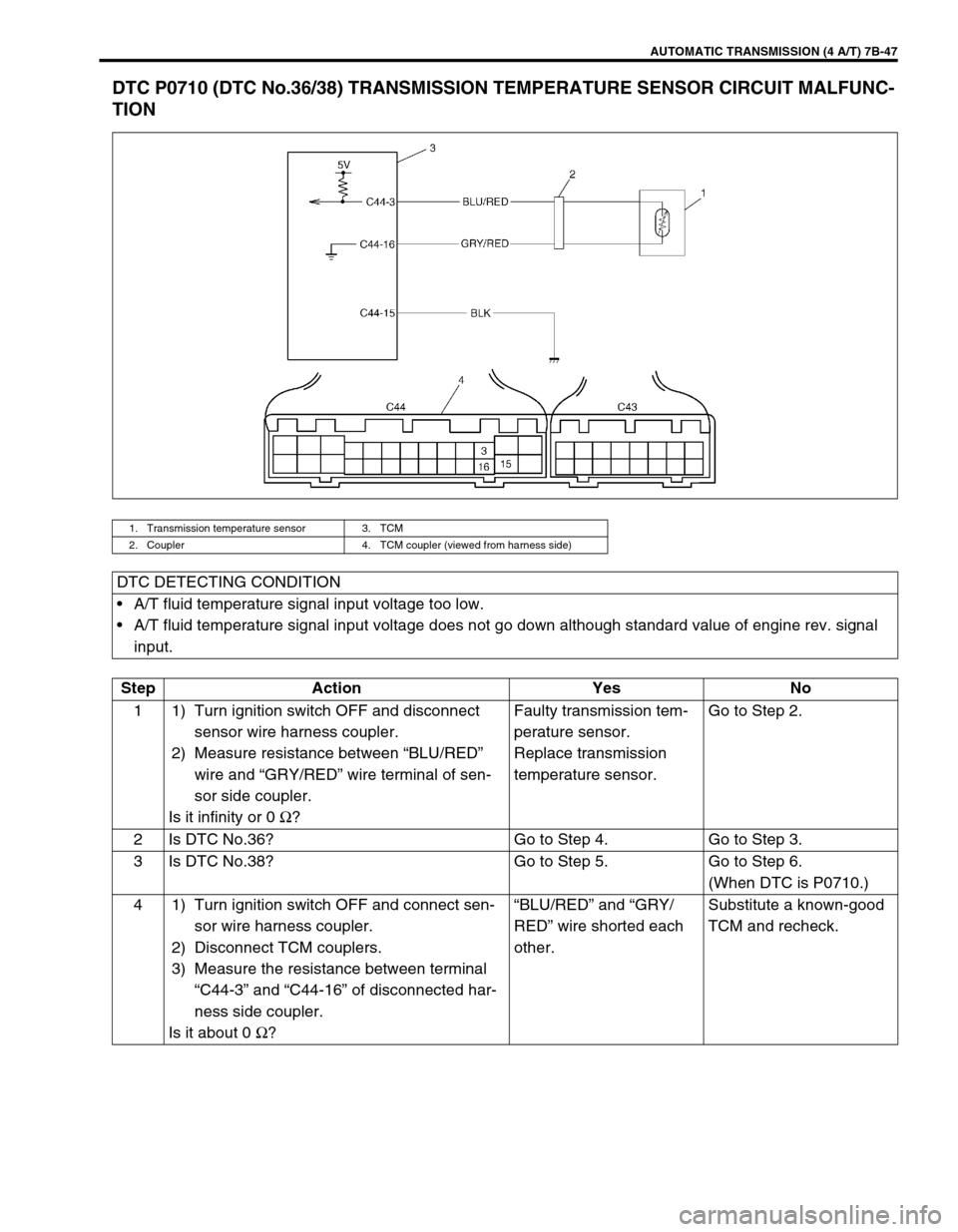

DTC P0710 (DTC No.36/38) TRANSMISSION TEMPERATURE SENSOR CIRCUIT MALFUNC-

TION

1. Transmission temperature sensor 3. TCM

2. Coupler 4. TCM coupler (viewed from harness side)

DTC DETECTING CONDITION

A/T fluid temperature signal input voltage too low.

A/T fluid temperature signal input voltage does not go down although standard value of engine rev. signal

input.

Step Action Yes No

1 1) Turn ignition switch OFF and disconnect

sensor wire harness coupler.

2) Measure resistance between “BLU/RED”

wire and “GRY/RED” wire terminal of sen-

sor side coupler.

Is it infinity or 0 Ω

?Faulty transmission tem-

perature sensor.

Replace transmission

temperature sensor.Go to Step 2.

2 Is DTC No.36? Go to Step 4. Go to Step 3.

3 Is DTC No.38? Go to Step 5. Go to Step 6.

(When DTC is P0710.)

4 1) Turn ignition switch OFF and connect sen-

sor wire harness coupler.

2) Disconnect TCM couplers.

3) Measure the resistance between terminal

“C44-3” and “C44-16” of disconnected har-

ness side coupler.

Is it about 0 Ω

?“BLU/RED” and “GRY/

RED” wire shorted each

other.Substitute a known-good

TCM and recheck.

Page 90 of 447

7B-48 AUTOMATIC TRANSMISSION (4 A/T)

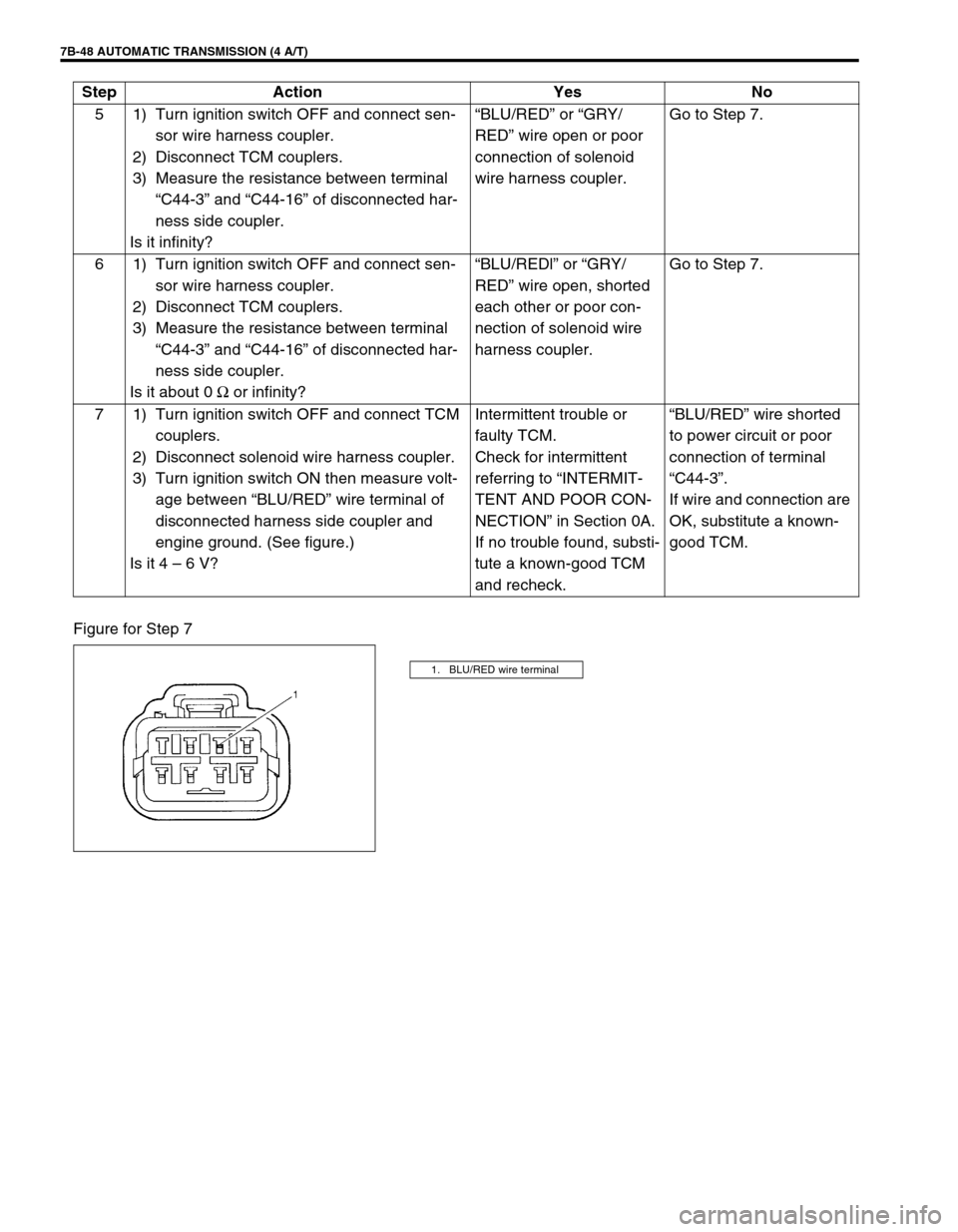

Figure for Step 75 1) Turn ignition switch OFF and connect sen-

sor wire harness coupler.

2) Disconnect TCM couplers.

3) Measure the resistance between terminal

“C44-3” and “C44-16” of disconnected har-

ness side coupler.

Is it infinity?“BLU/RED” or “GRY/

RED” wire open or poor

connection of solenoid

wire harness coupler.Go to Step 7.

6 1) Turn ignition switch OFF and connect sen-

sor wire harness coupler.

2) Disconnect TCM couplers.

3) Measure the resistance between terminal

“C44-3” and “C44-16” of disconnected har-

ness side coupler.

Is it about 0 Ω

or infinity?“BLU/REDl” or “GRY/

RED” wire open, shorted

each other or poor con-

nection of solenoid wire

harness coupler.Go to Step 7.

7 1) Turn ignition switch OFF and connect TCM

couplers.

2) Disconnect solenoid wire harness coupler.

3) Turn ignition switch ON then measure volt-

age between “BLU/RED” wire terminal of

disconnected harness side coupler and

engine ground. (See figure.)

Is it 4 – 6 V?Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.

If no trouble found, substi-

tute a known-good TCM

and recheck.“BLU/RED” wire shorted

to power circuit or poor

connection of terminal

“C44-3”.

If wire and connection are

OK, substitute a known-

good TCM. Step Action Yes No

1. BLU/RED wire terminal